A Wideband Termination Based on Laser-Scribed Lossy Microstrip Line Structures

Abstract

:1. Introduction

2. Structural Design

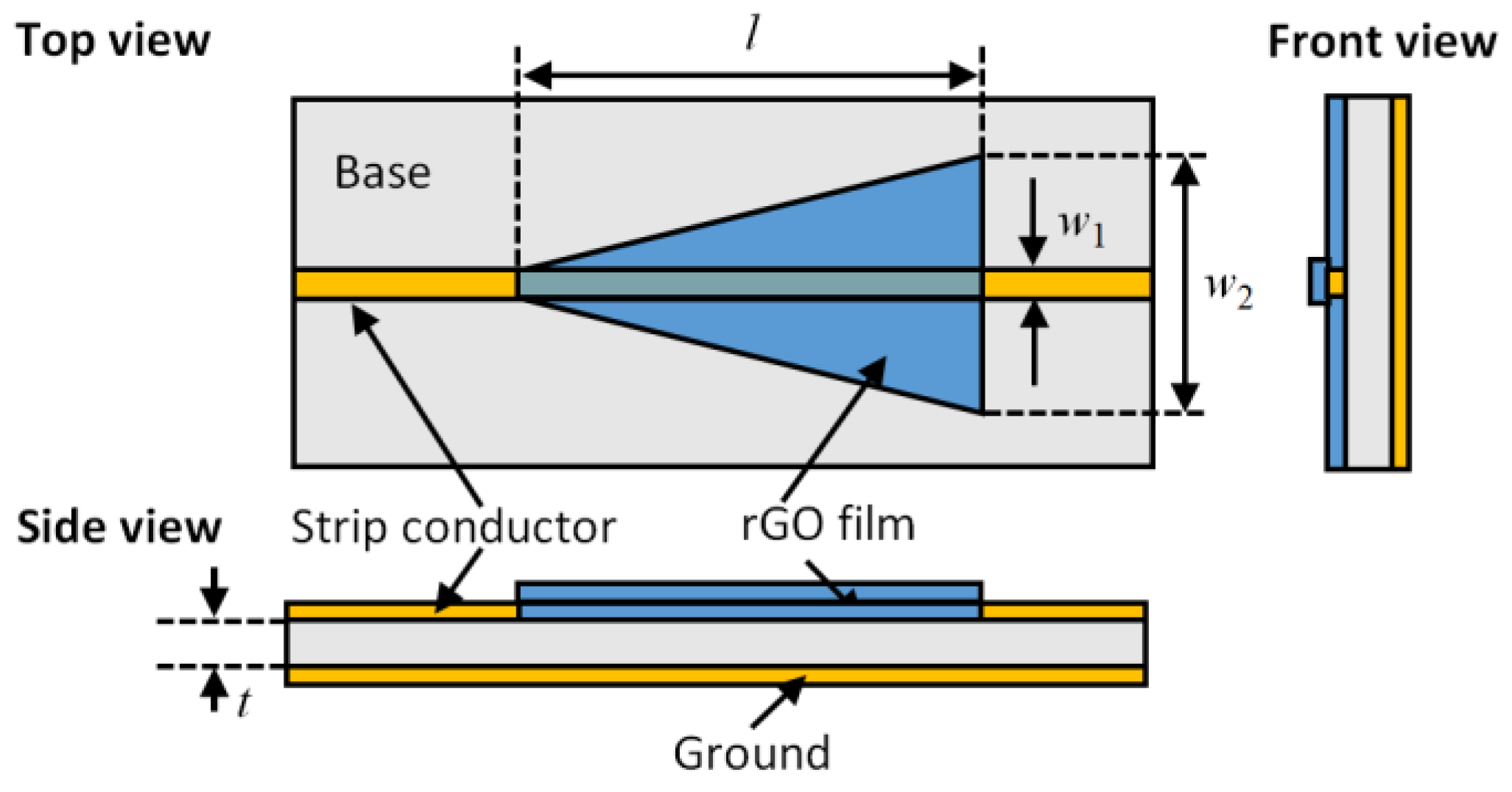

2.1. Device Structure

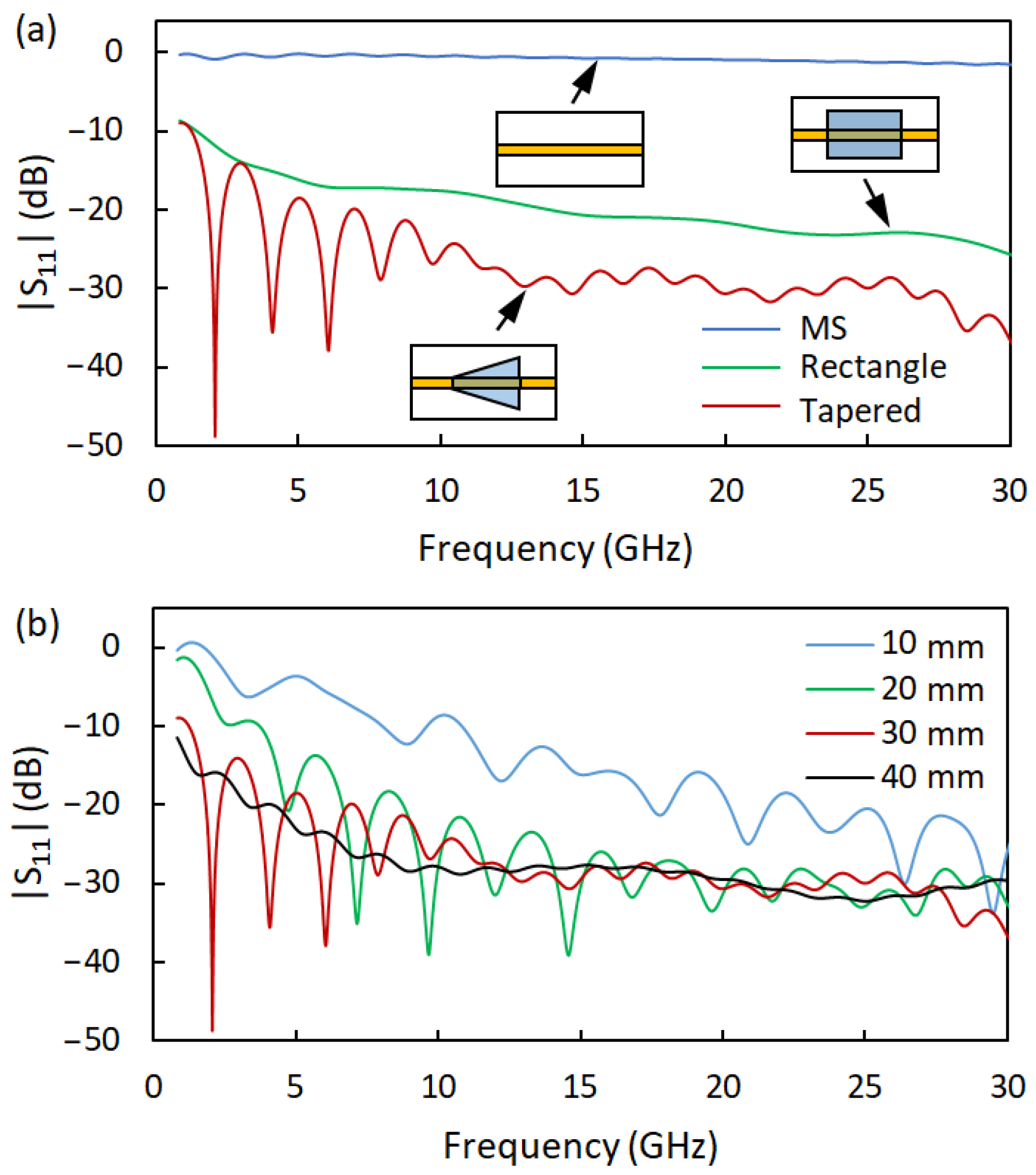

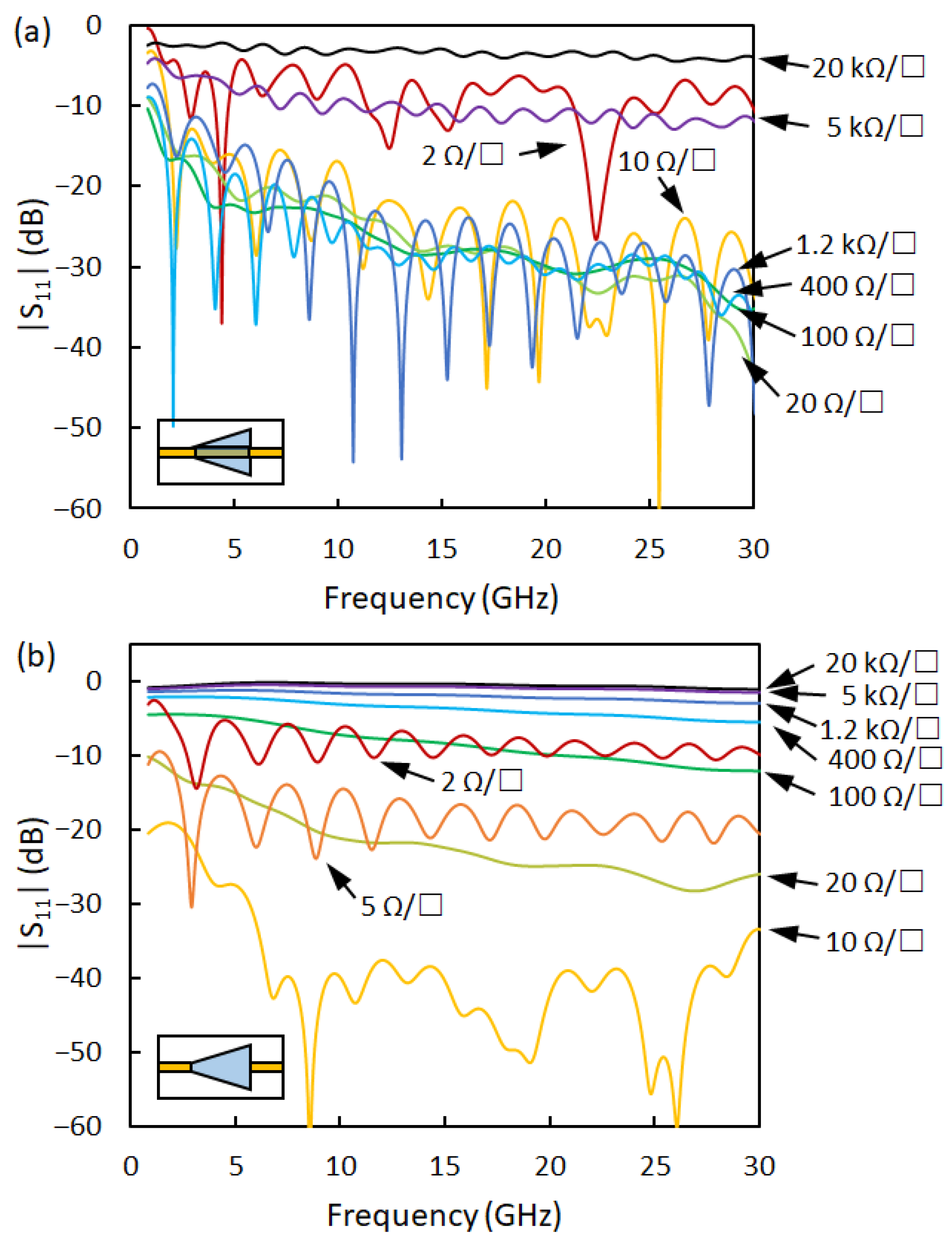

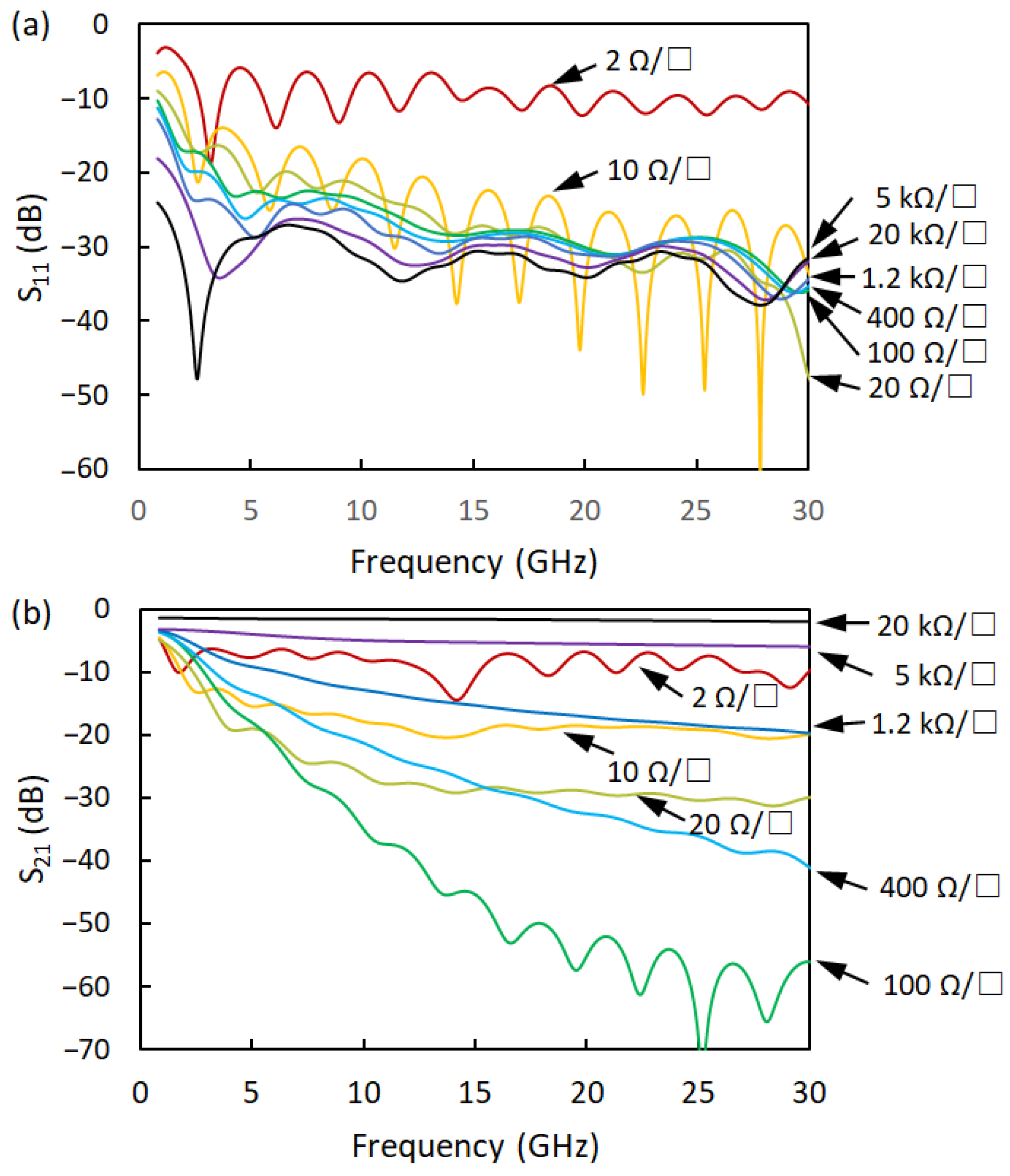

2.2. Open-End Configuration

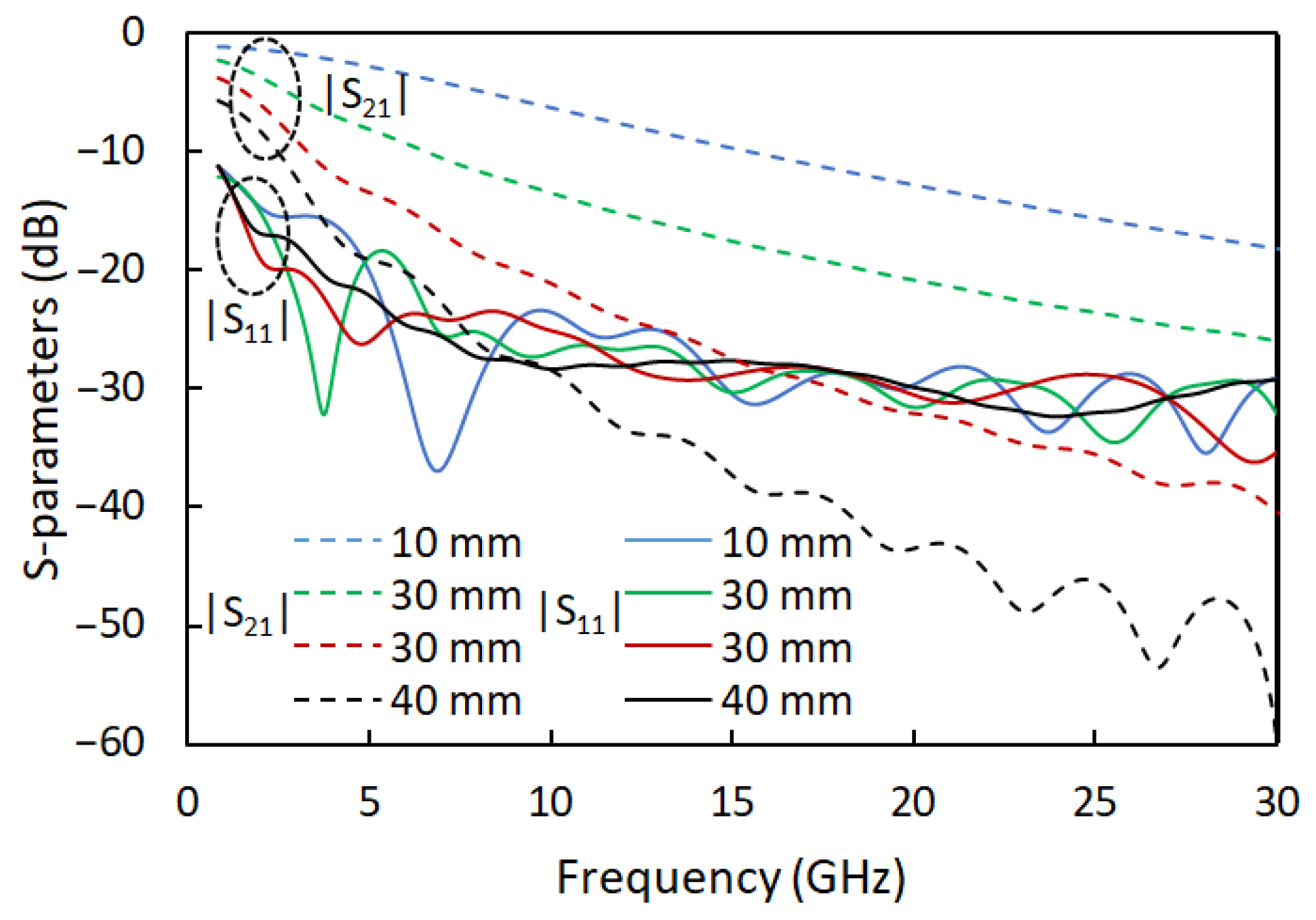

2.3. Two-Port Configuration

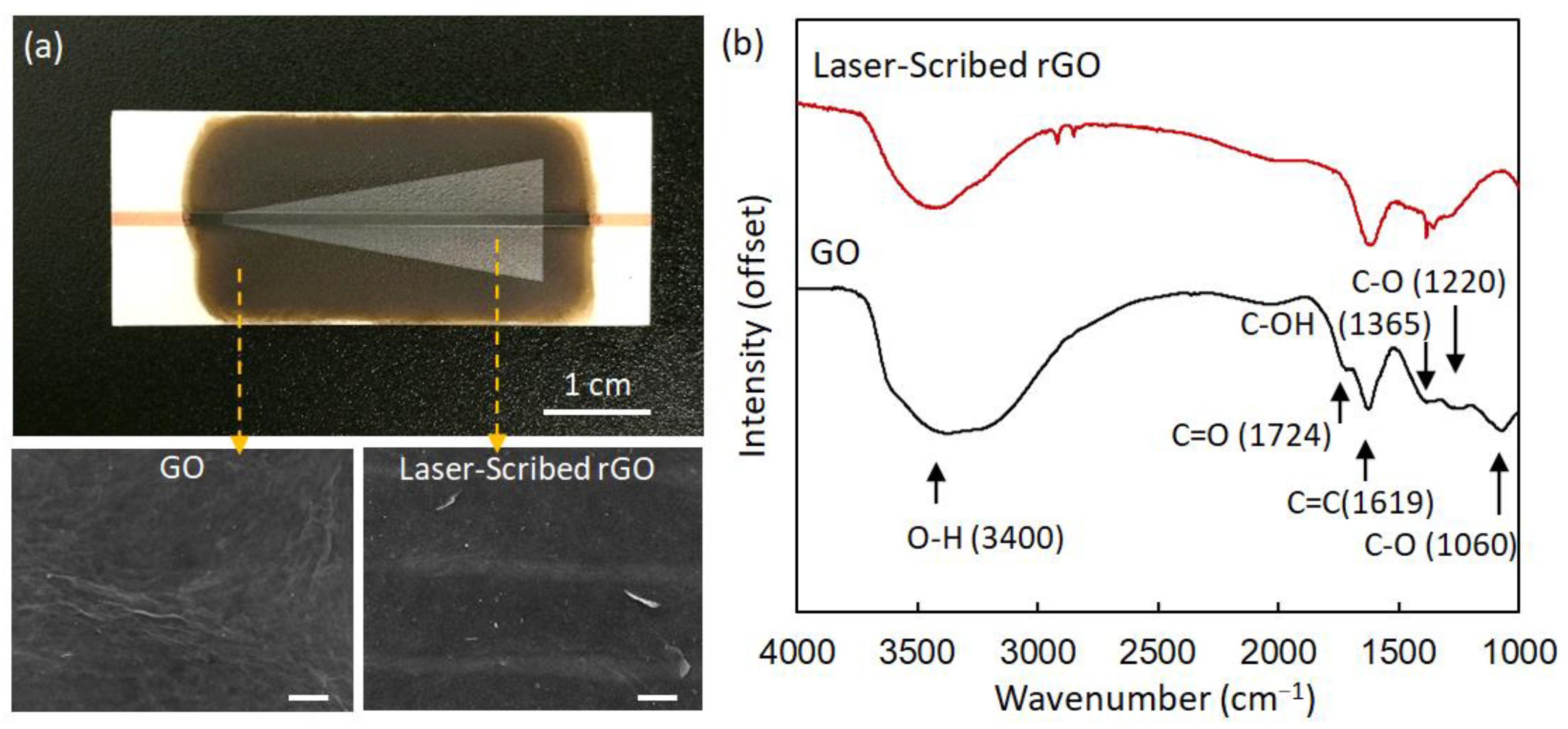

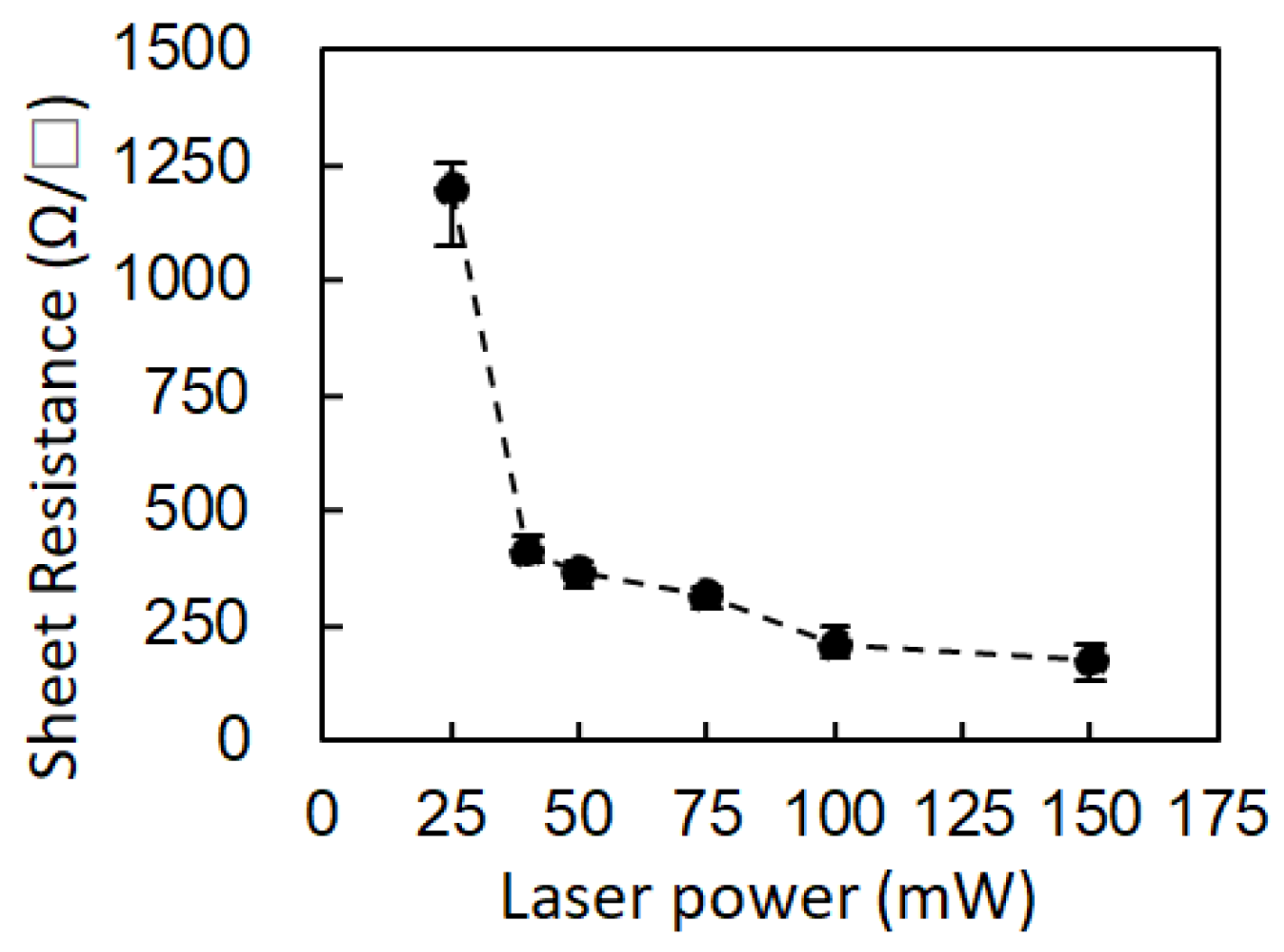

3. Fabrications

3.1. Device Fabrication

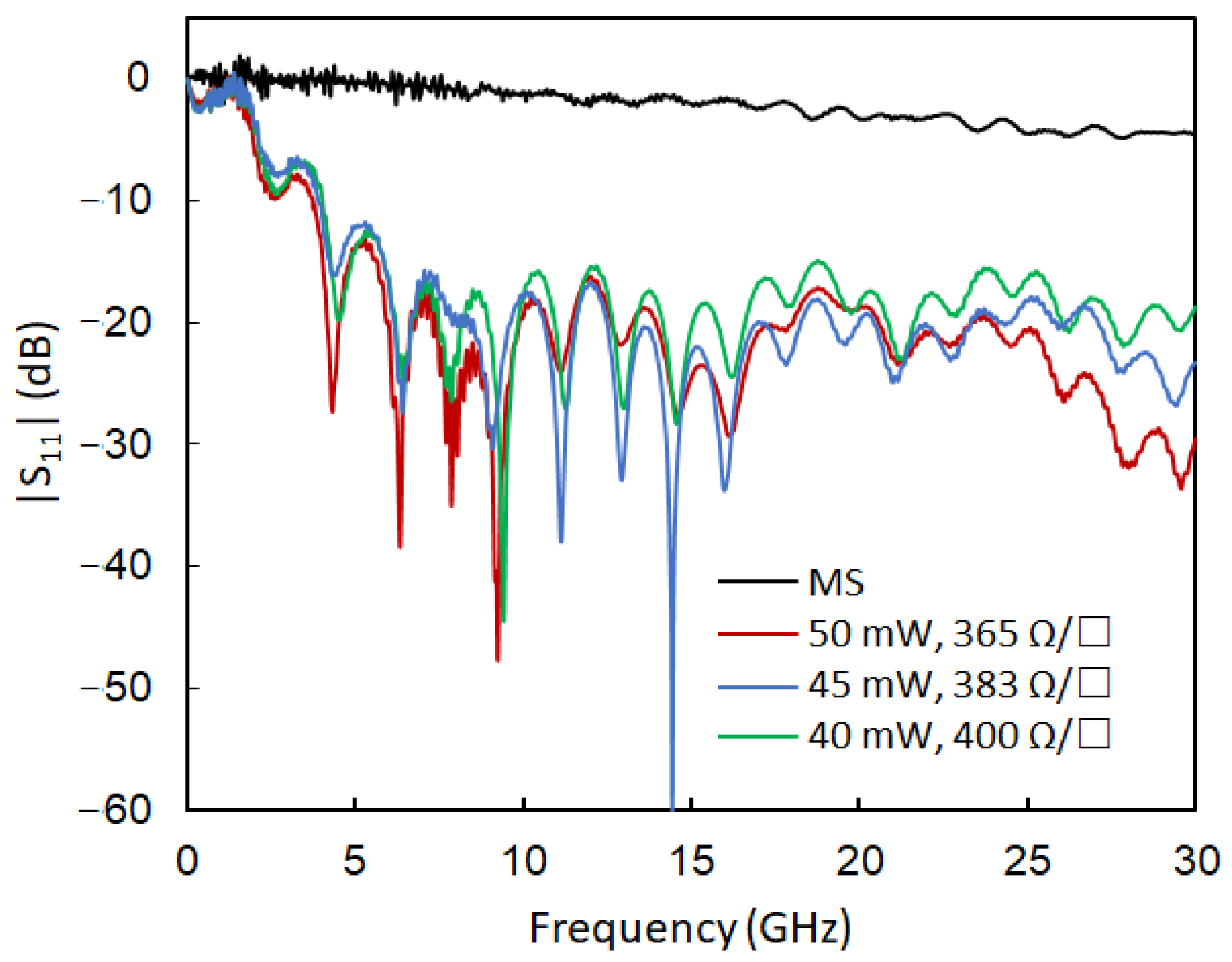

3.2. Characterization

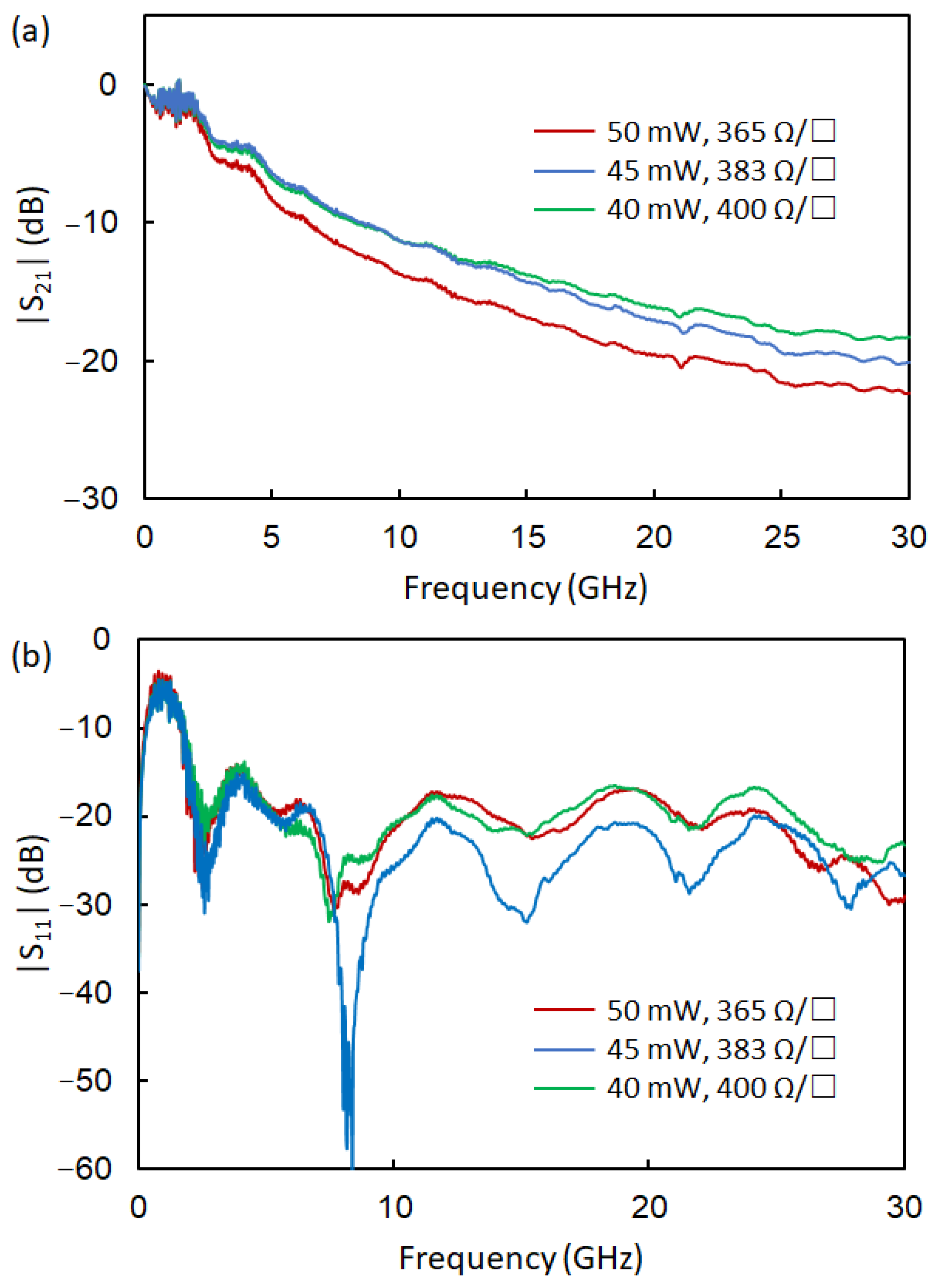

4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Morimoto, Y.; Memarian, M.; Li, X.; Itoh, T. Open-End Microstrip Line Terminations Using Lossy Gray-Scale Inkjet Printing. IEEE Trans. Microw. Theory Tech. 2017, 65, 4861–4870. [Google Scholar] [CrossRef]

- Lopez-Berrocal, B.; de-Oliva-Rubio, J.; Molina-Fernandez, I. Design and implementation of DC–20-GHz lumped resistor matched loads for planar microwave circuits. IEEE Trans. Microw. Theory Tech. 2009, 57, 2439–2443. [Google Scholar] [CrossRef]

- Dummer, M.M.; Sysak, M.N.; Tauke-Pedretti, A.; Raring, J.W.; Klamkin, J.; Coldren, L.A. Widely tunable separate absorption and modulation wavelength converter with integrated microwave termination. J. Lightwave Technol. 2008, 26, 938–944. [Google Scholar] [CrossRef]

- Arbaoui, Y.; Laur, V.; Maalouf, A.; Queffelec, P.; Passerieux, D.; Delias, A.; Blondy, P. Full 3-D printed microwave termination: A simple and low-cost solution. IEEE Trans. Microw. Theory Tech. 2015, 64, 271–278. [Google Scholar] [CrossRef]

- Lacombe, D. A Multioctave Microstrip 50-Ω Termination (Short Papers). IEEE Trans. Microw. Theory Tech. 1972, 20, 290–292. [Google Scholar] [CrossRef]

- Linner, L.; Lunden, H.B. Theory and design of broad-band nongrounded matched loads for planar circuits (short paper). IEEE Trans. Microw. Theory Tech. 1986, 34, 892–896. [Google Scholar] [CrossRef]

- Giannini, F.; Paoloni, C.; Ruggieri, M. A very broadband matched termination utilizing non-grounded radial lines. In Proceedings of the 1987 17th European Microwave Conference, Rome, Italy, 4–6 October 1987; pp. 1027–1031. [Google Scholar]

- Shu, M.; Guo, C.; Shang, X.; Zhu, W.; Zhang, A. A Ka-Band Wideband Matched Load Based on Lossy Waveguide Structures. IEEE Microw. Wirel. Compents 2020, 30, 1045–1048. [Google Scholar] [CrossRef]

- Lomakin, K.; Sippel, M.; Gold, G.; Froehlich, J.; Helmreich, K.; Ankenbrand, M.; Franke, J. Low reflective aerosol jet printed broadband matched load up to 67 GHz. In Proceedings of the 2018 11th German Microwave Conference (GeMiC), Freiburg, Germany, 12–14 March 2018; pp. 379–382. [Google Scholar]

- Hu, A.; Li, R.; Bridges, D.; Zhou, W.; Bai, S.; Ma, D.; Peng, P. Photonic nanomanufacturing of high performance energy devices on flexible substrates. J. Laser Appl. 2016, 28, 022602. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, S.; Ma, D.; Joshi, P.; Hu, A. Recent Progress on Laser Manufacturing of Microsize Energy Devices on Flexible Substrates. JOM 2018, 70, 1816–1822. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, W.; Zhu, Y.; Peng, P. The laser writing of highly conductive and anti-oxidative copper structures in liquid. Nanoscale 2020, 12, 563–571. [Google Scholar] [CrossRef]

- Li, R.-Z.; Peng, R.; Kihm, K.; Bai, S.; Bridges, D.; Tumuluri, U.; Wu, Z.; Zhang, T.; Compagnini, G.; Feng, Z. High-rate in-plane micro-supercapacitors scribed onto photo paper using in situ femtolaser-reduced graphene oxide/Au nanoparticle microelectrodes. Energy Environ. Sci. 2016, 9, 1458–1467. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Strong, V.; Dubin, S.; Kaner, R.B. Laser scribing of high-performance and flexible graphene-based electrochemical capacitors. Science 2012, 335, 1326–1330. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, W.; Singh, N.; Song, L.; Liu, Z.; Reddy, A.L.; Ci, L.; Vajtai, R.; Zhang, Q.; Wei, B.; Ajayan, P.M. Direct laser writing of micro-supercapacitors on hydrated graphite oxide films. Nat. Nanotechnol. 2011, 6, 496–500. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.; Wang, S.; Wu, J.; Yu, Y.; Li, R.; Eda, S.; Chen, J.; Feng, G.; Lawrie, B.; Hu, A. Bisphenol A Sensors on Polyimide Fabricated by Laser Direct Writing for Onsite River Water Monitoring at Attomolar Concentration. ACS Appl. Mater. Interfaces 2016, 8, 17784–17792. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhou, X.; Chen, J.; Guo, W.; He, S.; Gao, S.; Peng, P. Laser-Patterned Copper Electrodes for Proximity and Tactile Sensors. Adv. Mater. Interfaces 2020, 7, 1901845. [Google Scholar] [CrossRef]

- Li, R.; Yan, J.; Fang, Y.; Fan, X.; Sheng, L.; Ding, D.; Yin, X.; Yu, Y. Laser-Scribed Lossy Microstrip Lines for Radio Frequency Applications. Appl. Sci. 2019, 9, 415. [Google Scholar] [CrossRef] [Green Version]

- Peng, P.; Li, L.; He, P.; Zhu, Y.; Fu, J.; Huang, Y.; Guo, W. One-step selective laser patterning of copper/graphene flexible electrodes. Nanotechnology 2019, 30, 185301. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.-S.G.; Lancaster, M.J. Microstrip Filters for RF/Microwave Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004; Volume 167. [Google Scholar]

- Pozar, D.M. Microwave Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Sygellou, L.; Paterakis, G.; Galiotis, C.; Tasis, D. Work Function Tuning of Reduced Graphene Oxide Thin Films. J. Phys. Chem. C 2016, 120, 281–290. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, S.; Xiao, Z.; Hu, X.; Hong, Z.; Yi, R.; Shao, W.; Wang, Q. Preparation and characterization of novel alkali-resistant nanofiltration membranes with enhanced permeation and antifouling properties: The effects of functionalized graphene nanosheets. RSC Adv. 2017, 7, 18755–18764. [Google Scholar] [CrossRef] [Green Version]

- Dionigi, M.; Tomassoni, C.; Venanzoni, G.; Sorrentino, R. Simple High-Performance Metal-Plating Procedure for Stereolithographically 3-D-Printed Waveguide Components. IEEE Microw. Wirel. Compents 2017, 27, 953–955. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Width of the strip conductor, w1 | 1.15 mm |

| Width of the rGO resistive film, w2 | 11.70 mm |

| Length of the rGO resistive film, l | 30 mm |

| Thickness of the dielectric substrate, t | 0.508 mm |

| Thickness of the rGO film resistor, tr | 10 μm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.-Z.; Wu, Z.; Ji, J.; Yin, X.; Yan, J.; Fang, Y.; Yu, Y. A Wideband Termination Based on Laser-Scribed Lossy Microstrip Line Structures. Appl. Sci. 2021, 11, 6960. https://doi.org/10.3390/app11156960

Li R-Z, Wu Z, Ji J, Yin X, Yan J, Fang Y, Yu Y. A Wideband Termination Based on Laser-Scribed Lossy Microstrip Line Structures. Applied Sciences. 2021; 11(15):6960. https://doi.org/10.3390/app11156960

Chicago/Turabian StyleLi, Ruo-Zhou, Zheyuan Wu, Junhui Ji, Xiaoxing Yin, Jing Yan, Yuming Fang, and Ying Yu. 2021. "A Wideband Termination Based on Laser-Scribed Lossy Microstrip Line Structures" Applied Sciences 11, no. 15: 6960. https://doi.org/10.3390/app11156960

APA StyleLi, R.-Z., Wu, Z., Ji, J., Yin, X., Yan, J., Fang, Y., & Yu, Y. (2021). A Wideband Termination Based on Laser-Scribed Lossy Microstrip Line Structures. Applied Sciences, 11(15), 6960. https://doi.org/10.3390/app11156960