Noisy Optimization of Dispatching Policy for the Cranes at the Storage Yard in an Automated Container Terminal

Abstract

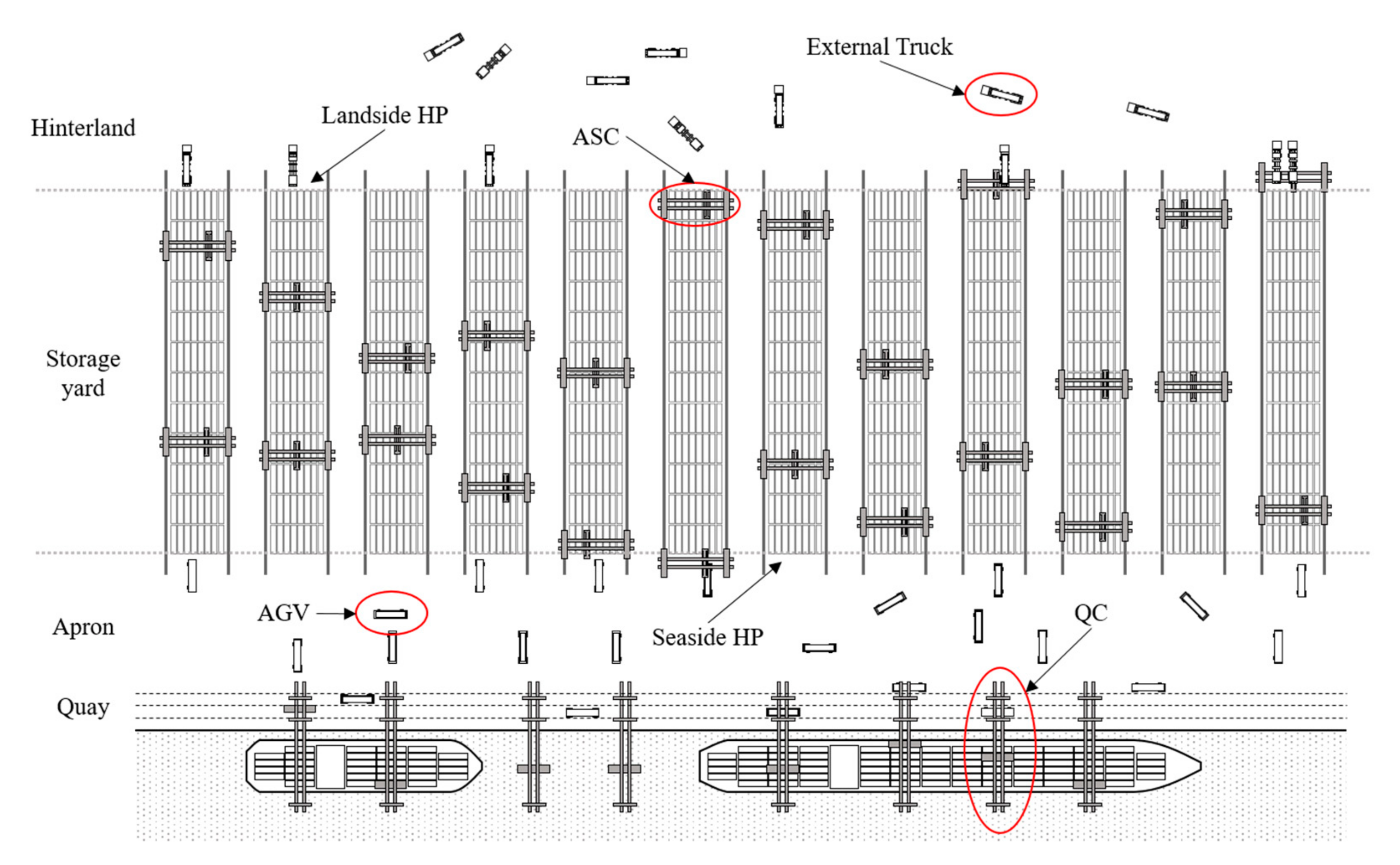

1. Introduction

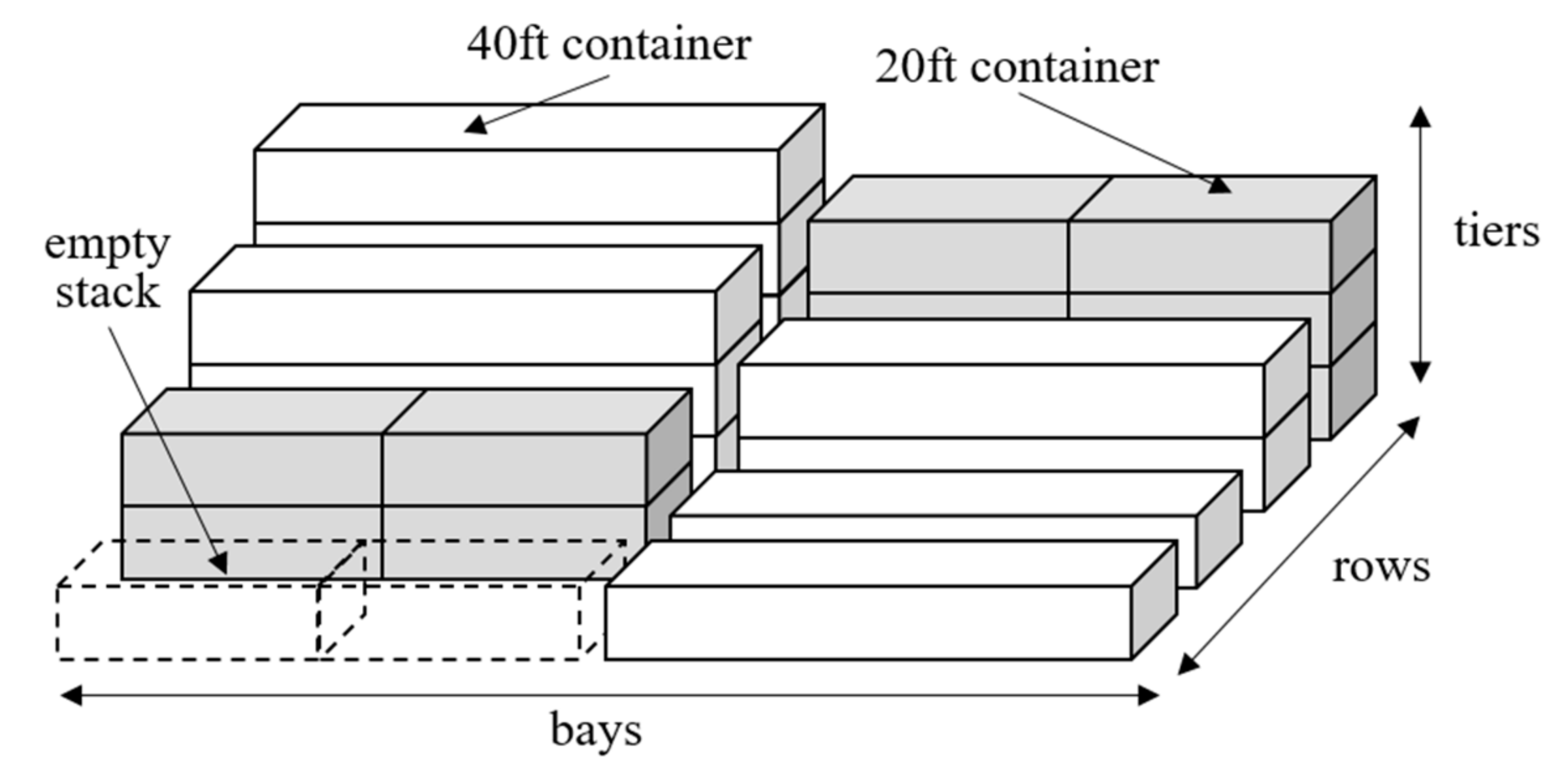

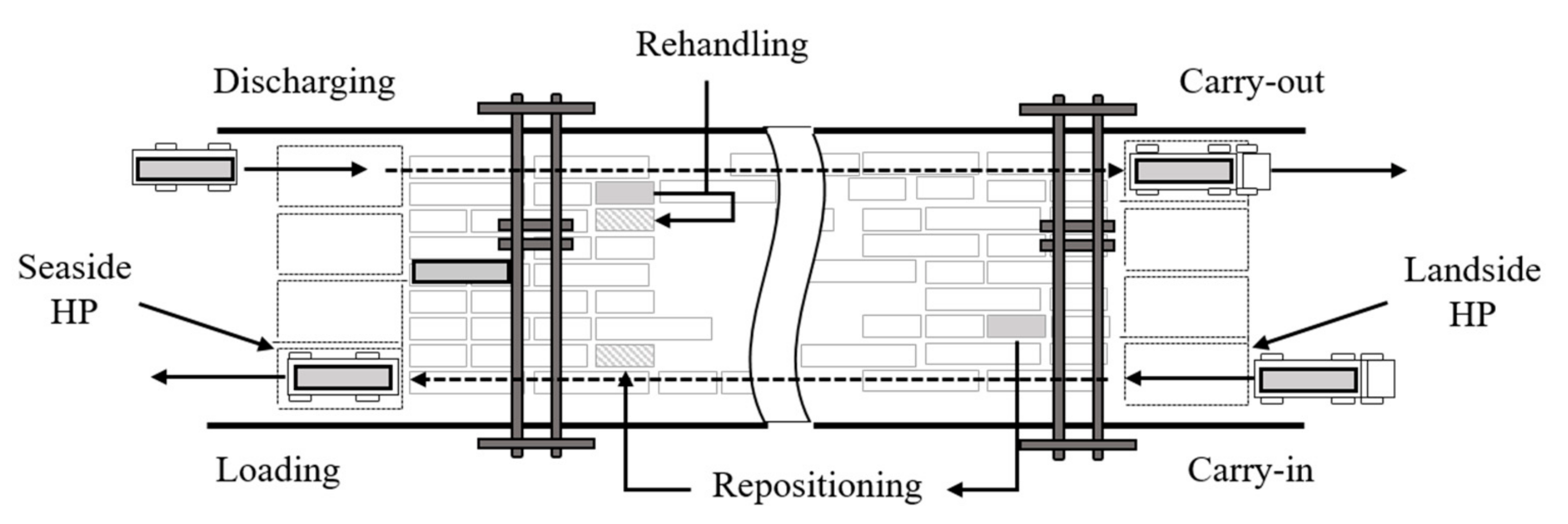

2. Operations of Automated Stacking Cranes

3. Related Work

4. Policy Optimization

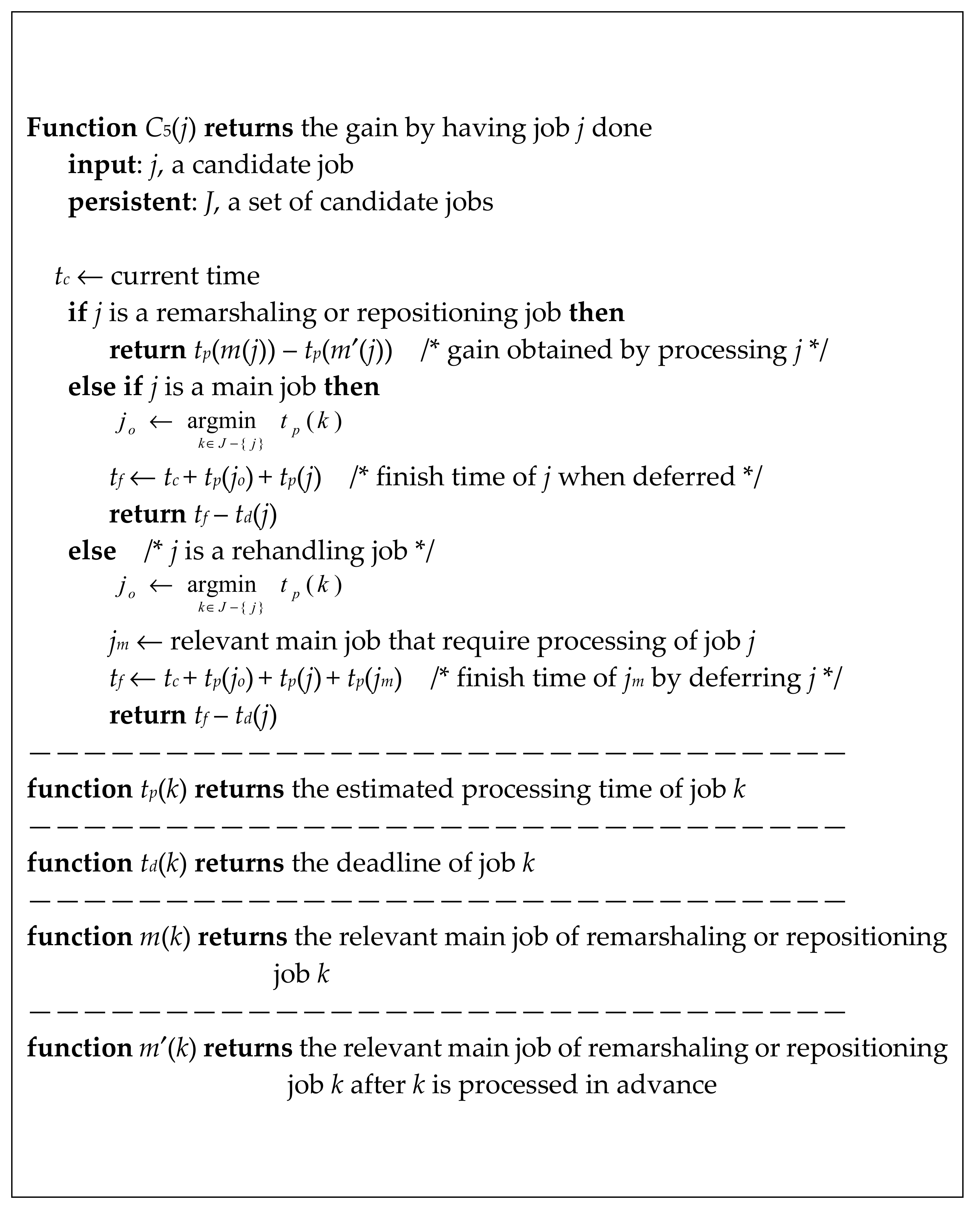

4.1. Crane Dispatching Policy

4.2. Objective Function

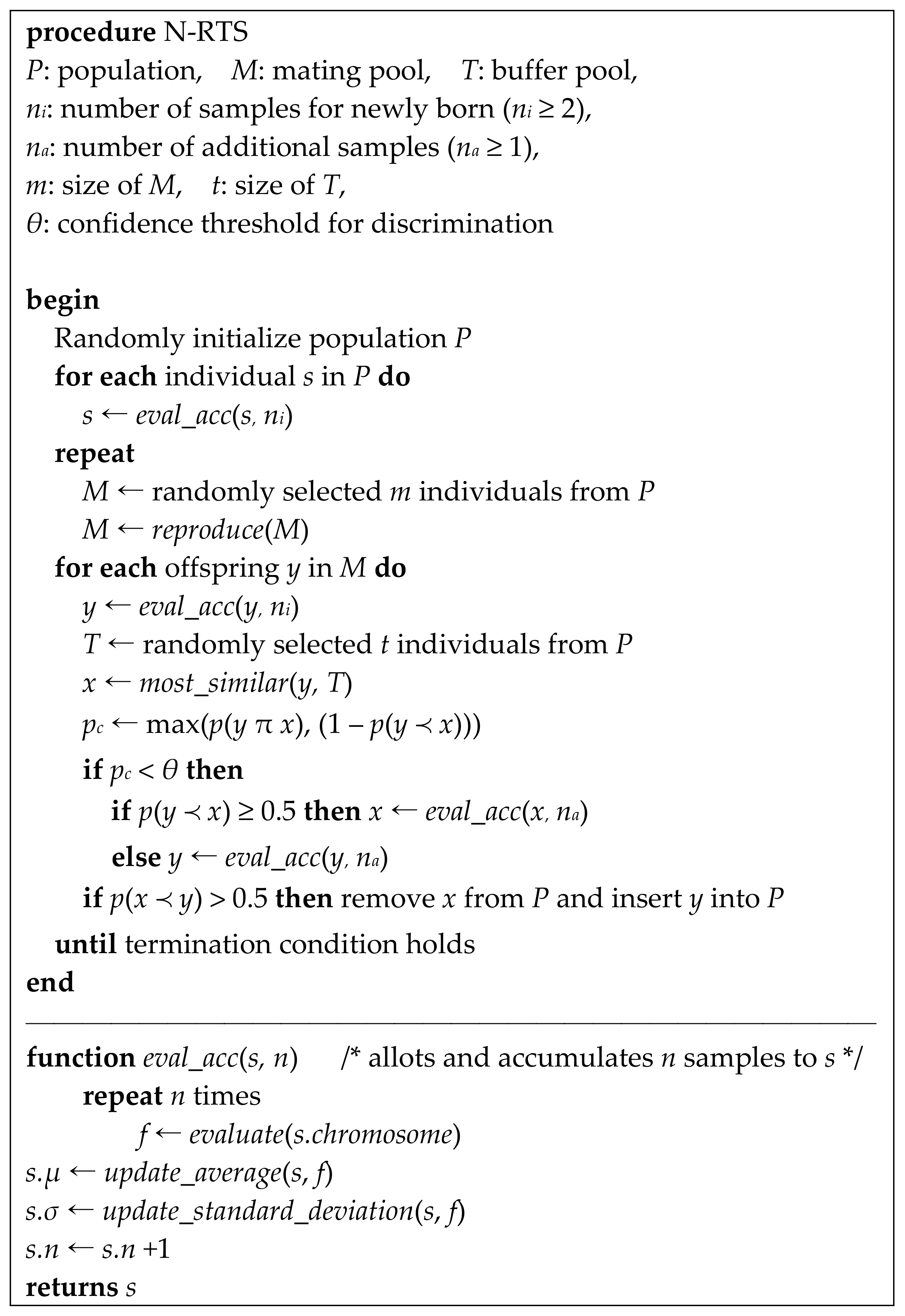

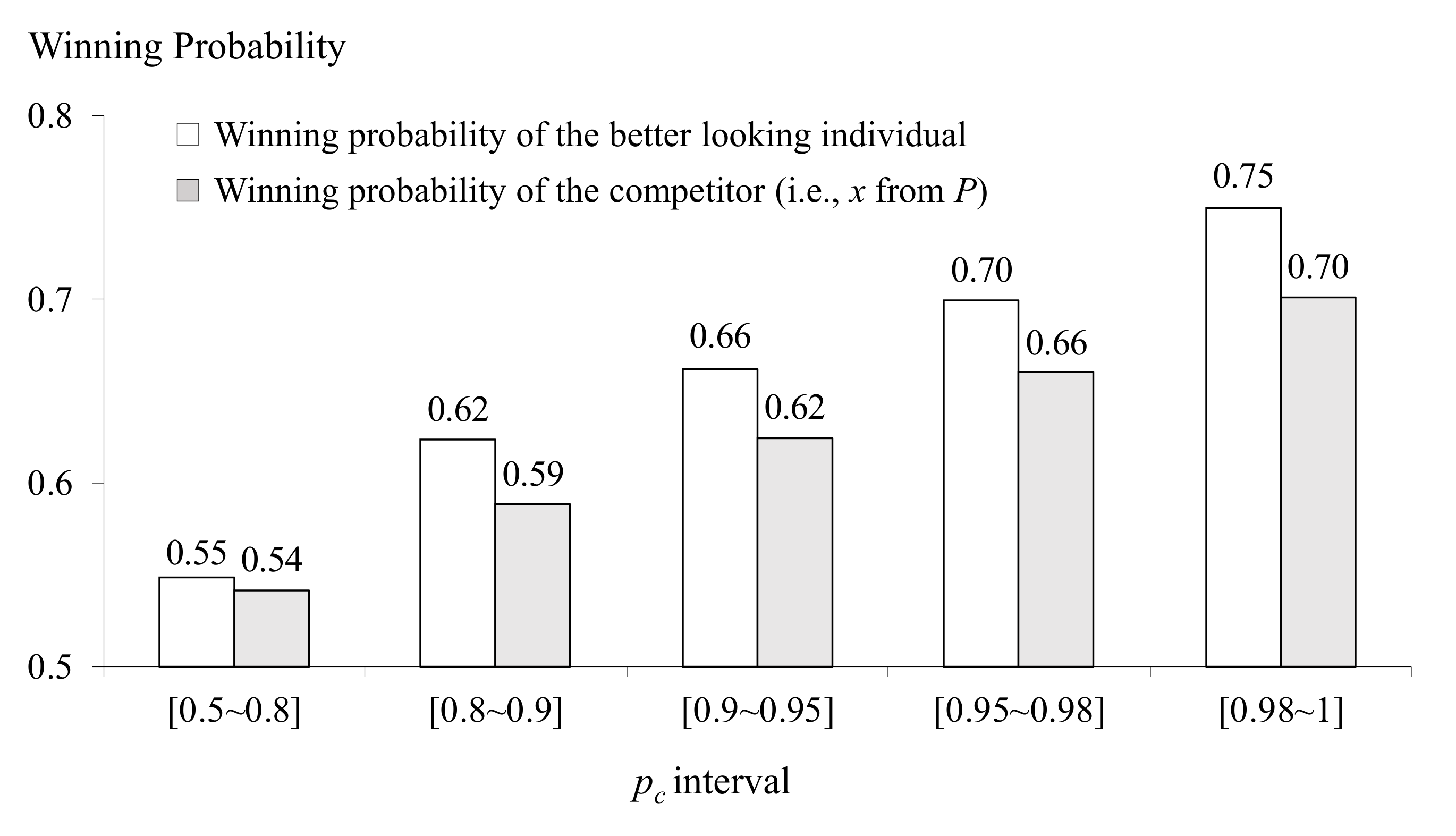

4.3. Noisy Optimization of Crane Dispatching Policy

5. Experimental Results

5.1. Simulation Scenarios

5.2. Experimental Setting

5.3. Performance Comparison

5.4. Test Results with Benchmark Functions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, T.; Choe, R.; Ok, S.M.; Ryu, K.R. Real-time scheduling for twin RMGs in an automated container yard. OR Spectr. 2010, 32, 593–615. [Google Scholar] [CrossRef]

- Ng, W.C.; Mak, K.L. Yard crane scheduling in port container terminals. Appl. Math. Model. 2005, 29, 263–276. [Google Scholar] [CrossRef]

- Li, W.; Wu, Y.; Petering, M.E.H.; Goh, M.; de Souza, R. Discrete time model and algorithms for container yard crane scheduling. Eur. J. Oper. Res. 2009, 198, 165–172. [Google Scholar] [CrossRef]

- He, J.; Chang, D.; Mi, W.; Yan, W. A hybrid parallel genetic algorithm for yard crane scheduling. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 136–155. [Google Scholar] [CrossRef]

- Choe, R.; Kim, T.S.; Kim, T.; Ryu, K.R. Crane scheduling for opportunistic remarshaling of containers in an automated stacking yard. Flex. Serv. Manuf. J. 2015, 27, 331–349. [Google Scholar] [CrossRef]

- Hu, Z.H.; Sheu, J.B.; Luo, J.X. Sequencing twin automated stacking cranes in a block at automated container terminal. Transp. Res. Part C Emerg. Technol. 2016, 69, 208–227. [Google Scholar] [CrossRef]

- Jiang, X.J.; Jin, J.G. A branch-and-price method for integrated yard crane deployment and container allocation in transshipment yards. Transp. Res. Part B Methodol. 2017, 98, 62–75. [Google Scholar] [CrossRef]

- Aizawa, A.N.; Wah, B.W. Scheduling of Genetic Algorithms in a Noisy Environment. Evol. Comput. 1994, 2, 97–122. [Google Scholar] [CrossRef]

- Di Pietro, A. Optimising Evolutionary Strategies for Problems with Varying Noise Strength; The University of Western Australia: Perth, Australia, 2007. [Google Scholar]

- Zhang, Z.; Xin, T. Immune Algorithm with Adaptive Sampling in Noisy Environments and Its Application to Stochastic Optimization Problems. IEEE Comput. Intell. Mag. 2007, 2, 29–40. [Google Scholar] [CrossRef]

- Park, T.; Ryu, K.R. Accumulative sampling for noisy evolutionary multi-objective optimization. In Proceedings of the 13th Annual Conference on Genetic and Evolutionary Computation—GECCO’11, Dublin, Ireland, 12–16 July 2011; ACM Press: New York, NY, USA, 2011; pp. 793–800. [Google Scholar]

- Jang, H.; Choe, R.; Ryu, K.R. Deriving a robust policy for container stacking using a noise-tolerant genetic algorithm. In Proceedings of the 2012 ACM Research in Applied Computation Symposium on—RACS’12, San Antonio, TX, USA, 23–26 October 2012; ACM Press: New York, NY, USA, 2012; p. 31. [Google Scholar] [CrossRef]

- Fieldsend, J.E.; Everson, R.M. The Rolling Tide Evolutionary Algorithm: A Multiobjective Optimizer for Noisy Optimization Problems. IEEE Trans. Evol. Comput. 2015, 19, 103–117. [Google Scholar] [CrossRef]

- Hong, J.H.; Ryu, K.R. Simulation-based multimodal optimization of decoy system design using an archived noise-tolerant genetic algorithm. Eng. Appl. Artif. Intell. 2017, 65, 230–239. [Google Scholar] [CrossRef]

- Choe, R.; Jang, H.; Ryu, K.R. Deriving a Robust Policy for Container Stacking Using a Noise-Tolerant Genetic Algorithm. Information 2013, 16, 6219–6242. [Google Scholar]

- Kim, J.; Ryu, K.R. An RTS-based algorithm for noisy optimization by strategic sample accumulation. In Proceedings of the 2020 Genetic and Evolutionary Computation Conference Companion, Cancún, Mexico, 8–12 July 2020; ACM: New York, NY, USA, 2020; pp. 45–46. [Google Scholar]

- Kim, T.; Yang, Y.; Bae, A.; Ryu, K.R. Optimization of Dispatching Strategies for Stacking Cranes including Remarshaling Jobs. J. Navig. Port Res. 2014, 38, 155–162. [Google Scholar] [CrossRef]

- Briskorn, D.; Emde, S.; Boysen, N. Cooperative twin-crane scheduling. Discret. Appl. Math. 2016, 211, 40–57. [Google Scholar] [CrossRef]

- Gharehgozli, A.H.; Laporte, G.; Yu, Y.; de Koster, R. Scheduling Twin Yard Cranes in a Container Block. Transp. Sci. 2015, 49, 686–705. [Google Scholar] [CrossRef]

- Hirashima, Y.; Takeda, K.; Harada, S.; Deng, M.; Inoue, A. A Q-Learning for Group-Based Plan of Container Transfer Scheduling. JSME Int. J. Ser. C 2006, 49, 473–479. [Google Scholar] [CrossRef][Green Version]

- Kang, J.; Oh, M.-S.; Ahn, E.Y.; Ryu, K.R.; Kim, K.H. Planning for Intra-block Remarshalling in a Container Terminal. In Advances in Applied Artificial Intelligence; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1211–1220. [Google Scholar] [CrossRef]

- Park, K.; Park, T.; Ryu, K.R. Planning for Selective Remarshaling in an Automated Container Terminal Using Coevolutionary Algorithms. Int. J. Ind. Eng. Theory Appl. Pract. 2013, 20, 176–187. [Google Scholar]

- Di Pietro, A.; While, L.; Barone, L. Applying evolutionary algorithms to problems with noisy, time-consuming fitness functions. In Proceedings of the 2004 Congress on Evolutionary Computation (IEEE Cat. No.04TH8753), Portland, OR, USA, 19–23 June 2004; pp. 1254–1261. [Google Scholar]

- Mininno, E.; Neri, F. A memetic Differential Evolution approach in noisy optimization. Memetic Comput. 2010, 2, 111–135. [Google Scholar] [CrossRef]

- Siegmund, F.; Ng, A.H.C.; Deb, K. A comparative study of dynamic resampling strategies for guided Evolutionary Multi-objective Optimization. In Proceedings of the 2013 IEEE Congress on Evolutionary Computation, CEC 2013, Cancun, Mexico, 20–23 June 2013. [Google Scholar]

- Harik, G.R. Finding Multimodal Solutions Using Restricted Tournament Selection. In Proceedings of the 6th International Conference on Genetic Algorithms, San Francisco, CA, USA, 15–19 July 1995; Morgan Kaufmann Publishers Inc.: San Francisco, CA, USA, 1995; pp. 24–31. [Google Scholar]

- Park, T.; Sohn, M.; Ryu, K.R. Optimizing stacking policies using an MOEA for an automated container terminal. In Proceedings of the 40th International Conference on Computers & Indutrial Engineering, Awaji, Japan, 25–28 July 2010; pp. 1–6. [Google Scholar]

- Jin, Y.; Branke, J. Evolutionary Optimization in Uncertain Environments—A Survey. IEEE Trans. Evol. Comput. 2005, 9, 303–317. [Google Scholar] [CrossRef]

- Yu, X.; Gen, M. Introduction to Evolutionary Algorithms; Decision Engineering; Springer: London, UK, 2010; ISBN 978-1-84996-128-8. [Google Scholar]

- Park, T.; Choe, R.; Hun Kim, Y.; Ryel Ryu, K. Dynamic adjustment of container stacking policy in an automated container terminal. Int. J. Prod. Econ. 2011, 133, 385–392. [Google Scholar] [CrossRef]

| Description | Criterion | Relevant Job Type |

|---|---|---|

| Empty travel distance | C1 | All types |

| Margin to due time | C2,a | Seaside job |

| Seaside rehandling job | ||

| Seaside repositioning job | ||

| C2,b | Landside job | |

| Landside rehandling job | ||

| Landside repositioning job | ||

| C2,c | Remarshaling job | |

| Probability of ASC interference | C3 | All types |

| Estimated processing time | C4 | All types |

| Gain by doing the current job | C5,d | Seaside job |

| C5,e | Seaside rehandling job | |

| C5,f | Seaside repositioning job | |

| C5,g | Landside job | |

| C5,h | Landside rehandling job | |

| C5,i | Landside repositioning job | |

| C5,j | Remarshaling job | |

| Advantage if done by the other ASC | C6 | All types |

| Waiting time by ASC interference | C7 | All types |

| Job priority | C8 | All types |

| Time available for remarshaling | C9 | All types |

| Parameter | Value |

|---|---|

| Block size | 41 bays, 10 rows, 5 tiers |

| Duration of simulation | 14 days of initialization + 7 days of evaluation |

| Discharging jobs per day | 120 containers |

| Loading jobs per day | 120 containers |

| Proportion of transshipment jobs | 45% |

| Average occupancy rate | 60% |

| OnS | PS | |

|---|---|---|

| Length of horizon | 30 min. | 60 min. |

| Rescheduling interval | 15 min. | After each job |

| No. of evaluations for search | 800/rescheduling | - |

| Weights for objectives | 300: 1 | 100: 1 |

| PS by N-RTS | PS by NTGA | OnS | |

|---|---|---|---|

| AGV delay (sec) | 16.9 ± 1.2 | 18.7 ± 0.8 | 19.3 ± 2.1 |

| ET waiting (sec) | 293.6 ± 59.6 | 370.2 ± 71.7 | 771.8 ± 69.7 |

| t-test (AGV delay) | NTGA, OnS | - | - |

| t-test (ET waiting) | NTGA, OnS | OnS | - |

| Horizon Length (min) | Objective Weights (AGV Delay: ET Waiting) | AGV Delay (sec) | ET Waiting (sec) |

|---|---|---|---|

| 30 | 50: 1 | 21.4 ± 1.9 | 550.3 ± 112.3 |

| 100: 1 | 26.4 ± 2.3 | 782.5 ± 135.2 | |

| 300: 1 | 20.4 ± 2.4 | 547.7 ± 89.4 | |

| 500: 1 | 24.1 ± 2.5 | 813.5 ± 90.2 | |

| 60 | 50: 1 | 23.5 ± 1.8 | 284.4 ± 82.1 |

| 100: 1 | 16.8 ± 1.4 | 298.2 ± 62.4 | |

| 300: 1 | 17.5 ± 2.3 | 287.3 ± 72.3 | |

| 500: 1 | 24.4 ± 2.6 | 361.5 ± 100.2 | |

| 90 | 50: 1 | 18.5 ± 2.9 | 346.3 ± 130.7 |

| 100: 1 | 21.6 ± 3.1 | 338.5 ± 149.1 | |

| 300: 1 | 21.3 ± 2.2 | 357.9 ± 101.2 | |

| 500: 1 | 28.8 ± 2.2 | 366.5 ± 200.6 |

| Function | Decision Space | |

|---|---|---|

| Ackley | [−1, 1]n | |

| Alpine | [−10, 10]n | |

| Axis-parallel | [−5.12, 5.12]n | |

| DeJong | [−5.12, 5.12]n | |

| Drop wave | [−5.12, 5.12]n |

| σ | Ackley | Alpine | Axis Parallel | DeJong | Drop Wave | |

|---|---|---|---|---|---|---|

| RTS | 5% | + | + | + | + | + |

| 10% | + | + | + | + | + | |

| 20% | + | + | + | + | + | |

| NTGA | 5% | + | + | = | = | = |

| 10% | + | + | = | = | = | |

| 20% | = | + | = | = | = | |

| DS | 5% | + | + | + | + | + |

| 10% | + | + | + | + | + | |

| 20% | + | + | + | + | + | |

| MDE | 5% | + | + | + | + | = |

| 10% | + | + | + | + | + | |

| 20% | + | + | + | + | + |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Hong, E.J.; Yang, Y.; Ryu, K.R. Noisy Optimization of Dispatching Policy for the Cranes at the Storage Yard in an Automated Container Terminal. Appl. Sci. 2021, 11, 6922. https://doi.org/10.3390/app11156922

Kim J, Hong EJ, Yang Y, Ryu KR. Noisy Optimization of Dispatching Policy for the Cranes at the Storage Yard in an Automated Container Terminal. Applied Sciences. 2021; 11(15):6922. https://doi.org/10.3390/app11156922

Chicago/Turabian StyleKim, Jeongmin, Ellen J. Hong, Youngjee Yang, and Kwang Ryel Ryu. 2021. "Noisy Optimization of Dispatching Policy for the Cranes at the Storage Yard in an Automated Container Terminal" Applied Sciences 11, no. 15: 6922. https://doi.org/10.3390/app11156922

APA StyleKim, J., Hong, E. J., Yang, Y., & Ryu, K. R. (2021). Noisy Optimization of Dispatching Policy for the Cranes at the Storage Yard in an Automated Container Terminal. Applied Sciences, 11(15), 6922. https://doi.org/10.3390/app11156922