Development of a Steel Plant Rescheduling Algorithm Based on Batch Decisions

Abstract

:Featured Application

Abstract

1. Introduction

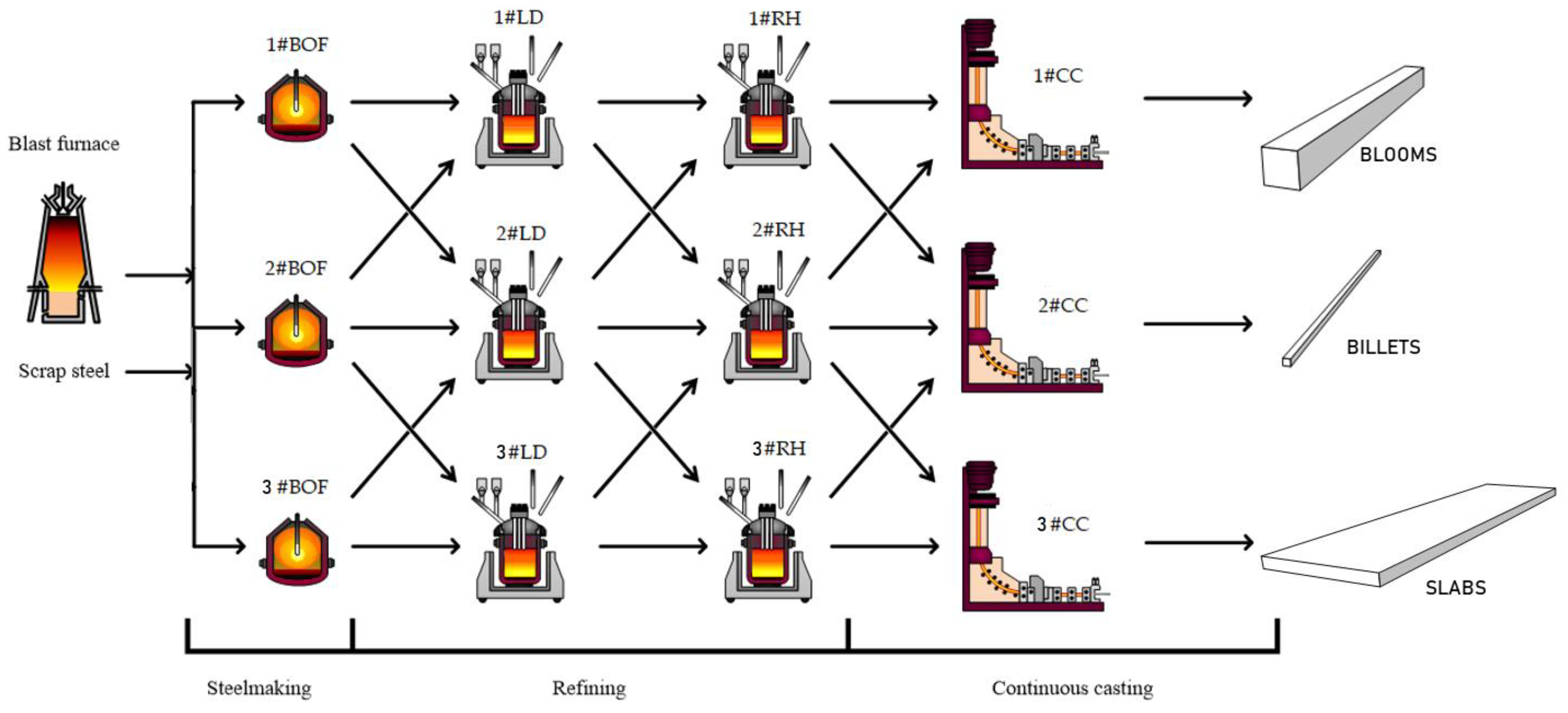

- Batch decisions, in which the primary requirements of orders are transformed into production batches. There are two types of batches in steel mill production. One is called heat and the other is cast or tundish.

- Scheduling decisions, i.e., allocation, sequencing and timing of heats and casts in the relevant facilities, from steel fabrication to continuous casting production, including intermediate treatments.

2. Method

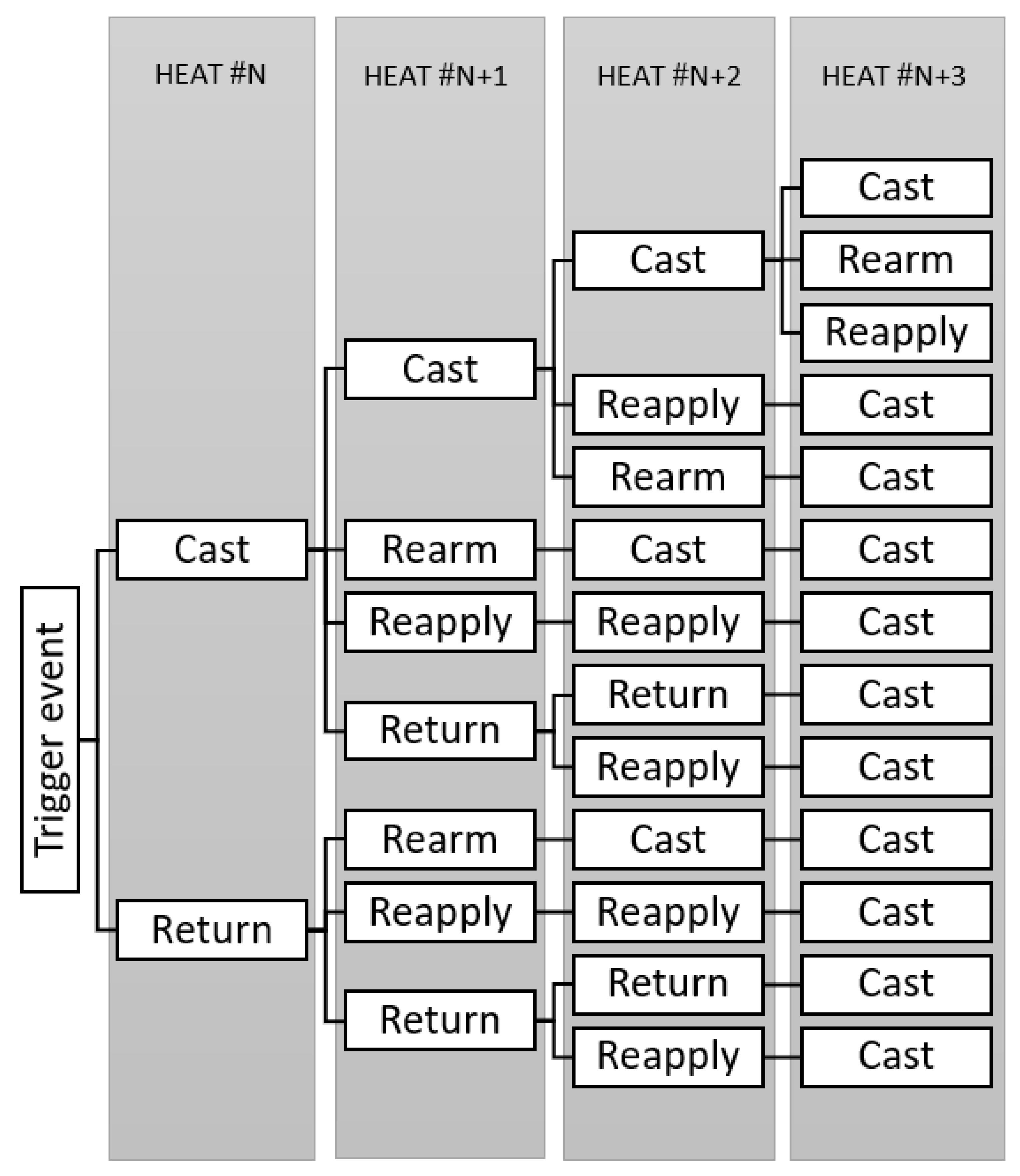

- Cast the heat, following the sequence;

- Return the heat to converter;

- Reapply the heat to a different quality;

- Rearm the machine and cast the heat by starting a new sequence.

- Only one of the heats can have the rearm condition,

- After a rearm, the heats can only have the condition of cast

- The first heat, located in the continuous casting machine at the time of event T, cannot have the condition of reapply or rearm.

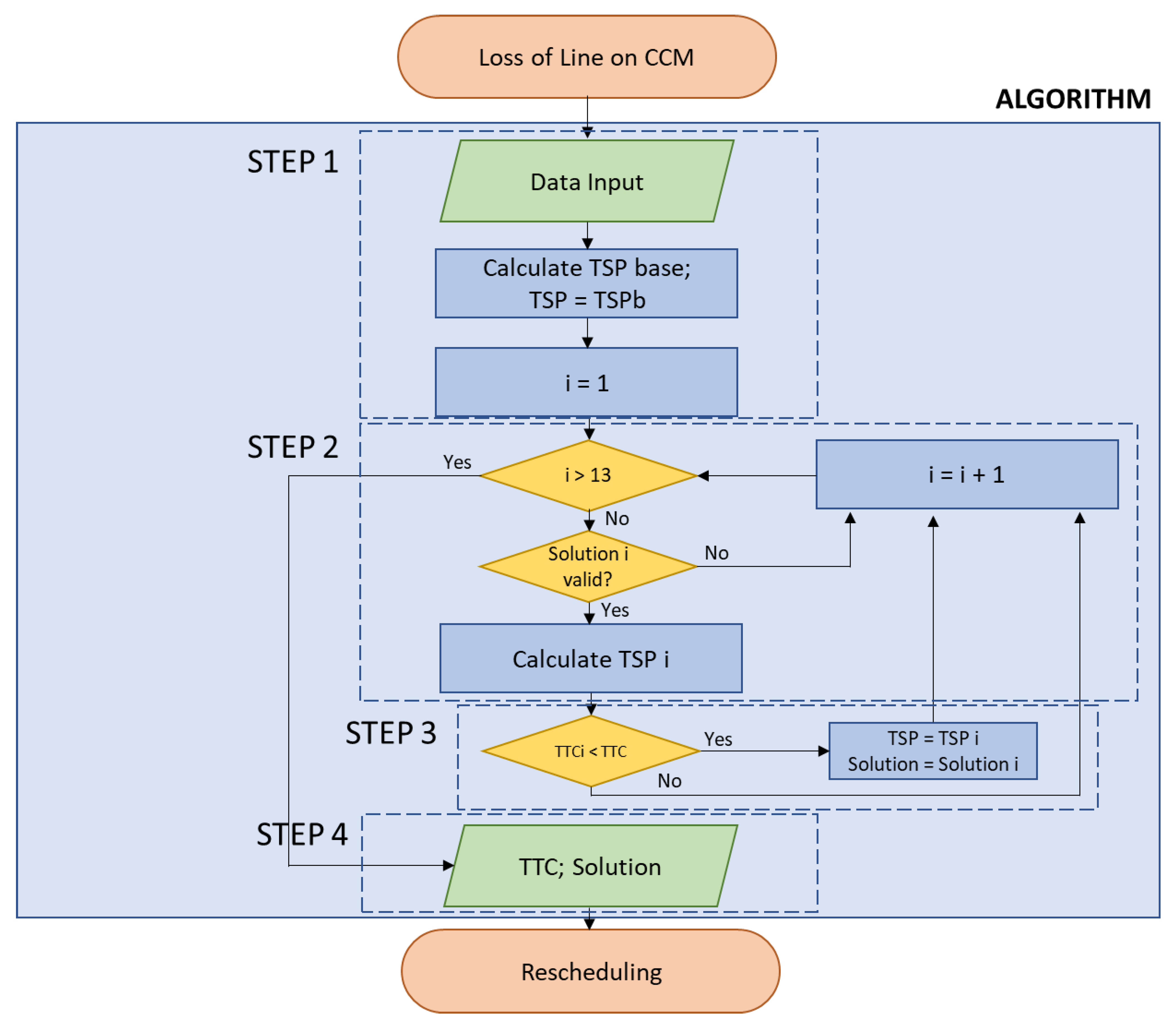

- Time instant (T): time at which the line loss trigger event occurs, as previously defined.

- Heat number (N): position in the tundish where the heat is scheduled in the casting machine at the time of the line loss.

- Tundish warm-up time (Tqt): Time that the tundish of the following sequence has been heating up at time T.

- Final casting time (TfcN + i): time required to finish the treatment in the continuous casting of the N + i heat, where I = {0,1,2,3,4,…}.

- Load start time (TckN + i): load start time in converters of the N + I heat, where I = {0,1,2,3,4,…}.

- Sequentially index (Sn + 1): this index is established between two consecutive heats and indicates whether a heat can be casted sequentially with the previous one without generating quality problems. S = {0.1}.

- Reapplicability Index (Rn): Indicates whether a heat can be reapplied to a different quality or not. R = {0.1}.

- Active lines (L): number of active lines after the disruptive event.

- No. of heat in tundish. Indicates the position in the tundish of the heat that is being casted in the casting machine when the partial or total closure of the lines occurs. This heat is called heat N.

- Total heats in tundish. Indicates the total number of heats scheduled in the current sequence. The algorithm defines the sequentially index between heats based on this number and the target quality for the steel grade of the sequence.

- Weight of ladle in T. Indicates the percentage of heat already processed at time T. It allows calculating the final casting time for the heat that is in process at time T, that is, casting N.

- Number of active lines after T (L). It indicates the number of active lines after the instant T, which allows calculating the time it would take each of the subsequent heats to be processed in Continuous Casting.

- Quality of the tundish. Indicates the steel quality target of the current tundish.

- Quality of the next tundish. Indicates the steel quality objective of the following tundish. Indicates if two tundish are sequential with each other, and therefore the heats included in these.

- N + 1 cast reapplicability. Indicates whether there is a possibility to adjust the composition of the N + 1 heat to the quality of the next scheduled tundish.

- N + 2 cast reapplicability. Indicates whether there is a possibility to adjust the composition of the N + 2 heat to the quality of the next scheduled tundish.

- Tundish warm-up time. Indicates if the physical tundish for the next sequence has been set to preheat before instant T, and in that case, how long it has been heating.

3. Results

3.1. Dataset

- Each continuous casting machine was assumed to process 12 to 16 casts continuously and uninterruptedly. The two machines were considered capable of casting different types of steel, being incompatible with each other and obtaining from one of them billets as semi-products, with six casting lines, and blooms from the other, with three casting lines.

- Seven different classes of steels were considered, representing their families. Five of these classes come from the billet machine, each one having its own casting speed, according to the characteristics of the machine and the steel class itself. The remaining two families are obtained from the bloom machine, also representing a different width format, and therefore, also a different casting speed.

- A machine casting time was set for each heat; this varies depending on the quality of the product and the number of lines available. A maximum ladle time in tundish was also assumed to prevent cold steel closures.

- It was considered as a rule that a tundish is sequential with the previous one if the heats share the same quality and therefore can be cast consecutively without degradation of quality.

- It was also considered that a certain heat is reapplicable if its composition at time T is such that, by means of additions, a new steel composition compatible with a change in the objective of quality of the heat can be achieved.

- A stipulated fixed time was defined for machine reset, also considering that it takes time to warm up the tundish before starting any sequence. If the interruption occurs at the end of the sequence, the tundish warm-up will have already started.

- No. of heats in tundish: Random number between 1 the total number of heats of the tundish.

- Total heats in tundish: Random number between 12 and 16, according to the normal operation of the steel mill.

- Number of active lines after T (L): Random number between 0 and 2 for Bloom Tundish and between 0 and 5 for Billet Tundish.

- Weight of laddle in T (Tn): The weight was considered as a random number between 5 (weight of a ladle at the end of the continuous casting phase and to be replaced by the next one) and 115 (weight of a ladle at the beginning of its continuous casting phase).

- Quality of the tundish: The different types of steel were numbered (7), and a random number between 0 and 7 was obtained to represent the quality of the tundish.

- Quality of the next tundish: The different types of steel were numbered (7), and a random number between 0 and 7 was obtained to represent the quality of the next tun-dish.

- N + 1 heat reapplicability: Always Yes if the N heat is last of tundish (and therefore, the initial programming for this heat is maintained, regardless of the machine), otherwise Yes or No randomly.

- N + 2 heat reapplicability: Always Yes if the N + 1 heat is reapplicable or if the Heat N is the penultimate of the tundish. Otherwise, Yes or No randomly.

- Tundish warm-up time (min): If the N heat is before the last 3 of the tundish, 0 (warm-up has not started yet). Otherwise, the number of remaining tundish casts after casting N is considered, plus the proportionate part of the cast N remaining to be cast (Weight of ladle in T), and the time is calculated as a function of of the nominal casting speed of the current tundish quality.

3.2. Evaluation Criteria

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, L.X.; Liu, J.Y.; Rong, A.Y.; Yang, Z.H. A Review of Planning and Scheduling Systems and Methods for Integrated Steel Production. Eur. J. Oper. Res. 2001, 133, 1–20. [Google Scholar] [CrossRef]

- Sun, L.; Liu, W.; Luh, P.B.; Chai, T.; Zheng, B. An Effective Approach for the Scheduling of Steel-Making and Continuous Casting System with Stochastic Processing Requirements. IFAC Proc. Vol. 2011, 44, 9500–9505. [Google Scholar] [CrossRef]

- Sun, L.; Luan, F. Near Optimal Scheduling of Steel-Making and Continuous Casting Process Based on Charge Splitting Policy. IFAC Pap. 2015, 48, 1610–1615. [Google Scholar] [CrossRef]

- Cui, H.; Luo, X. An Improved Lagrangian Relaxation Approach to Scheduling Steelmaking-Continuous Casting Process. Comput. Chem. Eng. 2017, 106, 133–146. [Google Scholar] [CrossRef]

- Ballester, A.; Verdeja, L.; Sancho, J. Metalurgia Extractiva. Volumen 1: Fundamentos; Sintesis: Madrid, Spain, 2000; ISBN 978-84-7738-802-9. [Google Scholar]

- Heaslip, L.J.; McLean, A.; Sommerville, I.D.; Claims, T. Continuous Casting Vol 1-Chemical and Physical Interactions During Transfer Operations (Continuous Casting); Iron & Steel Society of AIME: Warrendale, PA, USA, 1983; ISBN 978-0-89570-157-2.

- Tang, L.; Wang, G. Decision Support System for the Batching Problems of Steelmaking and Continuous-Casting Production. Omega-Int. J. Manag. Sci. 2008, 36, 976–991. [Google Scholar] [CrossRef]

- Chattopadhyay, K.; Isac, M.; Guthrie, R.I.L. Physical and Mathematical Modelling of Steelmaking Tundish Operations: A Review of the Last Decade (1999–2009). ISIJ Int. 2010, 50, 331–348. [Google Scholar] [CrossRef] [Green Version]

- Pérez, M.A.; Mateos, P.; Calleja, J.M. El Proceso Siderúrgico; Arcelor: Avilés, Spain, 2007; Código Manual 1-03-1137. [Google Scholar]

- Liu, J.; Fang, L. Steel-Making Process Scheduling Using Lagrangian Relaxation. Int. J. Prod. Res. 2002, 40, 55–70. [Google Scholar] [CrossRef]

- Jiang, S.; Zheng, Z.; Liu, M. A Multi-Stage Dynamic Soft Scheduling Algorithm for the Uncertain Steelmaking-Continuous Casting Scheduling Problem. Appl. Soft Comput. 2017, 60, 722–736. [Google Scholar] [CrossRef]

- Jiang, Z.; Yuan, S.; Ma, J.; Wang, Q. The Evolution of Production Scheduling from Industry 3.0 through Industry 4.0. Int. J. Prod. Res. 2021, 1–21. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart Manufacturing Process and System Automation—A Critical Review of the Standards and Envisioned Scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Chen, D.; Luh, P.B.; Thakur, L.S.; Moreno, J. Optimization-Based Manufacturing Scheduling with Multiple Resources, Setup Requirements, and Transfer Lots. Iie Trans. 2003, 35, 973–985. [Google Scholar] [CrossRef]

- de Souza, M.C.; Gomes, A.C.; Bretas, A.M.C.; Ravetti, M.G. Models for Scheduling Charges in Continuous Casting: Application to a Brazilian Steel Plant. Optim. Lett. 2016, 10, 667–683. [Google Scholar] [CrossRef]

- Schmidt, G. Scheduling with Limited Machine Availability. Eur. J. Oper. Res. 2000, 121, 1–15. [Google Scholar] [CrossRef]

- Worapradya, K.; Thanakijkasem, P. Proactive Scheduling for Steelmaking-Continuous Casting Plant with Uncertain Machine Breakdown Using Distribution-Based Robustness and Decomposed Artificial Neural Network. Asia-Pac. J. Oper. Res. 2015, 32, 1550010. [Google Scholar] [CrossRef]

- Vakhania, N.; Hernandez, J.A.; Werner, F. Scheduling Unrelated Machines with Two Types of Jobs. Int. J. Prod. Res. 2014, 52, 3793–3801. [Google Scholar] [CrossRef]

- Tang, L.; Wang, G.; Chen, Z.-L. Integrated Charge Batching and Casting Width Selection at Baosteel. Oper. Res. 2014, 62, 772–787. [Google Scholar] [CrossRef] [Green Version]

- Rossit, D.A.; Tohmé, F.; Frutos, M. Industry 4.0: Smart Scheduling. Int. J. Prod. Res. 2019, 57, 3802–3813. [Google Scholar] [CrossRef]

- Ouelhadj, D.; Petrovic, S. A Survey of Dynamic Scheduling in Manufacturing Systems. J. Sched. 2008, 12, 417. [Google Scholar] [CrossRef] [Green Version]

- Zandieh, M.; Gholami, M. An Immune Algorithm for Scheduling a Hybrid Flow Shop with Sequence-Dependent Setup Times and Machines with Random Breakdowns. Int. J. Prod. Res. 2009, 47, 6999–7027. [Google Scholar] [CrossRef]

- Tang, L.; Liu, W.; Liu, J. A Neural Network Model and Algorithm for the Hybrid Flow Shop Scheduling Problemin a Dynamic Environment. J. Intell. Manuf. 2005, 16, 361–370. [Google Scholar] [CrossRef]

- Long, J.; Zheng, Z.; Gao, X.; Pardalos, P.M. Scheduling a Realistic Hybrid Flow Shop with Stage Skipping and Adjustable Processing Time in Steel Plants. Appl. Soft Comput. 2018, 64, 536–549. [Google Scholar] [CrossRef]

- Han, D.; Tang, Q.; Zhang, Z.; Li, Z. An Improved Migrating Birds Optimization Algorithm for a Hybrid Flow Shop Scheduling within Steel Plants. Mathematics 2020, 8, 1661. [Google Scholar] [CrossRef]

- Sobottka, T.; Kamhuber, F.; Heinzl, B. Simulation-Based Multi-Criteria Optimization of Parallel Heat Treatment Furnaces at a Casting Manufacturer. J. Manuf. Mater. Process. 2020, 4, 94. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E. A Cloud-Based Cyber-Physical System for Adaptive Shop-Floor Scheduling and Condition-Based Maintenance. J. Manuf. Syst. 2018, 47, 179–198. [Google Scholar] [CrossRef]

- Li, J.; Pan, Q.; Mao, K. A Discrete Teaching-Learning-Based Optimisation Algorithm for Realistic Flowshop Rescheduling Problems. Eng. Appl. Artif. Intell. 2015, 37, 279–292. [Google Scholar] [CrossRef]

- Huang, K.-W.; Wang, D.-W.; Du, B.; Yi, J. Modeling and Optimal Algorithm of Charge and Cast Scheduling of Steelmaking-Continuous Casting. In Proceedings of the 2006 Chinese Control Conference, Harbin, China, 7–11 August 2006; pp. 1341–1345. [Google Scholar]

- Ojstersek, R.; Lalic, D.; Buchmeister, B. A New Method for Mathematical and Simulation Modelling Interactivity: A Case Study in Flexible Job Shop Scheduling. Adv. Prod. Eng. Manag. 2019, 14, 435–448. [Google Scholar] [CrossRef]

- Balog, M.; Dupláková, D.; Szilágyi, E.; Min, M.; Knapčíková, L. Optimization of Time Structures in Manufacturing Management by Using Scheduling Software Lekin. TEM J. 2016, 5, 319–323. [Google Scholar] [CrossRef]

- Missbauer, H.; Hauber, W.; Stadler, W. A Scheduling System for the Steelmaking-Continuous Casting Process. A Case Study from the Steel-Making Industry. Int. J. Prod. Res. 2009, 47, 4147–4172. [Google Scholar] [CrossRef] [Green Version]

- Li, C.-L.; Zhong, W. Task Scheduling with Progress Control. IISE Trans. 2018, 50, 54–61. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Mourtzis, D. Adaptive Scheduling in the Era of Cloud Manufacturing. In Scheduling in Industry 4.0 and Cloud Manufacturing; Sokolov, B., Ivanov, D., Dolgui, A., Eds.; International Series in Operations Research & Management Science; Springer International Publishing: Cham, Switzerland, 2020; pp. 61–85. ISBN 978-3-030-43177-8. [Google Scholar]

- García-Menéndez, D.; Morán-Palacios, H.; Ortega-Fernández, F.; Díaz-Piloñeta, M. Scheduling in Continuous Steelmaking Casting: A Systematic Review. ISIJ Int. 2019. [Google Scholar] [CrossRef] [Green Version]

- Pan, Q.; Wang, L.; Mao, K.; Zhao, J.; Zhang, M. An Effective Artificial Bee Colony Algorithm for a Real-World Hybrid Flowshop Problem in Steelmaking Process. IEEE Trans. Autom. Sci. Eng. 2013, 10, 307–322. [Google Scholar] [CrossRef]

- Cowling, P.; Johansson, M. Using Real Time Information for Effective Dynamic Scheduling. Eur. J. Oper. Res. 2002, 139, 230–244. [Google Scholar] [CrossRef]

- Jiang, S.-L.; Liu, M.; Lin, J.; Zhong, H. A Prediction-Based Online Soft Scheduling Algorithm for the Real-World Steelmaking-Continuous Casting Production. Knowl. Based Syst. 2016, 111, 159–172. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, J.; Guan, M.; Hong, Y.; Gao, S.; Guo, W.; Liu, Q. Fine Description of Multi-Process Operation Behavior in Steelmaking-Continuous Casting Process by a Simulation Model with Crane Non-Collision Constraint. Metals 2019, 9, 1078. [Google Scholar] [CrossRef] [Green Version]

- Ouelhadj, D.; Cowling, P.I.; Petrovic, S. Utility and Stability Measures for Agent-Based Dynamic Scheduling of Steel Continuous Casting. In Proceedings of the 2003 IEEE International Conference on Robotics and Automation (Cat. No.03CH37422), Taipei, Taiwan, 14–19 September 2003; Volume 1, pp. 175–180. [Google Scholar]

- Kammammettu, S.; Li, Z. Multistage Adaptive Optimization for Steelmaking and Continuous Casting Scheduling under Processing Time Uncertainty. IFAC Pap. 2018, 51, 262–267. [Google Scholar] [CrossRef]

- Pacciarelli, D.; Pranzo, M. Production Scheduling in a Steelmaking-Continuous Casting Plant. Comput. Chem. Eng. 2004, 28, 2823–2835. [Google Scholar] [CrossRef]

- Li, J.; Duan, P.; Sang, H.; Wang, S.; Liu, Z.; Duan, P. An Efficient Optimization Algorithm for Resource-Constrained Steelmaking Scheduling Problems. IEEE Access 2018, 6, 33883–33894. [Google Scholar] [CrossRef]

- Pang, X.; Gao, L.; Pan, Q.; Yu, S. Intelligent Rescheduling System for Steelmaking and Continuous Casting Production. In Proceedings of the 23rd International Conference on Industrial Engineering and Engineering Management 2016; Qi, E., Shen, J., Dou, R., Eds.; Atlantis Press: Amsterdam, The Netherlands, 2017; pp. 41–46. [Google Scholar]

- Pinto, J.M.; Grossmann, I.E. Assignment and Sequencing Models for the Scheduling of Process Systems. Ann. Oper. Res. 1998, 81, 433–466. [Google Scholar] [CrossRef]

- Framinan, J.M.; Fernandez-Viagas, V.; Perez-Gonzalez, P. Using Real-Time Information to Reschedule Jobs in a Flowshop with Variable Processing Times. Comput. Ind. Eng. 2019, 129, 113–125. [Google Scholar] [CrossRef]

- Hou, D.; Li, T. Analysis of Random Disturbances on Shop Floor in Modern Steel Production Dynamic Environment. Procedia Eng. 2012, 29, 663–667. [Google Scholar] [CrossRef] [Green Version]

- Pang, X.; Jiang, Y.; Yu, S.; Li, H.; Gao, L.; Che, Z. Flexible Job Shop Rescheduling Method of Steelmaking-Continuous Casting Base on Human-Computer Cooperation. CIMS 2018, 24, 2415–2427. [Google Scholar] [CrossRef]

- Long, J.; Zheng, Z.; Gao, X.; Pardalos, P.M. A Hybrid Multi-Objective Evolutionary Algorithm Based on NSGA-II for Practical Scheduling with Release Times in Steel Plants. J. Oper. Res. Soc. 2016, 67, 1184–1199. [Google Scholar] [CrossRef]

- Jiang, S.; Hao, J. A Two-Phase Soft Optimization Method for the Uncertain Scheduling Problem in the Steelmaking Industry. IEEE Trans. Syst. Man. Cybern. Syst. 2019, 47, 416–431. [Google Scholar] [CrossRef]

- Mourtzis, D.; Gargallis, A.; Angelopoulos, J.; Panopoulos, N. An Adaptive Scheduling Method Based on Cloud Technology: A Structural Steelwork Industry Case Study. In Proceedings of the 5th International Conference on the Industry 4.0 Model for Advanced Manufacturing; Wang, L., Majstorovic, V.D., Mourtzis, D., Carpanzano, E., Moroni, G., Galantucci, L.M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–14. [Google Scholar]

| Notation | Meaning |

|---|---|

| T | Time at which the line loss trigger event occurs. T = 0 for algorithm purposes |

| Tcn | Time for completely cast heat n at actual casting speed |

| Trn | Time for completely cast heat n, at nominal speed (after rearm the casting machine, or use the heat on other casting machine) |

| Trm | Time necessary to reset the machine and start a new tundish |

| Tdn | Equivalent time to produce the returned heat n, where n = 1,2,3 or 4, at nominal speed |

| Tfcn | Time to finish the cast of heat n, where n = 1,2,3 or 4, from T = 0. |

| TSPi | Time to reach standard production for the branch solution I, where I = 1,2 …. 13. It is equivalent to Tfc4 for the I solution. |

| TSPb | Time to reach standard production for the standard solution of the initial scheduling. |

| Decision Solutions | Heat N | Heat N + 1 | Heat N + 2 | Heat N + 3 | CCM Rearm Time | Returned Heat Time | TSP |

|---|---|---|---|---|---|---|---|

| Branch 1 | Cast | Cast | Cast | Cast | |||

| Solution 1 | Tc1 | Tc2 | Tc3 | Tc4 | - | - | Tc1 + Tc2 + Tc3 + Tc4 |

| Branch 2 | Cast | Cast | Cast | Rearm | |||

| Solution 2 | Tc1 | Tc2 | Tc3 | Tr4 | Trm | - | Tc1 + Tc2 + Tc3 + Tr4 + Trm |

| Branch 3 | Cast | Cast | Tc3 | Reapply | |||

| Solution 3 | Tc1 | Tc2 | Tc3 | Tr4 | Trm | - | Tc1 + Tc2 + Tc3 + Tr4 + Trm |

| Branch 4 | Cast | Cast | Reapply | Cast | |||

| Solution 4 | Tc1 | Tc2 | Tr3 | Tr4 | Trm | - | Tc1 + Tc2 + Tr3 + Tr4 + Trm |

| Branch 5 | Cast | Cast | Rearm | Cast | |||

| Solution 5 | Tc1 | Tc2 | Tr3 | Tr4 | Trm | - | Tc1 + Tc2 + Tr3 + Tr4 + Trm |

| Branch 6 | Cast | Rearm | Cast | Cast | |||

| Solution 6 | Tc1 | Tr2 | Tr3 | Tr4 | Trm | - | Tc1 + Tr2 + Tr3 + Tr4 + Trm |

| Branch 7 | Cast | Reapply | Reapply | Cast | |||

| Solution 7 | Tc1 | Tr2 | Tr3 | Tr4 | Trm | - | Tc1 + Tr2 + Tr3 + Tr4 + Trm |

| Branch 8 | Cast | Return | Return | Cast | |||

| Solution 8 | Tc1 | - | - | Tr4 | Trm | Td2 + Td3 | Tc1 + Tr4 + Trm + Td2 + Td3 |

| Branch 9 | Cast | Return | Reapply | Cast | |||

| Solution 9 | Tc1 | - | Tr3 | Tr4 | Trm | Td2 + Td3 | Tc1 + Tr3 + Tr4 + Trm + Td2 + Td3 |

| Branch 10 | Return | Rearm | Cast | Cast | |||

| Solution 10 | - | Tr2 | Tr3 | Tr4 | Trm | Td1 | Tr2 + Tr3 + Tr4 + Trm + Td1 |

| Branch 11 | Return | Reapply | Reapply | Cast | |||

| Solution 11 | - | Tr2 | Tr3 | Tr4 | Trm | Td1 | Tr2 + Tr3 + Tr4 + Trm + Td1 |

| Branch 12 | Return | Return | Return | Cast | |||

| Solution 12 | - | - | - | Tr4 | Trm | Td1 + Td2 + Td3 | Tr4 + Trm + Td1 + Td2 + Td3 |

| Branch 13 | Return | Return | Reapply | Cast | |||

| Solution 13 | - | - | Tr3 | Tr4 | Trm | Td1 + Td2 | Tr3 + Tr4 + Trm + Td1 + Td2 |

| Billet Casting Machine | |||

|---|---|---|---|

| Steel Grade | L | TII (min) | Qty. Test |

| FC800 | 0 | 3.86 | 11 |

| 1 | 7.06 | 13 | |

| 2 | 29.20 | 11 | |

| 3 | 54.19 | 17 | |

| 4 | 37.35 | 12 | |

| 5 | 11.74 | 10 | |

| Total | 26,25 | 74 | |

| HC650 | 0 | 0.00 | 10 |

| 1 | 8.74 | 12 | |

| 2 | 30.41 | 9 | |

| 3 | 48.73 | 14 | |

| 4 | 84.86 | 12 | |

| 5 | 9.75 | 11 | |

| Total | 32.15 | 68 | |

| PC480 | 0 | 0.00 | 16 |

| 1 | 9.79 | 9 | |

| 2 | 27.09 | 16 | |

| 3 | 45.73 | 10 | |

| 4 | 50.28 | 10 | |

| 5 | 6.58 | 8 | |

| Total | 22.23 | 69 | |

| PE325 | 0 | 4.32 | 14 |

| 1 | 5.95 | 11 | |

| 2 | 27.44 | 16 | |

| 3 | 53.04 | 15 | |

| 4 | 118.37 | 8 | |

| 5 | 0.00 | 6 | |

| Total | 32.96 | 70 | |

| PN156 | 0 | 3.59 | 15 |

| 1 | 3.79 | 9 | |

| 2 | 20.18 | 12 | |

| 3 | 59.58 | 15 | |

| 4 | 47.07 | 16 | |

| 5 | 12.13 | 10 | |

| Total | 27.25 | 77 | |

| Billet casting machine | Total | 28.13 | 358 |

| Bloom Casting Machine | |||

|---|---|---|---|

| Steel Grade | L | TII (min) | Qty. Test |

| BG125 | 0 | 2.74 | 22 |

| 1 | 15.62 | 22 | |

| 2 | 34.60 | 34 | |

| Total | 20.26 | 78 | |

| BP235 | 0 | 6.63 | 22 |

| 1 | 8.47 | 22 | |

| 2 | 61.30 | 20 | |

| Total | 24.35 | 64 | |

| Bloom casting machine | Total | 22.11 | 142 |

| Billet Casting Machine | ||

|---|---|---|

| L | TII (min) | Qty. Test |

| 0 | 2.37 | 66 |

| 1 | 7.12 | 54 |

| 2 | 26.71 | 64 |

| 3 | 52.82 | 71 |

| 4 | 63.27 | 58 |

| 5 | 8.86 | 45 |

| Total | 28.13 | 358 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Menéndez, D.; Morán-Palacios, H.; Vergara-González, E.P.; Rodríguez-Montequín, V. Development of a Steel Plant Rescheduling Algorithm Based on Batch Decisions. Appl. Sci. 2021, 11, 6765. https://doi.org/10.3390/app11156765

García-Menéndez D, Morán-Palacios H, Vergara-González EP, Rodríguez-Montequín V. Development of a Steel Plant Rescheduling Algorithm Based on Batch Decisions. Applied Sciences. 2021; 11(15):6765. https://doi.org/10.3390/app11156765

Chicago/Turabian StyleGarcía-Menéndez, David, Henar Morán-Palacios, Eliseo P. Vergara-González, and Vicente Rodríguez-Montequín. 2021. "Development of a Steel Plant Rescheduling Algorithm Based on Batch Decisions" Applied Sciences 11, no. 15: 6765. https://doi.org/10.3390/app11156765

APA StyleGarcía-Menéndez, D., Morán-Palacios, H., Vergara-González, E. P., & Rodríguez-Montequín, V. (2021). Development of a Steel Plant Rescheduling Algorithm Based on Batch Decisions. Applied Sciences, 11(15), 6765. https://doi.org/10.3390/app11156765