Multistate Diagnosis and Prognosis of Lubricating Oil Degradation Using Sticky Hierarchical Dirichlet Process–Hidden Markov Model Framework

Abstract

Featured Application

Abstract

1. Introduction

1.1. Lubricating Condition Monitoring (LCM)

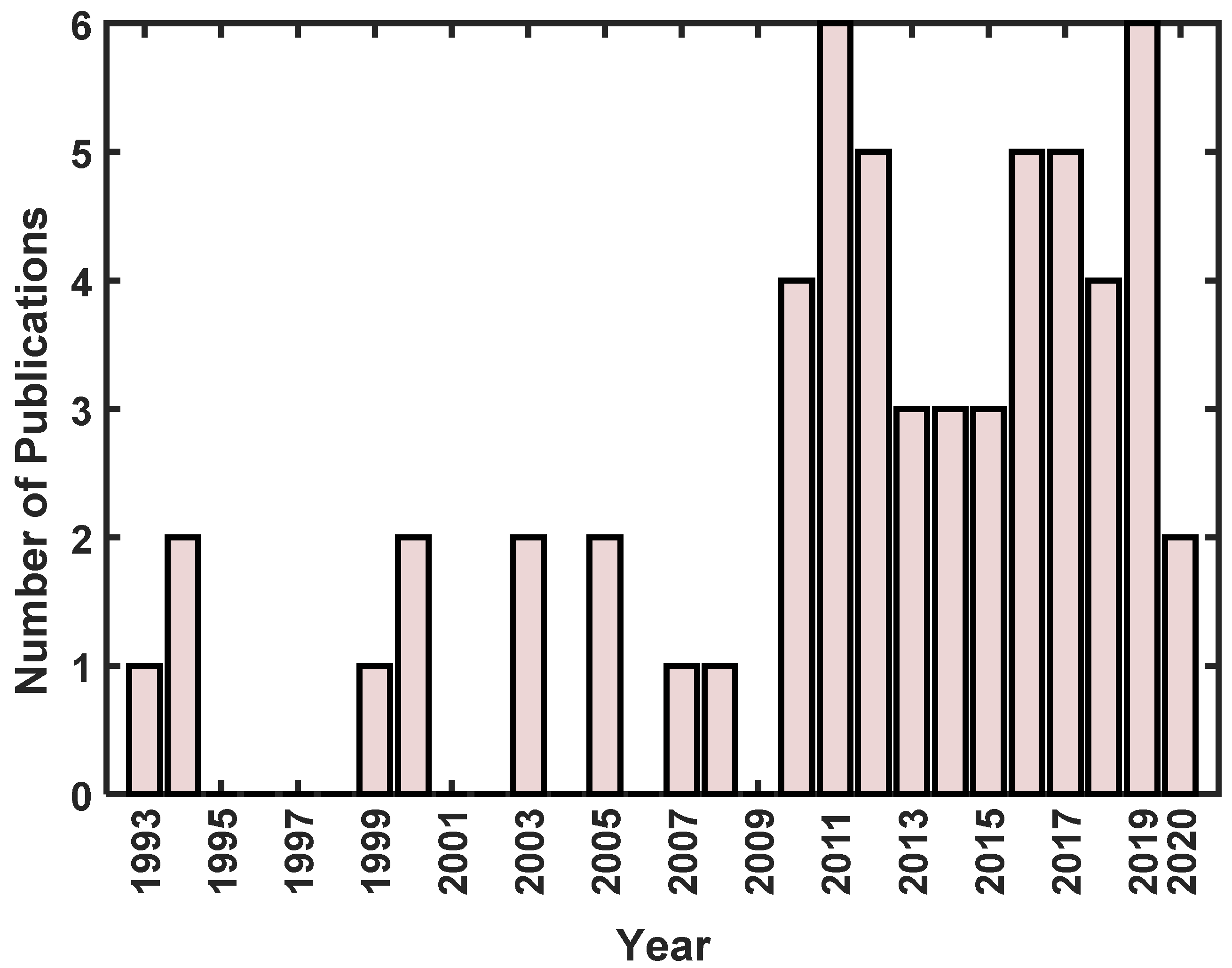

1.2. Diagnostics and Prognostics Using Hidden Markov Model (HMM)

- The state space is prespecified based on experience, assumption, or data segmentation;

- There is no possible update to the state space based on the trend of the degradation data second item;

- The number of parameters is limited;

- The analysis is based purely on the healthy portion of the oil data with minimal inherent nonlinearity.

- RUL prediction requires one or more historical degradation time-series patterns;

- Nonlinearity and nonmonotonicity of degradation trends affect the RUL prediction accuracy;

- Degradation states and state evolution trends cannot be extracted and estimated.

2. Model Framework and Methodology

2.1. Simulation of Degradation Data

- 5.

- Oil replenishment is an external event, and oil consumption is precisely equal to oil replenishment;

- 6.

- Wear production rate is equal to wear rate;

- 7.

- Wear debris are homogeneously distributed in the oil with negligible mixing time;

- 8.

- The system is in the wear-out (abnormal) phase of its life cycle;

- 9.

- Oil is changed every time the WDC reaches a threshold of 40 ppm.

2.2. Hidden Markov Model (HMM)

2.3. Hierarchical Dirichlet Process (HDP)-HMM

2.4. Sticky (HDP)-HMM

3. Model Evaluation

3.1. Hyperparameter Optimization

3.2. State-Space Estimation

4. Prediction of Residual Life

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, M.; Mukherjee, P.S.; Misra, N.M. Advancement and current status of wear debris analysis for machine condition monitoring: A review. Ind. Lubr. Tribol. 2013, 65, 3–11. [Google Scholar] [CrossRef]

- Wu, J.; Mi, X.; Wu, T.; Mao, J.; Xie, Y.-B. A wavelet-analysis-based differential method for engine wear monitoring via on-line visual ferrograph. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1356–1366. [Google Scholar] [CrossRef]

- Wu, T.; Peng, Y.; Wu, H.; Zhang, X.; Wang, J. Full-life dynamic identification of wear state based on on-line wear debris image features. Mech. Syst. Signal Process. 2014, 42, 404–414. [Google Scholar] [CrossRef]

- Cao, W.; Dong, G.; Chen, W.; Wu, J.; Xie, Y.-B. Multisensor information integration for online wear condition monitoring of diesel engines. Tribol. Int. 2015, 82, 68–77. [Google Scholar] [CrossRef]

- Peng, Y.; Wu, T.; Wang, S.; Peng, Z. Wear state identification using dynamic features of wear debris for on-line purpose. Wear 2017, 376–377, 1885–1891. [Google Scholar] [CrossRef]

- Wang, S.; Wu, T.; Wu, H.; Kwok, N. Modeling wear state evolution using real-time war debris features. Tribol. Trans. 2017, 60, 1022–1032. [Google Scholar] [CrossRef]

- Henneberg, M.; Eriksen, R.L.; Jørgensen, B.; Fich, J. A quasi-stationary approach to particle concentration and distribution in gear oil for wear mode estimation. Wear 2015, 324–325, 140–146. [Google Scholar] [CrossRef][Green Version]

- Henneberg, M.; Eriksen, R.L.; Fich, J. Modelling and measurement of wear particle flow in a dual oil filter system for condition monitoring. Wear 2016, 362–363, 153–160. [Google Scholar] [CrossRef]

- Tambadou, M.S.; Chao, D.; Duan, C.; Chaoqun, D. Lubrication Oil Anti-Wear Property Degradation Modeling and Remaining Useful Life Estimation of the System Under Multiple Changes Operating Environment. IEEE Access 2019, 7, 96775–96786. [Google Scholar] [CrossRef]

- Yan, L.; Chen, J.; Yu, P.; Yu, Y.; Cao, K.; Huang, S. Model parameter estimation and residual life span prediction of pneumatic diagram pump based on hidden Markov model in intelligent spraying. Intell. Manuf. Robot. 2019, 16, 1729881419874636. [Google Scholar]

- Telford, R.; Galloway, S. Fault classification and diagnostic system for unmanned aerial vehicle electrical networks based on hidden Markov models. IET Electr. Syst. Transp. 2015, 5, 103–111. [Google Scholar] [CrossRef][Green Version]

- Mba, C.U.; Makis, V.; Marchesiello, S.; Fasana, A.; Garibaldi, L. Condition monitoring and state classification of gearboxes using stochastic resonance and hidden Markov models. Measurement 2018, 126, 76–95. [Google Scholar] [CrossRef]

- Sadhu, A.; Prakash, G.; Narasimhan, S. A hybrid hidden Markov model towards fault detection of rotating components. J. Vib. Control 2017, 23, 3175–3195. [Google Scholar] [CrossRef]

- Choo, K.H.; Tong, J.C.; Zhang, L. Recent applications of Hidden Markov models in computational biology. Genom. Proteom. Bioinform. 2004, 2, 84–96. [Google Scholar] [CrossRef]

- Najkar, N.; Razzazi, F.; Sameti, H. A novel approach to HMM-based speech recognition systems using particle swarm optimization. Math. Comput. Model. 2010, 52, 1910–1920. [Google Scholar] [CrossRef]

- Li, J.; Najmi, A.; Gray, R. Image classification by a two-dimensional hidden Markov model. IEEE Trans. Signal Process. 2000, 48, 517–533. [Google Scholar] [CrossRef]

- Bunke, H.; Roth, M.; Schukat-Talamazzini, E. Off-line cursive handwriting recognition using hidden markov models. Pattern Recognit. 1995, 28, 1399–1413. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, X.; Fang, Z.; Zeng, Y.; Xu, K. High-order Hidden Markov Model for trend prediction in financial time series. Phys. A Stat. Mech. Appl. 2019, 517, 1–12. [Google Scholar] [CrossRef]

- Smyth, P. Hidden Markov models and neural networks for fault detection in dynamic systems. Pattern Recognit. 1994, 27, 149–164. [Google Scholar] [CrossRef]

- Monplaisir, M.H.; Arumugadasan, N.S. Maintenance decision support: Analyzing crankcase lubricant condition by Markov process modelling. J. Oper. Res. Soc. 1994, 45, 509–518. [Google Scholar] [CrossRef]

- Li, X.; Duan, F.; Mba, D.; Bennett, I. Multidimensional prognostics for rotating machinery: A review. Adv. Mech. Eng. 2017, 9, 1–20. [Google Scholar] [CrossRef]

- Mor, B.; Garhwal, S.; Kumar, A. A Systematic Review of Hidden Markov Models and Their Applications. Arch. Comput. Methods Eng. 2021, 28, 1429–1448. [Google Scholar] [CrossRef]

- Du, Y.; Wu, T.; Makis, V. Parameter estimation and remaining useful life prediction of lubricating oil with HMM. Wear 2017, 376–377, 1227–1233. [Google Scholar] [CrossRef]

- Zhu, J.; Yoon, J.M.; He, D.; Bechhoefer, E. Online particle-contaminated lubrication oil condition monitoring and remaining useful life prediction for wind turbines. Wind Energy 2015, 18, 1131–1149. [Google Scholar] [CrossRef]

- Wakiru, J.M.; Pintelon, L.; Muchiri, P.N.; Chemweno, P. A review on lubricant condition monitoring information analysis for maintenance decision support. Mech. Syst. Signal Process. 2019, 118, 108–132. [Google Scholar] [CrossRef]

- Khaleghei, A.; Makis, V. Model parameter estimation and residual life prediction for a partially observable falling system: Parameter estimation and residual life prediction. Nav. Res. Logist. 2015, 62, 190–205. [Google Scholar] [CrossRef]

- Si, X.-S.; Wang, W.; Hu, C.-H.; Zhou, D.-H. Remaining useful life estimation—A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Kim, M.J.; Makis, V.; Jiang, R. Parameter estimation for partially observable systems subject to random failure. Appl. Stoch. Model. Bus. Ind. 2012, 29, 279–294. [Google Scholar] [CrossRef]

- Qi, Y.; Paisley, J.W.; Carin, L. Music Analysis Using Hidden Markov Mixture Models. IEEE Trans. Signal Process. 2007, 55, 5209–5224. [Google Scholar] [CrossRef]

- Eddy, S.R. Hidden Markov models. Curr. Opin. Struct. Biol. 1996, 6, 361–365. [Google Scholar] [CrossRef]

- Tanwar, M.; Raghavan, N. Lubricating Oil Remaining Useful Life Prediction Using Multi-Output Gaussian Process Regression. IEEE Access 2020, 8, 128897–128907. [Google Scholar] [CrossRef]

- Fox, E.B.; Sudderth, E.B.; Jordan, M.I.; Willsky, A.S. The sticky HDP-HMM: Bayesian nonparametric hidden Markov models with persistent states. In MIT Laboratory for Information and Decision Systems Technical Report; P-2777; MIT LIDS: Cambridge, MA, USA, 2009; pp. 1–59. [Google Scholar]

- Sun, Z.; Zhang, N. Analysis of the Health Status of Railway Vehicle Bearings Based on Improved HDP-HMM. In 2018 5th International Conference on Systems and Informatics (ICSAI), Proceedings of the 2018 5th International Conference on Systems and Informatics (ICSAI), Nanjing, China, 10–12 November 2018; IEEE: Washington, DC, USA, 2018; pp. 507–513. [Google Scholar]

- Fan, B.; Li, B.; Feng, S.; Mao, J.; Xie, Y.-B. Modeling and experimental investigations on the relationship between wear debris concentration and wear rate in lubrication systems. Tribol. Int. 2017, 109, 114–123. [Google Scholar] [CrossRef]

- Teh, Y.W.; Jordan, M.I.; Beal, M.J.; Blei, D.M. Hierarchical Drichlet Process. J. Am. Stat. Assoc. 2006, 101, 1566–1581. [Google Scholar] [CrossRef]

- Fox, E.B.; Sudderth, E.B.; Jordan, M.I.; Willsky, A.S. An HDP-HMM for systems with state persistence. In Proceedings of the 25th International Conference on Machine Learning, Helsinki, Finland, 5–9 June 2008. [Google Scholar]

- Sheng, Y. Comparison of the power of the t test, Mann-Kendall and bootstrap tests for trend detection. Hydrol. Sci. J. 2004, 49, 1–37. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanwar, M.; Park, H.; Raghavan, N. Multistate Diagnosis and Prognosis of Lubricating Oil Degradation Using Sticky Hierarchical Dirichlet Process–Hidden Markov Model Framework. Appl. Sci. 2021, 11, 6603. https://doi.org/10.3390/app11146603

Tanwar M, Park H, Raghavan N. Multistate Diagnosis and Prognosis of Lubricating Oil Degradation Using Sticky Hierarchical Dirichlet Process–Hidden Markov Model Framework. Applied Sciences. 2021; 11(14):6603. https://doi.org/10.3390/app11146603

Chicago/Turabian StyleTanwar, Monika, Hyunseok Park, and Nagarajan Raghavan. 2021. "Multistate Diagnosis and Prognosis of Lubricating Oil Degradation Using Sticky Hierarchical Dirichlet Process–Hidden Markov Model Framework" Applied Sciences 11, no. 14: 6603. https://doi.org/10.3390/app11146603

APA StyleTanwar, M., Park, H., & Raghavan, N. (2021). Multistate Diagnosis and Prognosis of Lubricating Oil Degradation Using Sticky Hierarchical Dirichlet Process–Hidden Markov Model Framework. Applied Sciences, 11(14), 6603. https://doi.org/10.3390/app11146603