Abstract

Based on the novel structural online control policy (SOCP) deadlock handling method presented in our previous work, we have shown that for a specific group of use cases it is possible to relax the requirements of the method, providing an improvement in its performance. In the present work, a new type of deadlock-free zone was introduced which enabled the method to improve its efficiency for both bidirectional as well as unidirectional and mixed path systems. For bidirectional systems, a beneficial outcome was obtained by approaching the global problem solution using sequentially solved local problems. For unidirectional and mixed systems, on the other hand, this paper introduces a condition that allows verification of the feasibility of performing process reservations in a staged manner. The fulfillment of this condition means that there is a possibility of obtaining higher efficiency of the transportation system. The effectiveness of the proposed approaches has been verified by simulations. Their results were compared with the results of the original method resulting in a significant improvement.

1. Introduction

Sustainable development of production systems requires efficient material handling systems. Modern, smart production systems using technologies commonly referred to as Industry 4.0 open up new possibilities for automated transportation systems based on automated guided vehicles (AGVs) or autonomous mobile robots (AMRs). Such transportation systems are characterized by a high level of flexibility and reconfigurability, enabling their use in a wide range of production systems. They serve as an auxiliary system the performance of which is usually evaluated from the point of view of satisfying the following criteria [1]:

- maximize the throughput of the system;

- minimize vehicle travel times;

- minimize the time required to complete all tasks;

- minimize total costs of movement.

When considering the operation of a transportation system as an optimization task, it should be noted that constraints on various aspects of its operation play an important role in this task. These constraints also result from the specific nature of these systems, classified as discrete event systems. Transportation systems performing their tasks in a distributed production environment encounter many conflict situations, which must be solved efficiently to avoid situations such as collisions or deadlocks. It should be noted that the result of a deadlock handling method is not a specific value that can be compared with another method, but the operating state of the system without deadlocks. There are many different approaches in this area. The application of a specific approach depends on both the structure of the transportation system and the processes carried out. Methods characterized by adaptability to the specific nature of transportation tasks may be of particular interest. The scientific contribution of this work is a modified SOCP method [2] for collision and deadlock avoidance in multi-AGV systems, applicable in selected use cases. This approach allows for an increase in the efficiency of the transportation system based on AGVs.

The efficiency of a transportation system based on AGVs depends on many factors. Various management and control issues must be carried out before and during the AGVs operation. Design and control issues of AGV systems at manufacturing, distribution, transshipment, and transportation systems are discussed by Vis [1]. A broad overview of these issues may be found in the review papers by Le-Anh and De Koster [3] and Qiu et al. [4]. Fragapane et al. [5] identify and classifies research related to the planning and control of AGVs and AMRs. They propose an agenda for future research within this field.

The issues related to AGVs can be divided into two areas: transportation system design and transportation system management. The design stage includes such issues as

- guide-path design;

- estimating the number and location of parking, pick-up, and delivery points;

- estimating the number of required vehicles.

The management stage includes

- positioning of idle vehicles;

- vehicle dispatching;

- vehicle routing;

- vehicle scheduling;

- collision and deadlock handling;

- maintenance of vehicles.

The very first issue is the flow path structure setting. The topology of flow path layouts could be classified into two main categories: conventional and specific (loop, mesh, square). Depending on the type of topology, an appropriate traffic control strategy must be applied. In this area, the most important factor for the transportation system operation is an appropriate method for AGV collision and deadlock handling. These control methods can be classified into three categories: static, time-window-based, and dynamic.

In the conventional path topology, the transportation network can be built from unidirectional, bidirectional, and multiple lane flow paths. A bidirectional flow path network has a high throughput and a smaller number of required vehicles but appropriate control algorithms are more complicated. The comparisons and issues regarding unidirectional and bidirectional flow paths are described by Egbelu and Tanchoco [6].

Flow paths based on loops can include single loop, multi loops, or segmented zones. In this case, the AGVs control is relatively simple. Asef-Vaziri et al. [7] propose an integer programming formulation to design a loop material flow system. Ventura and Lee [8] propose a tandem loop with multiple vehicles. The segmented flow path approach was proposed by Sinriech and Tanchoco [9].

Transportation system layouts are very often arranged into regular shapes [4], e.g., at warehouses or container terminals. It can be described as a mesh-like path (Qiu and Hsu [10]) or a square topology (Małopolski [11]).

The most important issue to solve for any type of flow paths is to manage the AGVs deadlock states. There are three major approaches described by Coffman et al. [12]

- deadlock detection and resolution by online detection and recovery from deadlock states;

- deadlock prevention by specifying online how a process can allocate resources;

- deadlock avoidance by online analysis of current state information to control how a process can allocate resources.

Many authors have proposed different methods for the deadlock state resolution in the operation of AGVs. Banaszak and Krogh [13] propose a centralized deadlock avoidance algorithm. This approach is based on a Petri net model of concurrent job flow and dynamic resource allocation. In this algorithm, the production sequences are divided into zones in which resources are shared or not. The deadlock avoidance problem is solved by defining a restriction policy. Zając [14] introduces a structural online control policy for automated manufacturing systems which guarantees that the execution of an operation (an elementary step of a job) does not lead to a deadlock. Zhou et al. [15] propose a real-time and distributed algorithm for both collision and deadlock avoidance. Draganjac et al. [16] present an algorithm for decentralized control of multiple AGVs. Conflict resolution is based on a vehicle priority scheme. Fanti et al. [17] propose a distributed approach to AGV system control. The vehicle team must autonomously reach a consensus on the division of the set of tasks in the approach to zone control. Nielsen et al. [18] present a methodology for the implementation of a mobile robot in adaptive manufacturing environments. It is based on a mathematical model and a genetic algorithm-based heuristic. Xiao et al. [19] propose a collision and deadlock prevention method with a traffic sequence optimization strategy for the unidirectional guide-path network-based AGVs. This method is based on the semaphore theory and Internet of Things (IoT) positioning technology. To avoid cycle deadlocks an algorithm based on the digraph theory is developed. Pan et al. [20] introduce a method based on the design of square topology, chains of path planning reservations, and dynamic task priority of the logistics workshop, which effectively utilizes environmental resources of the workshop to avoid collision and to solve deadlocks. Du et al. [21] provide a reference source in the robust supervisory control policies for automated manufacturing systems with unreliable resources that may fail. Robust control in the supervisory control area addresses deadlock when some reliable resources unexpectedly fail to work. Witczak et al. [22] focused their research on the modeling and fault-tolerant control of multiple AGVs in a high-storage warehouse. They developed a mathematical description of a set of multiple AGVs along with an algorithm that can generate an optimum sequence. Drotos et al. [23] propose a centralized control method for routing and scheduling a fleet of autonomously guided vehicles. This method maintains a central schedule, which ensures provably conflict-free control of a large fleet of vehicles in almost any layout. Zhang et al. [24] present a new method to optimize the scheduling of automated stacking cranes and automated guided vehicles for automated container terminals. It is based on the genetic algorithm. Zou et al. [25] introduce a new method for AGV scheduling in a matrix manufacturing workshop. A multi-objective mixed-integer linear programming model is first formulated. Then an effective multi-objective evolutionary algorithm is developed for solving the problem. Farooq et al. [26] propose a novel heuristic approach for mixed-flow shop scheduling problems with automated guided vehicles. Yu et al. [27] describe a multi-AGVs path planning algorithm based on Grid Blocking Degree for the planning of a conflict-free handling path. It was implemented in automated sorting warehouses. Yunlong et al. [28] propose a spare zone-based hierarchical motion coordination algorithm supporting time-efficient collision and deadlock resolution among vehicles. Zhao et al. [29] introduce a method based on dynamic resource reservation supporting time-efficient scheduling and collision avoidance of multiple AGVs. Mohammadi et al. [30] propose a new approach named Tandem-Queue-Link with a look-ahead in which the look-ahead mechanism supports deadlock prevention.

The remainder of this paper is organized as follows Section 2 explains the structural control online policy method (SOCP) for collision and deadlock resolution in multi-AGV systems, Section 3 details how to improve the effectiveness of the SOCP method—use cases, Section 4 presents the simulation experiments and results. Finally, Section 5 concludes the paper.

2. The SOCP Control Policy

A new method for solving collision and deadlock problems in multi-AGV systems is proposed in [2] by presenting its specification with proof of correctness. The method is adapted from the general approach introduced by Zając [14]. In the following, for the sake of consistency, the essential features of the method will be presented, which will allow, on the one hand, to understand its principles and, on the other hand, to modify it in such a way that its efficiency can be improved for a specific type of use case.

Consider a manufacturing facility in which a set of transport tasks is performed by an AGV system denoted as . The transportation area in automated manufacturing plants can be partitioned into non-overlapping zones (squares) . A function is introduced. A zone is occupied by AGV if . Notation denotes that a zone is empty (free). The zone is sufficiently large that an AGV can be entirely within it, and at most one AGV can be in each zone (square) at the same time. Furthermore, when performing an elementary transport operation denoted as , an AGV cannot occupy more than these two zones simultaneously.

The set of zones is divided into two subsets and , each of them corresponding respectively to route generating elements and parking spaces. The route elements create a network of guide paths. A path is thus a finite sequence of transitions through neighboring zones. The transport task requires that each vehicle passes through a series of zones in a collision-free manner, starting at the parking place, transporting goods from the pick-up points to the delivery points, and finishing at the parking place.

All AGVs in the system may not change the guide paths determined before the start of each new transport task.

The guide path of the transportation system is a sequence of the set of zones that consists of lanes and crossings. In addition, parking places are also used in the transportation system, but they are not elements of paths. Each parking place situated in a zone is neighboring at least one guide path zone , and an AGV can move from its parking place to the neighboring zones and vice versa.

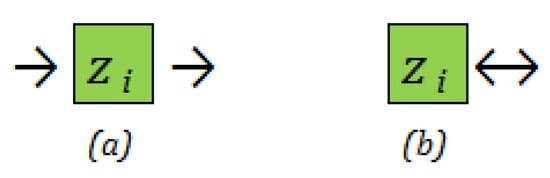

Consider the deadlock phenomenon from the point of view of the lane types of the guided path. They are either unidirectional or bidirectional . The unidirectional zone has only one predecessor and one successor (see Figure 1). Taking deadlock into account, it is important to point out an important difference between the two basic types of lanes. A unidirectional lane of a path is called deadlock-free because the execution of the elementary transportation operation in this lane cannot lead to deadlock. The bidirectional lanes do not have this property, so they are called deadlock risk lanes. Moreover, the same quality applies to intersections, so they are treated as deadlock risk zones and belong to the set .

Figure 1.

Deadlock-free zones: (a) A standard type. (b) A new type.

The guide path can be split into logical segments consisting of deadlock-free zones in which the AGV can move unidirectionally, and logical segments consisting of deadlock-risk zones that are bidirectional, e.g., in which the AGV can move in both directions. In addition, intersections are always deadlock-risk zones. All individual segments are assumed to be maximal (not contained within a larger segment), which means that they alternate in the path. Thus, the guide path can be partitioned into alternating subsequences consisting of deadlock-free segments and deadlock-risk segments .

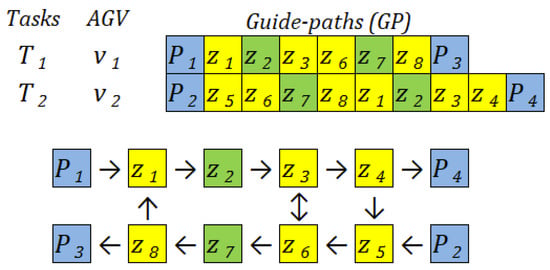

An image of such sequences is presented in Figure 2. Deadlock-free segments are highlighted in green and deadlock-risk segments in yellow. Note that the division of the path into logical segments does not eliminate the multiple existence of the same physical segments.

Figure 2.

An example of a transportation system.

The deadlock-free segment capacity is defined as the number of zones that make up the segment. In the proposed method, an action called process reservation is defined: . A unit of capacity of a logical deadlock-free segment can be reserved for a single AGV moving on that segment. Thus, the process reservation can only be made by a number of different AGVs whose number does not exceed the capacity of the logical segment. This condition is expressed by the following formula .

The structural online control policy guarantees that the execution of an elementary transport operation (moving the AGV from the current zone to the next) does not lead to a deadlock. This policy implements two rules [2]:

The first one demands a process reservation of one unit of capacity of the deadlock-free logical segment inside all such segments accessed by an AGV moving along the guide path. This action is denoted as and must be done before the AGV performs its first elementary transport operation. This means that if it is not possible to perform all process reservations, the execution of the elementary transport operation may lead to a deadlock. Performing a transport operation into a deadlock-free segment requires an empty zone represented by the condition , which is always possible due to the process reservation described above. That reservation in the logical segment is canceled when the AGV leaves this guide path segment.

The second rule guarantees that if an AGV performing an elementary transport operation enters a deadlock—risk segment (into the first zone of a segment) or into a zone inside such a segment, the capacity of all remaining zones in that segment is available (not occupied by another AGV) until . This condition can be denoted as . It should be noted that the decision to check the availability of the required capacities cannot be performed in parallel for more than one AGV.

Considering the standard division into deadlock-free and deadlock-risk zones presented above, it is important to note that classifying unidirectional zones as deadlock-free is not mandatory. These zones may also be deadlock-risk zones. On the other hand, it is not possible to classify an originally designated deadlock-risk zone as a deadlock-free zone. Depending on the system structure and the processes performed, it is thus possible to qualify individual unidirectional zones as deadlock-free or deadlock-risk zones to ensure the most efficient operation of the system and thus reduce the restrictiveness of the control policy.

The application of this online structural control policy also solves the problem of collision avoidance in an automated transportation system due to the assumptions made, as well as the demands on the availability of an empty next zone on the route before the elementary action is performed.

3. Improvement of the Effectiveness of the SOCP Method—Use Cases

From the presented description of the SOCP method, it can be seen that the deadlock-free zones are exclusively unidirectional (Figure 1a), i.e., zones with a single predecessor and successor, where the predecessor and successor are not the same zone. It should be noted, however, that in the source work [14] another deadlock-free zone is also introduced, the analogy of which is presented in the transportation system in Figure 1b. This zone has a single predecessor and successor, but both the predecessor and the successor are the same zone. This means that this deadlock-free zone is always adjacent to a deadlock-risk zone and as a consequence will always form a deadlock-free segment with a capacity equal to one.

This situation is generally unfavorable as shown by several examples in [2]. It should be noted, however, that for a certain group of use cases it is possible to relax the strict rules of the method, and the use of the deadlock-free zone shown in Figure 1b will make it possible to obtain significantly better results than with the general method as will be shown later in the paper.

Let us take a closer look at the first rule of the method concerning the necessity of process reservations of the capacity unit of all deadlock-free segments located on the AGV guided path. The rationale for the necessity of process reservation in this way instead of staged reservations in consecutive segments is the possibility of restricted deadlock, a concept introduced by Banaszak & Krogh [13]. This is a type of deadlock that does not concern the AGVs moving in the transportation system but concerns the method of deadlock handling itself. To show the essence of restricted deadlock in the example of the SOCP method, let us consider a simple transportation system shown in Figure 2.

In this system, there are two transport tasks and . It is easy to see that in the presented example deadlock cannot occur, so there is no need to use the SOCP method. It is demonstrated here because of its simplicity and the possibility of presenting the restricted deadlock issue clearly. According to the SOCP method, to be able to start a transport task, it is necessary to reserve one unit of capacity of the deadlock-free logical segment inside all such segments accessed by an AGV moving along the guide path. This means that both task and task must have and zones reserved to proceed to the execution stage. Let us now consider what would be the result of a staged execution of the process reservation, meaning in this case reservation of the nearest deadlock-free zone first and then, after the AGV reaches it, reservation of the next one. In this case, assuming that the start of both transport tasks is close in time, a situation might arise in which vehicle , before the start, makes a process reservation of zone and after reaching it wants to make a process reservation of zone , and this zone is reserved for vehicle , which had to reserve it before the start of the task. Once reaches the zone, however, it must make a process reservation for zone to be able to continue its movement. In this case, we are dealing with a stop in the functioning of the transportation system due to restricted deadlock i.e., the impossibility of meeting the conditions set by the method of deadlock handling.

The presented example shows that there are situations in which it is necessary to make process reservations in all deadlock-free segments of the AGV path, as presented in the first rule of the SOCP method. This means, therefore, that in a general-purpose method applicable to any structure of transportation systems, it is necessary to fulfill the conditions of this rule in order not to lead to a restricted deadlock. Accepting this conclusion, it should, however, be noted that there are certain groups of transport tasks, which we can call use cases, and for which there is a possibility to relax the restrictiveness of the discussed method. The staged execution of process reservations, due to a more efficient use of resources will make it possible to reduce the execution time of transport tasks. To work out how to implement this possibility, we must answer the question of whether there are deadlock-free segments on the AGV path on which the reservation process can be completed without causing a restricted deadlock when further deadlock-free segments have to be reserved. To answer this question, it is necessary to look at this issue in the same way as the issue of deadlock but considering only deadlock-free segments. Restricted deadlock occurs only when there is a cycle of expectations for process reservations, which is an analogy of the cycle of resource dependencies which is a necessary condition for the occurrence of deadlock. To simplify the analysis, let us assume that each deadlock-free segment consists of one zone. The cycle of expectations for process reservations will occur when the transportation processes have made a process reservation in a given deadlock-free zone, and to leave this zone, they need to make another reservation which they cannot make because this zone is already reserved by another process. This sequence of process reservations may lead to a cycle consisting of two processes, as shown in Figure 2, but can also arise in the case of more transportation processes.

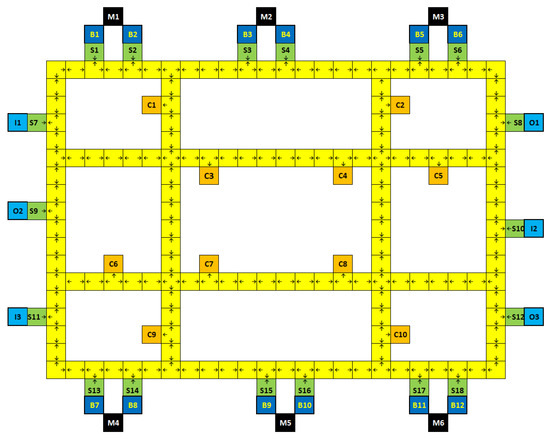

As we know that it is worth implementing process reservations in a staged manner and we know the risks associated with such an action, we should analyze certain cases in terms of the possibility of using the concept discussed above. Such an action will be demonstrated using three examples taken from [2]. The examples presented there have features similar to industrial systems and taking into account the considered concept of solving the problem we can qualify them as use cases. These examples differ only in the type of roads used (bidirectional—Figure 3, unidirectional—Figure 5 and mixed—Figure 7). The remaining issues concerning the transportation system and the tasks performed are relevant for all examples, so they will be presented together.

The principle adopted for all transportation system layouts consists of deadlock-free zones marked in green and deadlock-risk zones in yellow. The length of the side of the squares is set to 1[m]. There are 18 stations. Close to the stations are buffers marked in blue. Buffers: , and are input points to machines. Buffers: , and are output points from machines. There are 6 machines: , , , , , and , marked in black. Operations are performed on these machines. There are 3 sources of work-pieces: , and , marked in light-blue. Each source generates 20 parts (a part per second) at the beginning of the simulation. There are 3 sinks for work-pieces (disposal points): , and , also marked in light-blue.

In this manufacturing system, 3 different workpieces: , and are produced. On each part, two operations are performed. The process cycle time on each machine for each operation is set to 20[s]. The batch size and routing assigned to each work-piece are presented in Table 1. Finally, there are 10 AGVs, signed , parked in their parking places, marked in orange. The AGV transport task consists of three steps. In the first, the AGV travels from its parking (origin point) to the pick-up point, next from the pick-up point to the delivery point, and finally from the delivery point to the origin point.

Table 1.

The batch size and routing.

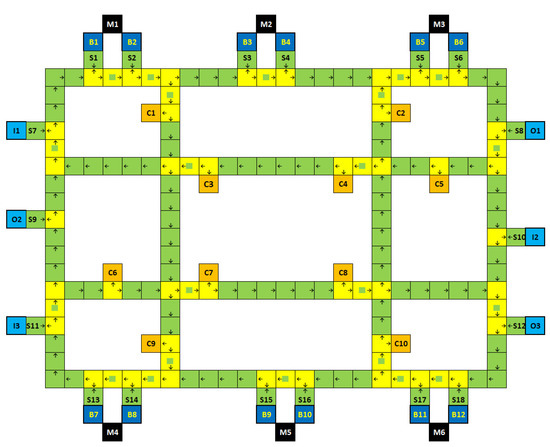

First of all, let us consider an example with bidirectional guide paths presented in Figure 3. It should be noted that in the work [2], stations S1–S18 were treated as deadlock-risk which resulted from the fact that only the zone presented in Figure 1a was considered to be a deadlock-free zone. By adding the zone shown in Figure 1b to the set of deadlock-free zones, these stations can be considered to be deadlock-free zones.

Figure 3.

The layout with bidirectional flow paths.

Let us consider the problem of process reservation for the transport tasks carried out in this example. All tasks shown in Table 1 can be divided into three stages. Stage one concerns the AGV’s drive from the parking area to the pick-up location. Stage two is the movement from the pick-up location to the delivery location. Stage three is the return of the AGV to the parking area. There are two deadlock-free segments along the route of each transport task, each consisting of one zone. This means that before the start of each task, it is necessary, according to the SOCP method, to reserve both zones. Taking into account the issue discussed above regarding the possibility of staging process reservations, let us analyze whether this way of execution does not lead to a restricted deadlock. Thus, it is necessary to check whether a waiting cycle for process reservations can be created.

In the transportation system under consideration, we have a set of deadlock-free zones from which we can distinguish the subset

containing the places (zones) from which the parts are taken and the subset of the places

(zones) containing to which they are transported. In addition, an important role is played by the set containing the dedicated car parking areas from which vehicles leave after the start of the transport task and return to after its completion. These vehicles form the set . All parking spaces in the considered system are deadlock-free zones. Assuming that , , and then the transport tasks can be divided into three consecutive stages , , and . However, it should be noted that, from the point of view of the SOCP method, the process reservation of the parking space is not necessary. This is due to the assumption made in the considered examples that each parking place is dedicated to a specific vehicle . This leaves the issue of analyzing the possibility of the emergence of a cycle of process reservations in the case of staged execution exclusively for elements and . Note that for the considered example, the following relation is satisfied.

This means that the and sets are disjoint and this is a sufficient condition for the impossibility of creating a restricted deadlock. This results from the fact that a cycle can only be formed by the zones from which parts are taken and to which parts are returned, i.e., the transport operation is started and the transport operation is finished. This means that the process reservations necessary for each transport task can be carried out in stages without creating a restricted deadlock.

4. Results

For the example presented above in which there is a possibility of staged implementation of process reservations, being a case study example for the SOCP method, simulations were carried out in the Delmia QUEST system. The results of these simulations were compared with the results published in [2] with the application of the original version of the SOCP method. The simulations were carried out for a number of AGVs varying from 1 to 10.

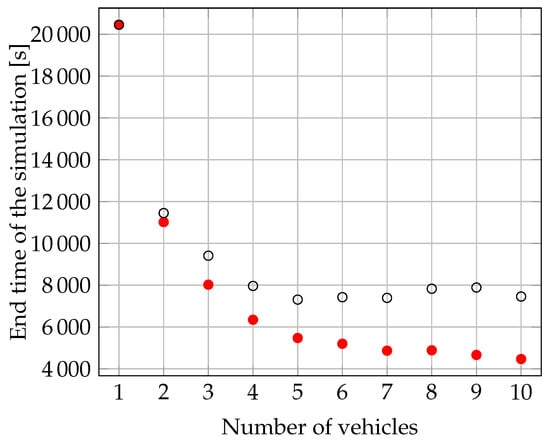

4.1. Bidirectional Paths

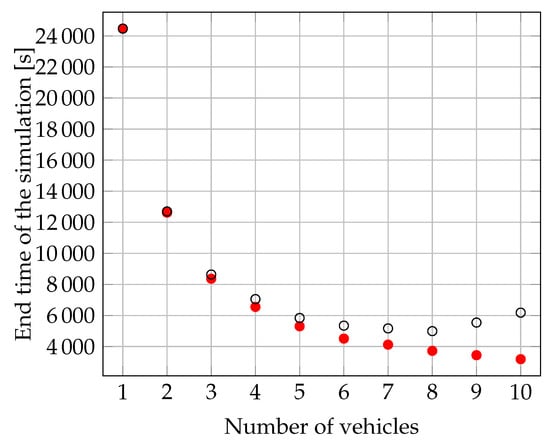

Figure 4 provides graphs for comparing the results of the two approaches depending on the number of vehicles used. In the case of the system shown in Figure 3, the way in which process reservations are carried out is irrelevant. This is due to the transport tasks implemented in this system, which use only dedicated stations belonging to the PU and DE sets. This means that regardless of whether we carry out process reservations in a staged manner or execute them once—we will obtain the same result of system operation. Moreover, dedicating these stations exclusively to specific tasks also means that the deadlock-free zones implemented in the system will have a positive impact on the system’s performance. They divide the entire bidirectional guide path of the vehicle into subsequent segments, which can be considered separately according to the SOCP method. Simulations for this example were carried out in the Delmia QUEST. Their results were compared with the results of simulations published in [2] concerning the application of the original version of the SOCP method for a system with bidirectional paths. The tests were carried out for the number of AGVs varying from 1 to 10. The results of the simulations are presented in Table 2.

Figure 4.

A comparison of the results for bidirectional paths.

Table 2.

The results of the simulation (bidirectional paths).

The empty circles present results for the original SOCP method while the red circles show the results of this method using the deadlock-free zones shown schematically in Figure 1b. The use of the new type of zone allowed for a significant reduction in transport task completion times of up to 40%, which is due to the reduction in the restrictiveness of the method by segmenting the guided paths.

4.2. Unidirectional Paths

Let us now consider two examples from [2], which can be considered to be use cases of staged process reservation. These examples are only different from the example in Figure 3 by the type of roads, while the road structure and the transport tasks performed are the same. It should be noted, however, that in both of these examples there are numerous deadlock-free zones that were not present in the example with two-way roads. The question that must be answered in this situation is whether the justification presented above for the staged manner of implementing process reservation is valid for these examples. The essential argument that supports this possibility is the important feature of the new type of deadlock-free zone shown in Figure 1b. The main argument that confirms this possibility is an important feature of the new type of deadlock-free zone, which was used to represent stations S1–S18 in all examples. The structure of this zone implies that it can only be connected to a deadlock-risk zone which means that it will form a single capacity deadlock-free segment. According to the SOCP method, it would therefore have to be reserved for the transport task that uses the station but, as shown earlier, the staged execution of the process reservation for the station, which for the examples below should be understood as stopping the process reservation on the segment representing the station, will not result in the possibility of a waiting cycle for process reservations and therefore will not lead to a restricted deadlock for the examples below.

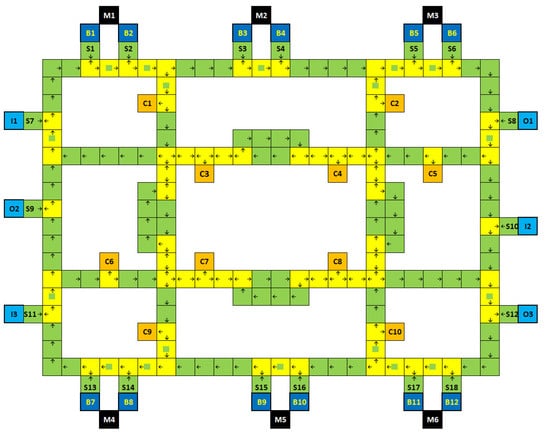

The first example, shown in Figure 5, concerns a system with unidirectional paths. In this system, to improve the efficiency of the SOCP method, modifications in the assignment of deadlock-free zones allowed by the method were introduced in [2]. The example also uses the deadlock-free zones shown schematically in Figure 1b. The simulations were also carried out in the Delmia QUEST system and the results were compared with those published in [2] and are summarized in Table 3.

Figure 5.

The layout with unidirectional flow paths.

Table 3.

The results of the simulation (unidirectional paths).

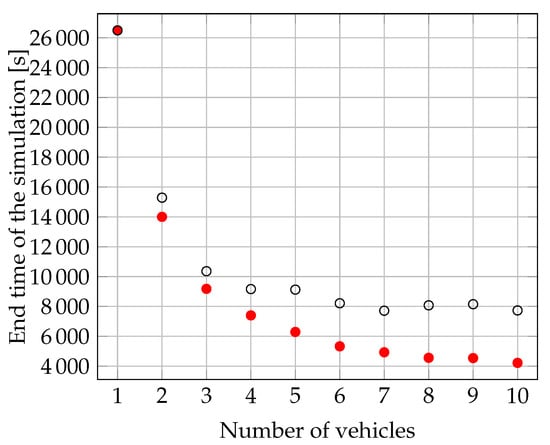

In Figure 6, the empty circles show the results of the original SOCP method in which the process reservations are made before the transport tasks start, while the red circles show the results of this method for a system using a new type of deadlock-free zone, which enabled the process reservation procedure to be carried out in a phased manner. As can be seen, the use of the new type of zone allowed a significant reduction in transport task completion times of up to 49% when 10 AGVs were used.

Figure 6.

A comparison of the results for unidirectional paths.

4.3. Mixed Paths

Example two, shown in Figure 7, concerns a system with mixed paths. As in example one, to improve the efficiency of the SOCP method, modifications have been made to the assignment of deadlock-free zones in [2]. The example also uses the zones shown schematically in Figure 1b. The results of the simulations carried out in the Delmia QUEST have been compared with the results published in [2] and are summarized in Table 4.

Figure 7.

The layout with mixed flow paths.

Table 4.

The results of the simulation (mixed paths).

In Figure 8, the empty circles show the results of the original SOCP method while the red circles show the results of this method using the deadlock-free zone shown schematically in Figure 1b. As can be seen, the use of a new type of zone enabled process reservations to be made in a staged manner which allowed for a significant reduction in transport task completion times of up to 45% when 10 AGVs were used.

Figure 8.

A comparison of the results for mixed paths.

5. Conclusions

This paper proposes a modification of the SOCP deadlock handling method. This modification limits the generality of the method, so it is dedicated to solving a specific type of use cases. This approach is suitable for a production system in which each station serves as either an input station or an output station, but never both and moreover the transport task requires that each vehicle starts at the parking place, transports parts from the pick-up points to the delivery points and finishes at the parking place. A condition (3) was defined to verify whether such modification for a given case will not lead to a restricted deadlock. The introduction of a staged method of process reservation instead of making all reservations at once before the start of the transport task makes it possible to reduce the restrictiveness of the method and thus increase its efficiency. An improvement in the efficiency of the transportation system was also achieved for the system with bidirectional paths. This effect is shown by the introduction of a new type of deadlock-free zone shown schematically in Figure 1b. The following conclusions can be drawn from the presented analyses and simulation studies:

- the use cases of the modified SOCP method discussed above show their higher efficiency than the source method, which justifies the introduction of the modification;

- condition (3) defined in this paper makes it possible to apply the modified method not only to the examples presented in this paper but to all cases for which this condition is met;

- methods of a general nature can be used to solve a wide range of problems for which they were developed, but their efficiency is usually worse than dedicated methods developed to solve a limited number of use cases.

As mentioned earlier the structural online control policy is based on two rules. Further work should be focused on the second rule, which corresponds to the deadlock-risk segments. Improvement of this rule can increase the efficiency of the SOCP method.

Author Contributions

Conceptualization, W.M. and J.Z.; methodology, J.Z.; software, W.M.; validation, J.Z.; resources, W.M.; writing—original draft preparation, J.Z. and W.M.; writing—review and editing, W.M.; visualization, W.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The source data cited in this study are available in the paper [2].

Conflicts of Interest

The authors declare no conflict of interest.

References

- Vis, I.F. Survey of research in the design and control of automated guided vehicle systems. Eur. J. Oper. Res. 2006, 170, 677–709. [Google Scholar] [CrossRef]

- Zaja̧c, J.; Małopolski, W. Structural online control policy for collision and deadlock resolution in multi-AGV systems. J. Manuf. Syst. 2021, 60, 80–92. [Google Scholar] [CrossRef]

- Le-Anh, T.; De Koster, M.B. A review of design and control of automated guided vehicle systems. Eur. J. Oper. Res. 2006, 171, 1–23. [Google Scholar] [CrossRef]

- Qiu, L.; Hsu, W.J.; Huang, S.Y.; Wang, H. Scheduling and routing algorithms for AGVs: A survey. Int. J. Prod. Res. 2002, 40, 745–760. [Google Scholar] [CrossRef]

- Fragapane, G.; de Koster, R.; Sgarbossa, F.; Strandhagen, J.O. Planning and control of autonomous mobile robots for intralogistics: Literature review and research agenda. Eur. J. Oper. Res. 2021. [Google Scholar] [CrossRef]

- Egbelu, P.; Tanchoco, J. Potentials for bi-directional guide-path for automated guided vehicle based systems. Int. J. Prod. Res. 1986, 24, 1075–1097. [Google Scholar] [CrossRef]

- Asef-Vaziri, A.; Dessouky, M.; Sriskandarajah, C. A loop material flow system design for automated guided vehicles. Int. J. Flex. Manuf. Syst. 2001, 13, 33–48. [Google Scholar] [CrossRef]

- Ventura, J.; Lee, C. A study of the tandem loop with multiple vehicles configuration for automated guided vehicle systems. J. Manuf. Syst. 2001, 20, 153–165. [Google Scholar] [CrossRef]

- Sinriech, D.; Tanchoco, J.M.A. An introduction to the segmented flow approach for discrete material flow systems. Int. J. Prod. Res. 1995, 33, 3381–3410. [Google Scholar] [CrossRef]

- Qiu, L.; Hsu, W.J. Adapting Sorting Algorithms for Routing AGVs on a Mesh-like Path Topology; Technical report; Centre for Advanced Information Systems, School of Applied Science, Nanyang Technological University: Singapore, 2000. [Google Scholar]

- Małopolski, W. A sustainable and conflict-free operation of AGVs in a square topology. Comput. Ind. Eng. 2018, 126, 472–481. [Google Scholar] [CrossRef]

- Coffman, E.G.; Elphick, M.; Shoshani, A. System Deadlocks. ACM Comput. Surv. (CSUR) 1971, 3, 67–78. [Google Scholar] [CrossRef]

- Banaszak, Z.A.; Krogh, B.H. Deadlock Avoidance in Flexible Manufacturing Systems with Concurrently Competing Process Flows. IEEE Trans. Robot. Autom. 1990, 6, 724–734. [Google Scholar] [CrossRef]

- Zajac, J. A deadlock handling method for automated manufacturing systems. CIRP Ann. 2004, 53, 367–370. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, H.; Liu, Y.; Ding, Z. Collision and deadlock avoidance in multirobot systems: A distributed approach. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 1712–1726. [Google Scholar] [CrossRef]

- Draganjac, I.; Miklic, D.; Kovacic, Z.; Vasiljevic, G.; Bogdan, S. Decentralized Control of Multi-AGV Systems in Autonomous Warehousing Applications. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1433–1447. [Google Scholar] [CrossRef]

- Fanti, M.P.; Mangini, A.M.; Pedroncelli, G.; Ukovich, W. Decentralized deadlock-free control for AGV systems. In Proceedings of the American Control Conference, Chicago, IL, USA, 1–3 July 2015; pp. 2414–2419. [Google Scholar] [CrossRef]

- Nielsen, I.; Dang, Q.V.; Bocewicz, G.; Banaszak, Z.; Banaszak ZBanaszak, Z. A methodology for implementation of mobile robot in adaptive manufacturing environments. J. Intell. Manuf. 2017, 28, 1171–1188. [Google Scholar] [CrossRef]

- Xiao, H.; Wu, X.; Qin, D.; Zhai, J. A Collision and Deadlock Prevention Method with Traffic Sequence Optimization Strategy for UGN-Based AGVS. IEEE Access 2020, 8, 209452–209470. [Google Scholar] [CrossRef]

- Pan, F.; Sun, Q. A Traffic Control Strategy of the Heavy-duty AGVS in a Square Topology. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation, ICMA 2019, Tianjin, China, 4–7 August 2019; pp. 263–268. [Google Scholar] [CrossRef]

- Du, N.; Hu, H. Robust Deadlock Detection and Control of Automated Manufacturing Systems With Multiple Unreliable Resources Using Petri Nets. IEEE Trans. Autom. Sci. Eng. 2020, 17. [Google Scholar] [CrossRef]

- Witczak, M.; Majdzik, P.; Stetter, R.; Lipiec, B. A fault-tolerant control strategy for multiple automated guided vehicles. J. Manuf. Syst. 2020, 55, 56–68. [Google Scholar] [CrossRef]

- Drótos, M.; Györgyi, P.; Horváth, M.; Kis, T. Suboptimal and conflict-free control of a fleet of AGVs to serve online requests. Comput. Ind. Eng. 2021, 152, 106999. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, W.; Duan, J.; Qin, J. Cooperative Scheduling of AGV and ASC in Automation Container Terminal Relay Operation Mode. Math. Probl. Eng. 2021, 2021, 5764012. [Google Scholar] [CrossRef]

- Zou, W.Q.; Pan, Q.K.; Wang, L. An effective multi-objective evolutionary algorithm for solving the AGV scheduling problem with pickup and delivery. Knowl. Based Syst. 2021, 218, 106881. [Google Scholar] [CrossRef]

- Farooq, B.; Bao, J.; Ma, Q. Flow-shop predictive modeling for multi-automated guided vehicles scheduling in smart spinning cyber–physical production systems. Electronics 2020, 9, 799. [Google Scholar] [CrossRef]

- Yu, N.N.; Li, T.K.; Wang, B.L.; Yuan, S.P.; Wang, Y. Reliability oriented multi-AGVs online scheduling and path planning problem of automated sorting warehouse system. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bandung, Indonesia, 20–21 April 2021; Volume 1043, p. 022035. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Wu, S.; Wang, G. Spare zone based hierarchical motion coordination for multi-AGV systems. Simul. Model. Pract. Theory 2021, 109, 102294. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Wang, G.; Wu, S.; Han, S. Dynamic Resource Reservation Based Collision and Deadlock Prevention for Multi-AGVs. IEEE Access 2020, 8, 82120–82130. [Google Scholar] [CrossRef]

- Mohammadi, E.K.; Shirazi, B. Toward high degree flexible routing in collision-free FMSs through automated guided vehicles’ dynamic strategy: A simulation metamodel. ISA Trans. 2020, 96, 228–244. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).