Characterization with X-rays of a Large-Area GEMPix Detector with Optical Readout for QA in Hadron Therapy

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

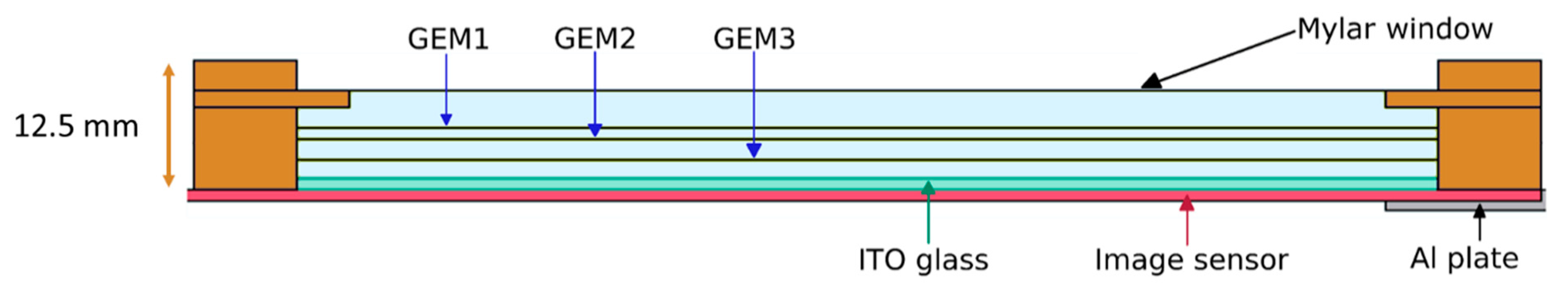

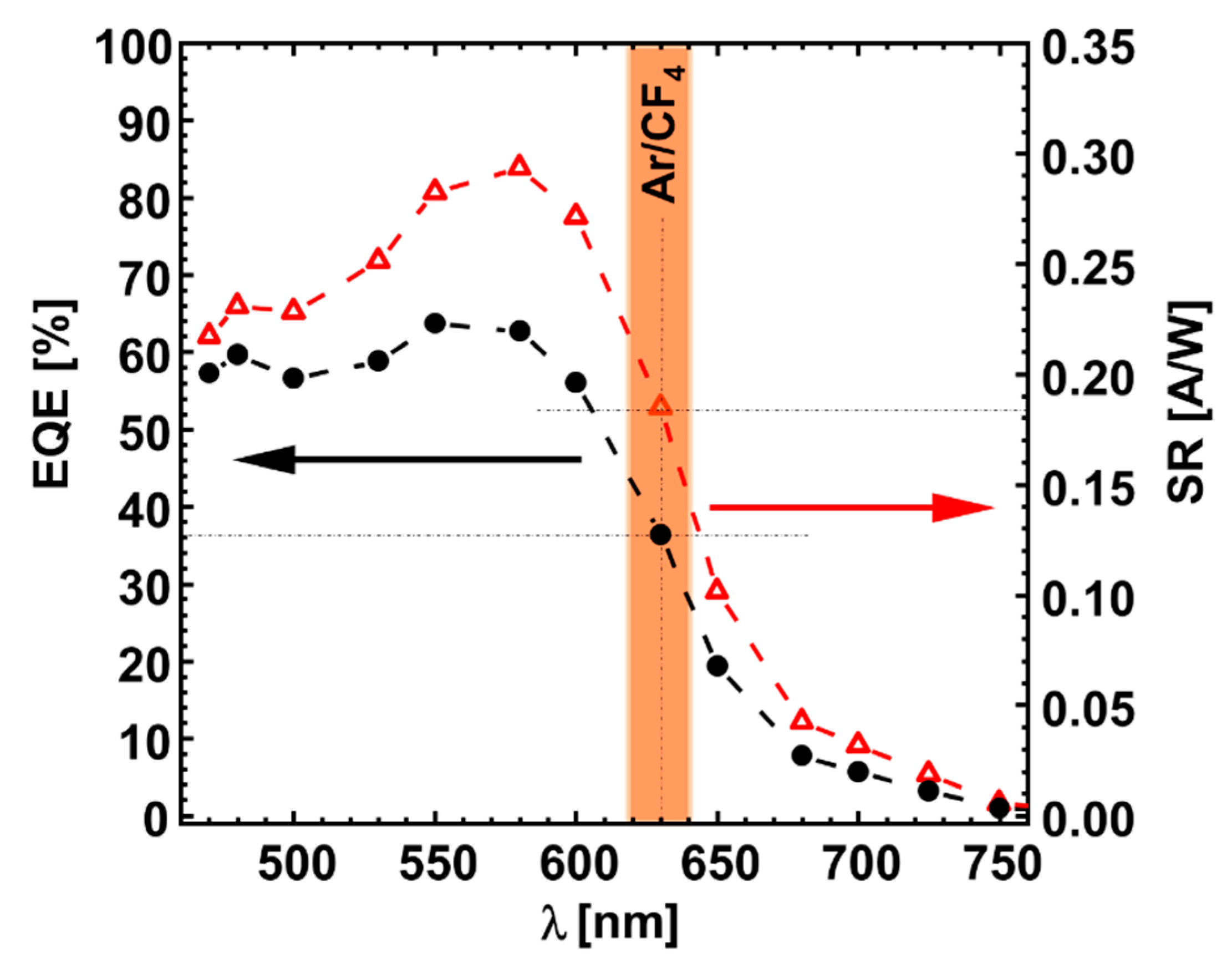

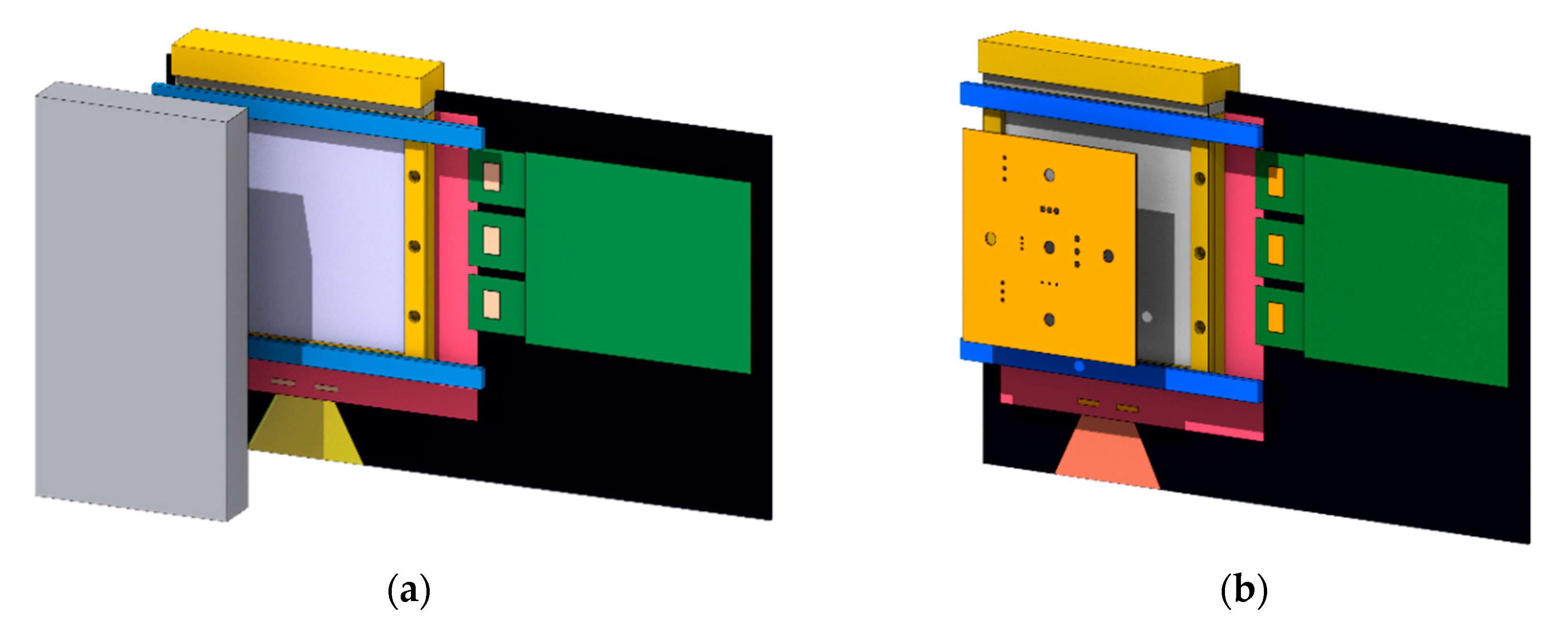

2.1. Detector Design

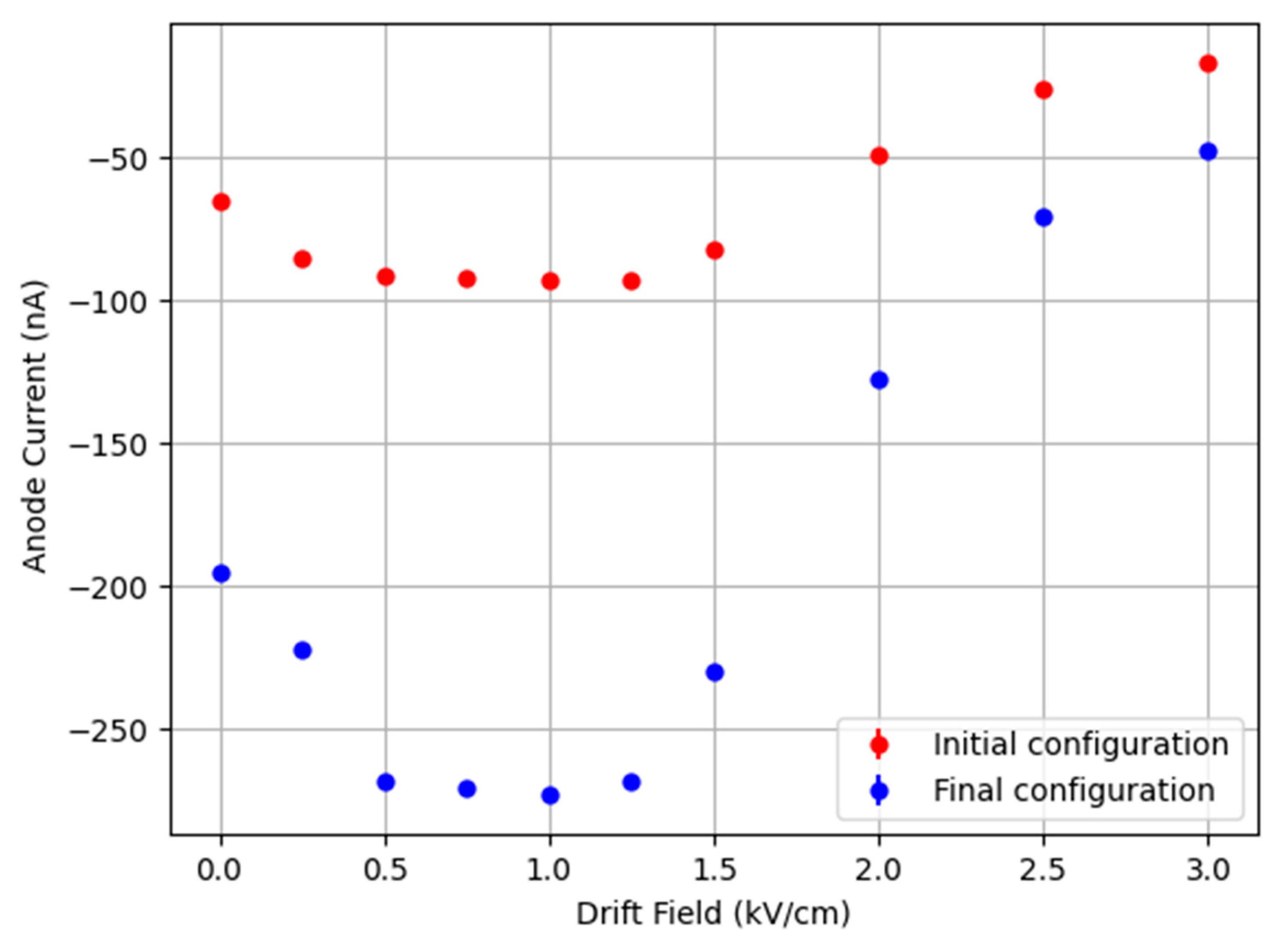

2.2. Optimization of Electric Fields

2.3. Spatial Resolution

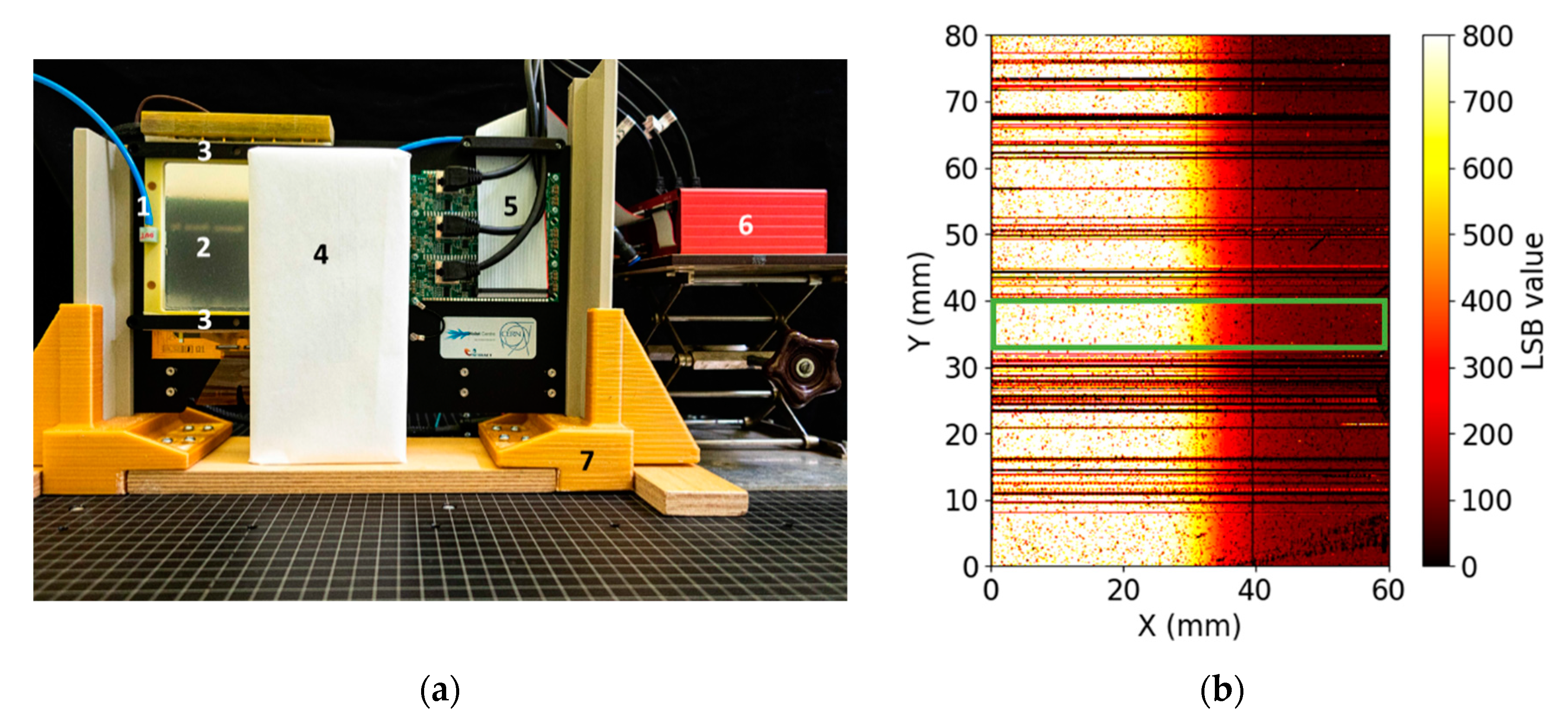

2.4. Experimental Set-Up to Determine the Spatial Resolution

2.5. FLUKA Simulations

3. Results

3.1. Optimization of the Electric Fields of the LaGEMPix

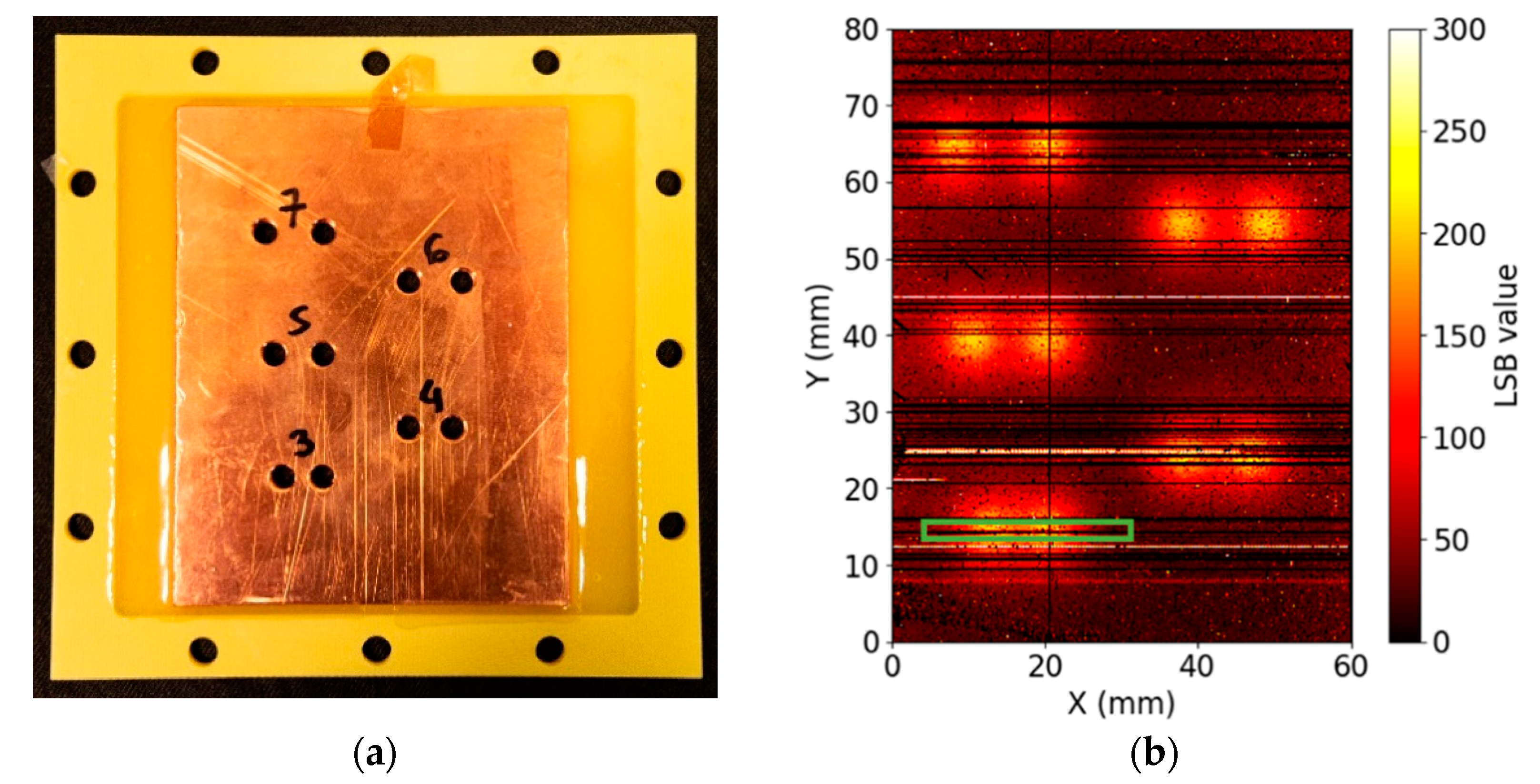

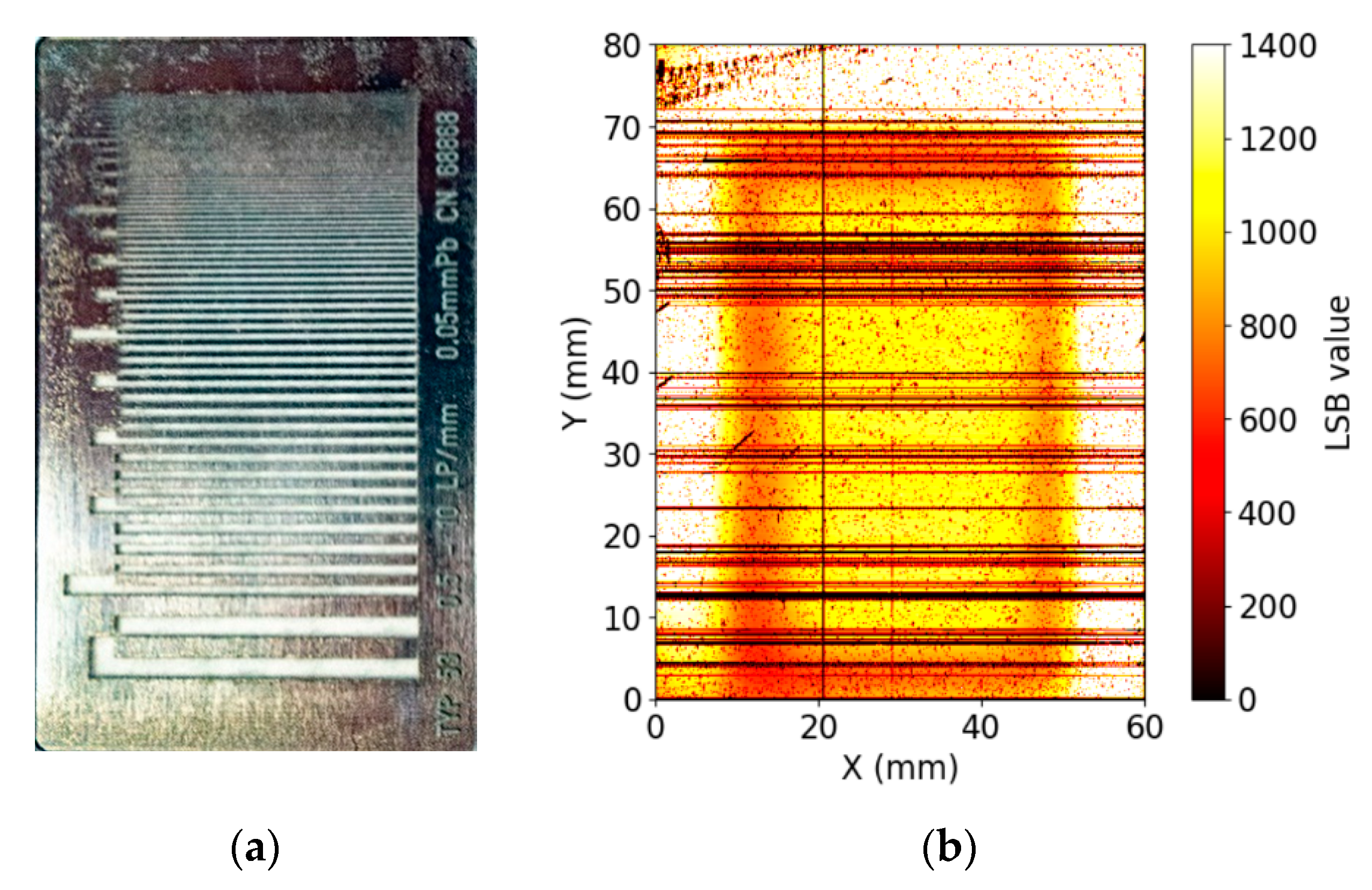

3.2. Spatial Resolution with the LaGEMPix

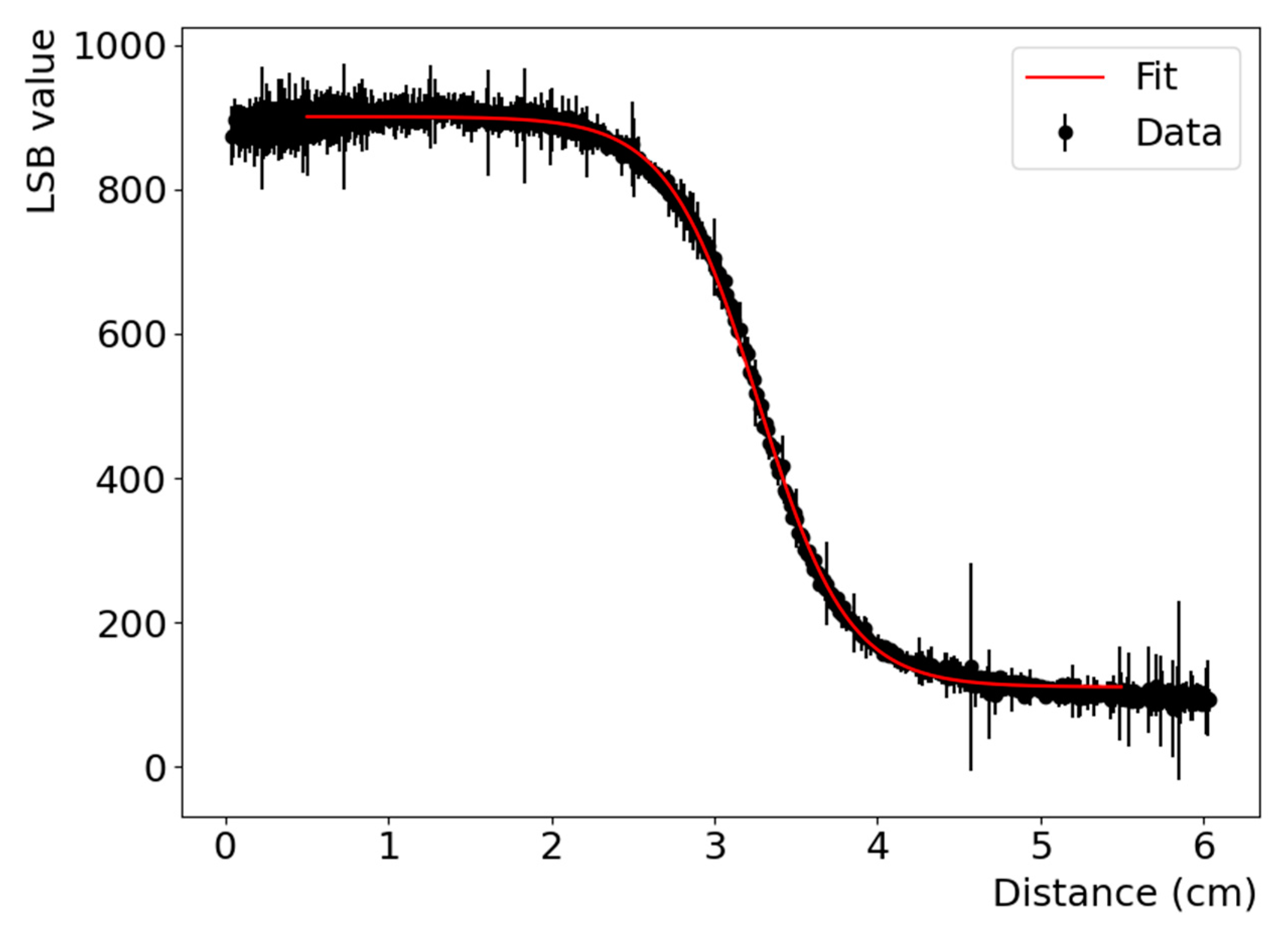

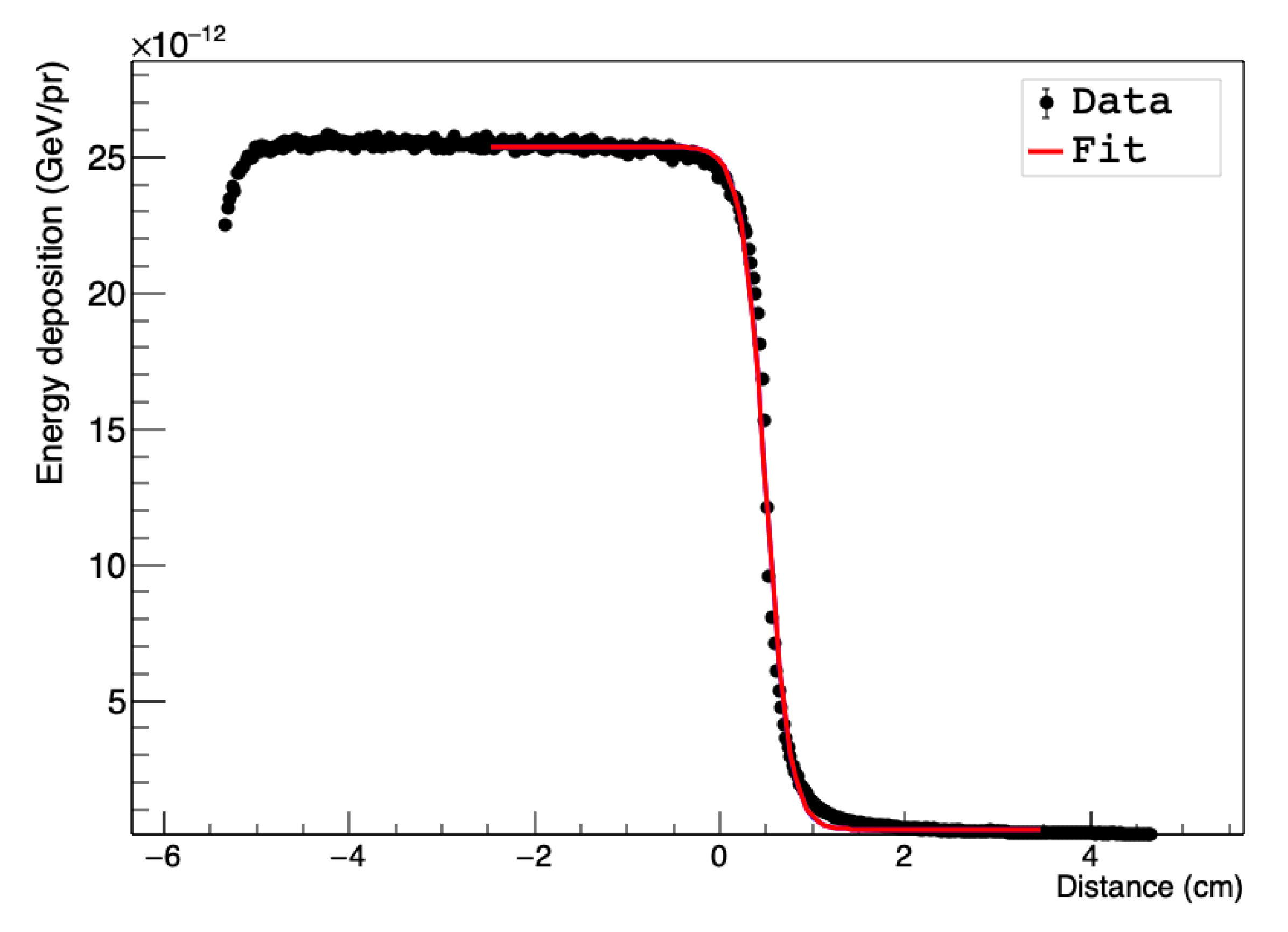

3.2.1. Edge Spread Function (ESF)

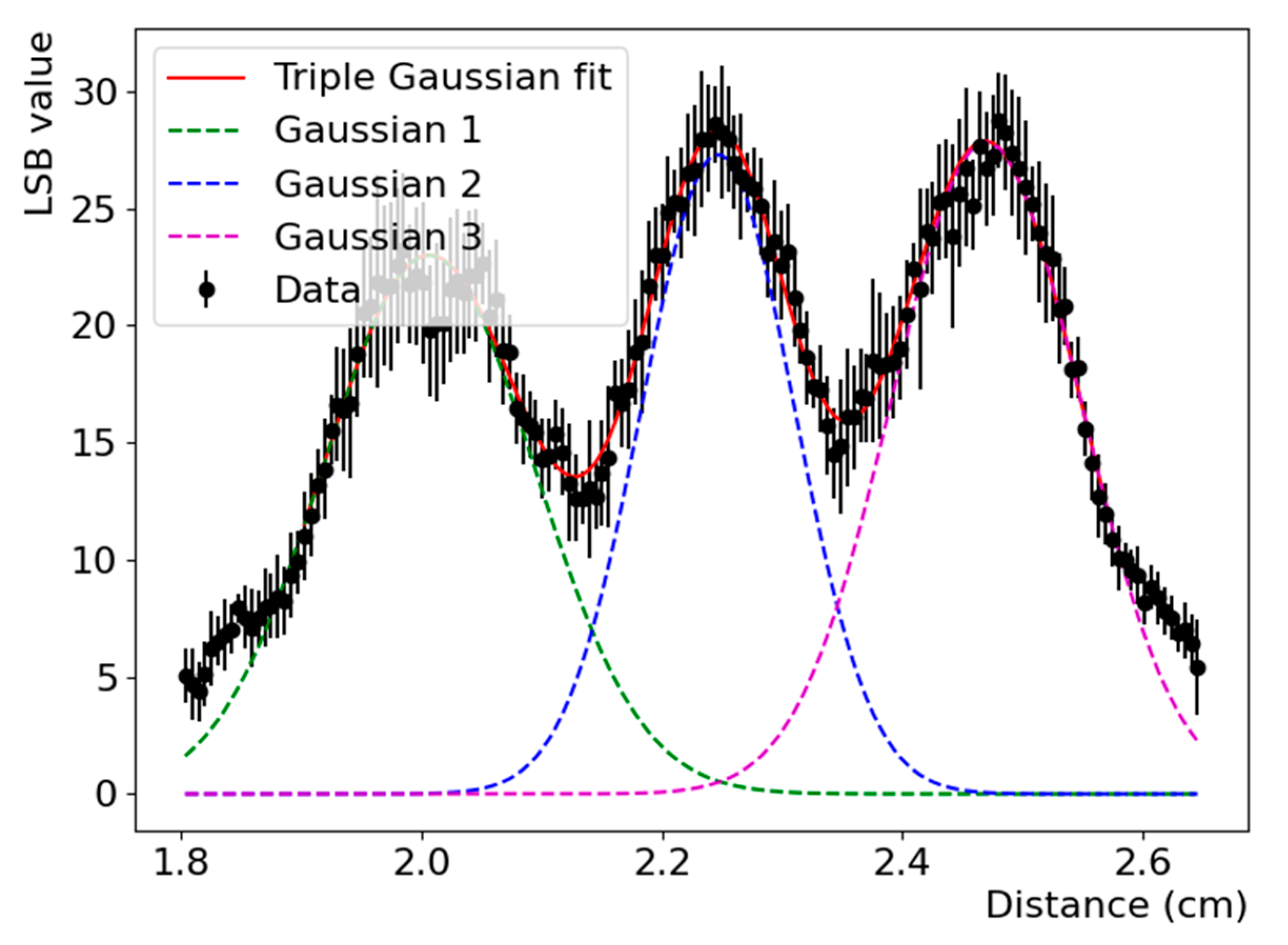

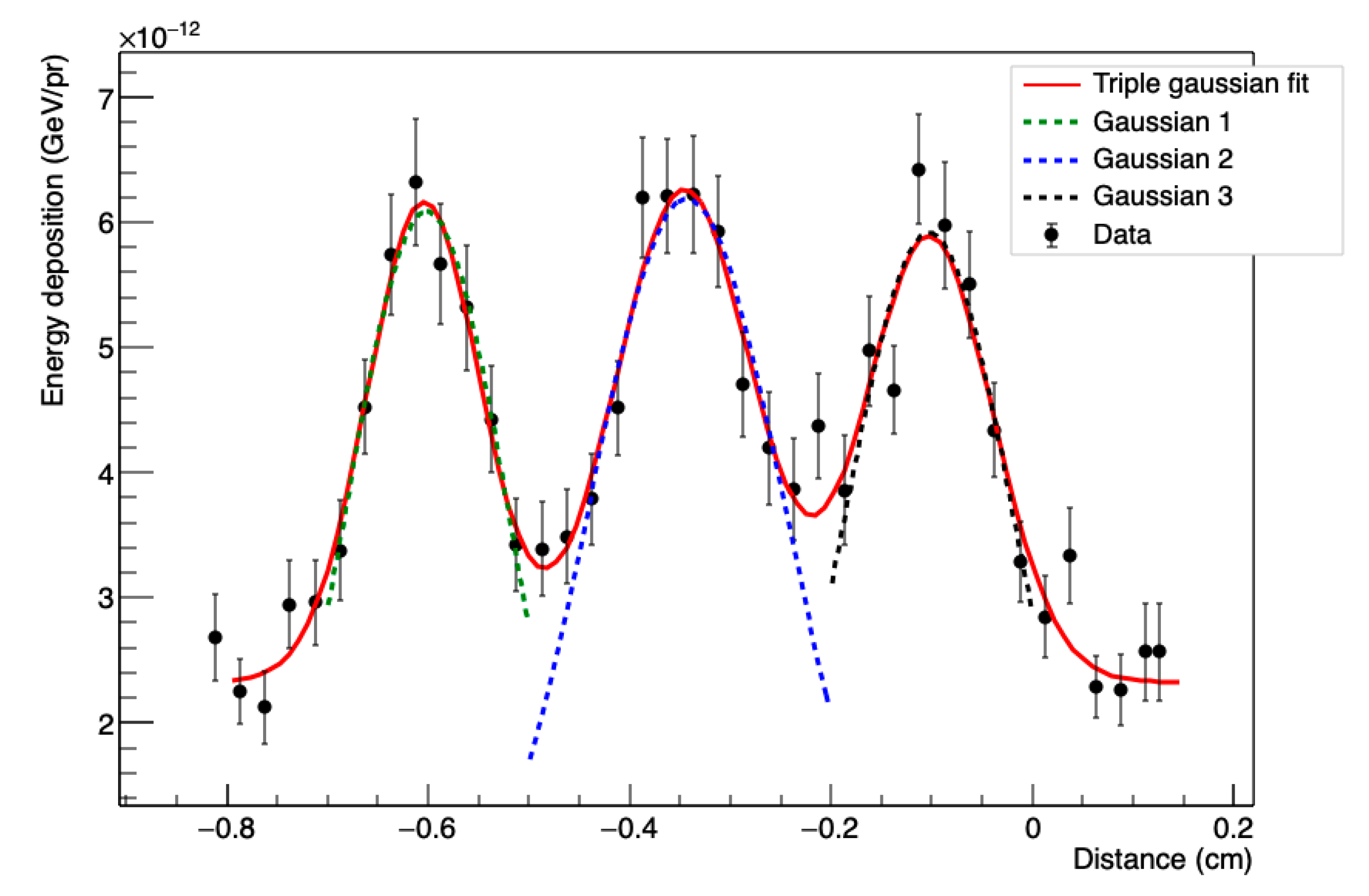

3.2.2. Line Spread Function (LSF)

3.2.3. Modulation Transfer Function (MTF)

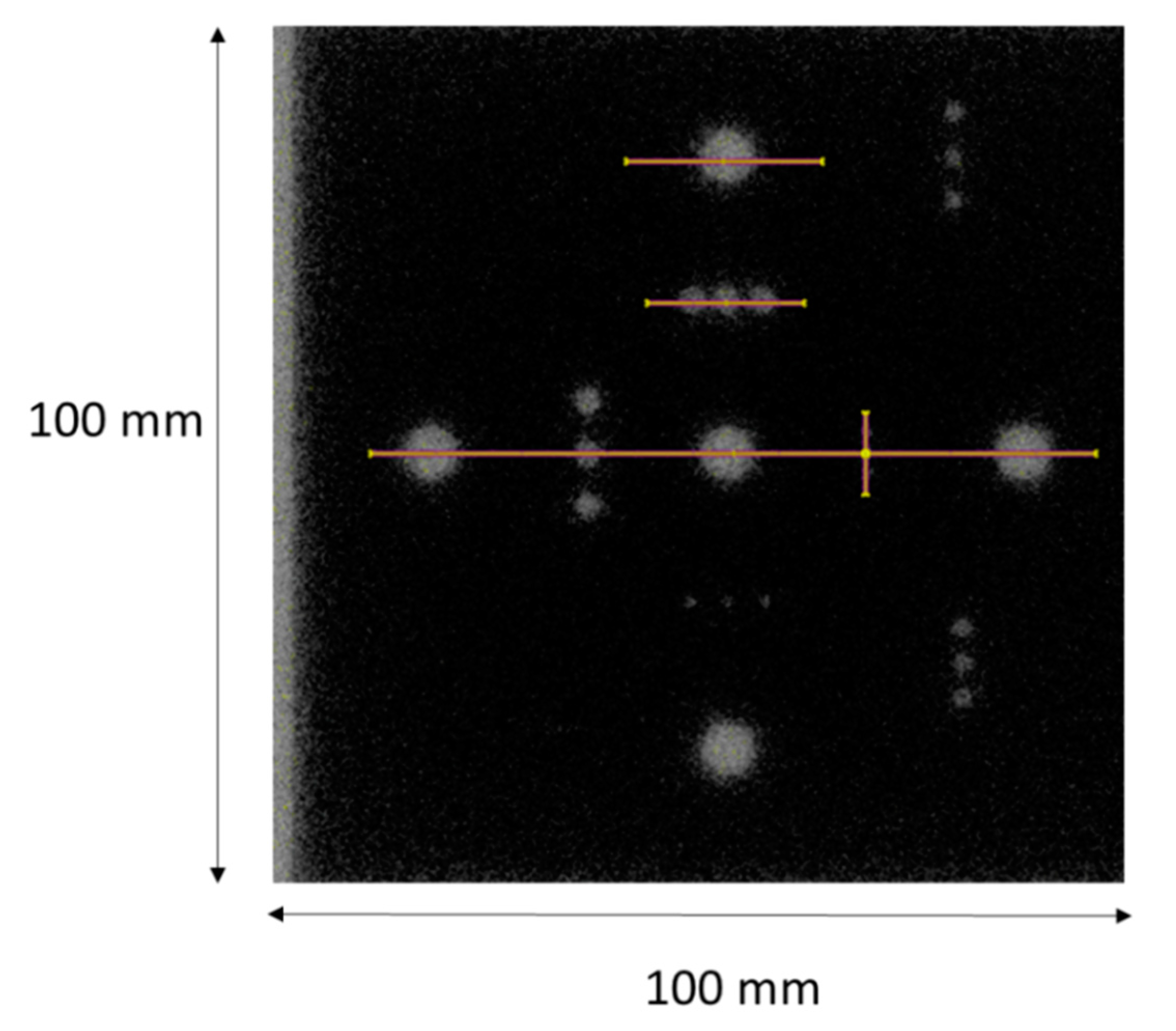

3.3. Spatial Resolution with the GEMPix

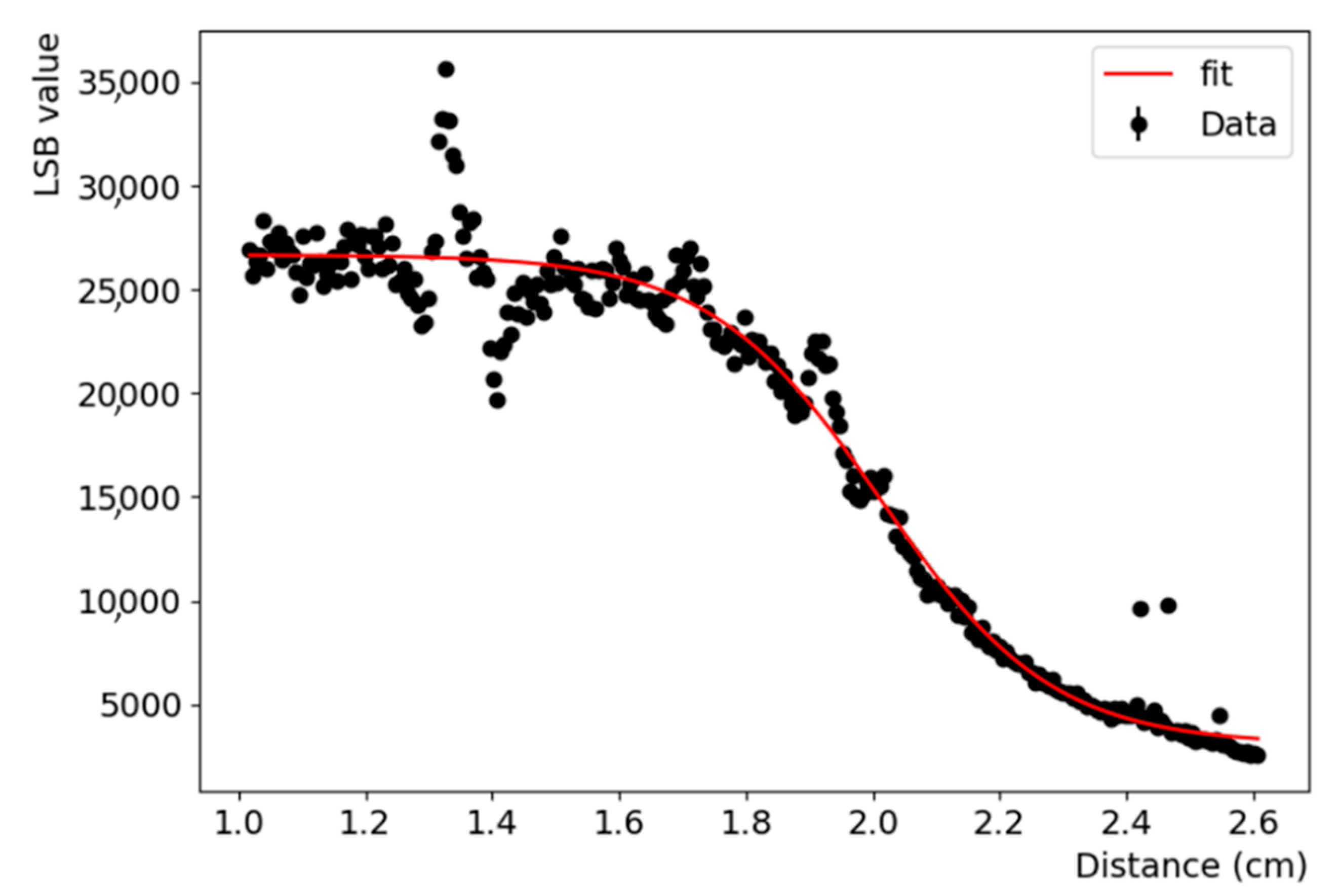

3.3.1. Edge Spread Function

3.3.2. Line Spread Function

3.3.3. Modulation Transfer Function

3.4. Spatial Resolution with GAFCHROMIC® Films

3.5. Spatial Resolution with the FLUKA Simulation

3.5.1. Edge Spread Function

3.5.2. Line Spread Function

4. Discussion on the Spatial Resolution

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Particle Therapy Facilities in Clinical Operation. Available online: https://www.ptcog.ch/index.php/facilities-in-operation (accessed on 17 January 2021).

- Ishikawa, H.; Nakai, K.; Nonaka, T.; Sakurai, H. Particle Therapy in Cancer Treatment-Current and Future Perspective. Gan to kagaku ryoho. Cancer Chemother. 2019, 46, 1219–1225. [Google Scholar]

- Rana, S.; Bennouna, J.; Samuel, E.J.J.; Gutierrez, A.N. Development and Long-Term Stability of a Comprehensive Daily QA Program for a Modern Pencil Beam Scanning (PBS) Proton Therapy Delivery System. J. Appl. Clin. Med Phys. 2019, 20, 29–44. [Google Scholar] [CrossRef] [Green Version]

- Sauli, F. The Gas Electron Multiplier (GEM): Operating Principles and Applications. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2016, 805, 2–24. [Google Scholar] [CrossRef]

- Leidner, J.; Ciocca, M.; Mairani, A.; Murtas, F.; Silari, M. A GEMPix-Based Integrated System for Measurements of 3D Dose Distributions in Water for Carbon Ion Scanning Beam Radiotherapy. Med. Phys. 2020, 47, 2516–2525. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leidner, J.; Murtas, F.; Silari, M. Medical Applications of the GEMPix. Appl. Sci. 2021, 11, 440. [Google Scholar] [CrossRef]

- Mirandola, A.; Molinelli, S.; Vilches Freixas, G.; Mairani, A.; Gallio, E.; Panizza, D.; Russo, S.; Ciocca, M.; Donetti, M.; Magro, G.; et al. Dosimetric Commissioning and Quality Assurance of Scanned Ion Beams at the Italian National Center for Oncological Hadrontherapy. Med. Phys. 2015, 42, 5287–5300. [Google Scholar] [CrossRef] [PubMed]

- Grevillot, L.; Osorio Moreno, J.; Letellier, V.; Dreindl, R.; Elia, A.; Fuchs, H.; Carlino, A.; Kragl, G.; Palmans, H.; Vatnitsky, S.; et al. Clinical Implementation and Commissioning of the MedAustron Particle Therapy Accelerator for Non-Isocentric Scanned Proton Beam Treatments. Med. Phys. 2020, 47, 380–392. [Google Scholar] [CrossRef] [PubMed]

- Van de Weijer, P.; Akkerman, H.B. Spotless Hybrid Thin-Film Encapsulation Stack for Organic Light-Emitting Diodes on Organic Foils. Org. Electron. 2019, 66, 43–46. [Google Scholar] [CrossRef]

- Bencivenni, G.; Felici, G.; Murtas, F.; Valente, P.; Bonivento, W.; Cardini, A.; Lai, A.; Pinci, D.; Saitta, B.; Bosio, C. A Triple GEM Detector with Pad Readout for High Rate Charged Particle Triggering. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2002, 488, 493–502. [Google Scholar] [CrossRef]

- Brunbauer, F.M. Applications of Gas Scintillation Properties in Optically Read out GEM-Based Detectors; Technical University of Vienna: Vienna, Austria, 2018. [Google Scholar]

- Indium Tin Oxide Glass. Available online: http://www.visionteksystems.co.uk/ito_glass_datasheet.htm (accessed on 21 February 2021).

- Fraga, M.; Fraga, F.; Fetal, S.T.G.; Margato, L.; Marques, R.; Policarpo, A. The GEM Scintillation in He-CF 4, Ar-CF 4, Ar-TEA and Xe-TEA Mixtures. Nucl. Instrum. Methods Phys. Res. A 2003, 504, 88–92. [Google Scholar] [CrossRef]

- Timmer, J.; Van Vuure, T.; Bom, V.; Eijk, C.W.E.; de Haas, J.; Schippers, J. A Scintillating GEM for 2D-Dosimetry in Radiation Therapy. Nucl. Instrum. Methods Phys. Res. A 2002, 478, 98–103. [Google Scholar] [CrossRef]

- Pansky, A.; Breskin, A.; Buzulutskov, A.; Chechik, R.; Elkind, V.; Va’vra, J. The Scintillation of CF4 and Its Relevance to Detection Science. Nucl. Instrum. Methods Phys. Res. A 1995, 354, 262–269. [Google Scholar] [CrossRef] [Green Version]

- Hamamatsu. Image Sensors. Available online: https://www.hamamatsu.com/resources/pdf/ssd/image_sensor_kmpd0002e.pdf (accessed on 4 July 2021).

- Hamamatsu. Handbook Image Sensors—Chapter 5. Available online: https://www.hamamatsu.com/resources/pdf/ssd/e05_handbook_image_sensors.pdf (accessed on 3 July 2021).

- Seravalli, E.; de Boer, M.R.; Geurink, F.; Huizenga, J.; Kreuger, R.; Schippers, J.M.; van Eijk, C.W.E. 2D Dosimetry in a Proton Beam with a Scintillating GEM Detector. Phys. Med. Biol. 2009, 54, 3755–3771. [Google Scholar] [CrossRef]

- Klyachko, A.V.; Moskvin, V.; Nichiporov, D.F.; Solberg, K.A. A GEM-Based Dose Imaging Detector with Optical Readout for Proton Radiotherapy. Nucl. Instrum. Methods Phys. Res. A 2012, 694, 271–279. [Google Scholar] [CrossRef]

- Kronemeijer, A.J.; Akkerman, H.; van der Steen, J.-L.; Steudel, S.; Pendyala, R.; Panditha, P.; Bel, T.; van Diesen, K.; de Haas, G.; Maas, J.; et al. P-127: Dual-Gate Self-Aligned IGZO TFTs Monolithically Integrated with High-Temperature Bottom Moisture Barrier for Flexible AMOLED. In SID Symposium Digest of Technical Papers; SID: Los Angeles, CA, USA, 2018; pp. 1577–1580. Volume 49. [Google Scholar] [CrossRef]

- Tordera, D.; Peeters, B.; Akkerman, H.B.; van Breemen, A.J.J.M.; Maas, J.; Shanmugam, S.; Kronemeijer, A.J.; Gelinck, G.H. A High-Resolution Thin-Film Fingerprint Sensor Using a Printed Organic Photodetector. Adv. Mater. Technol. 2019, 4, 1900651. [Google Scholar] [CrossRef]

- Kielar, M.; Dhez, O.; Pecastaings, G.; Curutchet, A.; Hirsch, L. Long-Term Stable Organic Photodetectors with Ultra Low Dark Currents for High Detectivity Applications. Sci. Rep. 2016, 6, 39201. [Google Scholar] [CrossRef] [Green Version]

- Sauli, F. GEM: A New Concept for Electron Amplification in Gas Detectors. Nucl. Instrum. Methods Phys. Res. A 1997, 386, 531–534. [Google Scholar] [CrossRef]

- Brunbauer, F.M.; Garcia, F.; Korkalainen, T.; Lugstein, A.; Lupberger, M.; Oliveri, E.; Pfeiffer, D.; Ropelewski, L.; Thuiner, P.; Schinnerl, M. Combined Optical and Electronic Readout for Event Reconstruction in a GEM-Based TPC. IEEE Trans. Nucl. Sci. 2018, 65, 913–918. [Google Scholar] [CrossRef]

- Brugger, M.; Carbonez, P.; Pozzi, F.; Silari, M.; Vincke, H. New Radiation Protection Calibration Facility at CERN. Radiat. Prot. Dosim. 2014, 161, 181–184. [Google Scholar] [CrossRef] [Green Version]

- Tektronix. Model 6517A Electrometer User’s Manual Rev. C. Available online: https://www.tek.com/manual/model-6517a-electrometer-users-manual-rev-d-manual (accessed on 23 February 2021).

- Curioni, A.; Dinar, N.; La Torre, F.P.; Leidner, J.; Murtas, F.; Puddu, S.; Silari, M. Measurements of 55Fe Activity in Activated Steel Samples with GEMPix. Nucl. Instrum. Methods Phys. Res. 2017, 849, 60–71. [Google Scholar] [CrossRef]

- Molinelli, S.; Mairani, A.; Mirandola, A.; Vilches Freixas, G.; Tessonnier, T.; Giordanengo, S.; Parodi, K.; Ciocca, M.; Orecchia, R. Dosimetric Accuracy Assessment of a Treatment Plan Verification System for Scanned Proton Beam Radiotherapy: One-Year Experimental Results and Monte Carlo Analysis of the Involved Uncertainties. Phys. Med. Biol. 2013, 58, 3837–3847. [Google Scholar] [CrossRef] [PubMed]

- Winter, J.; Ellerbrock, M.; Jäkel, O.; Greilich, S.; Bangert, M. Analytical Modeling of Depth-Dose Degradation in Heterogeneous Lung Tissue for Intensity-Modulated Proton Therapy Planning. Phys. Imaging Radiat. Oncol. 2020, 14, 32–38. [Google Scholar] [CrossRef] [PubMed]

- PTW Freiburg GmbH. Radiation Therapy. Available online: https://www.ptwdosimetry.com/en/solutions/radiation-therapy/ (accessed on 21 February 2021).

- GmbH. IBA Dosimetry. Available online: https://www.iba-dosimetry.com/ (accessed on 21 February 2021).

- Giordanengo, S.; Palmans, H. Dose Detectors, Sensors, and Their Applications. Med Phys. 2018, 45, e1051–e1072. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grevillot, L.; Stock, M.; Palmans, H.; Osorio Moreno, J.; Letellier, V.; Dreindl, R.; Elia, A.; Fuchs, H.; Carlino, A.; Vatnitsky, S. Implementation of Dosimetry Equipment and Phantoms at the MedAustron Light Ion Beam Therapy Facility. Med. Phys. 2018, 45, 352–369. [Google Scholar] [CrossRef]

- Russo, S.; Mirandola, A.; Molinelli, S.; Mastella, E.; Vai, A.; Magro, G.; Mairani, A.; Boi, D.; Donetti, M.; Ciocca, M. Characterization of a Commercial Scintillation Detector for 2-D Dosimetry in Scanned Proton and Carbon Ion Beams. Phys. Med. 2017, 34, 48–54. [Google Scholar] [CrossRef]

- ISO. ISO 12233:2017, Photography—Electronic Still Picture Imaging—Resolution and Spatial Frequency Responses; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Gopal, A.; Samant, S.S. Validity of the Line-Pair Bar-Pattern Method in the Measurement of the Modulation Transfer Function (MTF) in Megavoltage Imaging. Med Phys. 2008, 35, 270–279. [Google Scholar] [CrossRef]

- Smith, S.W. The Scientist and Engineer’s Guide to Digital Signal Processing; California Technical Pub.: San Diego, CA, USA, 1999; pp. 423–432. ISBN 9780966017649. [Google Scholar]

- Roque, R.; Carramate, L.; Amaro, F.; Natal da Luz, H.; Mir, J.A.; Azevedo, C.D.R. Spatial Resolution Properties of Krypton-Based Mixtures Using a 100 Μm Thick Gas Electron Multiplier. In Proceedings of the XRS 2018, Ljubljana, Slovenia, 26–29 June 2018. [Google Scholar]

- Jakubek, J.; Holy, T.; Lehmann, E.; Pospisil, S.; Uher, J.; Vacik, J.; Vavrik, D.; Andrikos, I.O. Properties of Neutron Pixel Detector Based on Medipix-2 Device. In Proceedings of the IEEE Symposium Conference Record Nuclear Science 2004, Rome, Italy, 16–22 October 2004; Volume 2, p. 949. [Google Scholar]

- Fujiwara, T.; Mitsuya, Y.; Fushie, T.; Murata, K.; Kawamura, A.; Koishikawa, A.; Toyokawa, H.; Takahashi, H. Gas Scintillation Glass GEM Detector for High-Resolution X-Ray Imaging and CT. Nucl. Instrum. Methods Phys. Res. A 2017, 850, 7–11. [Google Scholar] [CrossRef]

- Li, T.; Feng, H.; Xu, Z.; Li, X.; Cen, Z.; Li, Q. Comparison of Different Analytical Edge Spread Function Models for MTF Calculation Using Curve-Fitting. Proc. SPIE 2009, 7498. [Google Scholar] [CrossRef]

- Energy Resolution Due to Thermal Broadening (STM). Available online: https://shunchi100.wordpress.com/physics-research/energy-resolution-thermal-broadening/ (accessed on 23 February 2021).

- Alvarez, M.; Alves, A.; Neto, F.B.; Pavan, A.L.; Rosa, M.; Miranda, J.R.D.A.; de Pina, D.R. Comparison of Bar Pattern and Edge Method for MTF Measurement in Radiology Quality Control. Rev. Bras. Fis. Med. 2015, 9, 2–5. [Google Scholar] [CrossRef]

- ISO. ISO 4037-2:2019. Radiological Protection—X and Gamma Reference Radiation for Calibrating Dosemeters and Doserate Meters and for Determining Their Response as a Function of Photon Energy—Part 2: Dosimetry for Radiation Protection over the Energy Ranges from 8 keV to 1,3 MeV and 4 MeV to 9 MeV; ISO: Geneva, Switzerland, 2019. [Google Scholar]

- The Official CERN FLUKA Website. Available online: https://fluka.cern/ (accessed on 23 February 2021).

- Battistoni, G.; Boehlen, T.; Cerutti, F.; Chin, P.W.; Esposito, L.S.; Fassò, A.; Ferrari, A.; Lechner, A.; Empl, A.; Mairani, A.; et al. Overview of the FLUKA Code. Ann. Nucl. Energy 2015, 82, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Bohlen, T.T.; Cerutti, F.; Chin, M.P.W.; Fassò, A.; Ferrari, A.; Ortega, P.G.; Mairani, A.; Sala, P.R.; Smirnov, G.; Vlachoudis, V. The FLUKA Code: Developments and Challenges for High Energy and Medical Applications. Nucl. Data Sheets 2014, 120, 211–214. [Google Scholar]

- Marafini, M.; Patera, V.; Pinci, D.; Sarti, A.; Sciubba, A.; Spiriti, E. Optical Readout of a Triple-GEM Detector by Means of a CMOS Sensor. Nucl. Instrum. Methods Phys. Res. A 2016, 824, 562–564. [Google Scholar] [CrossRef]

- Ahmed, S.N. Position-sensitive detection and imaging. In Physics and Engineering of Radiation Detection, 1st ed.; Academic Press: Amsterdam, The Netherlands, 2007; pp. 423–463. ISBN 9780120455812. [Google Scholar]

- Seco, J.; Oumano, M.; Depauw, N.; Dias, M.F.; Teixeira, R.P.; Spadea, M.F. Characterizing the Modulation Transfer Function (MTF) of Proton/Carbon Radiography Using Monte Carlo Simulations. Med. Phys. 2013, 40, 091717. [Google Scholar] [CrossRef]

- Ghani, M.U.; Zhou, Z.; Ren, L.; Li, Y.; Zheng, B.; Yang, K.; Liu, H. Investigation of Spatial Resolution Characteristics of an in Vivo Micro Computed Tomography System. Nucl. Instrum. Methods Phys. Res. A 2016, 807, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Mahesh, M. Image Quality. In The Essential Physics of Medical Imaging, 3rd ed.; LWW: Philadelphia, PA, USA, 2013; pp. 60–101. Volume 40. [Google Scholar]

- QUART X-ray QA QC Solutions. Line Pair Patterns—Test Phantoms. Available online: https://quart.de/en/products/test-phantoms/resolution-patterns/line-pair-patterns (accessed on 6 June 2021).

- Murtas, F. The GEMPix Detector. Radiat. Meas. 2020, 138, 106421. [Google Scholar] [CrossRef]

- Jaccard, M.; Petersson, K.; Buchillier, T.; Bailat, C.; Germond, J.F.; Moeckli, R.; Bourhis, J.; Vozenin, M.C.; Bochud, F. EP-1494: Absolute Dosimetry with EBT3 Gafchromic Films in a Pulsed Electron Beam at High Dose-Rate. Radiother. Oncol. 2016, 119, S690. [Google Scholar] [CrossRef] [Green Version]

- Vlachoudis, V. Flair: A Powerful but User Friendly Graphical Interface for FLUKA. In Proceedings of the Conference on Mathematics, Computational Methods & Reactor Physics (M&C 2009), Saratoga Springs, NY, USA, 3–7 May 2009. [Google Scholar]

- Maia Oliveira, A.; Braccini, S.; Casolaro, P.; Heracleous, N.; Leidner, J.; Mateu, I.; Murtas, F.; Silari, M. Radiation-Induced Effects in Glass Windows for Optical Readout GEM-Based Detectors. arXiv 2021, arXiv:2106.04645. Available online: https://arxiv.org/abs/2106.04645 (accessed on 9 June 2021).

| FWHM (mm) | |||

|---|---|---|---|

| Ø Hole | Hole 1 | Hole 2 | Hole 3 |

| 6 mm | 6.60 ± 0.10 | - | - |

| 3 mm | 3.08 ± 0.06 | 3.04 ± 0.09 | 3.46 ± 0.09 |

| 1.3 mm | 2.07 ± 0.05 | 1.49 ± 0.03 | 1.85 ± 0.03 |

| FWHM (mm) | |||

|---|---|---|---|

| Ø Hole | Hole 1 | Hole 2 | Hole 3 |

| 6 mm | 5.70 ± 0.20 | 5.45 ± 0.11 | 5.26 ± 0.12 |

| 6 mm | 5.82 ± 0.13 | - | - |

| 3 mm | 2.96 ± 0.17 | 2.99 ± 0.24 | 2.82 ± 0.16 |

| 1.3 mm | 1.32 ± 0.12 | 1.61 ± 0.16 | 1.48 ± 0.17 |

| Spatial Resolution (mm) | |||

|---|---|---|---|

| Detector | Edge Response | 5 mm Cu Hole | Minimum Resolvable Hole Spacing |

| LaGEMPix | 9.70 ± 0.09 | 6.73 ± 0.08 | 3 mm (edge to edge) |

| GEMPix | 5.20 ± 0.10 | 5.23 ± 0.05 | 1 mm 1 (edge to edge) |

| GAFCHROMIC® | 0.86 ± 0.07 | 5.09 ± 0.03 | 1 mm 1 (edge to edge) |

| FLUKA simulation of LaGEMPix | 4.53 ± 0.01 | 4.87 ± 0.03 | 1 mm 1 (edge to edge) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maia Oliveira, A.; Akkerman, H.B.; Braccini, S.; van Breemen, A.J.J.M.; Gallego Manzano, L.; Heracleous, N.; Katsouras, I.; Leidner, J.; Murtas, F.; Peeters, B.; et al. Characterization with X-rays of a Large-Area GEMPix Detector with Optical Readout for QA in Hadron Therapy. Appl. Sci. 2021, 11, 6459. https://doi.org/10.3390/app11146459

Maia Oliveira A, Akkerman HB, Braccini S, van Breemen AJJM, Gallego Manzano L, Heracleous N, Katsouras I, Leidner J, Murtas F, Peeters B, et al. Characterization with X-rays of a Large-Area GEMPix Detector with Optical Readout for QA in Hadron Therapy. Applied Sciences. 2021; 11(14):6459. https://doi.org/10.3390/app11146459

Chicago/Turabian StyleMaia Oliveira, Andreia, Hylke B. Akkerman, Saverio Braccini, Albert J. J. M. van Breemen, Lucia Gallego Manzano, Natalie Heracleous, Ilias Katsouras, Johannes Leidner, Fabrizio Murtas, Bart Peeters, and et al. 2021. "Characterization with X-rays of a Large-Area GEMPix Detector with Optical Readout for QA in Hadron Therapy" Applied Sciences 11, no. 14: 6459. https://doi.org/10.3390/app11146459

APA StyleMaia Oliveira, A., Akkerman, H. B., Braccini, S., van Breemen, A. J. J. M., Gallego Manzano, L., Heracleous, N., Katsouras, I., Leidner, J., Murtas, F., Peeters, B., & Silari, M. (2021). Characterization with X-rays of a Large-Area GEMPix Detector with Optical Readout for QA in Hadron Therapy. Applied Sciences, 11(14), 6459. https://doi.org/10.3390/app11146459