Abstract

Additive manufacturing is becoming an increasingly important technique for the production of dental restorations and assistive devices. The most commonly used systems are based on vat polymerization, e.g., stereolithography (SLA) and digital light processing (DLP). In contrast, fused filament fabrication (FFF), also known under the brand name fused deposition modeling (FDM), is rarely applied in the dental field. This might be due to the reduced accuracy and resolution of FFF compared to vat polymerization. However, the use of FFF in the dental sector seems very promising for in-house production since it presents a cost-effective and straight forward method. The manufacturing of nearly ready-to-use parts with only minimal post-processing can be considered highly advantageous. Therefore, the objective was to implement FFF in a digital dental workflow. The present report demonstrates the production of surgical guides for implant insertion by FFF. Furthermore, a novel approach using a temperature-sensitive filament for bite registration plates holds great promise for a simplified workflow. In combination with a medical-grade filament, a multi-material impression tray was printed for optimized impression taking of edentulous patients. Compared to the conventional way, the printed thermoplastic material is pleasant to model and can allow clean and fast work on the patient.

1. Introduction

The development of computer-aided design and manufacturing (CAD-CAM) has facilitated manufacturing in dental laboratories. In combination with subtractive manufacturing (“milling/grinding”), reliable results and increased productivity can be achieved [1]. However, subtractive manufacturing has the disadvantage of high material loss and equipment wear. In addition, the manufactured parts can exhibit stress-related defects [2]. In contrast, with additive manufacturing (AM), components can be manufactured by adding material. This technology, also known as tool-less manufacturing technology, shows minimal wear and provides a greater degree of utilization of the feedstock material.

In AM, the virtual objects are digitally cut into layers prior to the manufacturing process. Subsequently, the virtual object is transformed into a solid component by depositing material layer by layer [3].

Currently, additive processes based on vat-polymerization, in particular stereolithography (SLA) and digital light processing (DLP) systems, are mainly used in dentistry [4,5]. These processes are based on the local light polymerization of a photosensitive resin. While the SLA process works with a laser for polymerization [6], DLP systems operate with a projector, which allows an entire layer to be exposed at the same time. This makes production time independent of the surface area covered by the object(s) and enables time-efficient production. After printing, both processes require washing of the object to remove the resin adhering to the surface. To obtain the final material properties, further post-processing by additional light-curing is necessary, which leads to the final crosslinking of the polymers [7,8]. However, post-processing equipment, consumables, such as isopropanol for the cleaning step, and requirements for occupational safety increase the costs. The use of photosensitive resin as feedstock material also requires special precautions and trained personnel to ensure adequate printing results. Especially in the case of medical products, regulations must be strictly followed during the entire manufacturing process. Therefore, a cost-efficient process with a straight-forward workflow that offers facile handling of materials and little post-processing appears promising. Thereby regulatory compliance is alleviated and the barrier to entry for the user is lowered.

Fused filament fabrication (FFF), which is also known by its trademark fused deposition modeling (FDM), represents a simplistic and low-cost method of additive manufacturing (AM). Invented in 1989 [9], the FFF process has experienced strong growth since the original patents began to expire from 2009 onwards. Today, both industrial customers and private users are stimulating the market. New FFF printers are available for a low budget, and the choice of materials is steadily increasing.

In the FFF process, a thermoplastic filament is fed to a heated nozzle. This is where the material is melted, and as the nozzle moves layer by layer in the x and y directions along the geometry, the material is deposited [10]. Apart from possible support structures for steep projections, which have to be removed, no post-processing is required and the parts can be used immediately. The simplicity makes the process very attractive, as evidenced by its widespread use.

However, FFF suffers from limited mechanical properties in build direction due to incomplete fusion of deposited strands and higher surface roughness [11]. Until now, SLA/DLP has been mainly used in dentistry, due to its superior accuracy and mechanical properties compared to FFF. Nevertheless, non-load-bearing medical devices and assistive devices with reduced accuracy requirements present a huge potential for FFF in dentistry.

2. Applied FFF Materials in Dentistry

FFF has a huge variety of available feedstock materials. Standard materials are filaments made of semi-crystalline thermoplastics such as the most commonly used polylactic acid (PLA) and the second group of amorphous polymers like (1) acrylonitrile-butadiene-styrene copolymers (ABS), (2) polycarbonates (PC), (3) polyethylene terephthalate glycol (PETG), and (4) water-soluble materials for support structures like polyvinyl alcohol (PVA) [12].

For medical use, filaments are available that are certified for short-term contact with skin and body fluids, such as polyphenylsulfone (PPSU) [13]. Surgical guides for oral implant insertion and bone-like models are made of a biocompatible filament made from a compound of polyamide-polyolefin and cellulose (PAPC) [14]. In addition, the manufacturing of polyetherketons like PEEK [15] with FFF printers for use in craniomaxillofacial implants is being evaluated [16,17,18]. Other filaments are certified as medical device class 1, which are products for the temporary use in the body and a low degree of invasiveness, like PETG [19], Polycaprocalactone (PCL), and poly(lactic-co-glycolic acid) (PLGA) filaments [20].

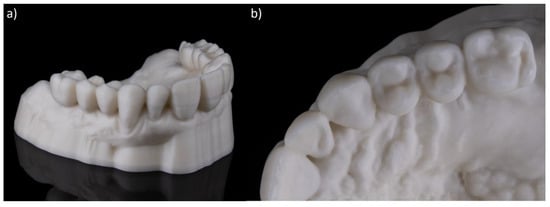

Currently, the most common application of FFF in dentistry is the production of dental models based on intraoral scans (Figure 1). Although models made by FFF are considered to have lower precision and trueness compared to SLA and DLP systems, they meet the requirement for many dental sectors [21,22]. For example, orthodontic models require a lower accuracy than models made for the manufacturing of prosthetic restorations. Low material and equipment costs and nearly ready-to-use models without post-processing make FFF economically attractive. The model shown in Figure 1 was manufactured by using a lignin-based filament (Greentec Pro, Extrudr FD3D GmbH, Lauterach, Austria) with a material cost of approximately 1 €. The printing time was comparable to SLA systems, but with no need for post-processing procedures and reduced material costs up to 80%. Additionally, other materials such as gypsum-containing filaments [23,24] can be used to produce dental models, which can also be used for thermoforming of splints.

Figure 1.

(a) Dental model of the upper jaw manufactured by fused filament fabrication (FFF), (b) Detailed view of highly accurate tooth structures.

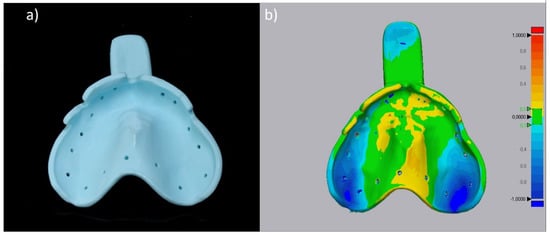

Another innovative application using FFF presents the manufacturing of customized impression trays [25,26] (Figure 2a). The utilized filament (Trayfill, Berhnardt Kunstoffverarbeitungs GmbH, Berlin, Germany) is a certified medical device class 1 and withstands autoclavation [27]. This tray was printed with material costs of about 1.70 € and was therefore highly cost-effective. In order to verify the fulfillment of the required accuracy, a comparison of the STL file and the printed part was performed. Therefore, the impression tray was digitized (Keyence VL 500, Keyence, Osaka Japan) and a best-fit analysis (Geomagic Control X, 3D Systems, Inc., Rock Hill, AC, USA) was conducted (Figure 2b.) The obtained results revealed negative deviations of approximately 0.9 mm in the areas of the tuber maxillae and positive deviations of 0.2 mm in the palatal area.

Figure 2.

(a) Customized impression tray fabricated by means of FFF (Filament: Trayfill), (b) Heatmap indicating the deviation between STL file and tray.

3. Novel Approaches of FFF in Dentistry

3.1. Thermoplastic Filament for Bite Registration

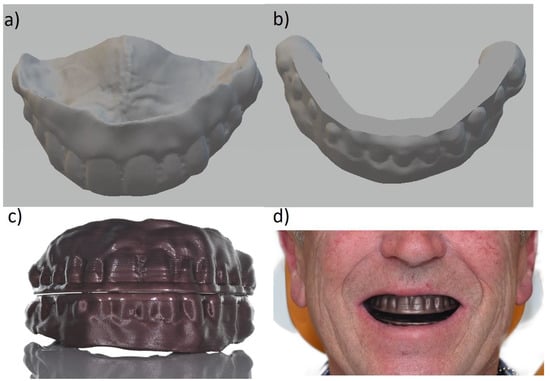

Using FFF in combination with a temperature-sensitive material, a novel approach for bite registration seems to be beneficial for both the patient and the dentist. In the conventional workflow, a bite registration is performed using base plates made of light-curing acrylic and attached wax walls. The wax bite blocks are adjusted on the patient according to functional and esthetic aspects in order to convey the relation of the jaws to the dental technician. Today, based on an intraoral scan, the base plates can be digitally designed and additively manufactured using FFF in a simple and cost-effective manner. The use of a temperature-sensitive filament (Thibra3D Skulpt, Formfutura, Nijmegen, The Netherlands) allows adjustments to be made to the printed material instead of wax bite blocks. For this purpose, the printed material is heated in a hot water bath, with an alcohol burner or a hot air gun. The printed filament has a low working temperature of 70 °C, which is ideal for modeling. It can be processed unlimitedly after 3D printing and also enables the further application of the thermoplastic material. The filament is not yet classified as a medical device but ongoing cytotoxicity tests reveal promising results. The presented feasibility test (Figure 3) aimed to demonstrate the use of a temperature-sensitive filament in the dental workflow. Compared to the conventional adjustment of wax, this material is pleasant to model and holds great promise for clean and fast work on the patient.

Figure 3.

(a) STL model of the upper jaw with a flat contact surface, (b) STL model of the lower jaw with a flat contact surface, (c) bite plates manufactured by FFF (d) fitting of the bite plates.

To further reduce treatment time on the patient, the jaw relation of existing prostheses can be implemented in the digital workflow. In the presented case (Figure 3), the intraoral implant scans (TRIOS 4, 3Shape, Copenhagen, Denmark) of the upper and lower jaw were the basis for the design of the registration plates. By utilizing the existing screw-retained antagonistic prosthesis, a buccal scan was taken to obtain a preliminary bite registration. An automated tooth set-up (Zirkonzahn, Gais, Italy) was integrated into the CAD of the base plates, which allowed the first visualization of a potential tooth set-up. In addition, a “Plane Cut” was inserted in the occlusal plane in the Meshmixer software (Autodesk, Mill Valley, CA, USA) so that the upper and lower jaw had a flat contact surface as known from the conventional procedure (Figure 3a,b). The final designed base plates were subsequently 3D printed with the Prusa i3 (Prusa, Prague, Czech Republic) at a printing temperature of 205 °C using the previously described temperature-sensitive filament (1.75 mm). Only minimal post-processing was needed to obtain the final bite plates.

On the patient, the bite planes were inspected and slightly adjusted after heating in a water bath (Figure 3c,d). Finally, the bite plates were attached to each other by heating the occlusal surface with a hot instrument, after which the guides were removed from the mouth as a pair.

3.2. Dual Material Customized Impression Trays

Another use case for FFF in dentistry is the additive manufacturing of customized impression trays. While digital impressions present sufficient accuracy for fixed dental prostheses [28,29], the acquisition of moving areas e.g., the alveolar mucosa in the vestibule, is still associated with limitations. These areas are especially important for the retention of prostheses for edentulous patients. In a conventional workflow, impression taking is split into two steps. Before using the main impression material e.g., a thermoplastic compound material is manually applied to the rim of an individualized impression tray and intraorally adjusted by both the patient and the dentist to seal the moving soft tissue. This enables precise capture of these areas during the final impression taking. The aim of our novel approach was to incorporate a temperature sensitive rim into the tray design of the printed individual impression tray.

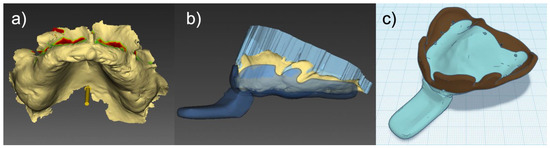

Based on an intraoral scan, an individual impression tray (Figure 4) was designed using CAD software (inLab, Dentsply Sirona, Charlotte, NC, USA). This was achieved by setting an insertion direction, blocking out undercuts, defining the length of the tray rim, and digitally positioning the tray handle.

Figure 4.

Design of a dual-material customized impression tray. (a) intraoral scan with undercuts shown in red, (b) finished one-piece custom tray design, (c) thermoplastic compound material (brown), and rigid (cyan) parts separated into two STL files.

Subsequently, using additional software (Tinkercad, Autodesk, San Rafael, CA, USA), the resulting STL was split into two parts. Hereby, the cut was drawn along the occlusal plane, separating around 1.5 cm of the part touching the vestibulum from the central tray-body. Using a multi-material printer equipped with an independent dual extrusion (IDEX) system (Sigmax R19, BCN3D, Barcelona, Spain) allowed for combining two materials with different properties into one print. This creates the possibility of using a rigid material for the tray body, whereas the part which comes in contact with the mobile mucosa was printed using a temperature-sensitive material (Figure 5).

Figure 5.

Dual material customized impression tray. The rigid body was manufactured with a polyethylene terephthalate glycol (PETG) filament (Trayfill), the rim was printed with a thermoplastic filament.

Compared to the conventional approach, our dual material design with an integrated functional margin allows for a clean and fast workflow, a reduced treatment time, and, thus, increased patient comfort. However, until there are software enhancements that fully automatize the dual-material custom design process, this production workflow must be considered time-consuming and therefore may not yet be cost-effective.

3.3. Surgical Guides

The manufacturing of surgical guides with FFF can offer a simple and cost-effective workflow. Inexpensive, biodegradable, and steam-sterilizable filaments [30] are an interesting choice of materials. In a former evaluation of the manufacturing procedure of surgical guides, difficulties regarding precision and the fitting of FFF printed surgical guides on a cast model were observed [31]. In contrast, other studies showed no difference when compared with surgical guides produced by means of DLP [32]. Besides accuracy, other factors resulted in a deviation between the planned and realized implant positions of >1 mm [33,34].

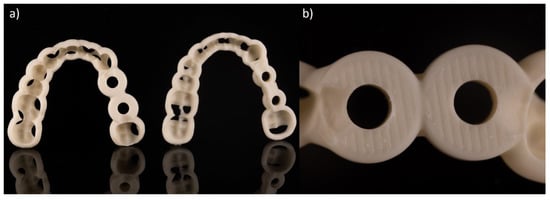

A workflow has been established in which surgical guides are planned digitally and manufactured using FFF. Two different design softwares were used (CoDiagnostix, Dental Wings GmbH, Chemnitz, Germany; ImplantStudio, 3Shape, Copenhagen, Denmark). In both cases, the exported STL file was transferred to the slicer software (PrusaSlicer, Prusa, Prague, Czech Republic) and printed without further modification (Figure 6a). A Prusa mini+ printer (Prusa, Prague, Czech Republic) with a biodegradable filament (Greentec Pro, Extrudr FD3D GmbH, Lauterach, Austria) was used for additive manufacturing. Although medical approval for this filament has yet to be obtained, pending cytotoxicity tests show promising initial results. The detailed view of the guiding structure of the coDiagnostic surgical guide (Figure 6b) reveals a smooth and precise surface, nevertheless, the individual layers of the FFF manufacturing process are visible.

Figure 6.

(a) Two FFF printed implant templates planed with coDiagnostix (l.) and ImplantStudio (r.). In both cases, the exported STL file was transferred to the slicer software and printed without further modification. (b) Close-up of the coDiagnostix surgical guide showing the guiding structure. The individual layers of the filament print become visible.

The accuracy of surgical guides manufactured with FFF is a discussed topic since FFF is considered less precise than SLA/DLP. The in vitro accuracy of placed implants in relation to their virtual position with guides printed with FFF has already been investigated. Implants inserted using FFF printed guides showed equivalent deviations to those inserted using SLA guides and were within clinical tolerances of <1 mm [30]. It was shown that printed drill sleeves integrated into the surgical guide do not cause more deviation in the implant position, compared to traditional metal sleeves. This can be a major advantage in clinical applications, especially considering the potentially good biocompatibility of the biodegradable filaments.

Great potential lies in the simplicity of handling and accessibility of the manufacturing process. The easy operability of the CAM software allows even first-time users to achieve useable objects. The surgical guides and the support structure are removable without tools. Without further post-processing, the guides can be steam-sterilized and directly used. Furthermore, this production route offers cost-effective manufacturing of surgical guides using FFF with printers available at competitive prices, software available free of charge, and a material cost of 50 cents per surgical guide. If a sleeveless design is adopted, further cost savings can be achieved. Further research on the design and optimization of surgical guides, as well as studies on the clinical application, are required. The influence of metal debris of the sleeves compromising the implant bed in conventional surgical guides compared to filament residues in sleeveless applications needs to be investigated.

4. Conclusions and Future Perspectives

Non-load bearing applications are a potential field of use for FFF in dentistry. Models, trays, and prototypes for denture try-ins can be manufactured with FFF. Materials which are certified are commercially accessible or under investigation. Multi-material printers are available which allow the easy testing of innovative concepts for the use of FFF in dentistry. The inexpensive initial cost of the printer and the price of materials allow FFF to be competitive. The possibility of open printers that allow the use of third-party materials seems to be a huge benefit. In most cases, the productivity of FFF printers is inferior compared to DLP systems. However, high productivity and high quantity do not always consider the needs of smaller medical clinics where printer capacity cannot always be fully utilized.

Author Contributions

Conceptualization, J.L.; F.B.; J.N. and B.C.S.; methodology, J.L.; F.B.; B.C.S.; formal analysis, J.L.; G.W.; investigation, J.L.; F.B.; J.N.; S.R.; resources, S.W.; data curation, S.W.; C.W.; S.P.; writing—original draft preparation, J.L.; F.B. and J.N.; writing—review and editing, J.L.; F.B.; J.N. and B.C.S.; visualization, G.W. and S.R.; supervision, B.C.S. All authors have read and agreed to the published version of the manuscript.

Funding

The article processing charge was funded by the Baden-Wuerttemberg Ministry of Science, Research and Art and the University of Freiburg in the funding programme Open Access Publishing.

Informed Consent Statement

Written informed consent has been obtained from the patient(s) to publish this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Goodacre, B.J.; Goodacre, C.J.; Baba, N.Z.; Kattadiyil, M.T. Comparison of denture base adaptation between CAD-CAM and conventional fabrication techniques. J. Prosthet. Dent. 2016, 116, 249–256. [Google Scholar] [CrossRef] [PubMed]

- Romanyk, D.L.; Martinez, Y.T.; Veldhuis, S.; Rae, N.; Guo, Y.; Sirovica, S.; Fleming, G.J.P.; Addison, O. Strength-limiting damage in lithium silicate glass-ceramics associated with CAD–CAM. Dent. Mater. 2019, 35, 98–104. [Google Scholar] [CrossRef] [PubMed]

- ASTM. ISO/ASTM 52900. In Additive Manufacturing—General Principles—Terminology; Beuth: Berlin, Germany, 2018; p. 73. [Google Scholar]

- Revilla-León, M.; Özcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schweiger, J.; Edelhoff, D.; Güth, J.-F. 3D Printing in Digital Prosthetic Dentistry: An Overview of Recent Developments in Additive Manufacturing. J. Clin. Med. 2021, 10, 2010. [Google Scholar] [CrossRef] [PubMed]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 4,575,330, 8 August 1984. [Google Scholar]

- Zguris, Z. How Mechanical Properties of Stereolithography 3D Prints are affected by UV Curing, Formlabs White Paper. Available online: https://3d.formlabs.com/mechanical-properties-of-uv-cured-3d-prints/ (accessed on 26 May 2021).

- Formlabs. White Paper 3d Printing Custom Trays. Available online: https://3d.formlabs.com/white-paper-de-3d-printing-custom-trays/ (accessed on 31 May 2021).

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent 5,121,329, 5 September 1989. [Google Scholar]

- Comb, J.; Priedman, W.; Turley, P.W. FDM Technology Process Improvements. In Proceedings of the 1994 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 1994. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stratasys. Thermoplastic: The Strongest Choise for 3D Printing, FDM Thermoplastic 3d Printing White Paper. Available online: https://www.stratasys.com/explore/whitepaper/thermoplastics (accessed on 26 May 2021).

- Solvay. Radel® PPSU HC AM Filament NT1. Available online: https://www.solvayamshop.com/ccrz__ProductDetails?viewState=DetailView&cartID=&sku=Z58-40004&portalUser=&store=&cclcl=en_US (accessed on 26 May 2021).

- FibreTuff. Fibre Tuff II Data Sheet. Available online: https://img1.wsimg.com/blobby/go/4fc374e5-752e-4d9c-9806-458efb923e97/downloads/FibreTuff%20II%20Data%20Sheet.pdf?ver=1621429055001 (accessed on 26 May 2021).

- Solvay. KetaSpire® PEEK HC FILAMENT CF10 LS1. Available online: https://www.solvayamshop.com/ccrz__ProductDetails?viewState=DetailView&cartID=&sku=Z58-40002&portalUser=&store=&cclcl=en_US (accessed on 26 May 2021).

- Honigmann, P.; Sharma, N.; Okolo, B.; Popp, U.; Msallem, B.; Thieringer, F.M. Patient-Specific Surgical Implants Made of 3D Printed PEEK: Material, Technology, and Scope of Surgical Application. BioMed Res. Int. 2018, 2018, 4520636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, N.; Honigmann, P.; Cao, S.; Thieringer, F. Dimensional characteristics of FDM 3D printed PEEK implant for craniofacial reconstructions. Trans. Addit. Manuf. Meets Med. 2020, 2. [Google Scholar] [CrossRef]

- Han, X.; Sharma, N.; Xu, Z.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Thieringer, F.M.; Spintzyk, S. An In Vitro Study of Osteoblast Response on Fused-Filament Fabrication 3D Printed PEEK for Dental and Cranio-Maxillofacial Implants. J. Clin. Med. 2019, 8, 771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- JohannesWeithasGmbH. Arfona Impression Tray Filament. Available online: https://www.weithas.de/de/prothetik/3d_druck_dental/fdm_3d-druck_loeffel_dental_filament (accessed on 26 May 2021).

- AdvancedBiomedicalTechnology. MeDFila® 3D Printing Filament. Available online: https://advbiomedtech.com/medfila/ (accessed on 26 May 2021).

- Kim, S.-Y.; Shin, Y.-S.; Jung, H.-D.; Hwang, C.-J.; Baik, H.-S.; Cha, J.-Y. Precision and trueness of dental models manufactured with different 3-dimensional printing techniques. Am. J. Orthod. Dentofac. Orthop. 2018, 153, 144–153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Etemad-Shahidi, Y.; Qallandar, O.B.; Evenden, J.; Alifui-Segbaya, F.; Ahmed, K.E. Accuracy of 3-Dimensionally Printed Full-Arch Dental Models: A Systematic Review. J. Clin. Med. 2020, 9, 3357. [Google Scholar] [CrossRef] [PubMed]

- 3dk.berlin. Filadental Gips Weiß. Available online: https://3dk.berlin/de/filadental/502-filadental-gips-weiss-4251163216986.html (accessed on 31 May 2021).

- JohannesWeithasGmbH. Weiton-3D Gips Bio-Filament. Available online: https://www.weithas.de/de/prothetik/3d_druck_dental/dentalgips_bio_filament (accessed on 31 May 2021).

- Chen, H.; Yang, X.; Chen, L.; Wang, Y.; Sun, Y. Application of FDM three-dimensional printing technology in the digital manufacture of custom edentulous mandible trays. Sci. Rep. 2016, 6, 19207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Y.; Chen, H.; Li, H.; Deng, K.; Zhao, T.; Wang, Y.; Zhou, Y. Clinical evaluation of final impressions from three-dimensional printed custom trays. Sci. Rep. 2017, 7, 14958. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IGO3D. Dental 3D Agency Trayfill Filament. Available online: https://www.igo3d.com/dental-3d-agency-trayfill-filament (accessed on 31 May 2021).

- Arcuri, L.; Lorenzi, C.; Vanni, A.; Bianchi, N.; Dolci, A.; Arcuri, C. Comparison of the accuracy of intraoral scanning and conventional impression techniques on implants: A review. J. Biol. Regul. Homeost. Agents 2020, 34, 89–97. [Google Scholar] [PubMed]

- Ender, A.; Zimmermann, M.; Mehl, A. Accuracy of complete- and partial-arch impressions of actual intraoral scanning systems in vitro. Int. J. Comput. Dent. 2019, 22, 11–19. [Google Scholar] [PubMed]

- Pieralli, S.; Spies, B.C.; Hromadnik, V.; Nicic, R.; Beuer, F.; Wesemann, C. How Accurate Is Oral Implant Installation Using Surgical Guides Printed from a Degradable and Steam-Sterilized Biopolymer? J. Clin. Med. 2020, 9, 2322. [Google Scholar] [CrossRef] [PubMed]

- Sommacal, B.; Savic, M.; Filippi, A.; Kühl, S.; Thieringer, F.M. Evaluation of Two 3D Printers for Guided Implant Surgery. Int. J. Oral Maxillofac. Implants 2018, 33, 743–746. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Y.; Ding, Q.; Tang, L.; Zhang, L.; Sun, Y.; Xie, Q. Accuracy of a chairside fused deposition modeling 3D-printed single-tooth surgical template for implant placement: An in vitro comparison with a light cured template. J. Cranio-Maxillofac. Surg. 2019, 47, 1216–1221. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Liu, Z.; Song, L.; Kuo, C.-l.; Shafer, D.M. Clinical Factors Affecting the Accuracy of Guided Implant Surgery—A Systematic Review and Meta-analysis. J. Evid. Based Dent. Pract. 2018, 18, 28–40. [Google Scholar] [CrossRef] [PubMed]

- Bover-Ramos, F.; Viña-Almunia, J.; Cervera-Ballester, J.; Peñarrocha-Diago, M.; García-Mira, B. Accuracy of Implant Placement with Computer-Guided Surgery: A Systematic Review and Meta-Analysis Comparing Cadaver, Clinical, and In Vitro Studies. Int. J. Oral Maxillofac. Implants 2018, 33, 101–115. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).