Abstract

Laminated ceramics with weak interface layers have been proven to be effective in toughening ceramics. The energy absorption ability of laminated ceramics may also benefit their ballistic performance. However, the effect of the layer structure on the ballistic performance of laminated ceramics has not been studied. Focusing on the application for body armor, this paper studied the effect of the different layer structures on the ballistic performance of laminated SiC ceramics. The laminated SiC ceramics with different layered structures were designed and prepared by tape-casting and hot-pressing. When used for the ‘in conjunction with’ armor system, the laminated SiC ceramics with a gradual-layered structure had the backface signature depth of 30% less than the laminated SiC with no interface structure and 50% less than the commercial solid-state sintered SiC. However, when used stand-alone, the laminated SiC had a similar ballistic performance regardless of the layer structure, which was likely due to the weak back support. In conclusion, the ballistic performance of the laminated ceramics was related to the back support of the armor system. When used for the ‘in conjunction with’ armor system, the laminated SiC had a better ballistic performance than that of the solid-state sintered SiC.

1. Introduction

With the development of military technology, armor protection for personnel is being increasingly emphasized. Body armor needs to resist the penetration of the bullet as well as absorb the energy of the bullet, preventing lethal damage to the personnel. Additionally, to effectively protect the person from auto weapons, multi-hit resistance is also required. Ceramics, compared to metals, have superior hardness, good strength, and low density, making them an attractive armor material. The ceramic armor plate has become an essential part of personal armor to protect from rifles or higher-level thread [1]. However, ceramics are brittle in nature with low toughness and are sensitive to defects [2]. Defects in the ceramics can facilitate crack propagation and effectively reduce the ballistic performance of the ceramics [3].

The defects are often introduced to the ceramic green body during fabrication and are not eliminated during sintering. The ceramics prepared by colloid processing have fewer defects in the final products compared to the ceramics made by the conventional dry-pressing route [4]. Laminated ceramics, which are prepared by stacking ceramic green tapes and sintering, allow for fabrication from colloid processing [5,6] and would be advantageous over conventional dry-pressed ceramics in armor application.

The introduction of the weak interface layer to the laminated ceramics has also been proven to be effective in toughening the ceramics and thus enhancing the energy absorption of the ceramics. The toughening mechanism of the laminated ceramics was proposed by Cook [7] in 1964 in that crack deflection would occur by introducing the weak interface in the composite. In 1990, Clegg [8] first prepared the SiC/C laminated composite using this strategy and reported that the material had several times higher toughness and 100 times higher work of fracture than that of the bulk SiC. Since then, many studies have been carried out on laminated ceramics to develop high toughness in ceramics. The layer-by-layer stacking method provided laminated ceramics many design variables, such as the layer composition, layer thickness, stacking sequence for layers with different compositions, etc. The effects of these designing factors were extensively studied to optimize mechanical performance. The strength of the matrix layer was found to be important to the final mechanical properties of the laminated ceramics [9]. Toughening the matrix layer of the laminated ceramics would provide more percentage of improvement to the overall toughness than toughening the monolithic ceramics [10]. An optimal range of the bonding strength of the interface layer also exists in which the toughness of the laminated ceramics reaches the maximum [6,10].

However, it is still in doubt whether the toughening mechanism of the layered ceramics for static mechanical loading is effective for the ballistic impact. The ballistic impact is a complex dynamic event that is very different from static mechanical loading [11]. Due to the difficulty in theoretical study and analysis, no conclusion has been drawn until now. The study for the ballistic performance of laminated ceramics has been very limited. The only study, carried out by Li et al. [12], reported that the laminated Si3N4/BN would remain a whole piece after ballistic impact, while the monolithic Si3N4 broke into pieces, but the penetration resistance of the laminated ceramics was decreased. Introducing the weak interface layer only at the backside of the ceramic plate would mitigate the penetration resistance decrease. The laminating structure is an important factor in the performance of laminated ceramics. Previous studies in the AlN/polymer laminated composite found that the composite would have a depth of penetration (DOP) greater or less than the monolithic AlN, depending on the layer structure [13,14]. However, such an effect on ballistic performance has not been studied for laminated ceramics.

This study aimed at the application of laminated ceramics as a body armor material. Based on this purpose, the effect of structure on the ballistic performance of laminated ceramics was studied. It was found that the laminated SiC with interface layers could provide good energy absorption ability under the ballistic impact when used in conjunction with a flexible armor jacket. The laminated SiC ceramics with differently layered structures were prepared by tape-casting and hot-pressing. The effects of layer structure on mechanical performance and ballistic performance were discussed. The results showed that when used for the ‘in conjunction with’ armor system, the laminated SiC ceramics with a gradual-layered structure had the backface signature depth of 30% less than the laminated SiC with no interface structure and 50% less than the commercially available solid-state sintered SiC.

2. Materials and Methods

The laminated ceramics were prepared by tape-casting followed by hot-press sintering. The ceramic slurry was prepared by ball-milling α-SiC (average particle size of 0.5 μm, North High-tech Industry Co., Ltd., Ningxia, China), Y2O3 (purity > 99%, average particle size of 1 μm, Shanghai Shuitian technology Co., Ltd., Shanghai, China), Al2O3 (purity > 99.8%, average particle size of 1 μm, Shanghai Shuitian technology Co., Ltd., Shanghai, China), BN (purity > 99.9%, average particle size of 0.2 μm, Shanghai Shuitian technology Co., Ltd., Shanghai, China), triethylphosphate, and ethanol for 24 h. The polyvinyl butyral, dioctyl phthalate, and glycerol were then added to the slurry and ball-milled for another 24 h. After de-gassing for 30 min, the slurry was tape-casted to tapes with the desired thickness.

Two types of ceramic green tapes, the matrix tapes and the interface tapes were prepared for the lamination. The matrix tape consisted of a 92 wt.% α-SiC and 8 wt.% Al2O3/Y2O3 mixture (the molar ratio of Al2O3 to Y2O3 was 3:2) of total ceramic powder. The interface tape consisted of a 46 wt.% α-SiC, 46 wt.% h-BN and 8 wt.% Al2O3/Y2O3 mixture of total ceramic powder. The thickness of the matrix tape and interface tape was approximately 0.25 mm and 0.05 mm, respectively.

The green tapes were then cut into 130 × 130 pieces and stacked as designed. The uniform-layered sample had a uniformly layered structure. In each repeating unit, the number of the matrix layer to the number of the interface layer was 10 to 1. The gradual-layered sample was designed as a gradually layered structure, i.e., the number of the matrix layer between two interface layers was gradually changed. The number of the matrix layers using the following sequence from strike face to the back: 10, 10, 5, 2, and 2. The layer structure for different sample types is listed in Table 1.

Table 1.

The layer structure for different sample types.

The ceramic green bodies were then prepared by pressing the stacked tapes under the pressure of 80 MPa. Before sintering, the green bodies were de-binded at 850 °C for 4 h in nitrogen. The de-binded samples were then sintered at temperature ranging from 1840 °C to 1900 °C for 1 h under the pressure of 40 MPa in argon. After firing, the sintered ceramic plates were cut and polished into the dimension of 120 × 120 × 5.5 mm, as shown in Figure 1.

Figure 1.

The image of the 120 × 120 × 5.5 mm laminated ceramic prepared in this study (gradual layered).

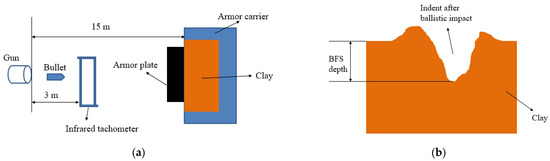

The ballistic performance was carried out following the Chinese national military standard, GJB4300-2002. The 5.8 mm × 42 mm type-87 steel core bullet was used in this study. The bullet had a full metal jacket and the mass of the bullet was 4.15 g. The velocity of the bullet was measured using an infrared tachometer. The infrared tachometer had two consecutive screens so that it could record the time for the bullet that passed through it and to calculate the velocity of the bullet. The gunpowder for the bullet was adjusted based on the velocity measured several times to guarantee that the velocity of the bullet was within the range of 900 to 920 m/s. The armor or armor system was mounted on the armor carrier. The armor carrier was filled with clay as the backface signature (BFS). The configuration for the ballistic testing is shown in Figure 2a. The BFS depths were measured for the shot that was partially penetrated. After ballistic impact, irregular bulges form around the indent. To avoid the interference of the bulge, the depth was counted from the original flat clay plane to the maximum depth of the indent after ballistic impact, as illustrated in Figure 2b. Two conditions were performed in this study. In one condition, the armor plate was tested in conjunction with a flexible armor jacket, named the CA test. In this test, the armor plate was inserted into the flexible armor jacket as a removable unit to enhance the ballistic performance of the armor system. The armor plate took one shot due to the limited space of the plate. In the other condition, the armor plate was tested stand-alone and the armor plates took three shots. This condition was named the SA test.

Figure 2.

The illustration of ballistic testing: (a) the configuration; (b) the measurement for the BFS depth.

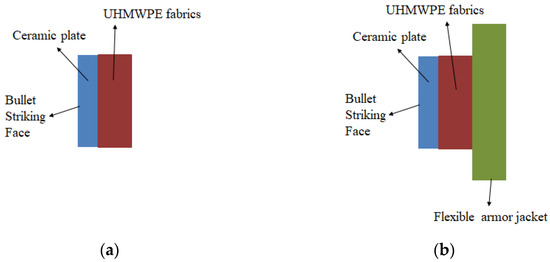

The armor plate was prepared in Zhejiang Light-Tough Composite Co., Ltd. For both the CA and SA tests, the ceramic plate was first bonded with ultra-high-molecular polyethylene (UHMWPE) fabrics layer by layer. The overall areal density of the UHMWPE fabrics was 7.3 kg/m2. The armor plate for the CA test used one piece of the ceramic plate and the dimension was 120 × 120 × 5.5 mm. The armor plate for the CA test was then attached to a flexible armor jacket made by UHMWPE fabrics with an areal density of 5.77 kg/m2 (FDF-15, Zhejiang Light-Tough Composite Co., Ltd., Huzhou, China). The armor plate for the SA test used four pieces of the ceramic plate to provide a dimension of 240 × 240 × 5.5 mm. The commercially available solid-state sintered SiC ceramic plate (SSIC plate, Ningbo FLK Co., Ltd., Ningbo, China) was also used to prepare an armor plate as a reference. Figure 3 illustrates how the armor or armor system was prepared for the CA and SA tests.

Figure 3.

The illustration of the armor or armor system prepared for (a) the CA test (b) the SA test.

The strength of the samples was measured using the three-point bending test. The specimens were cut into 3 × 4 × 35 mm in size. The fracture toughness of the samples was measured using the single-edge notched beam (SENB) method. The Vickers hardness was tested using a microhardness machine with a load of 1 kg. The surface and cross-section of the samples were studied using scanning electron microscopy (SEM).

3. Results and Discussion

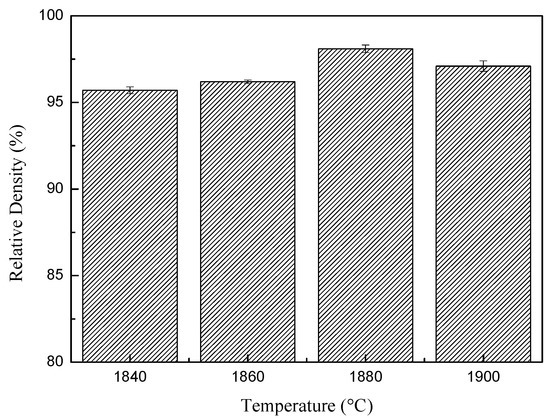

To optimize the sintering temperature of the laminated ceramics, pure-matrix samples were sintered at different sintering temperatures. The relative density of the pure-matrix ceramic at different sintering temperatures is shown in Figure 4. The relative density increased from 95.7% to 98.1% and the temperature increased from 1840 °C to 1880 °C and then slightly decreased to 97.2% at 1900 °C. The decrease of the density at a higher temperature was likely due to the evaporation of the sintering additives [6,15]. The liquid phase overflow was also observed at 1900 °C. The highest relative density of the ceramics, 98.1%, was achieved at the sintering temperature of 1880 °C. The samples prepared for ballistic testing were sintered at this temperature.

Figure 4.

The relative density of the sintered uniform-layered sample under different temperatures.

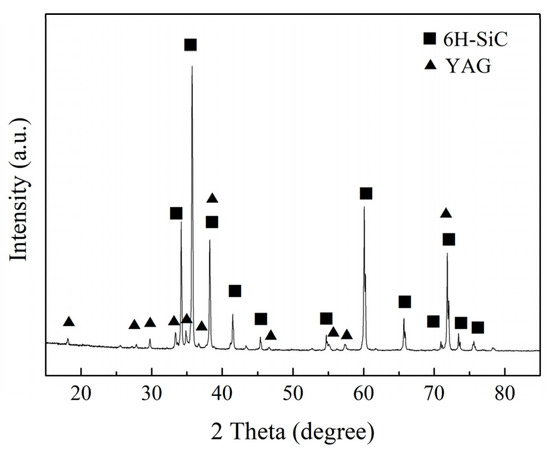

The X-ray spectrum of the pure-matrix sample is shown in Figure 5. α-SiC was the main phase in the final product. YAG phase was also observed, which was formed from the additives during sintering following the reaction:

Figure 5.

The X-ray spectrum of the sintered laminated SiC ceramics.

This result was consistent with other research [6].

The mechanical performance of the samples is shown in Table 2. The flexural strength of the uniform-layered, gradual-layered, and pure-matrix sample was 348 MPa, 396 MPa, and 640 MPa, respectively. The toughness of the uniform-layered sample was the highest at 7.4 MPa∙m1/2. The toughness of the gradual-layered and the pure-matrix sample was 6.8 and 6.9 MPa∙m1/2, respectively. The hardness of the matrix layer for the laminated SiC was 22 GPa. The SSIC sample had a flexural strength of 414 MPa and a toughness of 4.2 MPa∙m1/2. The hardness of the SSIC was 26 GPa, higher than that of the laminated SiC.

Table 2.

Mechanical performance of the samples.

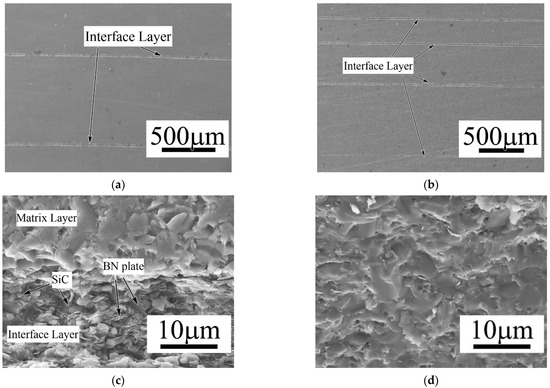

The microstructures of the laminated ceramics are shown in Figure 6. The thickness of the matrix layer in the uniform-layered sample was approximately 800 μm and the thickness of the interface layer was approximately 20 μm after sintering. The matrix layer thickness in the gradual-layered sample was gradually changed: from the bottom (i.e., the strike face in the ballistic test) to the top were 800 μm, 450 μm, and 250 μm, respectively. The interface layer of the gradual-layer sample was also 20 μm. The detail of the interface layer is shown in Figure 6c and the SiC particles and the BN plates were observed. The fracture surface of the matrix layer is shown in Figure 6d. The fracture mode was a combination of inter-granular and trans-granular fractures. The grain was fine with a size of 1–3 μm.

Figure 6.

The microstructure of the laminated ceramics: (a) uniform-layered; (b) gradual-layered; (c) high magnification of the interface layer; (d) the fracturing surface of the pure-matrix laminated ceramic.

The laminated SiC without the interface layer (pure-matrix) showed a high strength as well as toughness compared to the solid-state sintered SiC, SSIC. Previous studies [4,16] have shown that tape-casting is a colloid process that could leave fewer defects in the green body compared to the conventional dry-press method because the colloid process allows particles to be well-dispersed to avoid agglomerates. Since ceramics are a brittle material that is sensitive to defects, this would improve the strength of the final products. For liquid-phase-sintered SiC, the inter-granular crack deflection was the main toughening mechanism [17,18]. The phase formed in the grain boundary of the liquid phase sintering SiC (in this study, the phase was YAG) was weaker than SiC, so the cracks tended to propagate along the grain boundary rather than through the grain [15]. Moreover, the residual stress generated by the thermal mismatch of the phase in the grain boundary further weakened the grain boundary, facilitating the inter-granular crack deflection [15,16]. The crack deflection elongated the cracking path, leading to the high toughness of the liquid phase sintered SiC, compared to that of the solid-state sintered SiC. The degree of the inter-granular fracture reflected the effect of the inter-granular crack deflection. A higher inter-granular fracture indicated a weaker grain boundary, and the liquid phase sintered SiC with a higher degree of the inter-granular fracture tended to have higher toughness but lower strength and lower Vickers hardness, compared to the SiC with a lower degree of the inter-granular fracture [19,20]. In this study, the laminated SiC showed a low degree of inter-granular fracture, so the strength and Vickers hardness of the pure-matrix sample remained high among the liquid phase sintered SiC (approximately 450–650 MPa in strength and 18–20 GPa in Vickers hardness). The price for the high strength and hardness of the pure-matrix SiC was the reduced toughness. The toughness of the pure-matrix SiC (with 8 wt.% Al2O3-Y2O3) was 6.9 MPa∙m1/2, lower than that of the SiC prepared by She [15]. Their SiC with 5–10 wt.% Al2O3-Y2O3 additives was sintered pressureless but reached a toughness of 7.0–7.5 MPa∙m1/2. However, the toughness of the pure-matrix SiC was still higher than the SSIC due to the crack deflection effect.

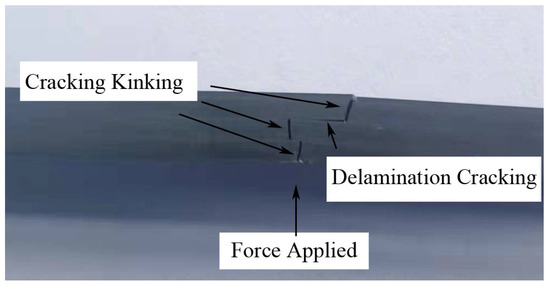

The introduction of the interface layer to the laminated ceramics in this study was to promote the energy absorption ability of the material. According to Sun’s study [6], the interface layer with a combination of SiC and BN (approximately 1:1 in weight) would facilitate the crack kinking and delamination cracking in the interface layer during fracturing and the crack would propagate step-like. In this study, the uniform-layered sample (10 matrix layers to 1 interface layer) had improved toughness compared to the pure-matrix sample. A step-like cracking path is observed in Figure 7, showing strong delamination cracking and crack kinking effect. The gradient-layered structure sample, however, did not have this effect and had similar toughness as the pure-matrix sample.

Figure 7.

Optical image of the side-view of the gradual-layered sample after the three-point-bending test.

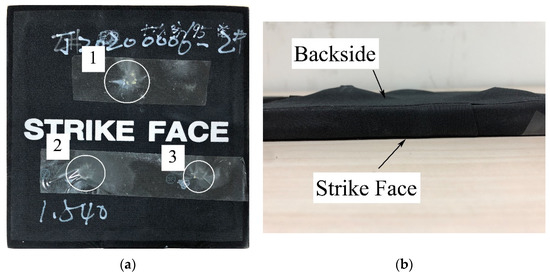

The ballistic results are shown in Table 3. In the CA test, all of the samples resisted the shot and were not completely penetrated by the bullets. The BFS depth of the uniform-layered, gradual-layered, pure-matrix, and SSIC samples was 7.2 mm, 5.6 mm, 9.1 mm, and 11.2 mm, respectively. All three types of the laminated SiC had decreased BFS depths compared to the SSIC sample. The BFS depth of the gradual-layered sample after ballistic impact, which was the least in this study, was 50% less than that of the SSIC. In the SA test, all three laminated ceramics resisted three hits and were not completely penetrated, showing good multi-hit resistance. The maximum BFS depth of the uniform-layered sample was 16.4 mm, slightly higher than that of gradual-layered and pure-matrix samples (both were 15.7 mm). A typical front and side view of the sample after ballistic impact was taken for the pure-matrix sample after the SA test and is shown in Figure 8.

Table 3.

Ballistic test results of the laminated SiC ceramics tested in conjunction with a flexible armor jacket (the CA test) and stand-alone (the SA test).

Figure 8.

The images for the pure-matrix sample after the SA test; (a) front view (the ballistic hitting sequence was labeled); (b) side view.

Generally, three stages occur during the projectile impact [21]: shattering, erosion, and catching. Shattering is the primary stage in defending the hard-core projectile. During the shattering stage, the projectile impacts the ceramic surface. A shock wave is generated and reflected from the back of the ceramic/backing interface. The reflected tensile wave initiates the damage accumulation and cracking in the ceramic. The interaction between projectile and ceramic also results in deforming, shattering, or eroding of the projectile. During the erosion stage, the ceramic is already cracked but still prevents the projectile or fragments from penetration by the erosion mechanism. In the last catching stage, the ceramic and its back-plate stops the projectile and fragments by momentum transfer.

The interaction between projectile and ceramic that results in the deforming or shattering of the projectile is a key process in defeating the projectile because the deformed, or even shattered, projectile dissipates its kinetic energy to a larger area and reduces the stress generated. To effectively deform or shatter the projectile, the ceramic needs to have sufficient hardness. Flinders et al. [22] reported that the hardness was negatively related to the depth of penetration (DOP) for several SiC ceramics, including solid-state sintered SiC and liquid-phase sintered SiC. Huang et al. [12] reported a decrease in the penetration resistance of the laminated ceramics with low-hardness interface layers and found that introducing the interface layer at the backside affected penetration resistance less. The interface layer in this study had very low Vickers hardness due to the 50 wt.% of BN, thus the interface layer may not provide an effective projectile-fracturing effect. To guarantee the projectile-fracturing effect of the laminated ceramics, no interface layer was introduced to the first 0.8 mm in the strike face side. As a result, the uniform-layered and gradual-layered samples both successfully defeated the 5.8 mm bullet, indicating a sufficient hardness of the sample to deform or shatter the bullet.

In this study, the laminated SiC was found to provide better energy absorption ability under the ballistic impact compared to the solid-state sintered SiC when used in conjunction with a flexible armor jacket. The BFS depths of the four types of the samples in the CA test were in the following sequences: gradual-layered < uniform-layered < pure-matrix < SSIC. The laminated SiC, even with no interface layer, had a BFS depth of 20% less than that of the SSIC. As can be seen in Table 2, the pure-matrix sample had a higher strength and a higher toughness but a slightly lower hardness than that of SSIC. Flinders et al. [22] reported that a higher hardness would benefit the ballistic performance when using 7.62 mm M993 (WC-Co core, designed to target light armor vehicles). However, in this study, the type-87 5.8 mm steel core is not designed as armor-piercing (AP) ammunition and the steel core had a much lower hardness than that of the WC-Co core. The hardness of the matrix SiC layer for the laminated ceramics, 22 GPa, was likely sufficient, and further increasing the hardness of the ceramic might not contribute to the ballistic performance [23]. High flexural strength would be beneficial to resist the tensile wave generated by the impact and the toughness would resist the penetration through energy absorption [24]. With a higher flexural strength and a higher toughness, the pure-matrix sample would have better energy absorption ability and thus less BFS depth compared to the SSIC sample. However, the mechanical performance of the laminated ceramics was not directly related to their ballistic performance of the CA test. The least BFS depth was obtained by the gradual-layered sample which had a lower strength and a close toughness compared to the pure-matrix sample. This indicated that the energy absorption effect by the layered structure was the dominating factor. Due to different mechanical properties between the matrix layer and the interface layer, the stress wave in the laminated ceramics or composites would be reflected at the interface and would be attenuated [14,25,26]. Li et al. [25] showed that laminated ceramics could have better impact resistance due to the multi-reflection and attenuation of the stress wave at the interfaces. The reflection and attenuation of the stress wave also reduced the wave propagation speed within the material and thus enhanced penetration resistance [14,26]. The gradual-layered sample, with more interface layers at the back face side, had a decreased BFS depth compared to the uniform-layered sample. This was in agreement with the studies mentioned above in that the introduction of the interface layers helps to improve the ballistic performance.

The ballistic performance of the laminated ceramics with interface layers not only depended on the layer structure of the ceramics itself but was also highly dependent on the testing conditions. The BFS depths of the uniform-layered, gradual-layered, and pure-matrix samples were similar in the SA test, while these ceramics had different BFS depths in the CA test. Of note is that the ballistic performance was highly related to the testing conditions as well as the armor itself, e.g., the back support [27], the confinement [28], or the pre-stress applied to the armor plate [29,30]. In the CA test, the armor plate was attached to a flexible armor jacket which provided stronger back support than the armor plate for the SA test. The stress wave generated by the ballistic impact was reflected at the ceramic/backing interface due to the mechanical impedance [2]. A theoretical study by Gour [27] also showed that a thicker back-plate would help to offset the tensile stress at the ceramics and support the ceramic for a longer time, preventing the premature failure of the ceramics. Compared to the laminated SiC ceramics for the CA test, the laminated SiC ceramics in the SA test had a weaker back support, thus they likely failed before the laminated structure could play a role. As a result, the BFS depths of the three laminated SiC ceramics in the SA test were close. It is still unclear whether there is a threshold for the laminated ceramics with interface layers to be effective, e.g., the critical impact energy or velocity of the wave. Additional experiments, as well as theoretical studies, are needed to explain this phenomenon.

4. Conclusions

The three types of laminated SiC ceramics, the uniform-layered, gradual-layered, and pure-matrix, were designed and prepared by tape-casting and hot-pressing. When tested in conjunction with a flexible armor jacket, the BFS depths of the samples were in the following sequences: gradual-layered < uniform-layered < pure-matrix and all the laminated SiC obtained less BFS depth than the solid-state sintered SiC. The layer structure was the main reason for the differences. The gradual-layered sample had the back face signature depth of 30% less than the laminated SiC with no interface structure and 50% less than the solid-state sintered SiC. However, the ballistic performance of the laminated ceramics with interface layers not only depended on the layer structure of the ceramics itself but was also highly dependent on the back support for the ceramics. When tested stand-alone, the laminated SiC armor plates had a similar ballistic performance regardless of the layer structure, which was likely because the armor plate for the stand-alone test had weaker back support compared to the armor plates tested in conjunction with a flexible armor jacket. All of the laminated SiC resisted three shots of the bullet in the stand-alone test, showing good multi-hit resistance. In conclusion, the ballistic performance of the laminated ceramics was related to the back support of the armor system. When used in the in conjunction armor system, the laminated SiC had a better ballistic performance than that of the solid-state sintered SiC, making the laminated ceramic a potential armor ceramic.

Author Contributions

Conceptualization, Y.H. and F.X.; Data curation, Y.H. and L.X.; Formal analysis, M.Y. and X.C.; Funding acquisition, G.W.; Investigation, M.Y., X.C. and Z.S.; Methodology, L.X.; Project administration, F.X. and G.W.; Resources, L.X. and M.Q.; Supervision, F.X. and T.M.; Validation, F.X.; Visualization, Y.H.; Writing—original draft, Y.H.; Writing—review and editing, Z.S., F.X., T.M. and N.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China, grant number 2017YFB1103503.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the Institute of Quartermaster Engineering Technology of the PLA Academy of Military Science for the support of ballistic testing.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Medvedovski, E. Advanced Ceramics for Personnel Armor: Current Status and Future. In Ceramic Armor and Armor Systems II; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; pp. 1–17. [Google Scholar]

- David, N.V.; Gao, X.L.; Zheng, J.Q. Ballistic Resistant Body Armor: Contemporary and Prospective Materials and Related Protection Mechanisms. Appl. Mech. Rev. 2009, 62, 1201–1210. [Google Scholar] [CrossRef]

- Medvedovski, E. Ballistic Performance of Armour Ceramics: Influence of Design and Structure. Part 1. Ceram. Int. 2010, 36, 2103–2115. [Google Scholar] [CrossRef]

- Alford, N.M.; Birchall, J.; Kendall, K. High-Strength Ceramics through Colloidal Control to Remove Defects. Nature 1987, 330, 51–53. [Google Scholar] [CrossRef]

- Kistic, Z.; Kistic, V.D. Young’s Modulus, Density and Phase Composition of Pressureless Sintered Self-Sealed Si3N4/BN Laminated Structures. J. Eur. Ceram. Soc. 2008, 28, 1723–1730. [Google Scholar] [CrossRef]

- Sun, M.; Bai, Y.; Li, M.; Fan, S.; Cheng, L. Structural Design and Energy Absorption Mechanism of Laminated SiC/BN Ceramics. J. Eur. Ceram. Soc. 2018, 38, 3742–3751. [Google Scholar] [CrossRef]

- Cook, J.; Gordon, J.E.; Evans, C.C.; Marsh, D.M. A Mechanism for the Control of Crack Propagation in All-Brittle Systems. Proc. R. Soc. A 1964, 282, 508–520. [Google Scholar]

- Clegg, W.J.; Kendall, K.; Alford, N.M.N.; Button, T.W.; Birchall, J.D. A Simple Way to Make Tough Ceramics. Nature 1990, 347, 455–457. [Google Scholar] [CrossRef]

- Clegg, W.J. The Fabrication and Failure of Laminar Ceramic Composites. Acta Metall. Et Mater. 1992, 40, 3085–3093. [Google Scholar] [CrossRef]

- Wang, C.; Huang, Y.; Zan, Q.; Zou, L.; Cai, S. Control of Composition and Structure in Laminated Silicon Nitride/Boron Nitride Composites. J. Am. Ceram. Soc. 2002, 85, 2457–2461. [Google Scholar] [CrossRef]

- Lankford, J., Jr. The Role of Dynamic Material Properties in the Performance of Ceramic Armor. Int. J. Appl. Ceram. Technol. 2010, 1, 205–210. [Google Scholar] [CrossRef]

- Cuiwei, L.; Changan, W.; Yong, H. Bullet-Proof Structure Design of Si3N4/BN Laminated Ceramics. Rare Metal Mater. Eng. 2007, 36, 351–353. [Google Scholar]

- Holmquist, T.J.; Templeton, D.W.; Bishnoi, K.D. Constitutive Modeling of Aluminum Nitride for Large Strain, High-Strain Rate, and High-Pressure Applications. Int. J. Impact Eng. 2001, 25, 211–231. [Google Scholar] [CrossRef]

- Yadav, S.; Ravichandran, G. Penetration Resistance of Laminated Ceramic/Polymer Structures. Int. J. Impact Eng. 2003, 28, 557–574. [Google Scholar] [CrossRef] [Green Version]

- She, J.H.; Ueno, K. Effect of Additive Content on Liquid-Phase Sintering on Silicon Carbide Ceramics. Mater. Res. Bull. 1999, 34, 1629–1636. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, R.; Gu, H.; Jiang, D.; Lin, Q.; Huang, Z. High Toughness in Laminated SiC Ceramics from Aqueous Tape Casting. Scr. Mater. 2005, 52, 381–385. [Google Scholar] [CrossRef]

- Faber, K.T.; Evans, A.G. Intergranular Crack-Deflection Toughening in Silicon Carbide. J. Am. Ceram. Soc. 2010, 66, C-94–C-95. [Google Scholar] [CrossRef]

- Kim, D.; Chong, H.K. Toughening Behavior of Silicon Carbide with Additions of Yttria and Alumina. J. Am. Ceram. Society 1990, 73, 1431–1434. [Google Scholar] [CrossRef]

- Suzuki, K.; Sasaki, M. Microstructure and Mechanical Properties of Liquid-Phase-Sintered Sic with AlN and Y2O3 Additions. Ceram. Int. 2005, 31, 749–755. [Google Scholar] [CrossRef]

- Ray, D.; Flinders, M.; Anderson, A.; Cutler, R.A. Hardness/Toughness Relationship for SiC Armor. In 27th Annual Cocoa Beach Conference on Advanced Ceramics and Composites: A: Ceramic Engineering and Science Proceedings; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; pp. 401–410. [Google Scholar]

- Gooch, W.A. An Overview of Ceramic Armor Applications. In Proceedings of the International Conference on Advanced Ceramics and Glasses PAC RIM IV, Maui, Hawaii, 4–8 November 2001. [Google Scholar]

- Flinders, M.; Ray, D.; Anderson, A.; Cutler, R.A. High-Toughness Silicon Carbide as Armor. J. Am. Ceram. Society 2005, 88, 2217–2226. [Google Scholar] [CrossRef]

- Karandikar, P.G.; Evans, G.; Wong, S.; Aghajanian, M.K.; Sennett, M. A Review of Ceramics for Armor Applications. Adv. Ceram. Armor IV 2009, 29, 163–175. [Google Scholar]

- Haney, E.J.; Subhash, G. Damage Mechanisms Perspective on Superior Ballistic Performance of Spinel over Sapphire. Exp. Mech. 2013, 53, 31–46. [Google Scholar] [CrossRef]

- Li, L.; Cheng, L.; Fan, S.; Gao, X.; Xie, Y.P.; Zhang, L. A Novel Fabrication Approach for Impact Resistance Laminated Ceramics. Mater. Des. 2015, 79, 26–31. [Google Scholar] [CrossRef]

- Zhuang, S.; Ravichandran, G.; Grady, D.E. An Experimental Investigation of Shock Wave Propagation in Periodically Layered Composites. J. Mech. Phys. Solids 2003, 51, 245–265. [Google Scholar] [CrossRef]

- Gour, G.; Serjouei, A.; Sridhar, I. Influence of Geometry and Hardness of the Backing Plate on Ballistic Performance of Bi-Layer Ceramic Armor. Procedia Eng. 2017, 173, 93–100. [Google Scholar] [CrossRef]

- Akella, K.; Naik, N.K. Composite Armour—A Review. J. Indian Inst. Sci. 2015, 95, 297–312. [Google Scholar]

- Sherman, D.; Ben-Shushan, T. Quasi-Static Impact Damage in Confined Ceramic Tiles. Int. J. Impact Eng. 1998, 21, 245–265. [Google Scholar] [CrossRef]

- Chi, R.; Serjouei, A.; Sridhar, I.; Geoffrey, T.E.B. Pre-Stress Effect on Confined Ceramic Armor Ballistic Performance. Int. J. Impact Eng. 2015, 84, 159–170. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).