BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations

Abstract

:1. Introduction

1.1. Background

1.2. Previous BIM-GIS Integration

1.3. Problem Statement and Research Scope

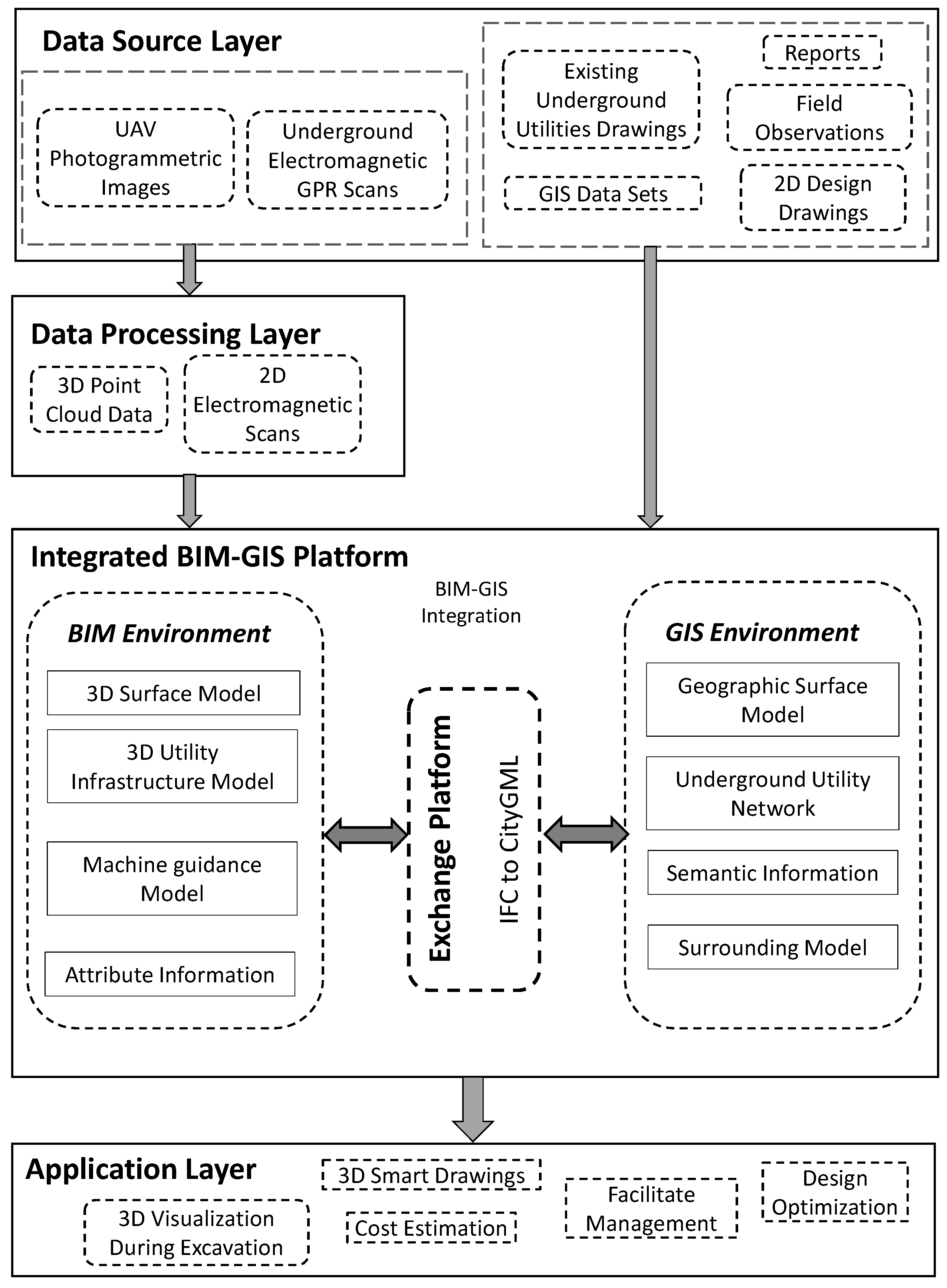

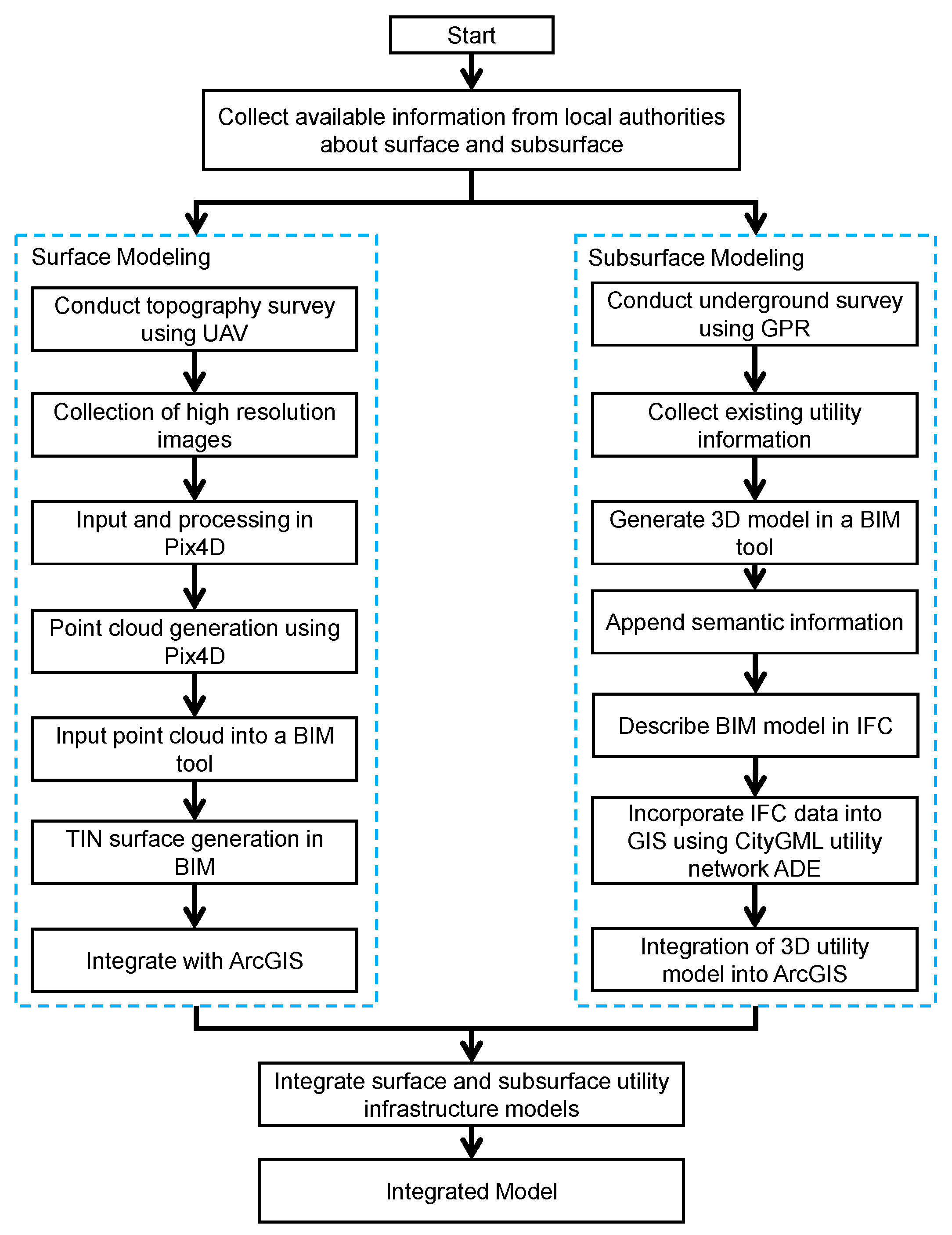

2. Materials and Methods

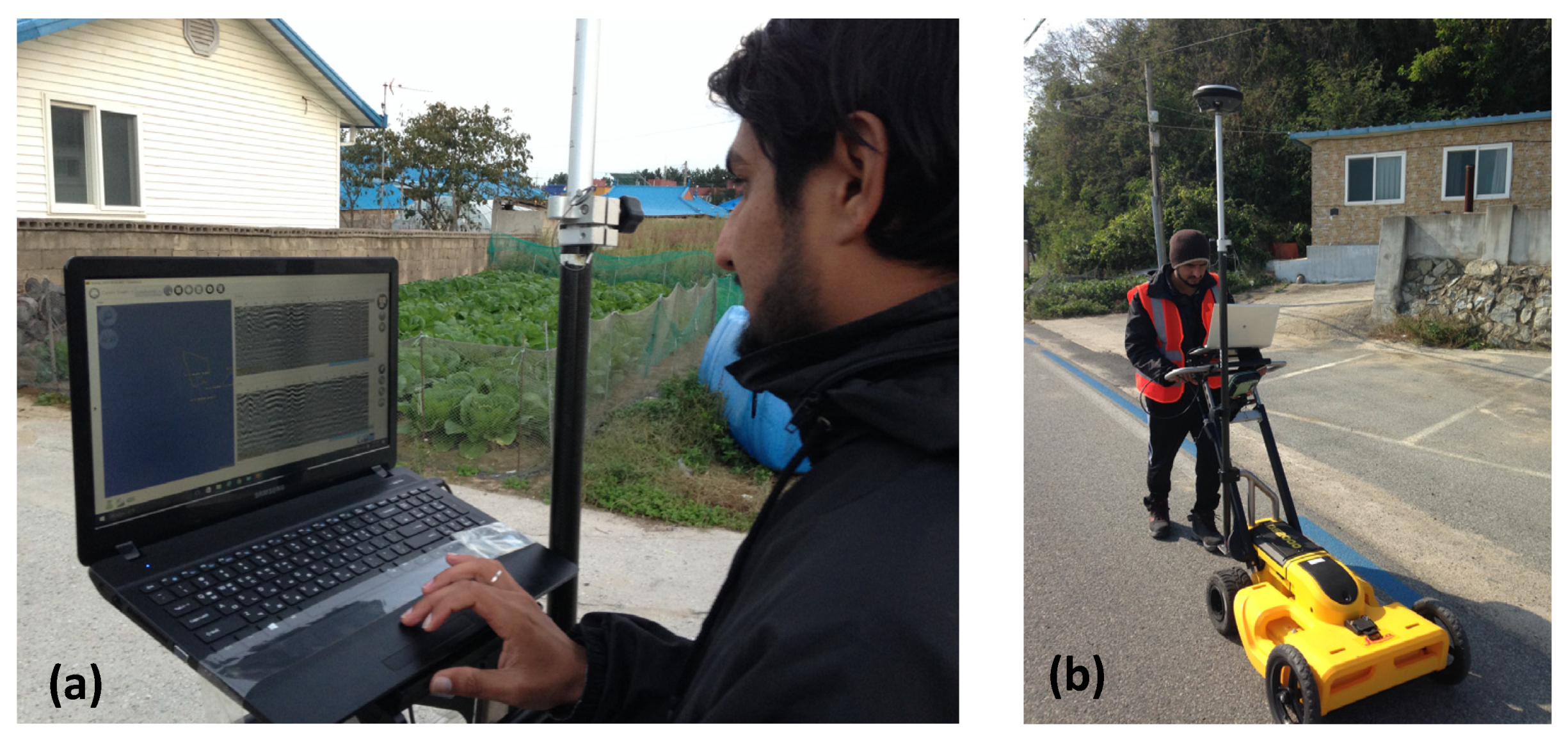

2.1. Data Source Layer

2.1.1. Existing Terrain Information

2.1.2. Underground Utility Information

2.2. Data Processing Layer

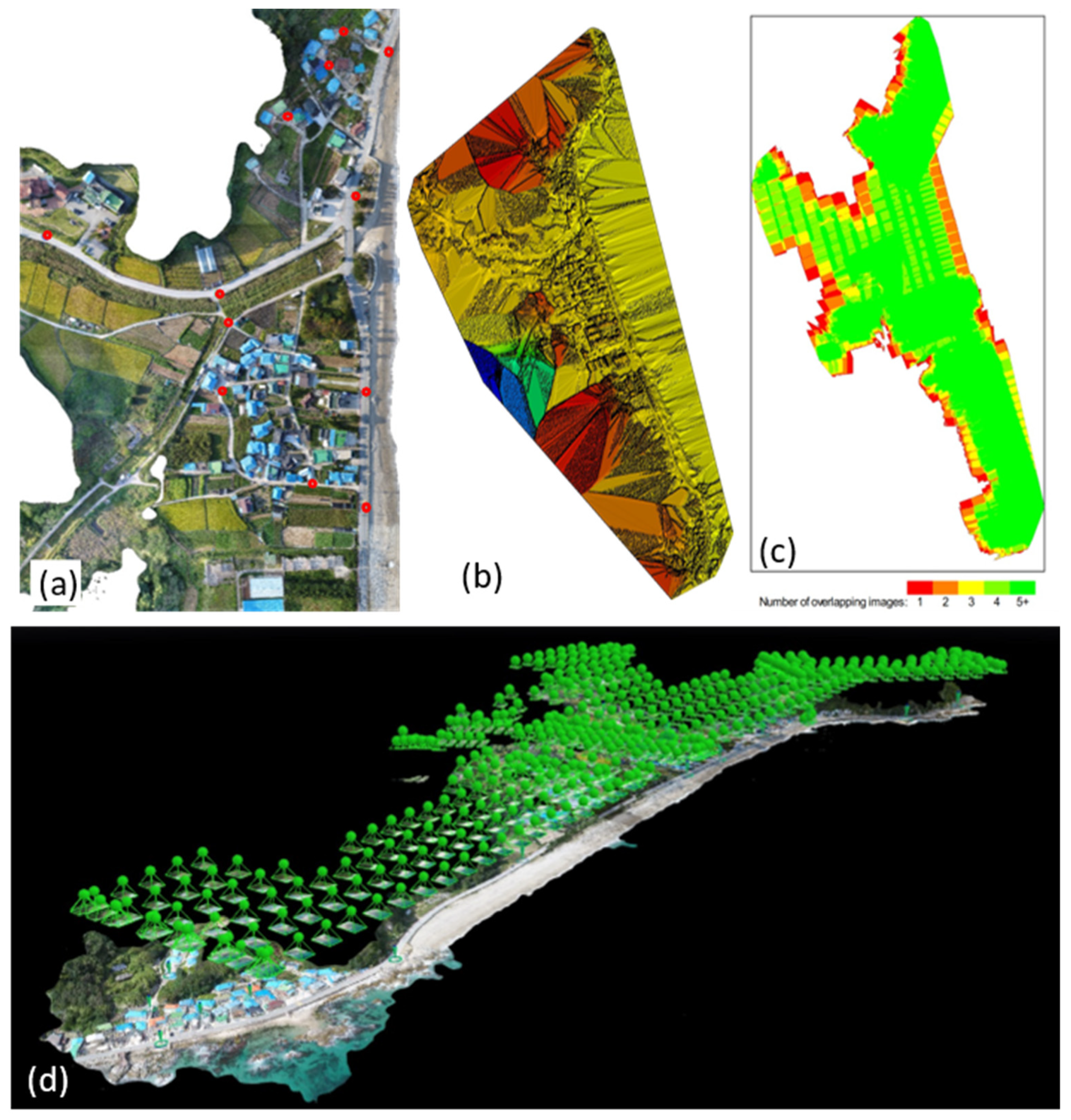

2.2.1. UAV Photogrammetric Data Processing

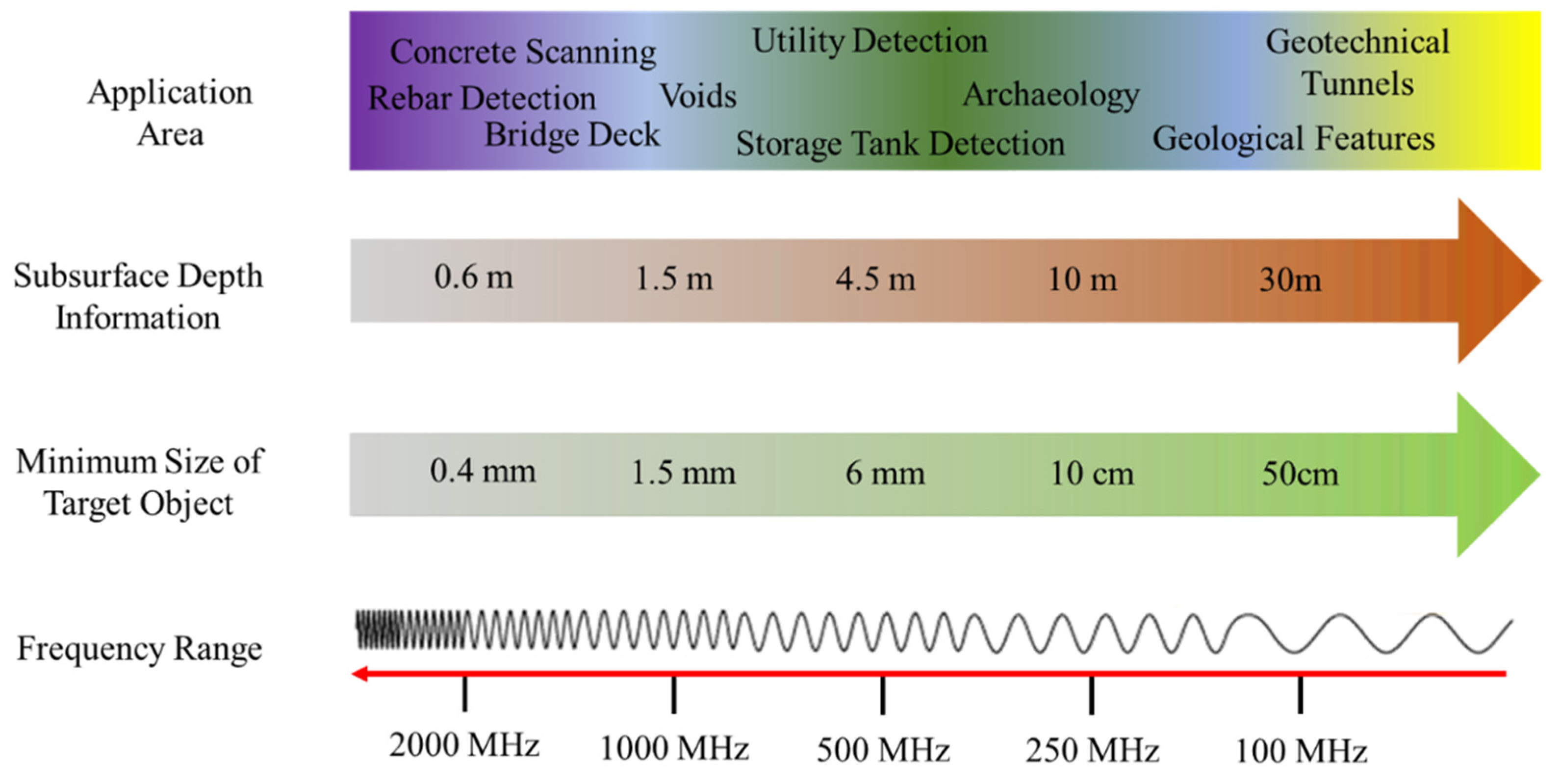

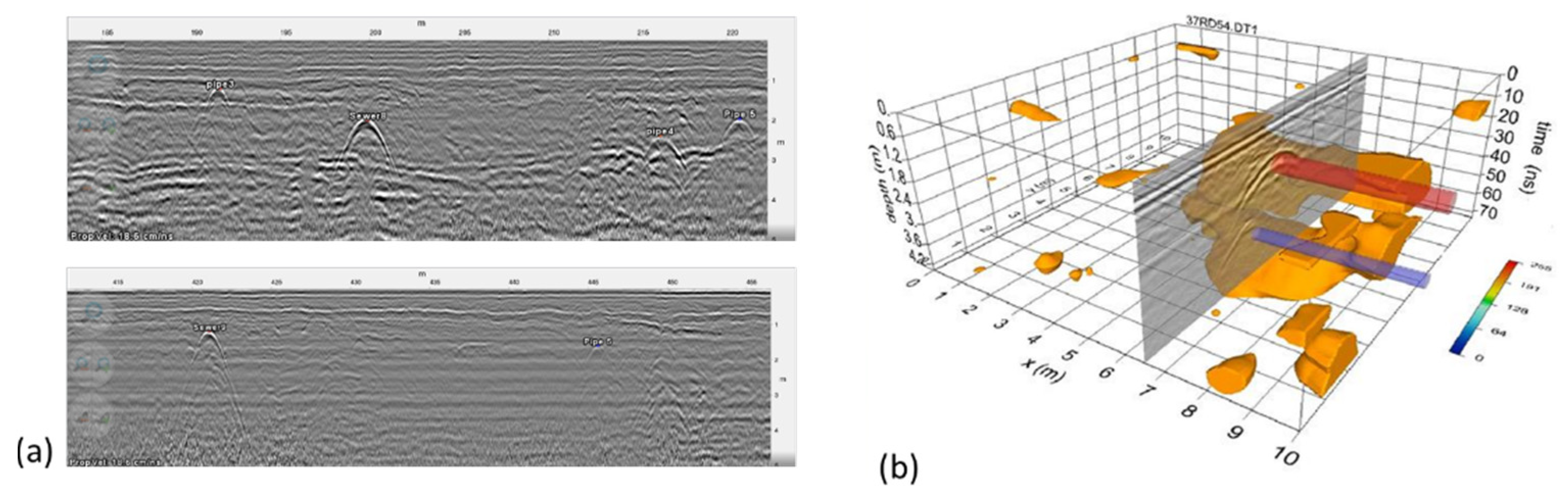

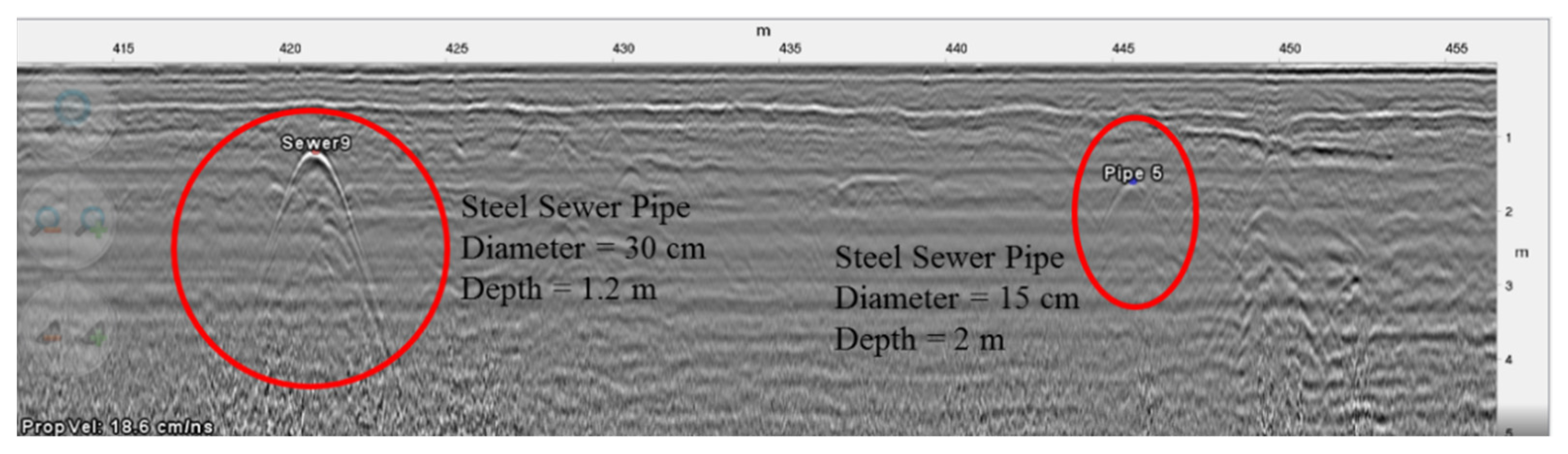

2.2.2. GPR Electromagnetic Data Processing

2.3. Integrated BIM-GIS Platform Layer

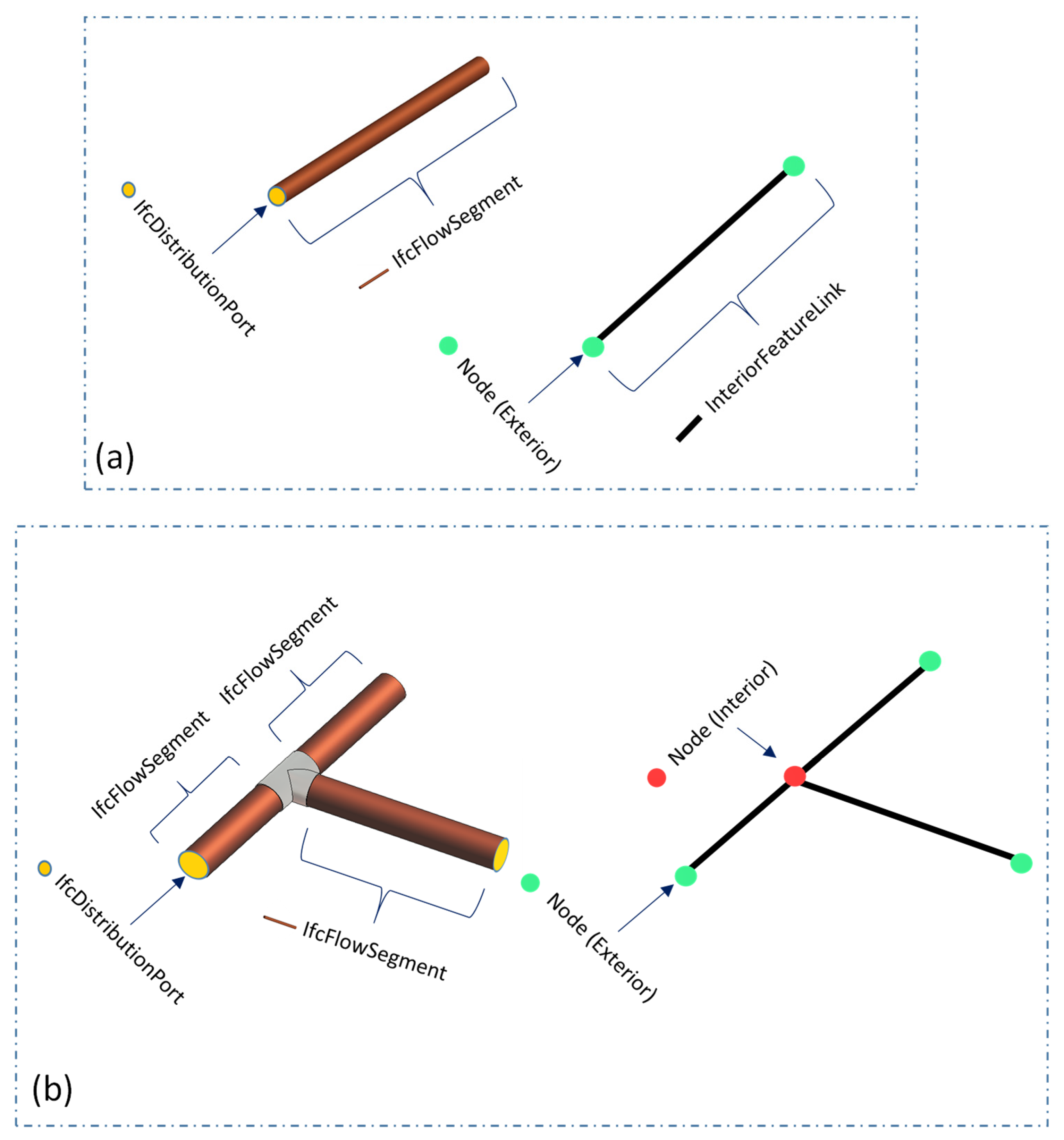

2.3.1. IFC Schema

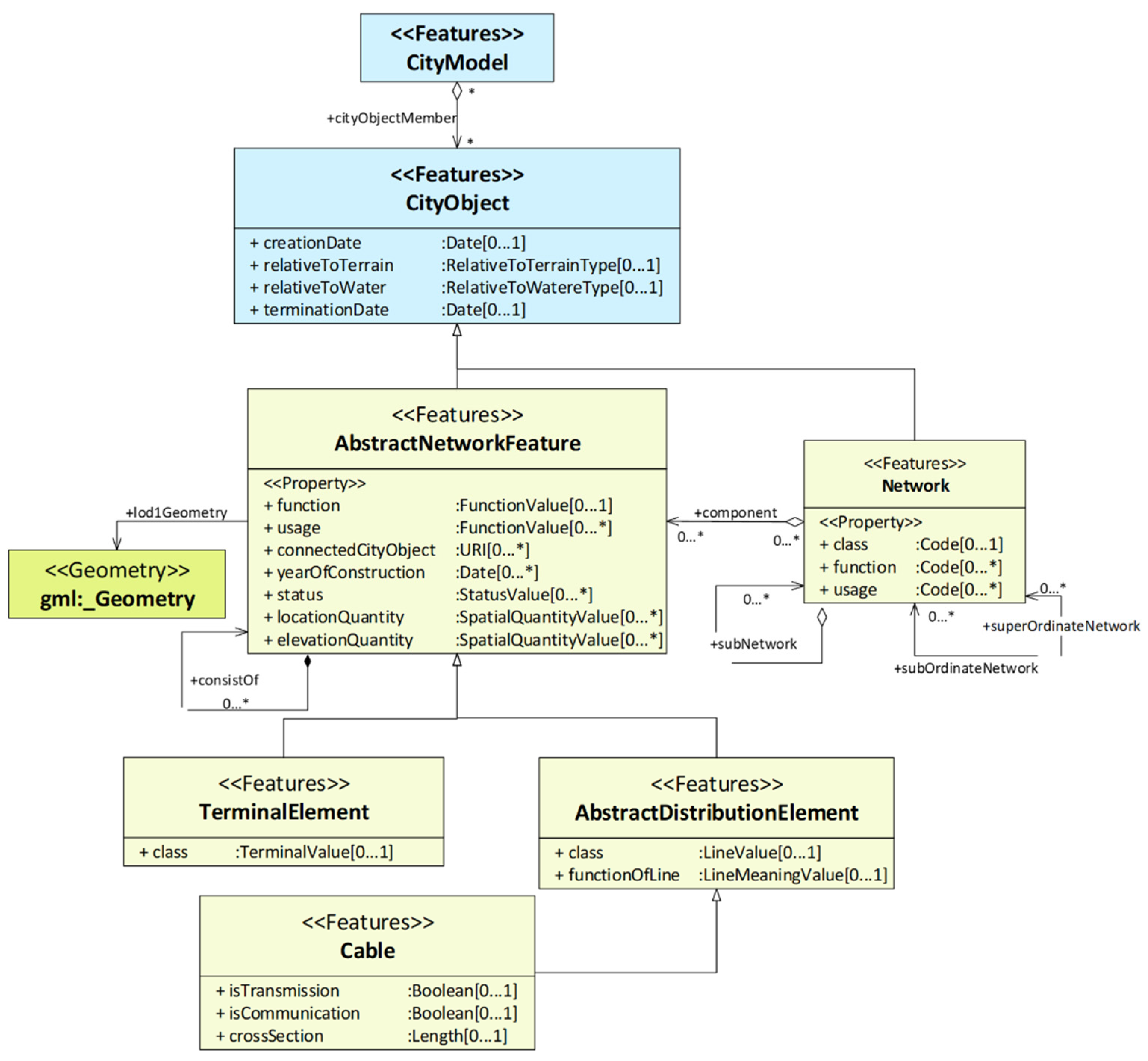

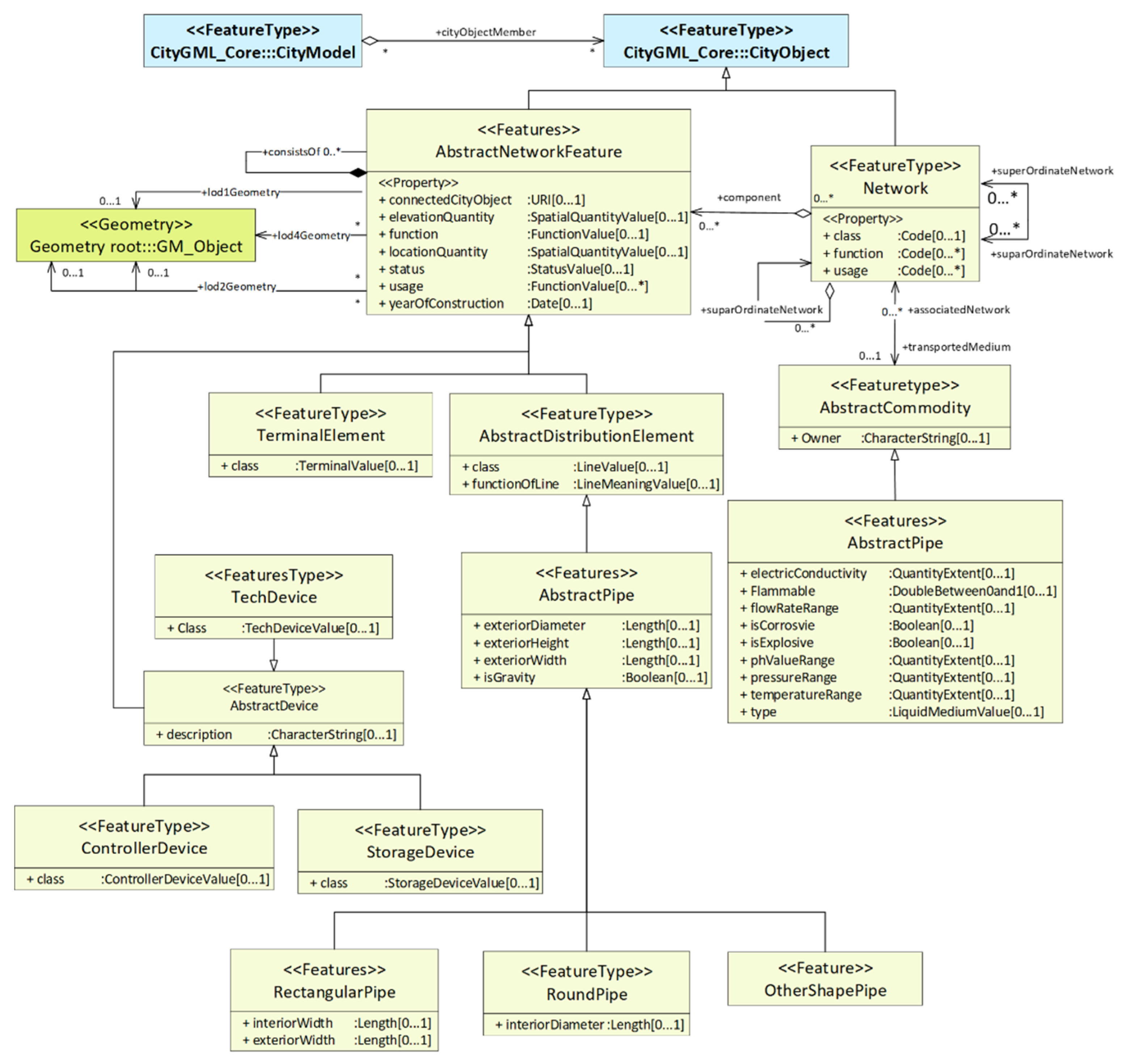

2.3.2. CityGML Schema

2.3.3. Mapping from IFC to CityGML Schema

2.4. Application Layer

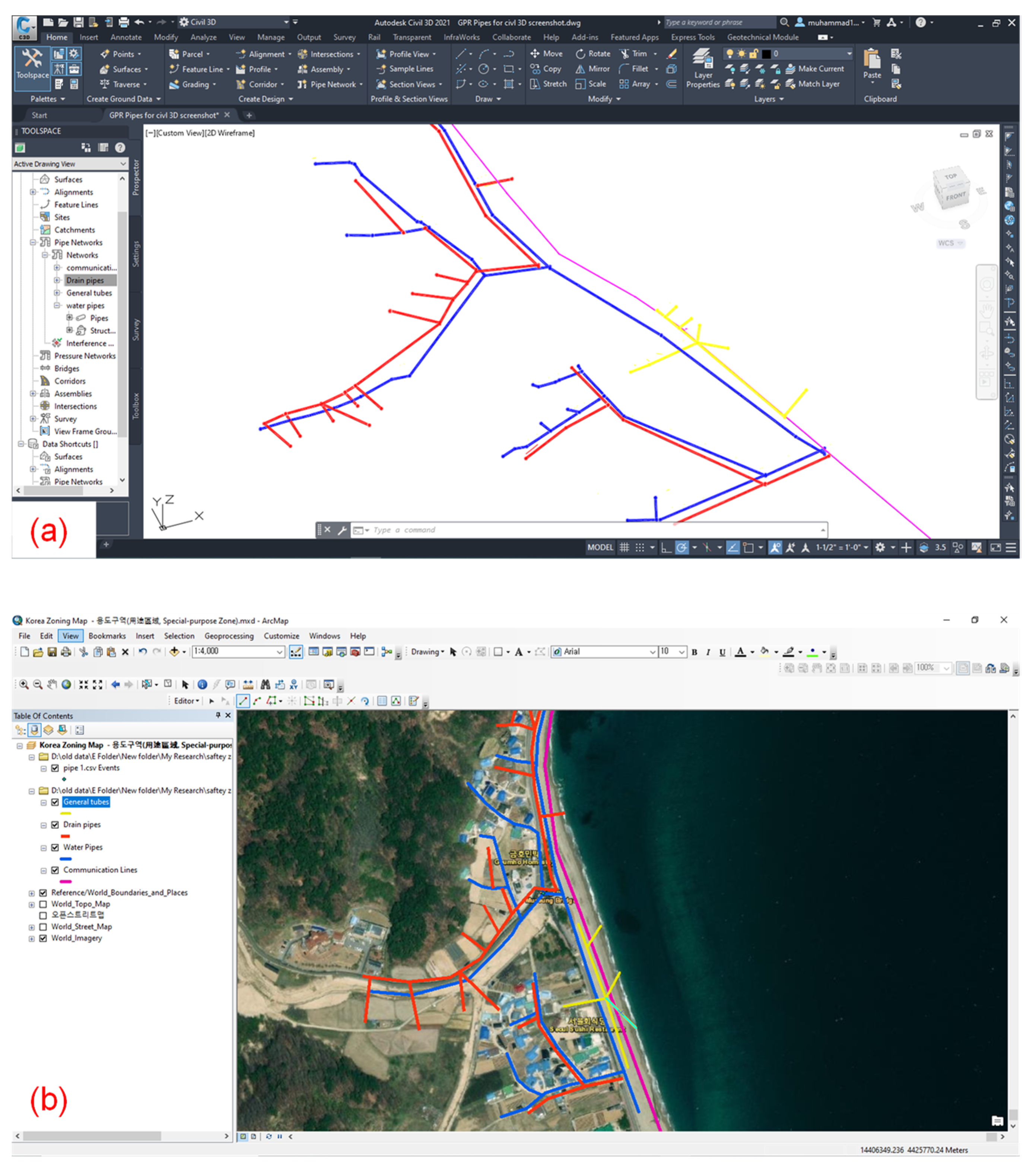

2.4.1. Visualization

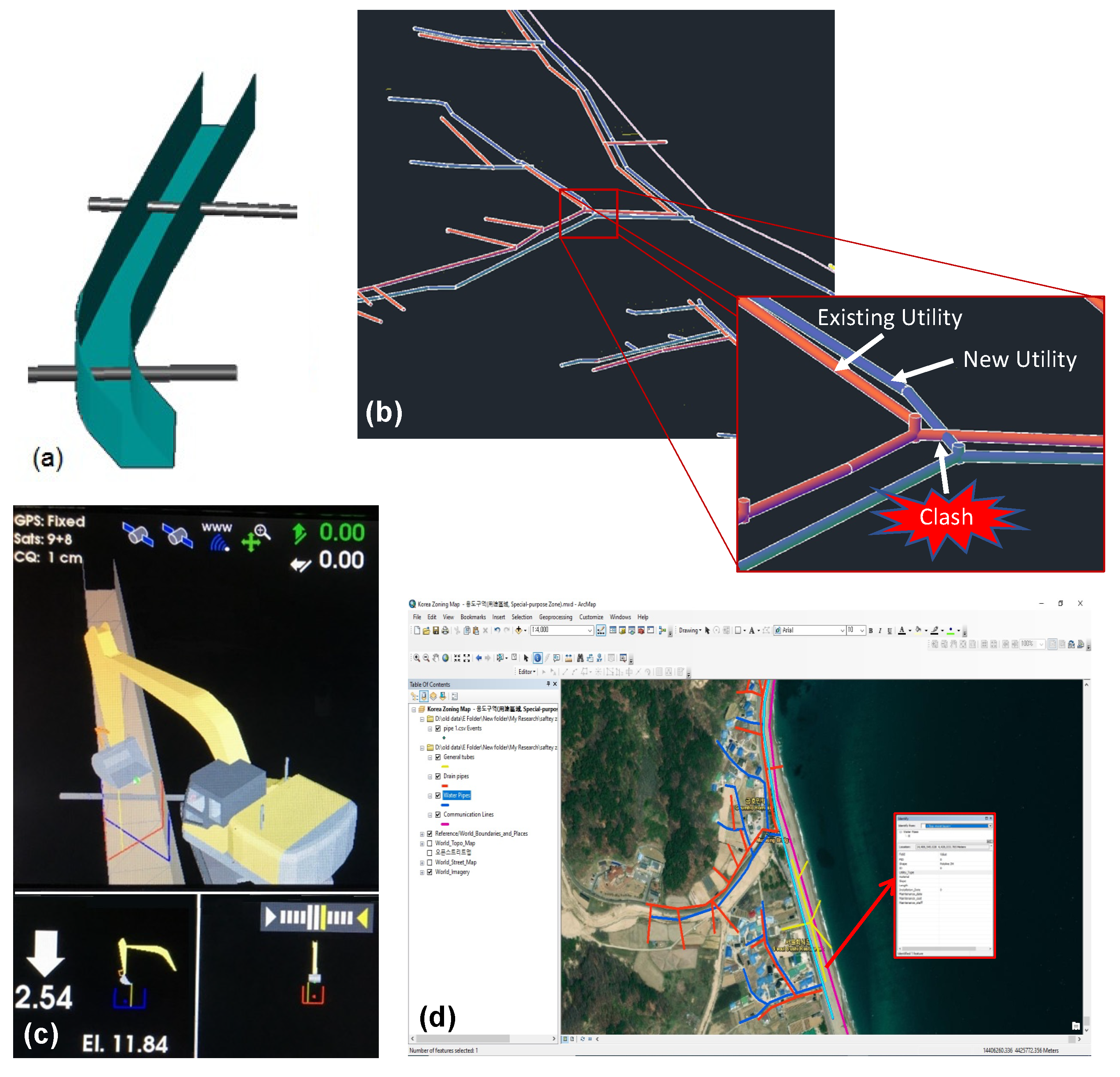

2.4.2. Machine Guidance

2.4.3. Facility Management

2.4.4. Clash Detection

3. Implementation of the Proposed BIM-GIS Utility Infrastructure Framework

3.1. Data Collection

3.2. Data Processing

3.3. Integrated BIM-GIS Modeling

3.4. Application

3.5. Evaluation

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Metje, N.; Crossland, S.M.; Ahmad, B. Causes, impacts and costs of strikes on buried utility assets. Proc. ICE Munic. Eng. 2015, 168, 165–174. [Google Scholar] [CrossRef] [Green Version]

- Sharafat, A.; Latif, K.; Seo, J. Risk analysis of TBM tunneling projects based on generic bow-tie risk analysis approach in difficult ground conditions. Tunn. Undergr. Sp. Technol. 2021, 111, 103860. [Google Scholar] [CrossRef]

- Kolera, B.T.; Bernold, L.E. Intelligent Utility Locating Tool for Excavators. J. Constr. Eng. Manag. 2006, 132, 919–927. [Google Scholar] [CrossRef]

- Su, X.; Talmaki, S.; Cai, H.; Kamat, V.R. Uncertainty-aware visualization and proximity monitoring in urban excavation: A geospatial augmented reality approach. Vis. Eng. 2013, 1, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Guerrero, J.; Zlatanova, S.; Meijers, M. 3D visualisation of underground pipelines: Best strategy for 3D scene creation. ISPRS Ann. Photogramm. Remote. Sens. Spat. Inf. Sci. 2013, 2, 139–145. [Google Scholar] [CrossRef] [Green Version]

- Tanoli, W.A.; Seo, J.W.; Sharafat, A.; Lee, S.S. 3D Design Modeling Application in Machine Guidance System for Earthwork Operations. KSCE J. Civ. Eng. 2018, 22, 4779–4790. [Google Scholar] [CrossRef]

- Khan, M.S.; Khan, A.; Adil, M.; Khalil, F. Role of Building Information Modelling (BIM) in Building Design Industry. In Proceedings of the INUMDC 2018: Iqra National University Multi-Disciplinary conference, Islamabad, Pakistan, 7–8 November 2018; Volume 9, pp. 119–123. [Google Scholar]

- Du, Y.; Zlatanova, S. An Approach for 3D Visualization of Pipelines. Innov. 3D Geo Inf. Syst. 2006, Volume 1, 501–517. [Google Scholar] [CrossRef] [Green Version]

- Moon, S.; Seo, J. Virtual graphic representation of construction equipment for developing a 3D earthwork BIM. J. Civ. Eng. Manag. 2017, 23, 977–984. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Wright, G.; Cheng, J.C.P.; Li, X.; Liu, R. A state-of-the-art review on the integration of Building Information Modeling (BIM) and Geographic Information System (GIS). ISPRS Int. J. Geo-Inf. 2017, 6, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature Building Information Modeling ( BIM ) for existing buildings–literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef] [Green Version]

- Tsilimantou, E.; Delegou, E.T.; Nikitakos, I.A.; Ioannidis, C.; Moropoulou, A. GIS and BIM as integrated digital environments for modeling and monitoring of historic buildings. Appl. Sci. 2020, 10, 1078. [Google Scholar] [CrossRef] [Green Version]

- Colucci, E.; de Ruvo, V.; Lingua, A.; Matrone, F.; Rizzo, G. HBIM-GIS integration: From IFC to cityGML standard for damaged cultural heritage in a multiscale 3D GIS. Appl. Sci. 2020, 10, 1356. [Google Scholar] [CrossRef] [Green Version]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, J.; Huang, W. Method for generation of indoor GIS models based on BIM models to support adjacent analysis of indoor spaces. ISPRS Int. J. Geo-Inf. 2020, 9, 508. [Google Scholar] [CrossRef]

- Teo, T.A.; Cho, K.H. BIM-oriented indoor network model for indoor and outdoor combined route planning. Adv. Eng. Inform. 2016, 30, 268–282. [Google Scholar] [CrossRef]

- Costa, G.; Lilis, G.N.; Rovas, D.V.; Izkara, J. A comprehensive ontologies-based framework to support the retrofitting design of energy-efficient districts. In eWork and eBusiness in Architecture, Engineering and Construction, Proceedings of the 11th European Conference on Product and Process Modelling, Limassol, Cyprus, 7–9 September 2016; CRC Press: Boca Raton, Florida, USA; pp. 673–681.

- Thiis, T.; Hjelseth, E. Use of BIM and GIS to enable climatic adaptations of buildings. In Proceedings of the eWork and eBusiness in Architecture, Engineering and Construction, Nice, France, 1 September 2008; pp. 409–417. [Google Scholar]

- Song, Y.; Wang, X.; Tan, Y.; Wu, P.; Sutrisna, M.; Cheng, J.C.P.; Hampson, K. Trends and opportunities of BIM-GIS integration in the architecture, engineering and construction industry: A review from a spatio-temporal statistical perspective. ISPRS Int. J. Geo-Inf. 2017, 6, 1–32. [Google Scholar] [CrossRef] [Green Version]

- Benner, J.; Geiger, A.; Leinemann, K.; Karlsruhe, F.; Informatik, A.; Benner, J.; Geiger, A.; Leinemann, K. Flexible Generation of Semantic 3D Building Models. In Proceedings of the Workshop on Next Generation 3D City Models, Bonn, Germany, 21–22 June 2005; Volume 49, pp. 17–22. [Google Scholar]

- Isikdag, U.; Underwood, J.; Aouad, G. An investigation into the applicability of building information models in geospatial environment in support of site selection and fire response management processes. Adv. Eng. Inform. 2008, 22, 504–519. [Google Scholar] [CrossRef]

- Kim, J.I.; Koo, B.; Suh, S.; Suh, W. Integration of BIM and GIS for formal representation of walkability for safe routes to school programs. KSCE J. Civ. Eng. 2016, 20, 1669–1675. [Google Scholar] [CrossRef]

- Tashakkori, H.; Rajabifard, A.; Kalantari, M. A new 3D indoor/outdoor spatial model for indoor emergency response facilitation. Build. Environ. 2015, 89, 170–182. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Mbachu, J. An Integrated BIM–GIS Method for Planning of Water Distribution System. ISPRS Int. J. Geo-Inf. 2019, 8, 331. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Deng, Y.; Won, J.; Cheng, J.C.P. An integrated underground utility management and decision support based on BIM and GIS. Autom. Constr. 2019, 107, 102931. [Google Scholar] [CrossRef]

- de Laat, R.; van Berlo, L. Integration of BIM and GIS: The Development of the CityGML GeoBIM Extension. In Advances in 3D Geo-Information Sciences; Kolbe, T.H., König, G., Nagel, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 211–225. ISBN 978-3-642-12670-3. [Google Scholar]

- Del Giudice, M.; Osello, A.; Patti, E. BIM and GIS for district modeling. In eWork and eBusiness in Architecture, Engineering and Construction, Proceedings of the 10th European Conference on Product and Process Modelling, Vienna, Austria, 17–19 Sepetember 2014; TU Wein: Vienna, Austria, 2015; pp. 851–854. [Google Scholar]

- Khan, M.S.; Park, J.; Seo, J. Geotechnical Property Modeling and Construction Safety Zoning Based on GIS and BIM Integration. Appl. Sci. 2021, 11, 4004. [Google Scholar] [CrossRef]

- Park, T.; Kang, T.; Lee, Y.; Seo, K. Project cost estimation of national road in preliminary feasibility stage using BIM/GIS platform. In Computing in Civil and Building Engineering, Proceedings of the International Conference on Computing in Civil and Building Engineering, 2014, 23-25 June 2014; American Society of Civil Engineers: Reston, VA, USA; pp. 423–430.

- Kang, T.W.; Hong, C.H. A study on software architecture for effective BIM/GIS-based facility management data integration. Autom. Constr. 2015, 54, 25–38. [Google Scholar] [CrossRef]

- Bansal, V.K. Application of geographic information systems in construction safety planning. Int. J. Proj. Manag. 2011, 29, 66–77. [Google Scholar] [CrossRef]

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Springer Transactions in Civil and Environmental Engineering. Civil Engineering Applications of Ground Penetrating Radar; Benedetto, A., Pajewski, L., Eds.; Springer International Publishing: Cham, Germany, 2015; ISBN 978-3-319-04812-3. [Google Scholar]

- Manacorda, G.; Persico, R.; Scott, H.F. Design of Advanced GPR Equipment for Civil Engineering Applications. In Civil Engineering Applications of Ground Penetrating Radar; Springer International Publishing: Cham, Germany, 2015; pp. 3–39. [Google Scholar]

- USRadarInc. Surface Imaging System. Available online: https://usradar.com/faq-items/gpr-recommendations/ (accessed on 31 May 2021).

- Lowe, D.G. Distinctive Image Features from Scale-Invariant Keypoints. Int. J. Comput. Vis. 2004, 60, 91–110. [Google Scholar] [CrossRef]

- Snavely, N.; Seitz, S.M.; Szeliski, R. Modeling the World from Internet Photo Collections. Int. J. Comput. Vis. 2008, 80, 189–210. [Google Scholar] [CrossRef] [Green Version]

- Furukawa, Y.; Curless, B.; Seitz, S.M.; Szeliski, R. Towards Internet-scale multi-view stereo. In Proceedings of the 2010 IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Francisco, CA, USA, 13–18 June 2010; pp. 1434–1441. [Google Scholar]

- Furukawa, Y.; Ponce, J. Accurate, Dense, and Robust Multiview Stereopsis. IEEE Trans. Pattern Anal. Mach. Intell. 2010, 32, 1362–1376. [Google Scholar] [CrossRef] [PubMed]

- Economou, N.; Vafidis, A.; Benedetto, F.; Alani, A.M. GPR Data Processing Techniques. In Civil Engineering Applications of Ground Penetrating Radar; Springer International Publishing: Cham, Germany, 2015; pp. 281–297. [Google Scholar]

- Deng, Y.; Cheng, J.C.P.; Anumba, C. A framework for 3D traffic noise mapping using data from BIM and GIS integration. Struct. Infrastruct. Eng. 2016, 12, 1267–1280. [Google Scholar] [CrossRef]

- Sharafat, A.; Khan, M.S.; Latif, K.; Seo, J. BIM-Based Tunnel Information Modeling Framework for Visualization, Management, and Simulation of Drill-and-Blast Tunneling Projects. J. Comput. Civ. Eng. 2021, 35, 04020068. [Google Scholar] [CrossRef]

- Gröger, G.; Kolbe, T.H.; Nagel, C.; Häfele, K.-H. OpenGIS City Geography Markup Language (CityGML) Encoding Standard, Version 2.0.0. Open Geospatial Consortium: Wayland, MA, USA, 2012. [Google Scholar]

- Tsai, C.F.; Xiao, Y.T.; Chen, H.S.; Ye, Y.X.; Wang, C.H.; Liang, T.W. Integration of BIM & GIS to query management on pipeline of building-A case study of dormitory. In Proceedings of the 2017 IEEE International Conference on Applied System Innovation, Sapporo, Japan, 13–17 May 2017; pp. 944–947. [Google Scholar] [CrossRef]

- Khan, M. Assessment Of Structural Design Capability Of Building Information Modeling (BIM) Tools In Building Industry Of Pakistan. J. Mech. Contin. Math. Sci. 2019, 14, 385–401. [Google Scholar] [CrossRef]

- Tanoli, W.A.; Sharafat, A.; Park, J.; Seo, J.W. Damage Prevention for underground utilities using machine guidance. Autom. Constr. 2019, 107, 102893. [Google Scholar] [CrossRef]

- DiBenedetto, S.P.; Mochny, H.R.; Hanson, D.R. Pipeline Case Histories with 2D and 3D Underground Imaging. In Proceedings of the Pipelines 2010, Reston, VA, USA, 28 August–1 September 2010; pp. 1038–1047. [Google Scholar]

- Li, S.; Cai, H.; Abraham, D.M.; Mao, P. Estimating Features of Underground Utilities: Hybrid GPR/GPS Approach. J. Comput. Civ. Eng. 2016, 30, 04014108. [Google Scholar] [CrossRef]

- Barlish, K.; Sullivan, K. How to measure the benefits of BIM-A case study approach. Autom. Constr. 2012, 24, 149–159. [Google Scholar] [CrossRef] [Green Version]

- Won, J.; Lee, G. How to tell if a BIM project is successful: A goal-driven approach. Autom. Constr. 2016, 69, 34–43. [Google Scholar] [CrossRef]

| Parameters | Details |

|---|---|

| Average ground samplingDistance (GSD) | 2.36 cm |

| Area covered | 0.7305 km2 |

| Images | Median of 52,717 key points per image |

| Dataset | 775 out of 775 images geolocated (100%)529 out of 775 images calibrated (68%) |

| Camera optimization | 0.41% relative difference between initial and optimized internal camera parameters |

| Matching | Median of 7579.05 matches per calibrated image |

| Georeferencing | 22 GCPs (22 3D), mean RMS error = 0.074 m |

| Mean reprojection error (pixels) | 0.194 |

| Number of 3D densified points | 52,790,183 |

| Average density (per m3) | 113.36 |

| Qualitative Metrices | Traditional Underground Utility Earthwork Operations | BIM-GIS-Based Integrated Framework |

|---|---|---|

| 2D visualization | Yes | Yes |

| 3D visualization | No | Yes |

| Quantity takeoff | Manual | Automated |

| Material information | Basic | Detailed |

| Data sharing | Manual | Automated |

| Excavator operator visualization | No | Yes |

| Utility clash analysis | Manual (hard) | Automated (easy) |

| Design change | Manual | Automated |

| Facility management | No | Yes |

| Quantitative Metrices | BIM-GIS-Based Integrated Framework Qualitative Performance |

|---|---|

| Total utilities excavated | 47 |

| Utility strikes | 0 |

| Safety accidents | 0 |

| Utility clash identified | 7 |

| Reworks | 2 |

| Additional utility identification | 5 |

| Missed utility identification | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharafat, A.; Khan, M.S.; Latif, K.; Tanoli, W.A.; Park, W.; Seo, J. BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations. Appl. Sci. 2021, 11, 5721. https://doi.org/10.3390/app11125721

Sharafat A, Khan MS, Latif K, Tanoli WA, Park W, Seo J. BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations. Applied Sciences. 2021; 11(12):5721. https://doi.org/10.3390/app11125721

Chicago/Turabian StyleSharafat, Abubakar, Muhammad Shoaib Khan, Kamran Latif, Waqas Arshad Tanoli, Wonyoung Park, and Jongwon Seo. 2021. "BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations" Applied Sciences 11, no. 12: 5721. https://doi.org/10.3390/app11125721

APA StyleSharafat, A., Khan, M. S., Latif, K., Tanoli, W. A., Park, W., & Seo, J. (2021). BIM-GIS-Based Integrated Framework for Underground Utility Management System for Earthwork Operations. Applied Sciences, 11(12), 5721. https://doi.org/10.3390/app11125721