2.1. Construction and Theoretical Values of the Swing

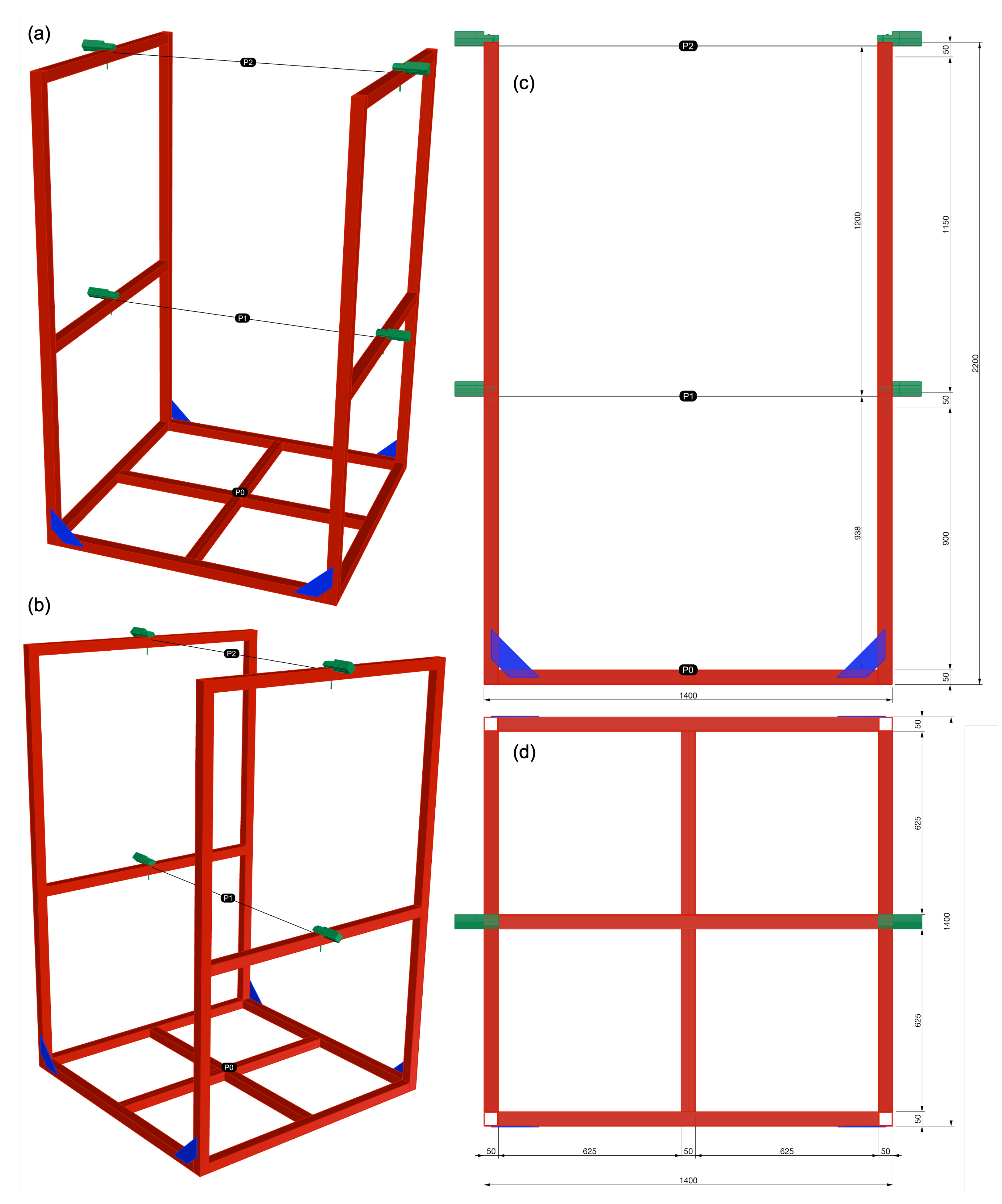

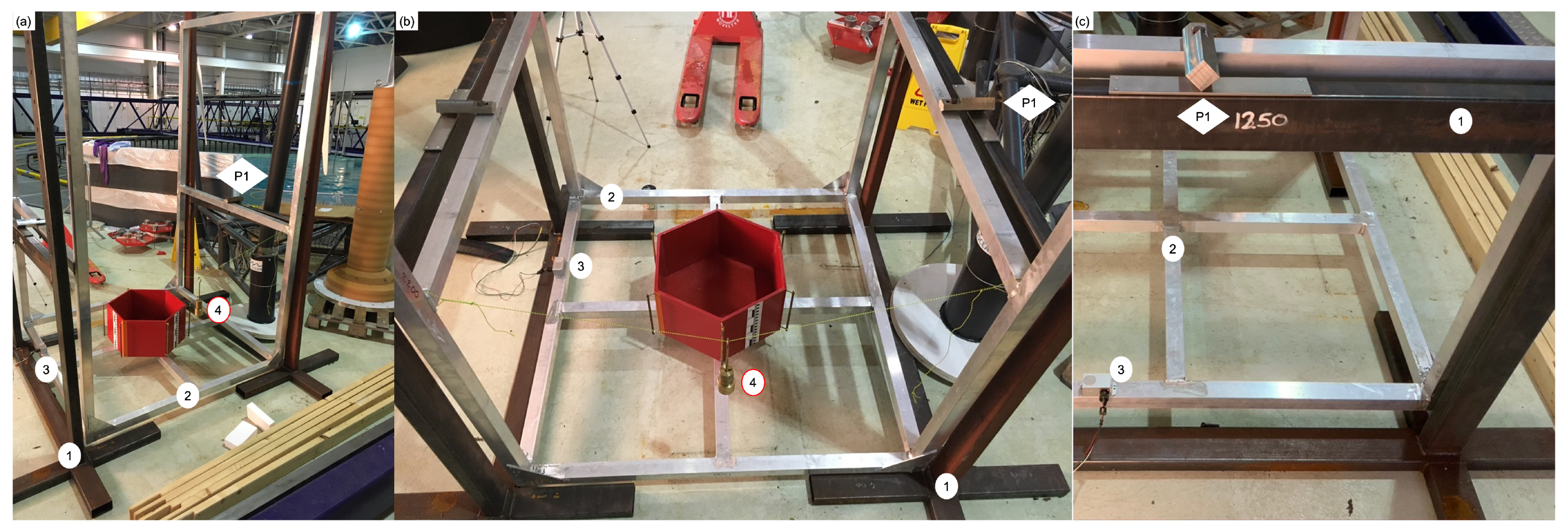

The newly constructed swing is split into two parts: (1) support structure and (2) the swing itself.

Figure 1 presents an overview of the experimental set-up. The support structure is made of two identical steel frames providing a stable support due to its mass and the extended footprint. It can be moved by two persons and allows the use of two different pivot axes of the swing. This oscillating part is made of aluminium to reduce the total mass of the moving section. It has an inner spacing of 1.3 by 1.3 m and is open at the top to enable crane access. The blade edges are constructed of a quadratic stainless steel profile, which is machined to ensure a sharp edge by mounting it with an angle of 45

onto the aluminium profiles. Those parts are coloured green in

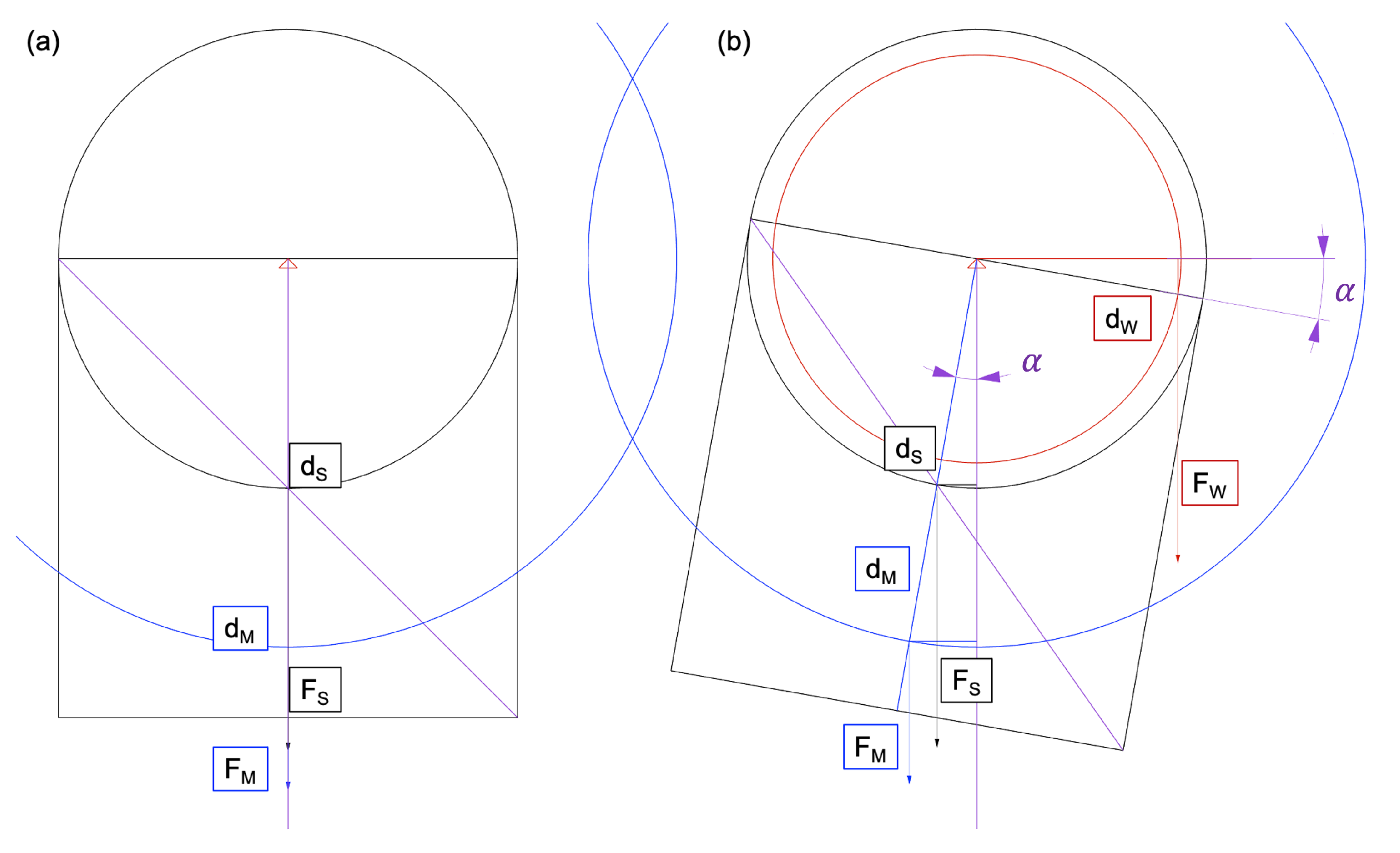

Figure 2, which presents the dimensions of the swing.

The values presented in

Table 1 are theoretical values based on the CAD model [

30] constructed with the software Rhinoceros. The only exception is the mass of the inclinometer (

Section 2.2), which is measured with a typical length of cable. The sum of the theoretical masses is 41.913 kg, which is slightly lower than the measured value of 41.980 kg (measurement conducted without the approximately 0.3 kg for the inclinometer). This difference may be caused by the weld bead at the bottom of the structure, which is neglected in this theoretical approximation. Based on these values, the total centre of gravity (CG) is 72.2 mm (

Table 1) under the pivot axis P1 and 1272.2 mm relative to P2 (

Figure 2). A value of 64.4 mm is found based on the theoretical mass of the swing (neglecting the inclinometer). The measured mass of the swing gives a value 0.067 kg greater than the theoretical value. This calculation is based on the assumption of a point mass located a half profile under P0 and half inclinometer over P0. The comparison with the measurement of the CG is presented in

Section 3.1 and

Section 3.3 focuses on the evaluation of the oscillation period, which leads to the calculation of the MI.

2.2. Measurement Instrument

Two different measurement systems are deployed to observe the inclination and the oscillation of the swing: (a) inertial inclinometer and (b) the motion capturing system. The latter is included as a verification instrument and covers oscillation for which the chosen inclinometer is not fast enough. It would not be required for routine deployment of the swing. A laser level helps to reduce the effort in the installation phase especially when an additional model is loaded in the swing.

The inclination of the swing is measured with a gravity referenced inclinometer provided by Sherborne (model LOCS 3) [

31]. Such an instrument is typically used in industrial applications including bore-hole mapping, pipeline levelling and observation of big structures such as dams, ships or barges as well as bridge deformation [

32] and medical applications for precise alignment of imaging systems [

33]. The measurement range of the inertial inclinometer covers ±3

resulting in a full range output (FRO) of 6

. Based on the manufacturer’s information [

31], the non-linearity (NL) of 0.05% of FRO and the non-repeatability (NR) 0.02% of FRO, which results in a

of

and

of

. 0.2 arc seconds is the resolution of the instrument, which is equal to

. The output voltage is captured by a National Instruments NI9220 differential voltage acquisition module operating with a measurement frequency of 256 Hz.

Beside the primary instrument, namely, the highly accurate gravity-referenced inclinometer, additional measurements are conducted with the motion capturing system provided by Qualisys. In this particular case the smaller system with four Oqus 300+ cameras is used [

29]. The four Oqus 300+ are arranged in an approximate semicircle on one side of the swing and captures the motion of markers with a very high accuracy less than 1 mm. The measurement frequency is set to 256 Hz, which is identical to the inertial inclinometer.

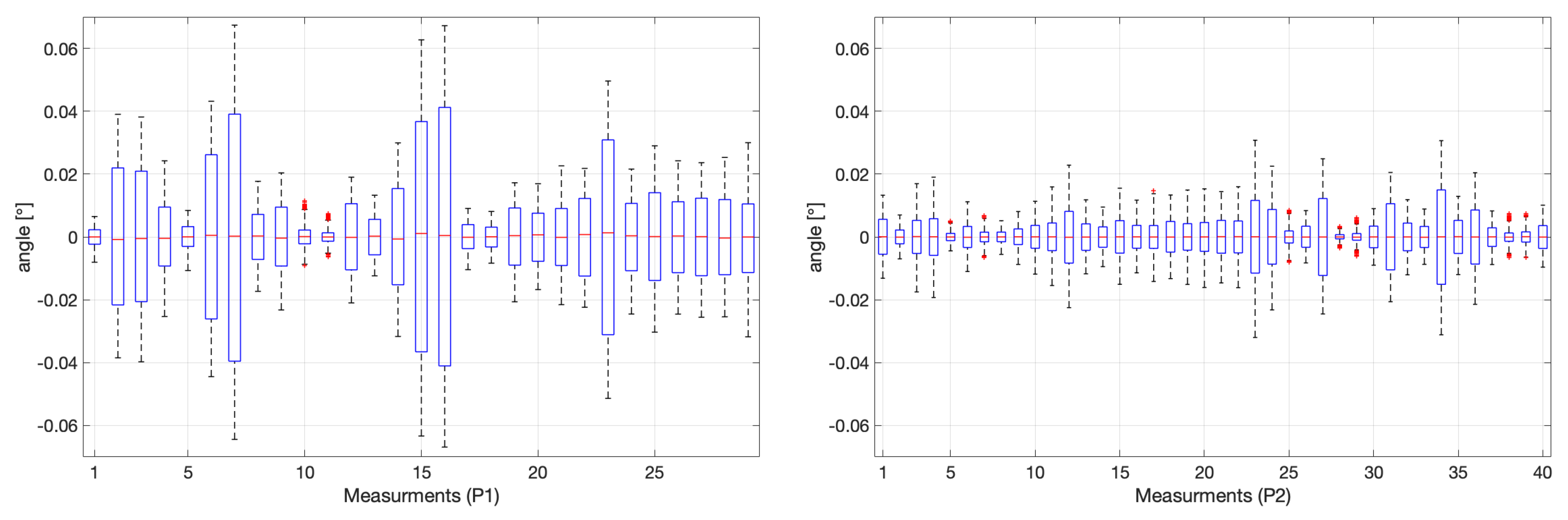

The deployment of the Qualisys motion capturing system brings an additional benefit for models, which are investigated in the wave and current tank and are thus typically already fitted with the necessary markers. Based on this the centre of gravity can be measured with a high accuracy in relation to the rigid body definition. For this current paper the swing itself is in the focus and hence additional markers are placed on the structure. The aim of the comparison is to provide an independent verification of the inclinometer and capture oscillations which are too fast for the instrument. A synchronisation of both systems was not conducted with a trigger signal but started manually at the same time, which is acceptable for the specific application. The comparison of the two instruments showed that the difference between the two measured inclination angles is smaller than or in the range of the remaining observed oscillation of the angle in a close to steady position of the swing.

2.3. Measurement Procedure

The swing itself is made of aluminium and has a mass of around 42 kg. This allows it to be safely handled by two trained persons and the crane is not needed. A pallet cart can be used for the installation at the pivot axis at P1 as shown in

Figure 1d. For both of the different pivot axis options, shown in

Figure 1 and

Figure 2, the swing rests on two cutting edges on top of the support structure, which only requires a very small adjustment. As part of the initial installation as well as after each change of the pivot axis, the inertial inclinometer is moved so that it is orientated parallel to the pivot axis. These measurements and the following adjustments ensure that the swing sits level on the support structure. After this, the instrument is brought back to the position shown in

Figure 1a to measure the angle around the pivot axis P1 or P2. It is placed on the level P0 (

Figure 2) aligned to the side of the swing. After the exact positioning of the device on this plane to reach an initial measurement close to 0

, it is secured with electrical tape to ensure that it stayed in place. With this, the swing is ready for use.

The specific construction allows for lifting of bigger models into the swing with the crane or investigation of taller models, for example, the floating wind turbine model which can be seen in the background of

Figure 1a. The width is limited to 1.3 m; and the other dimensions do not have a hard limit [

30]. Ideally, the investigated model is placed so that the swing stays in the zero position, which might be difficult to achieve for a heavier model. This can be corrected with an offset in the calculations introduced in

Section 2.4.

The next steps are dependent on the purpose of the investigation but, typically, the centre of gravity (CG) has to be measured first. Therefore, a rope is attached on the cross profile of the swing, which holds the relevant pivot axis at a distance of 0 to 0.65 m. This rope holds the hanger for the calibration weight. The smallest step used here is 50 g. After loading the swing or changing the mass, the oscillation of the swing is damped with the two finger tips of the operating person to introduce a certain amount of damping to achieve a new equilibrium faster. The angle is measured for typically 64 s to ensure that the magnitude of the remaining oscillation was captured and can be averaged out. This is followed by a further change of the mass until the maximum range of 3

is reached. Control measurements with at least one additional distance between rope and pivot axis are advisable. This ensures that potential user errors can be detected. The calculation of the CG is introduced in

Section 2.4 and

Section 3.1 presents the results for the empty swing which is expanded for an example model in

Section 3.2.

The distance of the CG as well as the mass of the object are a constant value and, by oscillating around a point/an axis, the moment of inertia (MI) can be calculated, knowing the period of the oscillation.

Section 2.4 provides the requisite mathematical background and

Section 3.3 compares the measurement of the empty swing with the theoretical values. For the presented experimental set-up, the initial inclination should be limited to

based on the range of the inertial inclinometer. If the changes are too fast, the reading of the instrument is not correct and underestimates the actual angles. This is to be expected given that the device is designed for high accuracy measurements of slow changing objects. The limitations were reached for oscillations around the pivot axis P2. In those cases, the motion capturing system can provide the observation and check with a stopwatch allows a further independent verification.

2.4. Basic Equations

Two different sets of equations are needed to calculate the centre of gravity (CG) as well as the moments of inertia (MI). The location of CG is based on steady measurements of an inclined swing due to added calibration weights. Knowing this value allows for the calculation of the MI based on the period or frequency of an oscillating system. The presented experimental set-up enabled measurements to be conducted with two different pivot points, but is limited to one direction at a time.

For the calculation of the CG, the starting point is Newton’s first law and the assumption that the system is in equilibrium and not moving. A zero acceleration results in a zero sum of forces in all directions. Furthermore, it can be assumed that the system can be reduced to a two-dimensional problem, hence all imbalances along the pivot axis are absorbed by the small changes in the reacting forces at the blade edges. Ideally, each side holds half of the sum of the mass of the swing

, the additional model

as well as the additional calibration weights

. The latter is applied to incline the swing with an angle of

. The purpose of the following equations is to connect the individual forces

F and distances or levers

d based on

i measurements with different

at

. To connect those, the moment balance of one example configuration is investigated in

Figure 3. In this example a large angle

of 10

is applied and the distances of the chosen to be easily identifiable.

The sum of the moments/torques around the pivot point (red triangle in

Figure 3) can be calculated based on the following equation:

All forces in this equation are known by weighting the model as well as the swing and for the additional

specific calibration weights are used. The distances

and

describe the distance of the pivot centre to the centre of gravity of the swing or the model, respectively. The distance

is also constant and predefined. By using the solution with the rope, the added force always acts at the same point and with a fixed distance to the pivot point. Alternatively, the calibration weights could be placed on the swing but in this particular case, the specific location of the CG for the masses has to be calculated, which could also result in inaccuracies. Furthermore, the angle

is the key output of the measurement and can be calculated based on the following equation:

The distance

should be the only unknown for future applications, which can fitted to a point cloud of different additional masses

at difference distances

. Therefore, the swing is analysed without an additional model (

) and the distance

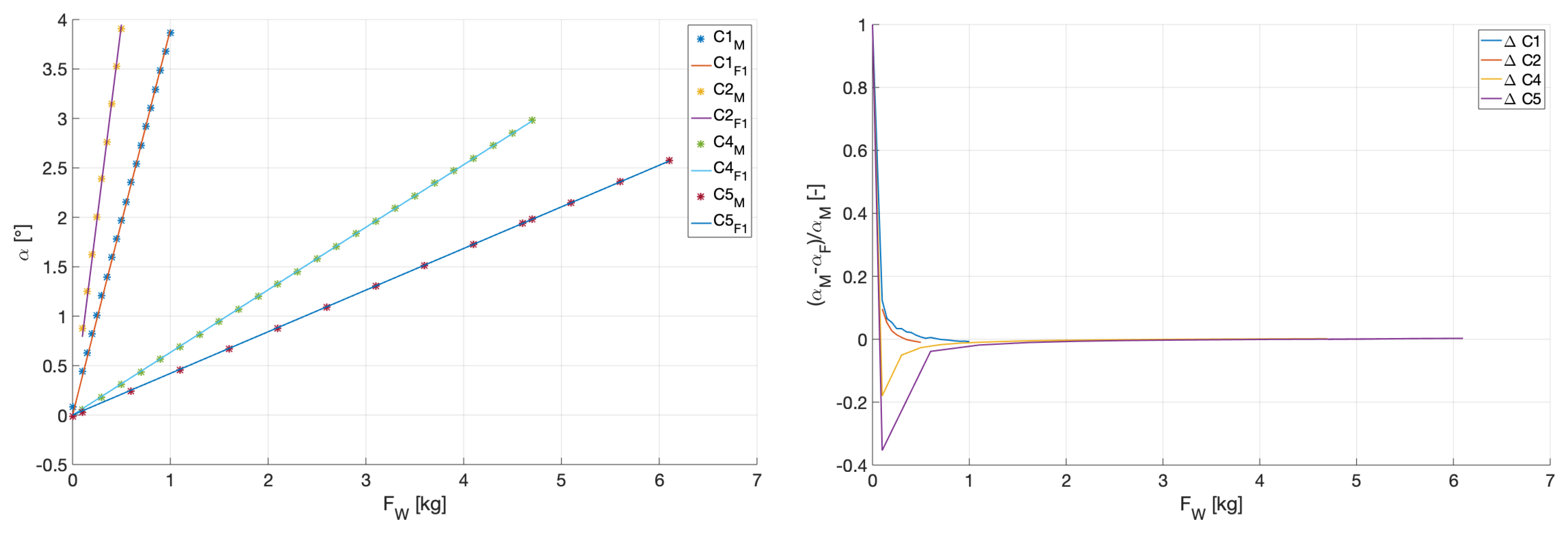

representing the distance between the CG of the swing to the pivot point can be calculated based on the following equation:

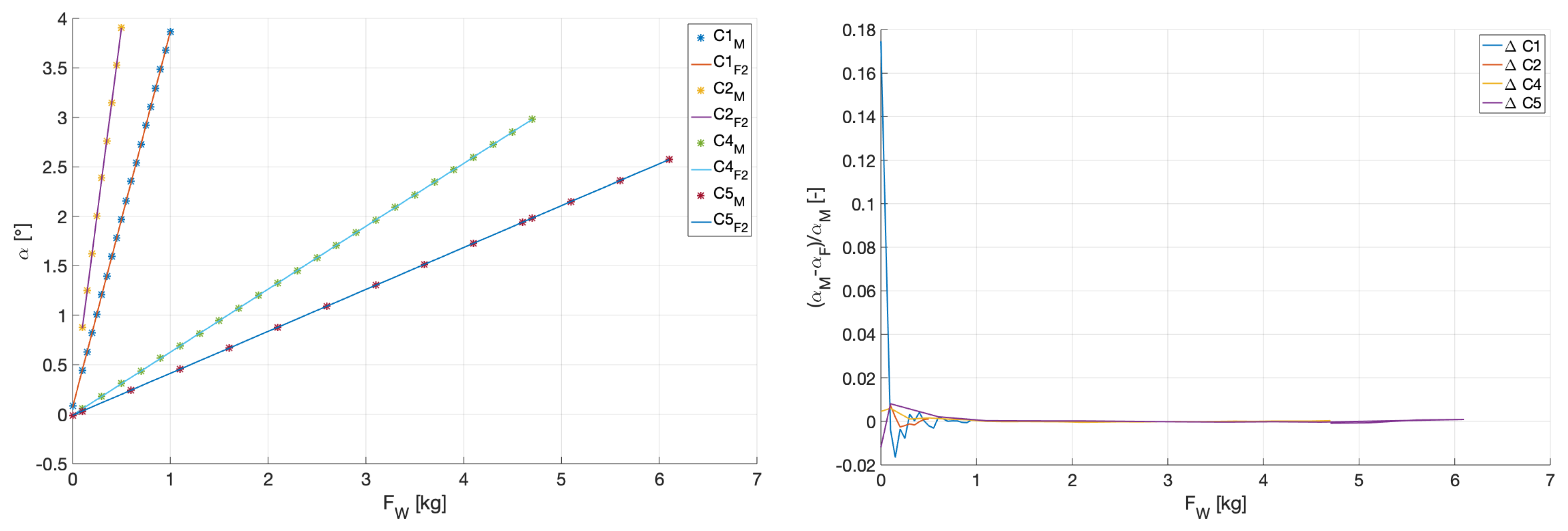

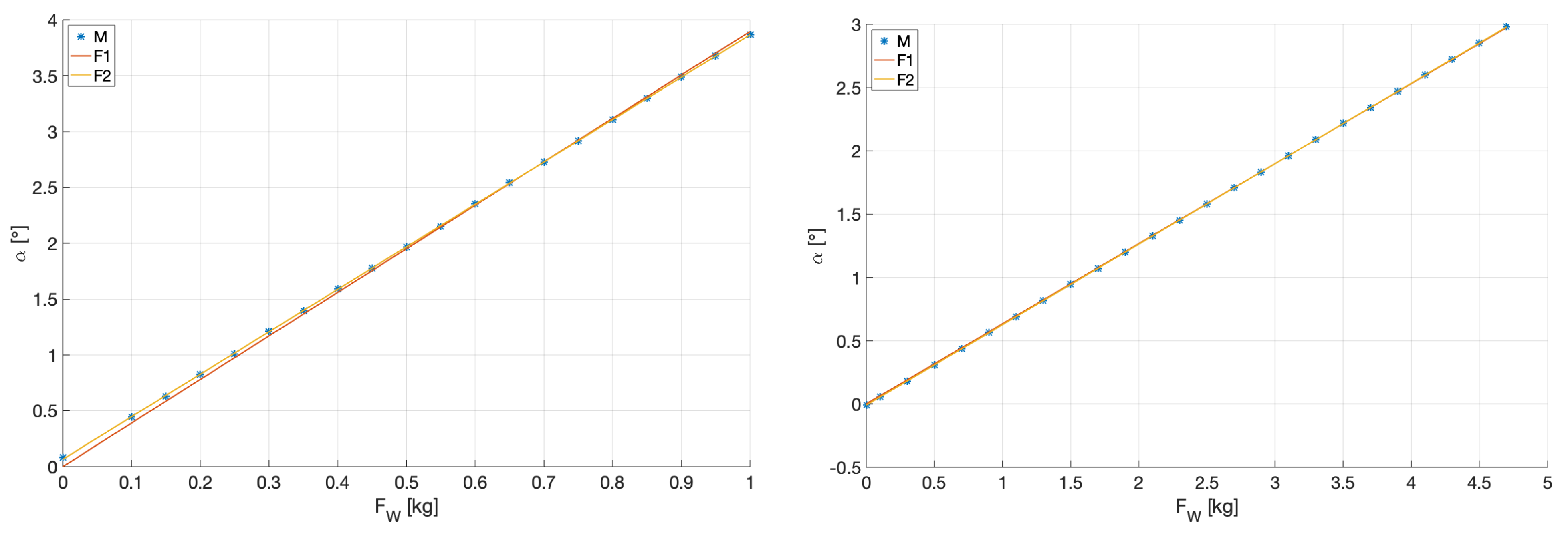

This equation is utilised and further investigated in

Section 3.1 based on measurements of a stable new equilibrium of the swing due the additional calibration weights. In a second step, the moment of inertia (MI) is evaluated based on the period of an oscillating swing based on the following equation for a free oscillating pendulum around a horizontal axis [

1]:

The variable

, representing the MI around the pivot axis, can be calculated based on the period of the oscillation

T, the mass of the rigid body

m, the constant gravity acceleration

g and the distance

R (length between the pivot point and the CG), which is equal to

from the previous CG calculation. The period

T of a damped oscillation can be evaluated based on:

In this case, the time depending amplitude

is identical to the measured angle

.

t represents the time. The oscillation starts with the initial amplitude

A. Two further constants

and

represent the decay constant and the phase angle. The dynamic measurement provides a time series of angles

in relation to the time vector

t, which can be used to fit Equation (

5). For the further analysis, only the time period

T is needed and all other constants can be used as control values.

The resulting moment of inertia output based on Equation (

4) is referenced around the pivot point and, to compare both pivot axes, the parallel axis theorem is used to calculate the MI around the centre of gravity

I in relation to the

, mass

m and distance

as following:

This connection is further used to calculate the MI of the empty swing (

Section 3.3). The specific MI around the two different pivot points are important for the further usage of this experimental set-up to evaluate the MI of added model

. The connection is shown in Equation (

7) for the pivot point P1 and can be transformed to alternative reference points based on the parallel axis theorem Equation (

6).

The presented equations for the calculation of the individual vales for CG as well as the MI are further used to analyse the conducted measurements. All those analyses are conducted with the software MATLAB.