The Structure and Mechanical Properties of Hemp Fibers-Reinforced Poly(ε-Caprolactone) Composites Modified by Electron Beam Irradiation

Abstract

1. Introduction

2. Experimental

2.1. Materials

- Poly(ε-caprolactone) (PCL), type CAPA6800 with a measured melt flow rate (MFR) of 5.1 g/10 min (2.16 kg, 190 °C), density of 1.15 g/cm3 and average molecular weight of ca. 82 kDa was supplied by Ingevity UK Ltd. (Warrington, UK);

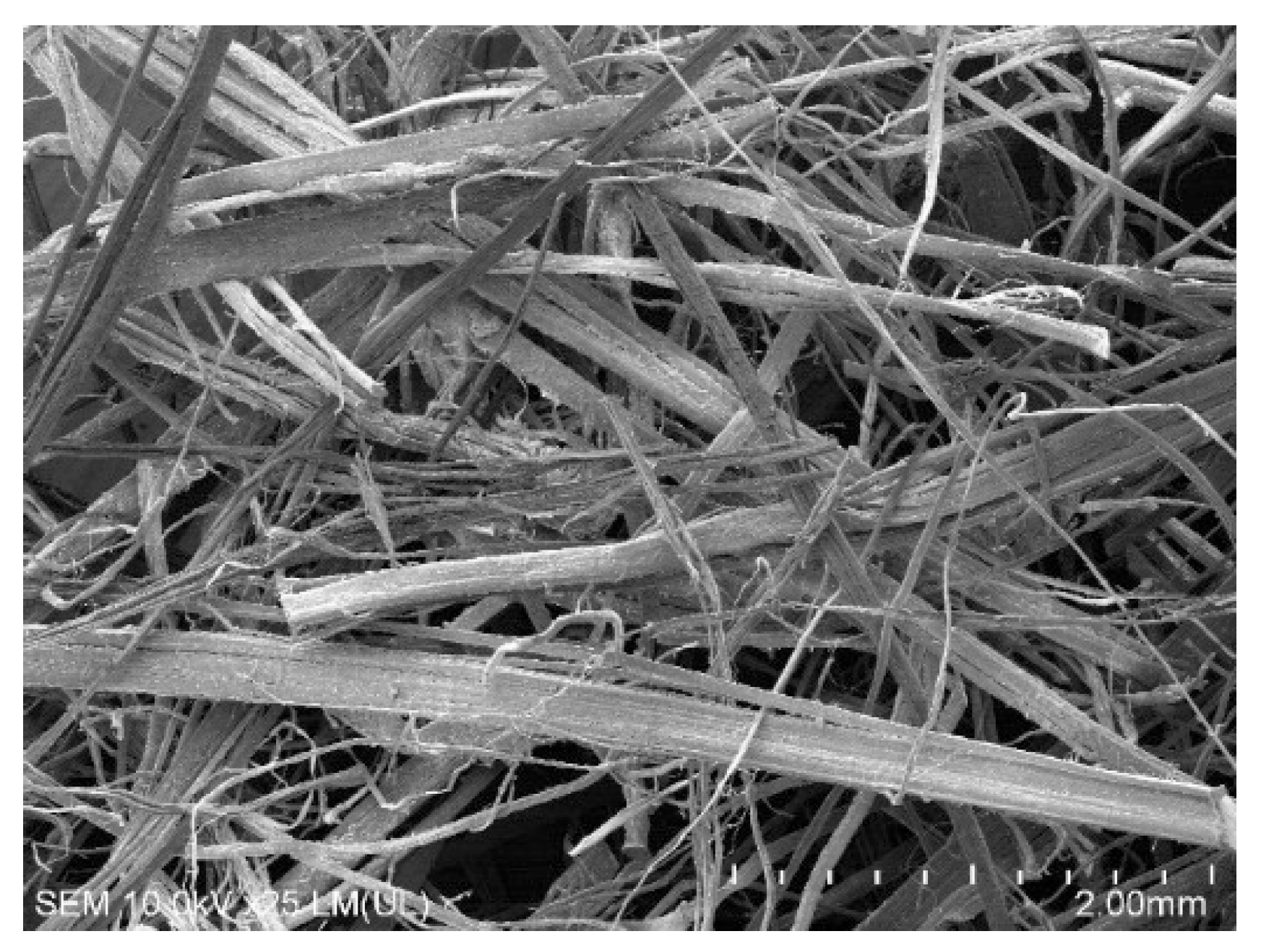

- Natural hemp fibers (HF), at 6 mm long, were purchased from the Institute of Natural Fibers and Medicinal Plants in Poznan (Poland). The cut hemp fibers’ structure is shown in Figure 1 were applied as the PCL filler.

2.2. Apparatus

- Co-rotating twin screw extruder of type BTSK 20/40D (Bühler, Germany), equipped with 20-mm diameter screws and L/D ratio of 40 intended to produce granulated PCL composites;

- Screw injection molding machine of type Battenfeld Plus 35/75 (Battenfeld GmbH, Solingen, Germany), equipped with 22-mm diameter screw and L/D ratio of 17 designed to produce standard dumbbell-shaped and bar-shaped specimens;

- Linear accelerator of type Elektronika 10/10 (Institute of Nuclear Chemistry and Technology in Warsaw, Poland) with energy of electrons 10 MeV and electron beam power 10 kW for irradiation of PCL composites;

- Shaker of type Unimax 1010 (Heidoplh, Germany) was used to extract fibers from obtained composites;

- Scanning electron microscope (SEM) of type Hitachi SU8010 (Hitachi, Japan) was used to examine the structure of HF as well as surface geometrical structure of sample fractures;

- Tensile testing machine of type TIRAtest 27025 (TIRA Maschinenbau GmbH, Schalkau, Germany) was used to examine mechanical properties under static tension and static three-point bending;

- Pendulum Impact Tester of type IMPats-15 (ATS FAAR, Novegro-Tregarezzo, Italy) was intended for the determination of Charpy impact strength.

2.3. Methods

3. Results and Discussion

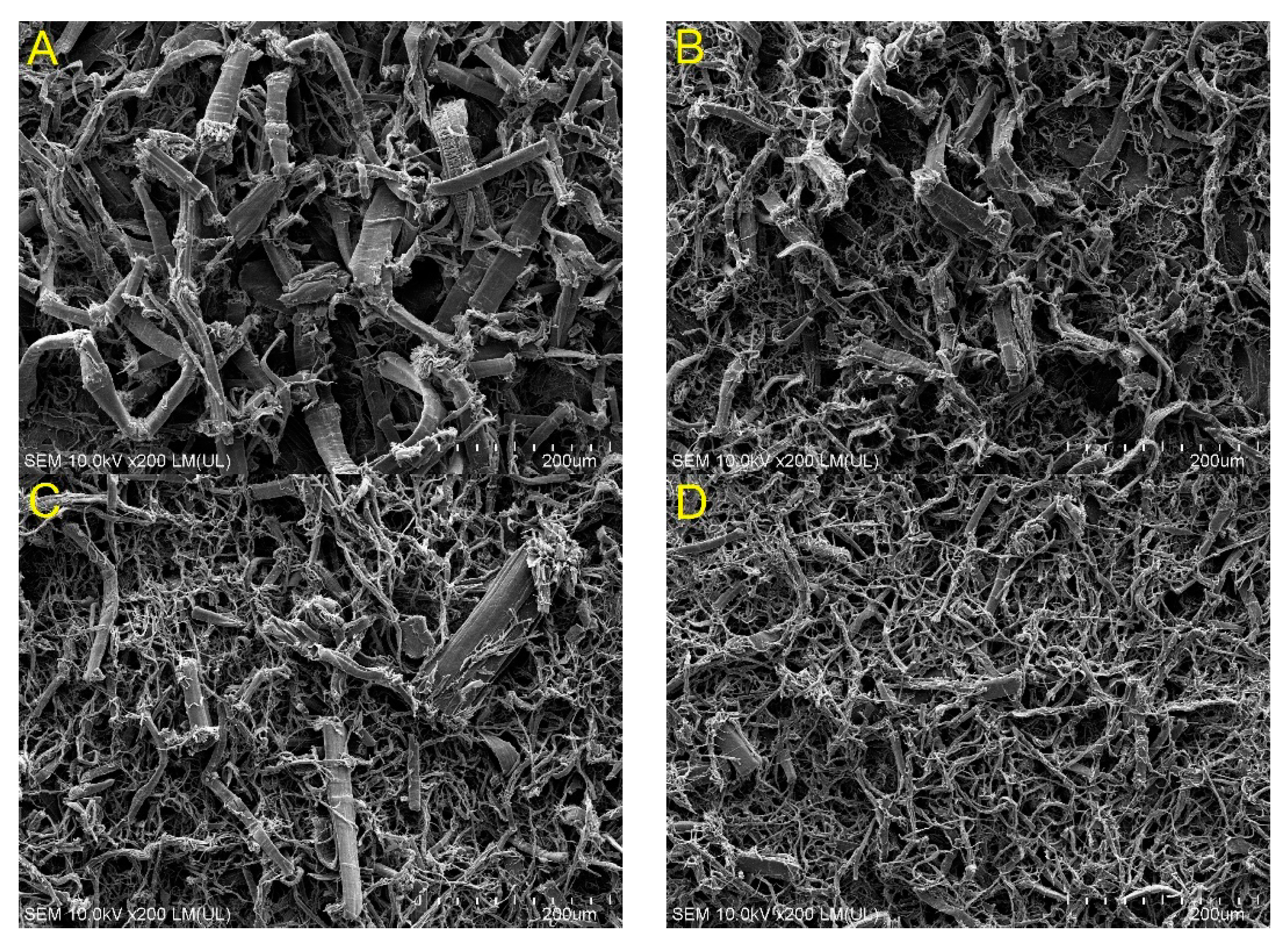

3.1. HF Structure in Obtained Composites

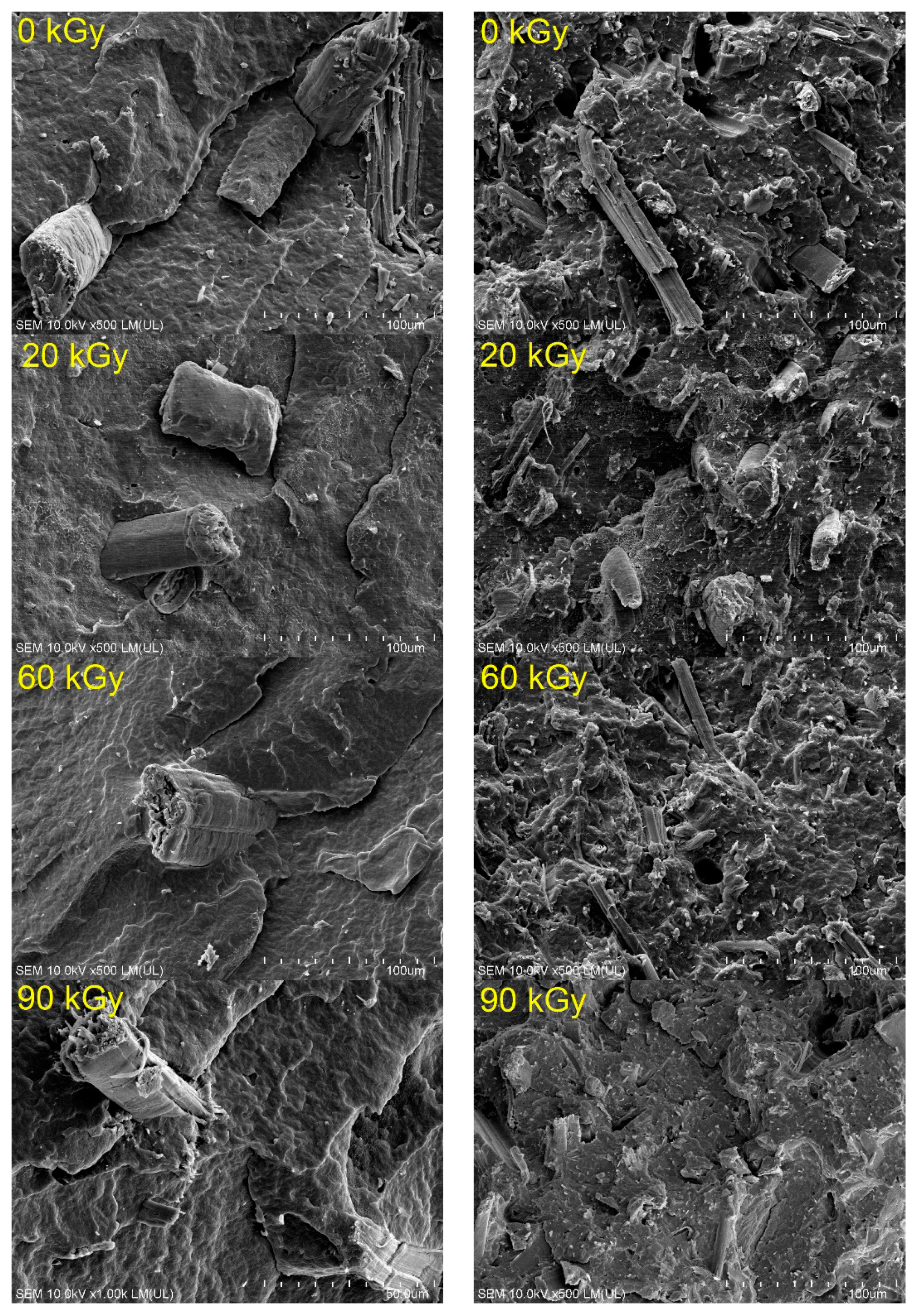

3.2. Composites Structure

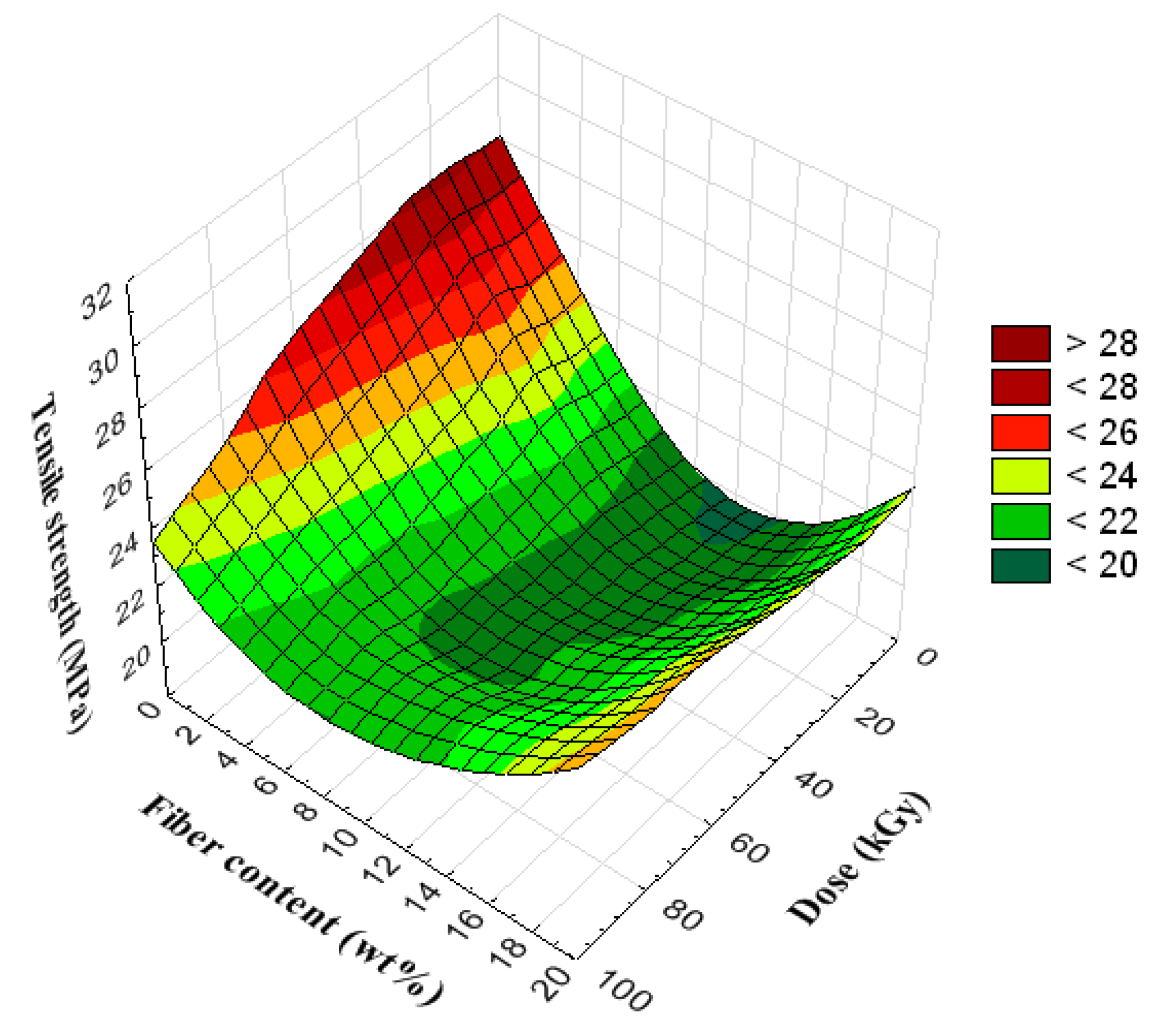

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohamed, R.M.; Yusoh, K. A review on the recent research of polycaprolactone (PCL). Adv. Mater. Res. 2016, 1134, 249–255. [Google Scholar] [CrossRef]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer—Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef]

- Labet, M.; Thielemans, W. Synthesis of polycaprolactone: A review. Chem. Soc. Rev. 2009, 38, 3484–3504. [Google Scholar] [CrossRef]

- Bastioli, C.; Cerruti, A.; Guanella, I.; Romano, G.C.; Tosin, M.J. Physical state and biodegradation behavior of starch-polycaprolactone systems. Environ. Polym. Degrad. 1995, 3, 81–95. [Google Scholar] [CrossRef]

- Amass, W.; Amass, A.; Tighe, B. A Review of Biodegradable Polymers: Uses, Current Developments in the Synthesis and Characterization of Biodegradable Polyesters, Blends of Biodegradable Polymers and Recent Advances in Biodegradation Studies. Polym. Int. 1998, 47, 89–144. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Follaina, N.; Belbekhouchea, S.; Brasb, J.; Siqueirab, G.; Chappeya, C.; Maraisa, S.; Dufresne, A. Tunable gas barrier properties of filled-PCL film by forming percolating cellulose network. Colloids Surf. A 2018, 545, 26–30. [Google Scholar] [CrossRef]

- Mellinas, C.; Ramos, M.; Grau-Atienza, A.; Jordà, A.; Burgos, N.; Jiménez, A.; Serrano, E.; Garrigós, M.C. Biodegradable Poly(ε-Caprolactone) Active Films Loaded with MSU-X Mesoporous Silica for the Release of α-Tocopherol. Polymers 2020, 12, 137. [Google Scholar] [CrossRef] [PubMed]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Sonchaeng, U.; Iniguez-Franco, F.; Auras, R.; Selke, S.; Rubino, M.; Lim, L.T. Poly(lactic acid) mass transfer properties. Prog. Polym. Sci. 2018, 86, 85–121. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iniguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliver. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Ahmed, J.; Varshney, S.K. Polylactides—Chemistry, Properties and Green Packaging Technology: A Review. Int. J. Food Prop. 2011, 14, 37–58. [Google Scholar] [CrossRef]

- Lim, L.T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Ge, C.; Lansing, B.; Lewis, C.L. Thermoplastic starch and poly(vinyl alcohol) blends centered barrier film for food packaging applications. Food Packag. Shelf Life 2021, 27, 100610. [Google Scholar] [CrossRef]

- Cuevas-Carballo, Z.B.; Duarte-Aranda, S.; Canché-Escamilla, G. Properties and Biodegradability of Thermoplastic Starch Obtained from Granular Starches Grafted with Polycaprolactone. Int. J. Polym. Sci. 2017, 2017. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic starch processing and characteristics—A review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef]

- Bajer, K.; Stasiek, A.; Raszkowska-Kaczor, A.; Bajer, D. Extrusion of thermoplastics starch with twin-screw extruders. Przem. Chem. 2014, 93, 192–195. [Google Scholar]

- Averous, L.; Moro, L.; Dole, P.; Fringant, C. Properties of thermoplastic blends: Starch-polycaprolactone. Polymer 2000, 41, 4157–4167. [Google Scholar] [CrossRef]

- Avella, M.; Errico, M.E.; Laurienzo, P.; Martuscelli, E.; Raimo, M.; Rimedio, R. Preparation and characterisation of compatibilised polycaprolactone/starch composites. Polymer 2000, 41, 3875–3881. [Google Scholar] [CrossRef]

- Wu, C.S. Physical properties and biodegradability of maleated-polycaprolactone/starch composite. Polym. Degrad. Stab. 2003, 80, 127–134. [Google Scholar] [CrossRef]

- Chavalitpanya, K.; Phattanarudee, S. Poly(Lactic Acid)/Polycaprolactone Blends Compatibilized with Block Copolymer. Energy Procedia 2013, 34, 542–548. [Google Scholar] [CrossRef]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Dell’Erba, R.; Groeninckx, G.; Maglio, G.; Malinconico, M.; Milgliozzi, A. Immiscible polymer blends of semicrystalline biocompatible components: Thermal properties and phase morphology analysis of PLLA/PCL blends. Polymer 2001, 42, 7831–7840. [Google Scholar] [CrossRef]

- Patrício, T.; Domingos, M.; Gloria, A.; Bártolo, P. Characterisation of PCL and PCL/PLA scaffolds for tissue engineering. Procedia CIRP 2013, 5, 110–114. [Google Scholar] [CrossRef]

- Sousa, F.M.; Costa, A.R.M.; Reul, L.T.; Cavalcanti, F.B.; Carvalho, L.H.; Almeida, T.G.; Canedo, E.L. Rheological and thermal characterisation of PCL/PBAT blends. Polym. Bull. 2018, 76, 1573–1593. [Google Scholar] [CrossRef]

- Daenin, R.D.; Zhang, Z.-B. Polycaprolactone as permanent plasticizer for poly(vinyl chloride). J. Vinyl Technol. 1984, 6, 18–21. [Google Scholar] [CrossRef]

- Saeed, K.; Park, S.Y. Preparation and Properties of Polycaprolactone/Poly(Butylene Terephthalate) Blend. Iran. J. Chem. Chem. Eng. 2010, 29, 77–81. [Google Scholar]

- Liang, J.Z.; Duan, D.R.; Tang, C.Y.; Tsui, C.P.; Chen, D.Z. Flexural Properties of Poly-L-Lactide and Polycaprolactone Shape Memory Composites Filled with Nanometer Calcium Carbonate. J. Macromol. Sci. B 2013, 52, 964–972. [Google Scholar] [CrossRef]

- Wu, T.; Xie, T.; Yang, G. Preparation and characterization of poly(ε-caprolactone)/Na+-MMT nanocomposites. Appl. Clay Sci. 2009, 45, 105–110. [Google Scholar] [CrossRef]

- Van der Schueren, L.; De Meyer, T.; Steyaert, I.; Ceylan, O.; Hemelsoet, K.; Van Speybroeck, V.; De Clerck, K. Polycaprolactone and polycaprolactone/chitosan nanofibres functionalised with the pH-sensitive dye Nitrazine Yellow. Carbohydr. Polym. 2013, 91, 284–293. [Google Scholar] [CrossRef] [PubMed]

- Arbelaiz, A.; Fernández, B.; Valea, A.; Mondragon, I. Mechanical properties of short flax fibre bundle/poly(ε-caprolactone) composites: Influence of matrix modification and fibre content. Carbohydr. Polym. 2006, 64, 224–232. [Google Scholar] [CrossRef]

- Shibata, M.; Yosomiya, R.; Ohta, N.; Sakamoto, A.; Takeishi, H. Poly(ε-caprolactone) composites reinforced with short abaca fibres. Polym. Compos. 2003, 11, 359–367. [Google Scholar] [CrossRef]

- Pan, P.; Zhu, B.; Dong, T.; Serizawa, S.; Iji, M.; Inoue, Y. Kenaf fiber/poly(ε-caprolactone) biocomposite with enhanced crystallization rate and mechanicalproperties. J. Appl. Polym. Sci. 2008, 107, 3512–3519. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczyńska, M.; Moraczewski, K.; Malinowski, R.; Jagodziński, B.; Żenkiewicz, M. Mechanical properties and biodegradability of flax fiber-reinforced composite of polylactide and polycaprolactone. Polimery 2018, 63, 603–610. [Google Scholar] [CrossRef]

- Berzin, F.; Vergnes, B.; Beaugrand, J. Evolution of lignocellulosic fibre lengths along the screw profile during twin screw compounding with polycaprolactone. Compos. Part A Appl. Sci. Manuf. 2014, 59, 30–36. [Google Scholar] [CrossRef]

- Duan, K.; Chen, H.; Huang, J.; Yu, J.; Liu, S.; Wang, D.; Li, Y. One-step synthesis of amino-reserved chitosan-graft-polycaprolactone as a promising substance of biomaterial. Carbohydr. Polym. 2010, 80, 498–503. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, L.; Li, C.; Zhang, D.; Xiao, Y.; Guan, G.; Zhu, W. A novel and simple procedure to synthesize chitosan-graft-polycaprolactone in an ionic liquid. Carbohydr. Polym. 2013, 94, 505–510. [Google Scholar] [CrossRef]

- Li, Z.; Tan, B.H. Towards the development of polycaprolactone based amphiphilic block copolymers: Molecular design, self-assembly and biomedical applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 45, 620–634. [Google Scholar] [CrossRef] [PubMed]

- Lipik, V.T.; Widjaja, L.K.; Liow, S.S.; Abadie, M.J.M.; Venkatraman, S.S. Effects of transesterification and degradation on properties and structure of polycaprolactone-polylactide copolymers. Polym. Degrad. Stab. 2010, 95, 2596–2602. [Google Scholar] [CrossRef]

- Narkis, M.; Sibony-Chaouat, S.; Siegmann, A.; Shkolnik, S.; Bell, J.P. Irradiation effects on polycaprolactone. Polymer 1985, 26, 50–54. [Google Scholar] [CrossRef]

- Malinowski, R. Mechanical properties of PLA/PCL blends crosslinked by electron beam and TAIC additive. Chem. Phys. Lett. 2016, 662, 91–96. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.E.; Beaugrand, J. Development of sustainable biodegradable lignocellulosic hemp fiber/polycaprolactone biocomposites for light weight applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Beaugrand, J.; Zhang, Z.; Zekonyte, J. Characterization of Nano-Mechanical, Surface and Thermal Properties of Hemp Fiber-Reinforced Polycaprolactone (HF/PCL) Biocomposites. Appl. Sci. 2020, 10, 2636. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Bourmaud, A.; Berzin, F.; Almansour, F.; Zhang, Z.; Shah, D.U.; Beaugrand, J. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind. Crop. Prod. 2018, 126, 394–402. [Google Scholar] [CrossRef]

- Beaugrand, J.; Berzin, F. Lignocellulosic Fiber Reinforced Composites: Influence of Compounding Conditions on Defibrization and Mechanical Properties. J. Appl. Polym. Sci. 2013, 128, 1227–1238. [Google Scholar] [CrossRef]

- Wahit, M.U.; Akos, N.I.; Laftah, W.A. Influence of natural fibers on the mechanical properties and biodegradation of poly(lactic acid) and poly(ε-caprolactone) composites: A review. Polym. Compos. 2013, 34, 763–768. [Google Scholar] [CrossRef]

- Cottam, E.; Hukins, D.W.L.; Lee, K.; Hewitt, C.; Jenkins, M.J. Effect of sterilisation by gamma irradiation on the ability of polycaprolactone (PCL) to act as a scaffold material. Med. Eng. Phys. 2009, 31, 221–226. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Rehim, H.A.; Yoshii, F.; Kume, T. Modification of polycaprolactone in the presence of polyfunctional monomers by irradiation and its biodegradability. Polym. Degrad. Stab. 2004, 85, 689–695. [Google Scholar] [CrossRef]

- Yoshii, F.; Darwis, D.; Mitomo, H.; Makuuchi, K. Crosslinking of poly(ε-caprolactone) by radiation technique and its biodegradability. Radiat. Phys. Chem. 2000, 57, 417–420. [Google Scholar] [CrossRef]

- Malinowski, R. Effect of electron radiation and triallyl isocyanurate on the average molecular weight and crosslinking of poly(ε-caprolactone). Polym. Adv. Technol. 2016, 27, 125–130. [Google Scholar] [CrossRef]

- Malinowski, R.; Rytlewski, P.; Janczak, K.; Raszkowska-Kaczor, A.; Moraczewski, K.; Stepczyńska, M.; Żuk, T. Studies on functional properties of PCL films modified by electron radiation and TAIC additive. Polym. Test. 2015, 48, 169–174. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczyńska, M.; Ghost, U.; Malinowski, R.; Budner, B.; Żenkiewicz, M. Flax fibres reinforced polylactide modified by ionizing radiation. Ind. Crop. Prod. 2018, 112, 716–723. [Google Scholar] [CrossRef]

- Rytlewski, P.; Stepczyńska, M.; Moraczewski, K.; Malinowski, R.; Karasiewicz, T.; Sikorska, W.; Żenkiewicz, M. Flax fibres reinforced polycaprolactone modified by triallyl isocyanurate and electron radiation. Polym. Compos. 2019, 40, 481–488. [Google Scholar] [CrossRef]

| Sample | M (Nm) | E (kW) | T (°C) | P (MPa) |

|---|---|---|---|---|

| C | 16–17 | 0.95–0.97 | 165 | 10–11 |

| CF2.5 | 18–20 | 0.98–1.02 | 166 | 12–14 |

| CF5 | 20–21 | 1.01–1.05 | 168 | 14–17 |

| CF10 | 21–22 | 1.04–1.08 | 170 | 16–19 |

| CF20 | 22–23 | 1.06–1.11 | 171 | 20–24 |

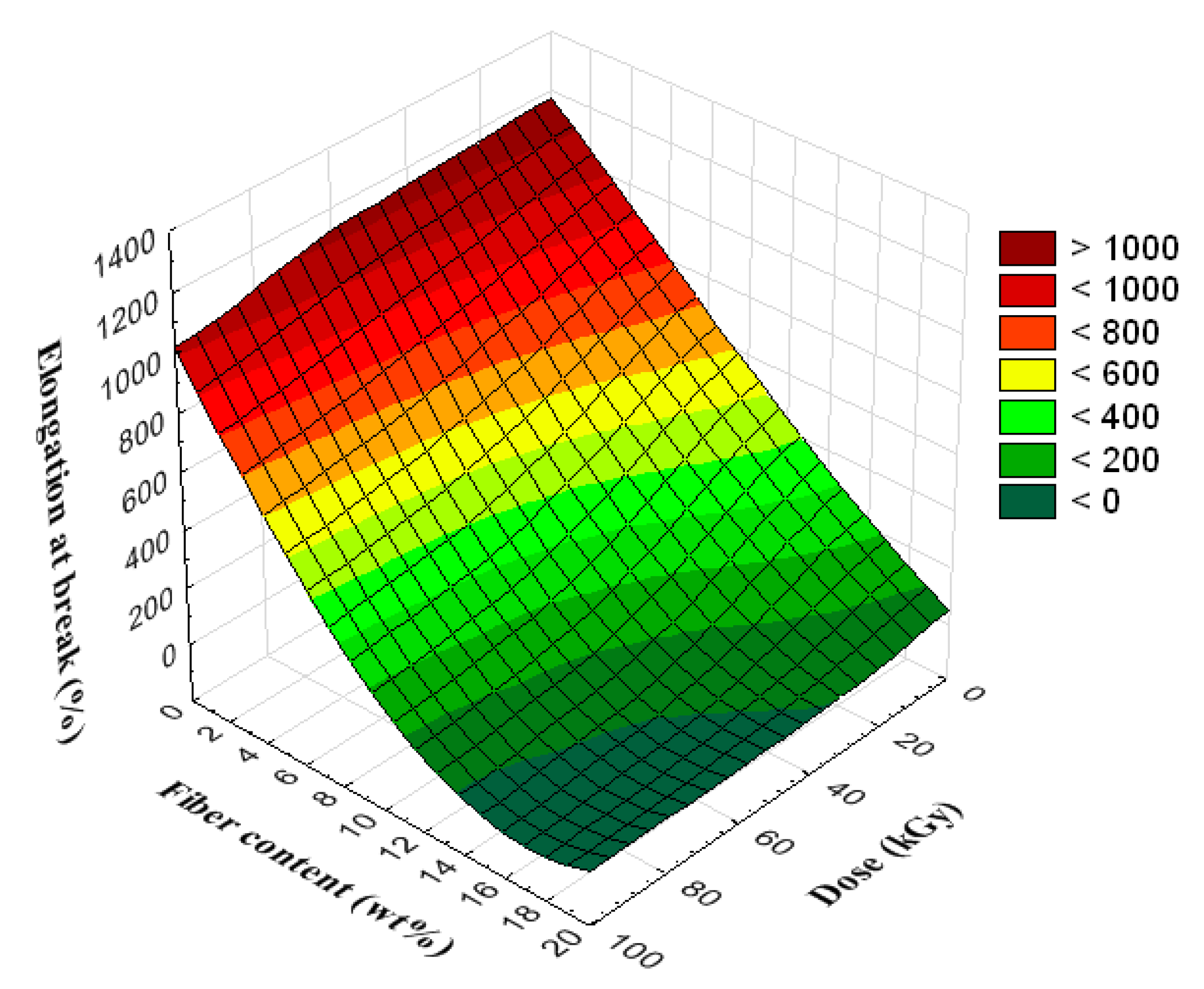

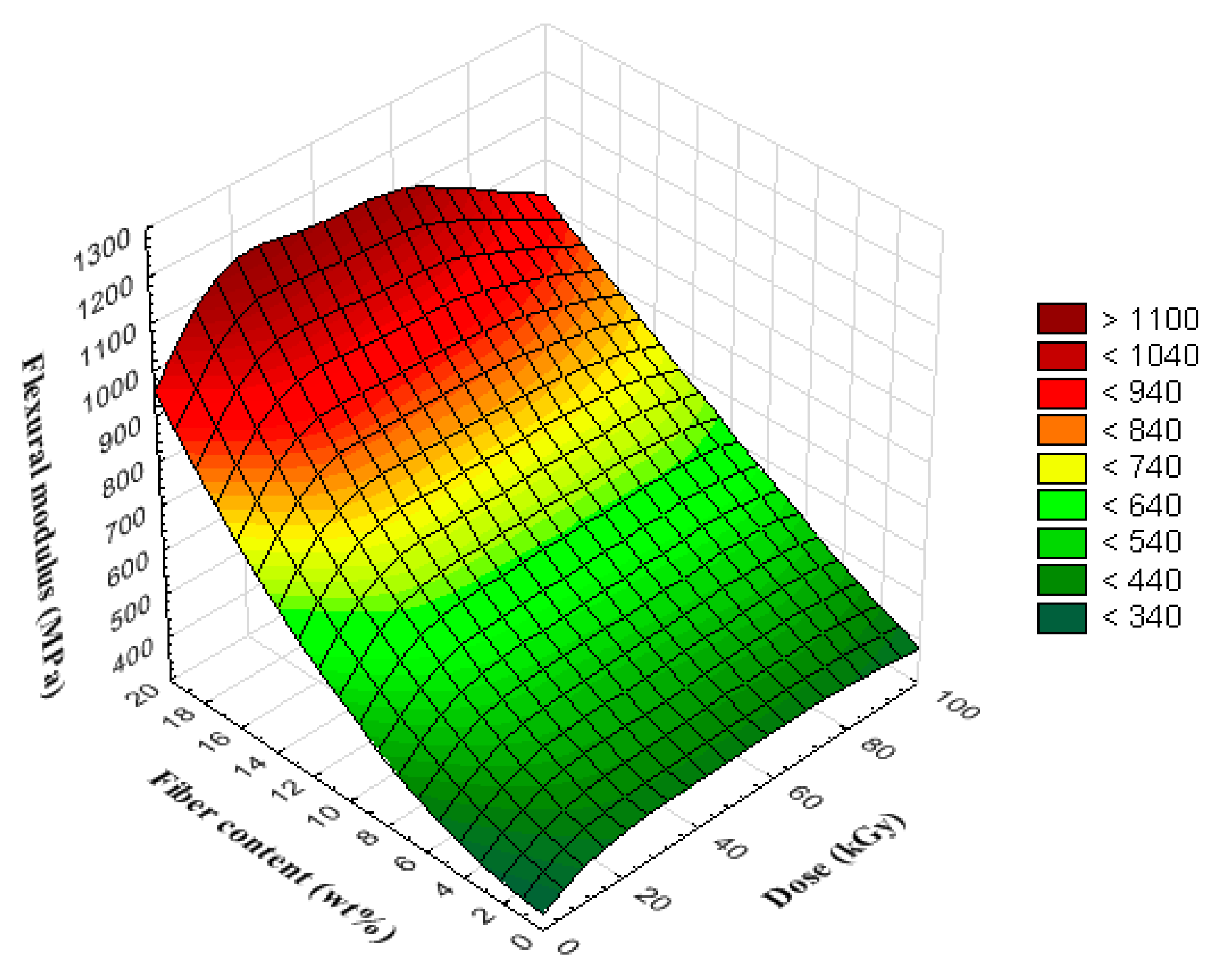

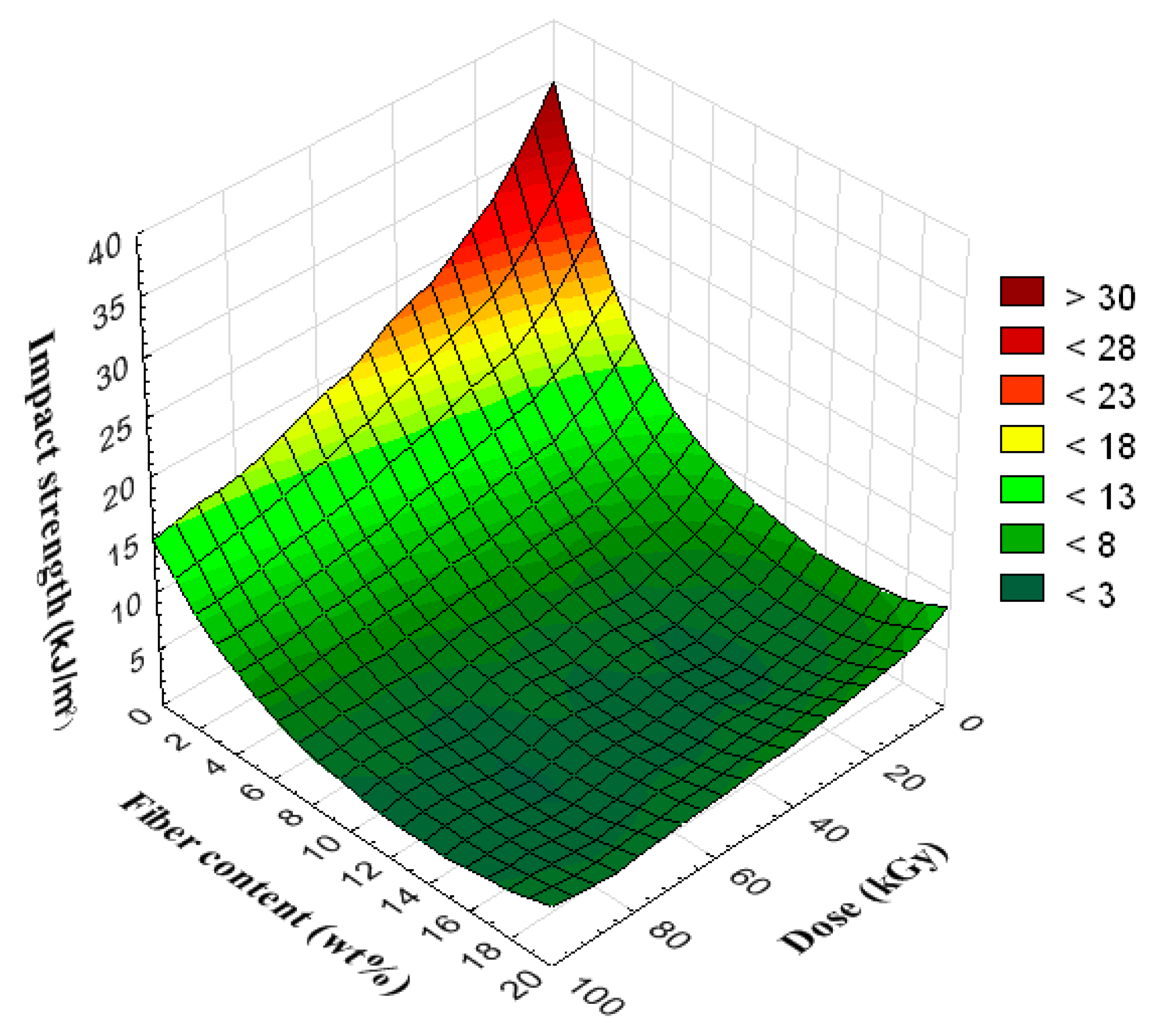

| Sample | Dose (kGy) | σM (MPa) | εB (%) | Mf (MPa) | acN (kJ/m2) |

|---|---|---|---|---|---|

| C | 0 | 27.0 ± 0.9 | 1091 ± 24 | 351 ± 26 | 39.4 ± 0.2 |

| CF2.5 | 0 | 27.6 ± 0.5 | 1105 ± 52 | 362 ± 35 | 15.7 ± 0.1 |

| CF5 | 0 | 23.4 ± 0.8 | 910 ± 9 | 395 ± 69 | 12.9 ± 0.3 |

| CF10 | 0 | 19.7 ± 0.4 | 518 ± 71 | 635 ± 68 | 11.4 ± 0.1 |

| CF20 | 0 | 23.6 ± 0.3 | 48 ± 8 | 880 ± 64 | 8.8 ± 0.1 |

| C | 10 | 27.7 ± 0.8 | 1128 ± 24 | 381 ± 21 | 33.8 ± 0.2 |

| CF2.5 | 10 | 26.2 ± 0.4 | 1077 ± 43 | 396 ± 42 | 12.0 ± 0.2 |

| CF5 | 10 | 23.6 ± 0.3 | 836 ± 25 | 487 ± 38 | 10.7 ± 0.2 |

| CF10 | 10 | 20.0 ± 0.1 | 527 ± 45 | 635 ± 68 | 8.7 ± 0.1 |

| CF20 | 10 | 23.4 ± 0.9 | 28 ± 1 | 1158 ± 68 | 7.1 ± 0.3 |

| C | 20 | 27.3 ± 0.9 | 1096 ± 26 | 392 ± 21 | 29.5 ± 0.1 |

| CF2.5 | 20 | 28.1 ± 0.4 | 1064 ± 70 | 435 ± 32 | 10.4 ± 0.1 |

| CF5 | 20 | 24.2 ± 0.7 | 820 ± 21 | 499 ± 41 | 9.5 ± 0.2 |

| CF10 | 20 | 20.0 ± 1.1 | 364 ± 41 | 639 ± 78 | 7.8 ± 0.1 |

| CF20 | 20 | 23.3 ± 0.8 | 26 ± 2 | 1220 ± 22 | 6.5 ± 0.3 |

| C | 40 | 27.7 ± 1.1 | 1076 ± 43 | 399 ± 31 | 25.2 ± 0.1 |

| CF2.5 | 40 | 24.8 ± 1.2 | 966 ± 76 | 433 ± 12 | 9.0 ± 0.1 |

| CF5 | 40 | 23.1 ± 0.6 | 811 ± 7 | 502 ± 29 | 8.3 ± 0.2 |

| CF10 | 40 | 20.6 ± 0.5 | 194 ± 70 | 640 ± 73 | 6.8 ± 0.2 |

| CF20 | 40 | 23.8 ± 1.2 | 9 ± 4 | 1080 ± 72 | 5.6 ± 0.2 |

| C | 60 | 26.1 ± 1.1 | 1073 ± 74 | 394 ± 16 | 21.0 ± 0.1 |

| CF2.5 | 60 | 25.8 ± 0.7 | 951 ± 71 | 457 ± 20 | 7.9 ± 0.1 |

| CF5 | 60 | 20.4 ± 0.3 | 648 ± 35 | 507 ± 55 | 7.4 ± 0.2 |

| CF10 | 60 | 21.4 ± 0.7 | 141 ± 49 | 636 ± 61 | 6.2 ± 0.1 |

| CF20 | 60 | 24.3 ± 0.4 | 6 ± 1 | 1146 ± 81 | 5.0 ± 0.1 |

| C | 90 | 23.6 ± 1.3 | 903 ± 65 | 404 ± 22 | 17.3 ± 0.3 |

| CF2.5 | 90 | 24.5 ± 1.9 | 954 ± 38 | 419 ± 30 | 6.8 ± 0.1 |

| CF5 | 90 | 19.8 ± 0.1 | 633 ± 26 | 498 ± 49 | 6.4 ± 0.3 |

| CF10 | 90 | 22.0 ± 0.3 | 41 ± 25 | 687 ± 52 | 5.3 ± 0.1 |

| CF20 | 90 | 24.6 ± 0.4 | 5 ± 1 | 951 ± 72 | 4.6 ± 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malinowski, R.; Raszkowska-Kaczor, A.; Moraczewski, K.; Głuszewski, W.; Krasinskyi, V.; Wedderburn, L. The Structure and Mechanical Properties of Hemp Fibers-Reinforced Poly(ε-Caprolactone) Composites Modified by Electron Beam Irradiation. Appl. Sci. 2021, 11, 5317. https://doi.org/10.3390/app11125317

Malinowski R, Raszkowska-Kaczor A, Moraczewski K, Głuszewski W, Krasinskyi V, Wedderburn L. The Structure and Mechanical Properties of Hemp Fibers-Reinforced Poly(ε-Caprolactone) Composites Modified by Electron Beam Irradiation. Applied Sciences. 2021; 11(12):5317. https://doi.org/10.3390/app11125317

Chicago/Turabian StyleMalinowski, Rafał, Aneta Raszkowska-Kaczor, Krzysztof Moraczewski, Wojciech Głuszewski, Volodymyr Krasinskyi, and Lauren Wedderburn. 2021. "The Structure and Mechanical Properties of Hemp Fibers-Reinforced Poly(ε-Caprolactone) Composites Modified by Electron Beam Irradiation" Applied Sciences 11, no. 12: 5317. https://doi.org/10.3390/app11125317

APA StyleMalinowski, R., Raszkowska-Kaczor, A., Moraczewski, K., Głuszewski, W., Krasinskyi, V., & Wedderburn, L. (2021). The Structure and Mechanical Properties of Hemp Fibers-Reinforced Poly(ε-Caprolactone) Composites Modified by Electron Beam Irradiation. Applied Sciences, 11(12), 5317. https://doi.org/10.3390/app11125317