Evaluation of Carbon Fiber Grid Reinforced Concrete Panel for Disaster Response and Improved Seismic Performance

Abstract

:1. Introduction

2. Experiments

3. Results and Discussion

4. Conclusions

- (1)

- The flexural strength of concrete panels was 8.08 MPa with no layers, 8.65 MPa with one layer, and 9.27 MPa with two layers, and increased with the increasing number of carbon fiber grids. Flexural strength increased by 7% with one layer and 15% with two layers compared with no layer.

- (2)

- The energy dissipation capacity of concrete panels was 0.06 kN∙m with no layers, 1.89 kN∙m with one layer, and 3.52 kN∙m with two layers, and increased with the increasing number of carbon fiber grids. Energy dissipation capacity increased by 30 times with one layer and 56 times with two layers compared with no layer and showed improvement in terms of seismic performance.

- (3)

- Concrete panels with carbon fiber grids showed 7–15% higher flexural strength and 30–56 times higher energy dissipation capacity compared with no carbon fiber grid. Especially because of the large increase in the energy dissipation capacity, the carbon fiber grid reinforcement method can be considered an effective method for improving seismic performance.

- (4)

- This study compared the flexural strength characteristics of panels using carbon grids to those of unreinforced concrete, and a comparison with panels using existing reinforcing bars and meshes will be carried out in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, Z.F.; Wang, W.W.; Harries, K.A.; Zheng, Y.Z. Uniaxial Tensile Stress–Strain Behavior of Carbon-Fiber Grid–Reinforced Engineered Cementitious Composites. J. Compos. Constr. 2018, 22, 04018057. [Google Scholar] [CrossRef]

- Aljazaeri, Z.; Alghazali, H.H.; Myers, J.J. Effectiveness of Using Carbon Fiber Grid Systems in Reinforced Two-Way Concrete Slab System. ACI Struct. J. 2020, 117, 81–90. [Google Scholar] [CrossRef]

- Yue, Q.; Liu, Z.; Li, R.; Chen, X. Experimental investigation into development length of carbon fiber reinforced polymer grids in concrete. Adv. Struct. Eng. 2017, 20, 953–962. [Google Scholar] [CrossRef]

- Yan, Y.; Cha, J.H.; Chai, C.; Lee, H.H.; Jeon, H.Y. Manufacture and Engineering Evaluation of Hybrid Grid Fabrics for Seismic Reinforced Carbon Fiber Composite Yarns. I. Manufacture of Carbon Fiber Composite Yarn and Fabric Design. J. Text. Eng. Korea 2018, 55, 280–285. [Google Scholar]

- Shao, Y.; Mirmiran, A. Control of Plastic Shrinkage Cracking of Concrete with Carbon Fiber-Reinforced Polymer Grids. J. Mater. Civ. Eng. 2007, 19, 441–444. [Google Scholar] [CrossRef]

- Ogawa, H. Architectural application of carbon fibers—Development of new carbon fiber reinforced glulam. Carbon 2000, 38, 211–226. [Google Scholar] [CrossRef]

- Shen, D.; Li, M.; Kang, J.; Liu, C.; Li, C. Experimental studies on the seismic behavior of reinforced concrete beam-column joints strengthened with basalt fiber-reinforced polymer sheets. Constr. Build. Mater. 2021, 287, 122901. [Google Scholar] [CrossRef]

- Tidarut, J.; Suched, L.; Nattanet, W.; Tamon, U.; Dawei, Z.; Marin, S. Structural behaviour of pre-damaged reinforced concrete beams strengthened with natural fibre reinforced polymer composites. Compos. Struct. 2020, 244, 112309. [Google Scholar]

- Shen, D.; Yang, Q.; Huang, C.; Cui, Z.; Zhang, J. Tests on seismic performance of corroded reinforced concrete shear walls repaired with basalt fiber-reinforced polymers. Constr. Build. Mater. 2021, 209, 508–521. [Google Scholar] [CrossRef]

- Ma, S.; Li, L.; Bao, P. Seismic Performance Test of Double-Row Reinforced Ceramsite Concrete Composite Wall Panels with Cores. Appl. Sci. 2021, 11, 2688. [Google Scholar] [CrossRef]

- Weina, M.; Kamal, H.K.; Yi, B. Flexural behaviors of fiber-reinforced polymer fabric reinforced ultra-high-performance concrete panels. Cem. Concr. Compos. 2018, 93, 43–53. [Google Scholar]

- Akram, J.; Issam, H.; Amir, F. Behavior of reinforced concrete beams strengthened with CFRP rod panels CRP 195. Structures 2018, 16, 239–253. [Google Scholar]

- Trevor, K.N.; Chris, P.P.; Clayton, A.B. Unidirectional GFRP composite connections between precast concrete wall panels under simulated seismic loads. Compos. Struct. 2018, 203, 624–635. [Google Scholar]

- Zhang, F.; Chen, H.; Li, X.; Li, H.; Lv, T.; Zhang, W.; Yang, Y. Experimental study of the mechanical behavior of FRP-reinforced concrete canvas panels. Compos. Struct. 2017, 176, 608–616. [Google Scholar] [CrossRef]

- Zhao, W.; Guo, Q. Experimental study on impact and post-impact behavior of steel-concrete composite panels. Thin-Walled Struct. 2018, 130, 405–413. [Google Scholar] [CrossRef]

- Huang, J.Q.; Dai, J.G. Direct shear tests of glass fiber reinforced polymer connectors for use in precast concrete sandwich panels. Compos. Struct. 2019, 207, 136–147. [Google Scholar] [CrossRef]

- Yao, W.; Sun, W.; Shi, Z.; Chen, B.; Chen, L.; Feng, J. Blast-Resistant Performance of Hybrid Fiber-Reinforced Concrete (HFRC) Panels Subjected to Contact Detonation. Appl. Sci. 2020, 10, 241. [Google Scholar] [CrossRef] [Green Version]

- Hanyong, J. Review of carbon Fiber Composite Grid with Manufacturing and Design Concepts for Seismic Resistance. Int. J. Mater. Sci. Eng. 2020, 8, 74–80. [Google Scholar]

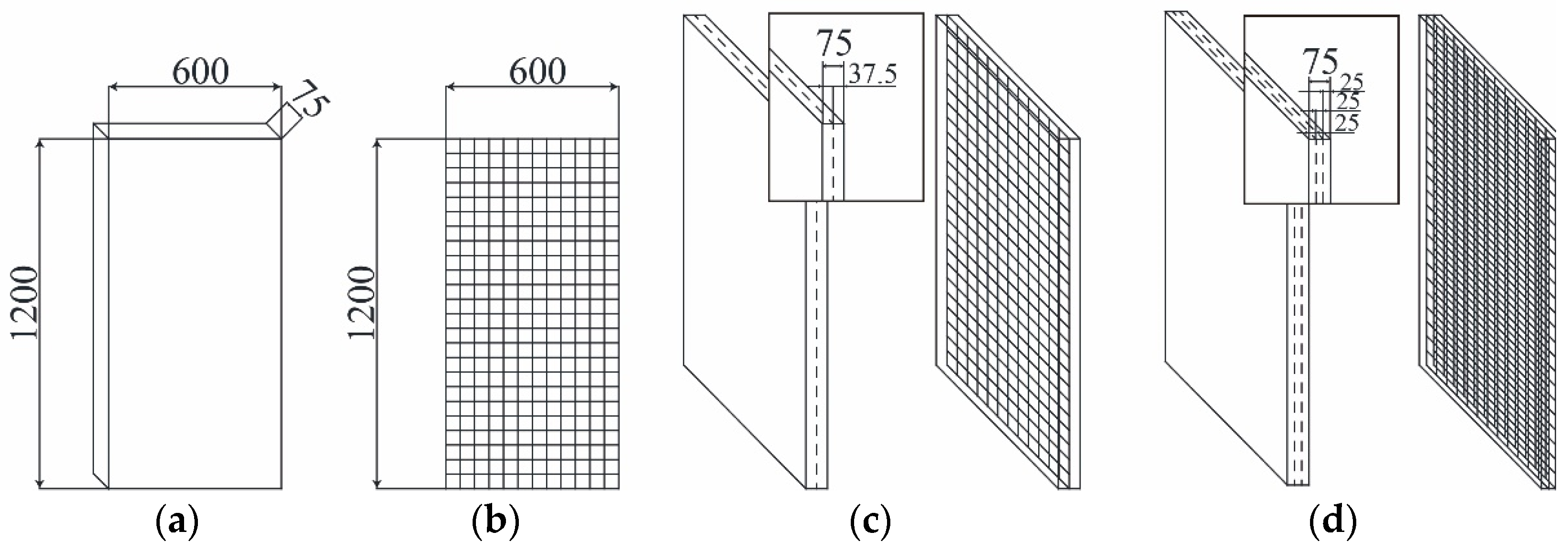

| Specimen Size (mm) | Carbon Grid | Concrete Compressive Strength (MPa) | Experiments | |||||||

| 1200 × 600 × 75 | -No layer -1 layer -2 layers | 50.0 | Flexural strength Energy dissipation capacity | |||||||

| Design strength (MPa) | W/B (%) | S/A (%) | Binding material (kg/) | Unit quantity (kg/) | Unit mass (kg/) | |||||

| Cement | Fly ash | Silica fume | Fine aggregate | Coarse aggregate | ||||||

| 50 | 29.6 | 49 | 550 | 163 | 418 | 110 | 22 | 815 | 875 | |

| Type of binder | Specific surface area () | Density () | Lg. loss | Chemical composition (%) | ||||||

| OPC | 3.14 | 3.15 | 1.32 | 21.7 | 5.7 | 3.2 | 63.1 | 2.8 | 2.2 | |

| Specific surface area () | Density () | Lg. loss | Chemical composition (%) | |||||||

| 160,000 | 2.21 | 1.38 | 96.65 | 1.87 | 0.03 | 0.38 | 0.19 | 0.32 | ||

| Admixture type | Specific gravity | Fineness () | Ignition loss (%) | Moisture content (%) | Unit quantity ratio (%) | (%) | Activity factor (%) | |||

| Boryeong fly ash | 2.22 | 2976 | 4.0 | 0.1 | 101 | 53.2 | 93.1 | |||

| Admixture type | Phase | Color | Main component | Toxicity | Specific gravity | |||||

| Superplasticizer | Liquid | Yellow | Polycarboxylic acid-based | None | 1.04 | |||||

| Type | Size (mm) | Fineness modulus (F.M.) | Specific gravity | Absorption rate (%) | Performance rate (%) | Unit weight (kg/l) | Remarks | |||

| Fine aggregate | 5 | 3.04 | 2.56 | 0.64 | 67.45 | 1.73 | Sea sand | |||

| Coarse aggregate | 20 | 6.02 | 2.65 | 1.39 | 62.52 | 1.66 | Crushed coarse aggregate | |||

| Type | Tensile strength (kN/m) | Secant modulus of elasticity (kN/m) | Tensile strain rate (%) | Nominal strength tensile strain rate (%) | ||||||

| Machine | Width | Machine | Width | Machine | Width | Machine | Width | |||

| Carbon fiber grids | 182.7 | 108.44 | 12,019 | 4180 | 2.2 | 3.6 | 3.5 | 3.8 | ||

| Results | No Layer | One Layer | Two Layers |

|---|---|---|---|

| Max. load (kN) | 27.3 | 29.2 | 31.3 |

| Max. displacement (mm) | 2.66 | 14.86 | 16.29 |

| Flexural strength (MPa) | 8.08 | 8.65 | 9.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Chai, C.; Hong, S. Evaluation of Carbon Fiber Grid Reinforced Concrete Panel for Disaster Response and Improved Seismic Performance. Appl. Sci. 2021, 11, 5223. https://doi.org/10.3390/app11115223

Kang S, Chai C, Hong S. Evaluation of Carbon Fiber Grid Reinforced Concrete Panel for Disaster Response and Improved Seismic Performance. Applied Sciences. 2021; 11(11):5223. https://doi.org/10.3390/app11115223

Chicago/Turabian StyleKang, Sukpyo, Charles Chai, and Seonguk Hong. 2021. "Evaluation of Carbon Fiber Grid Reinforced Concrete Panel for Disaster Response and Improved Seismic Performance" Applied Sciences 11, no. 11: 5223. https://doi.org/10.3390/app11115223

APA StyleKang, S., Chai, C., & Hong, S. (2021). Evaluation of Carbon Fiber Grid Reinforced Concrete Panel for Disaster Response and Improved Seismic Performance. Applied Sciences, 11(11), 5223. https://doi.org/10.3390/app11115223