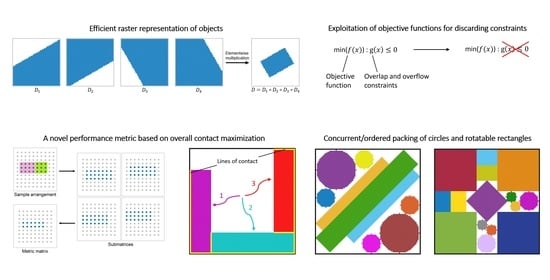

This section covers the results from different case studies that involved the packing of rectangular and circular objects into square bins. Both concurrent and sequential optimization strategies were explored. In the sequential placement, the objects were ordered with the decreasing diagonal length or area. The total number of ones (), objects’ rectilinear distances from the center (), objects’ distance from the bottom-left corner (), and the number of adjacent ones () were used as the objective functions. The combined influence of the optimization settings on COMPACT’s performance in solving different problems was investigated.

4.1. Non-Rotatable Objects

The developed methodology was initially utilized to obtain packing configurations for non-rotatable objects. The first study involved sets of rectangular objects whose heights and widths are given in

Table 1. These sets were obtained by splitting one rectangle into two new ones at each step as demonstrated in

Figure 5. Hence, the number of rectangles was regularly increased from 4 to 9 while going from the first case (a) to the last one (f).

Table 2 shows the success rates in packing all objects of each set for different optimization strategies and objective functions. For each case, the average results for 100 computations are presented. In the concurrent optimization, the effectiveness of maximizing total ones decreased with the increasing number of objects. Maximizing adjacent ones showed a similar trend but gave slightly better results for the higher number of objects. No collision avoidance constraints were considered in these studies since the higher values of the objectives also favor reducing the overlaps.

For the sequential optimization, the optimal solutions were found for all trials for the sets with four and five objects. For the analyzed sets, sorting by diagonal length generally performed better compared to area sorting, which was more slightly more effective for only intermediate numbers (6, 7) of objects. For the length sorting, using the distance to the bottom-left corner as the objective function provided the best results. However, maximizing adjacent ones also worked fairly well providing a 75% success rate for 9 objects.

For the second study, another set of objects with the quantities and dimensions specified in

Table 3 was used. This set perfectly occupies the domain for optimal packing, which requires placement of the objects according to a regular pattern. For concurrent optimization, the optimal packing could not be found using

as the performance metric, where

still succeeded 6 times out of 100 trials. For sequential placement,

delivered the best results by far with its 40% success rate, where

and

succeeded in 7% and none of the trials, respectively. The effectiveness of

originates from its inclination towards maximizing the line of contact, which in turn aids the formation of the required pattern. In

Figure 6, (a) one optimal solution for the second study and (b) positioning preferences of

and

during a sample run are demonstrated.

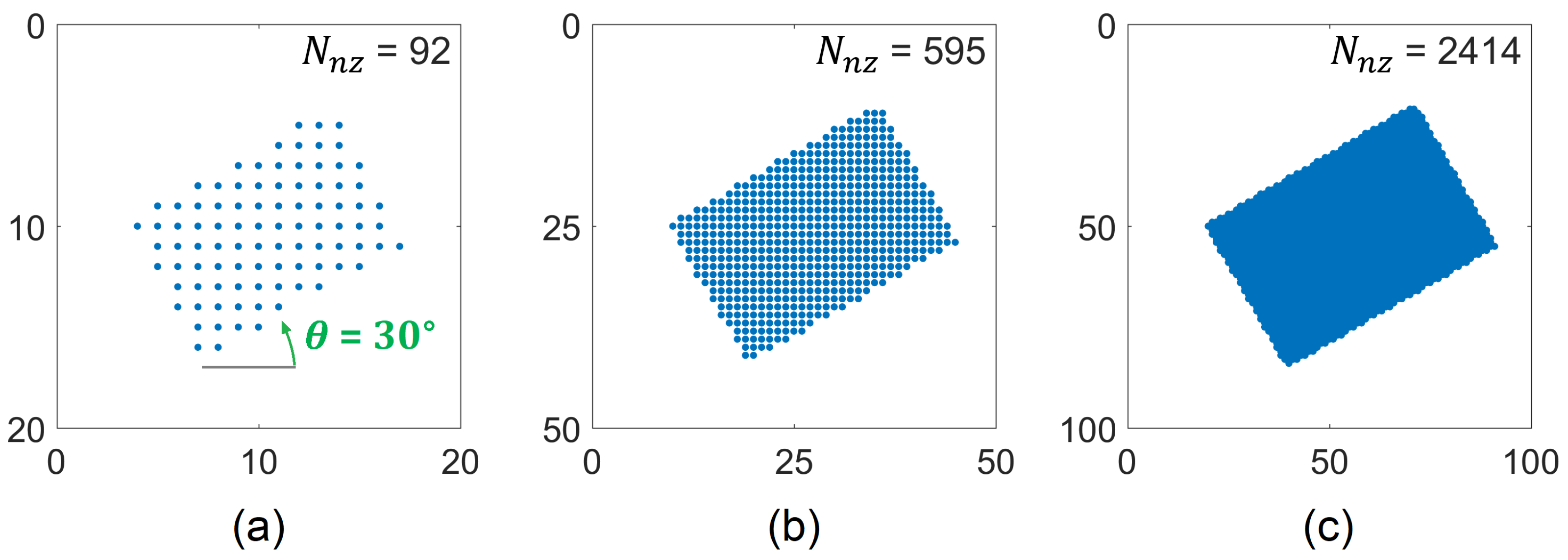

4.2. Rotatable Objects

Objects with large aspect ratios may require alteration of their orientation to be fit into the available space. New sets of objects were generated to test the developed methodologies on the packing problems with rotational degrees of freedom. The orientation angle was restricted to be a multiple of to cover diagonal placement possibilities while keeping the problem size minimal.

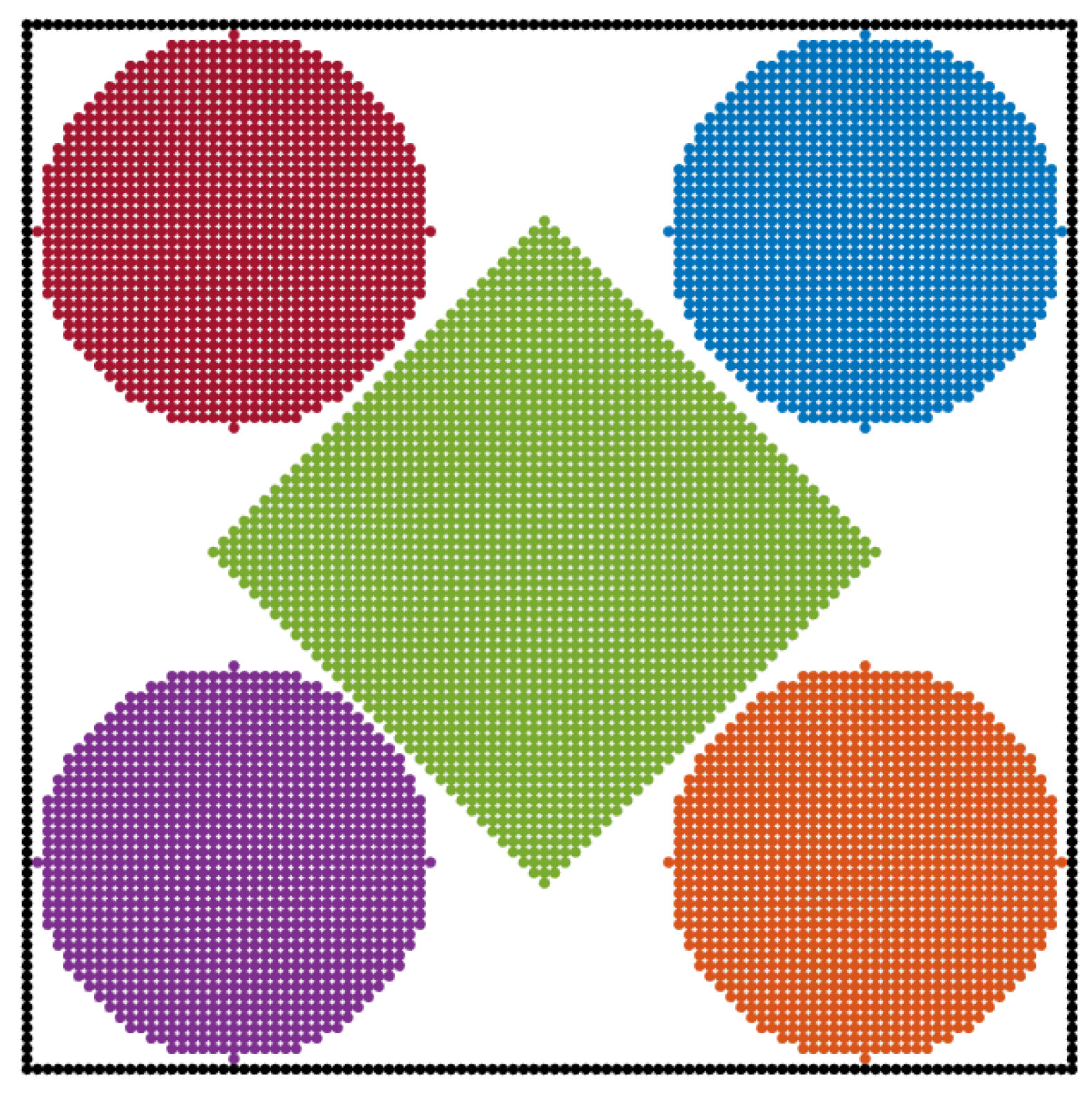

In the first investigation, a (

) square and four smaller circles of 39 units diameter were packed into the square domain.

Figure 7 shows the optimal packing configuration for these objects. Despite the relatively simple characteristics of the problem, the optimal solution cannot be attained with the ordered placement based on decreasing size.

The reason is that all three performance metrics (, , and ) tend to position the large square on a corner leaving room for only three of the circles. Only using with the small-to-big ordering leads to the optimal solution indicating that packing smaller objects first can be advantageous in certain problems. While the sequential placement performed ineffectively for this problem, concurrent placement with active constraints provided success rates of 5% and 7% for and metrics, respectively. Therefore, if the problem size permits its use, the concurrent optimization strategy can offer versatility in tackling different problems. As another investigation, the concurrent optimization cases were repeated by removing collision and containment constraints. In the absence of constraints, and still yielded 5% and 4% success rates, respectively. These results demonstrate that these metrics intrinsically facilitate the containment of rotatable objects in addition to collision avoidance.

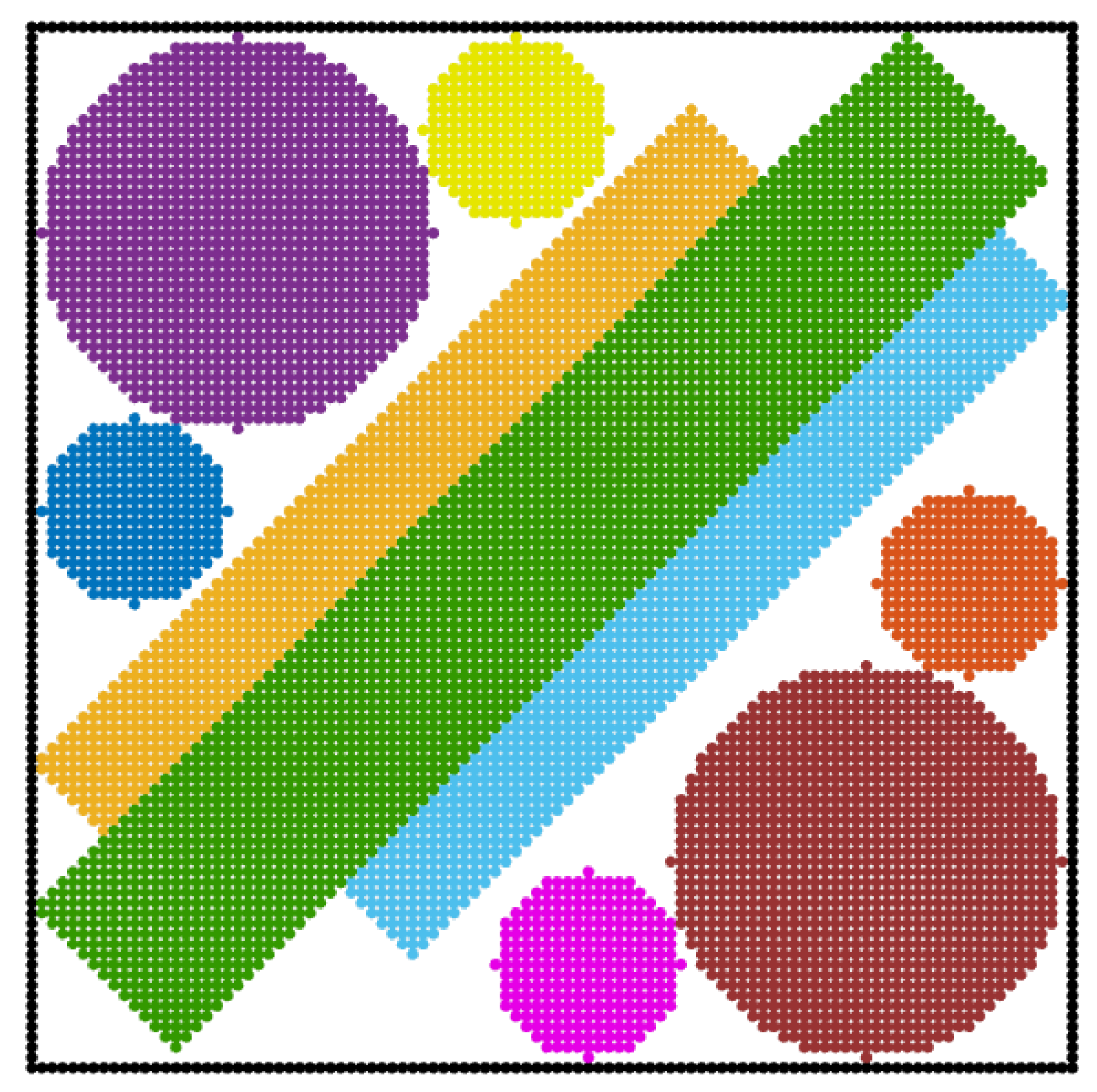

The second case study concerned packing three rectangles and six circles into a square domain. The quantities and dimensions of the objects used in this study are given in

Table 4. With the optimal packing, all objects in the set can be placed into the domain providing a filling ratio of 74.4% as shown in

Figure 8.

The concurrent optimization strategy was not effective for packing this set due to the increased number of objects and extra rotational degrees of freedom. For this problem, the filling ratios were compared for , , and metrics while collision and containment constraints were held active. When the objects were ordered in decreasing length (diagonal length for the rectangles and diameter for the circles) the average filling ratios over 100 trials were found as 56.7% and 67.7% using and , respectively. For this ordering, the best results were achieved with , which yielded an average filling ratio of 70.8%. In this case, outperformed the other metrics since it prefers positioning the smaller rectangles right next to the large rectangle, which is diagonally packed in the first step. Such placement leaves sufficient room at the corners where the large circles can be packed. When area-wise sorting was used, , , and provided 66.3%, 60.4%, and 56.5% mean filling ratios, respectively. Hence, the relative effectiveness of the utilized metrics can be significantly influenced by the ordering strategy.

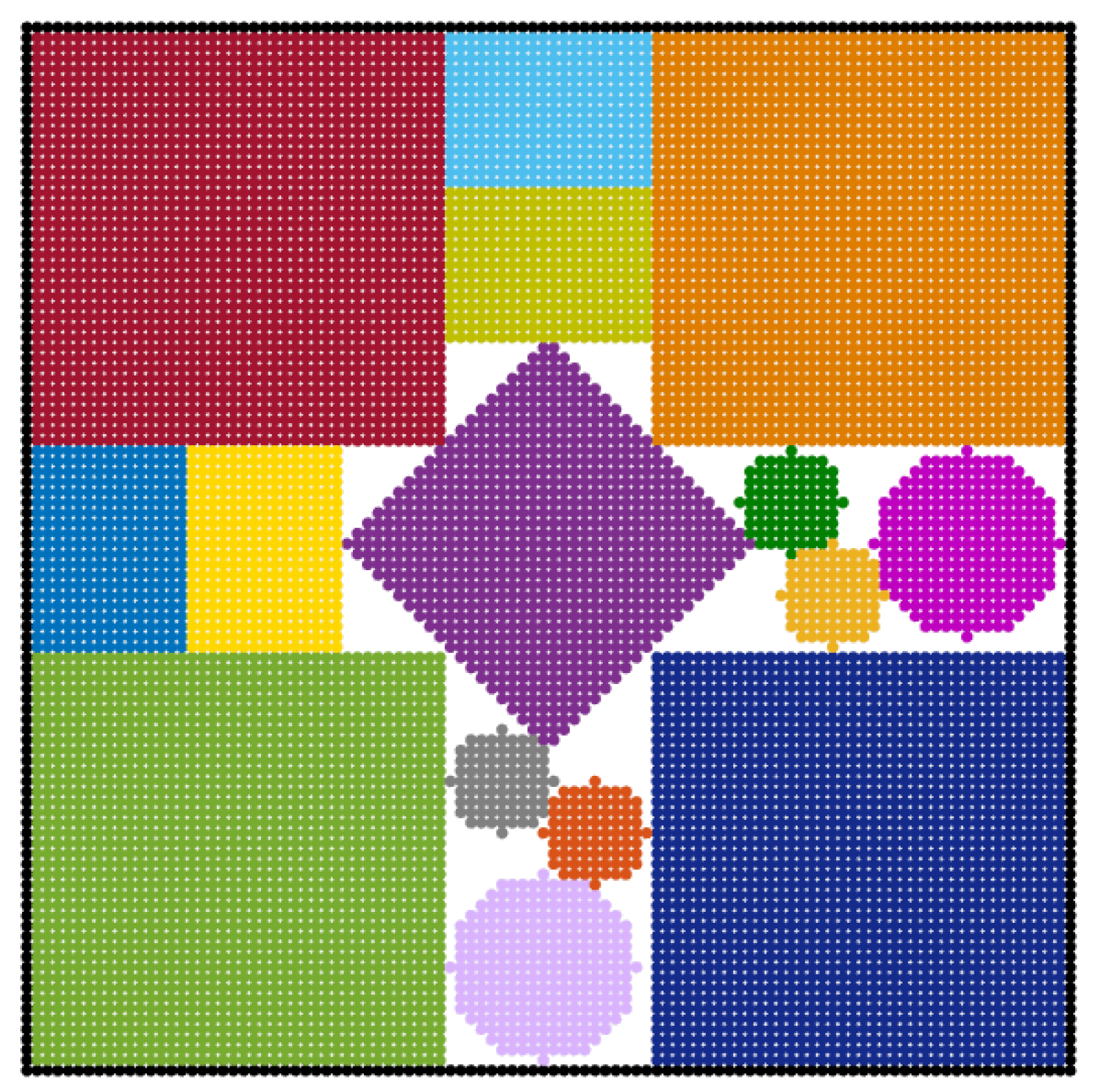

In the last study, the number of objects was increased to create a more difficult problem, where the quantities and dimensions of the packed objects are specified in

Table 5. One possible optimal packing configuration for these objects is depicted in

Figure 9, where the filling ratio is 92.3%. Note that, length-wise and area-wise ordering strategies are identical for this set.

For this problem, , , and provided average filling ratios of 87.2%, 84.3%, and 82.2%, respectively. In this case, slight superiority of is due to its preference of occupying the corners with the largest objects, which allows the intermediate rectangle to be diagonally placed into space in the middle. The configuration with the highest filling ratio (89.8%) was also achieved by . The metric provided the second-highest mean ratio and showed almost no variability over the runs. Although gave the lowest mean filling ratio, it showed greater variability compared to and provided a maximum value of 88.2%, which is higher than the maximum ratio obtained by .