Semantic Web and Knowledge Graphs for Industry 4.0

Abstract

:1. Introduction

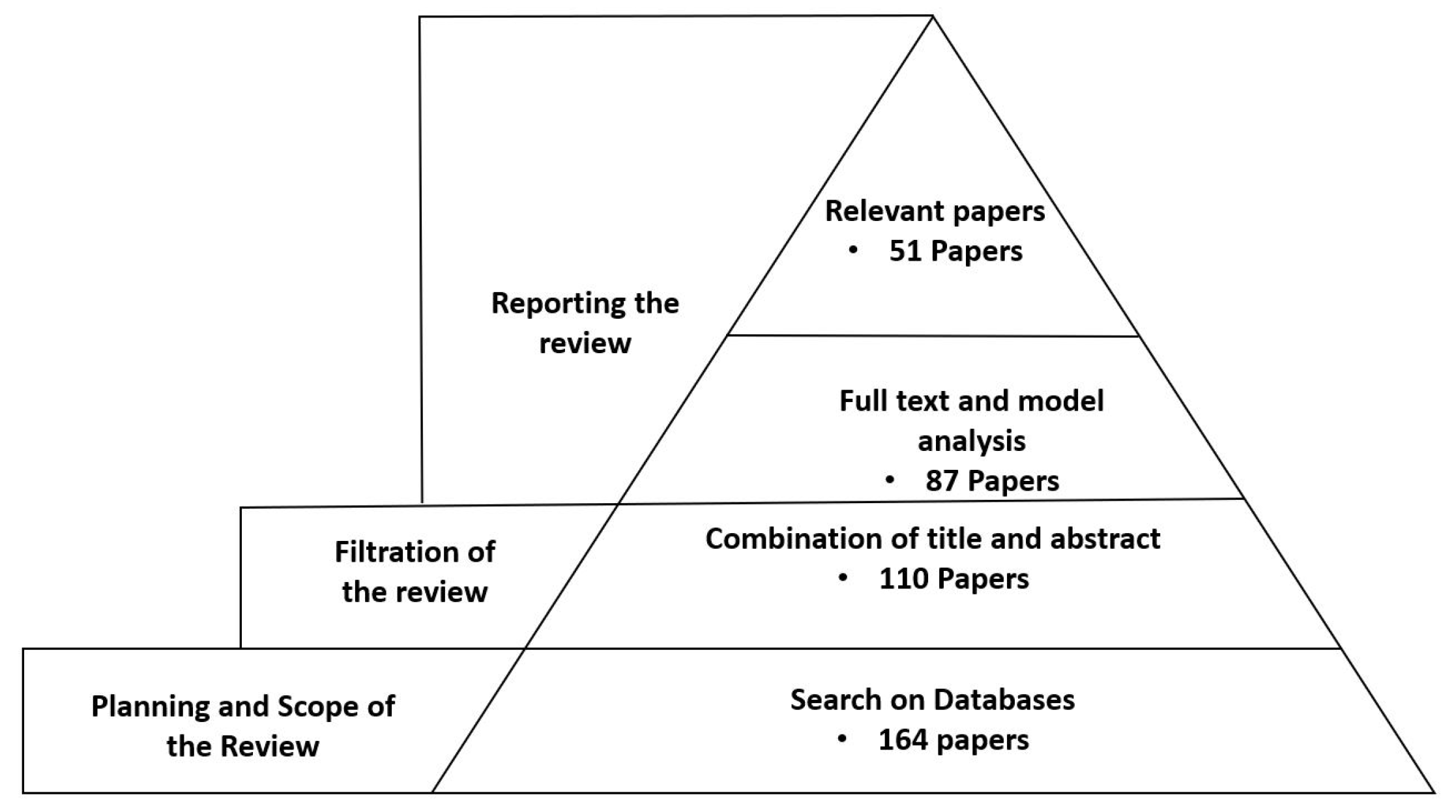

2. Methodology

- The most relevant ontologies covering reference architectures, manufacturing production line, predictive maintenance and supply chain concepts of I4.0 were captured.

- The study elaborated all versions of the chosen ontologies for understanding their functional behaviour and its adaptation in the study.

3. Industry 4.0

3.1. Vertical Integration in a Factory

3.2. Horizontal Integration Over-Value Network

3.3. End to End Integration

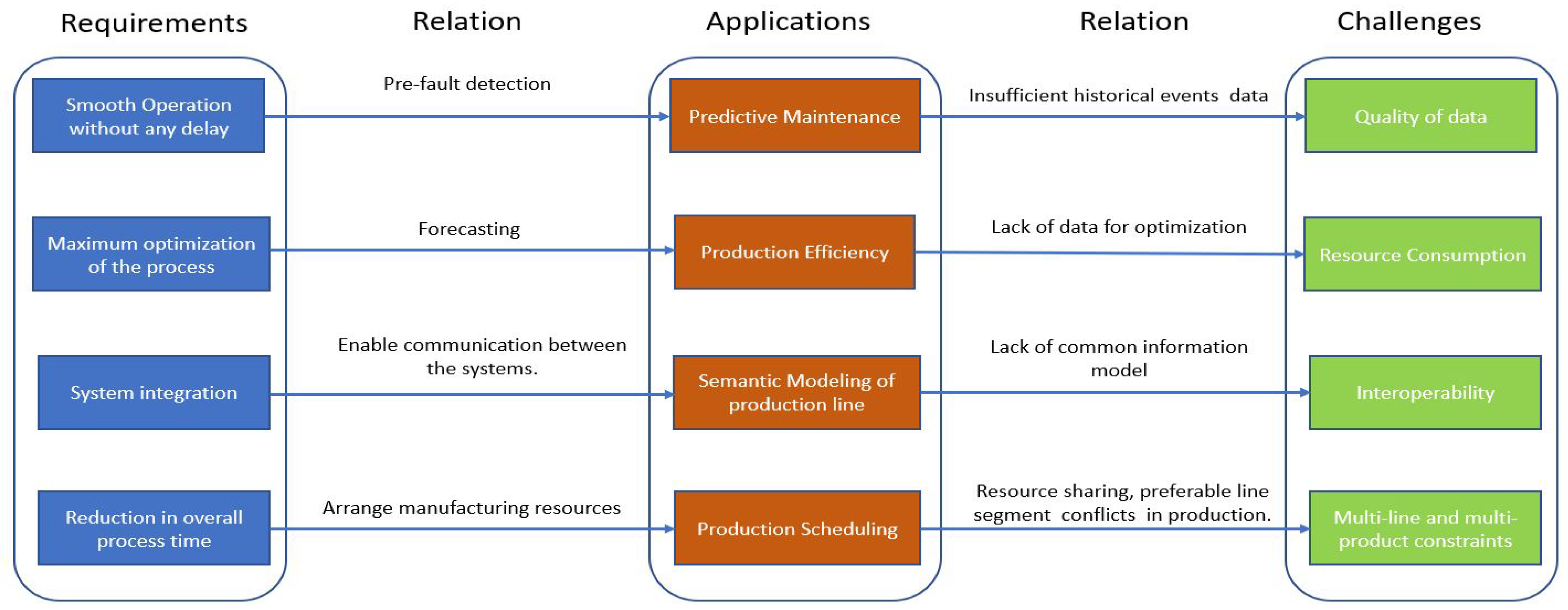

4. Manufacturing Production Line

4.1. Requirements

4.1.1. Smooth Operation without Any Delay

4.1.2. Maximum Optimization of the Process

4.1.3. System Integration

4.1.4. Reduction in Overall Process Time

4.2. Applications

4.2.1. Predictive Maintenance

4.2.2. Production Efficiency

4.2.3. Semantic Modeling of the Production Line

4.2.4. Production Scheduling

4.3. Challenges

4.3.1. Quality of Data

4.3.2. Resource Consumption

4.3.3. Interoperability

4.3.4. Multi-Line and Multi-Product Constraints

5. Semantic Web and Ontologies for Industry 4.0

5.1. Ontologies for I4.0 Reference Architectures and Standards

5.2. Ontologies for Industry 4.0 Manufacturing

5.3. Ontologies for Industry 4.0 Predictive Maintenance

5.4. Ontologies for Industry 4.0 Supply Chain Management

5.5. Analysis of Existing Ontological Approaches

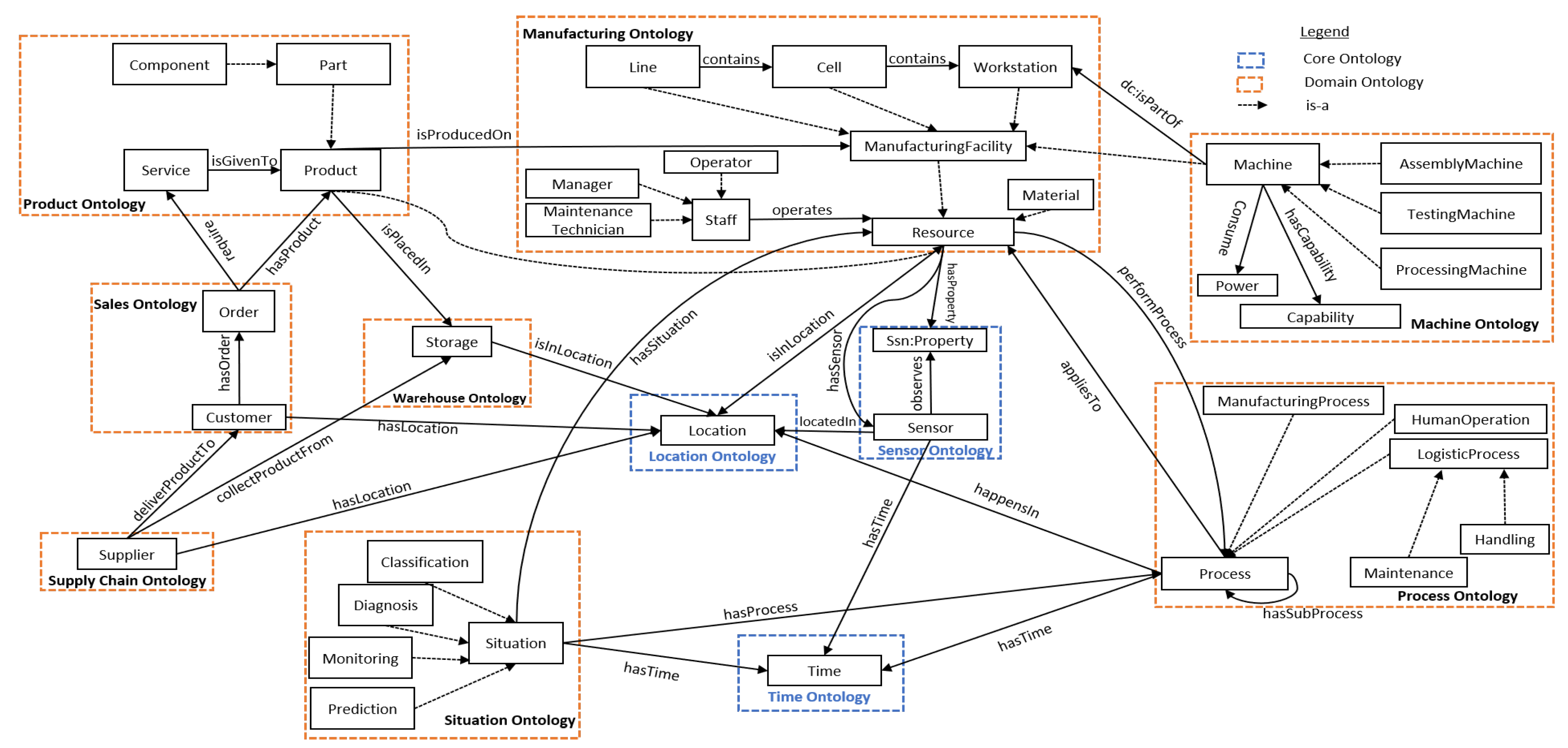

6. Reference Generalized Ontological Model

- A detailed survey is conducted by analyzing the recent literature for the ontological models for industry 4.0. In this step, key ontologies regarding the production line, supply chain, etc., were shortlisted based on the search methodology.

- Industry 4.0 architecture such as Reference architectural model Industrie 4.0 (RAMI 4.0) was studied to find out the requirements needed for the industry 4.0 production.

- A comparative study is then conducted to find out the gap between the standards and the current state of the art models. During this step, it was identified that the current ontologies do not follow the requirements of the RAMI4.0 and are unable to follow the reuse principle of linked open data.

- The existing vocabularies were reused with the additional concepts that were missing. The whole process was performed iteratively.

7. Discussion

7.1. Domain Knowledge Capture

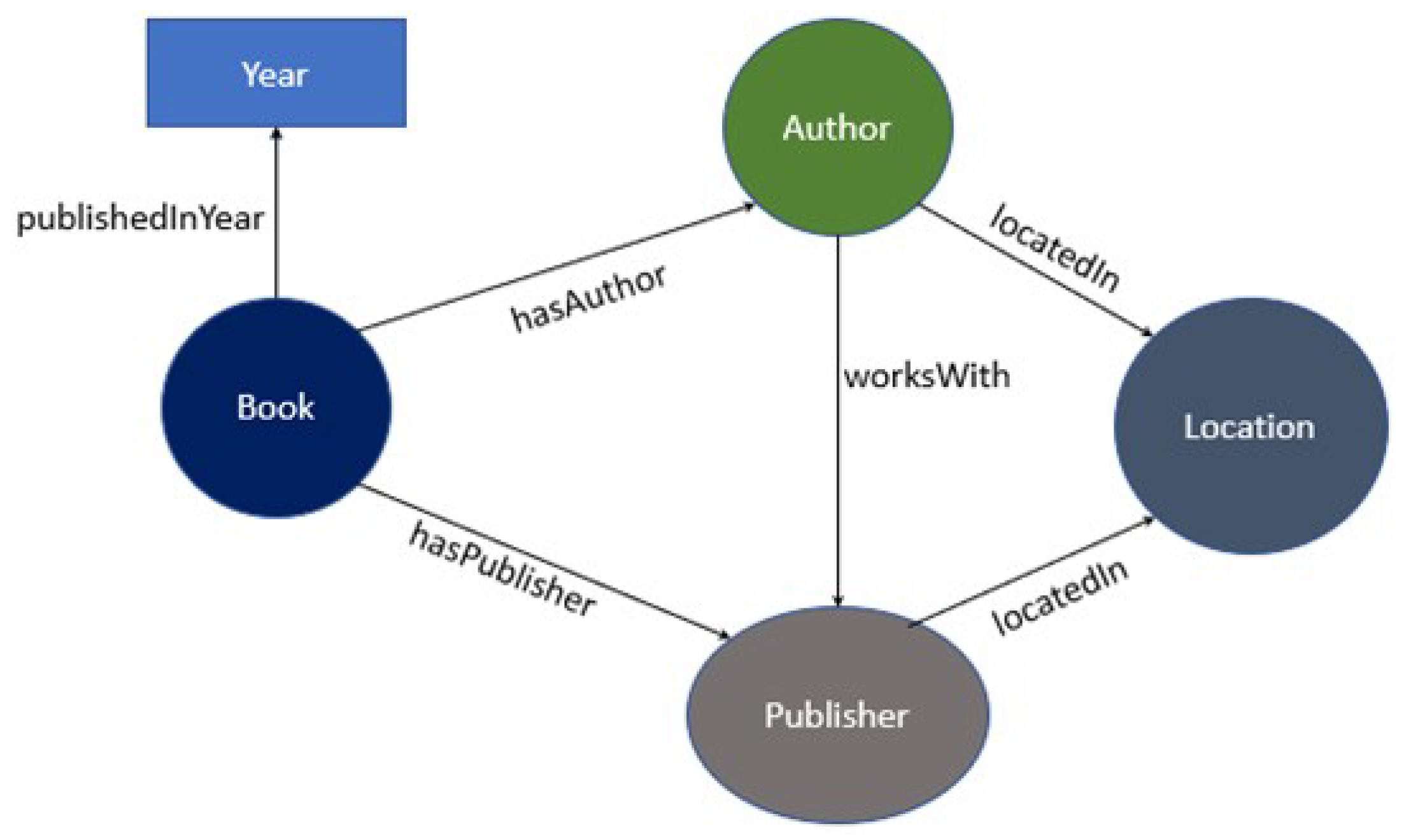

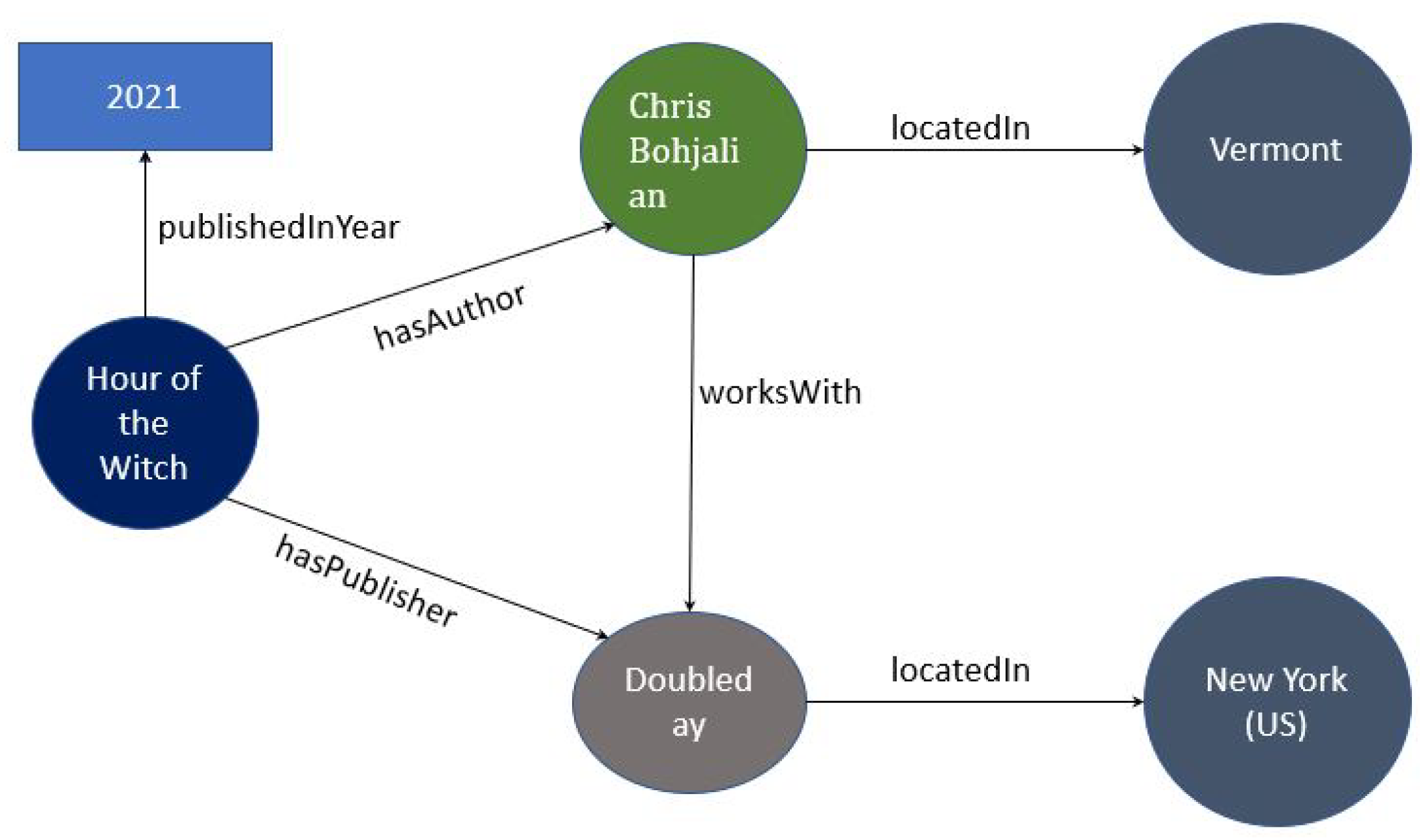

7.2. Knowledge Graphs

7.3. Comprehensive Information for Seamless Integration within and between Smart Factories

7.4. Elastic and Customised Assembly Lines

7.5. Intelligent and Adaptable Manufacturing

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Pullmann, J.; Petersen, N.; Mader, C.; Lohmann, S.; Kemeny, Z. Ontology-based information modelling in the industrial data space. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–8. [Google Scholar]

- Hoppe, T.; Eisenmann, H.; Viehl, A.; Bringmann, O. Shifting from data handling to knowledge engineering in aerospace industry. In Proceedings of the IEEE International Systems Engineering Symposium (ISSE), Vienna, Austria, 11–13 October 2017; pp. 1–6. [Google Scholar]

- Ahmed, Z.; Gerhard, D. Role of ontology in semantic web development. arXiv 2010, arXiv:1008.1723. [Google Scholar]

- Ehrlinger, L.; Wöß, W. Towards a Definition of Knowledge Graphs. SEMANTiCS 2016, 48, 1–4. [Google Scholar]

- Rivas, A.; Grangel-González, I.; Collarana, D.; Lehmann, J.; Vidal, M.E. Unveiling Relations in the Industry 4.0 Standards Landscape based on Knowledge Graph Embeddings. In Proceedings of the International Conference on Database and Expert Systems Applications, Bratislava, Slobakia, 14–17 September 2020; Springer: Cham, Switzerland, 2020; pp. 179–194. [Google Scholar]

- Cheng, H.; Zeng, P.; Xue, L.; Shi, Z.; Wang, P.; Yu, H. Manufacturing ontology development based on Industry 4.0 demonstration production line. In Proceedings of the 2016 Third International Conference on Trustworthy Systems and their Applications (TSA), Wuhan, China, 18–22 September 2016; pp. 42–47. [Google Scholar]

- Giustozzi, F.; Saunier, J.; Zanni-Merk, C. Context modeling for industry 4.0: An ontology-based proposal. Procedia Comput. Sci. 2018, 126, 675–684. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Nishioka, Y. Industrial Value Chain Initiative for Smart Manufacturing; Tokyo, Japan, 2015. [Google Scholar]

- Park, J. Korea Smart Factory Program; Tokyo, Japan, 2015. [Google Scholar]

- Broy, M.; Geisberger, E. (Eds.) AgendaCPS: Integrated Research Agenda; Cyber-Physical Systems; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Erboz, G. How to Define Industry 4.0: The Main Pillars of Industry 4. 0. In Proceedings of the 7th International Conference on Management (ICoM 2017), At Nitra, Slovakia, June 2017; pp. 1–2. [Google Scholar]

- Wegener, P.D. German Standardization Roadmap Industrie 4.0 Version 3; DIN e. V.: Berlin, Germany, 2018. [Google Scholar]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Umsetzungsempfehlungen für das Zukunftsprojekt Industrie 4.0: Deutschlands Zukunft als Produktionsstandort Sichern; Abschlussbericht des Arbeitskreises Industrie 4.0; Forschungsunion; Geschäftsstelle der Plattform Industrie 4.0: Berlin, Germany; Frankfurt/Main, Germany, 2013. [Google Scholar]

- The Great Soviet Encyclopedia, 3rd ed. S.v. Production-Line Manufacturing. Available online: https://encyclopedia2.thefreedictionary.com/Production-Line+Manufacturing (accessed on 20 July 2020).

- Ahmad, S.; Badwelan, A.; Ghaleb, A.M.; Qamhan, A.; Sharaf, M.; Alatefi, M.; Moohialdin, A. Analyzing critical failures in a production process: Is industrial IoT the solution. Wirel. Commun. Mob. Comput. 2018. [Google Scholar] [CrossRef]

- Shekhar, C.; Jain, M.; Iqbal, J.; Raina, A.A. Threshold control policy for maintainability of manufacturing system with unreliable workstations. Arab. J. Sci. Eng. 2017, 42, 4833–4851. [Google Scholar] [CrossRef]

- Sadati, N.; Chinnam, R.B.; Nezhad, M.Z. Observational data-driven modeling and optimisation of manufacturing processes. Expert Syst. Appl. 2018, 93, 456–464. [Google Scholar] [CrossRef] [Green Version]

- Ling, J.; Hutchinson, M.; Antono, E.; Paradiso, S.; Meredig, B. High-dimensional materials and process optimisation using data-driven experimental design with well-calibrated uncertainty estimates. Integr. Mater. Manuf. Innov. 2017, 6, 207–217. [Google Scholar] [CrossRef] [Green Version]

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in smart manufacturing: Research challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef] [Green Version]

- Chien, C.F.; Hsiao, C.W.; Meng, C.; Hong, K.T.; Wang, S.T. Cycle time prediction and control based on production line status and manufacturing data mining. In Proceedings of the IEEE International Symposium on Semiconductor Manufacturing, San Jose, CA, USA, 13–15 September 2005; pp. 327–330. [Google Scholar]

- Mourtzis, D.; Doukas, M.; Fragou, K.; Efthymiou, K.; Matzorou, V. Knowledge-based estimation of manufacturing lead time for complex engineered-to-order products. Procedia CIRP 2014, 17, 499–504. [Google Scholar] [CrossRef] [Green Version]

- Der Mauer, M.A.; Behrens, T.; Derakhshanmanesh, M.; Hansen, C.; Muderack, S. Applying sound-based analysis at porsche production: Towards predictive maintenance of production machines using deep learning and internet-of-things technology. In Digitalization Cases; Springer: Cham, Switzerland, 2019; pp. 79–97. [Google Scholar]

- Karray, M.H.; Chebel-Morello, B.; Zerhouni, N. A formal ontology for industrial maintenance. Appl. Ontol. 2012, 7, 269–310. [Google Scholar] [CrossRef] [Green Version]

- Hatefi, S.M.; Jolai, F.; Torabi, S.A.; Tavakkoli-Moghaddam, R. A Credibility-Constrained Programming for Reliable Forward–Reverse Logistics Network Design under Uncertainty and Facility Disruptions. Int. J. Comput. Integr. Manuf. 2015, 28, 664–678. [Google Scholar] [CrossRef]

- Rut, J.; Wołczański, T. Improving efficiency through optimization of the production process. Autobusy Tech. Eksploat. Syst. Transp. 2016, 17, 1841–1844. [Google Scholar]

- Kumar, N.; Kumar, J. Efficiency 4.0 for Industry 4.0. Hum. Technol. 2019, 15, 55–78. [Google Scholar] [CrossRef]

- Xavier, A.; de Melo Gonzalez, M. Analysis and improvement of production efficiency in a construction machine assembly line. Indep. J. Manag. Prod. 2016, 7, 606–626. [Google Scholar] [CrossRef] [Green Version]

- Ray, S.R.; Jones, A.T. Manufacturing interoperability. J. Intell. Manuf. 2006, 17, 681–688. [Google Scholar] [CrossRef]

- Chen, D.; Doumeingts, G.; Vernadat, F. Architectures for enterprise integration and interoperability: Past, present, and future. Comput. Ind. 2008, 59, 647–659. [Google Scholar] [CrossRef]

- Sabilla, S.I.; Sarno, R.; Effendi, Y.A. Optimizing time and cost using goal programming and FMS scheduling. In Proceedings of the International Conference on Information and Communications Technology (ICOIACT), Yogyakarta, Indonesia, 6–7 March 2018; pp. 244–249. [Google Scholar]

- Williams, D.; Tang, H. Data Quality Management for Industry 4.0: A Survey. Softw. Qual. Prof. 2020, 22, 26–35. [Google Scholar]

- Lusa, A. A survey of the literature on the multiple or parallel assembly line balancing problem. Eur. J. Ind. Eng. 2008, 2, 50–72. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Networks 2016, 101, 158–168. [Google Scholar] [CrossRef] [Green Version]

- Lasi, H.; Fettke, P.; Kemper, H.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Networks 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Maedche, A.; Staab, S. Ontology learning for the semantic web. IEEE Intell. Syst. 2001, 16, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Wan, J.; Chen, B.; Imran, M.; Tao, F.; Li, D.; Liu, C.; Ahmad, S. Toward dynamic resources management for IoT-based manufacturing. IEEE Commun. Mag. 2018, 56, 52–59. [Google Scholar] [CrossRef]

- Gruber, T.R. A translation approach to portable ontology specifications. Knowl. Acquis. 1993, 5, 199–220. [Google Scholar] [CrossRef]

- Corcho, O.; Gómez-Pérez, A.; Fernández-López, M. Ontological engineering. With examples from the areas of Knowledge Management, e-Commerce and the Semantic Web. Adv. Inf. Knowl. Process. 2004. [Google Scholar]

- Hobbs, J.R.; Pan, F. Time ontology in OWL. W3C Work. Draft. 2006, 27, 133. [Google Scholar]

- Compton, M.; Barnaghi, P.; Bermudez, L.; GarcíA-Castro, R.; Corcho, O.; Cox, S.; Graybeal, J.; Hauswirth, M.; Henson, C.; Herzog, A.; et al. The SSN ontology of the W3C semantic sensor network incubator group. J. Web Semant. 2012, 17, 25–32. [Google Scholar] [CrossRef]

- Grüninger, M. Using the PSL ontology. In Handbook on Ontologies; Springer: Berlin/Heidelberg, Germany, 2009; pp. 423–443. [Google Scholar]

- Lemaignan, S.; Siadat, A.; Dantan, J.Y.; Semenenko, A. MASON: A proposal for an ontology of manufacturing domain. In Proceedings of the IEEE Workshop on Distributed Intelligent Systems: Collective Intelligence and Its Applications, (DIS’06), Prague, Czech Republic, 15–16 June 2006; pp. 195–200. [Google Scholar]

- Grangel-González, I.; Baptista, P.; Halilaj, L.; Lohmann, S.; Vidal, M.E.; Mader, C.; Auer, S. The industry 4.0 standards landscape from a semantic integration perspective. In Proceedings of the 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–8. [Google Scholar]

- Chungoora, N.; Cutting-Decelle, A.F.; Young, R.I.; Gunendran, G.; Usman, Z.; Harding, J.A.; Case, K. Towards the ontology-based consolidation of production-centric standards. Int. J. Prod. Res. 2013, 51, 327–345. [Google Scholar] [CrossRef] [Green Version]

- Hodges, J.; García, K.; Ray, S. Semantic development and integration of standards for adoption and interoperability. Computer 2017, 50, 26–36. [Google Scholar] [CrossRef]

- Lu, Y.; Morris, K.C.; Frechette, S. Standards landscape and directions for smart manufacturing systems. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 998–1005. [Google Scholar]

- Darmois, E.; Elloumi, O.; Guillemin, P.; Moretto, P. IoT Standards–State-of-the-Art Analysis, Digitising the Industry Internet of Things Connecting the Physical, Digital and Virtual Worlds; Friess, P., Ed.; River Publishers: Gistrup, Denmark, 2016; pp. 237–263. [Google Scholar]

- Herzog, R.; Jacoby, M.; Žarko, I.P. Semantic interoperability in IoT-based automation infrastructures: How reference architectures address semantic interoperability. Automatisierungstechnik 2016, 64, 742–749. [Google Scholar] [CrossRef]

- Buchgeher, G.; Gabauer, D.; Martinez-Gil, J.; Ehrlinger, L. Knowledge Graphs in Manufacturing and Production: A Systematic Literature Review. IEEE Access 2021, 9, 55537–55554. [Google Scholar] [CrossRef]

- Kalaycı, E.G.; González, I.G.; Lösch, F.; Xiao, G.; Kharlamov, E.; Calvanese, D. Semantic integration of Bosch manufacturing data using virtual knowledge graphs. In Proceedings of the International Semantic Web Conference, Athens, Greece, 2–6 November 2020; Springer: Cham, Switzerland, 2020; pp. 464–481. [Google Scholar]

- Grangel-González, I.; Lösch, F.; ul Mehdi, A. Knowledge Graphs for Efficient Integration and Access of Manufacturing Data. In Proceedings of the 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 93–100. [Google Scholar]

- Wan, J.; Yin, B.; Li, D.; Celesti, A.; Tao, F.; Hua, Q. An ontology-based resource reconfiguration method for manufacturing cyber-physical systems. IEEE/ASME Trans. Mechatron. 2018, 23, 2537–2546. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Li, D.; Imran, M.; Zhang, C.; Liu, C.; Pang, Z. Reconfigurable smart factory for drug packing in healthcare industry 4.0. IEEE Trans. Ind. Informatics 2018, 15, 507–516. [Google Scholar] [CrossRef]

- Kovalenko, O.; Grangel-González, I.; Sabou, M.; Lüder, A.; Biffl, S.; Auer, S.; Vidal, M.E. AutomationML Ontology: Modeling Cyber-Physical Systems for Industry 4.0. IOS Press J. 2018. [Google Scholar]

- Grangel-González, I.; Halilaj, L.; Coskun, G.; Auer, S.; Collarana, D.; Hoffmeister, M. Towards a semantic administrative shell for industry 4.0 components. In Proceedings of the 2016 IEEE Tenth International Conference on Semantic Computing (ICSC), Laguna Hills, CA, USA, 4–6 February 2016; pp. 230–237. [Google Scholar]

- Grangel-González, I.; Halilaj, L.; Auer, S.; Lohmann, S.; Lange, C.; Collarana, D. An RDF-based approach for implementing industry 4.0 components with Administration Shells. In Proceedings of the 2016 IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016; Volume 6, pp. 1–8. [Google Scholar]

- Ramírez-Durán, V.J.; Berges, I.; Illarramendi, A. ExtruOnt: An ontology for describing a type of manufacturing machine for Industry 4.0 systems. Semant. Web 2020, 11, 887–909. [Google Scholar] [CrossRef]

- Jarvenpaa, E.; Siltala, N.; Hylli, O.; Lanz, M. The development of an ontology for describing the capabilities of manufacturing resources. J. Intell. Manuf. 2019, 30, 959–978. [Google Scholar] [CrossRef] [Green Version]

- Jarvenpaa, E.; Siltala, N.; Lanz, M. Formal resource and capability descriptions supporting rapid reconfiguration of assembly systems. In Proceedings of the 12th Conference on Automation Science and Engineering, and International Symposium on Assembly and Manufacturing, Fort Worth, TX, USA, 21–24 August 2016; pp. 120–125. [Google Scholar]

- Kaar, C.; Frysak, J.; Stary, C.; Kannengiesser, U.; Müller, H. Resilient ontology support facilitating multi-perspective process integration in industry 4.0. In Proceedings of the 10th International Conference on Subject-Oriented Business Process Management; ACM: New York, NY, USA, 2018; pp. 1–10. [Google Scholar]

- Petersen, N.; Galkin, M.; Lange, C.; Lohmann, S.; Auer, S. Monitoring and automating factories using semantic models. In Proceedings of the Joint International Semantic Technology Conference, Singapore, 26–28 November 2016; Springer: Cham, Switzerland, 2016; pp. 315–330. [Google Scholar]

- Mazzola, L.; Kapahnke, P.; Vujic, M.; Klusch, M. CDM-Core: A Manufacturing Domain Ontology in OWL2 for Production and Maintenance. In Proceedings of the KEOD, Porto, Portugal, 9–11 November 2016; pp. 136–143. [Google Scholar]

- Ferrer, B.R.; Mohammed, W.M.; Lobov, A.; Galera, A.M.; Lastra, J.L.M. Including human tasks as semantic resources in manufacturing ontology models. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 3466–3473. [Google Scholar]

- Ferrer, B.R.; Ahmad, B.; Vera, D.; Lobov, A.; Harrison, R.; Lastra, J.L.M. Product, process and resource model coupling for knowledge-driven assembly automation. Automatisierungstechnik 2016, 64, 231–243. [Google Scholar]

- Teslya, N.; Ryabchikov, I. Ontology-driven approach for describing industrial socio-cyberphysical systems’ components. In Proceedings of the MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 161, p. 03027. [Google Scholar]

- Bader, S.R.; Maleshkova, M. The Semantic Asset Administration Shell. In Proceedings of the International Conference on Semantic Systems, Karlsruhe, Germany, 9–12 September 2019; Springer: Cham, Switzerland, 2019; pp. 159–174. [Google Scholar]

- Cheng, H.; Xue, L.; Wang, P.; Zeng, P.; Yu, H. Ontology-based web service integration for flexible manufacturing systems. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 351–356. [Google Scholar]

- Seyedamir, A.; Ferrer, B.R.; Lastra, J.L.M. An ISA-95 based Ontology for Manufacturing Systems Knowledge Description Extended with Semantic Rules. In Proceedings of the 2018 IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 374–380. [Google Scholar]

- Saeidlou, S.; Saadat, M.; Amini Sharifi, E.; Jules, G.D. An ontology-based intelligent data query system in manufacturing networks. Prod. Manuf. Res. 2017, 5, 250–267. [Google Scholar] [CrossRef] [Green Version]

- Panetto, H.; Dassisti, M.; Tursi, A. ONTO-PDM: Product-driven ONTOlogy for Product Data Management interoperability within manufacturing process environment. Adv. Eng. Informatics 2012, 26, 334–348. [Google Scholar] [CrossRef] [Green Version]

- Borgo, S.; Leitao, P. Foundations for a Core Ontology of Manufacturing. In Ontologies; Springer: Boston, MA, USA, 2007; pp. 751–775. [Google Scholar]

- Prestes, E.; Carbonera, J.L.; Fiorini, S.R.; Jorge, V.A.M.; Abel, M.; Madhavan, R.; Locoro, A.; Goncalves, P.; Barreto, M.E.; Habib, M.; et al. Towards a core ontology for robotics and automation. Robot. Auton. Syst. 2013, 61, 1193–1204. [Google Scholar] [CrossRef]

- Olszewska, J.I.; Barreto, M.; Bermejo-Alonso, J.; Carbonera, J.; Chibani, A.; Fiorini, S.; Goncalves, P.; Habib, M.; Khamis, A.; Olivares, A.; et al. Ontology for autonomous robotics. In Proceedings of the IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN), Lisbon, Portugal, 28 August—1 September 2017; pp. 189–194. [Google Scholar]

- Kumar, V.R.S.; Khamis, A.; Fiorini, S.; Carbonera, J.L.; Alarcos, A.O.; Habib, M.; Goncalves, P.; Li, H.; Olszewska, J.I. Ontologies for industry 4.0. Knowl. Eng. Rev. 2019, 34. [Google Scholar]

- Schmidt, B.; Wang, L.; Galar, D. Semantic framework for predictive maintenance in a cloud environment. Procedia CIRP 2017, 62, 583–588. [Google Scholar] [CrossRef]

- Uddin, M.K.; Puttonen, J.; Scholze, S.; Dvoryanchikova, A.; Lastra, J.L.M. Ontology-based context-sensitive computing for FMS optimization. Assem. Autom. 2012, 32, 163–174. [Google Scholar] [CrossRef]

- Cao, Q.; Samet, A.; Zanni-Merk, C.; de Bertrand de Beuvron, F.; Reich, C. Combining chronicle mining and semantics for predictive maintenance in manufacturing processes. Semant. Web 2020, 1–22, in press. [Google Scholar] [CrossRef]

- Hussain, S.; Ahmed, M.A.; Kim, Y.C. Efficient power management algorithm based on fuzzy logic inference for electric vehicles parking lot. IEEE Access 2019, 7, 65467–65485. [Google Scholar] [CrossRef]

- Hussain, S.; Ahmed, M.A.; Lee, K.B.; Kim, Y.C. Fuzzy logic weight based charging scheme for optimal distribution of charging power among electric vehicles in a parking lot. Energies 2020, 13, 3119. [Google Scholar] [CrossRef]

- Hussain, S.; Lee, K.B.; Ahmed, M.A.; Hayes, B.; Kim, Y.C. Two-Stage Fuzzy Logic Inference Algorithm for Maximizing the Quality of Performance under the Operational Constraints of Power Grid in Electric Vehicle Parking Lots. Energies 2020, 13, 4634. [Google Scholar] [CrossRef]

- Cao, Q.; Samet, A.; Zanni-Merk, C.; de Beuvron, F.D.B.; Reich, C. An ontology-based approach for failure classification in predictive maintenance using fuzzy C-means and SWRL rules. Procedia Comput. Sci. 2019, 159, 630–639. [Google Scholar] [CrossRef]

- Aljumaili, M.; Wandt, K.; Karim, R.; Tretten, P. eMaintenance ontologies for data quality support. J. Qual. Maintenance Eng. 2015, 21, 358–374. [Google Scholar] [CrossRef]

- Pal, K. Integrating Heterogeneous Enterprise Data Using Ontology in Supply Chain Management. In Proceedings of the Big Data and Knowledge Sharing in Virtual Organizations 2019; IGI Global: Hershey, PA, USA, 2019; pp. 71–102. [Google Scholar]

- Giménez, D.M.; Vegetti, M.; Leone, H.P.; Henning, G.P. PRoduct ONTOlogy: Defining product-related concepts for logistics planning activities. Comput. Ind. 2008, 59, 231–241. [Google Scholar] [CrossRef]

- Vegetti, M.; Leone, H.; Henning, G. PRONTO: An ontology for comprehensive and consistent representation of product information. Eng. Appl. Artif. Intell. 2011, 24, 1305–1327. [Google Scholar] [CrossRef]

- Singh, S.; Ghosh, S.; Jayaram, J.; Tiwari, M.K. Enhancing supply chain resilience using ontology-based decision support system. Int. J. Comput. Integr. Manuf. 2019, 32, 642–657. [Google Scholar] [CrossRef]

- Hendi, H.; Ahmad, A.; Bouneffa, M.; Fonlupt, C. Logistics optimization using ontologies. In Proceedings of the 4th international Conference on Complex Systems and Applications, Normandy University, Le Havre, France, 23–26 June 2014. [Google Scholar]

- Du, J.; Jing, H.; Choo, K.K.R.; Sugumaran, V.; Castro-Lacouture, D. An ontology and multi-agent based decision support framework for prefabricated component supply chain. Inf. Syst. Front. 2019, 22, 1467–1485. [Google Scholar] [CrossRef]

- Wang, S.; Chen, K.; Liu, Z.; Guo, R.Y.; Chen, S. An ontology-based approach for supply-chain quality control: From a principal–agent perspective. J. Inf. Sci. 2019, 45, 283–303. [Google Scholar] [CrossRef]

- Pal, K. A Semantic Web Service Architecture for Supply Chain Management. Procedia Comput. Sci. 2017, 109, 999–1004. [Google Scholar] [CrossRef]

- Pal, K. Ontology-based web service architecture for retail supply chain management. Procedia Comput. Sci. 2018, 130, 985–990. [Google Scholar] [CrossRef]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation: A Preliminary Maturity Model for Leveraging Digitalization in Manufacturing Moving to smart factories presents specific challenges that can be addressed through a structured approach focused on people, processes, and technologies. Res. Technol. Manag. 2018, 61, 22–31. [Google Scholar]

| Keywords/Terms | |

|---|---|

| Method | (“ontology”) & |

| (“knowledge graph”) & | |

| Field | (“industry 4.0”) + |

| (“industrie 4.0”) + | |

| (“production line”) + | |

| (“smart manufacturing”) + | |

| (“industry 4.0 standards”) + | |

| (“reference architectures”) + | |

| (“machine process”) + | |

| (“resources”) + | |

| (“cyber physical system”) + | |

| (“data model”) + | |

| (“supply chain”) + | |

| (“predictive maintenance”) |

| Source | Name |

|---|---|

| Digital Library | IEEE Xplore |

| ACM Digital Library | |

| Scopus | |

| Science Direct | |

| Other | Google Scholar |

| Paper | Ontology | Research Focus | Dataset |

|---|---|---|---|

| Grangel-Gonzalez et al., 2017 | Standard Ontology (STO) | Solving interoperability issues between the analogous standards used by reference architectures. | STO dataset (https://github.com/i40-Tools/I40KG, accessed on 1 May 2021) |

| Wan, J. et al., 2018 | Resource reconfiguration ontology | Integration of intelligent manufacturing equipment using resource configuration ontology. | Populated the ontology with the data produced by the manipulator using raspberry pi. |

| Jarvenpaa, E. et al., 2018 | Manufacturing Resource Capability Ontology (MaRCO) | Development of resources ontology to describe manufacturing resources capabilities. | Data were taken from the Industrial laboratory Demonstration setup |

| Ferrer, B.R. et al., 2016 | Product, Process, Resource | Integration of Product, Process, and Resource | Festo Modular System (a testbed for an industrial test.) |

| Ramirez-Duran et al., 2020 | ExtruOnt | Describing extruder components, 3D representations, and spatial connections, features, and sensors capturing data. | Data were taken from the extruder manufacturing factory. |

| Kaar, C. et al., 2018 | Process | Decomposed the sentences of RAMI 4.0 standards, architectures, and models into concepts map to integrate the processes of industry 4.0. | X |

| Teslya, N. et al., 2018 | Components of Socio-Cyber Physical systems | Establishing a specific information space to connect all the production components. | X |

| Grangel-Gonzalez, et al., 2016 | I4.0 components | Semantically represented the I4.0 devices in administration shell | https://cdd.iec.ch/cdd/iec61360/iec61360.nsf, accessed on 1 May 2021 |

| Cheng, H. et al., 2016 | I4.0 Demonstration Production line | Modelled the I4.0 production line | X |

| Petersen et al., 2016 | Semantic Manufacturing Ontology (SMO) | Modeling of Smart factory | X |

| Seyedamir, A. et al., 2018 | Modular Ontologies (ISA-95) | Modeling Smart Factory | Data produced on FASTory simulator http://escop.rd.tut.fi:3000/fmw, accessed on 1 May 2021 |

| Kalaycı et al., 2020 | Surface Mounting Process (SMT Ontology) | Integration of Bosch Manufacturing Data for analysis | Data taken from Bosch, no information available |

| Grangel-Gonzalez et al, 2020 | SMT ontology combined with Domain ontologies | To acheive interoperability in I4.0. | Data taken from Bosch, no information available. |

| Article | Sales | Manufacturing Production Line | Predictive Maintenance | Industry Standard | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Device | Operator (Human) | Process/Operation | Product | Time | Sensor | Material | ||||

| Grangel-Gonzalez et al., 2017 | X | X | X | X | X | X | X | X | X | |

| Lemaignan, S. et al., 2006 | X | X | X | X | ||||||

| Wan, J. et al., 2018 | X | X | X | X | X | X | X | |||

| Jarvenpaa, E. et al., 2018 | X | X | X | X | X | X | X | |||

| Ferrer, B.R. et al., 2016 | X | X | X | X | ||||||

| Ramirez-Duran et al., 2020 | X | X | X | X | X | X | ||||

| Kaar, C. et al., 2018 | X | X | X | X | X | X | X | X | ||

| Teslya, N et al., 2018 | X | X | X | |||||||

| Grangel-Gonzalez et.al, 2016 | X | X | X | X | X | X | X | X | ||

| Cheng, H. et al., 2016 | X | X | X | X | ||||||

| Petersen, N. et al., 2016 | X | X | X | X | X | X | X | X | X | |

| Schmidt, B. et al., 2017 | X | X | X | X | X | X | X | X | X | |

| Giustozzi, F. et al., 2018 | X | X | X | |||||||

| Seyedamir, A. et al., 2018 | X | X | ||||||||

| Kalaycı et al., 2020 | X | X | X | X | X | X | ||||

| Grangel-Gonzalez et al, 2020 | X | X | X | X | X | |||||

| Our Proposed approach | ||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahya, M.; Breslin, J.G.; Ali, M.I. Semantic Web and Knowledge Graphs for Industry 4.0. Appl. Sci. 2021, 11, 5110. https://doi.org/10.3390/app11115110

Yahya M, Breslin JG, Ali MI. Semantic Web and Knowledge Graphs for Industry 4.0. Applied Sciences. 2021; 11(11):5110. https://doi.org/10.3390/app11115110

Chicago/Turabian StyleYahya, Muhammad, John G. Breslin, and Muhammad Intizar Ali. 2021. "Semantic Web and Knowledge Graphs for Industry 4.0" Applied Sciences 11, no. 11: 5110. https://doi.org/10.3390/app11115110

APA StyleYahya, M., Breslin, J. G., & Ali, M. I. (2021). Semantic Web and Knowledge Graphs for Industry 4.0. Applied Sciences, 11(11), 5110. https://doi.org/10.3390/app11115110