1. Introduction

The estimation of the soil resistivity as a function of the depth is a key point for modelling any grounding system [

1]. There are several methods to determine the soil resistivity. Most of them are indirect methods that use an intermediate magnitude as the apparent resistivity. In one of the most used methods, the resistivity is estimated from a vertical electrical sounding (VES) performed with a four-pin device as in the Wenner and Schlumberger arrays, from which the apparent resistivity is obtained [

2]. From the apparent resistivity, it is possible to find out the soil resistivity profile, provided that a constant multi-layered model has been adopted [

3,

4]. Even though the VES is a non-invasive procedure, small errors in the measuring procedure could lead to a soil model far from the real one. The ill-conditioned nature of the method to obtain the resistivity profile from the soil’s apparent resistivity is at the bottom of the issue [

5,

6]. On the other hand, in some sense a VES could be seen as a non-local test since the soil conductivity between the active electrodes of the test array is being checked. Note for instance that in a Wenner array the active electrodes are separated three times the distance between adjacent probes. The soil properties could change horizontally leading to a soil resistivity profile that would not match with the real one. This is especially important when a grounding system makes use of vertical rods as grounding electrodes, such as in the case of lightning protection electrodes.

Another indirect procedure sometimes used is the driven-rod method. In this method, the grounding resistance of a rod driven into the ground is measured by the fall-of-potential procedure [

7]. If the rod is modeled as a cylinder of length L and radius r, where L >> r and with a hemisphere at the end, the grounding resistance in a homogeneous medium of resistivity, rho, is

. On the other hand, if the rod is modeled as a half-ellipsoid of revolution, whose major axis is L and its minor axis is the diameter d, the expression

must be used. Another expression widely used to theoretically estimate grounding resistance is

[

8] in which the supplementary assumption is made that the ground leakage current has a constant distribution along the rod. By varying the length of the rod, an apparent resistivity profile

representing the resistivity seen by the rod of length L can be obtained.

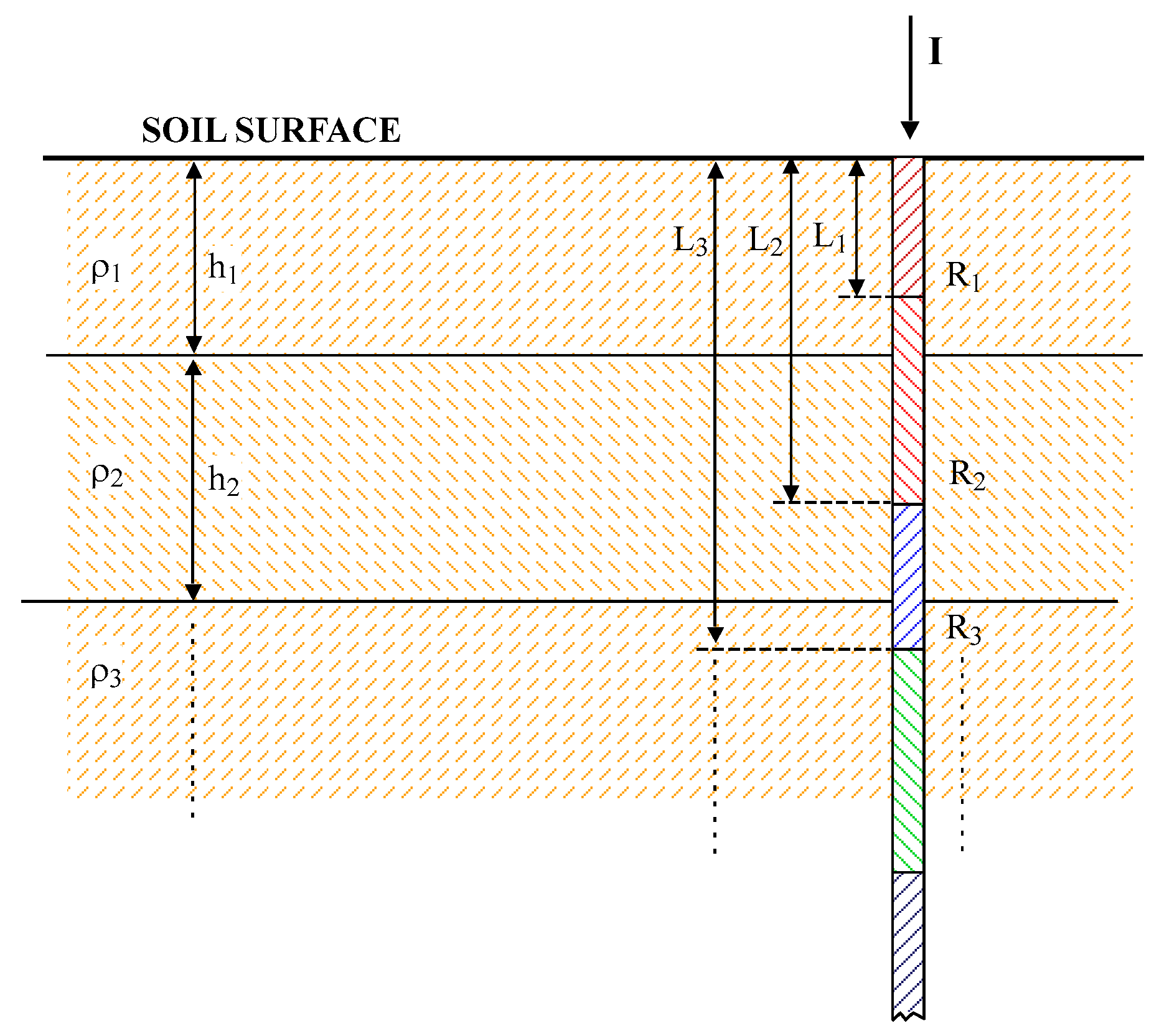

Figure 1 outlines the data that are necessary to implement the method. An advantage of the driven-rod method is that it allows obtaining valuable information on the feasibility of a grounding system. Knowing the necessary depth to obtain a given grounding resistance could greatly facilitate the final touch-up of the grounding system design.

An important observation is that the above mentioned VES method is not very sensitive to the state or type of electrodes used except for a shallow depth where the electrodes are very close together and their size and shape influence somewhat the potential [

9]. In general, it does not matter if the electrodes are corroded or if they have a great internal resistance since what is measured is a potential difference on the ground. In contrast, the driven-rod method is greatly affected by oxidation and the internal resistance of the rod. The previous expressions for the grounding resistance

R as a function of the rod length

L, were found under the condition that the rods are ideal conductors without internal resistance. Therefore, it is to be expected that this fact will need to be taken into account when looking for a model for soil resistivity. There are more reasons, in addition to those already exposed, to incorporate the internal resistance of the conductors into the calculation scheme of the electrical properties of a grounding electrode. The current trend of using materials with non-negligible internal resistance such as carbon steel or others for the electrodes of a grounding system makes it necessary to study their effect on the parameters of the system. After setting a calculation model for the electrodes that takes into account their internal resistance, the here called Resistive Driven-Rod method (RDR), which takes into account the internal resistance of the rod will be applied both to synthetic and real soils.

A direct method to determine the resistivity as a function of the depth is known in literature as normal resistivity logging (NRL) [

10]. This is a geophysical method for determining the rock’s conductivity by studying the drilling geological profile in a well. However, this technique requires the drilling of a well of a section large enough for the probes to be introduced. Resistivity is measured with a four-pin device taking a short electrode separation so that the well walls can be tested. To complete this brief review of several of the methods used to investigate the electrical structure of soils, mention should be made of the magnetic field-based eddy-current methods (ECM), framed in the transient electromagnetic methods class. By means of a coil near the soil surface, a variable magnetic field is produced. Eddy-currents are generated in the conductive soil, producing magnetic fields that depend on the layer structure. Although they are based on very different principles from those of the methods described so far, ECM are clearly non-invasive methods with high resolution at shallow depth [

11].

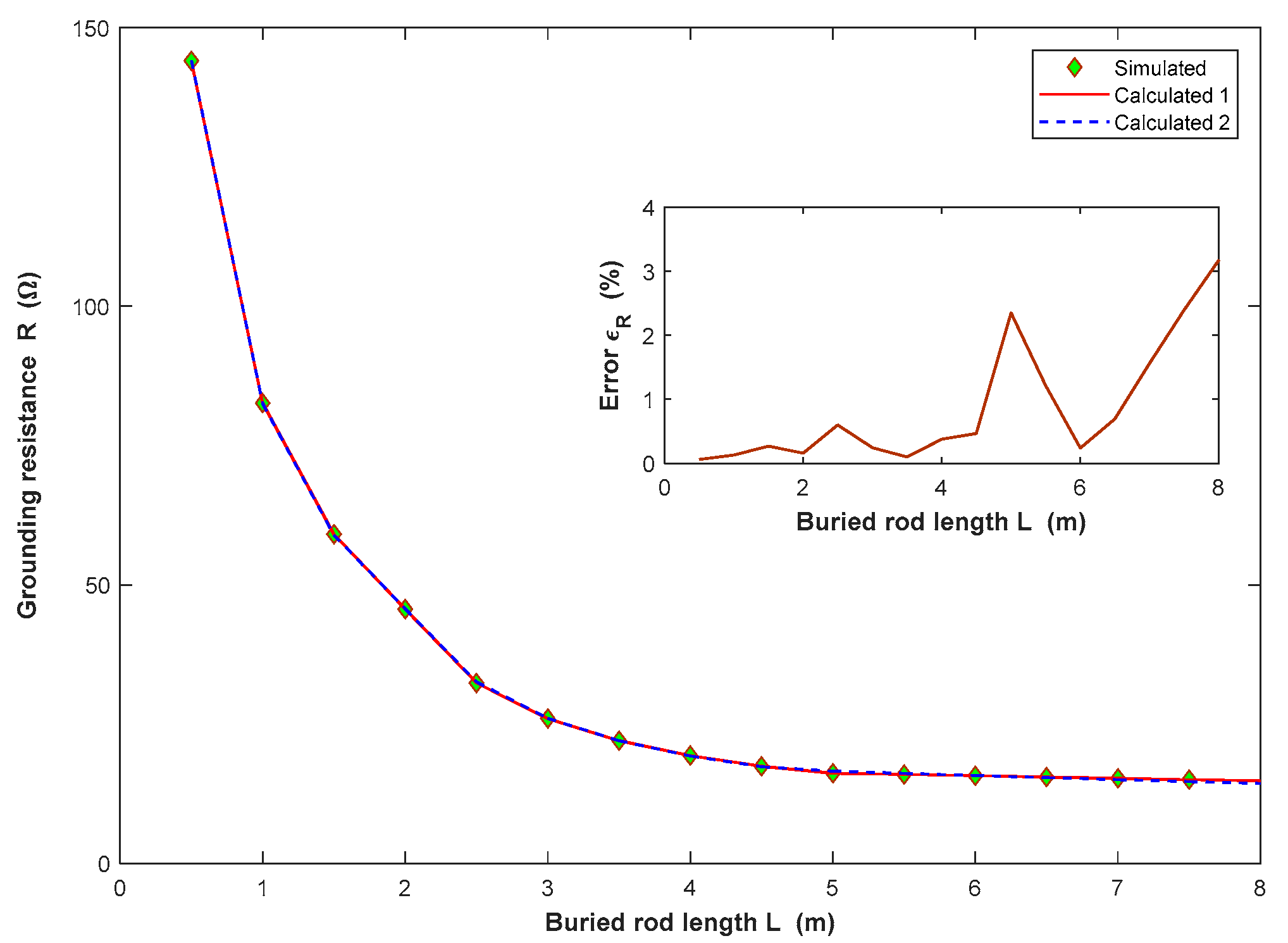

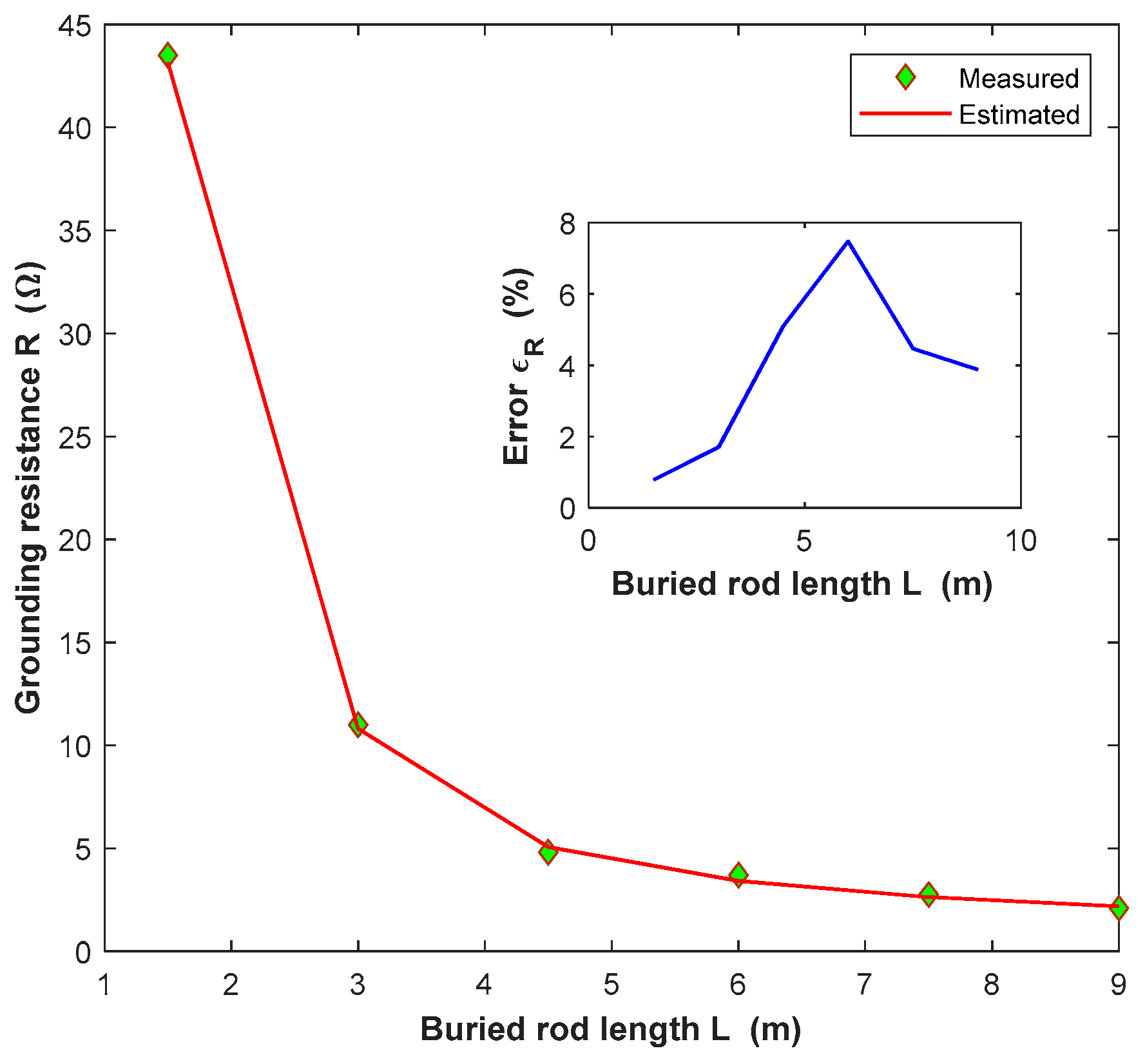

From the apparent resistivity data obtained with the indirect methods described above, the soil resistivity profile can be obtained by posing an inverse problem. Starting from semi-analytical expressions for the grounding resistance as a function of the parameters of a multilayer model, an optimization algorithm is implemented to find the set of parameters of the model that minimizes the squared differences between the values of the resistance measured in the field and those calculated with the theoretical expressions that contain the parameters. However, the techniques used in the inverse problem with the measurements made with the Wenner array cannot be extended when the measurements come from a driven-rod logging. Apparent resistivity has a different meaning depending on the type of measurement.

The main objectives of this paper are, firstly, to establish a systematic procedure to include the internal resistance of conductors in the calculation of the grounding resistance of buried electrodes, and secondly, testing the feasibility of the RDR method to determine the parameters of a multilayer soil model from grounding resistance measurements, pointing out its limitations. To achieve these goals, the paper is structured as follows. After the present introduction, the backgrounds section is intended to introduce the foundations of the proposed method. In the next section, some tests are carried out on synthetic soils in order to test the method relevance. In the same section some real examples are also studied. Finally, the conclusions of the work are collected in the last section.

2. Modeling Grounding Electrodes with Internal Resistance: Backgrounds

The calculation of the grounding resistance of an electrode needs the model for the electrical conductivity of the soil to be known. From a general point of view, it would be necessary to solve the equation together with some boundary conditions, where is the absolute potential at the point and represents the conductivity of the ground. For a multilayered model it is possible to find acceptable semi-analytical solutions for the potential. This model assumes that conductivity is just a non-continuous piecewise constant function. The soil is composed of horizontal layers of infinite extension and specific thickness in which the electrical conductivity takes a constant and different value in each layer. Thus, the actual conductivity is replaced by a step function although in practice, due to the difficulty of the calculations, only a few layers are considered. The soil conductivity profiles of interest for this work comprise layers of almost any conductivity with thicknesses ranging from a few centimeters to tens of meters. Although for applications in grounding design it is common to deal with models in which the top layer is a few meters thick in which to place the grounding electrode.

Choosing a constant conductivity in each layer allows calculating the potential from the equation for a generic conductivity. The connection between the solutions corresponding to each layer is made by imposing the continuity of the potential at the different interfaces as well as the continuity of the normal component of the current density through interfaces.

Due to the supposed cylindrical symmetry of the potential, which is associated with conductivity dependent only on the depth as the z coordinate, the procedure to solve the equation for the potential relies on using the method of separation of variables in a cylindrical coordinate system. Thus, the potential created in layer

j by an electric point current source of strength

I in layer

i could be written as [

12]

where

is the Kronecker delta and the unknown functions

and

need to be calculated by imposing the boundary conditions at each interface, namely

which stands for the null current flux through the soil surface and

what guarantees continuity of potential and normal current flux conservation through the interface separating the layers

j and

j + 1. In (1) and (2),

, is the constant resistivity of layer

i,

and

is the zero-order Bessel function. In (1) the functions

and

must be calculated by (2) at the above-mentioned interfaces. The calculation of the functions

f and

g can be difficult and the evaluation of the integral in (1) is only approximate due to the oscillatory character of the

Bessel function, in addition to the own singularities of the

f and

g functions [

13].

In order to properly implement the boundary conditions (2), it is necessary to convert the first term on the right hand of (7) to an integral form so that the entire expression is in an integral form. The integral forms of Lipschitz (3), allow such a conversion to be carried out [

14],

Thus, the boundary conditions (2) lead to a linear system in the unknowns and that is solved by symbolic calculus using the software Wolfram Mathematica.

The point current source potentials (1), serve as the basis for calculating the grounding resistance of any electrode, particularly a rod driven into the soil. If it is a perfectly conductive rod, the potential can be calculated using the superposition law and the grounding resistance, as well as the step and touch potentials can be obtained. Indeed, the expression (1) stands for the potential generated by a single point current source. When an extended electrode leaking a fault current to the ground is considered, expressions like (1) can be used under some conditions imposed on the electrodes. The electrodes are assumed as composed by thin wire pieces assembled to form the entire electrode. Thus, each thin wire could be considered as a distribution of point current sources located in the axis. The potential at point

of the layer

j generated by a thin wire of length L located in the layer

i, is given by

where

stands for the point current sources density along the thin wire axis and the functions

and

need to be calculated, again imposing the boundary conditions at each interface. A more general situation could take place when the thin wire is between several layers at the same time. In practice, the thin wire is segmented in M short pieces of length

each of them with constant point current sources density

, which are used to calculate the potential of the electrode itself by imposing a constant value of such potential along the entire electrode, the grounding electrode potential [

15]. Thus, the potential at point

of the layer

j becomes:

This procedure, known as moment method, gives rise to a system of linear equations whose unknowns are the constant densities

of point current sources in each segment [

16]. The knowledge of these densities allows the calculation of the potential at any point on the ground by superposition. The electrode potential itself is of special interest for this work. As it was pointed out, it is obtained as a part of the solution for the

densities and then the grounding resistance can be easily calculated.

When the electrode is a conductor with non-zero internal resistance, the calculation of the potential acquired by the electrode is somewhat more complicated since it is no longer equipotential. In this case, the electrode potential is commonly measured at the current injection point which is the point of the electrode where the fault current to be leaked to the ground enters. Usually, for electrodes with non-negligible internal resistance, both the current injection point and the measurement point are important parameters since the potential value is strongly dependent on the internal distribution of leakage currents to the ground. With respect to the model used to take into account the internal resistance of the electrodes, the one used here is the Circuit-Based Model (CBM) [

17,

18]. According to this model, the electrodes are broken down into branches and nodes to which circuit theory applies.

Figure 2 shows in the upper part a rod like the ones used in the driven-rod test, which is divided into N branches. The potential

Uk and the leakage current

Ik in each branch are displayed. At the bottom, the circuit-based model is shown. At each node of the circuit, the potential

Vt and the source of nodal leakage current

Jt are located. The internal currents

ik that move inside the conductor are also shown.

Each branch obeys a general equation for the potential difference between the ends (nodes) that for the generic branch k takes the form,

where

B is the number of branches of the electrode system containing

N nodes,

ir is the current through the branch

r,

zk is the internal resistance of the branch

k and

is the inductive impedance of the branch

k due to the branch

r (sometimes called longitudinal impedance), which can be neglected for stationary or low frequency currents.

Figure 3 shows a diagram of the magnitudes introduced for a branch of the circuit.

The branch currents ik and the node currents Jn are related by Kirchhoff’s law: for the node n, the algebraic sum of all currents that concur in the node is zero, , where the possible source or injection currents Fn on the node n have been introduced. This expression must be introduced in (6) so that only the currents and potentials of node, Jn and Vn respectively, together with the supply currents Fn, are considered as the main variables.

To establish the relationship between the currents in the nodes, it is necessary to agree on a consistent sign criterion. It will be agreed to consider positive the outgoing currents of the nodes either towards the branches,

ik, or towards the ground,

Jn, and the potential differences between the nodes of each branch will be evaluated from the node through which the current leaves until the node through which it enters. Using this convention, it can be written:

The square matrix G is constructed from Kirchhoff’s law in each node, Ohm’s law in each branch and the branch-node connection matrices, all together with the coherent criterion of signs for the currents.

At the same time that a potential difference due to the internal circulation of branch currents is generated in each branch, an absolute potential (with respect to the null potential of infinity) is also generated in each branch due to the leakage currents towards the surrounding conductive soil. Thus, each branch acquires a potential

Uk, which depends on the currents filtered to the ground by all other branches

Im, including the branch

k itself. Thus, it can be stated

where the impedance

Zkm (sometimes called transverse impedance [

19]) has the following expression for a multi-layered soil,

The expressions (8) and (9) are completely equivalent to (5) with

. Moreover,

is the soil resistivity around the branch

m and as it was already mentioned before, the functions

and

are calculated by imposing the boundary conditions at each interface [

12].

From the expressions (8) and (9) it is shown that the absolute potential acquired by the branch k as a result of the current filtered to the ground, can be put in the matrix form , where the subscripts indicate the dimension of the matrices (B will denote the number of branches and N will denote the number of nodes) and the square matrix (ZT) is the matrix of transverse impedances.

For a proper application of circuit analysis, it is necessary to establish a relationship between leakage currents and potentials in the branches and nodes. In

Figure 3, two types of currents are shown, the leakage current of the branch

Ii and those that go from the nodes of the branch

Jk+ y

Jk-, both towards the surrounding medium. It will be agreed that both node and branch currents to the surrounding medium are related by the matrix equation

where (

C) is a matrix of

N rows (nodes) and

B columns (branches) whose elements are

This means that each branch leakage current

Ii is divided into two halves that go to the currents of nodes

and

. With regard to the branch potential

Ui and the potentials of the branch nodes

Vi+ and

Vi-,

with (

K) being a matrix of

B rows (branches) and

N columns (nodes), whose elements are

which really means that the branch potential is the average value of the potentials of its nodes

. With Equations (7), (8), (10) and (12) a system of matrix equations can be proposed,

Defining a vector of unknowns consisting of currents and potentials

In y

Vn

the system of Equation (14) can be written as

which allows us to find the solution of the problem in terms of potentials and currents.

The electrode potential is the one corresponding to the node through which the current enters the electrode and the grounding resistance is the quotient between this potential and the injected current. Note that both depend on the parameters of the multilayer model chosen through and the functions and in (9).

For an

L length rod driven into the soil of parameters

, the calculated grounding resistance will be denoted as

. In practice, a direct measurement in the field of the grounding resistance

Rmeas of the rod by the fall-of-potential method is performed. The control variable is the rod length

L, thus a set of grounding resistance values corresponding to increasing lengths of the rod are available. From these measurements an optimization algorithm that minimizes

could be implemented. This problem falls into the category of so-called inverse problems, which are very often ill-conditioned. That means in practice that uncertainties in the measurements of grounding resistance can led to very dramatic changes in the parameter values of the multilayered model. Consequently, there may be no single solution to the resistivity profile from the measured grounding resistance series.

To finish this section, some considerations about the model presented here will be discussed. The internal resistance of a grounding electrode plays an important role for several reasons. In the first place, as already mentioned, the electrode is no longer equipotential, and the grounding resistance must be defined as indicated above. The current injection point is an important choice and must be chosen so that its potential is as low as possible. Second, the calculations made with this model allow validating or discarding materials to be used in electrodes on condition of verifying technical requirements on the value of the grounding resistance and the step and touch potentials required in an installation. Note that increasing the size of the electrodes can help to decrease the grounding resistance as long as the internal resistance of the conductors does not result in a final increase in the grounding resistance. Finally, another effect to consider that can only be evaluated with models such as the one presented here is the heating by the Joule effect on the electrodes. The heat generated can cause an unwanted increase in grounding resistance when taking into account the variation in resistivity with temperature. The effect must be studied and only models that take into account the internal resistivity of the conductors are valid for this purpose.