1. Introduction

The major components of the hydrological cycle are precipitation, evaporation, transpiration, infiltration, groundwater, and streamflow. Precipitation provides the input of water to watersheds, primarily as rain, snow, sleet, and hail. Precipitation moving in macropores and mesopores that are well connected vertically through the entire soil mantle is the primary mechanism for the resupply of groundwater, known as groundwater recharge [

1].

Evaporation is the movement of water from the liquid state to the vapor state and then to the atmosphere. Evaporation occurs from any wet surface. The process effectively reduces the moisture in the soil on leaves that have been moistened by rain, or the moisture in the water body itself. Transpiration, another major evaporative process, is water that moves from the soil and roots via the plant’s internal moisture supply system to the atmosphere. Transpiration moves through the stomates, which are minute openings in the leaves, mostly on their undersides, that allow the passage of oxygen, carbon dioxide, water vapor, and other gases. The combined evaporative processes are termed evapotranspiration [

2].

Streamflow is the combined result of all climatological and geographical factors that operate in a watershed. It is the only phase of the hydrological cycle in which the water is confined in well-defined channels, and this permits accurate measurements to be made of the involved quantities. Other measurements of the hydrological cycle are point measurements for which the uncertainties, on an area basis, are difficult or impossible to estimate [

3]. Point precipitation is measured using a gauge, which consists of a collector to delineate the area of the sample and a funnel leading to a storage device. The area of the collector and the size of the gauges vary depending on the amount of precipitation normally received in the region where the station is located [

4].

Several methods are available for estimating the evaporation from an open water body. These have significant drawbacks, mainly the requirement for several meteorological variables, for example: wind velocity and humidity measurements. These values are not commonly available in most watersheds [

5]. The evaporation pan method is generally considered the least accurate method. It is the only existing method that does not require site-specific measurements and that is commonly used in water resource investigations [

6].

The pan, which is a routine evaporometer at hydrological and meteorological stations, is the simplest, cheapest, and most practical meteorological method for measuring local atmospheric evaporation demand [

7]. Additionally, pan evaporation measurements provide an important reference for water resource assessment, hydrological research, climatic zoning, and for monitoring evaporative climate change [

7,

8,

9].

A basic tool for computing the water balance and for estimating water availability and requirements is the estimation of evapotranspiration from vegetated surfaces. Research in this area is abundant, and it has provided theoretical knowledge and practical applications, mainly validated through adequate field measurements [

10].

In addition to evapotranspiration, evaporation from the water surface is one of the determining components of the hydrological water cycle. Evaporometers are used to measure it. The simplest evaporometer is an evaporometer from the free water surface. The evaporation rate is calculated by the change in the level of the free water surface [

11].

The determining parameter of the evaporator is the accuracy with which it measures the change in water level, and thus the water loss in mm. The evaporation is most often measured in mm per day. In addition to operational shortcomings, the problem with professional evaporometers is the high price, which limits the scale of their use, and thus the spatial accuracy of the measurements [

12].

The most widely used method for measuring the water level in an evaporometer is currently a float connected via a pulley to a counterweight. The pulley is connected to a rotating resistor with a variable resistance, called a rheostat, and the rheostat resistance is measured. This method requires very precise calibration and is maintenance intensive and fault sensitive during operation. The main problem with this method is the presence of moving parts. The advantage of the method is the almost unlimited measuring range [

13].

Evaporometers were developed in the past with various level measurement methods. Float measurement was mainly used, then ultrasonic or laser measurements [

14]. Finally, measurements based on mass sensors and contact sensors were developed. Precise capacitive sensors do not use a plain direct current, but a signal with a particular frequency. The resulting signal from the sensor needs signal conditioning via several operational amplifiers and a bridge rectifier. In the conditioning circuit, there is also a multitude of different resistors [

15]. Another proven way to measure evaporation is to manually read the water level height using a calliper. All these methods have their advantages and disadvantages [

16].

Float measurement is prone to mechanical impurities and to failure of electromechanical parts due to moisture penetration along the rheostat axis. Ultrasonic measurement is not accurate enough for measuring evaporation in the field. Laser measurement is accurate but is sensitive to water turbidity. Mass measurement is accurate but is difficult to calibrate and is characterized by complex construction of the measuring vessel mounting. Contact measurement is characterized by a large number of contacts, and subsequently by a very complex electronic solution. A simple capacitive water level sensor has low accuracy. Manual reading is accurate and reliable, but it is impossible on a large scale and when there are a large number of evaporometers [

17].

3D printing technology in combination with the contact capacitive approach was tested as a new approach to evaporation measurements. 3D printing is a way to design and manufacture products. This technology has gained significant academic interest due to its ability to create complex geometries, and also due to the rapid prototyping that it can provide. 3D printing has also inspired the development of the maker movement by democratizing design and manufacturing [

18].

In the fused deposition modeling method, a continuous string of thermoplastic polymer filaments is used to 3D print layers of materials. The filament is heated at the nozzle to reach an almost liquid state, and is then extruded on the platform or on top of previously printed layers. In this way, the product is created layer by layer [

19]. The thermoelectricity of the filament is a crucial property for this method, which allows the filaments to fuse together during printing and then to solidify at room temperature after printing [

20]. The simplicity of the process drives its low cost and the high speed of production. Disadvantages of the method are weak mechanical properties, visible layers, and poor surface quality [

21].

3D printing technology, in combination with the microcontrollers and devices connected to them, enables the creation of prototypes of new sensors. One of the most widespread microcontrollers is the Arduino board [

22,

23]. This board, with a number of standard shields and sensors, can be used as a building block for the rapid development of intelligent devices for sensing, control, and Internet access. The Arduino family of boards is well known in the maker community, and a large number of units have been sold. The units combine open access, reliability, robustness, standard connections, and low price. Arduino boards can function independently, so they can perform various tasks requiring interaction with the environment. Arduino boards are programmed via a number of libraries which smooth the cooperation with sensors and other devices [

24]. A specific library has been created for measuring electrical capacitance [

25].

This technical background pushed us to use 3D printing in combination with open-source electronics to measure the change in the water depth in a Class A Pan Evaporometer, or another similar device. This approach required us to put the device on a support which would rise the device above the water level, and this support can also serve as a wave breaker. Thus, the basic idea of the device was set up. The device sits atop a water-calming support. An easy to modify but sturdy material for this support can be PVC sewer pipe.

2. Materials and Methods

This chapter describes the materials we used for the construction of the device and methods we used to build it and subsequently test it. This section is separated into sub-sections according to the particular field of problematics.

The initial approach to the problem started with the idea of measuring the water height by simple capacitive measurement. In this approach, the capacitance of the circuit is measured, and two insulated metal electrodes in the measured basin serve as a capacitor. A rising or falling water level changes the capacity of the circuit, because air and water have very different capacitances. The experimental setup, consisting of two steel plates joined by plastic screws, was created, and this capacitor was then insulated by insertion into the finger of a laboratory glove. Testing of the device was done by submerging the device in water.

2.1. 3D Printing

Accurate water level measurements are important for the development of the evaporometer. The accuracy of 3D printing with widely used materials depends on the nozzle that is used. The thickness of the layer usually lies within the range of 0.1 to 0.2 mm. This feature of 3D printing provides the option to place sensors with similar accuracy, and it is therefore possible to achieve the accuracy needed for water level measurements. In addition, rapid prototyping is one of the primary uses for 3D printing. We therefore chose this method for the first trial and error tests, and during the testing, we found several ways in which 3D printing can improve the final design.

All the 3D printing was done on an Original Prusa i3 MK3S+ 3D printer. This is the successor of the award-winning Original Prusa i3 MK2 3D printer. With the rebuilt extruder, a plethora of sensors and the new magnetic MK52 build platform with a replaceable PEI spring steel print sheet were available. This 3D printer is equipped with a multi-material upgrade, which allows materials of the source filament to be changed during printing. In this way, as many as five materials can be used while printing an individual product. The Prusa printer comes with slicer software, which enables all necessary print settings to be specified.

Several print settings were tested, and finally the printing style was stabilized as follows: (a.) the infill of the printing was chosen to be 20%, which avoids the device being structurally stressed, (b.) aesthetics was not an issue during printing, so printing scenario 0.20 SPEED was chosen, (c.) the design of the device allowed for printing without supports. The temperature of the nozzle was set to be in between the manufacturer’s advised values. This meant 175 °C for PLA and 240 °C for PETG. The build platform temperature was set to be 60 °C for PLA and 80 °C for PETG.

To ease the printing of multiple materials, mainly shortening the time needed to change the spool of different materials, we used the Multi Material 2S upgrade kit (MMU2S). This upgrade enables the printer to automatically change between up to 5 spools of 3D printing string. This switch can be done even during the printing of a layer. Prints consisting of multiple different materials can thus be made.

Some filament materials were tested for this device. The first prints were made with PLA plastic. This material showed good results for precision, for ease of printing, and for assembly. However, during reliability testing, the print of this material was severely deformed due to sun exposure. Testing continued with the universally used PETG plastic. This material proved to be reliable and stable enough, so it was chosen to be the final material.

Assembly jigs can provide improved precision, so it is also possible to work on the electronic part of the device in house. In particular, the through holes can be drilled and the circuit board can be etched.

Jigs are not structurally demanding parts of the device. Their lifespan is projected only during the manufacture of the device or set of devices. The use of PLA is therefore not a problem here.

2.2. Filament Selection

Several filaments were sourced from specialized e-shops and subsequently used and tested.

Prusament PLA Galaxy Silver in a 1kg bobbin was used for printing PLA parts. PLA has a melting point of 175 °C and a build platform temperature of 60 °C. It is possible to repeatedly heat PLA through its melting point with very little degradation of the material. It is a hard, but brittle, material, and shatters after breakage. PLA has several weaknesses, mainly low temperature resistance, as prints begin to lose mechanical strength at temperatures above 60 °C. The combination of biodegradability and low temperature resistance means that PLA prints are not ideal for outdoor use, not to mention low UV resistance. PLA is soluble in chemicals such as chloroform or hot benzene. It is possible to use glue to join several prints together.

Verbatim PETG Red in a 1 kg bobbin was used to print PETG parts. PETG is a very tough material with good heat resistance. PETG has a universal use. It can be used indoors and outdoors. PETG has a very low thermal expansion, so it does not twist on the substrate and therefore there is no problem with printing large models. Printing PETG is similar to printing with PLA, but unlike PLA, it can offer many better mechanical properties. The PETG printing temperature is 240 °C and the build platform temperature is 80 °C. PETG contains glycol, which is added during the manufacturing process. Glycol modifies PET properties to make it less brittle and easier to print. In addition, PETG is tough and flexible, and as a result it bends under stress, which prevents it from cracking.

During the material testing phase, the conductive filament was tested. Protopasta Conductive PLA is a made of Natureworks 4043D PLA, a dispersant, and conductive carbon black. In filament form, it is flexible and is printed like any PLA filament material, and the nozzle temperature is 175 °C.

The stability of materials was tested by exposing printed parts to expected field conditions. Parts which are submerged during the use of the device were submerged in water, and simultaneously these parts were exposed to direct sunlight. Parts were periodically checked, and stability was measured by a straight edge. Water damage was observed under a magnifying glass with an LED light.

2.3. Stainless Steel Needles

The stainless steel needles were made of industrially manufactured timber nails. Nails were manufactured according to the DIN 1151 code. The quality of the nails was A2. Four lengths of nails were used. These were: 30 mm long with diameter 2.1 mm; 40 mm long with diameter 2.4 mm; 60 mm long with diameter 3.0 mm; and 70 mm long with diameter 3.4 mm.

2.4. Electronics

The electronic part of the device was a hybrid of a custom-made circuit board and three commercial sub-boards. This approach was chosen because of the manufacturing ease. All electronic parts soldered on the circuit board were through hole mounted, including resistors, capacitors, wires, and connectors. Paths were created by drawing with a path-drawing pen and subsequently etched. Sub-boards were made commercially, and electronic components were mainly mounted by surface mounting. This is almost impossible to do by hand. Commercial sub-boards are manufactured precisely, tested, and standardized. These sub-boards are easy to use for people without an electrotechnical background, like environmental engineers.

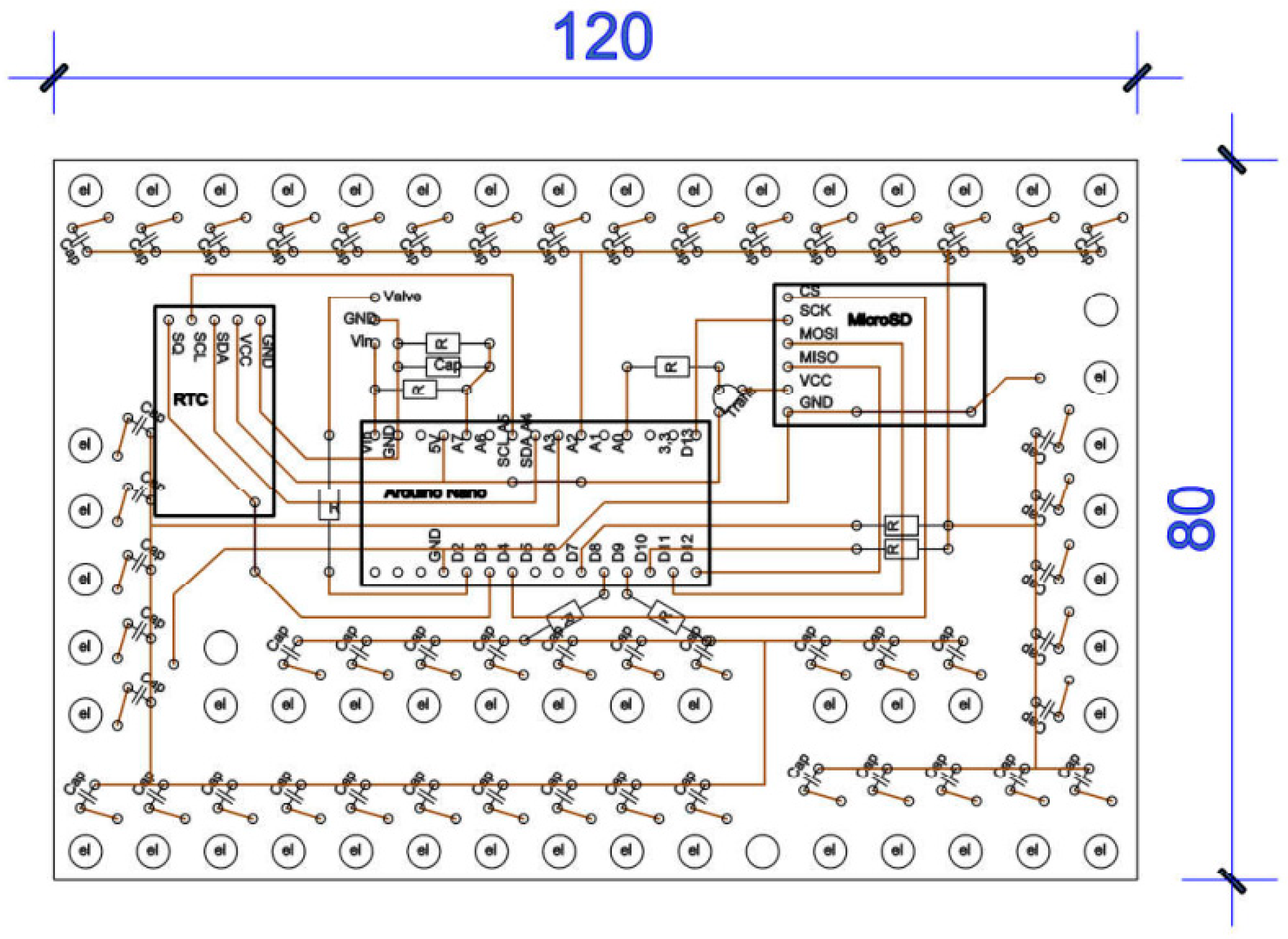

The circuit board was made of one sided EPCU120X80 sheet. Copper thickness was 35 µm, dimensions of the board were 120 by 80 mm, and the thickness was 1.5 mm. The material of the dielectric was glass fiber laminate. The manufacturer of the board was Bungard. Electrolytical radial capacitors CE 10 u/100 V HIT-ECR 6,3x11 RM2,5 BULK were used, made by Hitano. Metal oxide resistors, size 0204 with 1% accuracy were used, with values of 10 kΩ and 200 Ω. As a transistor, we used a bipolar transistor, PNP, THT, 45 V, 0.8 A, 0.625 W, TO92 BC327-40. All the components were supplied by a local vendor that specializes in electronics, tools, and electronic components. The microcontroller Original Arduino Nano R3 and shield ATmega328P and real-time clock DS3231 AT24C32, microSD card module SPI were attached to the circuit board. We decided to use these premanufactured elements to simplify the circuit board. The Arduino board and shields were bought from a specialized e-shop.

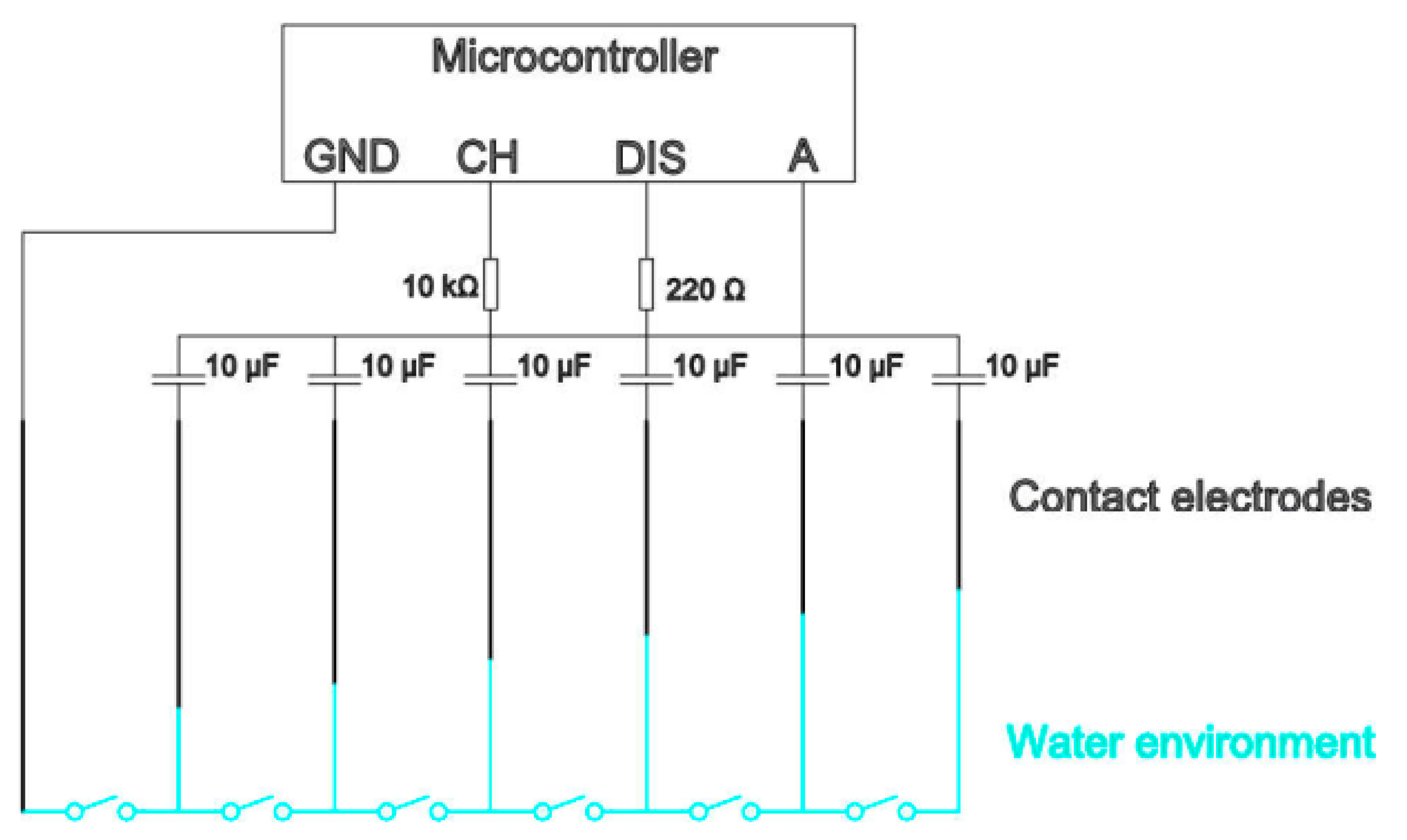

Figure 1 shows the scheme of the electronic part of the device.

Manufacturing the circuit board started with cutting the raw circuit board into suitable dimensions. This dimensionally corrected sheet was then thoroughly cleaned. The circuit board jig (

Figure 2E) was placed on the raw circuit board and fixed by clamps. The location of the through holes and the corners of the circuit were then drawn using a jig. The jig was then removed, and the circuits were finally drawn using a circuit board-drawing pen. After sufficient drying, the drawn circuit board was submerged in the etching solution. Premixed Circuit Board Etching Solution was used, and while the etching board was checked for possible errors, the solution was slowly mixed using a soft brush. Brushing the etched surface also speeds up the process. After sufficient etching, the circuit board was thoroughly cleaned. The circuit board jig was then again clamped onto the circuit board, and this assembly was performed with a vertical drill, and the through holes were made. The jig was then removed. Burrs were then removed by gentle brushing with smooth sandpaper. In this way, the circuit board was prepared for soldering the electronics. Lastly, a circuit board with electronic parts soldered on was set up on the electrode positioning jig (

Figure 2D). The electrodes were inserted into the drilled holes, secured in place with heat glue, and their connection wires were soldered to the circuit board. The position of the electrodes was then finally checked against the positioning jig. After the RTC, the SD card reader and the Arduino Nano board were attached, and the device was ready for uploading the code. The code is shown in the

Supplementary Materials.

2.5. Assembly

Assembly started with gluing together the pipe support and electronics compartment. PCB with attached sub-boards was then placed into the electronics compartment and secured by screws. Sealing foam was then inserted into the sealing groove and the assembly was finished by screwing on the lid. The assembled device was than ready for installation, either without the supporting sewer pipe for testing, or on the sewer pipe for field application.

2.6. Testing

Testing of the conductive filament and stainless steel resistivity was carried out. Two samples were selected, a 60 mm long stainless steel needle, and a piece of raw conductive filament 60 mm long. Using an electrical multimeter, the resistance of both samples was measured. Accuracy of the multimeter was 1.2%. Testing of the device was carried out by putting the device into a shallow uncovered water tank, and subsequently filling this water tank with water. The water level should be high enough to touch the uppermost electrode. Next, the device was turned on and the water level was periodically checked with a ruler. After the content of the tank evaporated, device was unplugged from the power source. Data were collected and the 3D printed construction of the device was inspected visually under a magnifying glass.

3. Results

3.1. 3D Printing

The fundamental innovative technical solution consists in a combination of several relatively low-cost techniques that are robust enough for use in the field. The principle of this precise solution lies in the contact capacitive water level measurement method. The basis of the contact capacitive approach for measuring the evaporator water level combines two principles. The first principle is contact measurement, where the water body serves as a conductive connection of two contacts that form an electrical circuit. Another way is to measure the electrical capacity of capacitors connected in parallel. A combination of these two principles creates a simple and reliable measurement method. The technical solution uniquely combines contact and capacitive level measurements. The individual electrodes serving as contacts are not directly connected to the digital inputs of the microcontroller, as shown in

Figure 1. This is replaced by aggregating the connected circuits by connecting or disconnecting individual capacitors to a parallel circuit. Subsequently, only one value is measured on one analog input of the microcontroller. This greatly simplifies the electronic solution of the device.

This measurement method consists of the gradual emergence of stainless steel electrodes of different lengths as the water level drops. The electrode tips have a height spacing of 1 mm, and thus the measurement accuracy is determined. The accuracy of electrode placement is made possible by accurate 3D printing of the assembly jig. The electrodes are connected to the negative contact of the capacitor. One electrode connected to the ground terminal of the microcontroller is also immersed in the bath. Each time the electrode emerges, one capacitor is disconnected from the system. If the electrical capacity of the system is measured, only the capacitors connected to the immersed electrodes will be measured. This clearly determines the level in the evaporometer. Further refinement is ensured by remeasurement with a time interval and subsequent averaging of the measured values.

3.2. Electronics

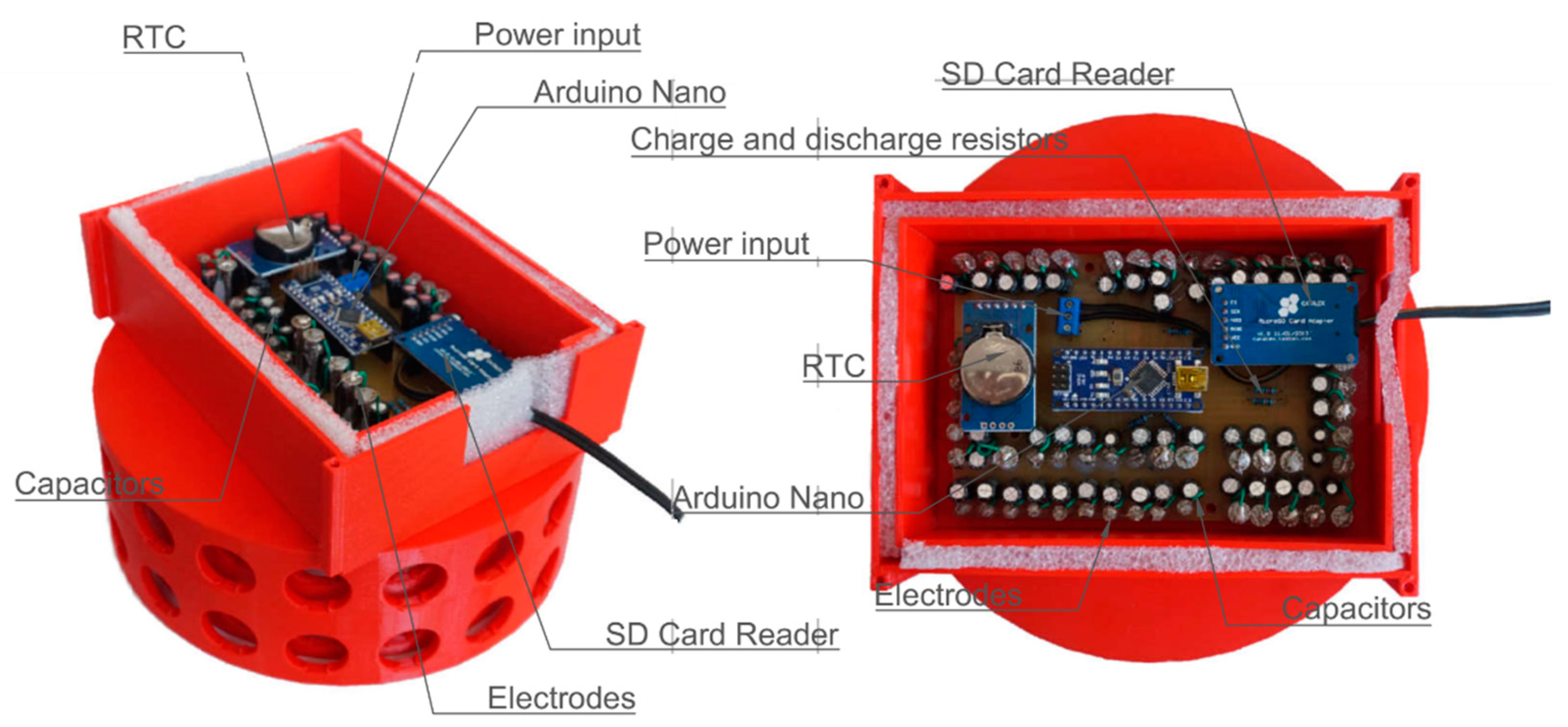

The main electronic parts of the device are integrated in the 3D printed housing of the device (

Figure 2B). This housing protects the electronics against rain and splashing water. However, the housing does not provide protection against pressurized water, in the event that the device becomes submerged. The main electronic parts of the device are a microcontroller, a clock, and a microSD card reader. The battery is located outside the unit itself for better accessibility and for ease of replacement.

Figure 2A shows a 3D model of a unit of the device as a version for placement on a DN150 sewer pipe. This tube (commercially produced dimensions) serves as a calming tank to reduce the effects of waves. The holes in it also serve as a screen, preventing the ingress of dirt in the electrodes.

Figure 3 shows a descriptive image of the electronic part of the prototype.

Figure 4 shows the printed circuits and the drilling of the supporting printed circuit board.

The whole system for contact capacitive level measurements of the evaporator includes a unit and a water tank in which the unit is located. The operation of the unit is provided by a control microcontroller (Arduino Nano), the measurement time and wake-up of the unit from sleep are provided by a real-time clock (RTC), and the measured values are written by a microSD card reader (microSD) to a microSD card. Other elements of the unit are the capacitors (Cap) and the electrodes (el) formed by industrially produced stainless steel electrodes of various lengths. The different electrode lengths ensure that the measurements of different heights at the same time make it possible to simplify the design of the device. The power supply is assumed to be 230 V in combination with a voltage regulator to 12 V or a 12 V battery.

3.3. Device Functionality Verification

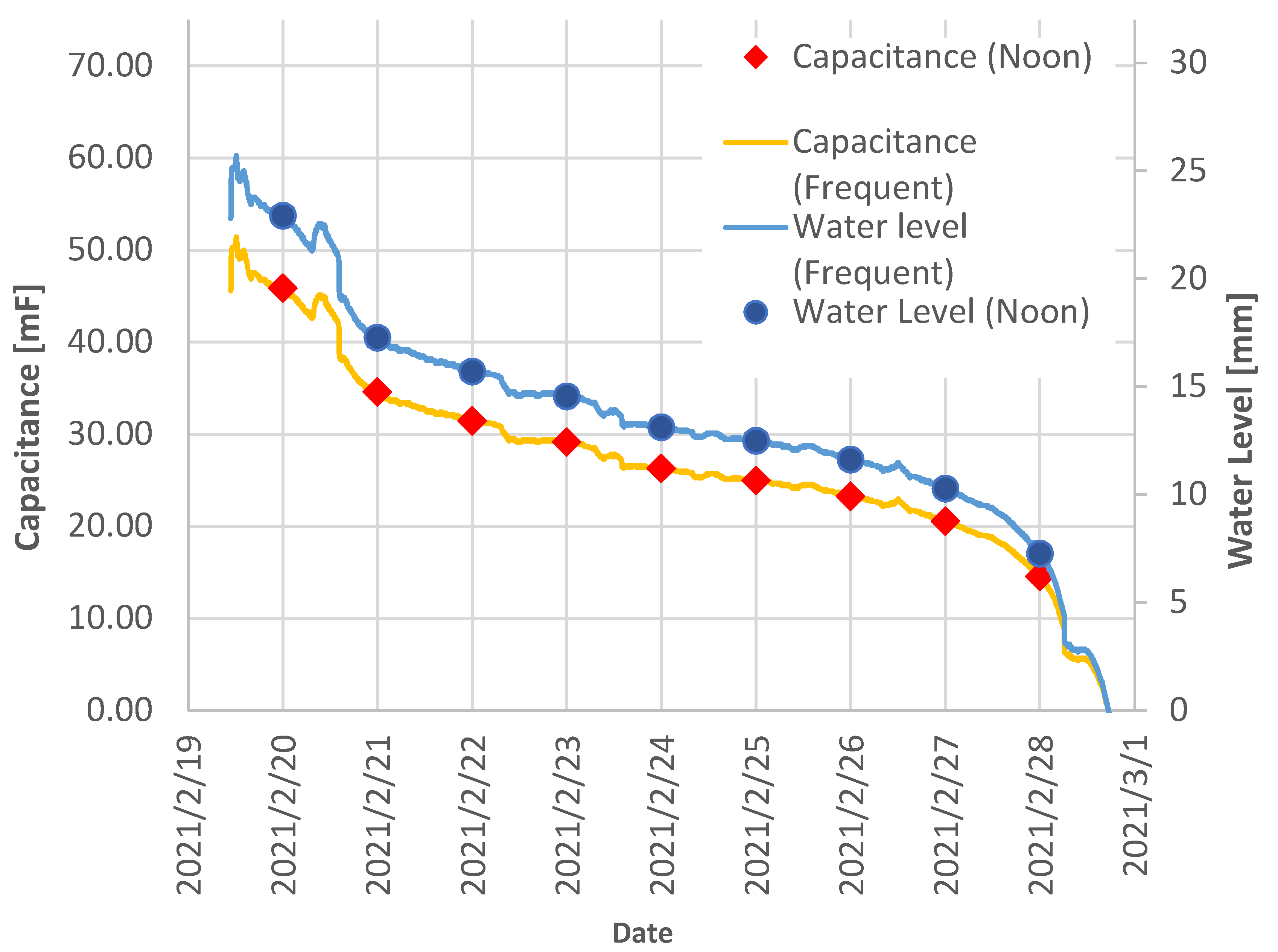

The final experimental setup was tested over a 12-day period. The measuring interval was set to 3 min, and the number of measurements before averaging was set to 10. This setup was chosen to test the durability of the device, its power consumption, and the electrolytic stability of the needles.

Another test run was conducted over an 11-day period. The measuring interval was set to 10 min, and the number of measurements before averaging was set to 10. This setup was chosen to further test the durability of the device, and the electrolytic stability of the needles. After 5 days, the water level was artificially lowered to approximately a 6 mm depth and after another 2 days, water was added to increase the level to approximately 8 mm. The rest of the test was conducted without interactions with the testing setup.

4. Discussion

Testing of the experimental capacitance measurement did not give a clear result. Values observed in the dry and submerged conditions clearly differ, nonetheless removing the noise observed on the values between these two extremes was beyond our capacity. The construction of a complex professional capacitance water level measurement sensor needs greater depth of electronics knowledge to construct a signal conditioning circuit.

The contact capacitive approach does not need any conditioning circuit. All special electronics are factory made on the bought Arduino sub-board. Thus, this design is more suitable for environmental engineers, who do not have a full electronics background. The contact capacitive approach also promised a much better result because the values are not continuous but discrete, thus reading of the data should be easier. Additionally, there is no need for continuous sub-millimeter reading precision.

In preliminary testing, we used a prototyping board (Perfboard) with different lengths of wires soldered on. After a long run of several days in submerged conditions, submerged copper surfaces started to develop greenish crystals and white crystals started to develop on soldered covered surfaces. However, the principle of measurement worked, as when the water level dropped below the soldered-on wire end, the capacitor was disconnected, and the total capacitance also dropped.

The first prototype was equipped with 3D printed electrodes made of conductive PLA. This material has shown good results for ease of printing and for stability in a water environment. However, the device equipped with 3D printed contact electrodes did not work. To further investigate why the conductive filament did not work, we tested resistivity of the materials. Conductive filament gave a value of 2.3 kΩ. Stainless steel gave a value of 0.5 Ω. This large difference between resistivities of the materials convinces us that resistivity is one of the main problems when using conductive filament as a needle material. Another problem can be the screwed connections of the printed needle and copper plating of PCB. Thus, we switched from 3D printed electrodes to stainless steel electrodes, and the device started to work. For this reason, we decided to use stainless steel for electrodes. Stainless steel requires a special soldering liquid for soldering, but this liquid is readily available.

Stainless electrodes proved to be a viable solution to problems with electrolytical erosion and after the experiment, no corrosion was found on the electrodes. Evaluation of the electrodes was carried out under a magnifying glass with an LED light. No discoloration was found on the surface of the stainless steel electrodes, and sharp points were still sharp and sturdy. Data were successfully saved on the SD card and no loss of data was observed. The real-time clock worked perfectly, and there was no time distortion.

The first prints were made with PLA plastic. This material showed good results for precision, for ease of printing, and for assembly. However, during reliability testing, the print of this material was severely deformed due to sun exposure. Testing continued with the universally used PETG plastic. This material proved to be reliable and stable enough, so it was chosen to be the final material. The PETG plastic material withstood the water immersion without any problems. The surface of the printed device was coated with limescale after the water evaporated. Although the device was not protected against sunlight, no distortion of the plastic structure was found.

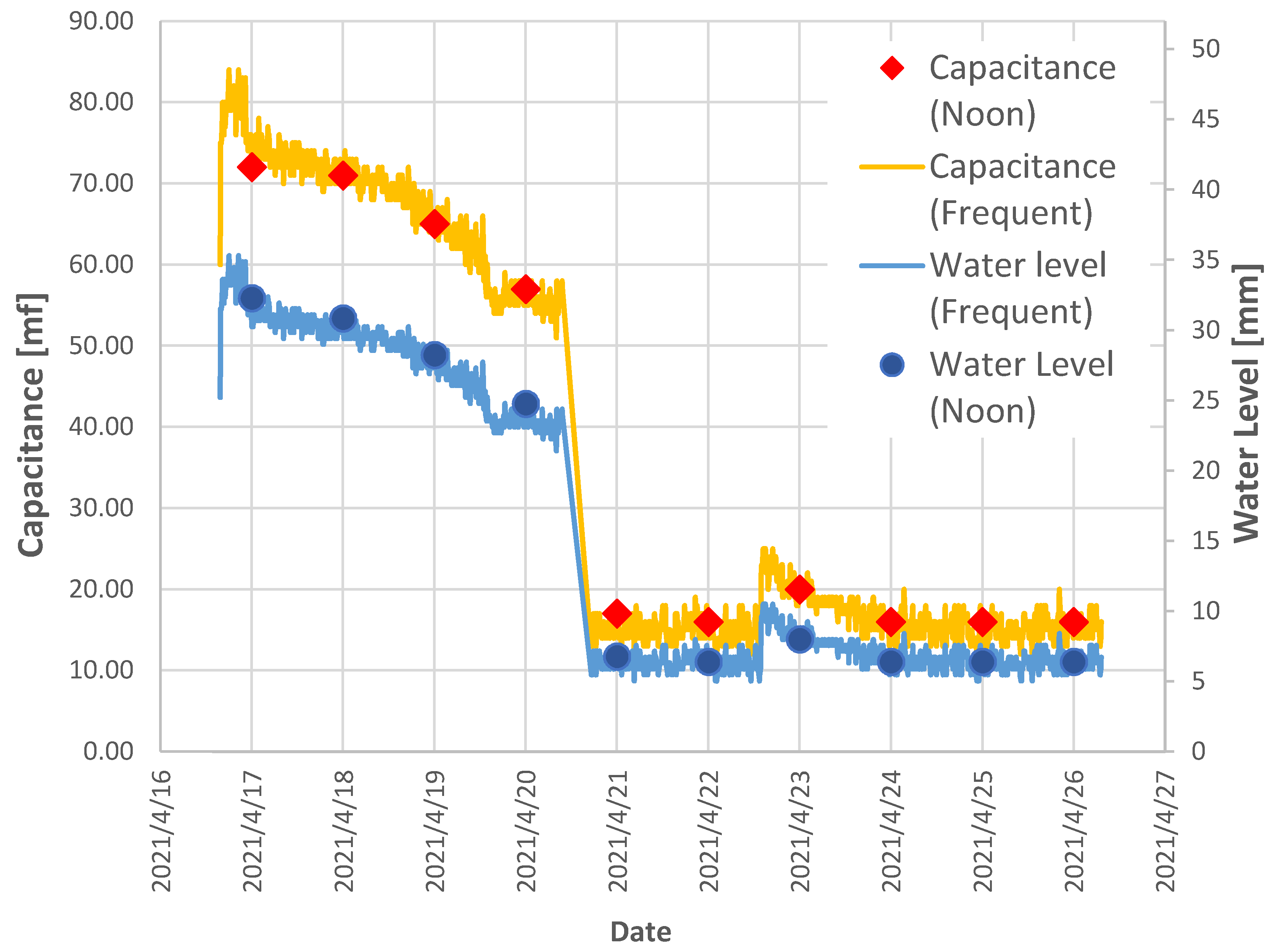

The data shown in

Figure 5 and

Figure 6 show a continuous decrease in the measured value and clear steps on the graph at the moment when the needle was disconnected from the circuit. This proved the working principle of the measurement method. In general, the contact capacitive measurement principle proved to be much more precise in a simple configuration than resistance-based measurement, which can be used as a preliminary approach to a problem. The resistance-based method measured the drop in voltage regarding the increase in the electrical power traveling distance through the water. This distance increased with each emerging electrode, because the electrodes were located in line. This measurement principle proved to be too difficult to calibrate, as the signal was very noisy, and minor changes in water quality dramatically changed the voltage drop. Contact capacitive measurement principles are significantly less correlated with water quality, and the signal was much clearer.

The measuring device was mounted on top of a PVC sewage pipe with an internal diameter of 150 mm. The pipe was connected to the bottom of the evaporation pan. Small holes in the lower part of the pipe wall enabled a hydraulic connection of the two water environments. The small diameter of the holes (circa 5 mm) meant that they served as grates, protecting the contact electrodes from debris. The enclosed space inside the pipe was protected from sunlight, and this reduced the growth of algae on the device.

The total measuring capacity of 5 cm is a limiting factor of the device. In areas with severe evaporation, the evaporation pans need to be refilled frequently. This problem can be solved by automatic refilling, which is managed by contact limit switches. This device refills the evaporation pan whenever the water level is about to drop below the measurable height. Water is supplied from a barrel, which is raised above the evaporometer to give the water a sufficient head. The barrel and the evaporometer are connected by a flexible hose. The flow is controlled by a solenoid valve. It is essential to seal the valve, because leakage can compromise the evaporation measurements. This setup increases the independence of the evaporometer. It is not necessary to make frequent visits to individual evaporometers, and it is therefore possible to use more of them.

The device does not achieve the quality and the measuring precision of professional products. However, that was not a goal of our research. For example, the Keller Water Level Sensor for Pans from Metos achieves an accuracy of 0.2% and a precision is 0.1 mm. These values are tenfold better than the accuracy of our device. The more modest aim of our research was to increase the number of measured locations throughout the watershed and thus to make possible a study of the spatial variation of evaporation throughout the watershed or in one water body.

5. Conclusions

The presented system in its current form was tested, the device worked properly and fulfilled the requirements of evaporation measurement for evaporation research. The use of open-source electronics reduced the cost of the device well below the cost of devices available on the market. The cost of the components and the material to make one device can be around EUR 20. This does not include work and does not include basic electrotechnical tools and materials such as wires.

The precision of the 3D printing allowed the creation of this device. Setting of the 50 stainless steel needles would be time consuming and difficult without a 3D printed assembly jig. Furthermore, drilling of the circuit board was carried out via another 3D printing jig. The circuit board is another component requiring high precision. Holes for the Arduino and sub-board connectors were spaced 2.54 mm apart. Manual positioning of the circuit board in the drill, with such precision, would be highly difficult.

The technology of the device is based on a combination of 3D printing and a simple measuring microcontroller, in this case based on the Arduino platform, which provides the possibility of a connection with a set of other environmental values. Data collection and storage can be carried out remotely with WIFI or GSM modules.

3D printing offers a very useful way to create complex devices for hydrological research. The inert nature of plastics is useful for the construction of devices partially immersed in a water environment. The insulating properties of 3D printed plastics are also viable in cooperation with electronics. In general, the use of 3D printers allows the design to be changed rapidly and to be adapted to different needs. Precise positioning of the contact needles via a 3D printed jig allowed high resolution of the water level measurements. Quite good data were therefore obtained during the experimental measurements. These data show the gradual decrease in the water level over time, which followed the real evaporation of water from the testing evaporation pan. In field conditions, this evaporation pan should be accompanied by a rain gauge, a wind velocity meter, and other climate measurement devices. This setup allows evapotranspiration to be calculated via the evapotranspiration coefficient.