Investigation of Stray Radiation Suppression in Infrared Imaging System Using a Novel Broadband and High-Absorption Ceramic Coating

Abstract

:1. Introduction

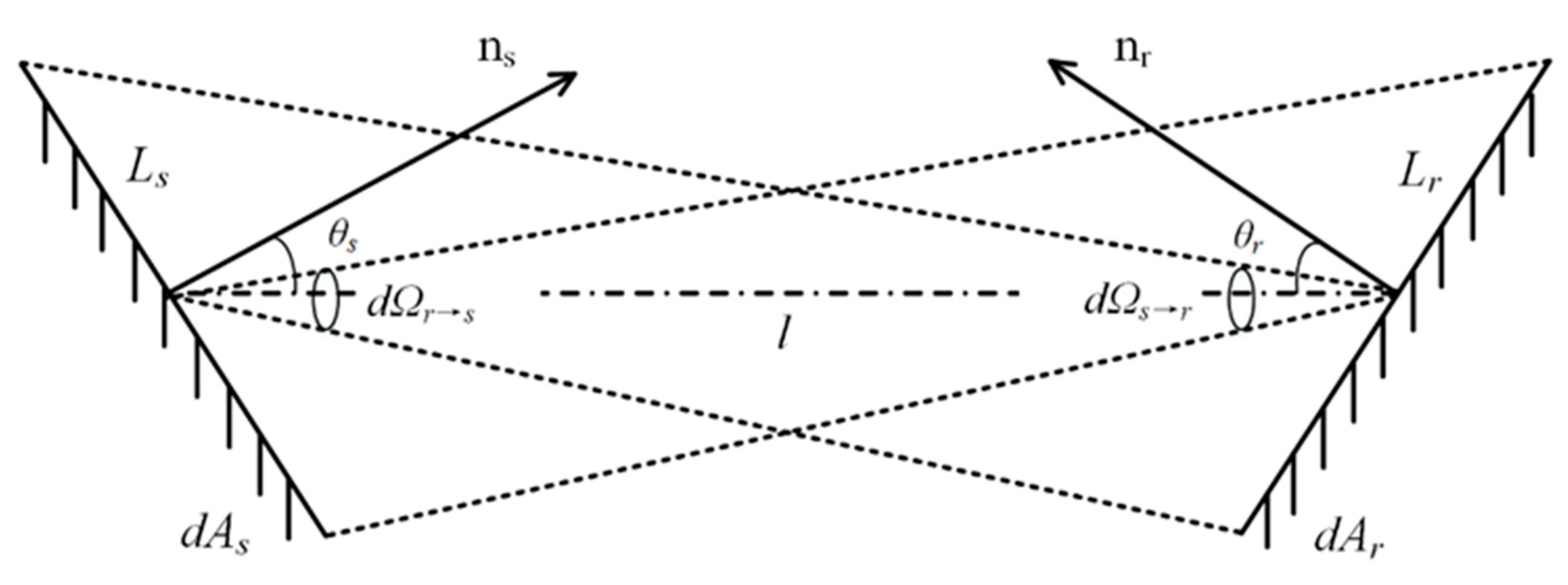

2. Transmission Model of Stray Radiation

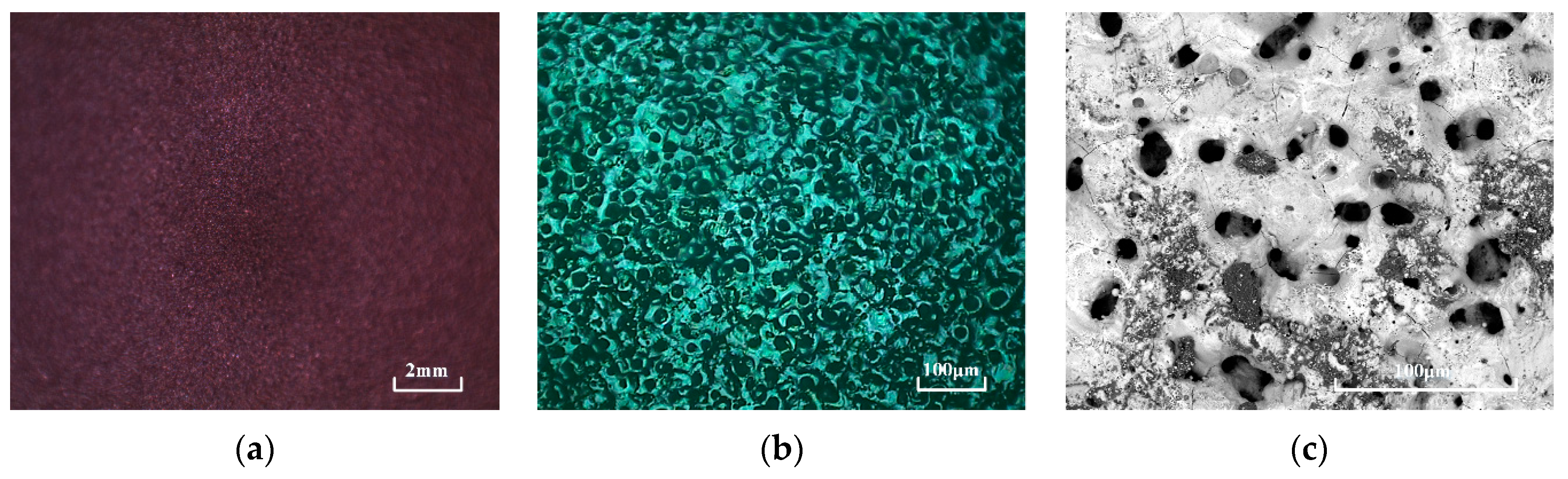

3. Preparation and Characteristics of High-Absorption Ceramic Coating

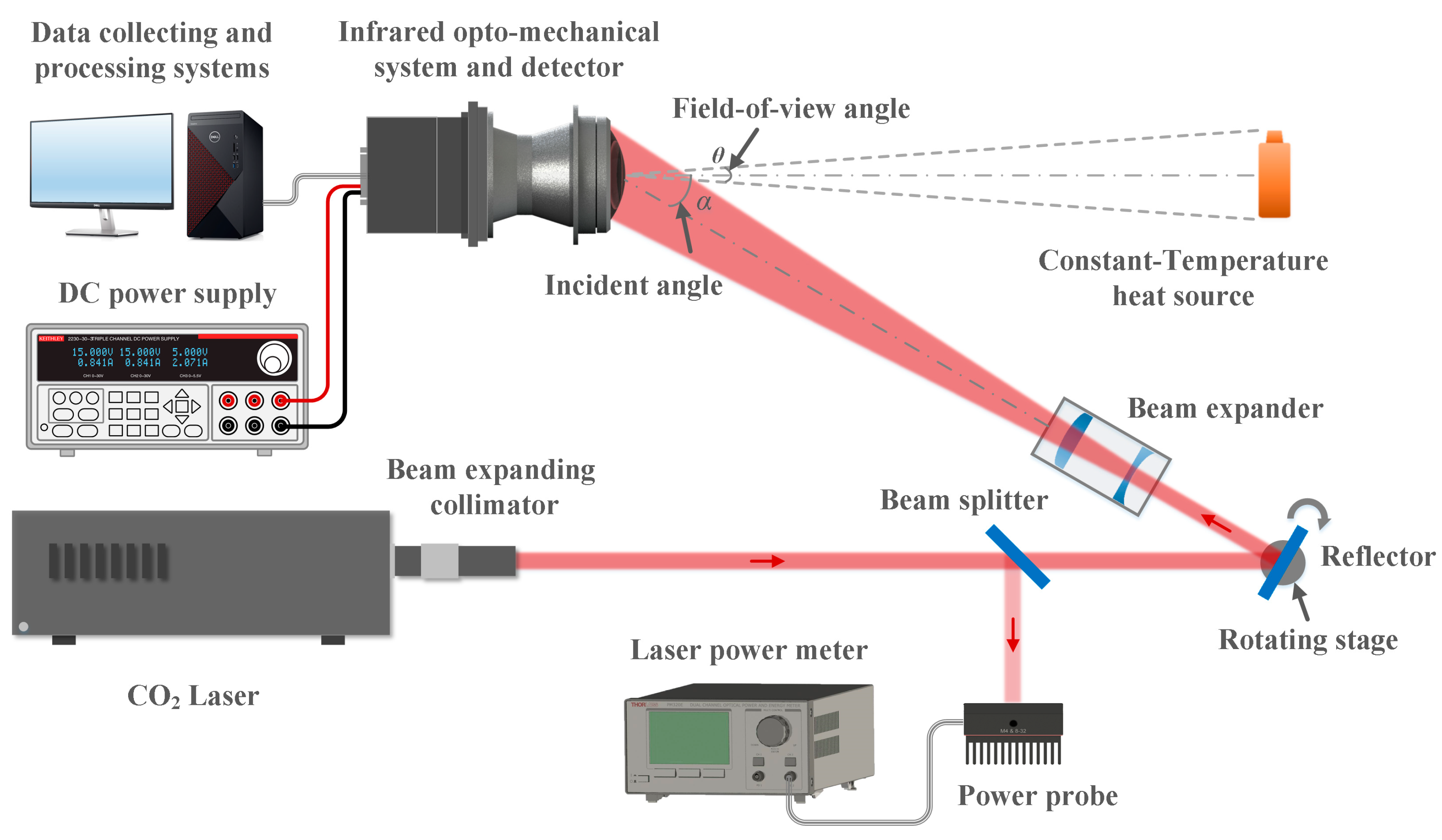

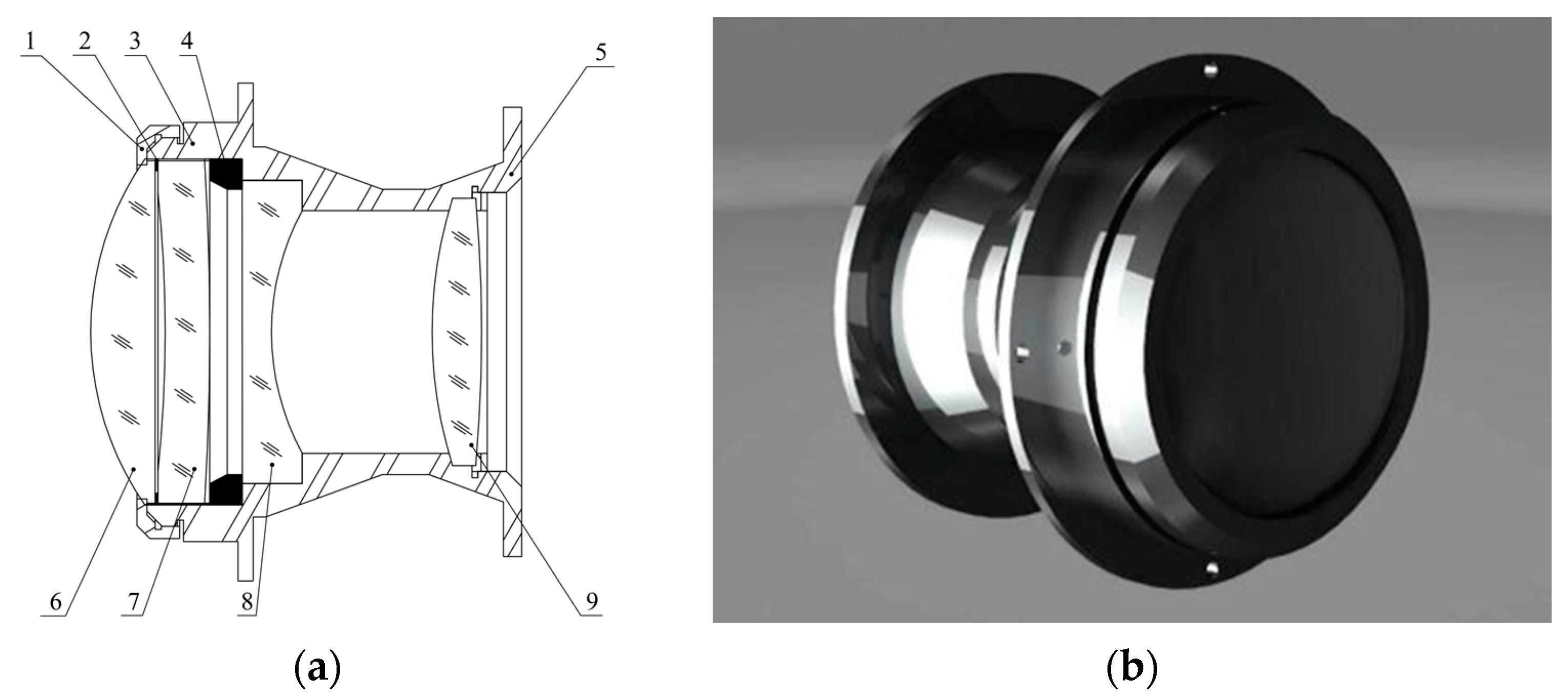

4. Experimental Setup

5. Experimental Results and Discussion

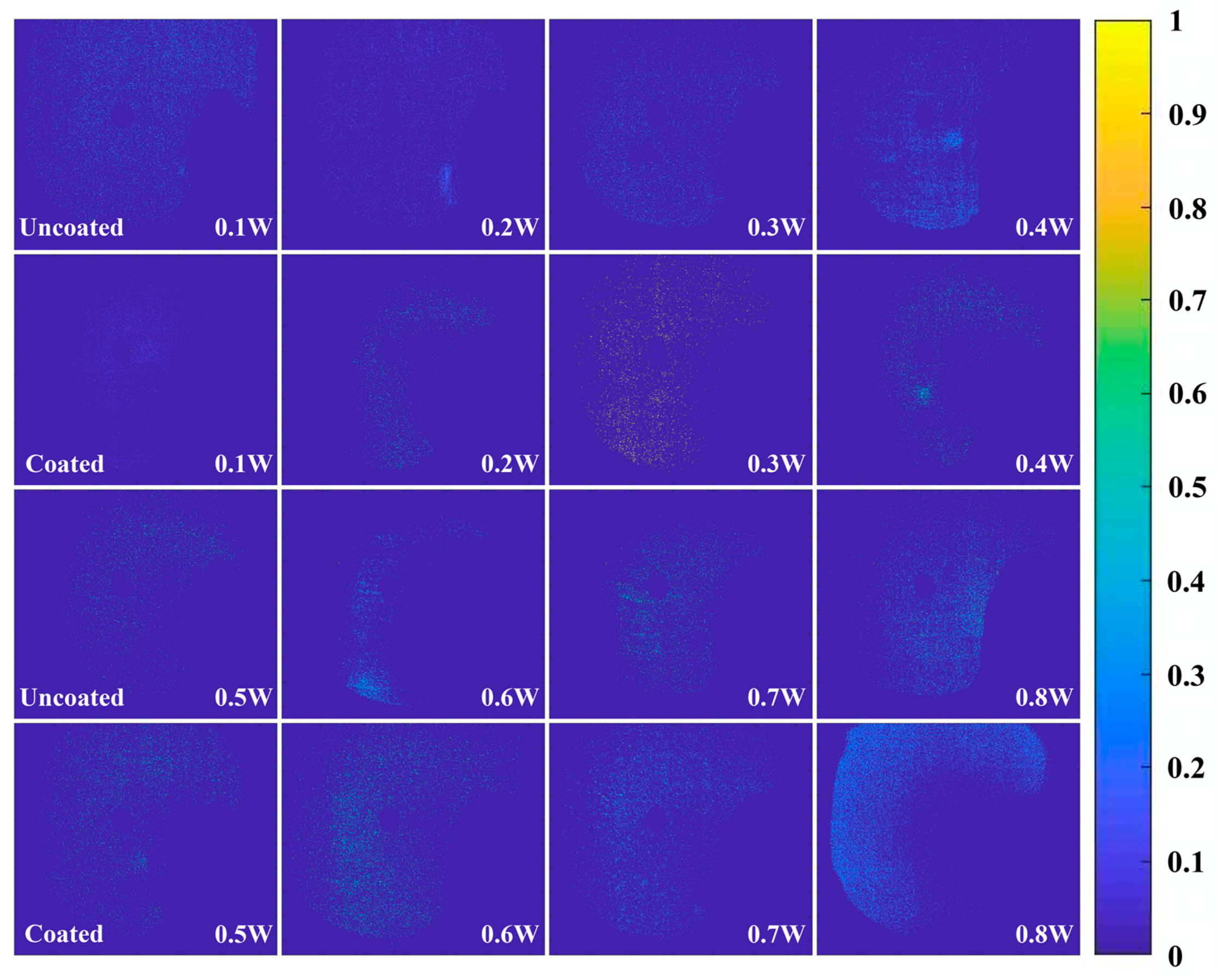

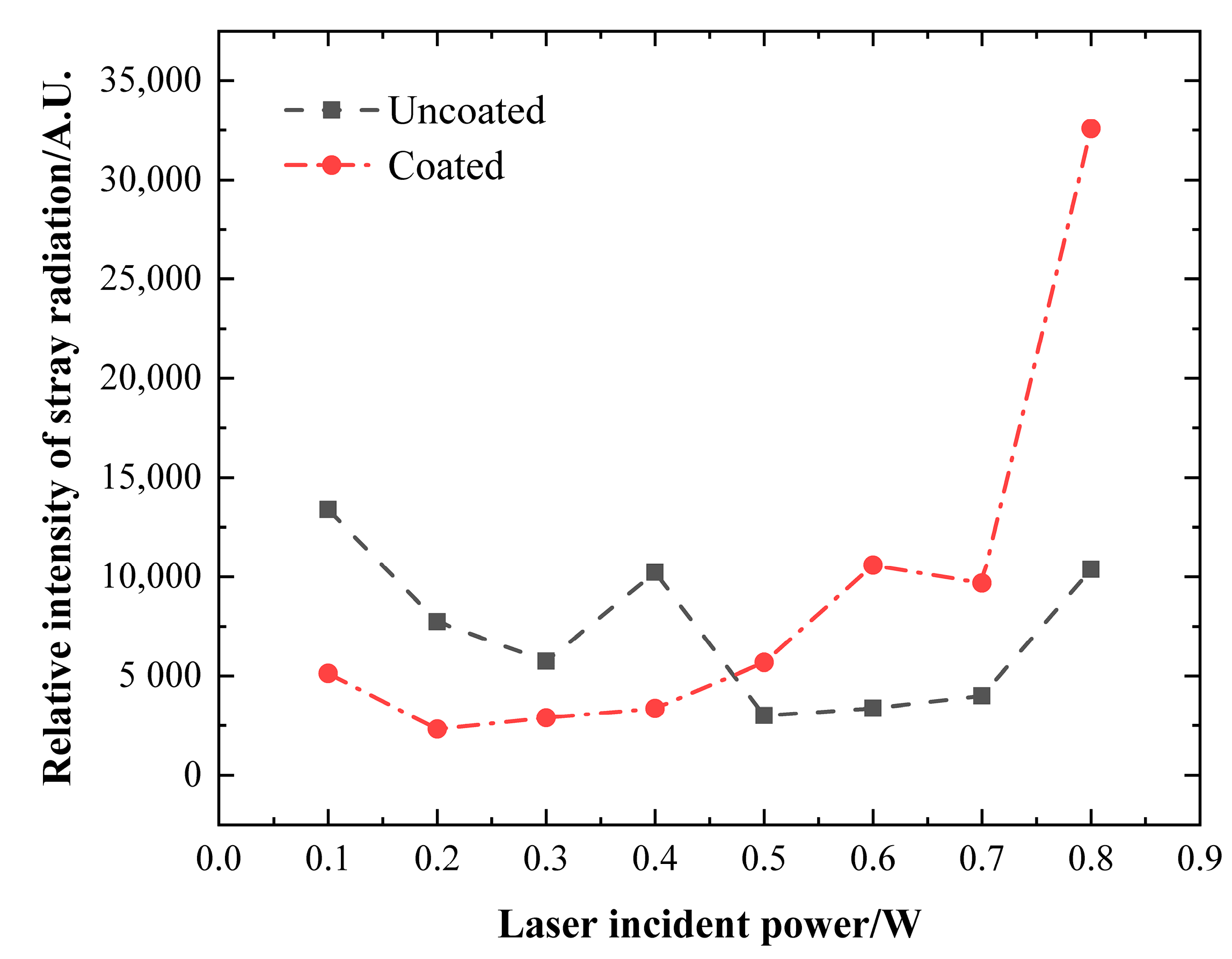

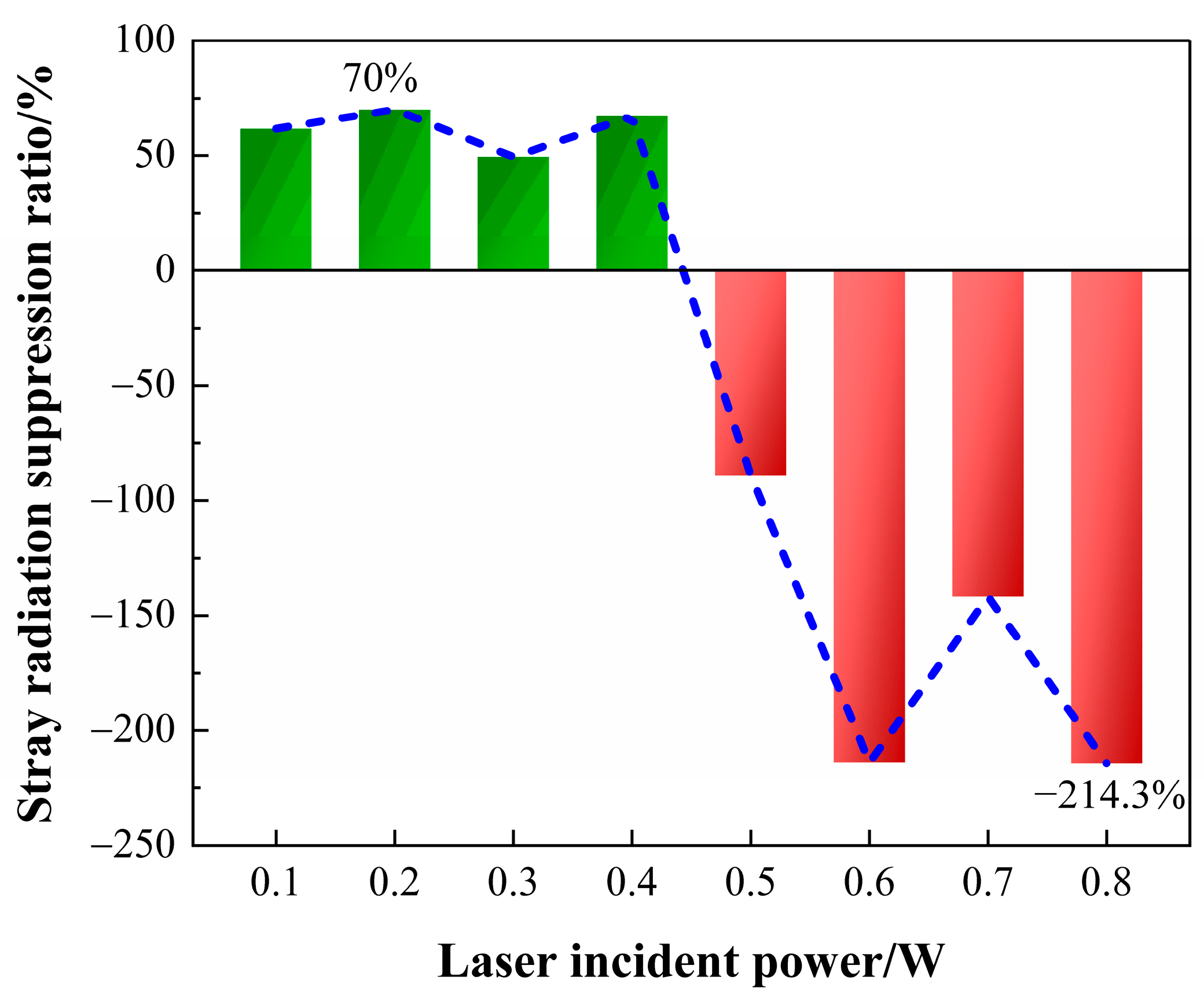

5.1. Effect of Incident Power on Stray Radiation

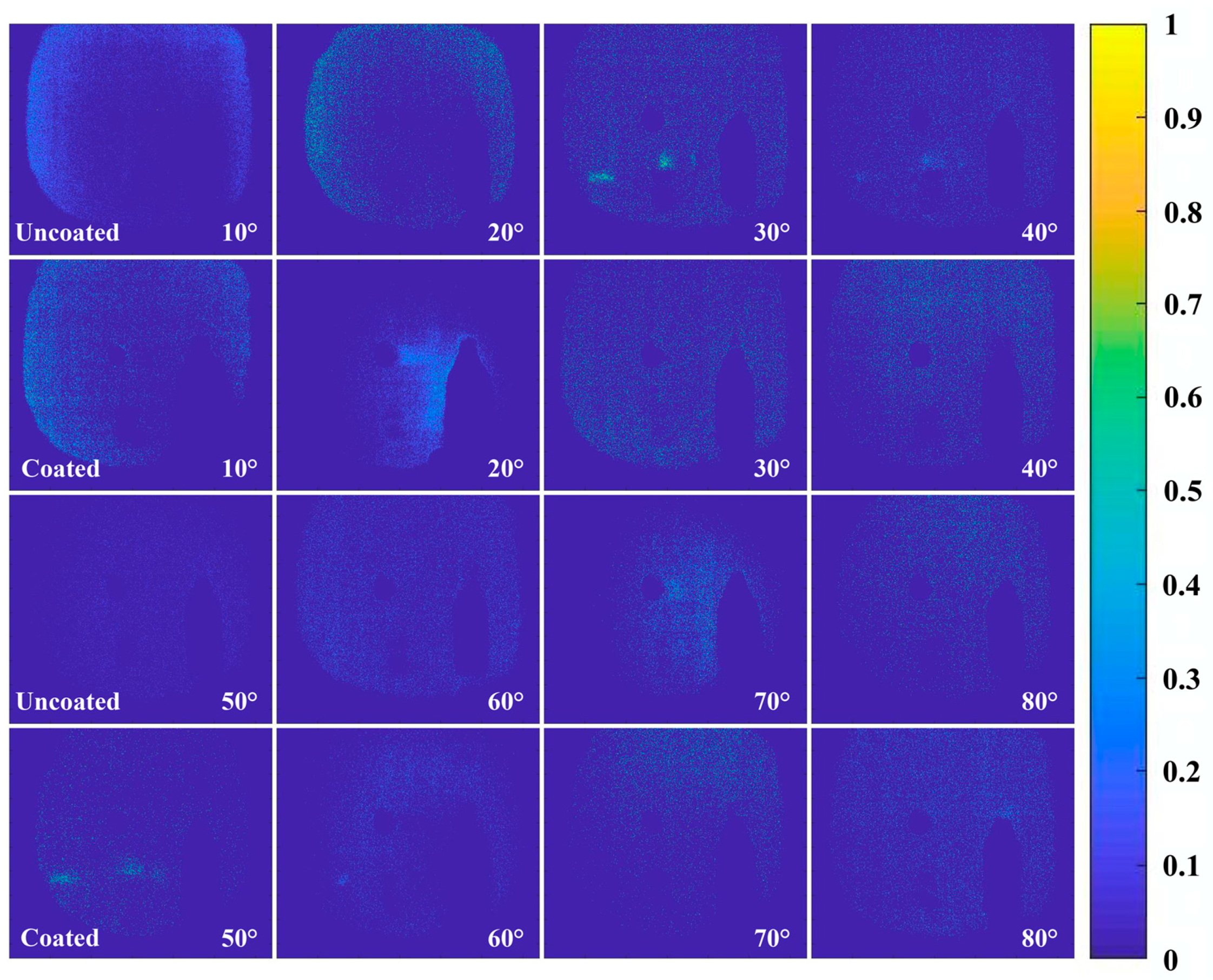

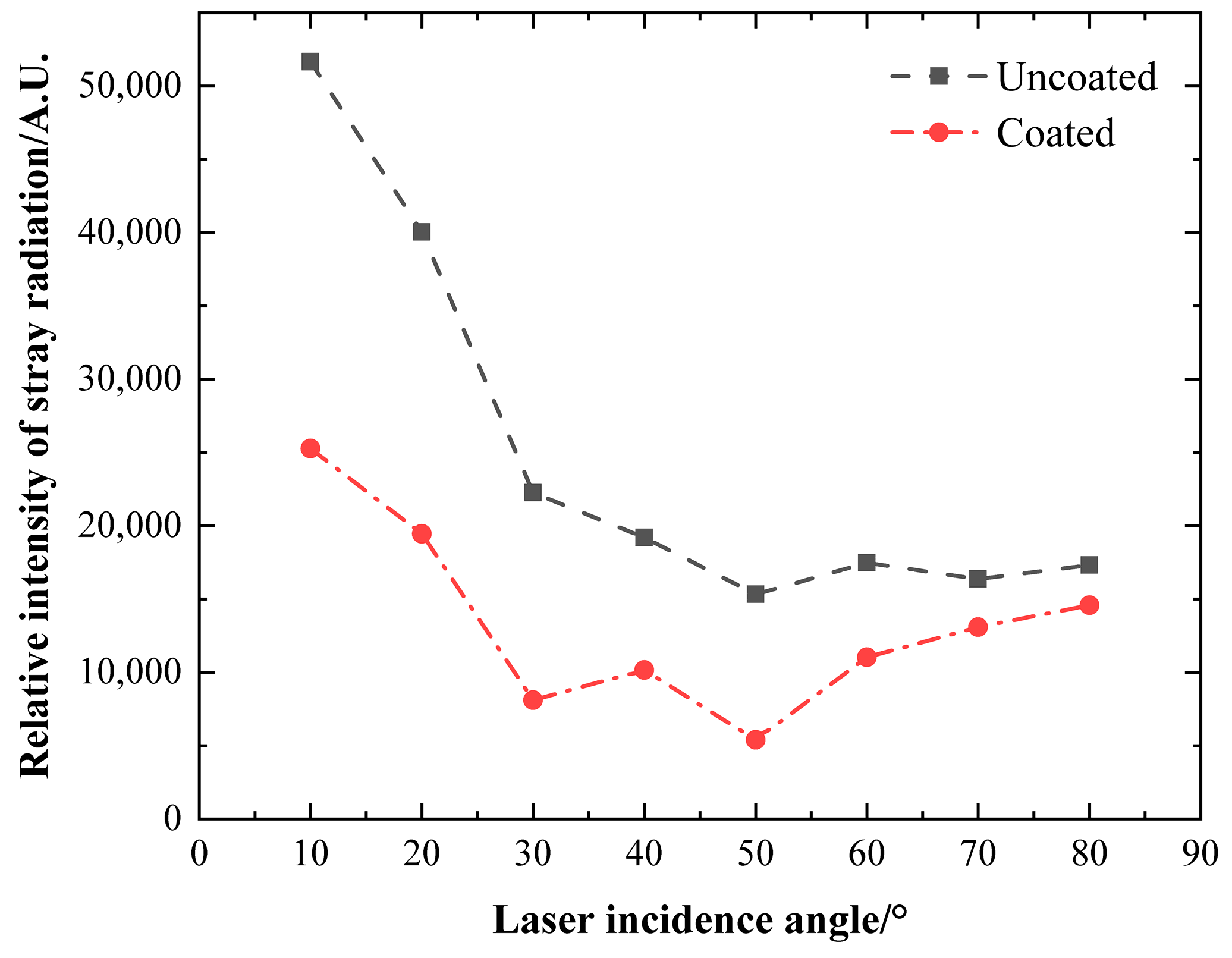

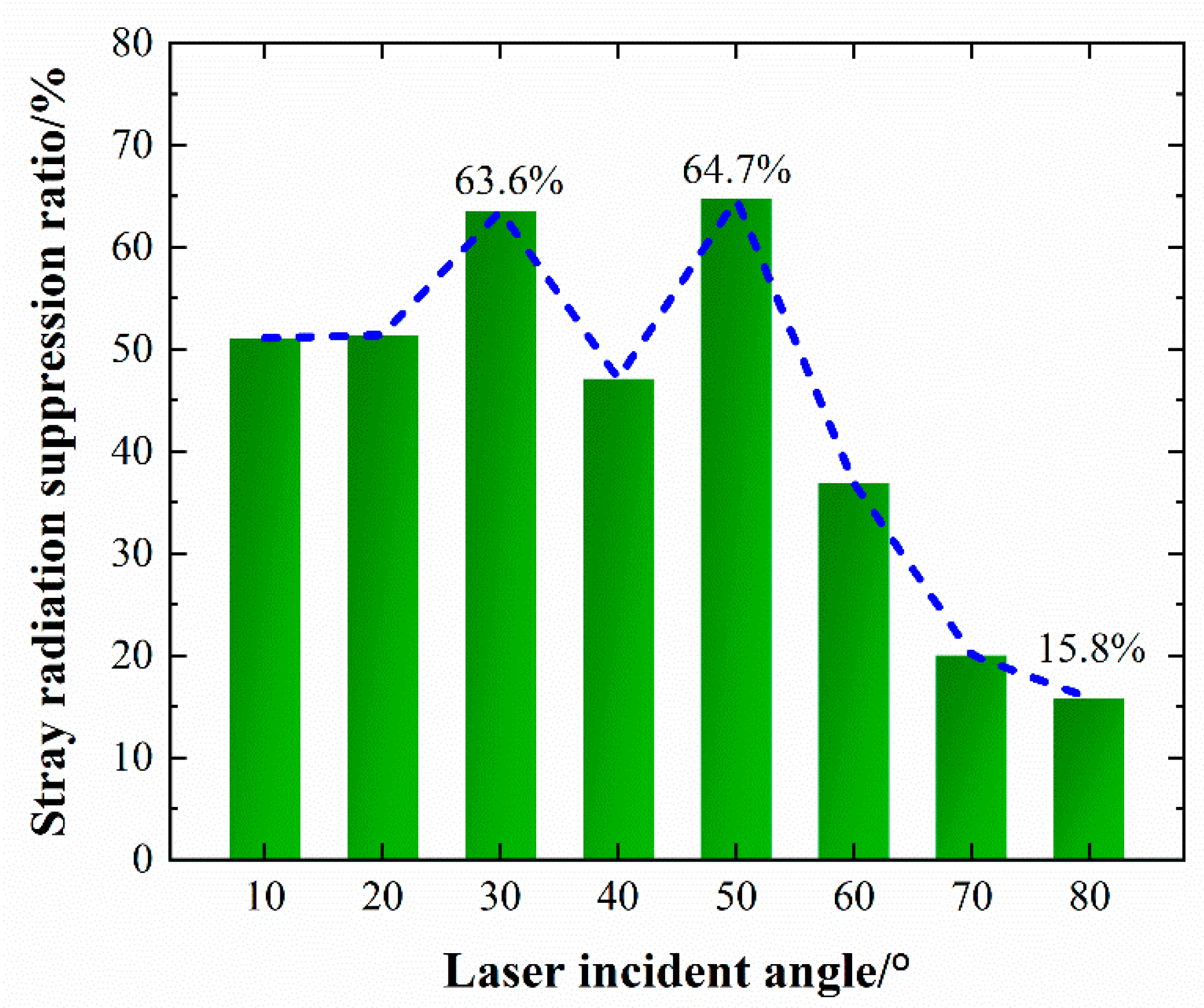

5.2. Effects of Incident Angle on Stray Radiation

6. Conclusions

- (1)

- The surface of the high-absorption ceramic coating was characterized by a dense porous structure. It was able to achieve absorption in a wide range of infrared wave band (the average absorptivity of ceramic coating is 95.4% in the range of 0.2–16 μm) due to the absorption of a large number of micro-pores on the surface of the coating for the radiation from different wave bands. The experimental results showed that there was a saturation upper limit for the absorption capacity of the coating to stray radiation. Under the condition of a laser incident angle of 50°, the saturation absorption laser power threshold of ceramic coating was 0.4 W.

- (2)

- A novel ceramic coating with a broad absorption band and high absorption was developed, which could obviously suppress the stray radiation in the opto-mechanical system of infrared imaging caused by laser. When the incident laser angle was 50° and the incident laser power was no more than 0.4 W, the ceramic coating could obviously suppress the stray radiation. Then, the stray radiation intensity in the system showed an obvious upward trend with the increase in laser power. At this stage, the ceramic coating mainly played the role of enhancing the stray radiation. The calculation of the average suppression ratio for stray radiation showed that adding a ceramic coating would decrease the stray radiation intensity in the system by 70% compared with that without coating, under the condition of a laser power of 0.2 W. When the laser power was 0.8 W, the average stray radiation ratio of the ceramic coating was lowest at −214.3%.

- (3)

- When the incident laser power was unchanged, the stray radiation intensity in the infrared opto-mechanical system strongly depended on the change in incident laser angle. The average stray radiation suppression ratio increased first and then decreased rapidly with the increase in laser incidence angle, under the condition of a laser power of 0.4 W. When the laser incident angle reached 50°, the average stray radiation suppression ratio reached the maximum of 64.7%; when the laser incident angle dropped to 80°, the average stray radiation ratio reached the minimum of 15.8%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smith, C.R.; Grasso, R.; Pledger, J.; Murarka, N. Trends in electro-optical electronic warfare. Proc. SPIE 2012, 8543, 85430201–85430217. [Google Scholar]

- William, C. Requirements for laser countermeasures against imaging seekers. Proc. SPIE 2014, 9251, 92510301–92510310. [Google Scholar]

- Fan, J.X.; Li, L.; Li, W.J. Development of direct infrared countermeasure system and technology. Infrared Laser Eng. 2015, 44, 789–794. [Google Scholar]

- Niu, Y.X.; Zhang, P.; Yao, J.Q.; Duan, X.F.; Wang, Y.Y.; Guo, L. Investigation of laser disturbance and damage to satellite-borne photoelectric detecting system. Acta Photon. Sin. 2004, 33, 793–796. [Google Scholar]

- Li, Y.; Wang, R.Z.; Tittel, F.K.; Ma, Y.F. Sensitive methane detection based on quartz-enhanced photoacoustic spectroscopy with a high-power diode laser and wavelet filtering. Opt. Lasers Eng. 2020, 132, 106155. [Google Scholar] [CrossRef]

- Pravdivtsev, A.V.; Akram, M.N. Simulation and assessment of stray light effects in infrared cameras using non-sequential ray tracing. Infrared Phys. Technol. 2013, 60, 306–311. [Google Scholar] [CrossRef]

- Yang, Z.H.; Ma, Y.H.; Guo, J.G.; Jiang, W.W.; Geng, A.H. Analysis and correction of stray thermal radiation in infrared optical systems including an experimental case study. Appl. Opt. 2019, 58, 3582–3588. [Google Scholar] [CrossRef]

- Wang, G.; Xing, F.; Wei, M.S.; You, Z. Rapid optimization method of the strong stray light elimination for extremely weak light signal detection. Opt. Express 2017, 25, 26175–26185. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Z.Y.; Cheng, X.H.; Xia, X.L. Simulation and evaluation of stray radiation from optical window effects on infrared detection system. Infrared Phys. Technol. 2018, 94, 200–206. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, X.; Liu, T.; Wu, Y.X.; Shi, G.W.; Wang, L.J. Internal and external stray radiation suppression for LWIR catadioptric telescope using non-sequential ray tracing. Infrared Phys. Technol. 2015, 71, 163–170. [Google Scholar] [CrossRef]

- Wang, Y.; Shen, Y.Z.; Chen, J.L.; Xu, L.; Mo, D.F.; Liu, D.F. Research of suppressing stray light of cold shield with different black coating. Proc. SPIE 2019, 10841, 108411701–108411718. [Google Scholar]

- He, S.F.; Wang, Y.F.; Dai, C.H.; Liu, J.Y.; Feng, G.J. Analysis and suppression of stray radiation in infrared spectral radiation measurement. Proc. SPIE 2019, 11337, 11337041–11337047. [Google Scholar]

- Reininger, F.M. Stray light performance optimization through system design. Proc. SPIE 1994, 2260, 17–28. [Google Scholar]

- Cranmer, S.R.; Gardner, L.D.; Kohl, J.L. A model for the stray-light contamination of the UVCS instrument on SOHO. Sol. Phys. 2010, 263, 275–291. [Google Scholar] [CrossRef] [Green Version]

- Buisset, C.; Prasit, A.; Leckngam, A.; Lepine, T.; Poshyajinda, S.; Soonthornthum, B.; Irawati, P.; Richichi, A.; Sawangwit, U.; Dhillon, V.; et al. Progress on the prevention of stray light and diffraction effects on the Thai National Telescope. Proc. SPIE 2015, 9626, 96262E. [Google Scholar]

- Luo, C.J.; Jiao, T.; Gu, J.W.; Tang, Y.S.; Kong, J. Graphene shield by SIBCN ceramic: A promising high-temperature electromagnetic wave-absorbing material with oxidation resistance. Appl. Mater. Interfaces 2018, 10, 39307–39318. [Google Scholar] [CrossRef]

- Bian, D.; Guo, Y.X.; Zhao, Y.W. Influence of zinc oxide on corrosion resistance of alumina based chemically bonded ceramic coatings. J. Appl. Chem. 2016, 89, 2091–2094. [Google Scholar] [CrossRef]

- Hlincik, T.; Berka, J.; Kutzendorfer, J.; Hamacek, J.; Sajdl, P. The effect of long-term exposure to high temperature atmosphere on the mechanical properties of Al2O3-based ceramic materials. Ceram. Silik. 2020, 64, 35–39. [Google Scholar] [CrossRef] [Green Version]

- Li, W.Z.; Kong, J.; Wu, T.T.; Gao, L.H.; Ma, Z.; Liu, Y.B.; Wang, F.C.; Wei, C.H.; Wang, L.J. Characterization, optical properties and laser ablation behavior of epoxy resin coatings reinforced with high reflectivity ceramic particles. Mater. Res. Express. 2018, 5, 046202. [Google Scholar] [CrossRef]

- Ji, M.M.; Zhu, S.Z.; Ma, Z.; Li, H.Z. Effects of adhesive modulus and curing conditions on curing behavior of silicate based ceramic coatings on carbon fiber reinforced resin matrix composites. Ceram. Int. 2021, 47, 11089–11096. [Google Scholar] [CrossRef]

- Yan, D.R.; He, J.N.; Li, X.Z.; Dong, Y.C.; Liu, Y.; Zhang, J.X. Corrosion behavior in boiling dilute HCI solution of different ceramic coatings fabricated by plasma spraying. J. Therm. Spray Technol. 2004, 13, 503–507. [Google Scholar] [CrossRef]

- Yao, Z.P.; Jiang, Y.L.; Jiang, Z.H.; Wang, F.P.; Wu, Z.D. Preparation and structure of ceramic coatings containing zirconium oxide on Ti alloy by plasma electrolytic oxidation. J. Mater. Process. Technol. 2008, 205, 303–307. [Google Scholar] [CrossRef]

- Gu, W.C.; Shen, D.J.; Wang, Y.L.; Chen, G.L.; Feng, W.R.; Zhang, G.L.; Liu, C.Z.; Yang, S.Z. Preparation of Al2O3 ceramic coating by electrolytic plasma processing and its properties. Acta Phys. Sin. 2005, 54, 3263–3267. [Google Scholar]

- Chen, Z.; Trice, R.W.; Besser, M.; Yang, X.Y.; Sordelet, D. Air-plasma spraying colloidal solutions of nanosized ceramic powders. J. Mater. Sci. 2004, 39, 4171–4178. [Google Scholar] [CrossRef] [Green Version]

- Dubourg, L.; Lima, R.S.; Moreau, C. Properties of alumina-titania coatings prepared by laser-assisted air plasma spraying. Surf. Coat. Technol. 2007, 201, 6278–6284. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.Y.; Song, X.F.; Jin, D.L.; Xing, C.; Shan, X.; Zhao, X.F.; Guo, F.W.; Xiao, P. A robust quasi-superhydrophobic ceria coating prepared using air-plasma spraying. J. Am. Ceram. Soc. 2019, 102, 1386–1393. [Google Scholar] [CrossRef] [Green Version]

- Deng, W.; Hou, G.L.; Li, S.J.; Han, J.S.; Zhao, X.Q.; Liu, X.; An, Y.L.; Zhou, H.D.; Chen, J.M. A new methodology to prepare ceramic-organic composite coatings with good cavitation erosion resistance. Ultrason. Sonochem. 2018, 44, 115–119. [Google Scholar] [CrossRef]

- Lu, J.P.; He, X.; Li, H.X.; Song, R.G. Microstructure and corrosion resistance of PEO coatings formed on KBM10 mg alloy pretreated with Nd(NO3)3. Materials 2018, 11, 1062. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.L.; Wang, M.; Zhou, M.; Li, B.J.; Amoako, G.; Jiang, Z.H. Microstructure characterisation of alumina coating on steel by PEO. Surf. Eng. 2013, 29, 271–275. [Google Scholar] [CrossRef]

- Xu, Y.J.; Yao, Z.P.; Jia, F.Z.; Wang, Y.L.; Jiang, Z.H.; Bu, H.T. Preparation of PEO ceramic coating on Ti alloy and its high temperature oxidation resistance. Curr. Appl. Phys. 2010, 10, 698–702. [Google Scholar] [CrossRef]

- Molaei, M.; Nouri, M.; Babaei, K.; Fattah-Alhosseini, A. Improving surface features of PEO coatings on titanium and titanium alloys with zirconia particles: A review. Surf. Interfaces 2021, 22, 100888. [Google Scholar] [CrossRef]

- Darband, G.B.; Aliofkhazraei, M.; Hamghalam, P.; Valizade, N. Plasma electrolytic oxidation of magnesium and its alloys: Mechanism, properties and applications. J. Magnes. Alloy. 2017, 5, 74–132. [Google Scholar] [CrossRef]

- Yerokhin, A.L.; Nie, X.; Leyland, A.; Matthews, A.; Dowey, S.J. Plasma electrolysis for surface engineering. Surf. Coat. Technol. 1999, 122, 73–93. [Google Scholar] [CrossRef]

- Attarzadeh, N.; Molaei, M.; Babaei, K.; Fattah-alhosseini, A. New promising ceramic coatings for corrosion and wear protection of steels: A review. Surf. Interfaces 2021, 23, 100997. [Google Scholar] [CrossRef]

- Walsh, F.C.; Low, C.T.J.; Wood, R.J.K.; Stevens, K.T.; Archer, J.; Poeton, A.R.; Ryder, A. Plasma electrolytic oxidation (PEO) for production of anodised coatings on lightweight metal (Al, Mg, Ti) alloys. Trans. Inst. Metal Finish. 2009, 87, 122–135. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.P.; Li, X.J.; Xu, H.; Xia, Q.X.; Chen, C.J.; Jiang, Z.H. Application of Micro-arc Oxidation Technology in Thermal Control Coating. Surf. Technol. 2019, 48, 24–36+60. [Google Scholar]

- Yao, Z.P.; Li, X.J.; Wei, H.; Xia, Q.X.; Wang, Y.; Li, D.Q.; Jiang, Z.H. Black ceramic coatings on Ti alloy with enhanced high absorptivity and high emissivity by plasma electrolytic oxidation. Int. J. Appl. Ceram. Technol. 2019, 16, 994–1003. [Google Scholar] [CrossRef]

- Kim, D.; Sung, D.; Lee, J.; Kim, Y.; Chung, W. Composite plasma electrolytic oxidation to improve the thermal radiation performance and corrosion resistance on an Al substrate. Appl. Surf. Sci. 2015, 357, 1396–1402. [Google Scholar] [CrossRef]

| System Component | Parameter | Specifics |

|---|---|---|

| CO2 laser | Maximum output power | 1 W |

| Wavelength | 10.6 μm | |

| Power stability | ±5% | |

| Infrared imaging Optical system | Working wavelength | 8~12 μm |

| Exit pupil diameter | 44 mm | |

| Entrance pupil diameter | 57 mm | |

| Minimum resolvable temperature difference (MRTD) | 450 mK (2.5 cycle/mrad) | |

| Infrared detector | Resolution | 640 × 512 |

| Pixel Size | 17 μm | |

| f-Number | 1 | |

| Field-of-view (FOV) angle | 10° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Guo, X.; Lu, S.; Zhang, Y.; Hu, H.; Lu, K.; Zhang, J. Investigation of Stray Radiation Suppression in Infrared Imaging System Using a Novel Broadband and High-Absorption Ceramic Coating. Appl. Sci. 2021, 11, 4952. https://doi.org/10.3390/app11114952

Yang Z, Guo X, Lu S, Zhang Y, Hu H, Lu K, Zhang J. Investigation of Stray Radiation Suppression in Infrared Imaging System Using a Novel Broadband and High-Absorption Ceramic Coating. Applied Sciences. 2021; 11(11):4952. https://doi.org/10.3390/app11114952

Chicago/Turabian StyleYang, Zhen, Xinmin Guo, Songtao Lu, Yong Zhang, Haili Hu, Kaichang Lu, and Jianlong Zhang. 2021. "Investigation of Stray Radiation Suppression in Infrared Imaging System Using a Novel Broadband and High-Absorption Ceramic Coating" Applied Sciences 11, no. 11: 4952. https://doi.org/10.3390/app11114952

APA StyleYang, Z., Guo, X., Lu, S., Zhang, Y., Hu, H., Lu, K., & Zhang, J. (2021). Investigation of Stray Radiation Suppression in Infrared Imaging System Using a Novel Broadband and High-Absorption Ceramic Coating. Applied Sciences, 11(11), 4952. https://doi.org/10.3390/app11114952