Handling Enhancement of Autonomous Emergency Steering for Reduced Road Friction Using Steering and Differential Braking

Abstract

1. Introduction

1.1. Related Work

1.2. Main Contributions

- The dynamic responses of the vehicle model in the previous work might deviate from those of the actual vehicle model with actuator dynamics for severe maneuvers. The EPS and EHB dynamics are integrated with the four-state bicycle model to enhance the accuracy of the prediction model.

- A diagonal matrix with components of tire workload ratios is used to replace the identity weighting matrix of CA to prevent saturating tire forces while generating the desired DYM.

- Different road friction coefficients are used for sensitivity analysis to evaluate the robustness and handling enhancement of the proposed algorithm at different vehicle velocities via simulation studies.

1.3. Organization

2. Modeling

2.1. Actuator Dynamics

2.2. Bicycle Model

2.3. Model Discretization

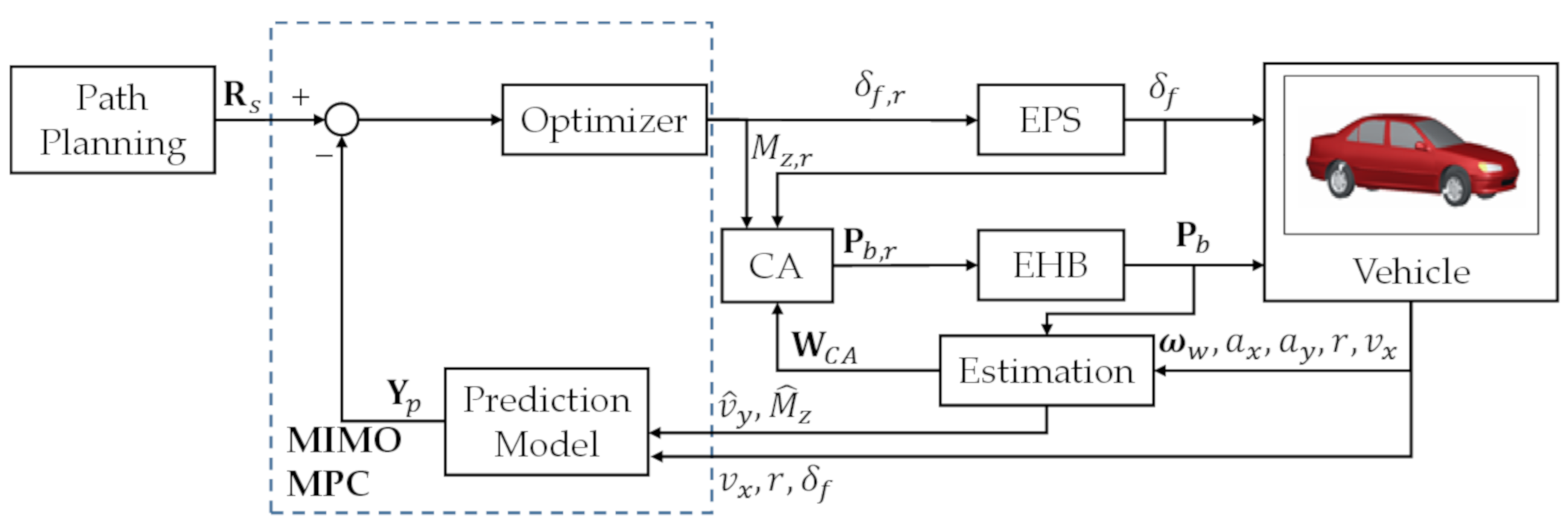

3. Controller Design

3.1. Model Predictive Controller

3.2. Evasive Path Generation

3.3. Control Allocation

| Algorithm 1 Saturation Prevention |

| ; |

4. Simulation Results

4.1. Comparison of Prediction Models

4.2. Nominal Road Friction Coefficient of 0.9

4.3. Nominal Road Friction Coefficient of 0.7

4.4. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- NHTSA. Traffic Safety Facts 2017 a Compilation of Motor Vehicle Crash Data; NHTSA: Washington, DC, USA, 2019.

- Singh, S. Critical Reasons for Crashes Investigated in the National Motor Vehicle Crash Causation Survey. Available online: https://crashstats.nhtsa.dot.gov/Api/Public/ViewPublication/812506 (accessed on 24 May 2021).

- Lich, T.; Mettler, A.; Georgi, A.; Danz, C.; Doopyo, L.; Sooncheol, L.; Sul, J. Benefit Analysis of Predictive Rear End Collision Avoidance and Mitigation Systems for South Korea Using Video Documented Accident Data. In Proceedings of the 11th International Symposium on Advanced Vehicle Control, Seoul, Korea, 9–12 September 2012. [Google Scholar]

- Eckert, A.; Hartmann, B.; Sevenich, M.; Rieth, P. Emergency Steer & Brake Assist—A Systematic Approach for System Integration of Two Complementary Driver Assistance Systems. In Proceedings of the 22nd ESV Enhanced Safety of Vehicles Conference, Washington, WA, USA, 13–16 June 2011. [Google Scholar]

- EuroNCAP. Euro NCAP 2025 Roadmap; EuroNCAP: Leuven, Belgium, 2018. [Google Scholar]

- Choi, J.; Yi, K. Design and Evaluation of Emergency Driving Support Using Motor Driven Power Steering and Differential Braking on a Virtual Test Track. SAE Int. J. Passeng. Cars–Mech. Syst. 2013, 6, 691–704. [Google Scholar] [CrossRef]

- Choi, J.; Yi, K.; Suh, J.; Ko, B. Coordinated Control of Motor-Driven Power Steering Torque Overlay and Differential Braking for Emergency Driving Support. IEEE Trans. Veh. Technol. 2014, 63, 566–579. [Google Scholar] [CrossRef]

- Keller, M.; Hass, C.; Seewald, A.; Bertram, T.; Keller, M. Driving simulator study on an emergency steering assist. In Proceedings of the 2014 IEEE International Conference on Systems, Man, and Cybernetics (SMC), San Diego, CA, USA, 5–8 October 2014; pp. 3008–3013. [Google Scholar]

- Zhao, Z.; Zhou, L.; Luo, Y.; Li, K. Emergency Steering Evasion Assistance Control Based on Driving Behavior Analysis. IEEE Trans. Intell. Transp. Syst. 2018, 20, 457–475. [Google Scholar] [CrossRef]

- Shimizu, M.; Usami, M.; Fujinami, H. Development of Collision-Avoidance Assist System Operating at Driver Steering. Trans. Soc. Automot. Eng. Jpn. 2008, 39, 441–446. [Google Scholar] [CrossRef]

- Choi, C.; Kang, Y. Simultaneous braking and steering control method based on nonlinear model predictive control for emergency driving support. Int. J. Control. Autom. Syst. 2017, 15, 345–353. [Google Scholar] [CrossRef]

- Ferdinand, J.; Yi, B. Trajectory planning for collision avoidance in urban area. In Proceedings of the 2016 IEEE Intelligent Vehicles Symposium (IV), Gothenburg, Sweden, 19–22 June 2016; pp. 202–207. [Google Scholar]

- Hayashi, R.; Isogai, J.; Raksincharoensak, P.; Nagai, M. Autonomous collision avoidance system by combined control of steering and braking using geometrically optimised vehicular trajectory. Veh. Syst. Dyn. 2012, 50, 151–168. [Google Scholar] [CrossRef]

- Zhou, L.; Zhao, Z.; Shen, P.; Li, M.; Li, K. Emergency Steering Evasion Control by Combining the Yaw Moment with Steering Assistance. In Proceedings of the SAE 2018 World Congress and Exhibition, Detroit, MI, USA, 10–12 April 2018. [Google Scholar] [CrossRef]

- Cui, Q.; Ding, R.; Wu, X.; Zhou, B. A new strategy for rear-end collision avoidance via autonomous steering and differential braking in highway driving. Veh. Syst. Dyn. 2019, 58, 955–986. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Waslander, S.L.; Gong, J.; Xiong, G.; Yang, T.; Liu, K. Hybrid Trajectory Planning for Autonomous Driving in Highly Constrained Environments. IEEE Access 2018, 6, 32800–32819. [Google Scholar] [CrossRef]

- Stahl, T.; Wischnewski, A.; Betz, J.; Lienkamp, M. Multilayer Graph-Based Trajectory Planning for Race Vehicles in Dynamic Scenarios. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference (ITSC), Paris, France, 9–12 June 2019. [Google Scholar]

- McNaughton, M.; Urmson, C.; Dolan, J.M.; Lee, J.-W. Motion planning for autonomous driving with a conformal spatiotemporal lattice. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 4889–4895. [Google Scholar]

- Srinivasan, S.; Giles, S.N.; Liniger, A. A Holistic Motion Planning and Control Solution to Challenge a Professional Racecar Driver. arXiv 2021, arXiv:2103.00358. Available online: https://arxiv.org/abs/2103.00358 (accessed on 24 May 2021).

- Qian, X.; Altché, F.; Bender, P.; Stiller, C.; Fortelle, A. La Optimal Trajectory Planning for Autonomous Driving Integrating Logical Constraints: An MIQP Perspective. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems, Rio de Janeiro, Brazil, 1–4 November 2016; pp. 205–210. [Google Scholar]

- Dolgov, D.; Thrun, S.; Montemerlo, M.; Diebel, J. Path Planning for Autonomous Vehicles in Unknown Semi-structured Environments. Int. J. Robot. Res. 2010, 29, 485–501. [Google Scholar] [CrossRef]

- Nelson, W. Continuous-curvature paths for autonomous vehicles. In Proceedings of the 1989 International Conference on Robotics and Automation, Scottsdale, AZ, USA, 14–19 May 1989; Volume 3, pp. 1260–1264. [Google Scholar]

- Sotelo, M.A. Lateral control strategy for autonomous steering of Ackerman-like vehicles. Robot. Auton. Syst. 2003, 45, 223–233. [Google Scholar] [CrossRef]

- Cremean, L.B.; Foote, T.B.; Gillula, J.H.; Hines, G.H.; Kogan, D.; Kriechbaum, K.L.; Lamb, J.C.; Leibs, J.; Lindzey, L.; Rasmussen, C.E.; et al. Alice: An information-rich autonomous vehicle for high-speed desert navigation. J. Field Robot. 2006, 23, 777–810. [Google Scholar] [CrossRef]

- Chatzikomis, C.I.; Spentzas, K.N. A path-following driver model with longitudinal and lateral control of vehicle’s motion. Forsch. Ing. 2009, 73, 257–266. [Google Scholar] [CrossRef]

- Chen, B.; Li, L.; Zhang, W.; Dong, H.; Wang, Y.; Xiao, L. A Data-Based Approach to Path Following Controller Design for Autonomous Vehicles. In Proceedings of the CICTP 2019, Nanjing, China, 6–8 July 2019; pp. 367–378. [Google Scholar]

- Chen, I.-M.; Chan, C.-Y. Deep reinforcement learning based path tracking controller for autonomous vehicle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2020, 1–11. [Google Scholar] [CrossRef]

- Grigorescu, S.; Trasnea, B.; Cocias, T.; Macesanu, G. A survey of deep learning techniques for autonomous driving. J. Field Robot. 2020, 37, 362–386. [Google Scholar] [CrossRef]

- Chen, B.-C.; Luan, B.-C.; Lee, K. Design of lane keeping system using adaptive model predictive control. In Proceedings of the 2014 IEEE International Conference on Automation Science and Engineering (CASE), Taipei, Taiwan, 18–22 August 2014; pp. 922–926. [Google Scholar]

- Skarpetis, M.G.; Koumboulis, F.N.; Papanikolaou, P. Vehicle lateral control using a robust tracking controller based on vision look ahead system. In Proceedings of the 2015 International Conference on Electrical, Electronics, Signals, Communication and Optimization (EESCO), Visakhapatnam, India, 24–25 January 2017; pp. 000213–000218. [Google Scholar]

- Song, L.; Guo, H.; Wang, F.; Liu, J.; Chen, H. Model predictive control oriented shared steering control for intelligent vehicles. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 7568–7573. [Google Scholar]

- Falcone, P.; Borrelli, F.; Asgari, J.; Tseng, H.E.; Hrovat, D. A model predictive control approach for combined braking and steering in autonomous vehicles. In Proceedings of the 2007 Mediterranean Conference on Control & Automation, Athens, Greece, 27–29 June 2007; pp. 1–6. [Google Scholar]

- Hajiloo, R.; Abroshan, M.; Khajepour, A.; Kasaiezadeh, A.; Chen, S.-K. Integrated Steering and Differential Braking for Emergency Collision Avoidance in Autonomous Vehicles. IEEE Trans. Intell. Transp. Syst. 2021, 22, 3167–3178. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, B.; Chan, Y. Design of Autonomous Emergency Steering Using Multi-Input Multi-Output Model Predictive Control. In Proceedings of the Advanced Vehicle Control Proceedings of the 14th International Symposium on Advanced Vehicle Control (AVEC’18), Beijing, China, 14–18 July 2018. [Google Scholar]

- Chen, B.-C.; Tsai, C.-T.; Lin, Y.-M.; Lee, K. Design of an automated steering controller with steering actuator dynamics and adaptive preview time. In Proceedings of the Advanced Vehicle Control AVEC’16, Munich, Germany, 13–16 September 2016; pp. 163–168. [Google Scholar]

- Kim, E.; Kim, J.; Sunwoo, M. Model predictive control strategy for smooth path tracking of autonomous vehicles with steering actuator dynamics. Int. J. Automot. Technol. 2014, 15, 1155–1164. [Google Scholar] [CrossRef]

- Thornton, S.; Zhang, V.; Varnhagen, S.; Gerdes, J. Comparative Analysis of Steering System Models in Model Predictive Control of Automated Vehicles. In Proceedings of the 14th International Symposium on Advanced Vehicle Control (AVEC 2018), Beijing, China, 16–20 July 2018. [Google Scholar]

- Soltani, A.; Assadian, F.; Soltani, A. New Slip Control System Considering Actuator Dynamics. SAE Int. J. Passeng. Cars–Mech. Syst. 2015, 8, 512–520. [Google Scholar] [CrossRef]

- Ulsoy, A.G.; Peng, H.; Cakmakci, M. Automotive Control Systems; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Wischnewski, A.; Stahl, T.; Betz, J.; Lohmann, B. Vehicle Dynamics State Estimation and Localization for High Performance Race Cars. IFAC-PapersOnLine 2019, 52, 154–161. [Google Scholar] [CrossRef]

- Chen, B.-C.; Hsieh, F.-C. Sideslip angle estimation using extended Kalman filter. Veh. Syst. Dyn. 2008, 46, 353–364. [Google Scholar] [CrossRef]

- Chen, B.-C.; Kuo, C.-C. Electronic stability control for electric vehicle with four in-wheel motors. Int. J. Automot. Technol. 2014, 15, 573–580. [Google Scholar] [CrossRef]

- Bryson, A.E. Control of Spacecraft and Aircraft; De Gruyter: Berlin, Germany, 1994. [Google Scholar]

- Ahn, C.S. Robust Estimation of Road Friction Coefficient for Vehicle Active Safety Systems; University of Michigan: Ann Arbor, MI, USA, 2011. [Google Scholar]

- Wielitzka, M.; Dagen, M.; Ortmaier, T. State and maximum friction coefficient estimation in vehicle dynamics using UKF. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017; pp. 4322–4327. [Google Scholar] [CrossRef]

- Hermansdorfer, L.; Betz, J.; Lienkamp, M. A Concept for Estimation and Prediction of the Tire-Road Friction Potential for an Autonomous Racecar. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference (ITSC), Auckland, New Zealand, 27–30 October 2019; pp. 1490–1495. [Google Scholar]

- Oppenheimer, M.W.; Doman, D.B.; Bolender, M.A. Control Allocation for Over-actuated Systems. In Proceedings of the 2006 14th Mediterranean Conference on Control and Automation, Ancona, Italy, 28–30 June 2006; pp. 1–6. [Google Scholar]

- Car Insurers Warn on “Autonomous” Vehicles—BBC News. Available online: https://www.bbc.com/news/technology-44439523 (accessed on 21 May 2021).

- NHTSA. Laboratory Test Procedure for Dynamic Rollover the Fishhook Maneuver Test Procedure; NHTSA: Washington, DC, USA, 2013.

- He, X.; Liu, Y.; Lv, C.; Ji, X.; Liu, Y. Emergency steering control of autonomous vehicle for collision avoidance and stabilisation. Veh. Syst. Dyn. 2018, 57, 1163–1187. [Google Scholar] [CrossRef]

| Name | Value |

|---|---|

| Vehicle mass (m) | 1530 kg |

| Yaw-plane rotational inertia of vehicle (Iz) | 2315 kg–m2 |

| Distances from the C.G. to the front axles (lf) | 1.1 m |

| Wheel base (L) | 2.78 m |

| Cornering stiffness of the front axles (Cαf) | 150.3 kN/rad |

| Cornering stiffness of the rear axles (Cαr) | 104.9 kN/rad |

| Model | State | Input | Output |

|---|---|---|---|

| Four-states | |||

| Five-states | |||

| Six-states |

| 0.9 | |||||

|---|---|---|---|---|---|

| SISO | 0.51 m | 0.53 m | 0.52 m | 0.47 m | 0.36 m |

| MIMO | 0.48 m | 0.49 m | 0.51 m | 0.51 m | 0.45 m |

| 0.9 | ||||||

|---|---|---|---|---|---|---|

| SISO | rms | 1.1° | 1.5° | 3.2° | 62.3° | 77.2° |

| max | 4.4° | 6° | 14.2° | 180° | 180° | |

| MIMO | rms | 1° | 1.2° | 1.6° | 2.2° | 3.1° |

| max | 4.3° | 4.7° | 5.9° | 9° | 13° | |

| 0.9 | 0.85 | ||||||

|---|---|---|---|---|---|---|---|

| SISO | 0.44 m | 0.45 m | 0.47 m | 0.47 m | 0.45 m | 0.39 m | 0.27 m |

| MIMO | 0.40 m | 0.42 m | 0.43 m | 0.43 m | 0.42 m | 0.36 m | 0.24 m |

| 0.9 | 0.85 | |||||||

|---|---|---|---|---|---|---|---|---|

| SISO | rms | 1.7° | 2.2° | 3.1° | 4.3° | 6.2° | 66.7° | 73.2° |

| max | 5.1° | 6.9° | 9.9° | 13.8° | 19.1° | 180° | 180° | |

| MIMO | rms | 1.5° | 1.7° | 2.2° | 3.1° | 4.2° | 5.6° | 6.7° |

| max | 4.7° | 5.4° | 6.8° | 9.8° | 13.4° | 17° | 19.8° | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-M.; Chen, B.-C. Handling Enhancement of Autonomous Emergency Steering for Reduced Road Friction Using Steering and Differential Braking. Appl. Sci. 2021, 11, 4891. https://doi.org/10.3390/app11114891

Lin Y-M, Chen B-C. Handling Enhancement of Autonomous Emergency Steering for Reduced Road Friction Using Steering and Differential Braking. Applied Sciences. 2021; 11(11):4891. https://doi.org/10.3390/app11114891

Chicago/Turabian StyleLin, Yu-Min, and Bo-Chiuan Chen. 2021. "Handling Enhancement of Autonomous Emergency Steering for Reduced Road Friction Using Steering and Differential Braking" Applied Sciences 11, no. 11: 4891. https://doi.org/10.3390/app11114891

APA StyleLin, Y.-M., & Chen, B.-C. (2021). Handling Enhancement of Autonomous Emergency Steering for Reduced Road Friction Using Steering and Differential Braking. Applied Sciences, 11(11), 4891. https://doi.org/10.3390/app11114891