Coupling Effect of Air Flow Rate and Operating Conditions on the Performance of Electric Vehicle R744 Air Conditioning System

Abstract

:1. Introduction

2. Materials and Methods

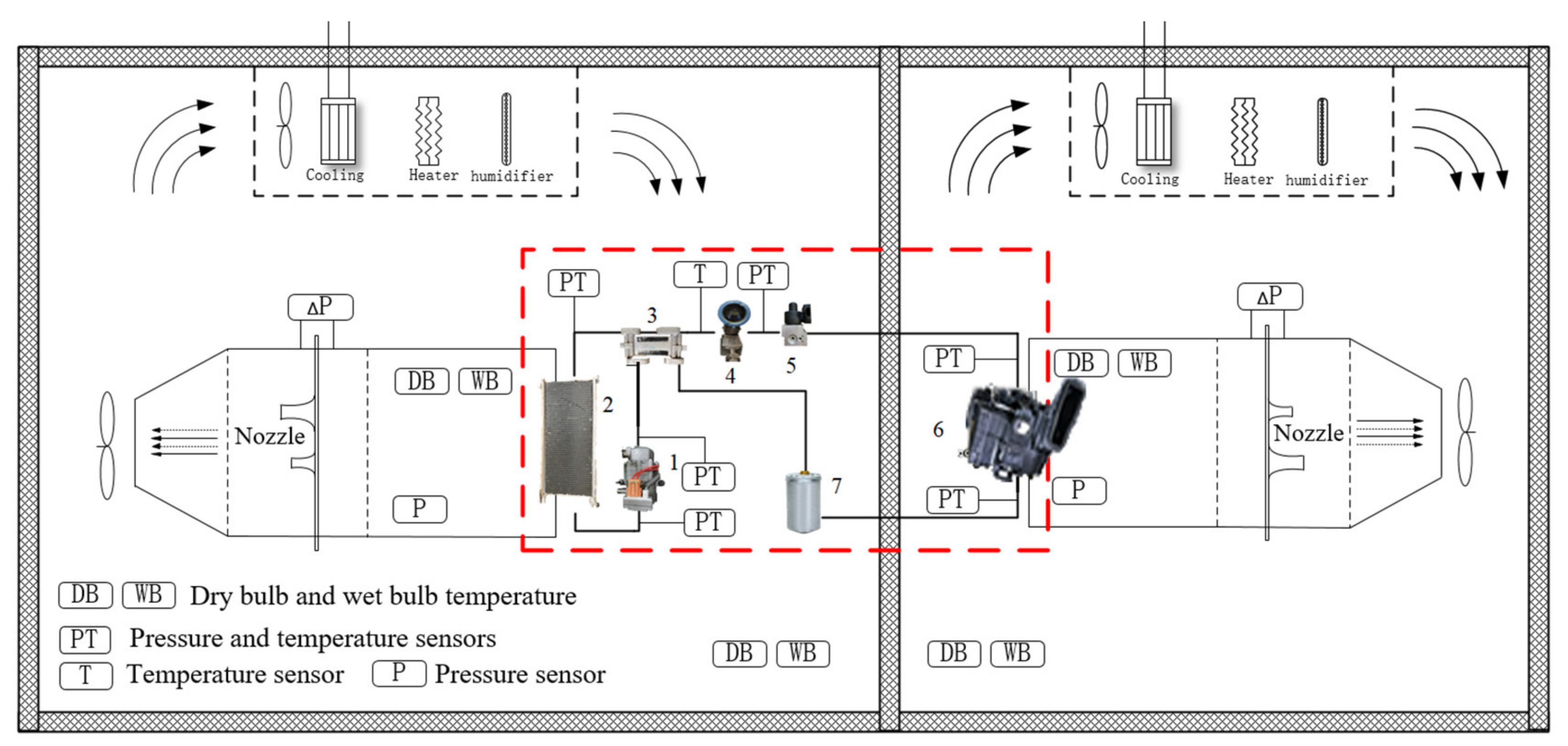

2.1. Experimental Setup Description

2.2. Experiment Conditions

2.3. Uncertainty Analysis

3. Results and Discussion

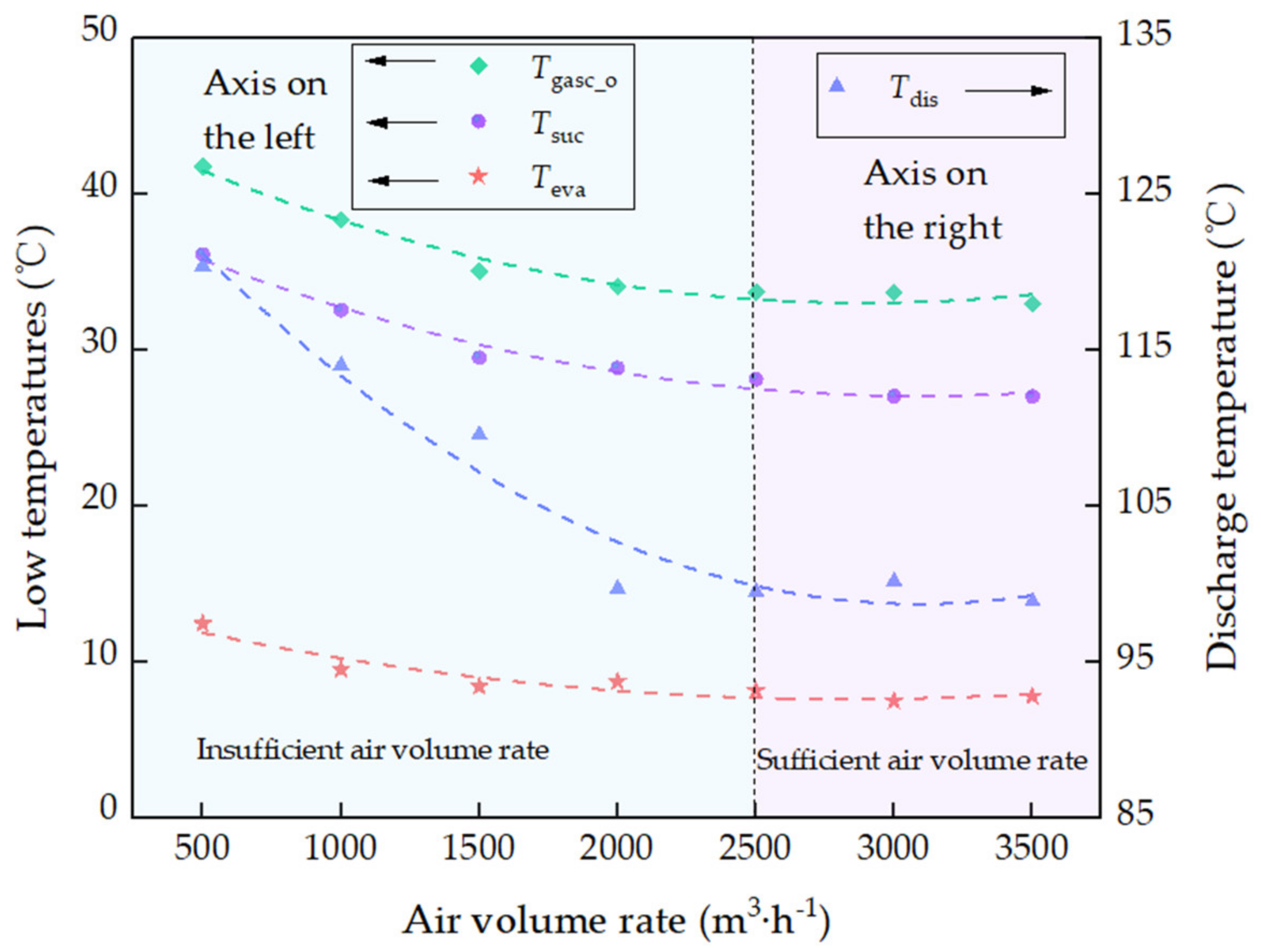

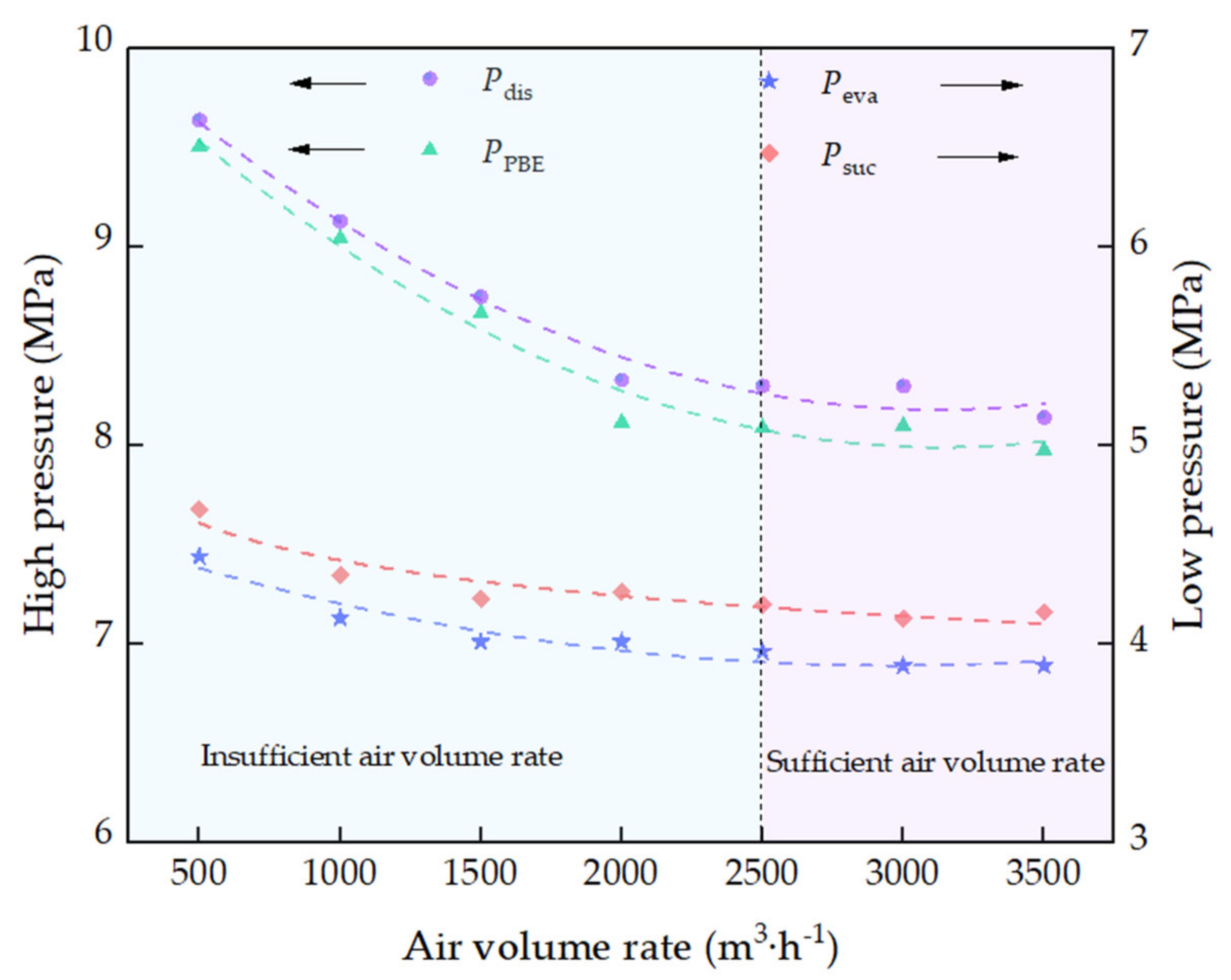

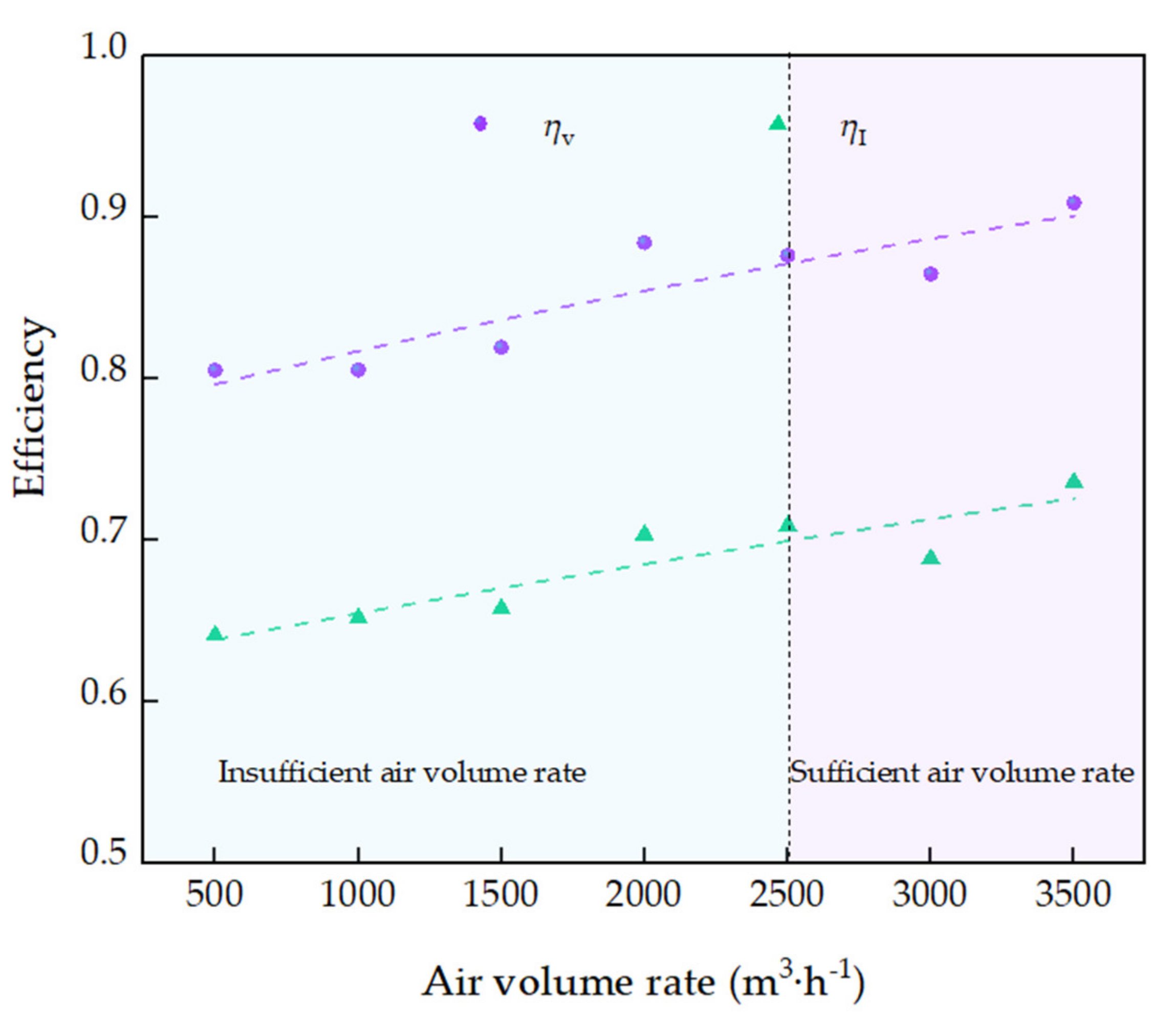

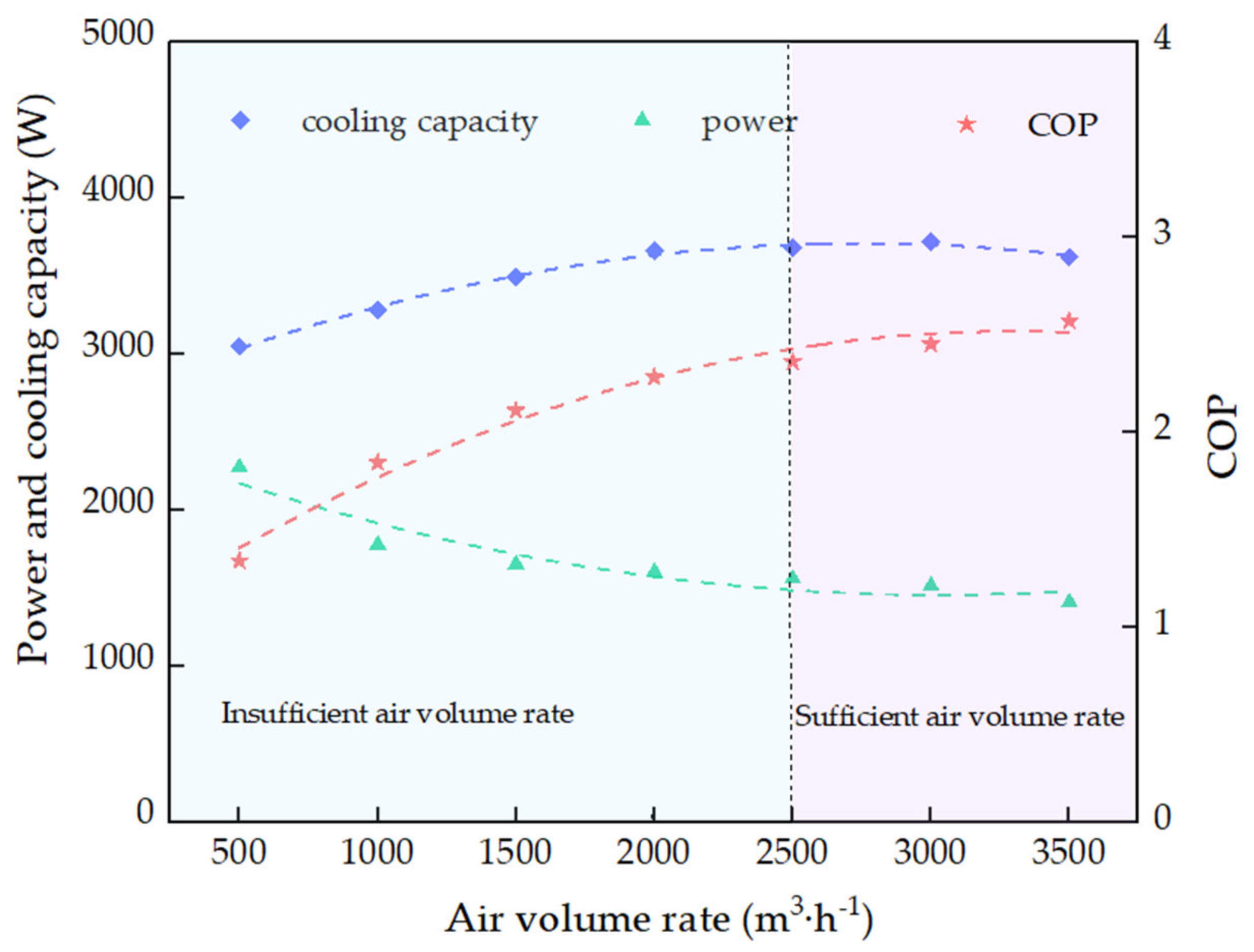

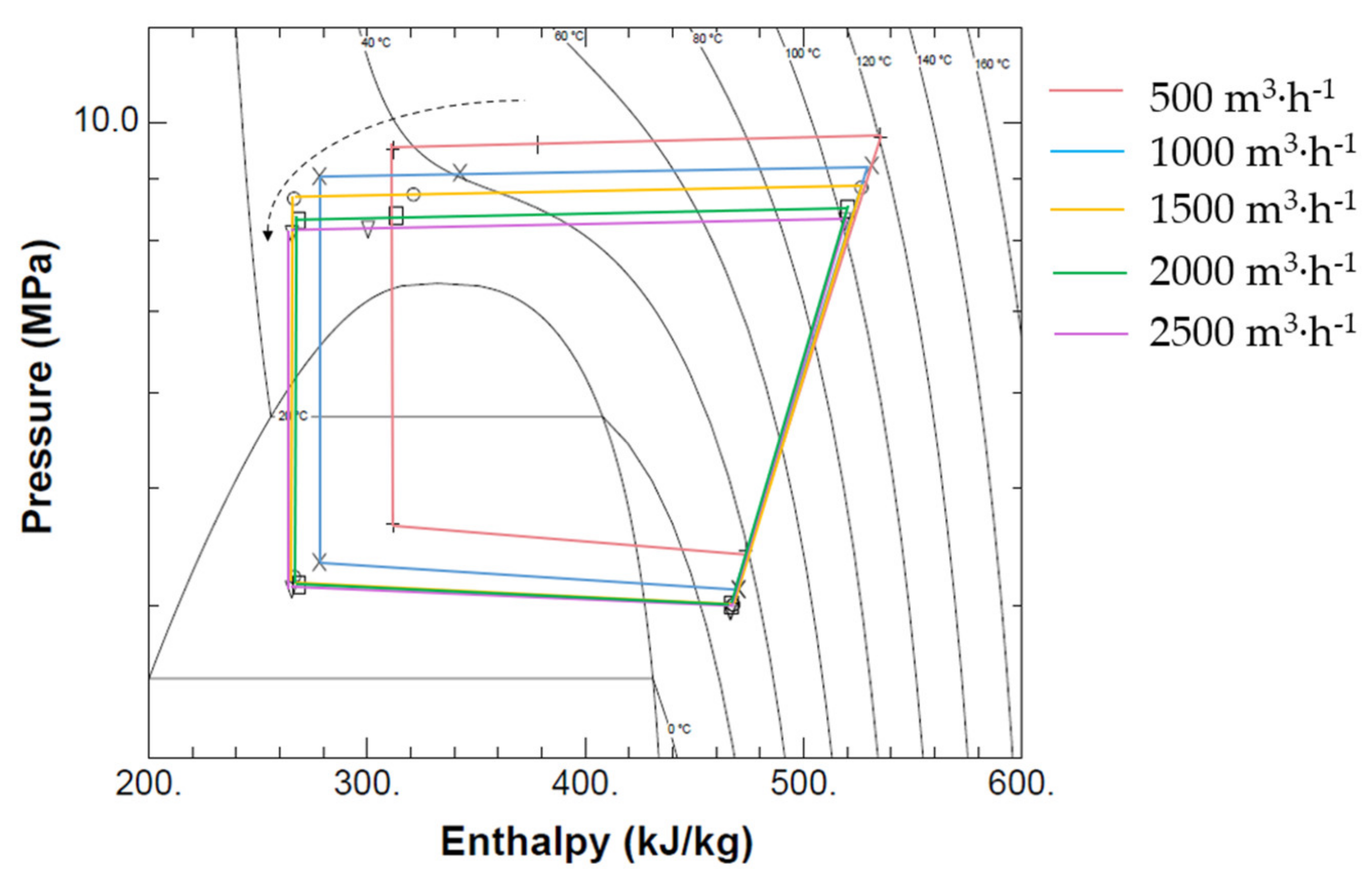

3.1. Influence of Gas Cooler Air Volume Flow Rate on Key Temperatures and Pressures

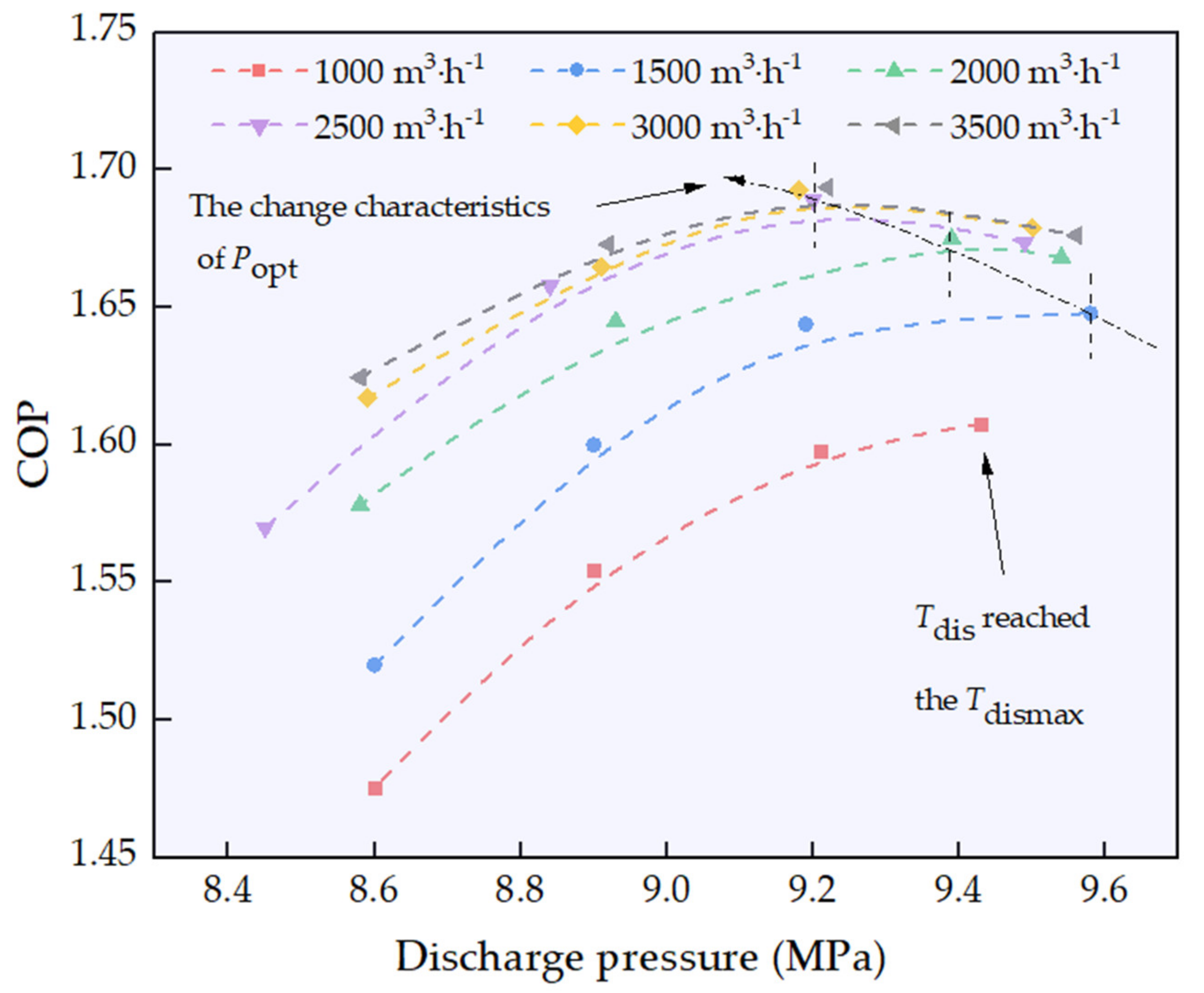

3.2. Influence of Gas Cooler Air Volume Flow Rate on Optimal Discharge Pressure

3.3. Effect of Compressor Speed and Ambient Temperature on Optimal Gas Cooler Air Volume Flow Rate

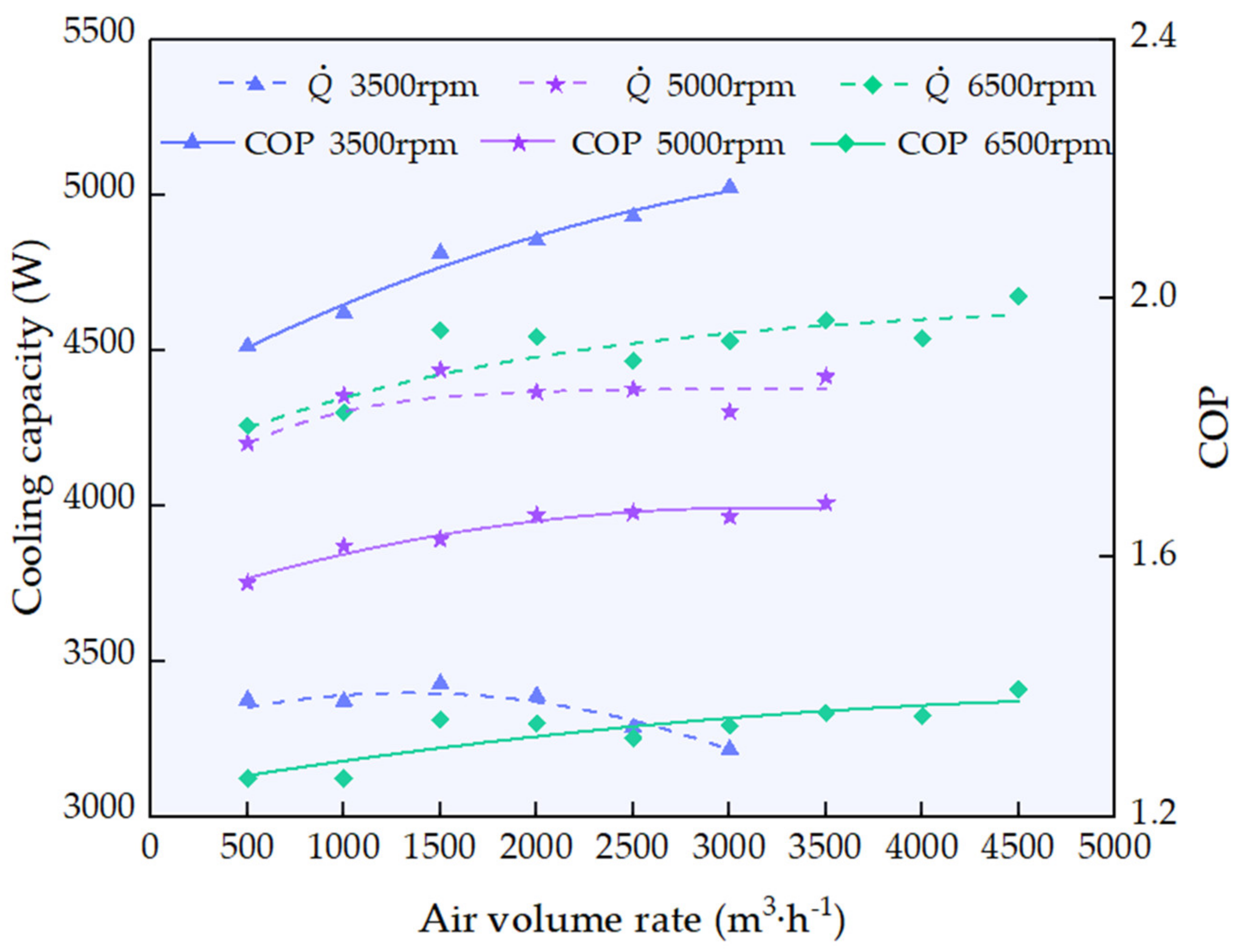

3.3.1. Influence of Compressor Speed on Optimal Gas Cooler Air Volume Flow Rate

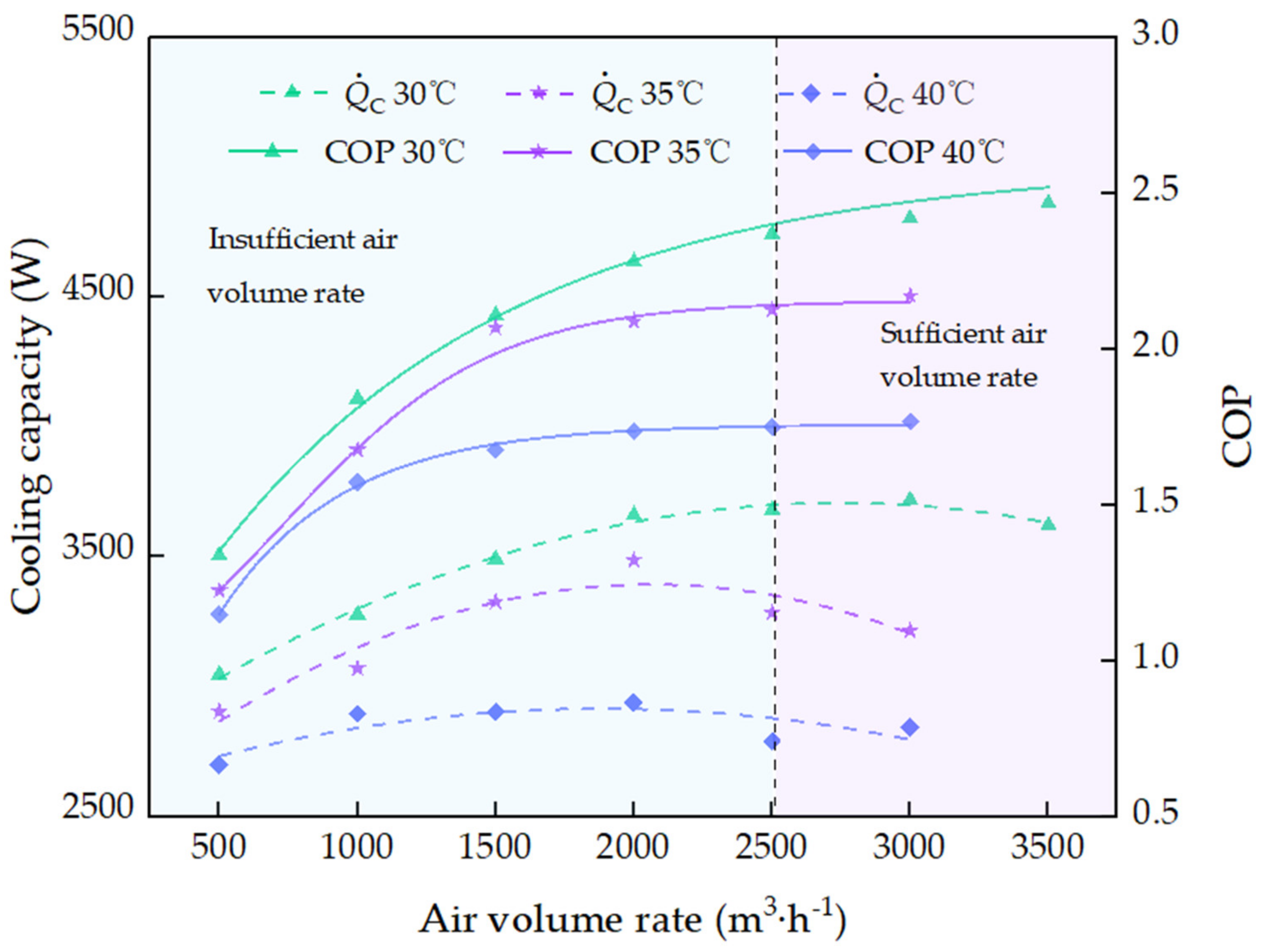

3.3.2. Influence of Ambient Temperature on Optimal Gas Cooler Air Volume Flow Rate

4. Conclusions

- the new approach suggests that the optimal gas cooler air volume flow rate can be selected as the one, which results in the discharge temperature, gas cooler outlet temperature and discharge pressure change rates below 2%;

- high compressor speeds are recommended in order to promote optimal gas cooler air volume rates;

- the ambient temperature does not influence the optimal gas cooler air volume rate significantly;

- for the single-row and dual-process microchannel heat exchanger used in the experiment, the recommended value of the optimal air flow rate is about 2500 m3·h−1.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | |

| COP | Coefficient of performance |

| D | Depth, mm |

| EXV | Expansion valve |

| GWP | Global warming potential |

| h | Specific enthalpy, kJ·kg−1 |

| H | Height, mm |

| HVAC | Heating, ventilation and air conditioning |

| IHX | Internal heat exchanger |

| L | Length, mm |

| ODP | Ozone depletion potential |

| P | Pressure, MPa |

| PBE | Pressure upstream of expansion valve |

| Cooling capacity, W | |

| SGC | Series gas cooler |

| T | Temperature, °C |

| Volume flow rate, m3·h−1 | |

| Power input, W | |

| x | Uncertainty of independent variable |

| Greek symbols | |

| ω | Resulting uncertainty |

| ρ | Density, kg·m−3 |

| η | efficiency |

| Subscripts | |

| air | Air |

| airW | Wet bulb temperature of air |

| airD | Dry bulb temperature of air |

| dis | Discharge |

| eva | Evaporation |

| eva i | Evaporator inlet |

| eva o | Evaporator outlet |

| gasc_o | Gas cooler outlet |

| opt | Optimal |

| suc | Suction |

| V | Volumetric |

| I | Isentropic |

| R | Representation of the parameter |

References

- Kumar, R.R.; Alok, K. Adoption of electric vehicle: A literature review and prospects for sustainability. J. Clean. Prod. 2020, 253, 119911. [Google Scholar] [CrossRef]

- Hannan, M.A.; Azidin, F.A.; Mohamed, A. Hybrid electric vehicles and their challenges: A review. Renew. Sustain. Energy Rev. 2014, 29, 135–150. [Google Scholar] [CrossRef]

- Daviran, S.; Kasaeian, A.; Golzari, S.; Mahian, O.; Nasirivatan, S.; Wongwises, S. A comparative study on the performance of HFO-1234yf and HFC-134a as an alternative in automotive air conditioning systems. Appl. Therm. Eng. 2017, 110, 1091–1100. [Google Scholar] [CrossRef]

- Nekså, P.; Pettersen, J.; Hafner, A. Life Cycle Climate Performance (LCCP) of mobile air-conditioning systems with HFC-134a, HFC-152a and R-744. In Proceedings of the MAC (Mobile air Conditioning) Summit 2004, Washington, DC, USA, 14 April 2004. [Google Scholar]

- Meng, Z.; Zhang, H.; Lei, M.; Qin, Y.; Qiu, J. Performance of low GWP R1234yf/R134a mixture as a replacement for R134a in automotive air conditioning systems. Int. J. Heat Mass Transf. 2018, 116, 362–370. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, J.; Jia, S.; Huang, L. Experimental comparison of R744 and R134a heat pump systems for electric vehicle application. Int. J. Refrig. 2021, 121, 10–22. [Google Scholar] [CrossRef]

- Wang, D.; Yu, B.; Hu, J.; Chen, L.; Shi, J.; Chen, J. Heating performance characteristics of CO2 heat pump system for electrical vehicle in a cold climate. Int. J. Refrig. 2018, 85, 27–41. [Google Scholar] [CrossRef]

- Gaurav, K.R. Sustainability of alternative material of R-134a in mobile air-conditioning system: A review. Mater. Today Proc. 2017, 4, 112–118. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, G.; Wang, M. A comprehensive assessment of refrigerants for cabin heating and cooling on electric vehicles. Appl. Therm. Eng. 2020, 174, 115258. [Google Scholar] [CrossRef]

- Lorentzen, G.; Pettersen, J. A new, efficient and environmentally benign system for car air-conditioning. Int. J. Refrig. 1993, 16, 4–12. [Google Scholar] [CrossRef]

- Brown, J.S.; Yana-Motta, S.F.; Domanski, P.A. Comparitive analysis of an automotive air conditioning systems operating with CO2 and R134a. Int. J. Refrig. 2002, 25, 19–32. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Y.; Jia, S.; Zhang, X.; Huang, L. Experimental study of R744 heat pump system for electric vehicle application. Appl. Therm. Eng. 2020, 116191. [Google Scholar] [CrossRef]

- Gullo, P.; Hafner, A.; Banasiak, K. Transcritical R744 refrigeration systems for supermarket applications: Current status and future perspectives. Int. J. Refrig. 2018, 93, 269–310. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, D.; Zhang, C.; Chen, J. Electric vehicle range extension strategies based on improved AC system in cold climate–A review. Int. J. Refrig. 2018, 88, 141–150. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Yu, B.; Shi, J.; Chen, J. Numerical study on heat transfer performance of micro-channel gas coolers for automobile CO2 heat pump systems. Int. J. Refrig. 2019, 106, 639–649. [Google Scholar] [CrossRef]

- Li, J.; Jia, J.; Huang, L.; Wang, S. Experimental and numerical study of an integrated fin and micro-channel gas cooler for a CO2 automotive air-conditioning. Appl. Therm. Eng. 2017, 116, 636–647. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, D.; Yu, B.; Shi, J.; Chen, J. Experimental and numerical investigation of a CO2 heat pump system for electrical vehicle with series gas cooler configuration. Int. J. Refrig. 2018, 100, 156–166. [Google Scholar] [CrossRef]

- Yang, J.; Yu, B.; Chen, J. Improved genetic algorithm-based prediction of a CO2 micro-channel gas-cooler against experimental data in automobile air conditioning system. Int. J. Refrig. 2019, 106, 517–525. [Google Scholar] [CrossRef]

- Jin, J.; Chen, J.; Chen, Z. Development and validation of a microchannel evaporator model for a CO2 air-conditioning system. Appl. Therm. Eng. 2011, 31, 137–146. [Google Scholar] [CrossRef]

- Qi, Z.; Chen, J.; Radermacher, R. Investigating performance of new mini-channel evaporators. Appl. Therm. Eng. 2009, 29, 3561–3567. [Google Scholar] [CrossRef]

- Shi, J.; Qu, X.; Qi, Z.; Chen, J. Investigating performance of microchannel evaporators with different manifold structures. Int. J. Refrig. 2011, 34, 292–302. [Google Scholar] [CrossRef]

- Zheng, S.; Wei, M.; Song, P.; Hu, C.; Tian, R. Thermodynamics and flow unsteadiness analysis of trans-critical CO2 in a scroll compressor for mobile heat pump air-conditioning system. Appl. Therm. Eng. 2020, 175, 115368. [Google Scholar] [CrossRef]

- Ye, Z.; Wang, Y.; Song, Y.; Yin, X.; Cao, F. Optimal discharge pressure in transcritical CO2 heat pump water heater with internal heat exchanger based on pinch point analysis. Int. J. Refrig. 2020, 118, 12–20. [Google Scholar] [CrossRef]

- Yin, X.; Wang, A.; Fang, J.; Cao, F.; Wang, X. Coupled effect of operation conditions and refrigerant charge on the performance of a transcritical CO2 automotive air conditioning system. Int. J. Refrig. 2021, 123, 72–80. [Google Scholar] [CrossRef]

- Kline, S.J.; McClintock, F.A. Describing uncertainties in single-sample experiments. Mech. Eng. 1953, 75, 3. [Google Scholar]

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0; National Institute of Standards and Technology, Standard Reference Data Program: Gaithersburg, MD, USA, 2018. [Google Scholar]

| Component | Main Parameters | Other Parameters |

|---|---|---|

| Compressor | 6.8 cc, 1000 to 8000 rpm | two-stage rotary type, aluminum |

| Gas cooler | 312 H·600 L·23 D (mm) | aluminum micro-channel fin-tube, single-row |

| IHX | 5.8 H·30 L·0.6 D (mm) | aluminum cross flow |

| EXV | Range of 0 to 576 step | driven by a stepper motor |

| Evaporator | 218 H·200 L·38 D (mm) | aluminum micro-channel fin-tube, three-rows |

| Accumulator | 500 mL | aluminum |

| Component | Parameter | Calibration range | Uncertainty |

|---|---|---|---|

| K-type thermocouples | Temperature (°C) | −50 °C to 200 °C | ±0.5 °C |

| PT100 | Temperature (°C) | −50 °C to 200 °C | ±(0.15 + 0.2% of reading) |

| Pressure transmitters | Pressure (MPa) | 0 MPa to 20 MPa | ±2.5 ‰ of full scale |

| WT500 power meter | Power (W) | 15 V to 1000 V and 0.5 A to 40 A | ±0.1% of reading |

| Electronic mass scale | CO2 charge (g) | 0 kg to 100 kg | ±0.02 kg |

| Mass flow meter | CO2 mass flow rate (kg·h−1) | 0 kg·h−1 to 11,500 kg·h−1 | ±1% of reading |

| Volume flow meter | Air volume flow rate (m3·h−1) in gas cooler | 600 m3·h−1 to 9000 m3·h−1 | ±0.01 m3·h −1 of reading |

| Parameter | Evaporator Side | Gas Cooler Side |

|---|---|---|

| Ambient temperature and humidity | 30 °C, 50% | |

| 27 °C, 50% | 35 °C, 50% | |

| 40 °C, 50% | ||

| Air volume flow rate | 480 m3·h−1 | 500/1000/1500/2000/2500/3000/3500 m3·h−1 |

| Refrigerant charge | 700 g [24] | |

| Compressor speed | 3500/5000/6500 rpm | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, A.; Fang, J.; Yin, X.; Song, Y.; Cao, F.; Gullo, P. Coupling Effect of Air Flow Rate and Operating Conditions on the Performance of Electric Vehicle R744 Air Conditioning System. Appl. Sci. 2021, 11, 4855. https://doi.org/10.3390/app11114855

Wang A, Fang J, Yin X, Song Y, Cao F, Gullo P. Coupling Effect of Air Flow Rate and Operating Conditions on the Performance of Electric Vehicle R744 Air Conditioning System. Applied Sciences. 2021; 11(11):4855. https://doi.org/10.3390/app11114855

Chicago/Turabian StyleWang, Anci, Jianmin Fang, Xiang Yin, Yulong Song, Feng Cao, and Paride Gullo. 2021. "Coupling Effect of Air Flow Rate and Operating Conditions on the Performance of Electric Vehicle R744 Air Conditioning System" Applied Sciences 11, no. 11: 4855. https://doi.org/10.3390/app11114855

APA StyleWang, A., Fang, J., Yin, X., Song, Y., Cao, F., & Gullo, P. (2021). Coupling Effect of Air Flow Rate and Operating Conditions on the Performance of Electric Vehicle R744 Air Conditioning System. Applied Sciences, 11(11), 4855. https://doi.org/10.3390/app11114855