Tribological Performance of Friction Pairs with Different Materials and Bi-Composite Surface Texture Configurations

Abstract

:1. Introduction

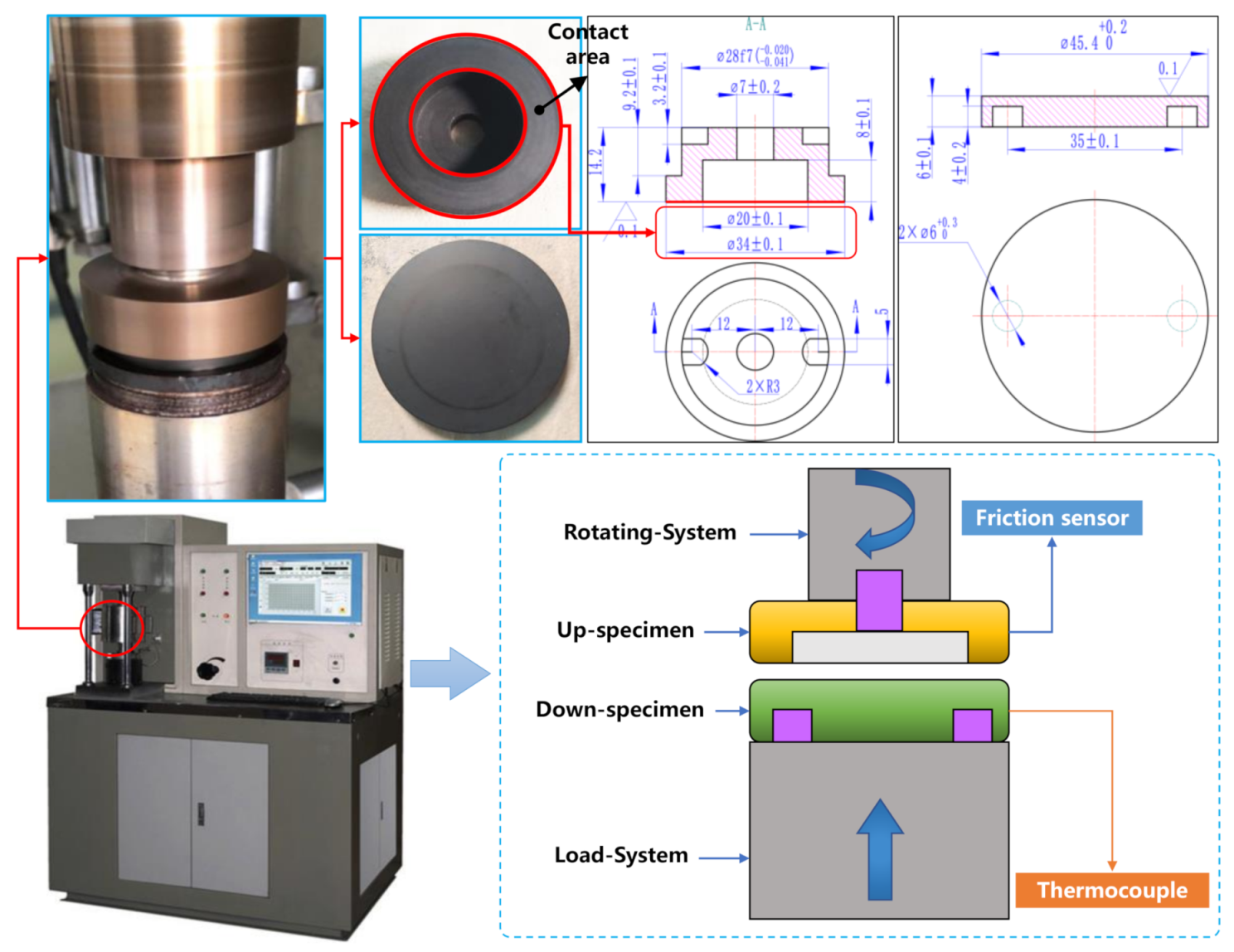

2. Test Equipment and Specimens

2.1. End Surface Friction and Wear Testing Apparatus

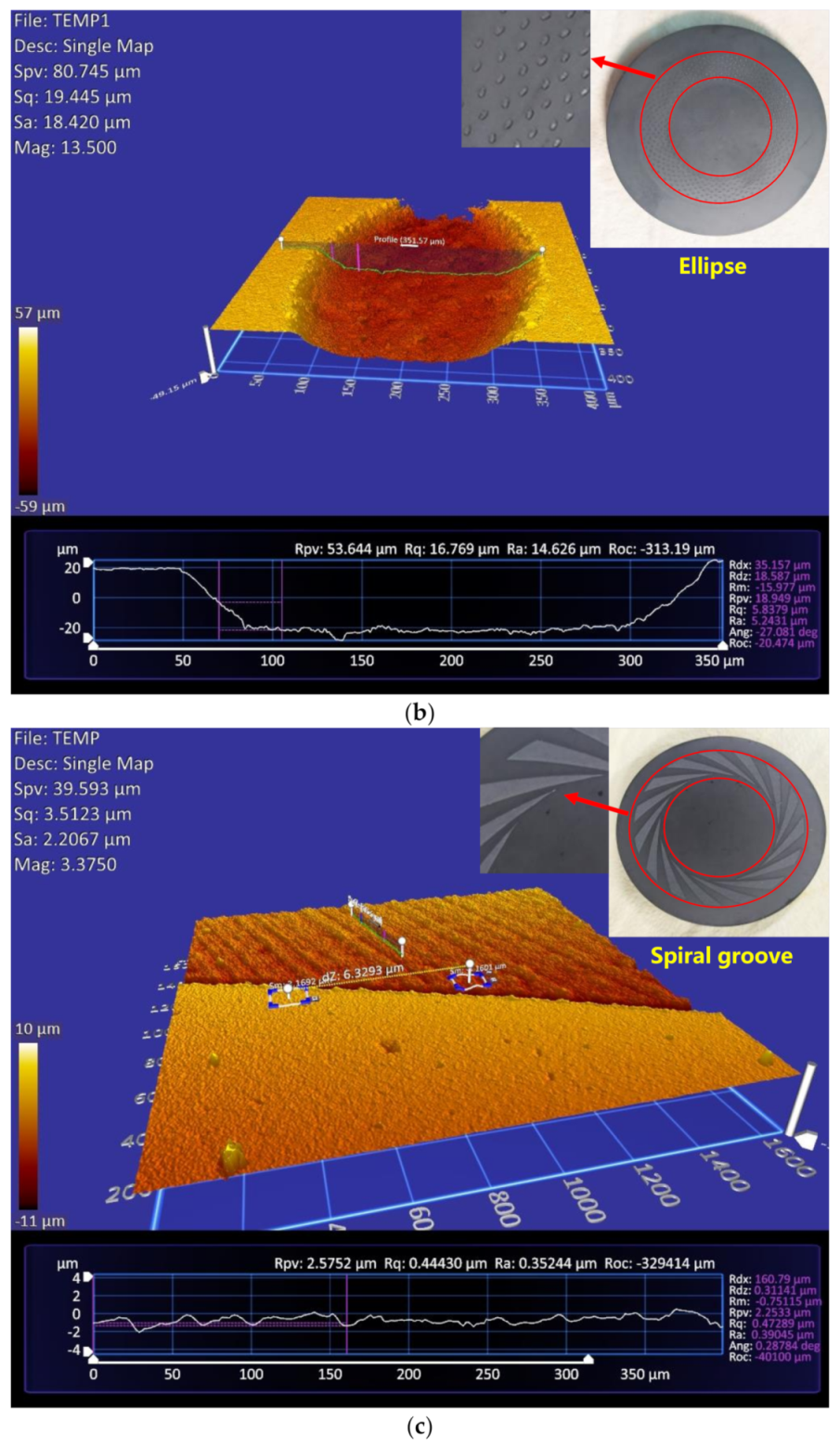

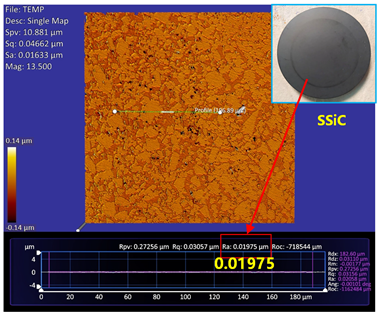

2.2. Test Specimens

- The laser power was set to 80%, and the engraving was performed repeatedly at this power to obtain the required depth of the texture.

- The laser power was set to 50%. The surface was scanned, and finishing was performed on the texture areas that met the depth requirement. The uneven bottoms of the texture areas were repaired, and the roughness was improved.

- The laser power was reduced to 20%. The burr on the edge of the pattern was improved.

- Fine polishing was performed on the engraved specimens to further improve the quality of the bottoms of the texture.

- Ultrasonic cleaning was performed on the specimen, after which it was placed in a drying oven to remove surface moisture.

3. Test Plan and Process

3.1. Test Plan

- (1)

- Friction pairs with different materials

- (2)

- Single surface texture patterns

- (3)

- Bi-composite surface texture configurations

3.2. Test Procedure

- (1)

- (2)

- All the specimens were cleaned and dried, and the surface morphologies of all specimens were measured and scanned by white-light interference three-dimensional profiler and SEM (scanning electron microscope). The average surface topography parameters were read after three consecutive scans in the white-light interference three-dimensional profiler.

- (3)

- The initial weight of the sealing rings (M120D) was measured and recorded.

- (4)

- According to the plan of the experiment and Table 4, friction pairs with different materials were carried out first.

- (5)

- The specimen was installed in the end surface friction and wear testing apparatus.

- (6)

- The friction test was started, and the relevant data were recorded, such as friction torque, friction coefficient, and surface temperature of the friction pairs. After the load, speed and running time were set. Friction coefficient and surface temperature of the friction pairs were dynamic measurements, and each test corresponds to only one set of the friction pairs (stationary ring and rotating ring), so every group friction pair was tested only once.

- (7)

- At the end of a group test, the specimen was removed, cleaned, and dried. The sealing ring of M120D was weighed, and then the surface topography parameters of the specimen were measured by white-light interference three-dimensional profiler and SEM.

- (8)

- At the end of the first part of the testing plan, repeat the test steps of (5)–(7) to test the second group of single surface texture patterns and the third group of bi-composite surface texture configurations.

- (9)

- The weight of the sealing ring (M120D) was measured before and after the test, that is, the sealing rings (M120D) in the 1-A1, 2-B1, 2-B2 and 2-B3 groups. To ensure the accuracy of the data, the sealing rings (M120D) were measured three times each time, and the average weight of these three measurements was taken as the test result.

4. Discussion and Analysis

4.1. Performance of Friction Pairs with Different Materials

4.1.1. Friction Coefficient

4.1.2. Surface Temperature of Friction Pairs

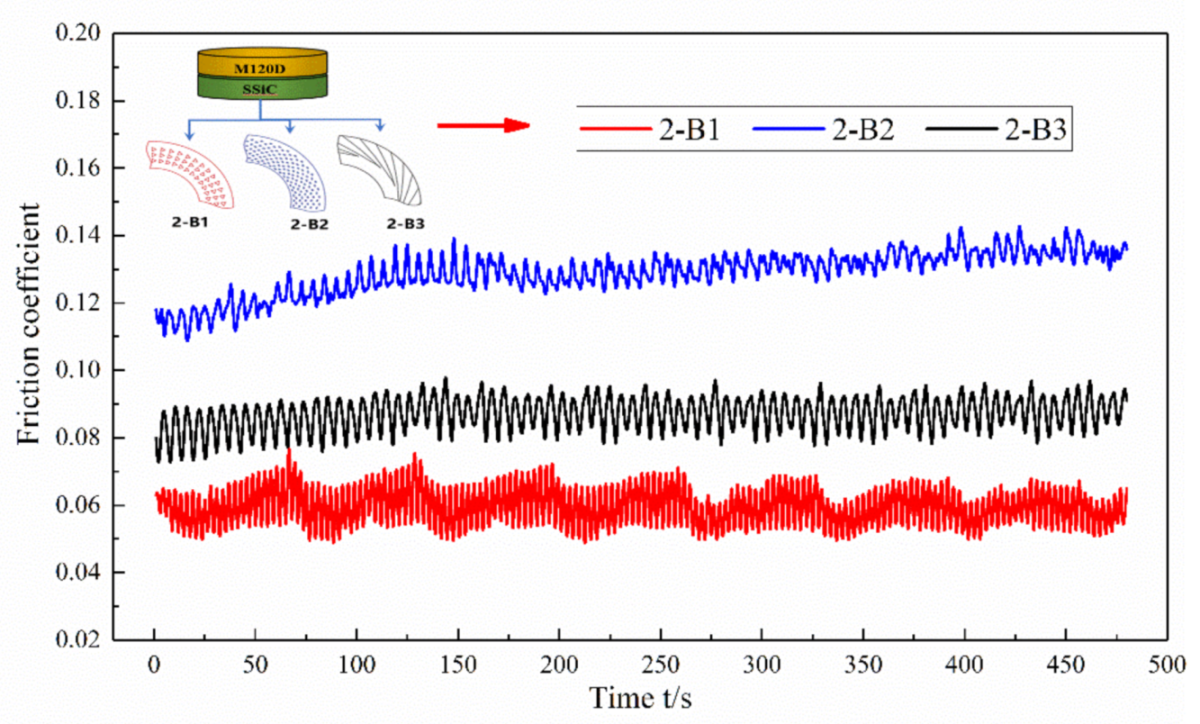

4.2. Performances of Friction Pairs with Single Texture Patterns

4.2.1. Friction Coefficient

4.2.2. Surface Temperature of Friction Pairs

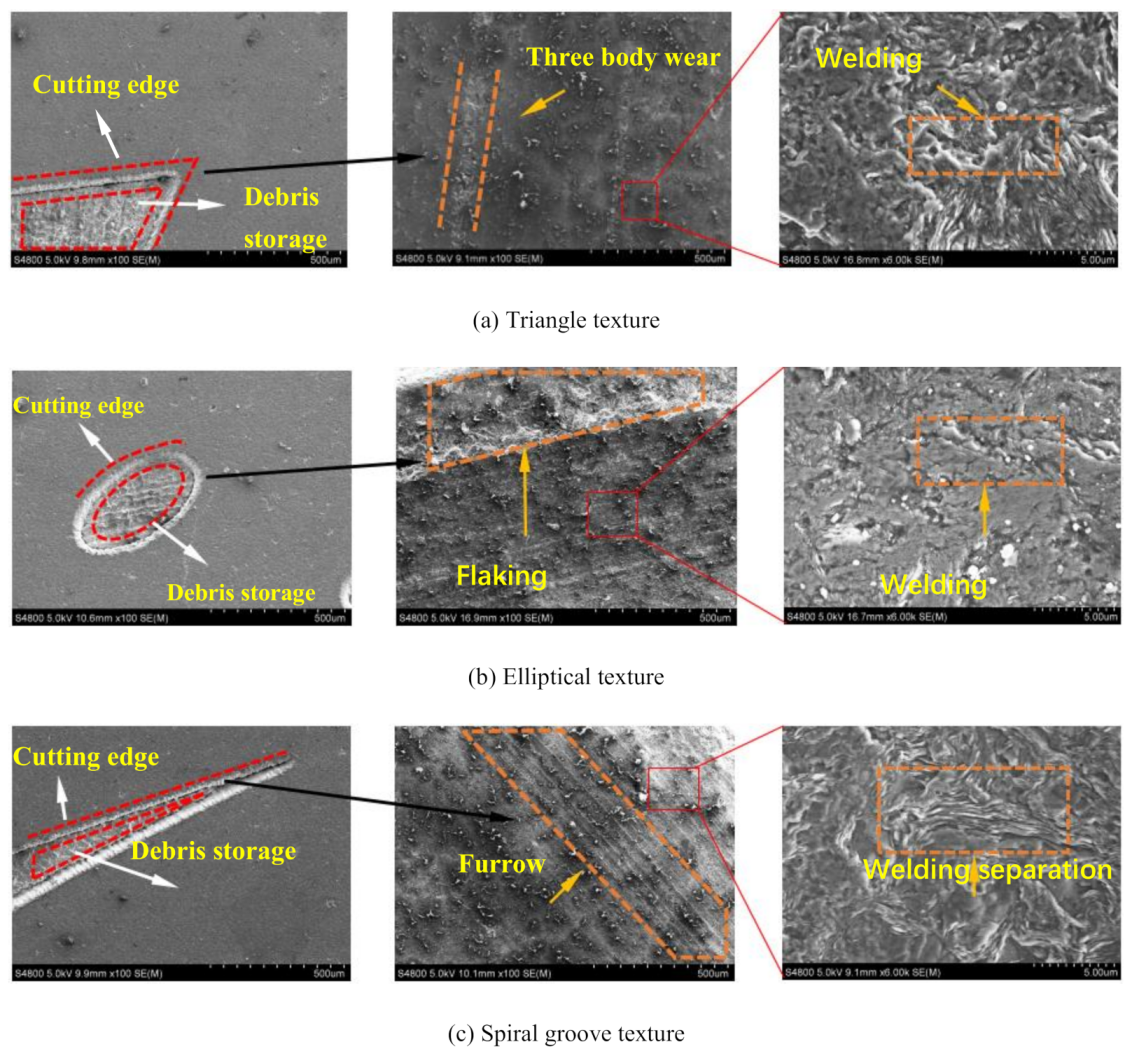

4.2.3. M120D Wear Quantity

4.2.4. Micro Morphology of Friction Pairs

4.3. Performance of Friction Pairs in Bi-Composite Surface Texture Configurations

4.3.1. Friction Coefficient

4.3.2. Surface Temperature of Friction Pairs

5. Conclusions

- (1)

- The 3-C3 group has the smallest friction coefficient and lowest temperature rise of all the test subjects.

- (2)

- For single texture patterns, such as micro-groove or micro-dimple, the tribological performance was affected by the shape of the texture, which was confirmed by the wear process of M120D.

- (3)

- A ‘synergistic effect’ was exhibited by the conventional spiral grooves and triangular grooves on the surface of the friction pairs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shankar, S.; Praveenkumar, G.; Kumar, P.K. Experimental study on frictional characteristics of tungsten carbide versus carbon as mechanical seals under dry and eco-friendly lubrications. Int. J. Refract. Met. Hard Mater. 2016, 54, 39–45. [Google Scholar] [CrossRef]

- Sinou, J.J.; Cayer-Barrioz, J.; Berro, H. Friction-induced vibration of a lubricated mechanical system. Tribol. Int. 2013, 61, 156–168. [Google Scholar] [CrossRef] [Green Version]

- Kanda, K.; Sato, H.; Miyakoshi, T.; Kitano, T.; Kanebako, H.; Adachi, K. Friction control of mechanical seals in a ventricular assist device. Biosurf. Biotribol. 2015, 1, 135–143. [Google Scholar] [CrossRef] [Green Version]

- Tomioka, J.; Miyanaga, N. Effect of surface roughness of mechanical seals for rotary blood pumps under blood sealing. J. Adv. Mech. Des. Syst. Manuf. 2014, 8, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Tomioka, J.; Miyanaga, N. Blood sealing properties of magnetic fluid seals. Tribol. Int. 2017, 113, 338–343. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Elam, J.W.; Erdemir, A.; Carlisle, J.A.; Auciello, O.; Libera, J.A.; Pellin, M.J.; Gruen, D.M.; Hryn, J.N. Development of ultrananocrystalline diamond (UNCD) coatings for multipurpose mechanical pump seals. Wear 2011, 270, 325–331. [Google Scholar] [CrossRef]

- Yamakiri, H.; Sasaki, S.; Kurita, T.; Kasashima, N. Effects of laser surface texturing on friction behavior of silicon nitride under lubrication with water. Tribol. Int. 2011, 44, 579–584. [Google Scholar] [CrossRef]

- Shi, L.; Wang, X.; Su, X.; Huang, W.; Wang, X. Comparison of the load-carrying performance of mechanical gas seals textured with microgrooves and microdimples. J. Tribol. 2016, 138, 021701. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Wang, X.; Shi, L.; Huang, W.; Wang, X. A multi-objective optimization approach on the spiral grooves for gas mechanical seals. J. Tribol. 2018, 140, 041710–041711. [Google Scholar] [CrossRef]

- Bai, S.; Peng, X.; Li, Y.; Sheng, S. A hydrodynamic laser surface-textured gas mechanical face seal. Tribol. Lett. 2010, 38, 187–194. [Google Scholar] [CrossRef]

- Yu, X.Q.; Liu, Q.G.; Gao, H.Q.; Yu, J.H. Liquid film performance analysis of the mechanical seals with a laser-textured micro-pore face. Adv. Mater. Res. 2010, 139–141, 418–421. [Google Scholar] [CrossRef]

- Yu, X.Q.; Liu, Q.G.; Gao, H.Q.; Yu, J.H. Numerical analysis on sealing properties of mechanical seals with a laser-textured face. Appl. Mech. Mater. 2012, 189, 429–432. [Google Scholar]

- Zhang, G.; Zhao, Y.; Zhao, W.; Liang, M. Study on the friction and wear performance of the micro-surface textured face seal under the water-lubricated conditions. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 1–11. [Google Scholar] [CrossRef]

- Adjemout, M.; Brunetière, N.; Bouyerv, J. Friction and temperature reduction in a mechanical face seal by a surface texturing: Comparison between TEHD simulations and experiments. Tribol. Trans. 2018, 61, 1084–1093. [Google Scholar] [CrossRef]

- Hu, T.Q. Friction and wear performance research and forecast of graphite sealing materials in high temperature. Ph.D. Thesis, Northeastern University, Shenyang, China, 2012. (In Chinese). [Google Scholar]

- Adjemout, M.; Andrieux, A.; Bouyer, J.; Brunetière, N.; Marcos, G.; Czerwiec, T. Influence of the real dimple shape on the performance of a textured mechanical seal. Tribol. Int. 2017, 115, 409–416. [Google Scholar] [CrossRef]

- Wang, X.Y.; Li, S.Y.; Dai, Q.W.; Huang, W.; Wang, X.L. Research progress in coordinated optimization of lubrication and leakage for textured mechanical seal. Surf. Technol. 2019, 48, 1–8. (In Chinese) [Google Scholar]

- Ryk, G.; Etsion, I. Testing piston rings with partial laser surface texturing for friction reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Marchetto, D.; Rota, A.; Calabri, L.; Gazzadi, G.C.; Menozzi, C.; Valeri, S. AFM investigation of tribological properties of nano-patterned silicon surface. Wear 2008, 265, 577–582. [Google Scholar] [CrossRef]

- Walker, J.C.; Kamps, T.J.; Lam, J.W.; Mitchell-Smith, J.; Clare, A.T. Tribological behaviour of an electrochemical jet machined textured Al-Si automotive cylinder liner material. Wear 2017, 376–377, 1611–1621. [Google Scholar] [CrossRef]

- Qiu, Y.; Khonsari, M.M. Investigation of tribological behaviors of annular rings with spiral groove. Tribol. Int. 2011, 44, 1610–1619. [Google Scholar] [CrossRef]

- Zhang, Y.A. Analysis on influential factors of end face specific pressure in mechanical seal of water joint. Mod. Radar 2018, 40, 87–90. (In Chinese) [Google Scholar]

- Chang, J.; Zhao, K.J.; Zheng, C.R.; Hu, F.; Liu, W.K. Leakage malfunction analysis and processing of ground-based radar liquid rotary joint. Mach. Electron. 2018, 36, 33–36. (In Chinese) [Google Scholar]

| Material Parameter | M120D | SSiC |

|---|---|---|

| Elastic modulus (MPa) | 25 | 410 |

| Poisson ratio | 0.15 | 0.15 |

| Density (kg/m3) | 1.8 × 103 | 3.21 |

| Thermal conductivity (W·m−1·K−1) | 96.3 | 110 |

| Hardness (MPa) | 30 | 2840 |

| Roughness (μm) | 0.026 | 0.02 |

|  |

| Texture Parameter | Spiral Groove | Triangle | Ellipse |

|---|---|---|---|

| Outer diameter (mm) | 34 | 34 | 34 |

| Root diameter (mm) | 25.4 | / | / |

| Inner diameter (mm) | 20 | 20 | 20 |

| Deflection angle (°) | / | / | ±9 |

| Spiral angle (°) | 30 | / | |

| Radial number | 1 | 3 | 5 |

| Circumferential number | 15 | 52 | 96 |

| Side length (mm) | / | 1 | / |

| Half of the long axis (mm) | / | / | 0.25 |

| Half of the short axis (mm) | / | / | 0.125 |

| Groove depth (mm) | 0.04 | 0.04 | 0.04 |

|  |  |

| Operation Parameters | Symbol | Value |

|---|---|---|

| Rotating speed | nr | 15–35 rpm |

| Cruising speed | nr | 32 rpm |

| Pressure of water intake | pin | 0.8–1 MPa |

| Pressure of backwater | pout | 0.2–0.4 MPa |

| Flow | Q | 66 m3/h |

| Medium pressure | p | 0.3 MPa |

| Outer diameter of the seal face | do | 210 mm |

| Inner diameter of the seal face | di | 198 mm |

| Group 1 Friction Pairs of Different Materials | ||||

| No | Friction Materials | Load F (N) | Speed nr (rpm) | Time t (s) |

| 1-A1 | M120D–SSiC | 200 | 100–300 | 480 |

| 1-A2 | SSiC–SSiC | 200 | 100–300 | 480 |

| Group 2 Friction pairs of single surface texture patterns | ||||

| No | Texture | Load F (N) | Speed nr (rpm) | Time t (s) |

| 2-B1 | Triangle | 200 | 250 | 480 |

| 2-B2 | Ellipse | 200 | 250 | 480 |

| 2-B3 | Conventional spiral groove | 200 | 250 | 480 |

| Group 3 Friction pairs of bi-composite surface texture configurations | ||||

| No | Texture | Load F (N) | Speed nr (rpm) | Time t (s) |

| 3-C1 | / | 200 | 250 | 480 |

| 3-C2 | Triangle–Ellipse | 200 | 250 | 480 |

| 3-C3 | Triangle–Conventional spiral groove | 200 | 250 | 480 |

| Load | 200 N | ||||||

|---|---|---|---|---|---|---|---|

| Rotating Speed | 100 rpm | 150 rpm | 200 rpm | 250 rpm | 300 rmin | ||

| Friction Coefficient | Real time | 1-A1 | 0.087–0.1 | 0.078–0.09 | 0.061–0.08 | 0.058–0.079 | 0.056–0.063 |

| 1-A2 | 0.146–0.197 | 0.129–0.153 | 0.111–0.154 | 0.094–0.147 | 0.08–0.197 | ||

| Average | 1-A1 | 0.091 | 0.085 | 0.074 | 0.071 | 0.061 | |

| 1-A2 | 0.173 | 0.142 | 0.126 | 0.123 | 0.095 | ||

| Surface Temperature | Real time | 1-A1 | 24–29 °C | 24.1–31.4 °C | 24–34 °C | 23.9–36.2 °C | 24.4–27.1 °C |

| 1-A2 | 24.1–27.5 °C | 24.2–30.7 °C | 24.1–32.4 °C | 24.8–34.7 °C | 23.8–26.3 °C | ||

| Rise | 1-A1 | 5 °C | 7.3 °C | 10 °C | 12.3 °C | 2.7 °C | |

| 1-A2 | 3.4 °C | 6.5 °C | 8.3 °C | 9.9 °C | 2.5 °C | ||

| Load | Rotating Speed | Friction Coefficient | 2-B1 | 2-B2 | 2-B3 |

|---|---|---|---|---|---|

| 200 N | 250 rpm | Real time | 0.044–0.082 | 0.107–0.146 | 0.07–0.1 |

| Average | 0.060 | 0.129 | 0.081 | ||

| Surface temperature | 2-B1 | 2-B2 | 2-B3 | ||

| Real time | 23.5–27.7 °C | 24.6–37 °C | 24.1–39.4 °C | ||

| Rise | 4.1 °C | 12.3 °C | 15.3 °C |

| Friction Pairs | Friction Coefficient | Temperature Rise | Wear Quantity | ||

|---|---|---|---|---|---|

| Rotational speed: 250 rpm, Load: 200 N, and Time: 480 s | |||||

| 1-A1 |  | 0.071 |  26.76% (3-C3 V.S. 1-A1) 26.76% (3-C3 V.S. 1-A1) | 12.3 °C | 3.1 |

| 1-A2 |  | 0.123 |  57.72% (3-C3 V.S. 1-A2) 57.72% (3-C3 V.S. 1-A2) | 9.9 °C | / |

| 2-B1 |  | 0.060 |  12.90% (3-C3 V.S. 2-B1) 12.90% (3-C3 V.S. 2-B1) | 4.1 °C | 1.6 |

| 2-B2 |  | 0.129 |  59.69% (3-C3 V.S. 2-B2) 59.69% (3-C3 V.S. 2-B2) | 12.3 °C | 2.8 |

| 2-B3 |  | 0.081 |  35.80% (3-C3 V.S. 2-B3) 35.80% (3-C3 V.S. 2-B3) | 15.3 °C | 3.3 |

| 3-C1 |  | 0.123 |  57.72% (3-C3 V.S. 3-C1) 57.72% (3-C3 V.S. 3-C1) | 9.9 °C | / |

| 3-C2 |  | 0.129 |  59.69% (3-C3 V.S. 3-C2) 59.69% (3-C3 V.S. 3-C2) | 11.1 °C | / |

| 3-C3 |  | 0.052 | 3.8 °C | / | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Wang, T.; Ding, X.; Song, H.; Li, H. Tribological Performance of Friction Pairs with Different Materials and Bi-Composite Surface Texture Configurations. Appl. Sci. 2021, 11, 4738. https://doi.org/10.3390/app11114738

Lu J, Wang T, Ding X, Song H, Li H. Tribological Performance of Friction Pairs with Different Materials and Bi-Composite Surface Texture Configurations. Applied Sciences. 2021; 11(11):4738. https://doi.org/10.3390/app11114738

Chicago/Turabian StyleLu, Junjie, Tianrui Wang, Xuexing Ding, Hui Song, and He Li. 2021. "Tribological Performance of Friction Pairs with Different Materials and Bi-Composite Surface Texture Configurations" Applied Sciences 11, no. 11: 4738. https://doi.org/10.3390/app11114738

APA StyleLu, J., Wang, T., Ding, X., Song, H., & Li, H. (2021). Tribological Performance of Friction Pairs with Different Materials and Bi-Composite Surface Texture Configurations. Applied Sciences, 11(11), 4738. https://doi.org/10.3390/app11114738