Experimental and Numerical Model Investigations of Oxygen-Enriched Characteristics in Air-Conditioned Rooms

Abstract

:1. Introduction

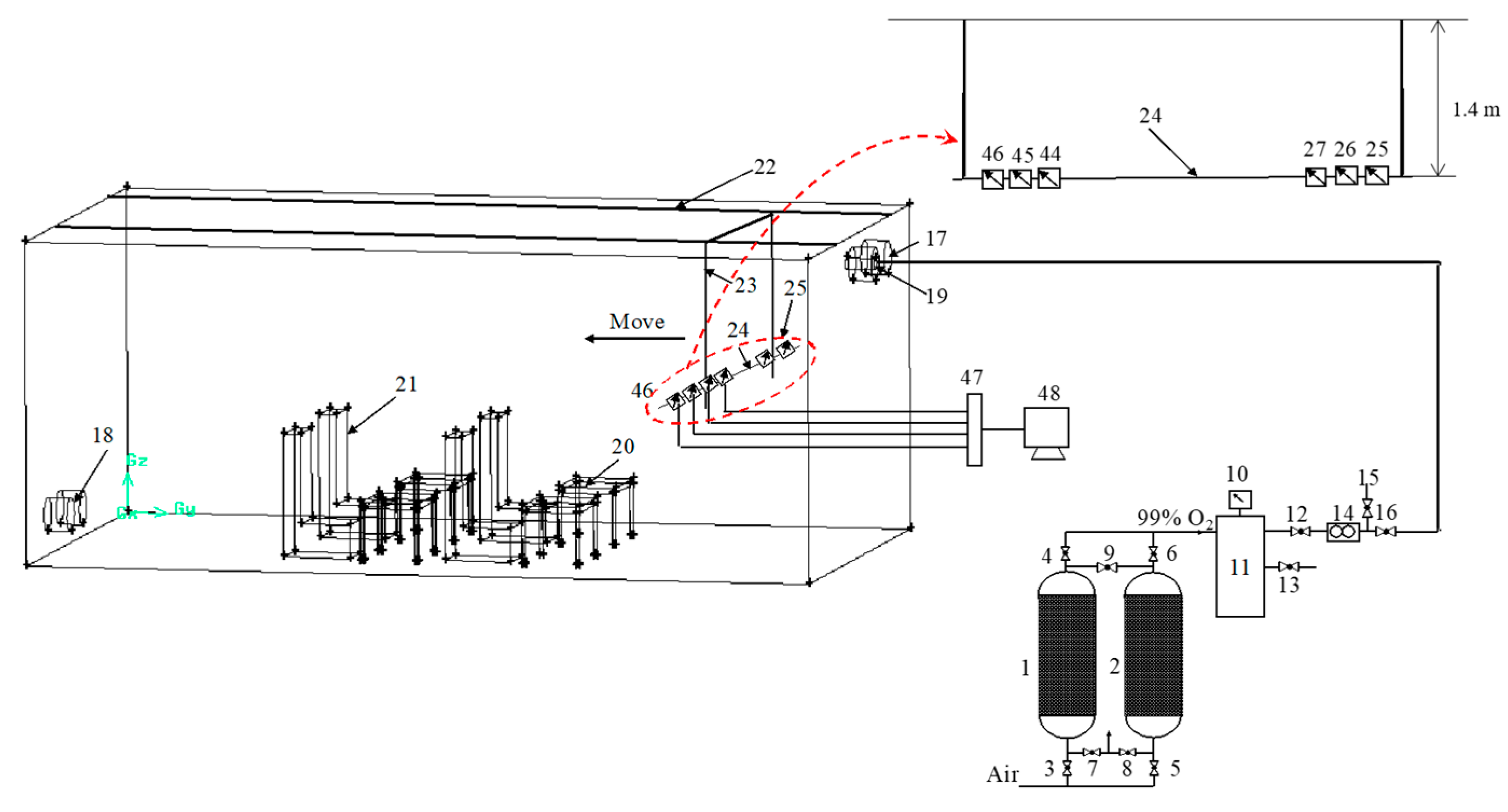

2. Experimental Investigation

3. Modeling and Simulation

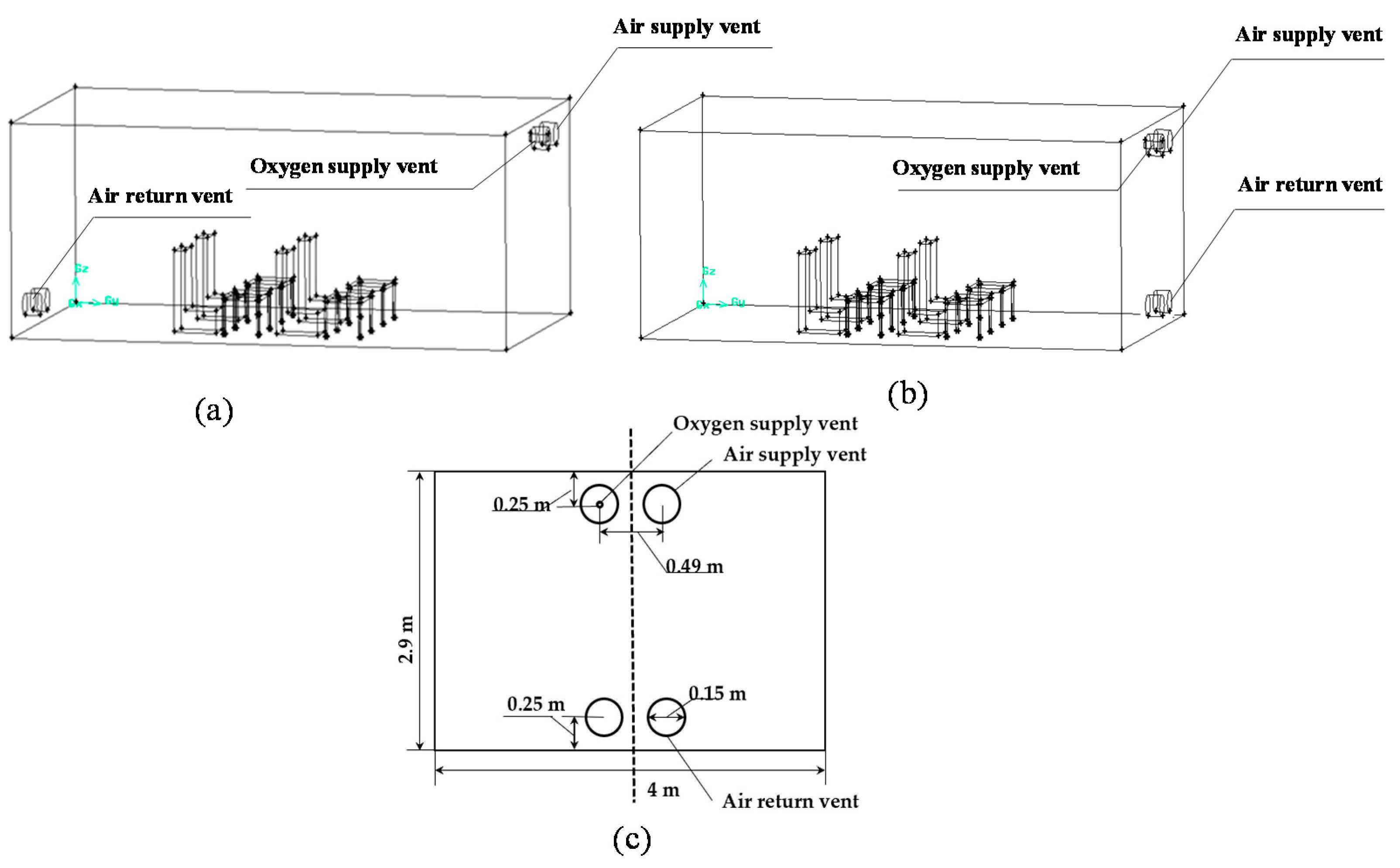

3.1. Physical Model

3.2. Mathematical Model

- (1)

- The oxygen supply vent sends out oxygen-enriched gas in the form of a jet, which is mainly a binary ideal gas mixture of O2 and N2, and the oxygen volume fraction is 99%.

- (2)

- The oxygen supply vent has a small diameter and limited diffusion effect in a closed room after being sent out as a jet; therefore, the free jet theory can be used to describe this flow accordingly.

- (3)

- The fluid is considered incompressible and steady, and the turbulence model uses a dual equation model [42].

3.3. Initial and Boundary Conditions

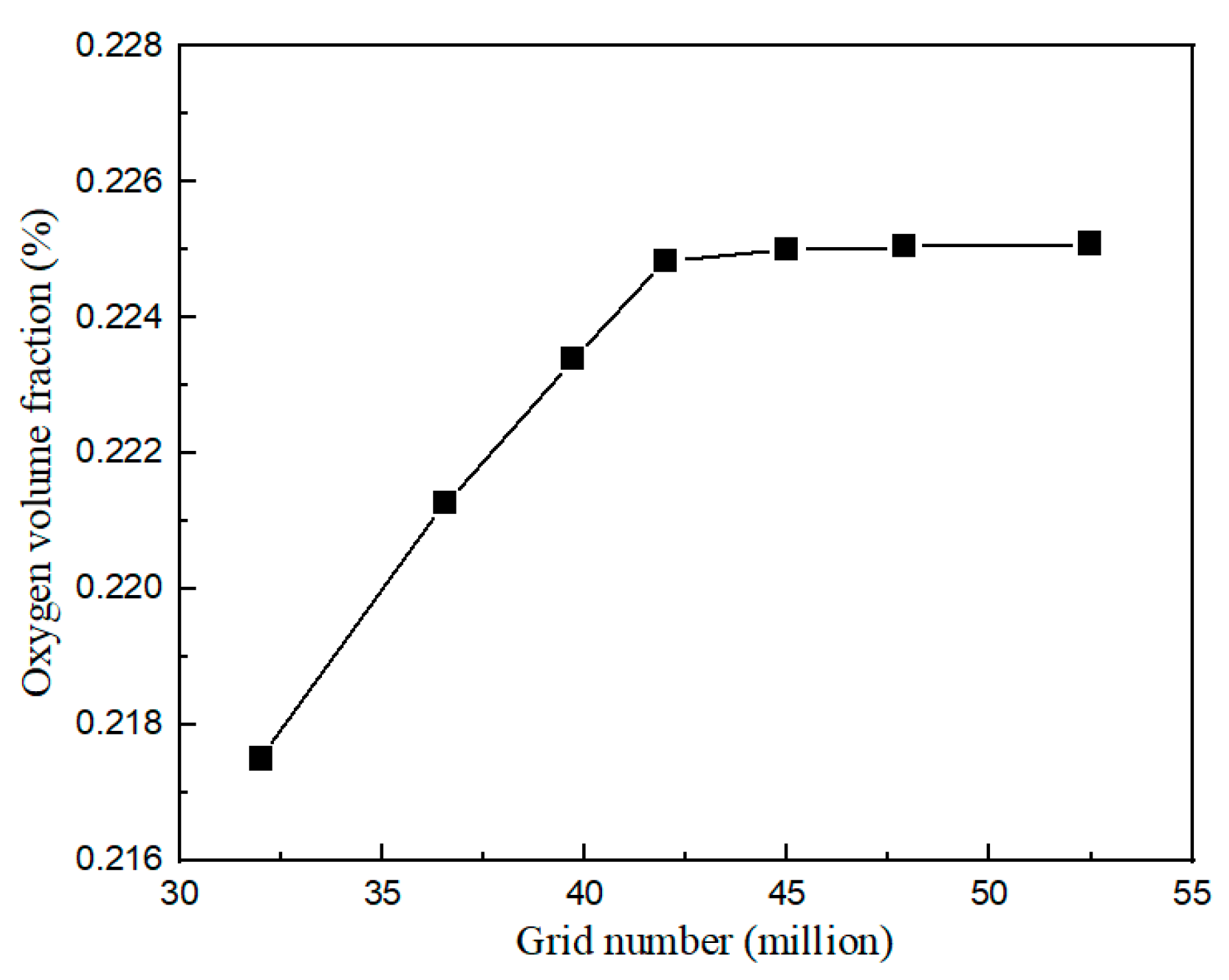

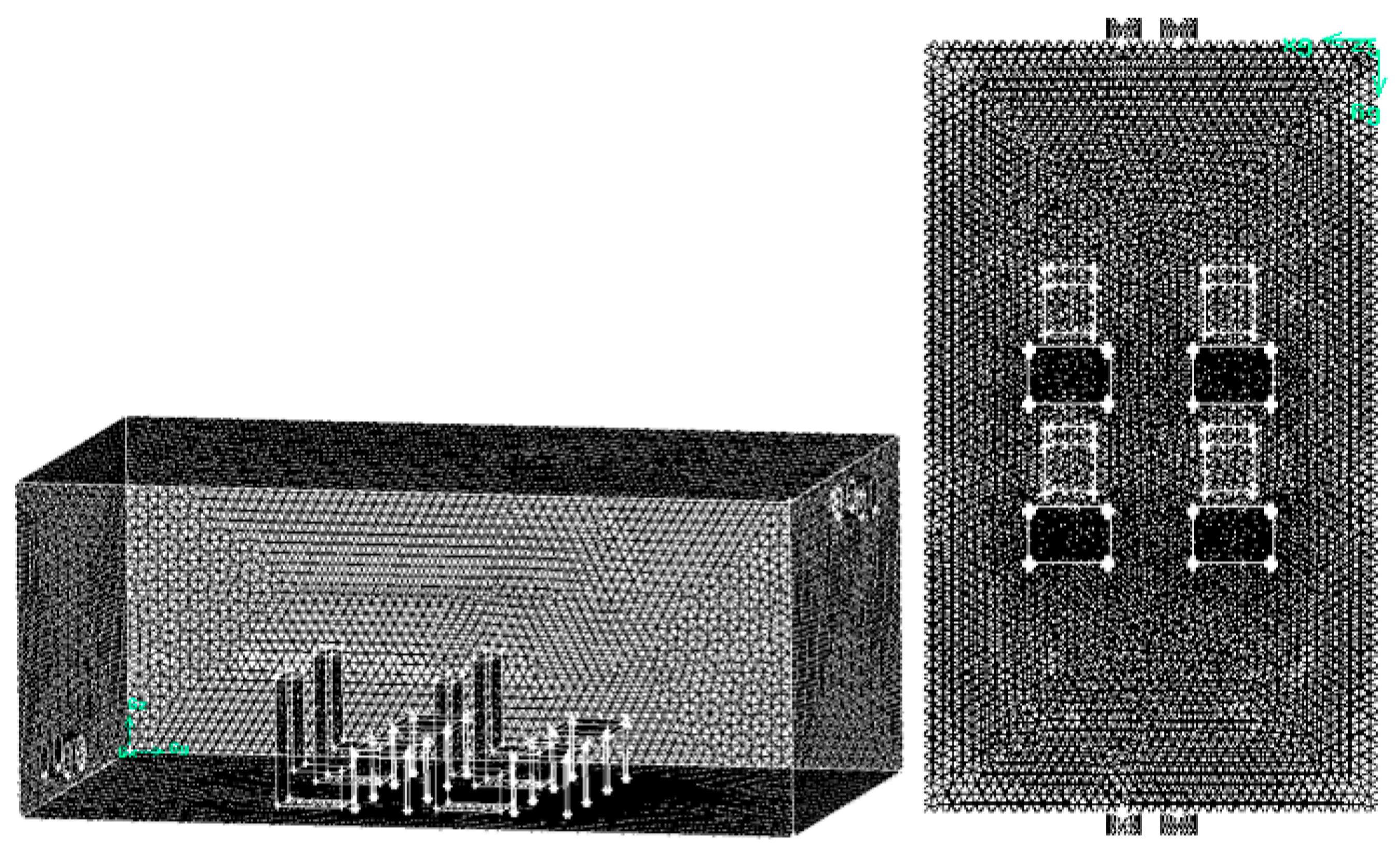

3.4. Meshing and Method of Solution

4. Results and Discussion

4.1. Model Validation

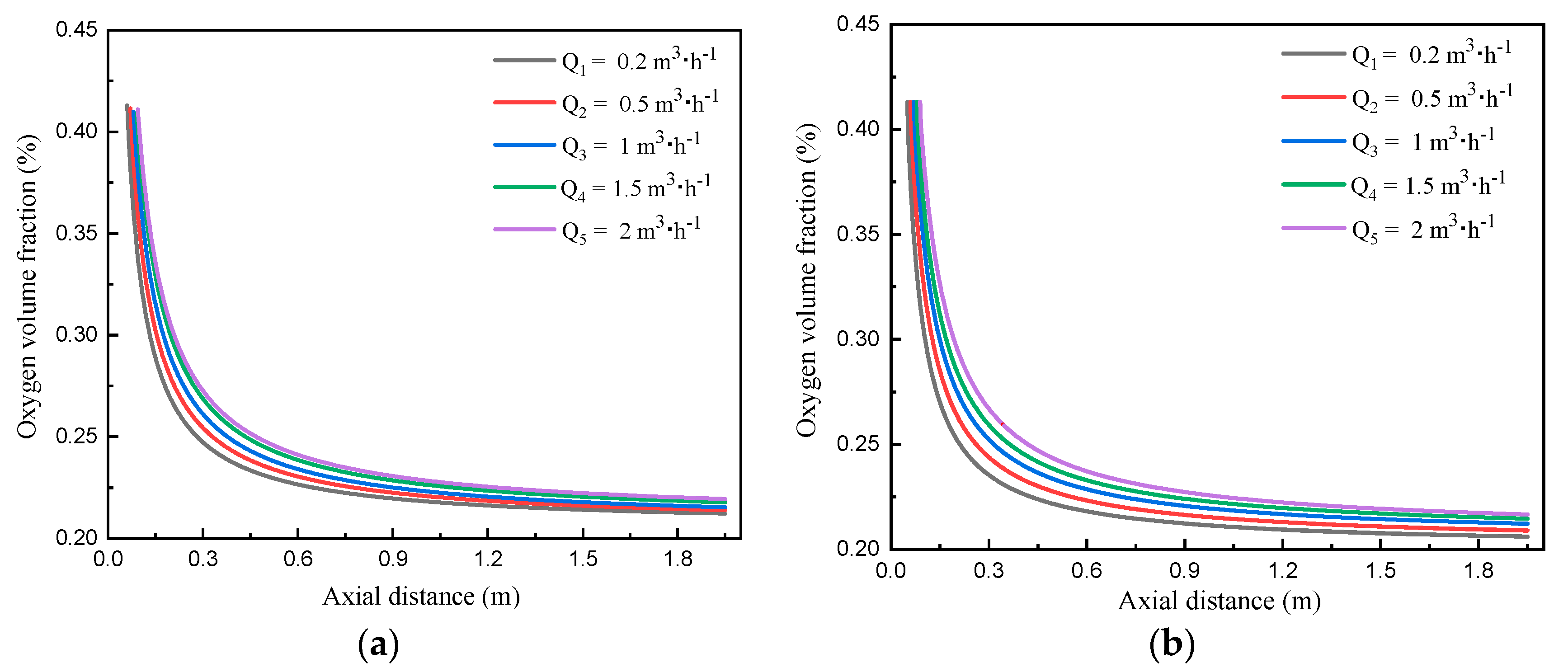

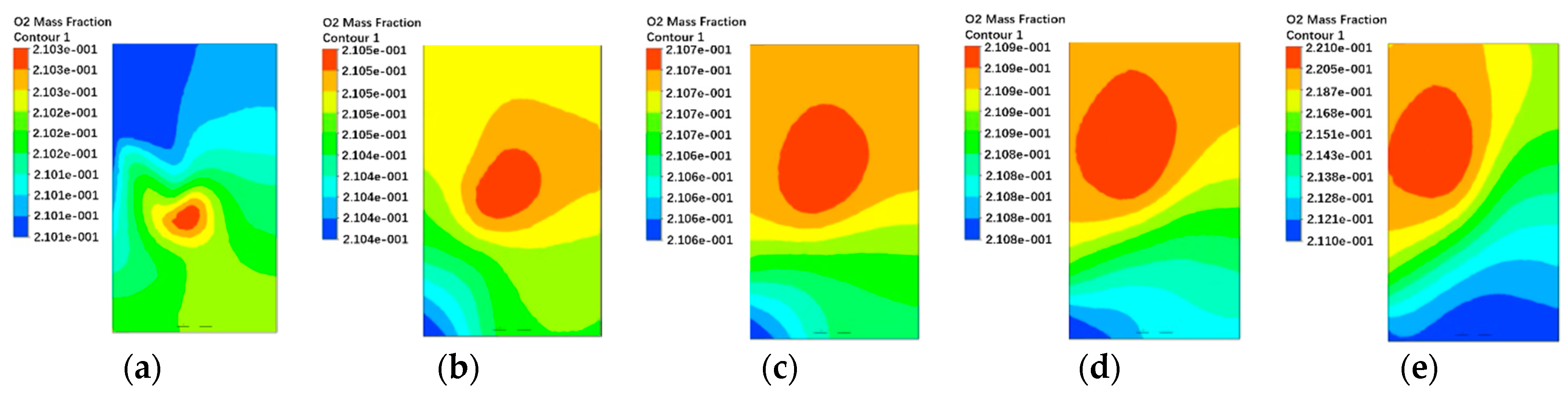

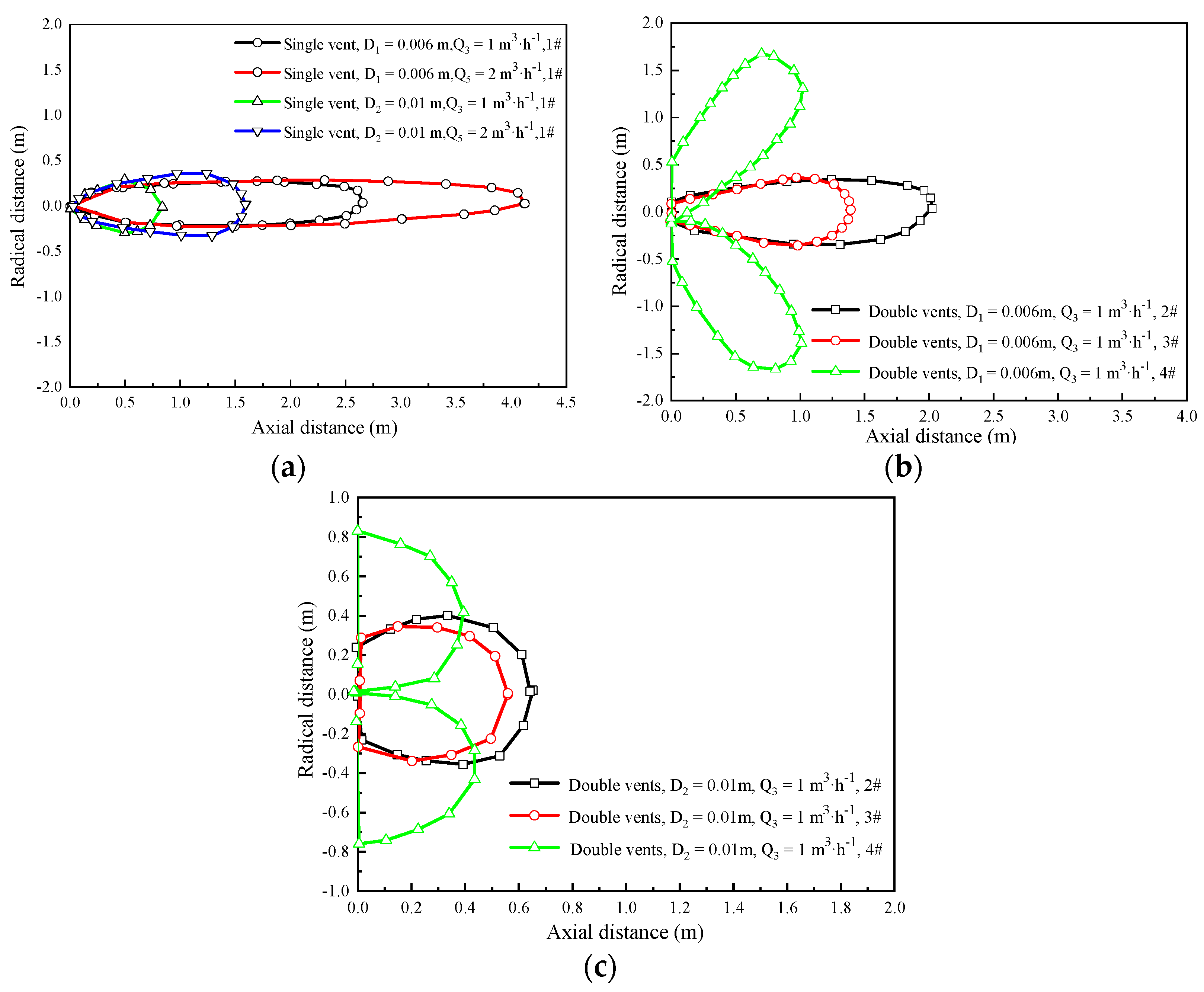

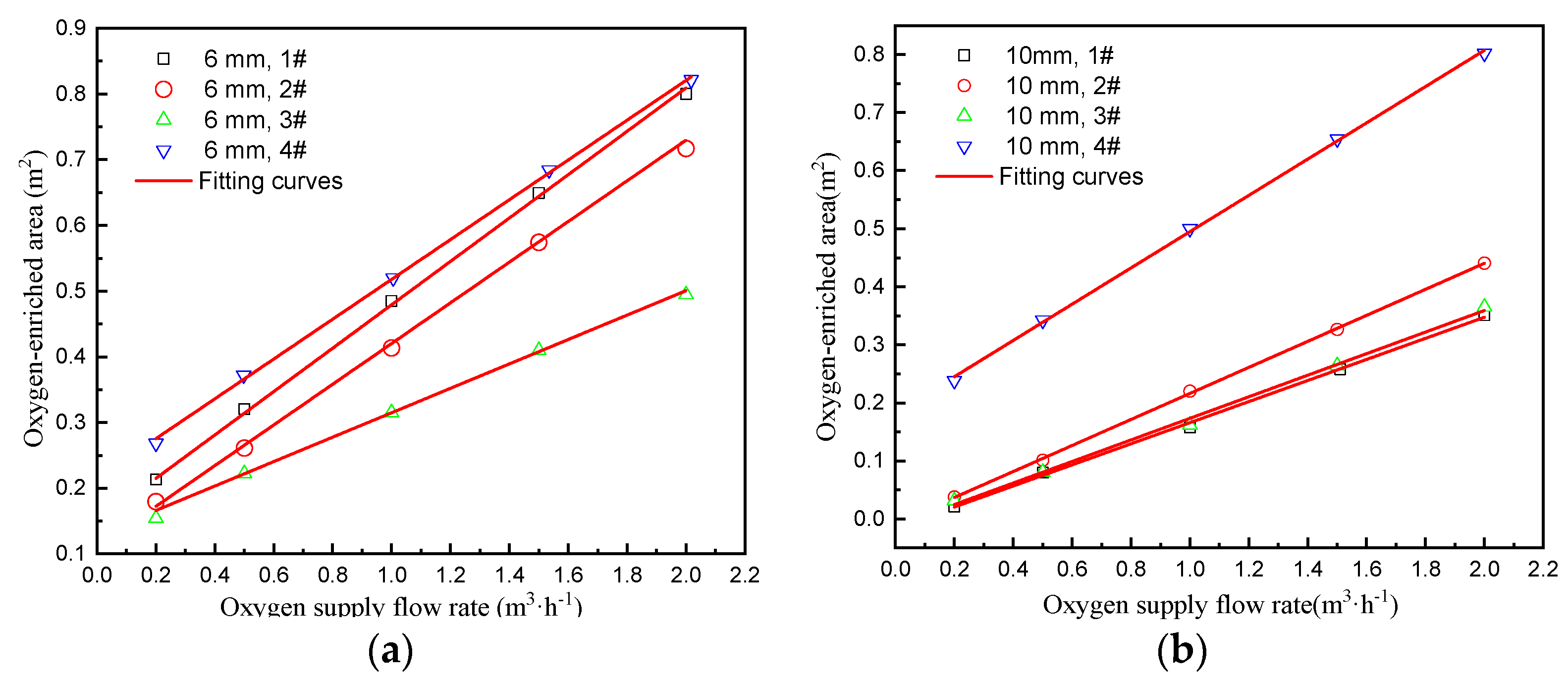

4.2. Oxygen-Enriched Flow Characteristics and Oxygen-Enriched Area under Un-Air-Conditioned Conditions

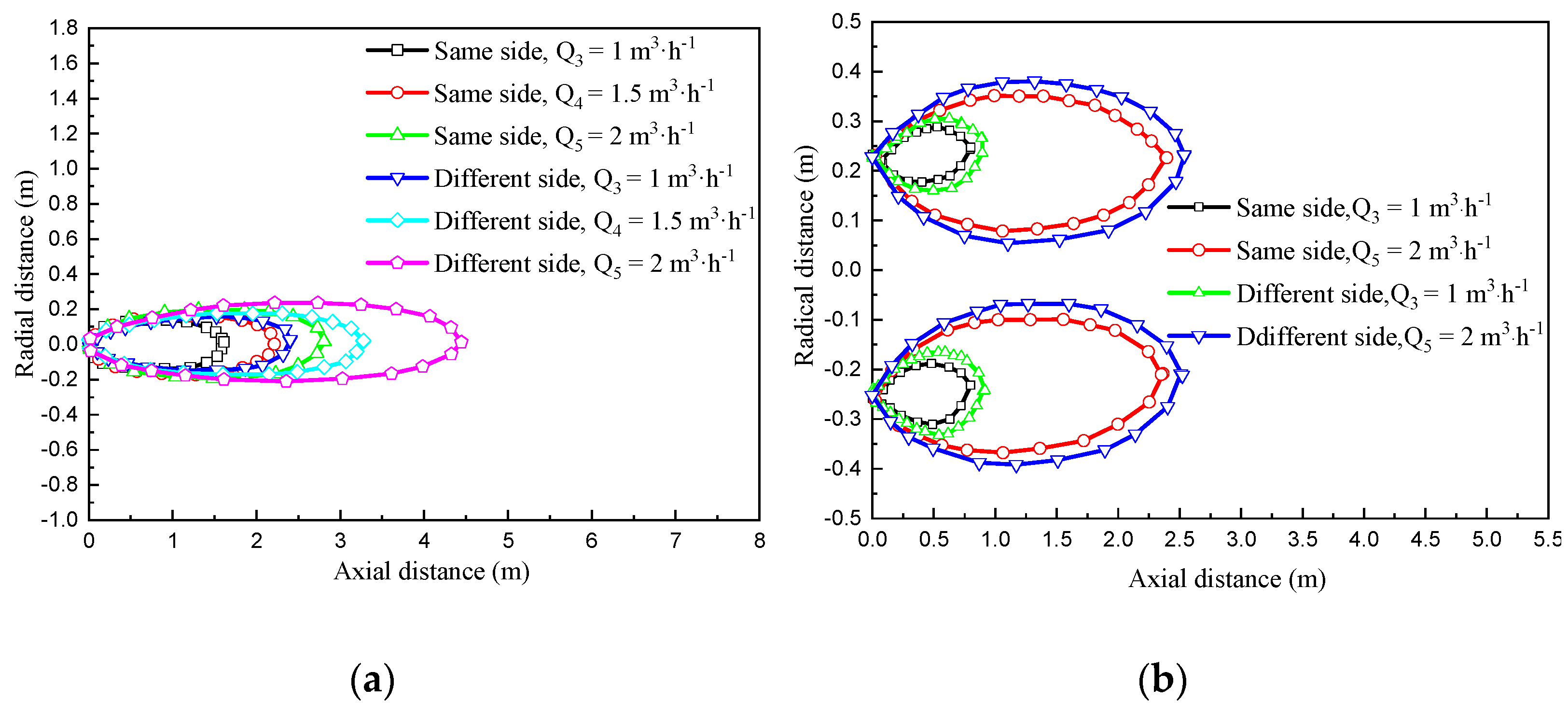

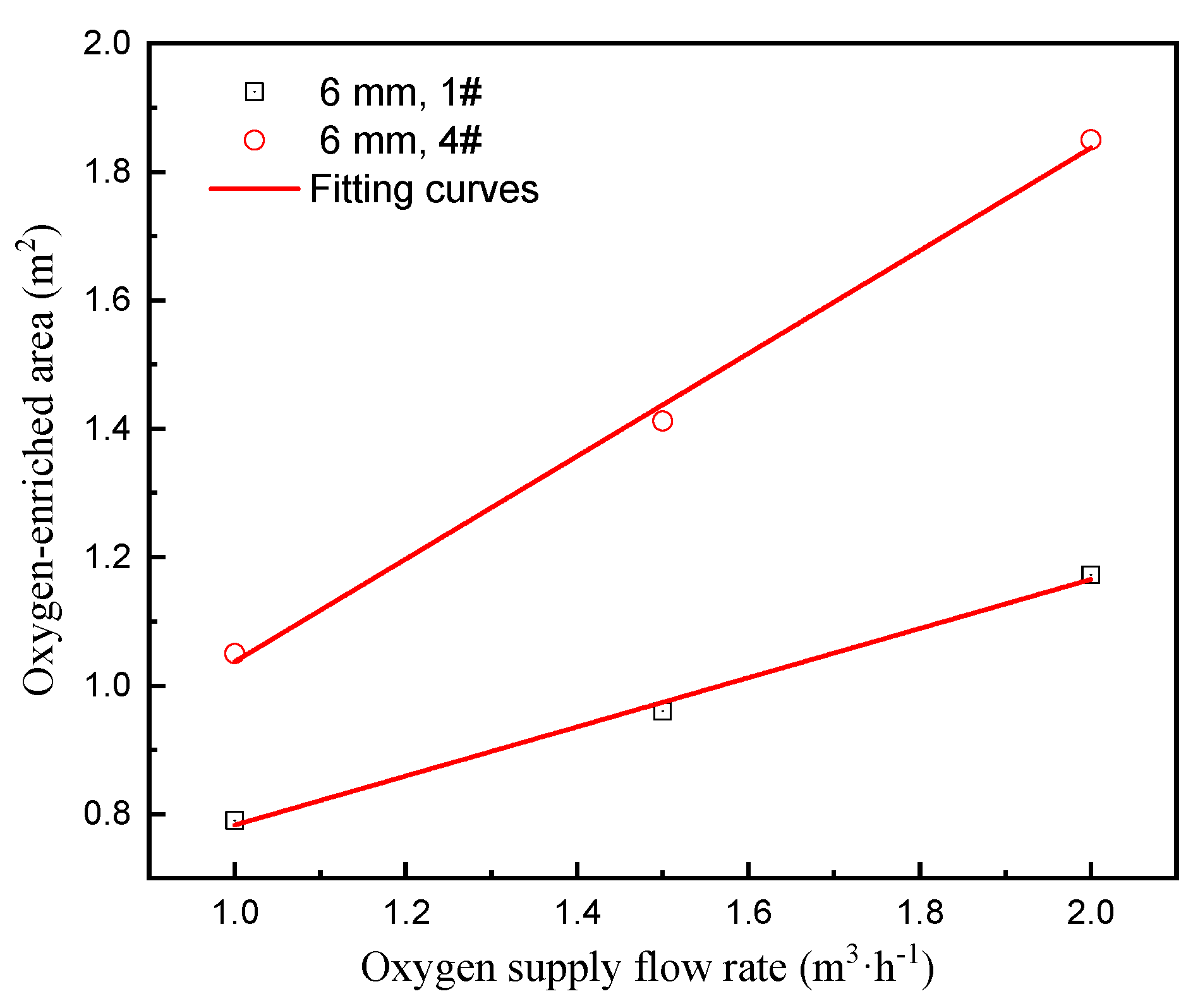

4.3. Oxygen-Enriched Flow Characteristics and Oxygen-Enriched Area under Air-Conditioned State

4.4. Energy Consumption and Economic Analysis in Conventional HVAC

4.4.1. Energy Consumption in Traditional Method of Increasing Fresh Air Volume for Oxygen Supplementation

4.4.2. Energy Consumption in PSA Oxygen Generation for Oxygen Supplementation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| p | Gas pressure, Pa |

| Si | Generalized source term of the momentum conservation equation |

| t | Time, s |

| CA | Molar concentration of component A |

| ui, uj | Velocity vector, m·s−1 |

| DAB | Diffusion coefficient of component A in component B |

| DT | Turbulent diffusion coefficient |

| μ | Dynamic viscosity of the fluid, Pa·s |

| μt | Turbulence viscosity of the fluid |

| ρ | Density of fluid, kg·m−3 |

| LQW | Fresh air load, kW |

| GW | Fresh air rate, kg/s |

| hW | Outdoor air enthalpy, kJ/kg |

| hN | Indoor air enthalpy, kJ/kg |

References

- World Hearth Origanization (WHO). WHO Guidelines for Indoor Air Quality: Selected Pollutants, WHO Regional Office for Europe; WHO: Geneva, Switzerland, 2010. [Google Scholar]

- Martin, B. Air Quality in Airplane Cabin and Similar Enclosed Spaces; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Lee, S.; Li, W.; Ao, C. Investigation of indoor air quality at residential homes in Hong Kong-case study. Atmos. Environ. 2002, 36, 225–237. [Google Scholar] [CrossRef]

- Wyon, D. The effects of indoor air quality on performance and productivity. Indoor Air 2004, 14, 92–101. [Google Scholar] [CrossRef] [PubMed]

- Cao, Z.; Zhao, L.; Shi, Y.; Feng, X. Pollution and exposure characteristics of polycyclic aromatic hydrocarbons in indoor dust in Xinxiang. Environ. Monit. Assess 2017, 187, 4150–4158. [Google Scholar]

- Xu, X.; Zhang, L.; Liu, Z.; Wang, Y. Simulation analysis of indoor PM2.5 concentration. Chin. J. Environ. Eng. 2017, 11, 1755–1760. [Google Scholar]

- Yue, G.; Lu, M.; Jia, H. Numerical simulation of indoor pollutant diffusion on ventilation optimization. Fluid Mach. 2014, 42, 81–85. [Google Scholar]

- Zaatari, M.; Novoselac, A.; Siegel, J. The relationship between filter pressure drop, indoor air quality, and energy consumption in rooftop HVAC units. Build. Environ. 2014, 73, 151–161. [Google Scholar] [CrossRef]

- Yang, F.; Kang, Y.; Gao, Y.; Zhong, K. Numerical simulations of the effect of outdoor pollutants on indoor air quality of buildings next to a street canyon. Build. Environ. 2015, 87, 10–22. [Google Scholar] [CrossRef]

- Zani, C.; Donato, F.; Grioni, S.; Viola, G.; Feretti, D. Feasibility and reliability of a questionnaire for evaluation of the exposure to indoor and outdoor air pollutants, diet and physical activity in 6–8-year-old children. Ann. Ig. 2015, 27, 646–656. [Google Scholar]

- Park, J.; Loftness, V.; Aziz, A.; Wang, T. Critical factors and thresholds for user satisfaction on air quality in office environments. Build. Environ. 2019, 164, 1–16. [Google Scholar] [CrossRef]

- Choi, J.; Moon, J. Impacts of human and spatial factors on user satisfaction in office environments. Build. Environ. 2017, 114, 23–35. [Google Scholar] [CrossRef]

- Azuma, K.; Uchiyama, I.; Uchiyama, S.; Kunugita, N. Assessment of inhalation exposure to indoor air pollutants: Screening for health risks of multiple pollutants in Japanese dwellings. Environ. Res. 2016, 145, 39–49. [Google Scholar] [CrossRef] [PubMed]

- Jafari, M.; Khajevandi, A.; Mousavi Najarkola, S.; Yekaninejad, M.; Pourhoseinhholi, M.; Omidi, L.; Kalanyary, S. Association of sick building syndrome with indoor air parameters. Tanaffos 2015, 14, 55–62. [Google Scholar]

- Pitarma, R.; Marques, G.; Ferreira, B. Monitoring indoor air quality for enhanced occupational health. J. Med. Syst. 2017, 41, 23–30. [Google Scholar] [CrossRef]

- Pettit, T.; Irga, P.; Torpy, F. Towards practical indoor air phytoremediation: A review. Chemosphere 2018, 208, 960–974. [Google Scholar] [CrossRef] [PubMed]

- Pitarma, R.; Marques, G.; Caerano, F. Monitoring indoor air quality to improve occupational health. Mobile Wirel. Health 2017, 41, 23–31. [Google Scholar]

- Liu, Y.; Du, X.; Zhao, H.; Che, X. Feasibility of oxygen enriched air conditioning. J. HV AC 2006, 4, 38–42. [Google Scholar]

- Wei, Y.; Yang, H.; Liu, J. Probe into specific characteristics of transportation organization and safety system of Qinghai-Tibet railway. China Saf. Sci. J. 2003, 3, 22–26. [Google Scholar]

- Wei, J.; Xu, Z.; Li, C.; Xu, M. Discussion on severely cold and oxygen deficiency problems and their countermeasures in Qing-Zang railway construction. China Saf. Sci. J. 2006, 4, 72–75. [Google Scholar]

- Jia, Y.; Liu, Y.; Liu, W.; Li, H.; Wang, H. Study on the effect of oxygen supplementation for tunneling workers of plateau mine. Met Mine. 2012, 41, 142–146. [Google Scholar]

- Liu, Y.; Cui, H.; Liu, W.; Feng, J.; Yue, K.; Yu, Q. Study on technology of oxygen supply in tunnel development in high attitude area. Min Metall. 2005, 14, 5–12. [Google Scholar]

- Xiang, G. Application of emergency shelter in mine disaster rescue. Labour Prot. 2006, 4, 92–93. [Google Scholar]

- Zhu, Y.; Jia, X.; Zhang, X. Circumstances controlling technology of high altitude tunnel during construction in permafrost regions. Rock Soil Mech. 2006, 27, 2177–2180. [Google Scholar]

- Zhang, X.; Lian, Z.; Lan, L. Improving measures of thermal comfort and air quality in submarine cabin. Chin. J. Ship Res. 2012, 7, 11–16. [Google Scholar]

- Wang, S.; Jin, L.; Ou, S.; Li, F.; Li, J. Prediction model of human comfort index in underground emergency refuge facilities. Chin. J. Eng. 2015, 37, 551–555. [Google Scholar]

- Yang, G.; Liu, Y.; Che, X. Experimental study on oxygen enrichment in a relatively closed environment. Build. Sci. 2008, 24, 24–28. [Google Scholar]

- Liu, Z.; Zhou, Y.; Huang, P.; Sun, R.; Wang, S.; Ma, X. Scaled field test for CO2 leakage and dispersion from pipelines. CIESC J. 2012, 63, 1651–1659. [Google Scholar]

- Jin, W.; Zhang, N.; Zhang, Y.; Bai, X. Experimental study on the leakage and diffusion performance of flammable refrigerant R32 in split-type air-conditioner. J. Refrig. 2015, 6, 10–16. [Google Scholar]

- Fu, J.; Zhao, Z.; Chen, G.; Luo, H.; Zhang, B.; Zhang, B.; Ye, C.; Zhu, Y. Influences of liquid pipeline flow and pressure on small-hole leakage rate. Acta Petro. Sin. 2016, 37, 257–265. [Google Scholar]

- Liu, P. Free Turbulent Jet Theory; Beihang University Press: Beijing, China, 2007. [Google Scholar]

- Xie, X. Turbulent Jet Theory and Computation; Science Press: Beijing, China, 1975. [Google Scholar]

- Qu, Y.; Chen, S.; Wang, X.; Teng, S. Discussion on the numerical simulation of ax-symmetric jet with different turbulent model. J. Eng. Thermophys. 2008, 29, 957–959. [Google Scholar]

- Christopher, D.; Bi, J.; Li, X. Integral model and CFD simulations for hydrogen leaks. CIESC J. 2013, 64, 3088–3095. [Google Scholar]

- Wang, J.; Wang, Z.; Li, M. Heat transfer characteristics of square wave impinging jets with different duty cycles. CIESC J. 2013, 64, 2428–2435. [Google Scholar]

- Cai, S.; Cai, C.; Zhang, K.; Li, J. Rarefication effects on jet impingement loads. Aerospace 2017, 4, 48. [Google Scholar] [CrossRef] [Green Version]

- Naruemon, I.; Liu, L.; Mei, Q.; Ma, X. Investigation on an injection strategy optimization for diesel engines using a one-dimensional spray model. Energies 2019, 12, 4221. [Google Scholar] [CrossRef] [Green Version]

- Chien, T.; Liang, C.; Wu, F.; Chen, C.; Pan, T.; Wan, G. Comparative Analysis of Energy Consumption, Indoor Thermal–Hygrometric Conditions, and Air Quality for HVAC, LDAC, and RDAC Systems Used in Operating Rooms. Appl. Sci. 2020, 10, 3721. [Google Scholar] [CrossRef]

- Cui, H. Experimental Study and Mathematical Simulation on Two Stage Pressure Swing Adsorption Processes of Producing High Purity Oxygen; University of Science and Technology Beijing: Beijing, China, 2004. [Google Scholar]

- Yue, K.; Yu, Q.; Liu, Y.; Cui, H.; Zhang, D. High purity oxygen production system by PSA based on PLC. J. Univ. Sci. Technol. Beijing 2003, 23, 185–188. [Google Scholar]

- Wang, H.; Liu, Y.; Zhang, C.; Chen, F.; Ma, X.; Li, C. Simulation of oxygen enrichment characteristics and effect in hypoxia air-conditioning room. Chin. J. Eng. 2019, 42, 1061–1073. [Google Scholar]

- Zhang, C.; Liu, Y.; Wang, H.; Wu, Y.; Ma, X.; Chen, F. Oxygen enrichment characteristics of an enclosed architectural space under anoxic conditions. Chin. J. Eng. 2018, 40, 1380–1388. [Google Scholar]

- Stakic, M.B.; Zivkovic, G.S.; Sijercic, M.A. Numerical analysis of discrete phase induced effects on a gas flow in a turbulent two-phase free jet. Int. J. Heat Mass Transfer. 2011, 54, 2262–2269. [Google Scholar] [CrossRef]

- Mohsen, K.; Madjid, B.; Brahim, S. Numerical simulation of a turbulent free jet issuing from a rectangular nozzle. Comput. Therm. Sci. 2012, 4, 1–22. [Google Scholar]

- Yong, L.; Xia, S.; Zhu, J. Study on flow characteristics of gas-mist two phase confined jet. J. Sichuan Univ. Eng. Sci. Ed. 2001, 33, 54–58. [Google Scholar]

- Liu, Y.; Zhang, H.; Liu, W. Anoxic Environment Oxygen Making and Supply Technology; Metallurgical Industry Press: Beijing, China, 2010; pp. 207–263. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China (GB 50736-2012). Design Code for Heating Ventilation and Air Conditioning of Civil Buildings; China Architecture Publishing & Media Co, Ltd.: Beijing, China, 2012. [Google Scholar]

- Wang, H.; Liu, Y.; Zhang, C.; Li, C.; Wu, Y.; Chen, F. Influence of hypoxia problem in air-conditioned room on human bodyand the oxygenating method. Low Temp. Spec. Cases 2018, 36, 10–15. [Google Scholar]

| Parameter (m) | Values |

|---|---|

| Diameter of air supply and return vent | 0.15/0.15 |

| Distance between the center of the air supply and return vent to the ground | 2.65/0.25 |

| Center distance between two air supply and return vents | 0.49/0.49 |

| Diameter of oxygen supply vent | 0.006/0.01 |

| Table surface and legs () | |

| Chair surface and back () | / |

| Number of Oxygen Supply Vents | Oxygen Supply Method | Symbol | Schematic Diagram |

|---|---|---|---|

| Single vent | vertical | 1# |  |

| Double vents | vertical | 2# |  |

| Double vents | relative 45 o | 3# |  |

| Double vents | opposite 45° | 4# |  |

| Oxygen Supply Methods | Oxygen Supply Vent Diameter (m) | Oxygen Supply Flow Rate (m3·h−1) | Oxygen Supply Velocity (m·s−1) |

|---|---|---|---|

| Single vent (1#) | D1 = 0.006 | 0.2, 0.5, 1, 1.5, 2 | 1.96, 4.91, 9.83, 14.74, 19.66 |

| Single vent (1#) | D2 = 0.01 | 0.2, 0.5, 1, 1.5, 2 | 0.71, 1.77, 3.54, 5.31, 7.08 |

| Double vents (2#,3#,4#) | D1 = 0.006 | 0.2, 0.5, 1, 1.5, 2 | 0.98, 2.46, 4.91, 7.37, 9.83 |

| Double vents (2#,3#,4#) | D2 = 0.01 | 0.2, 0.5, 1, 1.5, 2 | 0.36, 0.89, 1.77, 2.66, 3.54 |

| Air Supply Format | Velocity (m·s−1) | ||

|---|---|---|---|

| Up supply down return on the same side | Vin = 0.85 | Vin = 1 | Vin = 1.4 |

| Up supply down return on the opposite side | Vin = 0.85 | Vin = 1 | Vin = 1.4 |

| Oxygen Supply Method | Relation of Oxygen-Enriched Area (m2) | |

|---|---|---|

| D1 = 0.006 m | D1 = 0.01 m | |

| 1# | F = 0.149 + 0.33 Q | F = −0.016 + 0.182 Q |

| 2# | F = 0.11 + 0.309 Q | F = −0.008 + 0.224 Q |

| 3# | F = 0.129 + 0.186 Q | F = −0.013 + 0.186 Q |

| Oxygen Supply Method | Relation of Oxygen-Enriched Area (m2) |

|---|---|

| 1# | F = 0.4 + 0.383 Q |

| 4# | F = 0.237 + 0.8 Q |

| Summer | Winter | |||

|---|---|---|---|---|

| Outhoor | Indoor | Indoor | Outhoor | |

| Temperature (K) | 299 | 306.2 | 295 | 261 |

| Relative humidity (%) | 50 | 60 | 45 | 45 |

| Enthalpy (kJ/kg) | 59 | 82.5 | 40.9 | −10.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yang, X.; Li, Z.; Liu, Y.; Zhao, Y.; Wang, H.; Ma, X.; Li, C.; Zhang, Y. Experimental and Numerical Model Investigations of Oxygen-Enriched Characteristics in Air-Conditioned Rooms. Appl. Sci. 2021, 11, 4733. https://doi.org/10.3390/app11114733

Zhang C, Yang X, Li Z, Liu Y, Zhao Y, Wang H, Ma X, Li C, Zhang Y. Experimental and Numerical Model Investigations of Oxygen-Enriched Characteristics in Air-Conditioned Rooms. Applied Sciences. 2021; 11(11):4733. https://doi.org/10.3390/app11114733

Chicago/Turabian StyleZhang, Chuanzhao, Xiong Yang, Ziyi Li, Yingshu Liu, Yu Zhao, Haoyu Wang, Xiaojun Ma, Chunwang Li, and Yuanhui Zhang. 2021. "Experimental and Numerical Model Investigations of Oxygen-Enriched Characteristics in Air-Conditioned Rooms" Applied Sciences 11, no. 11: 4733. https://doi.org/10.3390/app11114733

APA StyleZhang, C., Yang, X., Li, Z., Liu, Y., Zhao, Y., Wang, H., Ma, X., Li, C., & Zhang, Y. (2021). Experimental and Numerical Model Investigations of Oxygen-Enriched Characteristics in Air-Conditioned Rooms. Applied Sciences, 11(11), 4733. https://doi.org/10.3390/app11114733