Construction Planning and Scheduling of a Renovation Project Using BIM-Based Multi-Objective Genetic Algorithm

Abstract

Featured Application

Abstract

1. Introduction

1.1. Building Information Modeling

1.2. Construction Planning and Scheduling Optimization

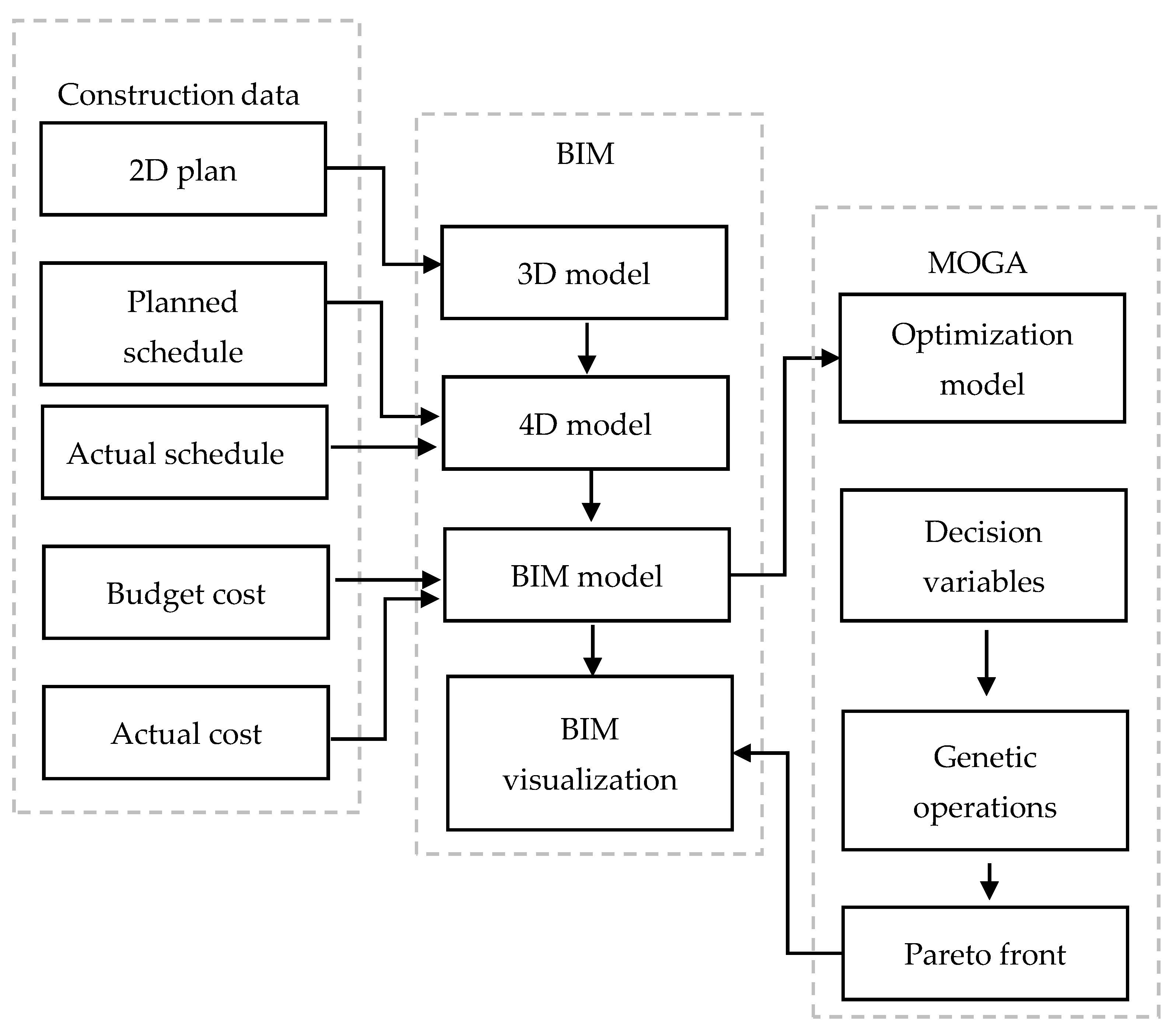

2. Materials and Methods

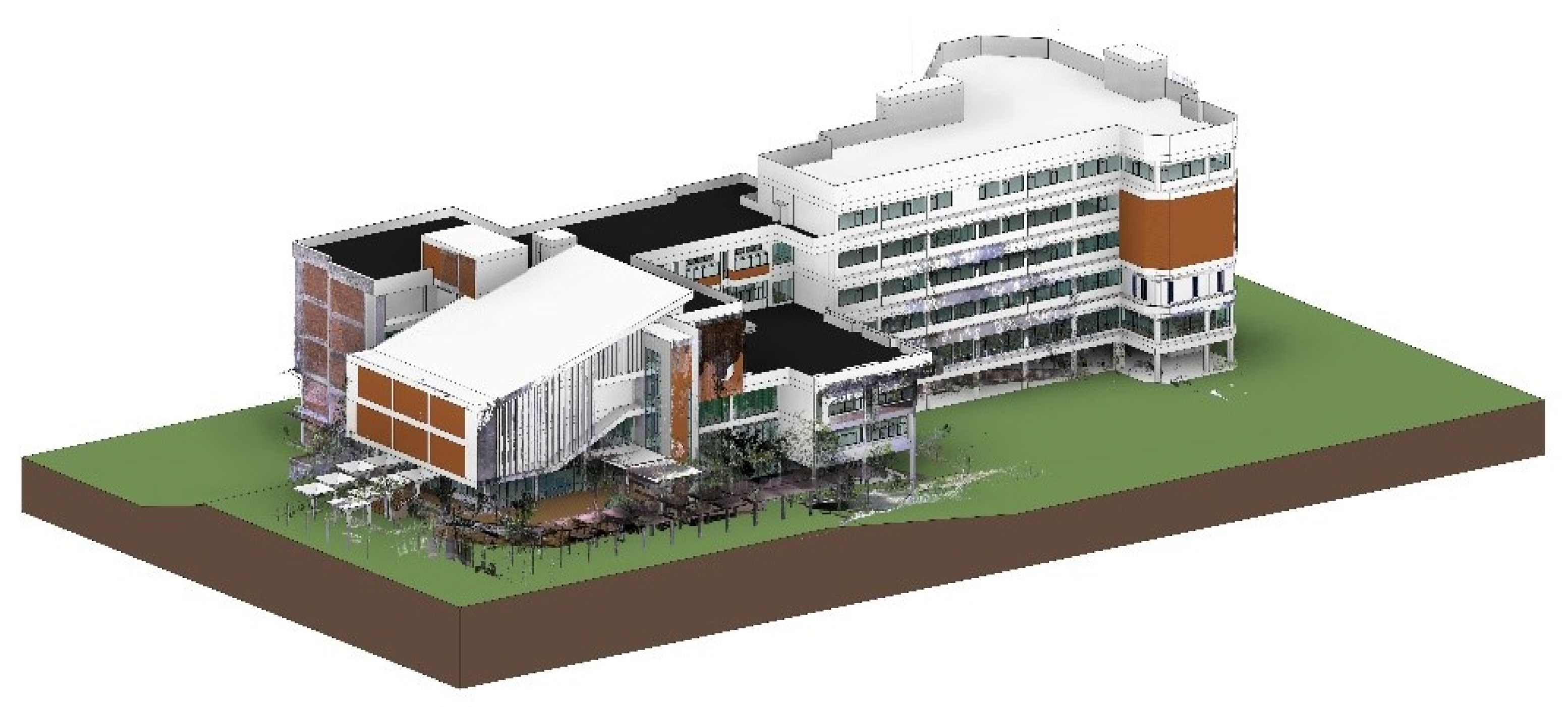

2.1. Project Background

2.1.1. Construction Scheduling

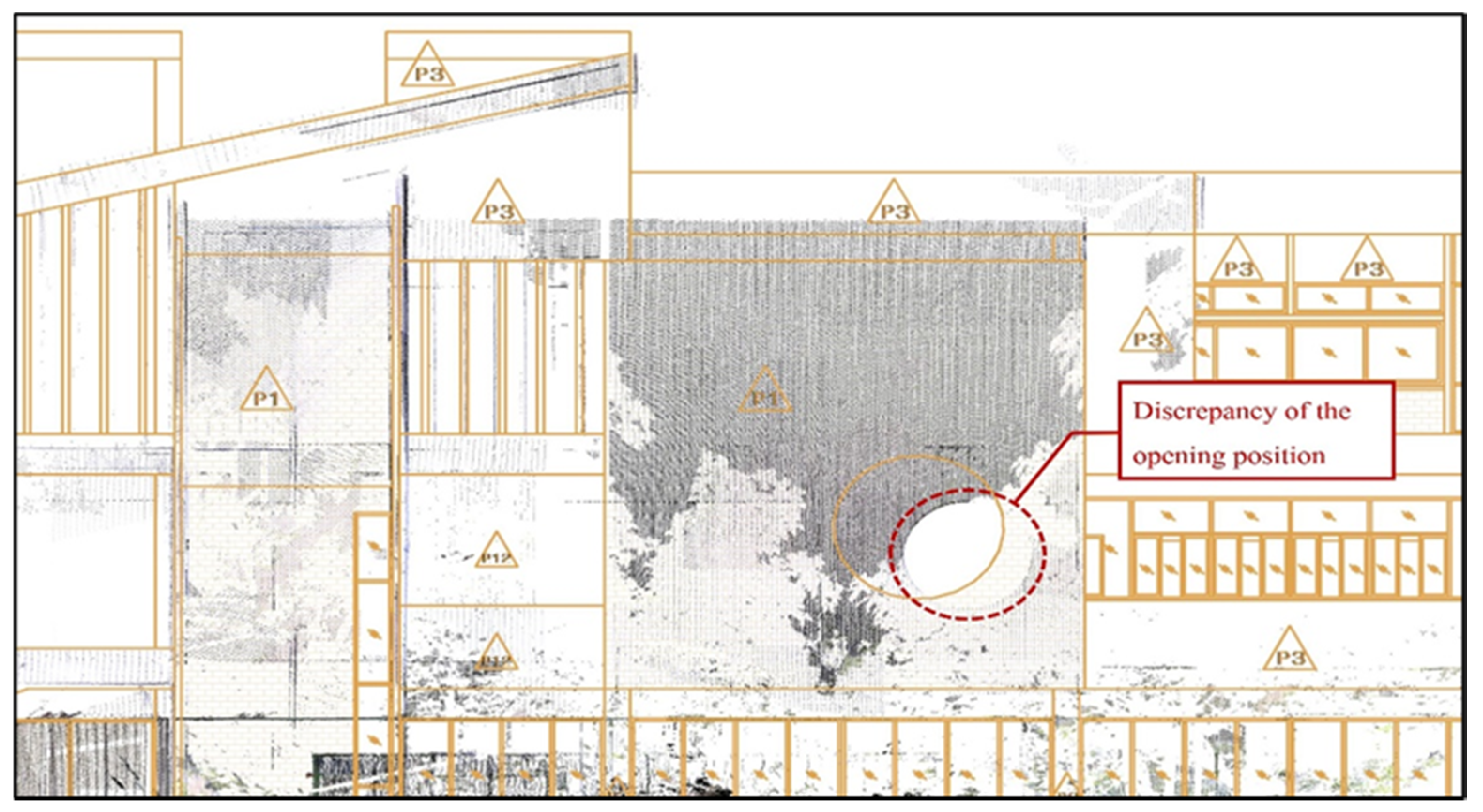

2.1.2. BIM Model Development

2.2. Optimization Definitions

2.3. Problem Definitions

2.4. BIM-MOGA Model

3. Optimization Model

3.1. Initialization Module

3.1.1. Actual Construction Time (Ta) Calculations

3.1.2. Resource Utilization Fluctuation (Mx) Calculations

3.1.3. Total Cost (Ct) Calculations

3.2. BIM Module

3.3. MOGA Module

3.3.1. Optimization Model

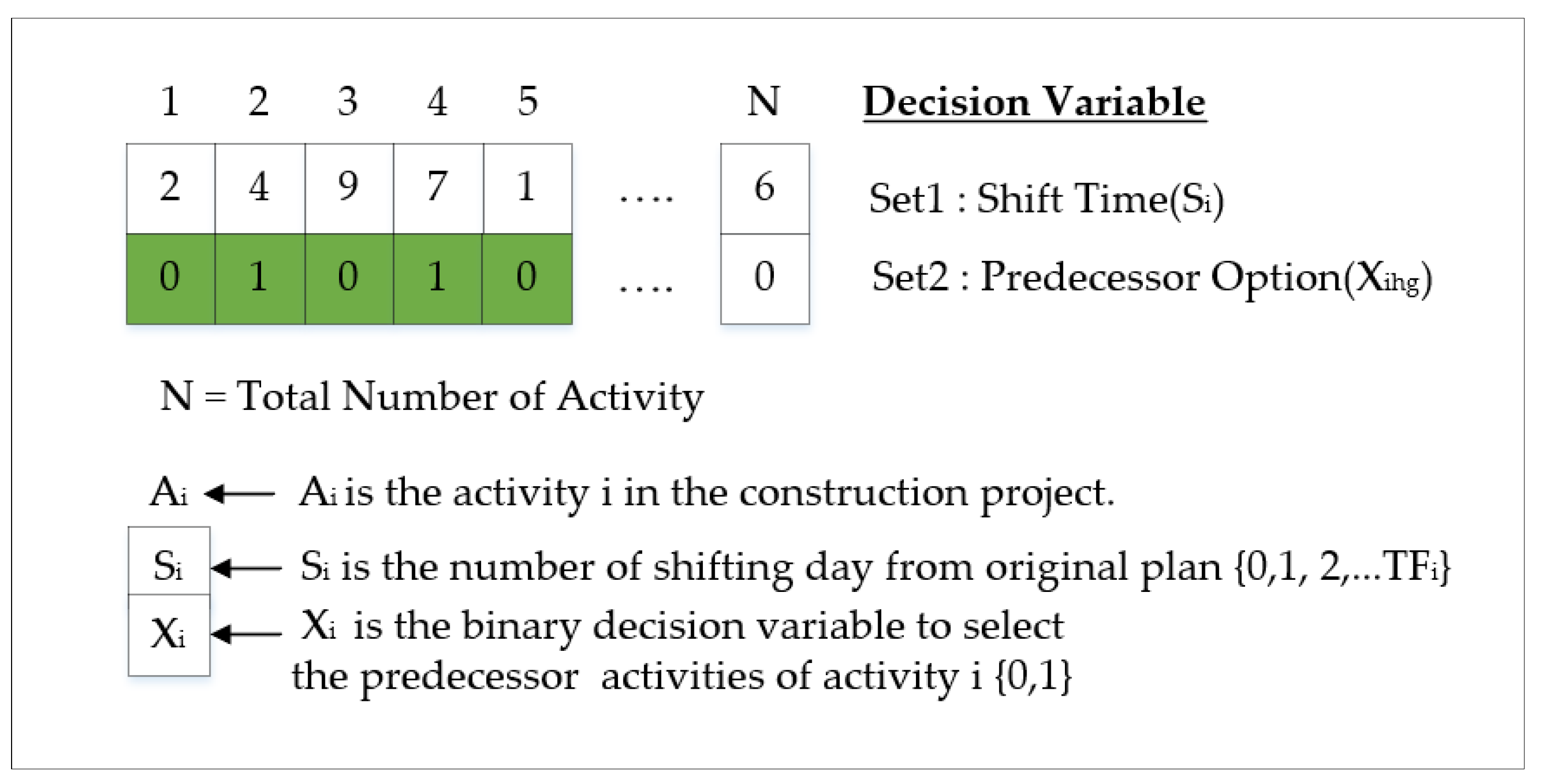

3.3.2. Decision Variables

- Set1:

- Defines shifting time and sets lower and upper bounds(Si = 0 to total float of activity i)

- Set2:

- Defines predecessor option (Xihg) and sets lower and upper bounds(Xihg = [0, 1])

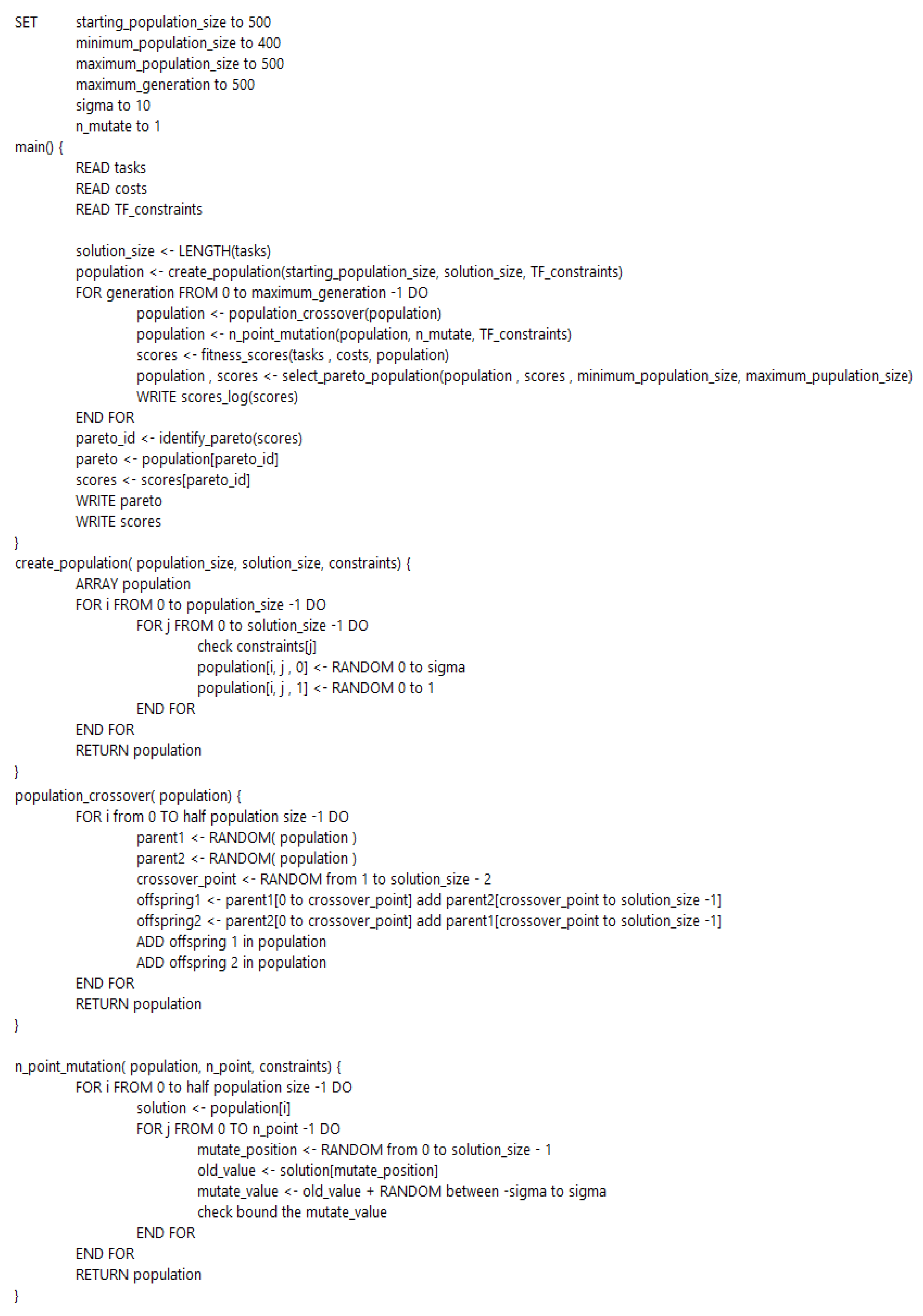

3.3.3. Genetic Operations

- Population creation: in each solution, the shifting time set values (Set1) and predecessor option set values (Set2) are randomized. Set1 is uniformly randomized from 0 to a sigma parameter value, while Set2 is uniformly randomized from 0 to 1. From continuous adjustment, the sigma parameter value in this research was set at 10, which is within the upper and lower bounds.

- Parent selection: the uniform random technique is used to select two parents with equal selection probability. After the parents are selected, they breed with the one-point crossover method.

- Crossover: one crossover point is selected randomly with the one-point crossover method. The initial solution values are copied from the first parent, while the other solution values are copied from the second parent.

- N-point mutation: this paper also proposed an n-point mutation technique to reduce computation complexity. The technique initially selects n number of decision variables in a solution by uniform randomization. Then, they are mutated by uniform randomization around old values with upper and lower bounds. The upper bound is the old value that adds the sigma value, while the lower bound is the old value that subtracts the sigma value. If the mutated values are out of bounds, then the value is uniformly randomized in possible value bounds. The parameters set, in this research, were n as 1 and possible values were between 0 and TF value. However, if the shifting time was out of bounds, the sigma value was used instead.

- Fitness calculation: the NSGA-II algorithm is used to calculate fitness scores, which are used to find non-dominated solutions, called a Pareto front. A challenge of the fitness score calculation in this research was the requirement for the PDM network to re-create everytime after mutation, resulting in complexity of the computation.

- Pareto front selection: the Pareto front selection uses the crowding distance technique to reduce the number of Pareto front which is over the upper bound. This is based on a tournament of crowding distances.

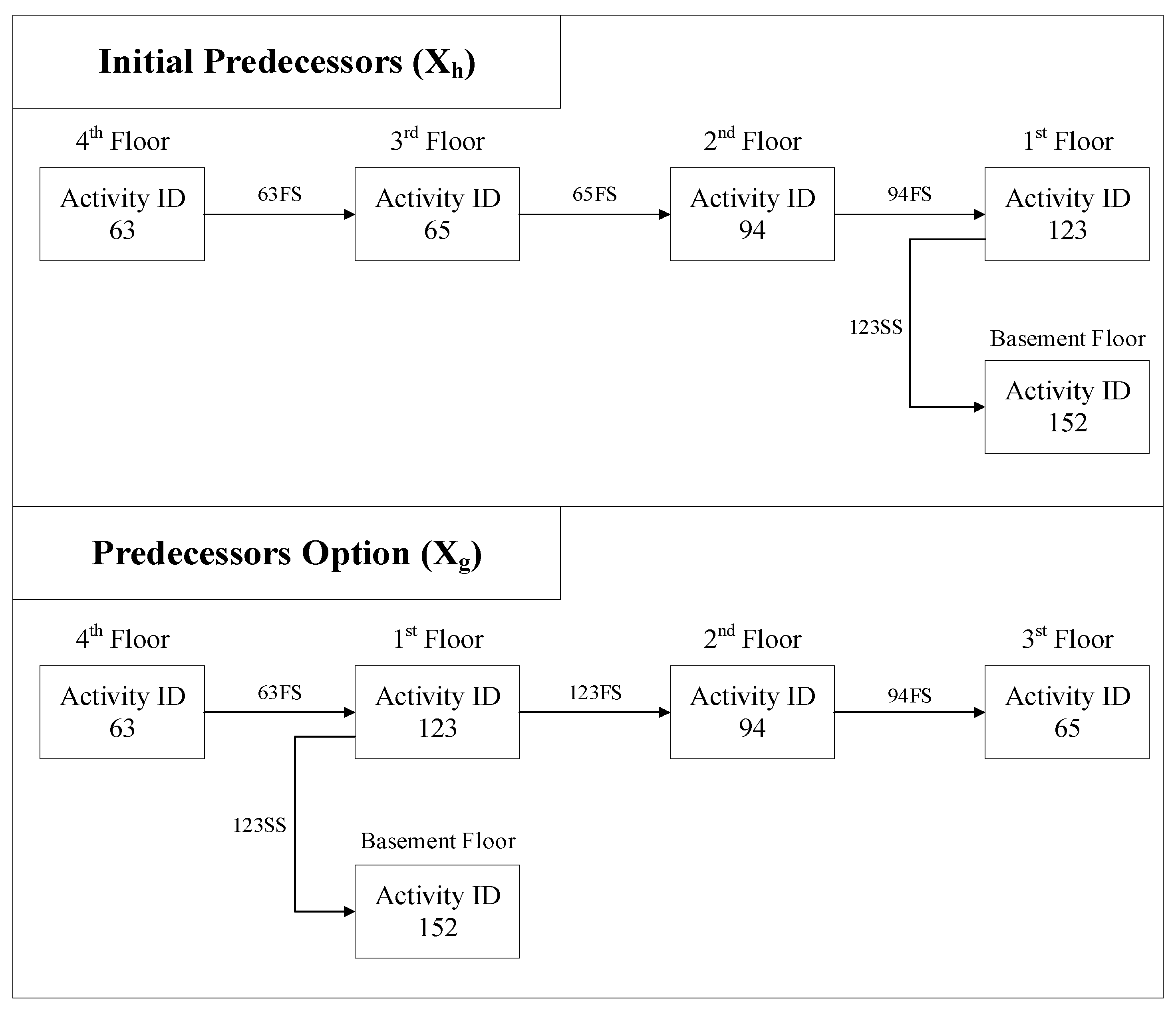

- Predecessor option (Xihg): In renovation projects, construction phases are normally considered based on work spaces. This is also defined as Set2 decision variables. Figure 7 illustrates the initial predecessor (Xh), where construction sequences start with the 4th floor, followed by the 3rd, 2nd, and 1st floors, and then the basement. A suggestion of renovation sequences is displayed as an alternative (Xihg). The renovation starts from the 4th floor, followed by the the 3rd, 2nd, and 1st floors, while simultaeneously working on the basement.

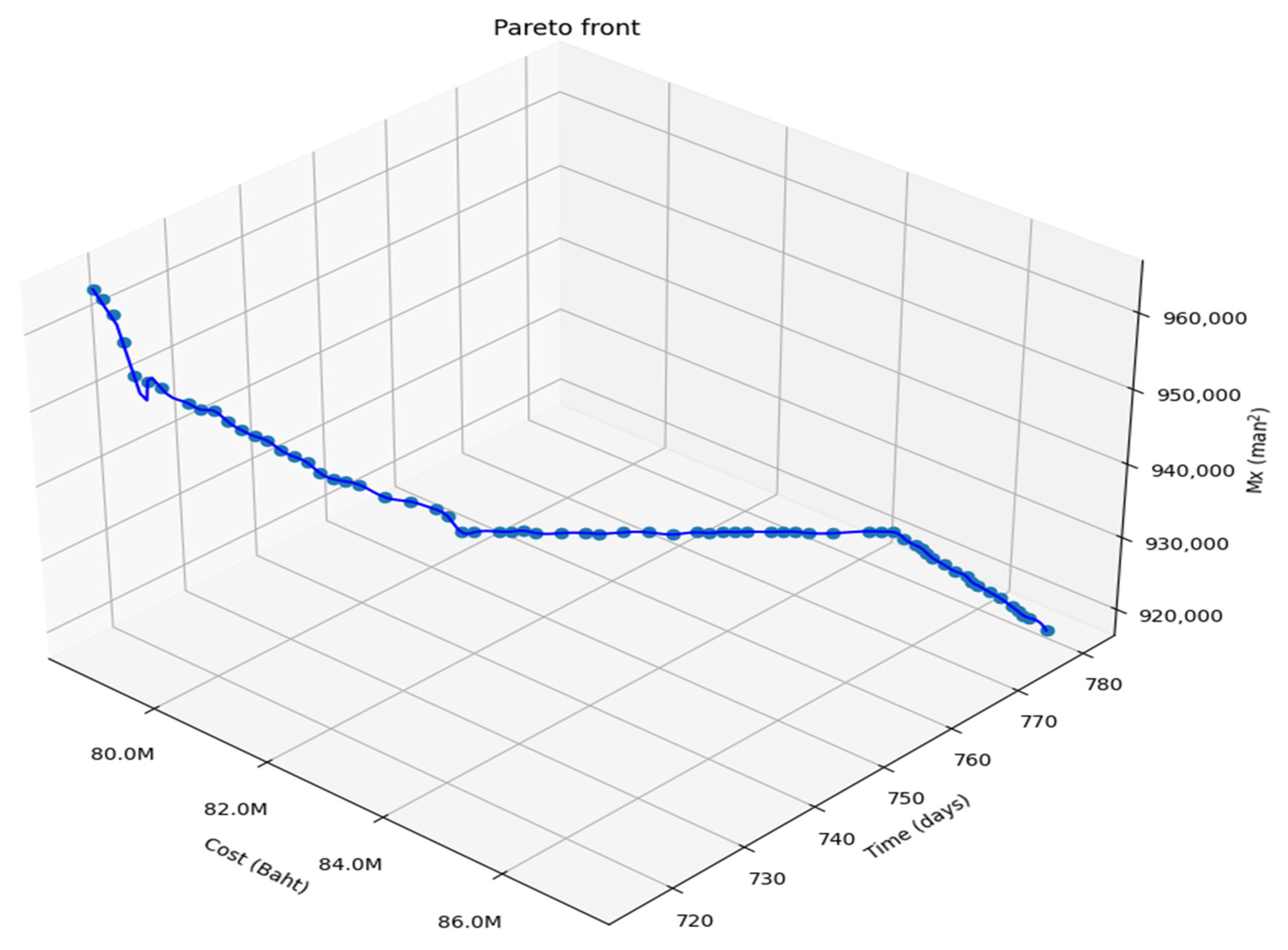

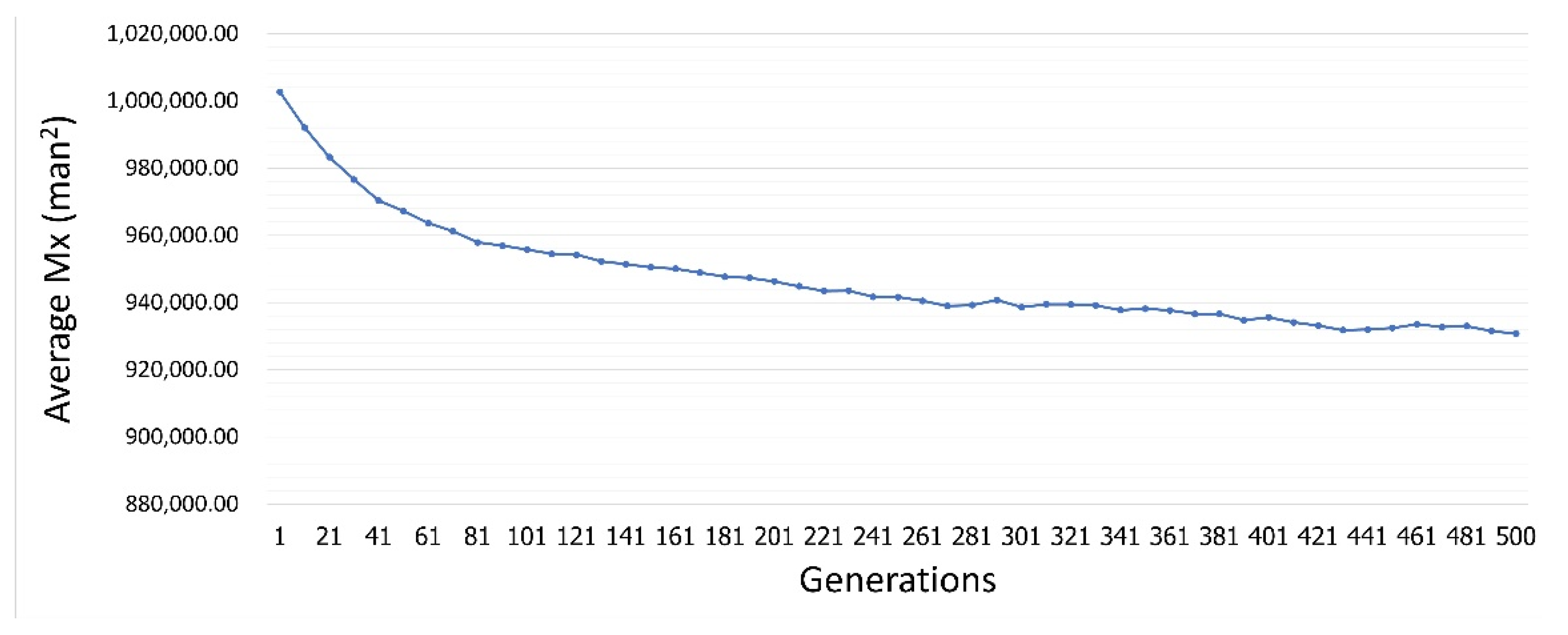

4. Results

5. Discussion

5.1. Cost

5.2. Time

5.3. Resource Utilization Fluctuation (Mx)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Olawale, Y.A.; Sun, M. PCIM: Project Control and Inhibiting-Factors Management Model. J. Manag. Eng. 2013, 29, 60–70. [Google Scholar] [CrossRef]

- Marle, F.; Vidal, L.-A. Managing Complex, High Risk Projects. Manag. Complex High Risk Proj. 2016. [Google Scholar] [CrossRef]

- Czmoch, I.; Pękala, A. Traditional Design versus BIM Based Design. Procedia Eng. 2014, 91, 210–215. [Google Scholar] [CrossRef]

- Hardin, B.; Mccool, D. BIM and Construction Management ProvenTools, Methods, and Workflws, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Howell, G.A. Renovation Projects: Design Process Problems and Improvement Mechanisms. J. Manag. Eng. 2002, 18, 179–185. [Google Scholar] [CrossRef]

- Luo, L.; He, Q.; Jaselskis, E.J.; Xie, J. Construction Project Complexity: Research Trends and Implications. J. Constr. Eng. Manag. 2017, 143, 04017019. [Google Scholar] [CrossRef]

- Shiue, F.-J.; Zheng, M.-C.; Lee, H.-Y.; Khitam, A.F.; Li, P.-Y. Renovation Construction Process Scheduling for Long-Term Performance of Buildings: An Application Case of University Campus. Sustainability 2019, 11, 5542. [Google Scholar] [CrossRef]

- Dasović, B.; Galić, M.; Klanšek, U. A Survey on Integration of Optimization and Project Management Tools for Sustainable Construction Scheduling. Sustainability 2020, 12, 3405. [Google Scholar] [CrossRef]

- Lee, D.G.; Park, J.Y.; Song, S.H. BIM-Based Construction Information Management Framework for Site Information Man-agement. Adv. Civ. Eng. 2018, 2018, 5249548. [Google Scholar]

- Arayici, Y.; Aouad, G. Building information modelling (BIM) for construction lifecycle management. In Construction and Building: Design, Materials, and Techniques; Nova Science Publishers: New York, NY, USA, 2010; pp. 99–118. [Google Scholar]

- Li, J.; Wang, Y.; Wang, X.; Luo, H.; Kang, S.-C.; Wang, J.; Guo, J.; Jiao, Y. Benefits of Building Information Modelling in the Project Lifecycle: Construction Projects in Asia. Int. J. Adv. Robot. Syst. 2014, 11, 124. [Google Scholar] [CrossRef]

- Kocakaya, M.N.; Namlı, E.; Işıkdağ, Ü. Building Information Management (BIM), A New Approach to Project Management. J. Sustain. Constr. Mater. Technol. 2019, 4, 323–332. [Google Scholar] [CrossRef]

- Saad, M.; Baba, S.; Amoudi, O. A suggested solution to improve the traditional construction planning approach. Jordan J. Civ. Eng. 2015, 9, 185–196. [Google Scholar]

- Pūlmanis, E. Public Sector Project MANAGEMENT EFFICIENCY PROBLEMS, CASE OF LATVIA. Reg. Form. Dev. Stud. 2021, 11, 177–188. [Google Scholar] [CrossRef][Green Version]

- Carbonari, G.; Stravoravdis, S.; Gausden, C. Building information model implementation for existing buildings for facilities management: A framework and two case studies. Build. Inf. Model. BIM Des. Constr. Oper. 2015, 1, 395–406. [Google Scholar] [CrossRef]

- Khaddaj, M.; Srour, I. Using BIM to Retrofit Existing Buildings. Procedia Eng. 2016, 145, 1526–1533. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Mill, T.; Alt, A.; Liias, R. Combined 3D building surveying techniques-Terrestrial laser scanning (TLS) and total station sur-veying for BIM data management purposes. J. Civ. Eng. Manag. 2013, 19, 23–32. [Google Scholar] [CrossRef]

- Barazzetti, L.; Banfi, F.; Brumana, R.; Gusmeroli, G.; Previtali, M.; Schiantarelli, G. Cloud-to-BIM-to-FEM: Structural simulation with accurate historic BIM from laser scans. Simul. Model. Pract. Theory 2015, 57, 71–87. [Google Scholar] [CrossRef]

- Zhou, J.; Love, P.E.D.; Wang, X.; Teo, K.L.; Irani, Z. A review of methods and algorithms for optimizing construction scheduling. J. Oper. Res. Soc. 2013, 64, 1091–1105. [Google Scholar] [CrossRef]

- Fahmy, A.M. Optimization Algorithms in Project Scheduling. Optim. Algorithm. Methods Appl. 2016. [Google Scholar] [CrossRef]

- Werner, F.; Burtseva, L.; Sotskov, Y.N. Special Issue on Algorithms for Scheduling Problems. Algorithms 2018, 11, 87. [Google Scholar] [CrossRef]

- Ipsilandis, P.G. Multiobjective Linear Programming Model for Scheduling Linear Repetitive Projects. J. Constr. Eng. Manag. 2007, 133, 417–424. [Google Scholar] [CrossRef]

- Joy, J.; Rajeev, S.; Narayanan, V. Particle Swarm Optimization for Resource Constrained-project Scheduling Problem with Varying Resource Levels. Procedia Technol. 2016, 25, 948–954. [Google Scholar] [CrossRef]

- Zhang, H. Ant Colony Optimization for Multimode Resource-Constrained Project Scheduling. J. Manag. Eng. 2012, 28, 150–159. [Google Scholar] [CrossRef]

- Hegazy, T. Optimization of Resource Allocation and Leveling Using Genetic Algorithms. J. Constr. Eng. Manag. 1999, 125, 167–175. [Google Scholar] [CrossRef]

- Chan, W.T.; Hu, H. Precast production scheduling with genetic algorithms. In Proceedings of the 2000 Congress on Evolutionary Computation, CEC00 (Cat. No.00TH8512), La Jolla, CA, USA, 16–19 July 2002; Volume 2, pp. 1087–1094. [Google Scholar]

- El-Rayes, K.; Jun, D.H. Optimizing Resource Leveling in Construction Projects. J. Constr. Eng. Manag. 2009, 135, 1172–1180. [Google Scholar] [CrossRef]

- Venkrbec, V.; Galić, M.; Klanšek, U. Construction process optimisation—Review of methods, tools and applications. J. Croat. Assoc. Civ. Eng. 2018, 70, 593–606. [Google Scholar] [CrossRef]

- Obradović, D. Review of Nature-Inspired Optimization Algorithms Applied in Civil Engineeering. Elektron. Časopis Građevinskog Fak. Osijek 2018, 74–88. [Google Scholar] [CrossRef]

- Sanchez, B.; Rausch, C.; Haas, C.; Saari, R. A selective disassembly multi-objective optimization approach for adaptive reuse of building components. Resour. Conserv. Recycl. 2020, 154, 104605. [Google Scholar] [CrossRef]

- Liang, C.; Xu, X.; Chen, H.; Wang, W.; Zheng, K.; Tan, G.; Gu, Z.; Zhang, H. Machine Learning Approach to Develop a Novel Multi-Objective Optimization Method for Pavement Material Proportion. Appl. Sci. 2021, 11, 835. [Google Scholar] [CrossRef]

- Murata, T.; Ishibuchi, H. MOGA: Multi-objective genetic algorithms. In Proceedings of the 1995 IEEE International Conference on Evolutionary Computation, Perth, Australia, 29 November–1 December 1995; Volume 1, pp. 289–294. [Google Scholar]

- Eshtehardian, E.; Afshar, A.; Abbasnia, R. Fuzzy-based MOGA approach to stochastic time–cost trade-off problem. Autom. Constr. 2009, 18, 692–701. [Google Scholar] [CrossRef]

- Peng, B.; Flager, F.L.; Wu, J. A method to optimize mobile crane and crew interactions to minimize construction cost and time. Autom. Constr. 2018, 95, 10–19. [Google Scholar] [CrossRef]

- Zhao, S.; Li, Z. Multi-objective Optimization for Construction Site Layout Planning Problem under Fuzzy Random Environment. In Proceedings of the 2014 Seventh International Joint Conference on Computational Sciences and Optimization, Beijing, China, 4–6 July 2014; pp. 641–645. [Google Scholar]

- Monghasemi, S.; Nikoo, M.R.; Khaksar Fasaee, M.A.; Adamowski, J. A novel multi criteria decision making model for optimizing time-cost-quality trade-off problems in construction projects. Expert Syst. Appl. 2015, 42, 3089–3104. [Google Scholar] [CrossRef]

- Tachaudomdach, S.; Upayokin, A.; Kronprasert, N.; Arunotayanun, K. Quantifying Road-Network Robustness toward Flood-Resilient Transportation Systems. Sustainability 2021, 13, 3172. [Google Scholar] [CrossRef]

- Faghihi, V.; Reinschmidt, K.F.; Kang, J.H. Construction scheduling using Genetic Algorithm based on Building Information Model. Expert Syst. Appl. 2014, 41, 7565–7578. [Google Scholar] [CrossRef]

- Moon, H.; Kim, H.; Kamat, V.R.; Kang, L. BIM-Based Construction Scheduling Method Using Optimization Theory for Reducing Activity Overlaps. J. Comput. Civ. Eng. 2015, 29, 04014048. [Google Scholar] [CrossRef]

- Gbadamosi, A.Q.; Mahamadu, A.M.; Oyedele, L.O.; Akinade, O.O.; Manu, P.; Mahdjoubi, L.; Aigbavboa, C. Offsite construction: Developing a BIM-Based optimizer for assembly. J. Clean. Prod. 2019, 215, 1180–1190. [Google Scholar] [CrossRef]

- Asl, M.R.; Bergin, M.; Menter, A.; Yan, W. BIM-based Parametric Building Energy Performance MultiObjective Optimization. In Proceedings of the 32nd eCAADe Conference—Volume 2, Newcastle, UK, 10–12 September 2014; pp. 455–464. [Google Scholar]

- Amiri, R.; Sardroud, J.M.; Soto, B.G. De BIM-based Applications of Metaheuristic Algorithms to Support the Decision-making Process: Uses in the Planning of Construction Site Layout. Procedia Eng. 2017, 196, 558–564. [Google Scholar] [CrossRef]

- Huang, J.-W.; Wang, X.-X.; Chen, R. Genetic Algorithms for Optimization of Resource Allocation in Large Scale Construction Project Management. J. Comput. 2010, 5, 1916–1924. [Google Scholar] [CrossRef]

- Agrama, F.A. Multi-objective genetic optimization for scheduling a multi-storey building. Autom. Constr. 2014, 44, 119–128. [Google Scholar] [CrossRef]

- Eid, M.S.; Elbeltagi, E.E.; El-Adaway, I.H. Simultaneous multi-criteria optimization for scheduling linear infrastructure projects. Int. J. Constr. Manag. 2021, 21, 41–55. [Google Scholar] [CrossRef]

- Kemmer, S. Development of a Method for Construction Management in Refurbishment Projects. Technol. Forecast. Soc. Chang. 2018, 104, 1–15. [Google Scholar]

- Zanchetta, C.; Cecchini, C.; Bellotto, C. BIM-Based multi-objective optimization process for energy and comfort simulation: Existing tools analysis and workflow proposal on a case study. J. Build. Sustain. 2018, 1, 11–26. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Salama, T.; Moselhi, O. Multi-objective optimization for repetitive scheduling under uncertainty. Eng. Constr. Arch. Manag. 2019, 26, 1294–1320. [Google Scholar] [CrossRef]

- Rao, S.S. Engineering Optimization: Theory and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Palisade Corporation. Palisada Corporation Evolver User’s Guide. In The Genetic Algorithm Solver for Microsoft Excel, Version 7; Palisade Corporation: Ithaca, NY, USA, 2015; p. 14850. [Google Scholar]

- Ghoddousi, P.; Eshtehardian, E.; Jooybanpour, S.; Javanmardi, A. Multi-mode resource-constrained discrete time–cost-resource optimization in project scheduling using non-dominated sorting genetic algorithm. Autom. Constr. 2013, 30, 216–227. [Google Scholar] [CrossRef]

| Parameter Name | Values |

|---|---|

| The size of start population | 500 |

| The size of minimum population | 400 |

| The size of maximum population | 500 |

| The maximum generation | 500 |

| The crossover rate (Pc) | 0.5 |

| The mutation rate (Pm) | 0.004 |

| n | 1 |

| sigma | 10 |

| Maximum days (from construction contract) | 780 days |

| Solution No. | Cost | Time | Mx | Solution No. | Cost | Time | Mx |

|---|---|---|---|---|---|---|---|

| 1 | 78,701,296 | 716 | 965,714 | 36 | 82,230,313 | 756 | 925,806 |

| 2 | 78,718,612 | 717 | 964,056 | 37 | 82,422,522 | 758 | 925,672 |

| 3 | 78,735,928 | 718 | 961,692 | 38 | 82,614,730 | 760 | 925,346 |

| 4 | 78,753,245 | 719 | 957,788 | 39 | 82,806,939 | 762 | 924,718 |

| 5 | 78,770,561 | 720 | 952,956 | 40 | 82,999,147 | 764 | 924,690 |

| 6 | 78,866,665 | 721 | 951,930 | 41 | 83,095,252 | 765 | 924,434 |

| 7 | 78,962,770 | 722 | 951,030 | 42 | 83,191,356 | 766 | 924,418 |

| 8 | 79,154,978 | 724 | 948,698 | 43 | 83,287,460 | 767 | 924,216 |

| 9 | 79,251,082 | 725 | 947,646 | 44 | 83,383,564 | 768 | 924,112 |

| 10 | 79,347,187 | 726 | 947,372 | 45 | 83,575,773 | 770 | 923,754 |

| 11 | 79,443,291 | 727 | 945,760 | 46 | 83,671,877 | 771 | 923,644 |

| 12 | 79,539,395 | 728 | 944,508 | 47 | 83,767,981 | 772 | 923,458 |

| 13 | 79,635,499 | 729 | 943,500 | 48 | 83,864,085 | 773 | 923,114 |

| 14 | 79,731,603 | 730 | 942,752 | 49 | 84,056,294 | 775 | 922,744 |

| 15 | 79,827,708 | 731 | 941,304 | 50 | 84,344,607 | 778 | 922,526 |

| 16 | 79,923,812 | 732 | 940,276 | 51 | 84,440,711 | 779 | 922,330 |

| 17 | 80,019,916 | 733 | 939,348 | 52 | 84,536,815 | 780 | 922,084 |

| 18 | 80,116,020 | 734 | 937,714 | 53 | 84,729,024 | >780 | 921,826 |

| 19 | 80,212,125 | 735 | 936,752 | 54 | 84,921,232 | >780 | 921,552 |

| 20 | 80,308,229 | 736 | 936,274 | 55 | 85,017,336 | >780 | 921,494 |

| 21 | 80,404,333 | 737 | 935,688 | 56 | 85,113,440 | >780 | 921,134 |

| 22 | 80,596,542 | 739 | 933,630 | 57 | 85,209,545 | >780 | 920,800 |

| 23 | 80,788,750 | 741 | 932,710 | 58 | 85,401,753 | >780 | 920,500 |

| 24 | 80,980,958 | 743 | 931,312 | 59 | 85,593,962 | >780 | 920,228 |

| 25 | 81,077,063 | 744 | 930,128 | 60 | 85,786,170 | >780 | 920,194 |

| 26 | 81,173,167 | 745 | 927,824 | 61 | 85,882,274 | >780 | 919,716 |

| 27 | 81,269,271 | 746 | 927,640 | 62 | 85,978,379 | >780 | 919,604 |

| 28 | 81,461,480 | 748 | 927,430 | 63 | 86,170,587 | >780 | 919,362 |

| 29 | 81,557,584 | 749 | 927,246 | 64 | 86,362,795 | >780 | 919,130 |

| 30 | 81,653,688 | 750 | 927,210 | 65 | 86,555,004 | >780 | 918,650 |

| 31 | 81,653,688 | 750 | 927,210 | 66 | 86,651,108 | >780 | 918,378 |

| 32 | 81,653,688 | 750 | 927,210 | 67 | 86,651,108 | >780 | 918,378 |

| 33 | 81,749,792 | 751 | 926,716 | 68 | 86,747,212 | >780 | 918,094 |

| 34 | 81,942,001 | 753 | 926,384 | 69 | 86,843,317 | >780 | 918,084 |

| 35 | 82,134,209 | 755 | 926,072 | 70 | 87,131,629 | >780 | 917,338 |

| Cost | Time | Mx | |

|---|---|---|---|

| Original Plan | 78,701,296 | 716 | 1,009,040 |

| An Optimal Plan | 78,701,296 | 716 | 965,714 |

| Difference | 0% | 0% | 4.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nusen, P.; Boonyung, W.; Nusen, S.; Panuwatwanich, K.; Champrasert, P.; Kaewmoracharoen, M. Construction Planning and Scheduling of a Renovation Project Using BIM-Based Multi-Objective Genetic Algorithm. Appl. Sci. 2021, 11, 4716. https://doi.org/10.3390/app11114716

Nusen P, Boonyung W, Nusen S, Panuwatwanich K, Champrasert P, Kaewmoracharoen M. Construction Planning and Scheduling of a Renovation Project Using BIM-Based Multi-Objective Genetic Algorithm. Applied Sciences. 2021; 11(11):4716. https://doi.org/10.3390/app11114716

Chicago/Turabian StyleNusen, Pornpote, Wanarut Boonyung, Sunita Nusen, Kriengsak Panuwatwanich, Paskorn Champrasert, and Manop Kaewmoracharoen. 2021. "Construction Planning and Scheduling of a Renovation Project Using BIM-Based Multi-Objective Genetic Algorithm" Applied Sciences 11, no. 11: 4716. https://doi.org/10.3390/app11114716

APA StyleNusen, P., Boonyung, W., Nusen, S., Panuwatwanich, K., Champrasert, P., & Kaewmoracharoen, M. (2021). Construction Planning and Scheduling of a Renovation Project Using BIM-Based Multi-Objective Genetic Algorithm. Applied Sciences, 11(11), 4716. https://doi.org/10.3390/app11114716