Analysis of Biodiesel Influence on Unregulated Gaseous Emissions of Diesel Motor Vehicles

Abstract

1. Introduction

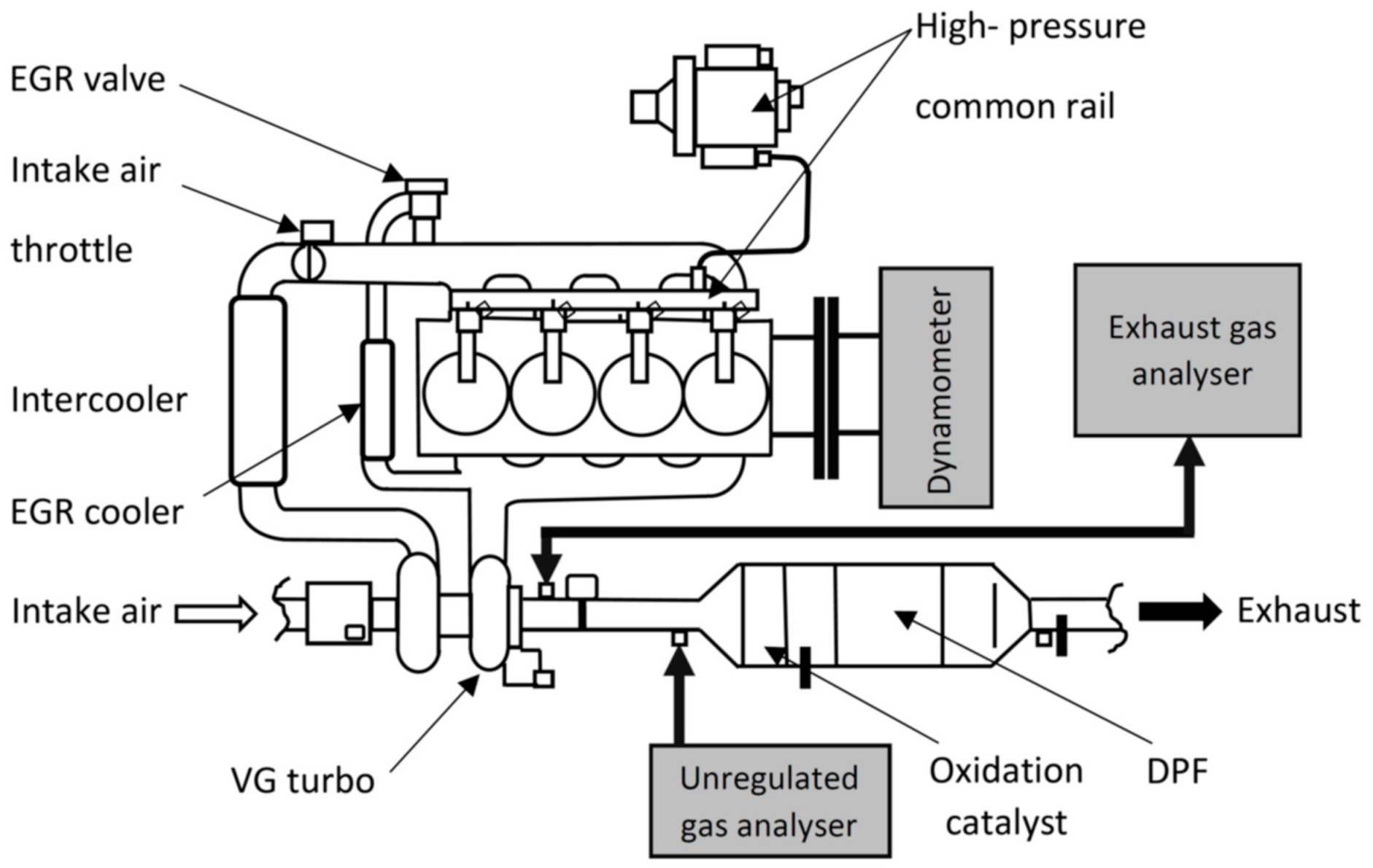

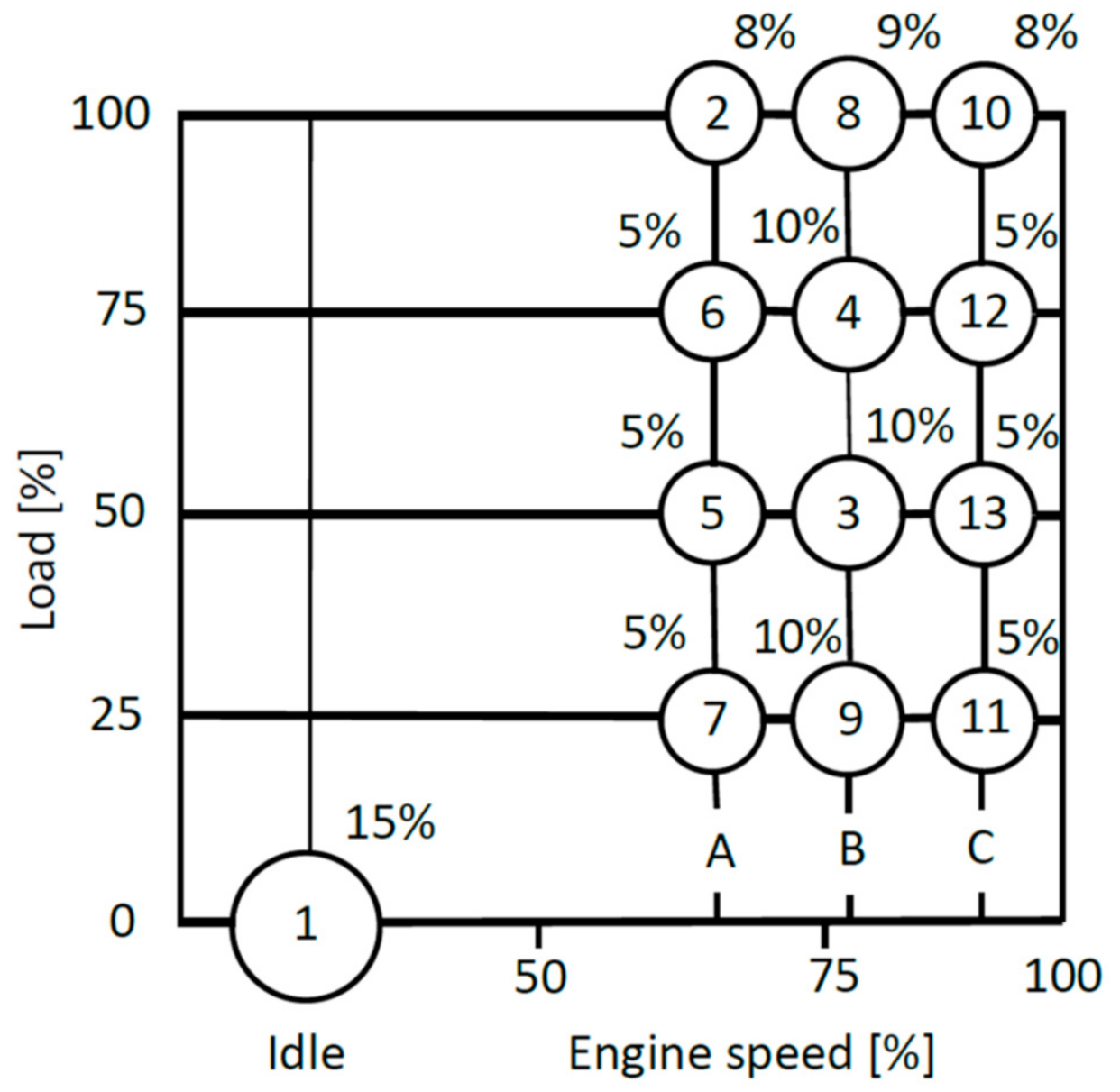

2. Experiment Conditions

3. Results and Discussion

3.1. Parameters of the Experimental Engine

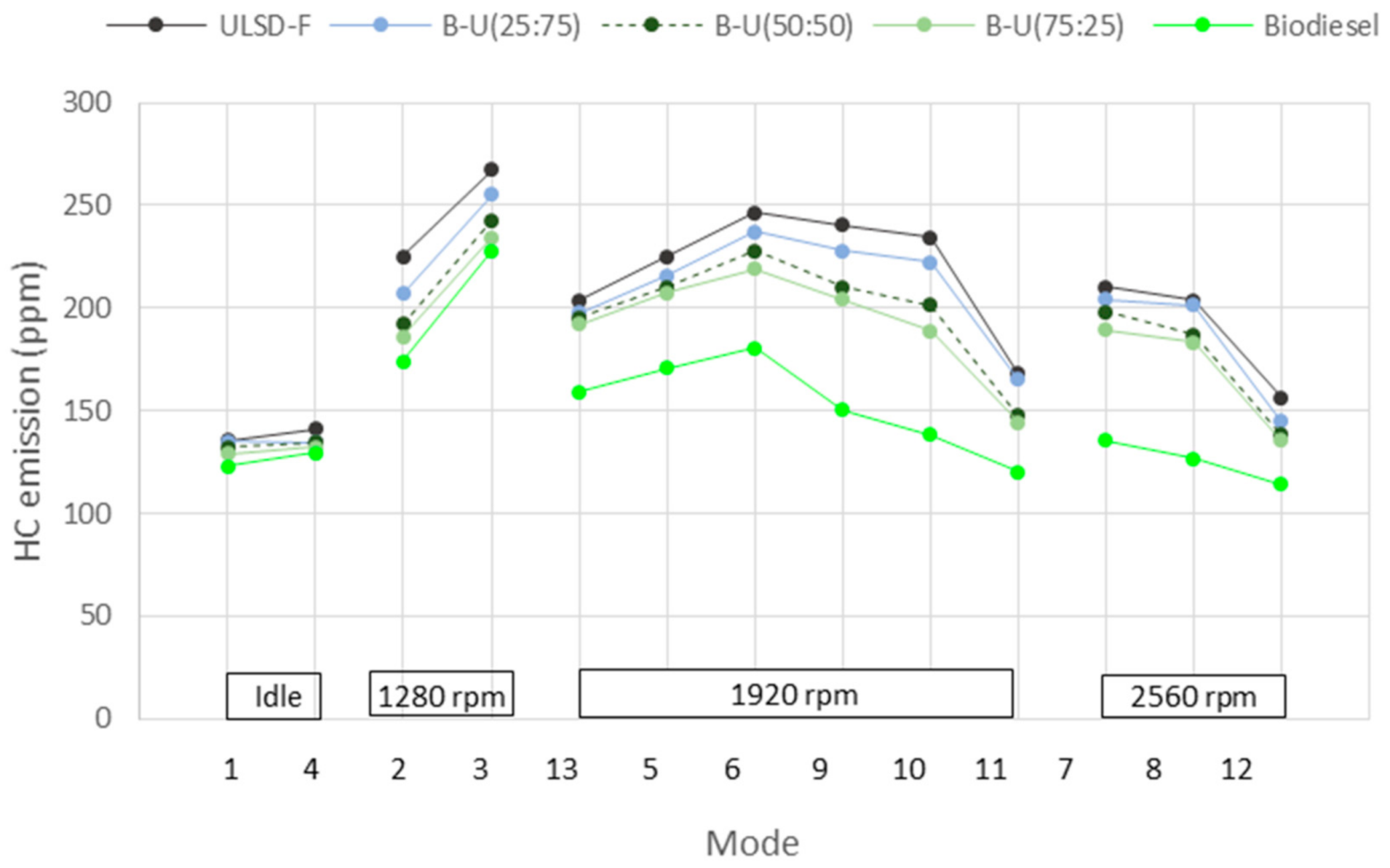

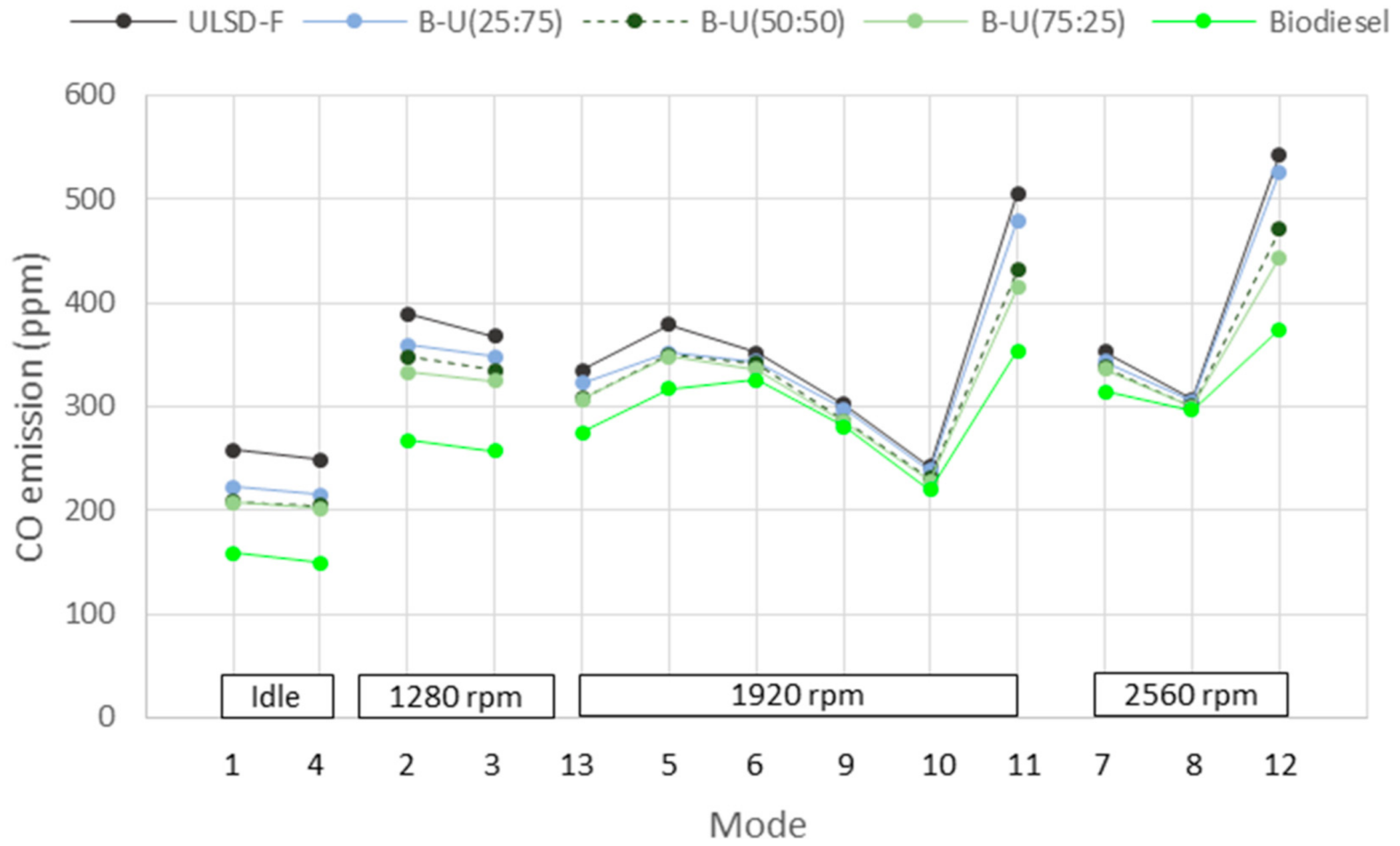

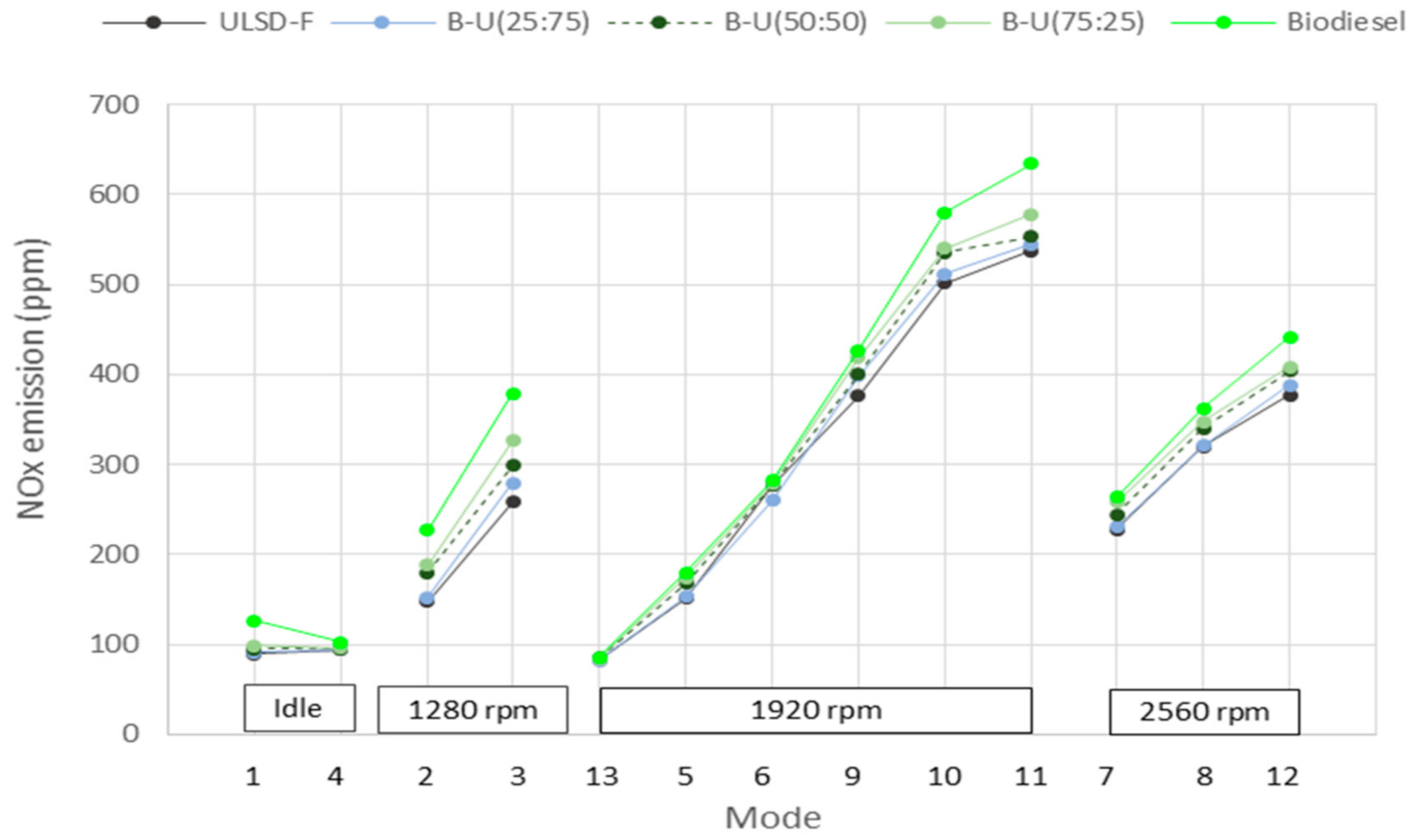

3.2. The Regulated Emissions

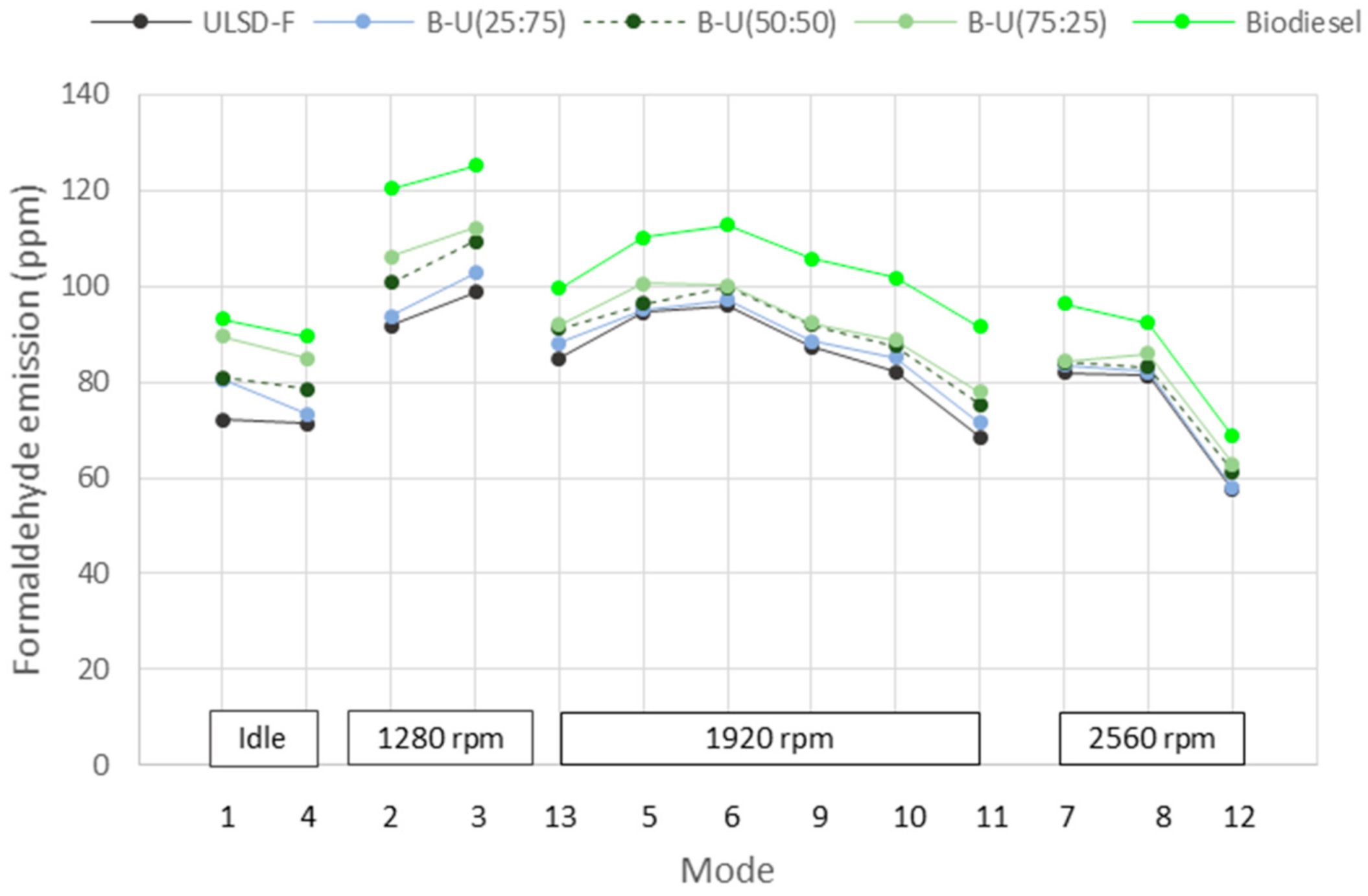

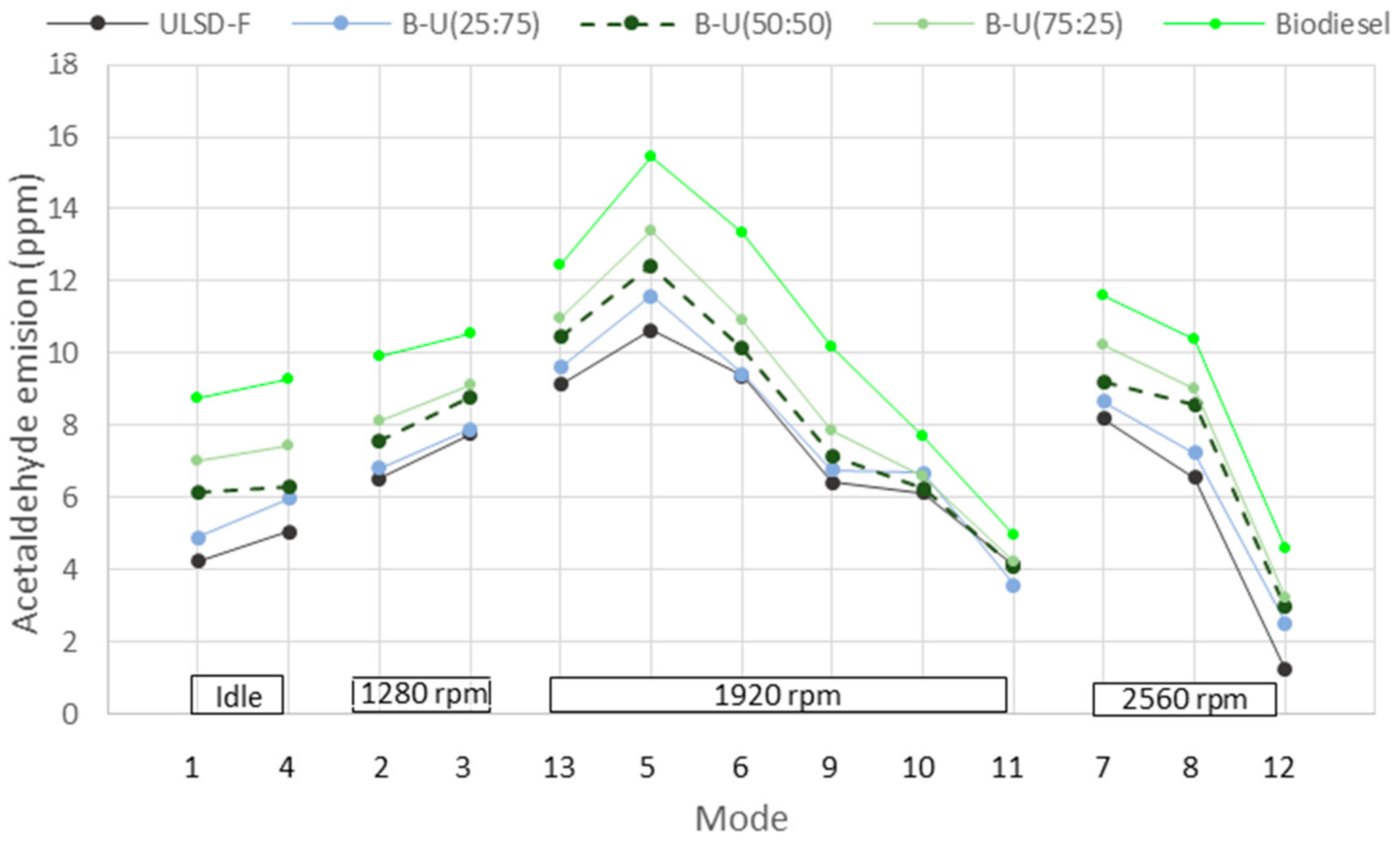

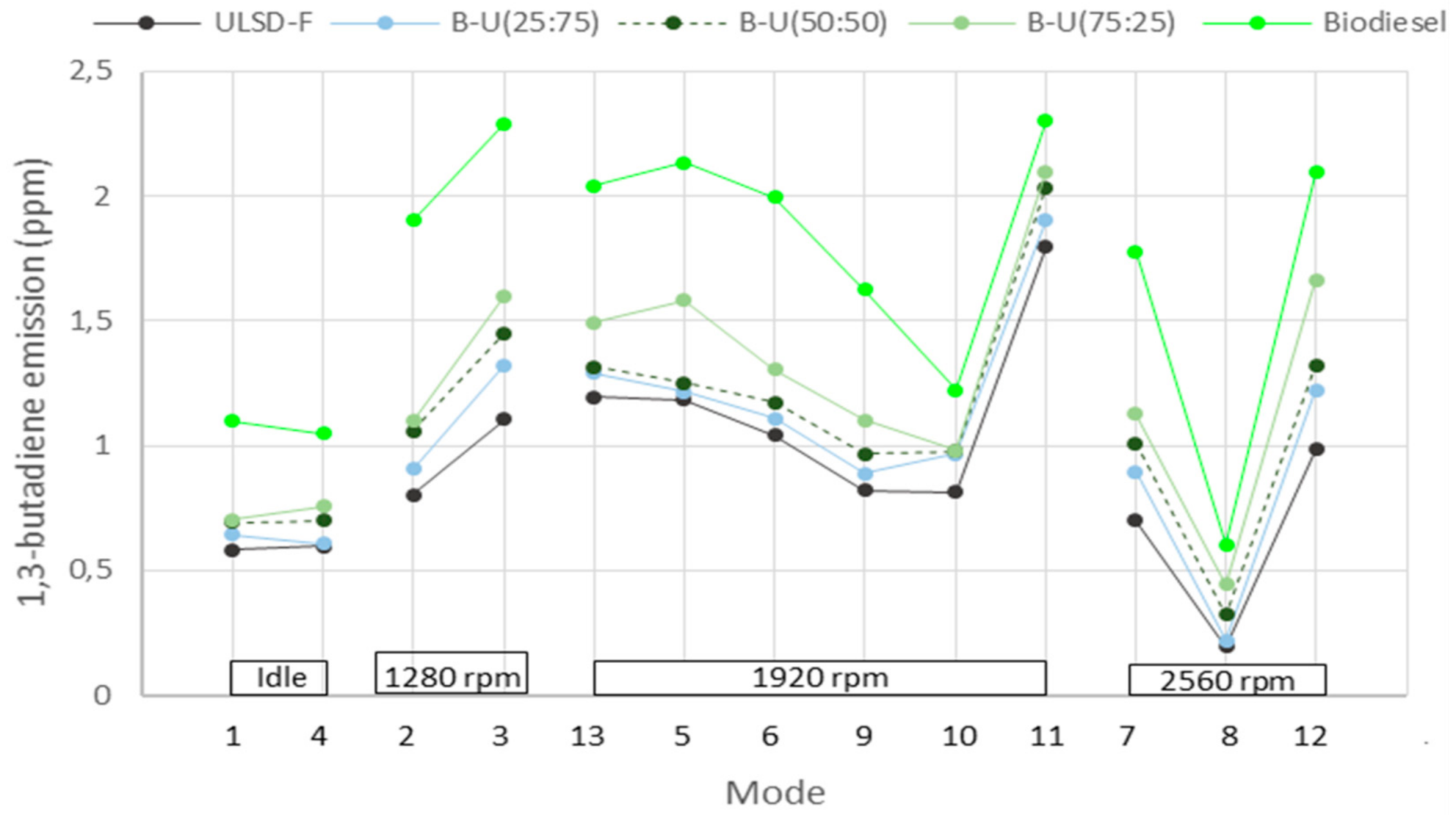

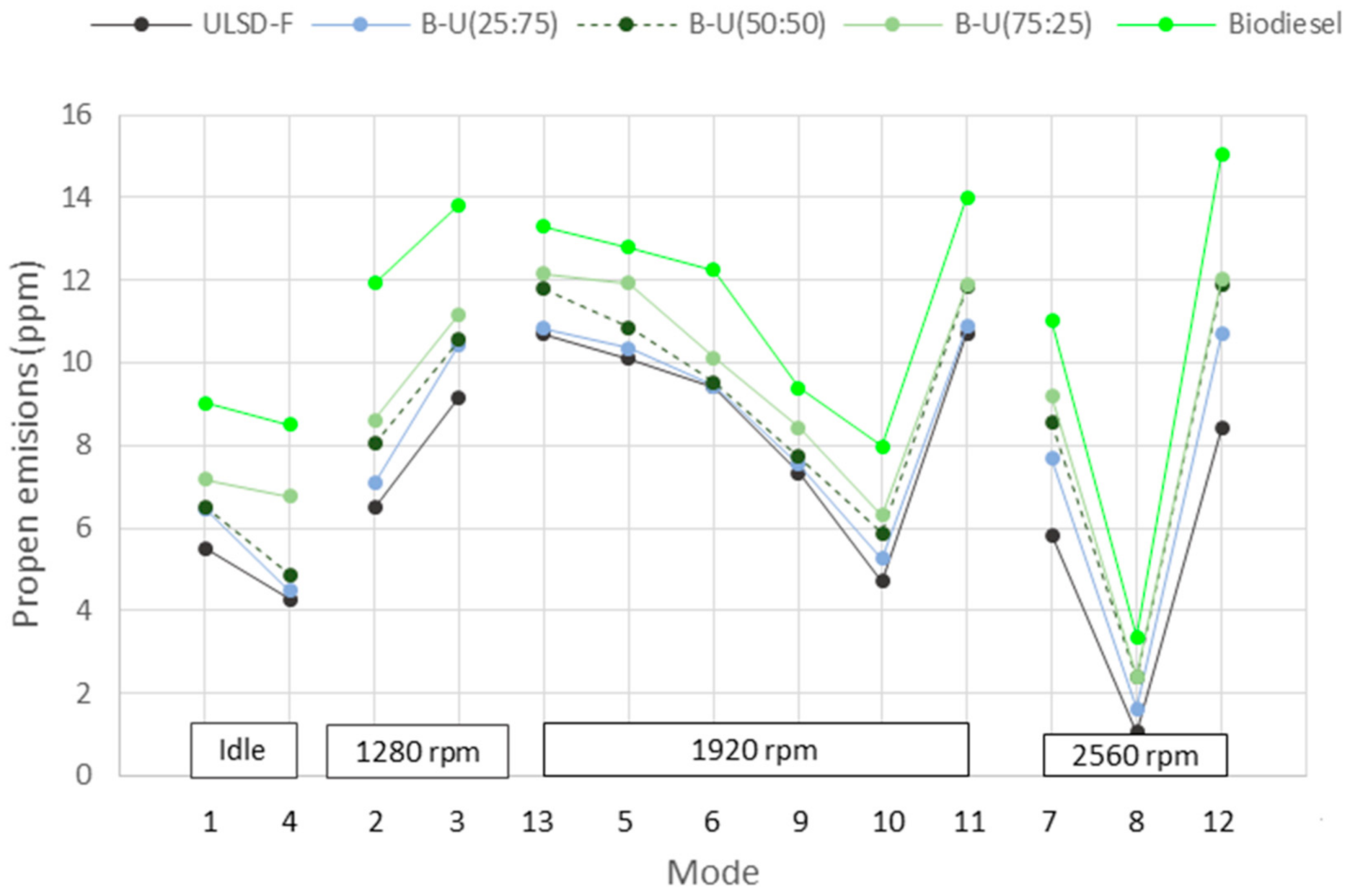

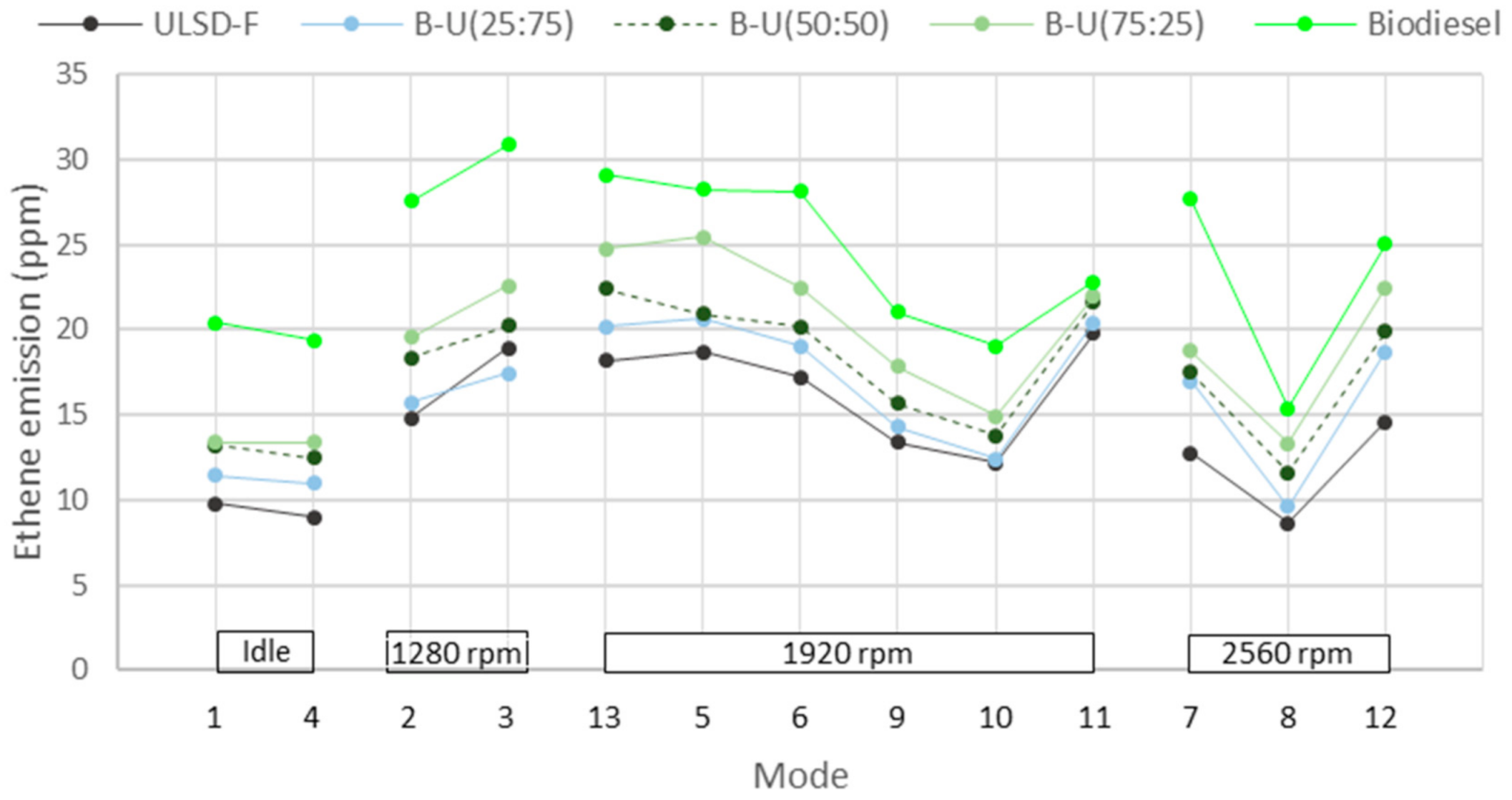

3.3. The Unregulated Emissions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Basha, S.A.; Gopal, K.R.; Jebaraj, S. A review on biodiesel production, combustion, emissions and performance. Renew. Sustain. Energy Rev. 2009, 13, 1628–1634. [Google Scholar] [CrossRef]

- Utlu, Z.; Koçak, M.S. The effect of biodiesel fuel obtained from waste frying oil on direct injection diesel engine performance and exhaust emissions. Renew. Energy 2008, 33, 1936–1941. [Google Scholar] [CrossRef]

- Wang, T.; Liu, J.; Sun, P.; Ji, Q.; Gao, W.; Yang, C. Influence of injection parameters on combustion, gaseous emissions and particle size distribution of a CRDI diesel engine operating with PODE/diesel blends. Fuel 2020, 281, 118733. [Google Scholar] [CrossRef]

- Sinay, J.; Puškár, M.; Kopas, M. Reduction of the NOx emissions in vehicle diesel engine in order to fulfill future rules concerning emissions released into air. Sci. Total Environ. 2018, 624, 1421–1428. [Google Scholar] [CrossRef] [PubMed]

- Puškár, M.; Jahnátek, A.; Kádárová, J.; Šoltésová, M.; Kovanič, L.; Krivosudská, J. Environmental study focused on the suitability of vehicle certifications using the new European driving cycle (NEDC) with regard to the affair “dieselgate” and the risks of NOx emissions in urban destinations. Air Qual. Atmos. Health 2019, 12, 251–257. [Google Scholar] [CrossRef]

- Puškár, M.; Kopas, M.; Puškár, D.; Lumnitzer, J.; Faltinová, E. Method for reduction of the NOX emissions in marine auxiliary diesel engine using the fuel mixtures containing biodiesel using HCCI combustion. Mar. Pollut. Bull. 2018, 127, 752–760. [Google Scholar] [CrossRef] [PubMed]

- Sharp, C.A.; Howell, S.A.; Jobe, J. The effect of biodiesel fuels on transient emissions from modern diesel engines, part II unreg-ulated emissions and chemical characterization. SAE Trans. 2000, 1784–1807. [Google Scholar] [CrossRef]

- Agency, E.P. A Comprehensive Analysis of Biodiesel Impacts on Exhaust Emissions; US Environmental Protection Agency: Washington, DC, USA, 2002.

- McGill, R.; Storey, J.; Wagner, R.; Irick, D.; Aakko, P.; Westerholm, M.; Nylund, N.-O.; Lappi, M. Emission Performance of Selected Biodiesel Fuels; SAE Technical Paper 2003-01-1866; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Di, Y.; Cheung, C.; Huang, Z. Experimental investigation on regulated and unregulated emissions of a diesel engine fueled with ultra-low sulfur diesel fuel blended with biodiesel from waste cooking oil. Sci. Total Environ. 2009, 407, 835–846. [Google Scholar] [CrossRef] [PubMed]

- Lapuerta, M.; Armas, O.; Rodriguezfernandez, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Zouaoui, N.; Brilhac, J.-F.; Mechati, F.; Jeguirim, M.; Djellouli, B.; Gilot, P. Study of experimental and theoretical procedures when using thermogravimetric analysis to determine kinetic parameters of carbon black oxidation. J. Therm. Anal. Calorim. 2010, 102, 837–849. [Google Scholar] [CrossRef]

- Tsolakis, A. Effects on Particle Size Distribution from the Diesel Engine Operating on RME-Biodiesel with EGR. Energy Fuels 2006, 20, 1418–1424. [Google Scholar] [CrossRef]

- Guarieiro, L.L.N.; Pereira, P.A.D.P.; Torres, E.A.; Da Rocha, G.O.; De Andrade, J.B. Carbonyl compounds emitted by a diesel engine fuelled with diesel and biodiesel–diesel blends: Sampling optimization and emissions profile. Atmos. Environ. 2008, 42, 8211–8218. [Google Scholar] [CrossRef]

- Krahl, J.; Munack, A.; Schröder, O.; Stein, H.; Bunger, J. Influence of Biodiesel and Different Designed Diesel Fuels on the Exhaust Gas. Emissions and Health Effects. SAE Trans. 2003, 112, 2447–2455. [Google Scholar]

- Takada, K.; Yoshimura, F.; Ohga, Y.; Kusaka, J.; Daisho, Y. Experimental Study on Unregulated Emission Characteristics of Tur-Bocharged DI Diesel Engine with Common Rail Fuel Injection System; SAE Technical Paper 2003-01-3158; SAE International: Warrendale, PA, USA, 2003. [Google Scholar] [CrossRef]

- Kuric, I.; Cisar, M.; Tlach, V.; Zajacko, I.; Gál, T.; Więcek, D. Technical diagnostics at the department of automation and production systems. In International Conference on Intelligent Systems in Production Engineering and Maintenance; Springer: Cham, Switzerland, 2019; Volume 835, pp. 474–484. [Google Scholar]

| Type | 4-Cylinders, Common-Rail Diesel |

|---|---|

| Compression ratio (CR) | 16.2:1 |

| Bore × stroke | 81 × 95.5 mm |

| Displacement | 1968 cm3 |

| Rated output | 110 kW |

| Engine speed | 3500–4000 rpm |

| Biodiesel | ULSD-F | |

|---|---|---|

| Density, 15 (kg·m−3) | 860 ÷ 920 | 820 ÷ 845 |

| Viscosity (40 °C) (mm2·s−1) | 3.8 ÷ 5.1 | 1.9 ÷ 4.1 |

| Cetane number | min 55 | min 47 |

| Sulphur content (mg·kg−1) | max 10 | max 10 |

| Heat of evaporation (kJ·kg−1) | 252 ÷ 295 | 285 ÷ 338 |

| Flash point (°C) | 103 | 82 |

| Carbon content (wt %) | 81.6 | 97.2 |

| Hydrogen content (wt %) | 12.4 | 13.4 |

| Oxygen content (wt %) | 10.5 | 0 |

| Mode | Engine Speed | Load (%) | Weight (%) | Duration (min) |

|---|---|---|---|---|

| 1 | Low idle | 0 | 15 | 4 |

| 2 | A | 100 | 8 | 2 |

| 3 | B | 50 | 10 | 2 |

| 4 | B | 75 | 10 | 2 |

| 5 | A | 50 | 5 | 2 |

| 6 | A | 75 | 5 | 2 |

| 7 | A | 25 | 5 | 2 |

| 8 | B | 100 | 9 | 2 |

| 9 | B | 25 | 10 | 2 |

| 10 | C | 100 | 8 | 2 |

| 11 | C | 25 | 5 | 2 |

| 12 | C | 75 | 5 | 2 |

| 13 | C | 50 | 5 | 2 |

| Mode | ULSD-F | B-U (25:75) | B-U (50:50) | B-U (75:25) | Biodiesel | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| FC (kg/h) | BTE (%) | FC (kg/h) | BTE (%) | FC (kg/h) | BTE (%) | FC (kg/h) | BTE (%) | FC (kg/h) | BTE (%) | |

| 1 | 0.68 | 0.70 | 0.73 | 0.77 | 0.85 | |||||

| 2 | 2.18 | 25.01 | 2.21 | 25.30 | 2.25 | 25.62 | 2.35 | 25.92 | 2.43 | 26.12 |

| 3 | 3.31 | 33.15 | 3.32 | 33.40 | 3.44 | 33.52 | 3.54 | 33.82 | 3.69 | 34.31 |

| 4 | 0.67 | 0.70 | 0.72 | 0.77 | 0.83 | |||||

| 5 | 3.64 | 23.31 | 3.70 | 23.51 | 3.81 | 23.52 | 3.98 | 23.69 | 4.14 | 23.83 |

| 6 | 5.49 | 31.04 | 5.56 | 31.25 | 5.70 | 31.43 | 5.92 | 31.73 | 6.15 | 31.92 |

| 7 | 8.02 | 27.22 | 8.25 | 27.32 | 8.37 | 27.62 | 8.37 | 27.62 | 9.02 | 28.01 |

| 8 | 11.00 | 30.19 | 11.18 | 30.38 | 11.36 | 30.48 | 11.36 | 30.48 | 12.18 | 31.05 |

| 9 | 7.62 | 33.61 | 7.79 | 33.87 | 7.92 | 34.00 | 7.92 | 34.00 | 7.97 | 34.93 |

| 10 | 9.73 | 35.13 | 9.89 | 35.33 | 10.11 | 35.52 | 10.11 | 35.52 | 10.87 | 36.12 |

| 11 | 11.21 | 34.24 | 11.38 | 34.20 | 11.72 | 34.19 | 11.72 | 34.19 | 12.60 | 34.78 |

| 12 | 14.78 | 29.95 | 14.91 | 30.19 | 15.24 | 30.29 | 15.24 | 30.29 | 16.41 | 30.79 |

| 13 | 2.18 | 9.52 | 2.31 | 9.34 | 2.46 | 9.14 | 2.46 | 9.14 | 2.65 | 9.32 |

| Mode | Fuel | Benzene (mg/kWh) | Toluene (mg/kWh) | Xylene (mg/kWh) |

|---|---|---|---|---|

| 5 | ULSD-F | 79.0 | 9.5 | 34.1 |

| B-U (25:75) | 83.8 | 8.2 | 27.0 | |

| B-U (50:50) | 88.2 | 6.7 | 22.7 | |

| B-U (75:25) | 91.5 | 5.4 | 20.2 | |

| Biodiesel | 95.1 | 4.3 | 8.5 | |

| 9 | ULSD-F | 43.2 | 3.6 | 12.8 |

| B-U (25:75) | 44.3 | 3.0 | 9.9 | |

| B-U (50:50) | 45.9 | 2.5 | 8.0 | |

| B-U (75:25) | 47.2 | 2.0 | 5.9 | |

| Biodiesel | 49.8 | 1.7 | 3.5 | |

| 11 | ULSD-F | 21.0 | 1.7 | 5.3 |

| B-U (25:75) | 22.1 | 1.5 | 4.2 | |

| B-U (50:50) | 22.5 | 1.4 | 3.1 | |

| B-U (75:25) | 23.4 | 1.2 | 2.5 | |

| Biodiesel | 25.2 | 1.0 | 1.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puškár, M.; Živčák, J.; Král, Š.; Kopas, M.; Lavčák, M. Analysis of Biodiesel Influence on Unregulated Gaseous Emissions of Diesel Motor Vehicles. Appl. Sci. 2021, 11, 4646. https://doi.org/10.3390/app11104646

Puškár M, Živčák J, Král Š, Kopas M, Lavčák M. Analysis of Biodiesel Influence on Unregulated Gaseous Emissions of Diesel Motor Vehicles. Applied Sciences. 2021; 11(10):4646. https://doi.org/10.3390/app11104646

Chicago/Turabian StylePuškár, Michal, Jozef Živčák, Štefan Král, Melichar Kopas, and Matúš Lavčák. 2021. "Analysis of Biodiesel Influence on Unregulated Gaseous Emissions of Diesel Motor Vehicles" Applied Sciences 11, no. 10: 4646. https://doi.org/10.3390/app11104646

APA StylePuškár, M., Živčák, J., Král, Š., Kopas, M., & Lavčák, M. (2021). Analysis of Biodiesel Influence on Unregulated Gaseous Emissions of Diesel Motor Vehicles. Applied Sciences, 11(10), 4646. https://doi.org/10.3390/app11104646