Analysis of Variance of Dissimilar Cu-Al Alloy Friction Stir Welded Joints with Different Offset Conditions

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

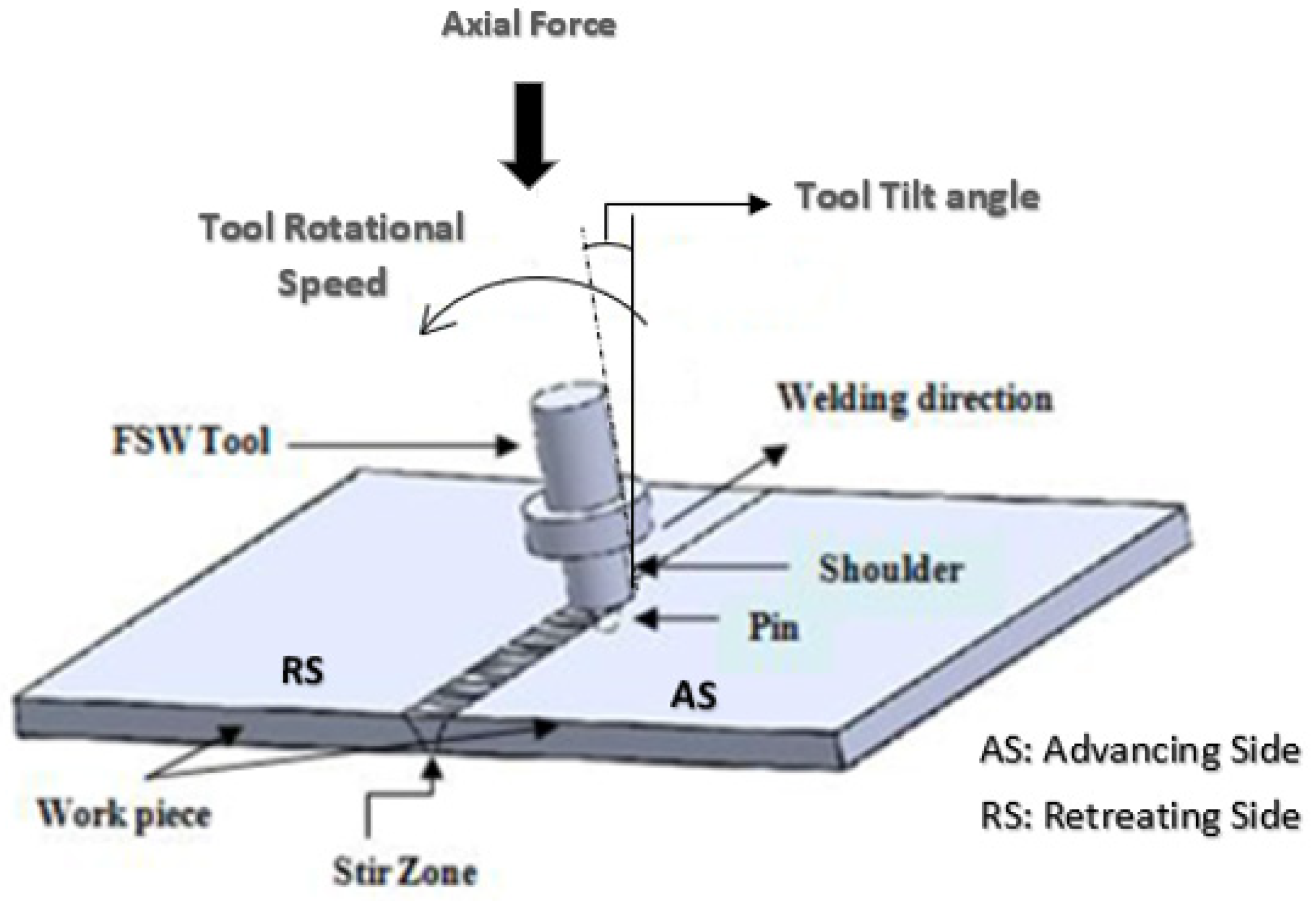

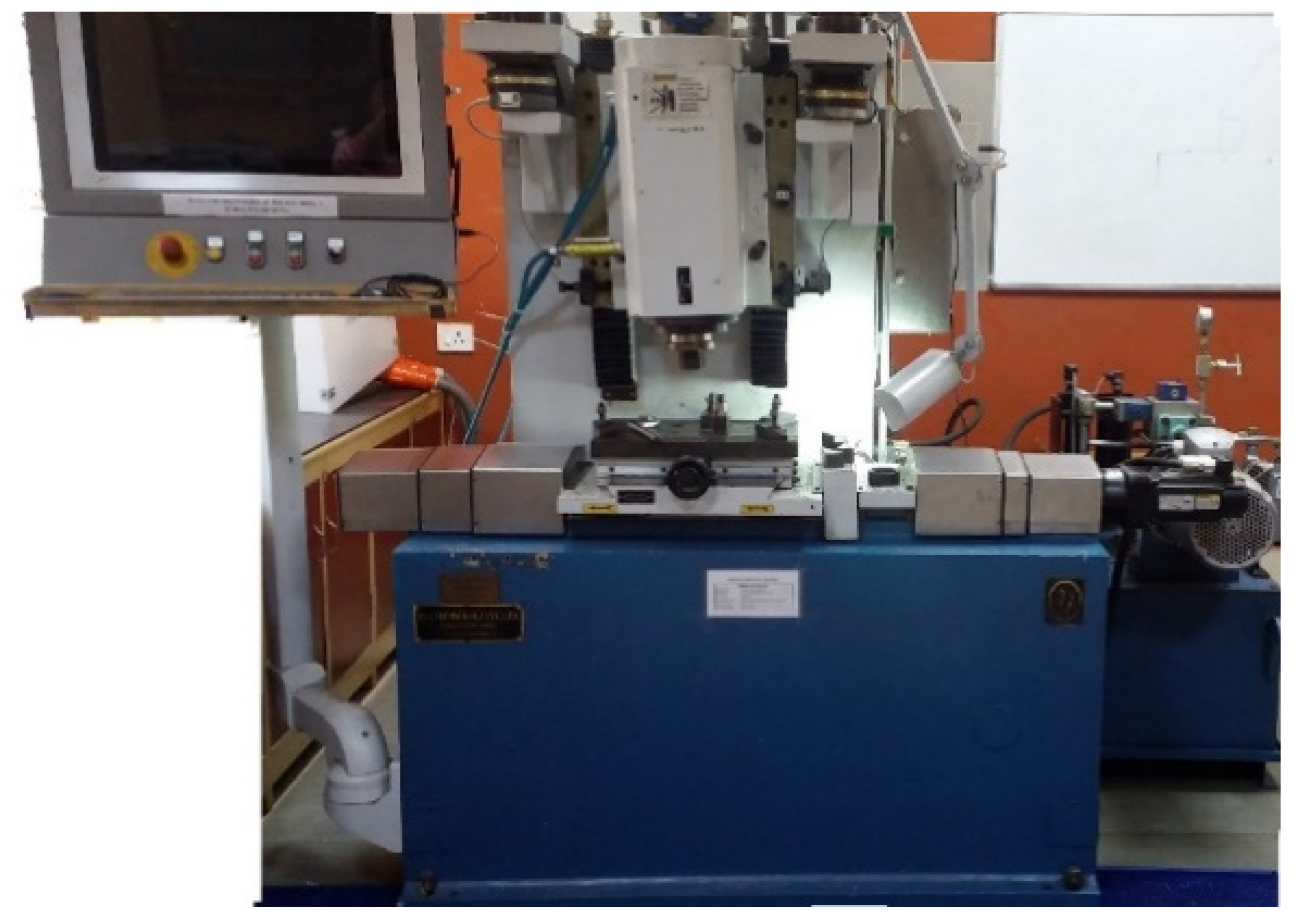

2.2. Experimental Set-Up

2.3. Experimental Design

2.4. Tensile Testing Machine and Specimens

3. Experimental Results

3.1. Experimental Data of Tensile Properties

3.2. Development of the Statistical Model

- (a)

- Yield strength (YS):YS = 72.0 + 0.0126 × Rotation Speed + 0.114 × Weld Speed

- (b)

- Ultimate tensile strength (UTS):UTS = 95.6 + 0.00808 × Rotation Speed + 0.0695 × Weld Speed

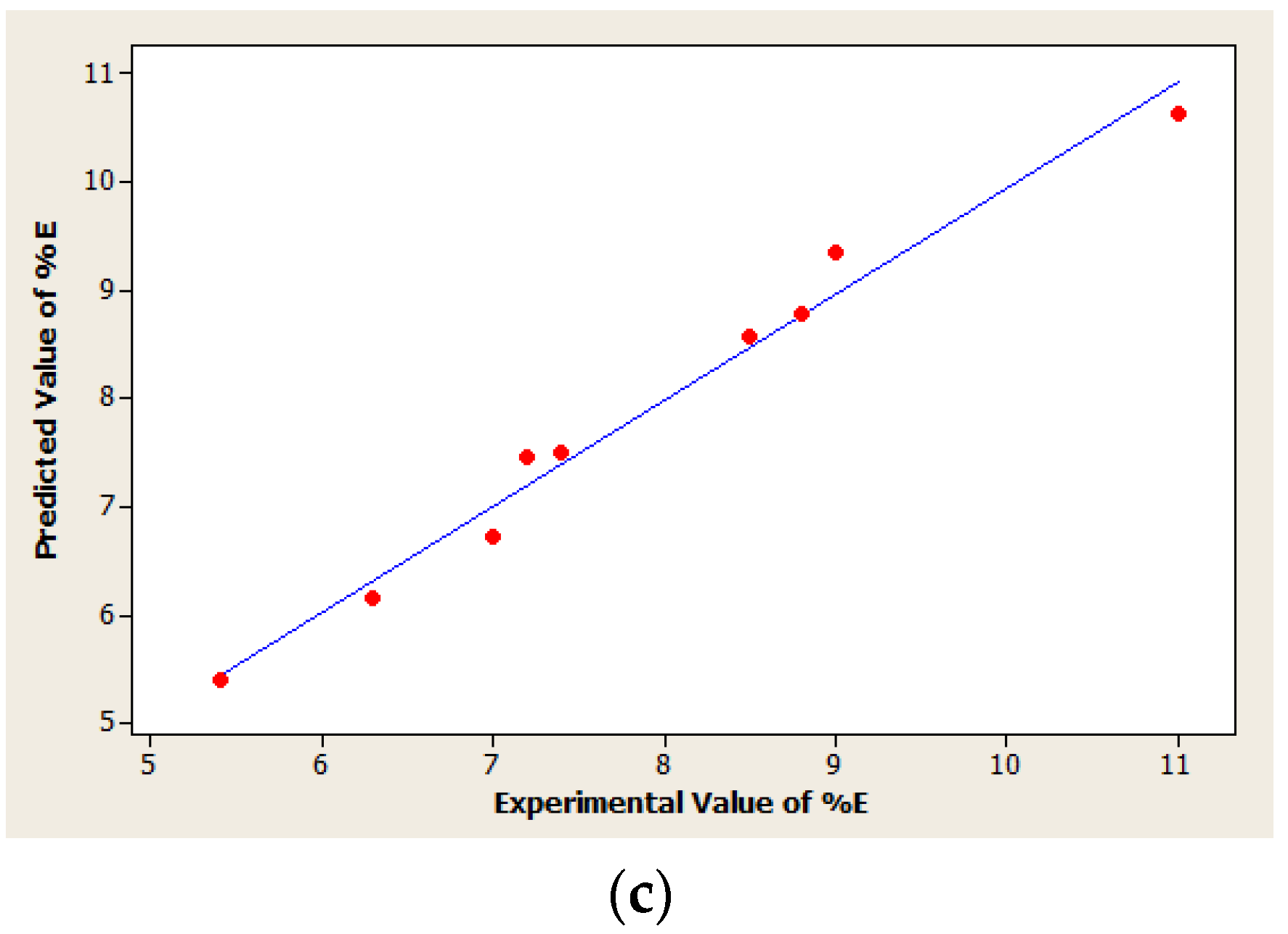

- (c)

- % Elongation (% E):% E = 0.819 + 0.00462 × Rotation Speed + 0.0515 × Weld Speed

4. Analyses

4.1. Testing Accuracy of Statistical Model

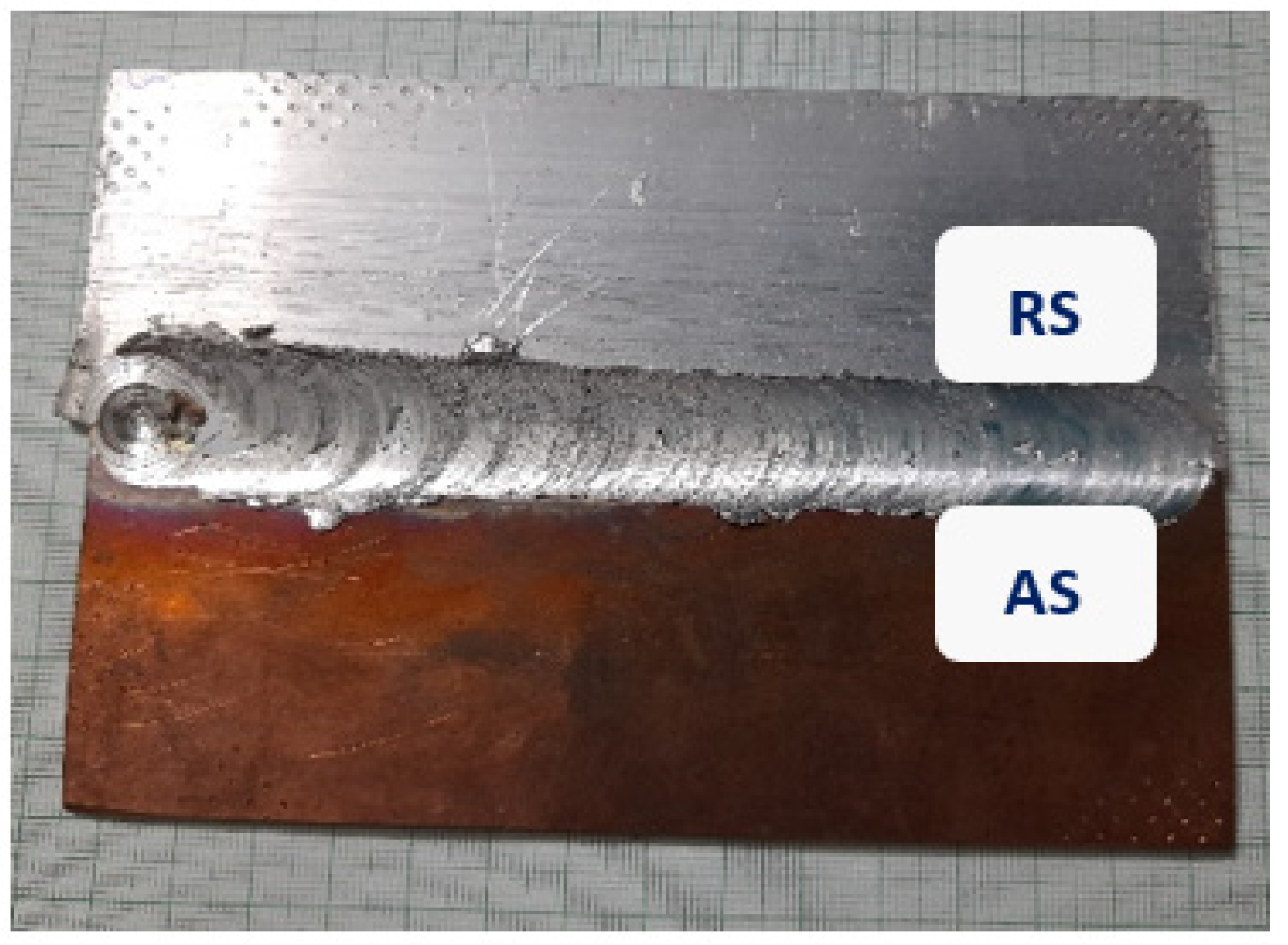

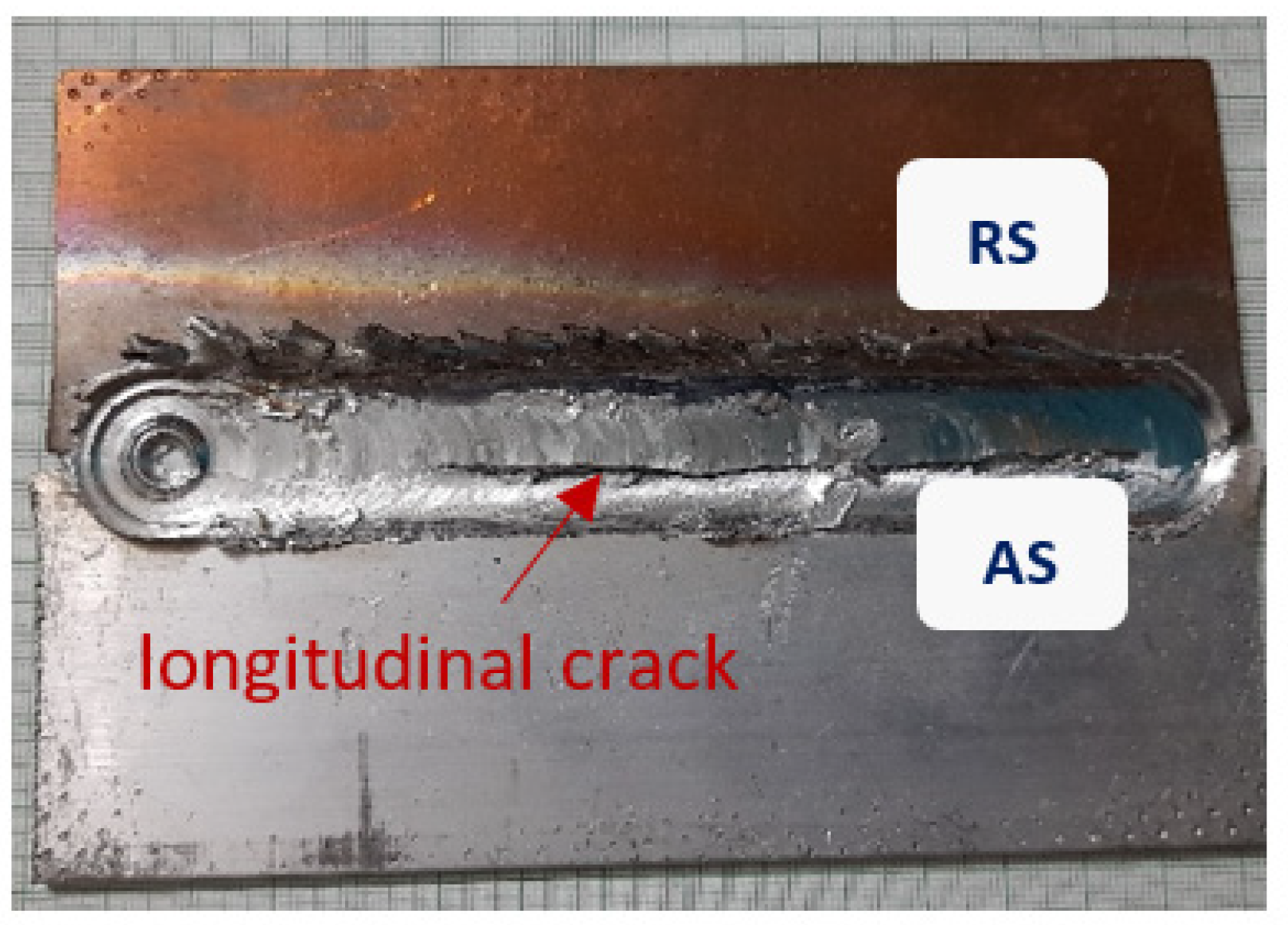

4.2. Analysis on Effect of Position of Fixed Base Plate

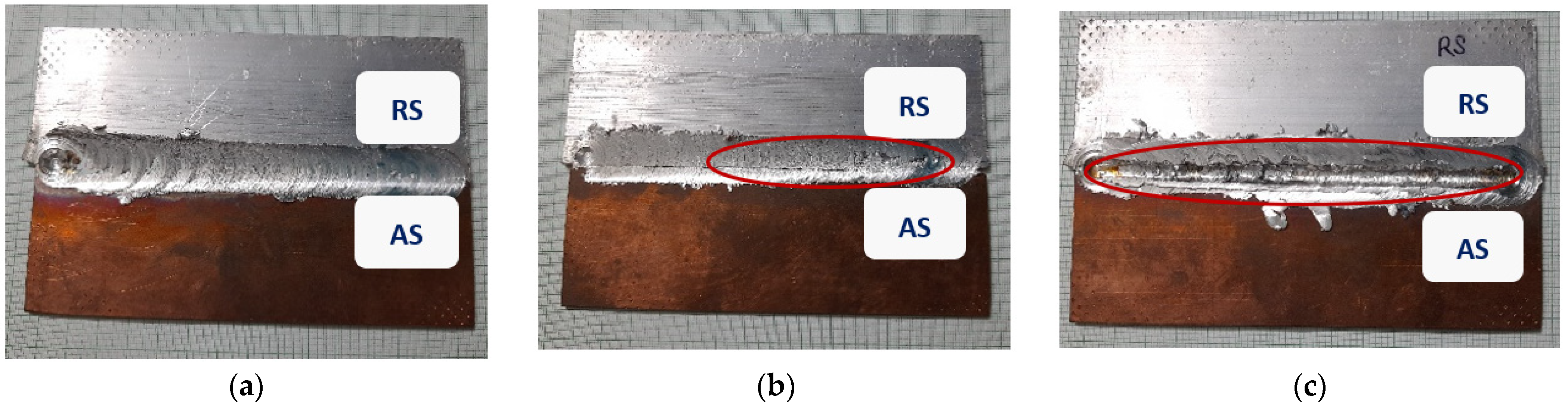

4.3. Analysis on Effect of Probe Offset

4.4. Analysis on Impacts of Welding Variables on Outcomes (YS, UTS and % E)

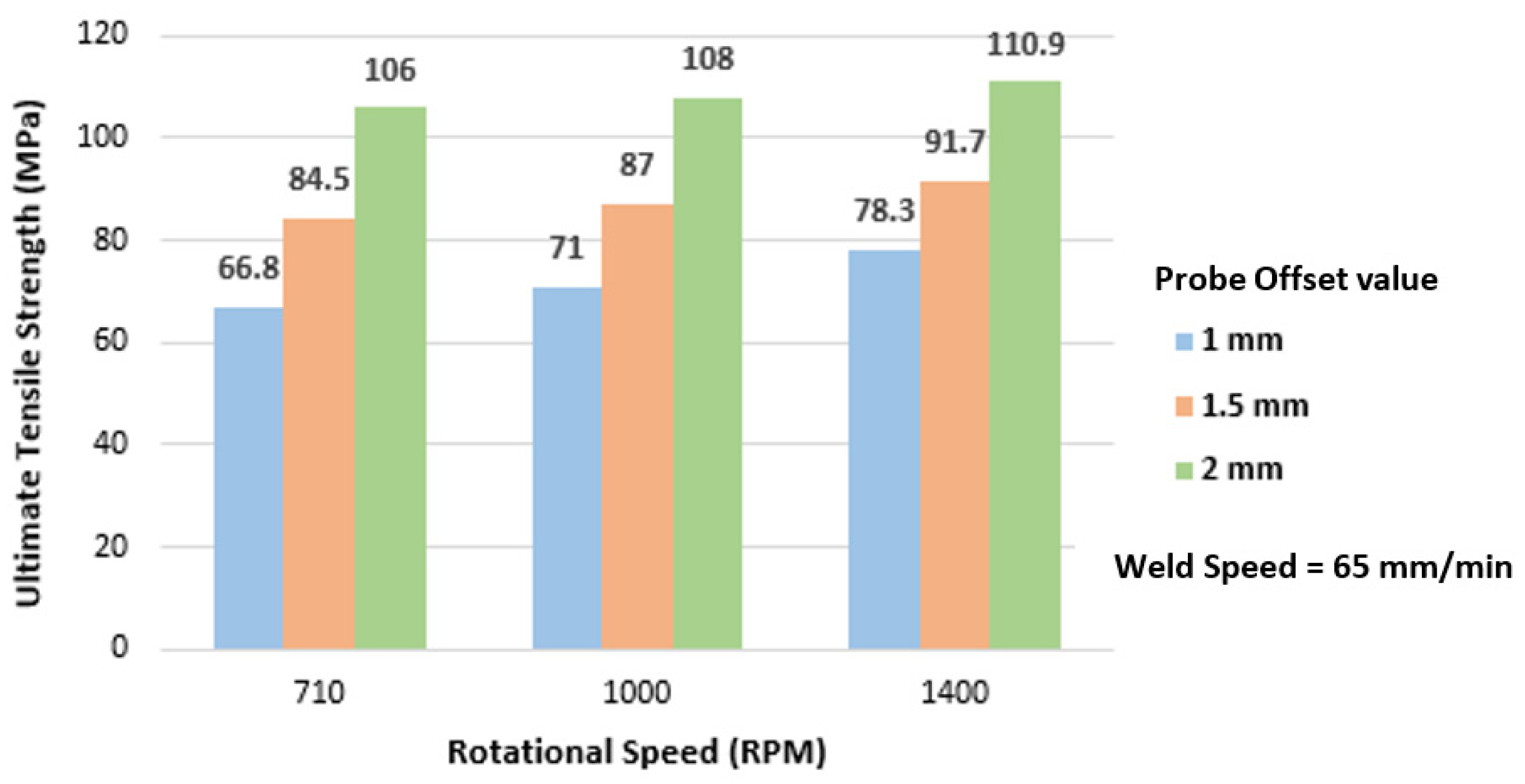

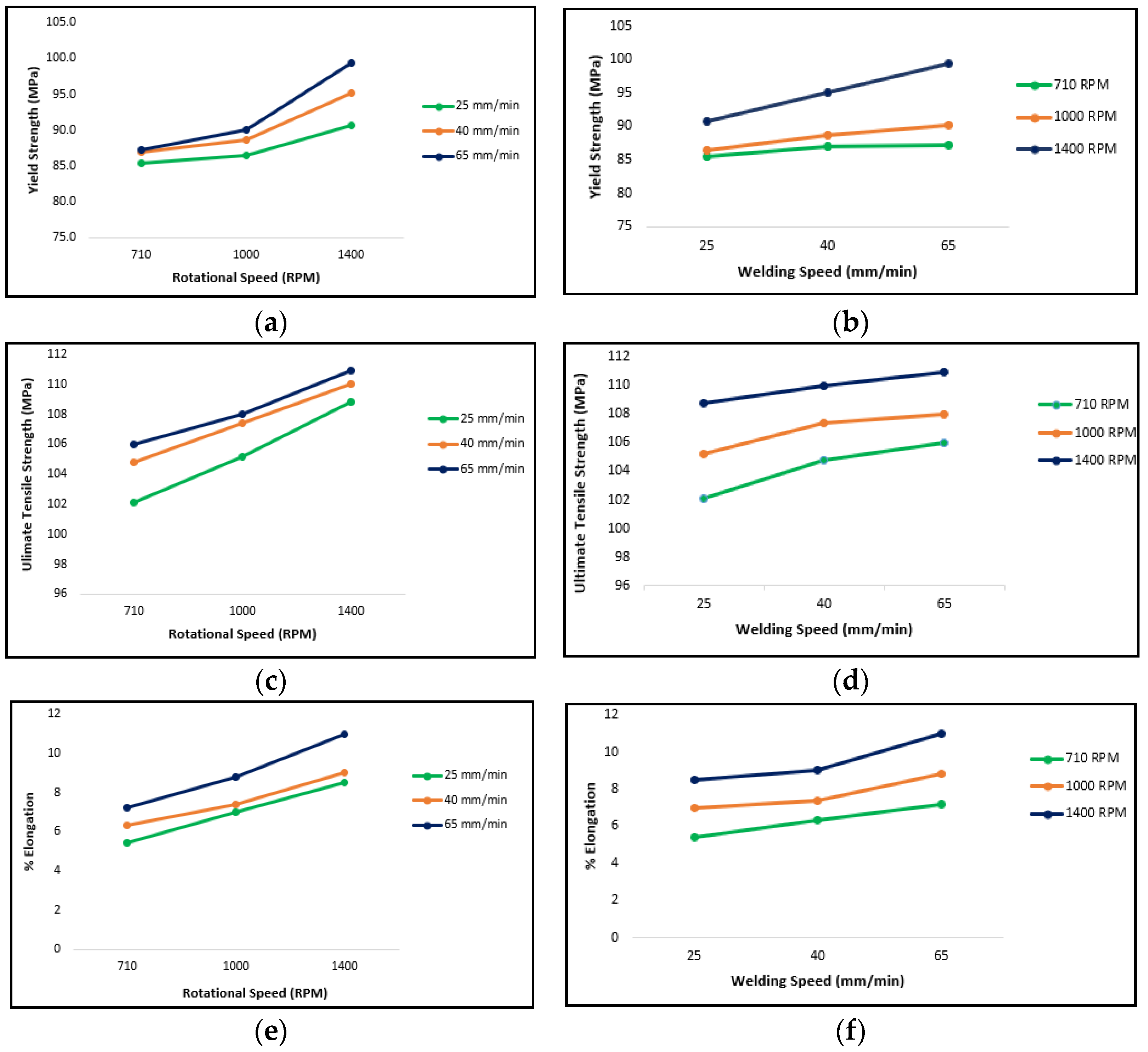

4.4.1. Impact of Probe Offset on Tensile Properties

4.4.2. Impact of Tool Rotation Speed and Weld Speed on YS, UTS and % E

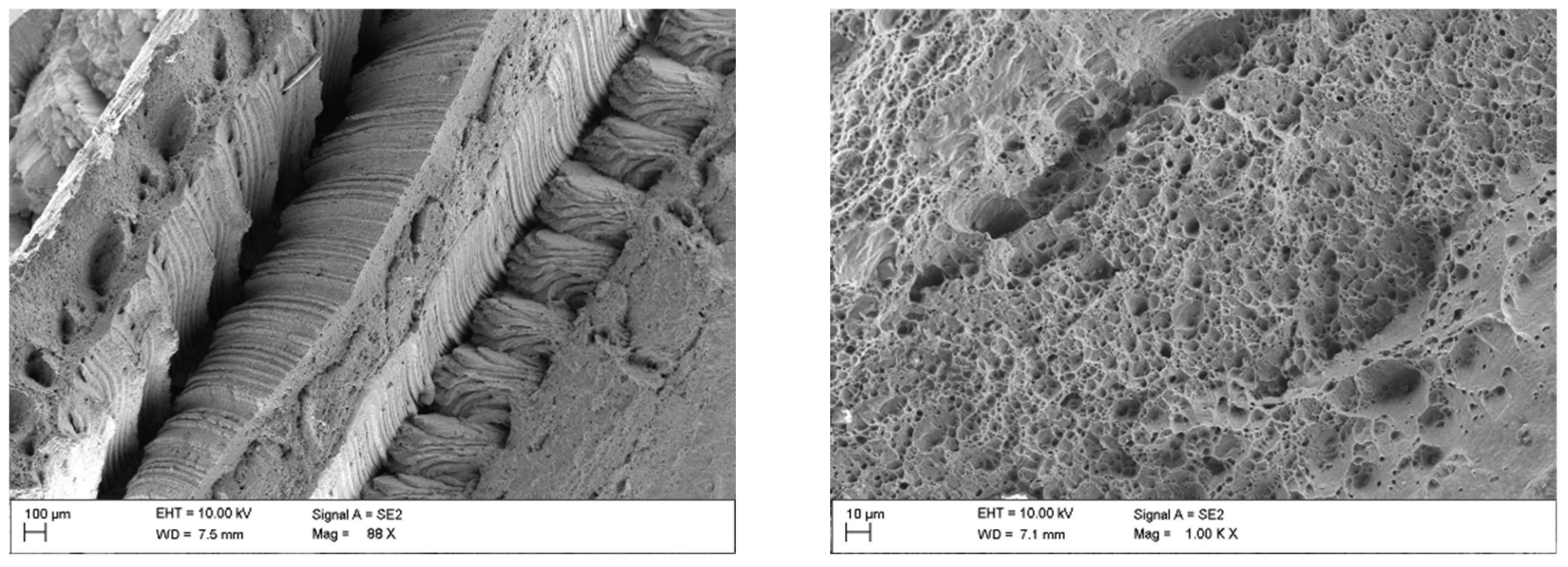

4.5. Analysis on Fracture Surface

5. Conclusions

- Dissimilar materials, AA 6061-T6 and Cu B370, were successfully joined using FSW at various tool rotation speeds, weld speeds, and probe offsets towards the softer material, Al, side.

- An excellent weld joint and surface was obtained at a probe offset of 2.0 mm towards the Al side and with the configuration of keeping the copper plate at the AS and the aluminum plate at the RS.

- From the F-test of ANOVA and from scatter diagrams, it can be concluded that the formulated statistical (mathematical) model is suitable enough to predict the output responses at a 95% confidence level.

- From the experimental investigations, it was observed that the maximum tensile properties were obtained at a higher tool rotation speed by keeping the weld speed constant. A similar behavior was observed at a higher weld speed by keeping the tool rotation speed constant.

- From SEM morphologies of the fracture surfaces, it can be noted that when the probe offset is 2.0 mm, the failure mode is ductile in nature and the tensile properties are at their maximum. However, the tensile strength decreased as the probe offset became less. For a probe offset of 1.0 mm, the failure mode was found to be brittle in nature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, N.; Khan, Z.A.; Siddiquee, A.N. Friction stir welding of aluminum to copper—An overview. Trans. Nonferrous Met. Soc. China 2017, 27, 2113–2136. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing Material. Processes and Systems, 7th ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2019; pp. 657–663. [Google Scholar]

- Bora, B.; Kumar, R.; Chattopadhyaya, S. Friction Stir Welding: A Green Technology for Welding Joints with Dissimilar Metals (Al Alloy-Cu Alloy). J. Indian Chem. Soc. 2020, 97. in press. [Google Scholar]

- Bora, B.; Chattopadhyaya, S.; Kumar, R. Development of mathematical model for friction stir welded joint using ‘R’ Programming. Mater. Today Proc. 2020, 27, 2142–2146. [Google Scholar] [CrossRef]

- Mubiayi, M.P.; Akinlabi, E.T. Friction Stir Welding of Dissimilar Materials between Aluminium Alloys and Copper—An Overview. In Proceedings of the World Congress on Engineering (WCE), London, UK, 3–5 July 2013; Volume 3. [Google Scholar]

- Prabhu, L.; Kumar, S.S. Tribological characteristics of FSW tool subjected to joining of dissimilar AA6061-T6 and Cu alloys. Mater. Today Proc. 2020, 33, 741–745. [Google Scholar] [CrossRef]

- Sahu, S.K.; Haldar, N.; Datta, S.; Kumar, R. Experimental studies on AA6063-Cu dissimilar friction stir welding using Inconel 601 tool. Mater. Today Proc. 2020, 26, 180–188. [Google Scholar] [CrossRef]

- Kadian, A.K.; Biswas, P. The study of material flow behaviour in dissimilar material FSW of AA6061and Cu-B370 alloys plates. J. Manuf. Process. 2018, 34, 96–105. [Google Scholar] [CrossRef]

- Khojastehnezhad, V.M.; Pourasl, H.H. Microstructural characterization and mechanical properties of aluminum 6061-T6 plates welded with copper insert plate (Al/Cu/Al) using friction stir welding. Trans. Nonferrous Met. Soc. China 2018, 28, 415–426. [Google Scholar] [CrossRef]

- Shankar, S.; Vilaça, P.; Dash, P.; Chattopadhyaya, S.; Hloch, S. Joint strength evaluation of friction stir welded Al-Cu dissimilar alloys. Measurement 2019, 146, 892–902. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 5th ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2000; pp. 11–20. [Google Scholar]

- Kumar, K.P.V.; Balasubramanian, M. Analyzing the Effect of FSW Process Parameter on Mechanical Properties for a Dissimilar Aluminium AA6061 and Magnesium AZ31B Alloy. Mater. Today Proc. 2020, 22, 2883–2889. [Google Scholar] [CrossRef]

- Prasad, M.V.R.D.; Namala, K.K. Process Parameters Optimization in Friction Stir Welding by ANOVA. Mater. Today Proc. 2018, 5, 4824–4831. [Google Scholar] [CrossRef]

- Pandya, S.N.; Menghani, J. Developments of Mathematical Models for Prediction of Tensile Properties of Dissimilar AA6061-T6 to Cu Welds Prepared by Friction Stir Welding Process Using Zn Interlayer. Indian Acad. Sci. 2018, 43, 43–168. [Google Scholar] [CrossRef]

- Reddy, R.; Tandle, A.; Srikanth, S.; Singh, R.; Kolli, R. Design and Analysis of Friction Stir Welding Using Dissimilar Alloys (AA 6061 and AA 6082) Aluminum Alloys. Int. Res. J. Eng. Technol. IRJET 2018, 5, 138–147. [Google Scholar]

- Xue, P.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Effect of friction stir welding parameters on the microstructure and mechanical properties of the dissimilar Al–Cu joints. Mater. Sci. Eng. 2011, 528, 4683–4689. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S.; Pal, S.K.; Jain, R. Influence of plate position, tool offset and tool rotational speed on mechanical properties and microstructures of dissimilar Al/Cu friction stir welding joints. J. Mater. Process. Technol. 2016, 235, 55–67. [Google Scholar] [CrossRef]

- Hou, W.; Shah, L.H.A.; Huang, G.; Shen, Y.; Gerlich, A. The role of tool offset on the microstructure and mechanical properties of Al/Cu friction stir welded joints. J. Alloy. Compd. 2020, 825, 154045. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, Q.; Liu, Q.; Xie, R.; Zhang, G.; Chen, G. Effects of tool tilt angle on the in-process heat transfer and mass transfer during friction stir welding. Int. J. Heat Mass Transf. 2018, 125, 32–42. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M. Effect of the Tool Tilt Angle on the Heat Generation and the Material Flow in Friction Stir Welding. Metals 2019, 9, 28. [Google Scholar] [CrossRef]

- Wu, D.; Li, W.Y.; Gao, Y.J.; Yang, J.; Su, Y.; Wen, Q.; Vairis, A. Effect of an improved pin design on weld formability and mechanical properties of adjustable-gap bobbin-tool friction stir welded Al-Cu aluminum alloy joints. J. Manuf. Process. 2020, 58, 1182–1188. [Google Scholar] [CrossRef]

- Tan, C.W.; Jiang, Z.G.; Li, L.Q.; Chen, Y.B.; Chen, X.Y. Microstructural evolution and mechanical properties of dissimilar Al–Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Muthu, M.F.X.; Jayabalan, V. Effect of pin profile and process parameters on microstructure and mechanical properties of friction stir welded Al−Cu joints. Trans. Nonferrous Met. Soc. China 2016, 26, 984–993. [Google Scholar] [CrossRef]

- Zhang, Q.; Gong, W.; Liu, W. Microstructure and mechanical properties of dissimilar Al−Cu joints by friction stir welding. Trans. Nonferrous Met. Soc. China 2015, 25, 1779–1786. [Google Scholar] [CrossRef]

- Sorger, G.; Wang, H.; Vilaça, P. FSW of aluminum AA5754 to steel DX54 with innovative overlap joint. Weld World 2017, 61, 257–268. [Google Scholar] [CrossRef]

- Lukács, J.; Meilinger, Á.; Pósalaky, D. High cycle fatigue and fatigue crack propagation design curves for 5754-H22 and 6082-T6 aluminium alloys and their friction stir welded joints. Weld World 2018, 62, 737–749. [Google Scholar] [CrossRef]

- Kumar, R.; Bora, B.; Chattopadhyaya, S.; Krolczyk, G.; Hloch, S. Experimental and mathematical evaluation of thermal and tensile properties of friction stir welded joint. Int. J. Mater. Prod. Technol. 2018, 57, 1–3. [Google Scholar] [CrossRef]

- Harry, M.J.; Mann, P.S.; de Hodgins, O.C.; Hulbret, R.L.; Lacke, C.J. The Practitioner’s Guide to Statistics and Lean Six Sigma For. Process. Improvement, 1st ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 507–522. [Google Scholar]

- Palanivel, R.; Mathews, P.K.; Murugan, N. Development of mathematical model to predict the mechanical properties of friction stir welded AA6351 aluminum alloy. J. Eng. Sci. Technol. 2011, 4, 25–31. [Google Scholar] [CrossRef]

- Singh, K.; Singh, G.; Singh, H. Investigation of microstructure and mechanical properties of friction stir welded AZ61 magnesium alloy joint. J. Magnes. Alloy. 2018, 6, 292–298. [Google Scholar] [CrossRef]

- Kumar, G.; Kumar, R.; Kumar, R. Optimization of process parameters of friction stir welded AA5082-AA7075 butt joints using resonance fatigue properties. Bull. Pol. Acad. Sci. Tech. Sci. 2020, 68, 99–108. [Google Scholar]

- Yang, J.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Friction stir welding of as-extruded Mg–Al–Zn alloy with higher Al content. Part I: Formation of banded and line. Mater. Charact. 2014, 96, 142–150. [Google Scholar] [CrossRef]

| (a) AA 6061-T6 | |||||||||

| Element | Mg | Si | Fe | Cu | Cr | Zn | Ti | Mn | Al |

| Composition (weight%) | 1.07 | 0.58 | 0.54 | 0.32 | 0.13 | 0.14 | 0.13 | 0.07 | 96.97 |

| (b) Cu B370 | |||||||||

| Element | Cu | Ag | |||||||

| Composition (weight%) | 99.7 | Balance | |||||||

| Mechanical Property | AA 6061-T6 | Cu B370 |

|---|---|---|

| Ultimate tensile strength | 310 MPa | 260 MPa |

| Yield strength | 276 MPa | 205 MPa |

| Modulus of elasticity | 68.9 GPa | 115 GPa |

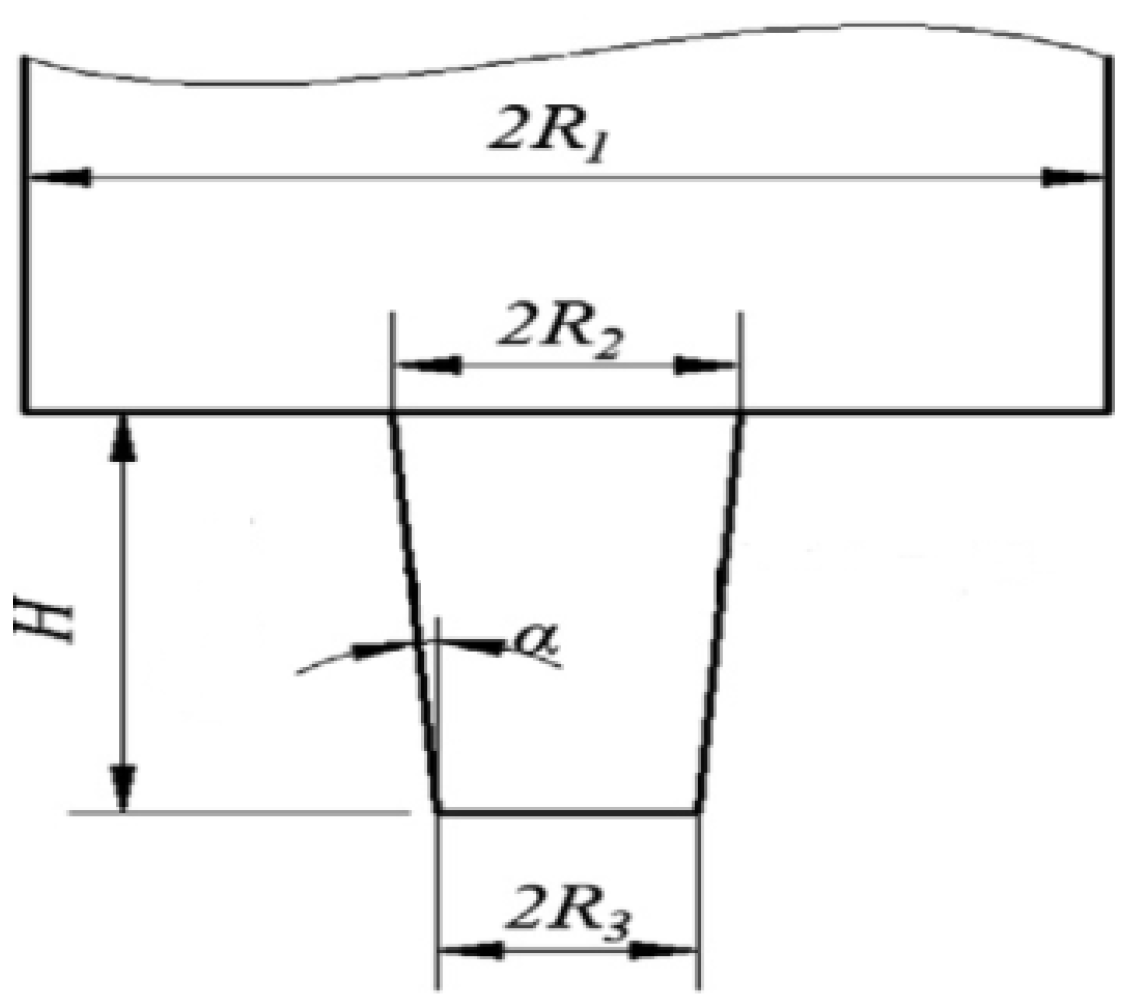

| Parameters | Value (mm) |

|---|---|

| Shank height | 70 |

| Shank diameter | 20 |

| Shoulder height | 30 |

| Shoulder diameter (2R1) | 25 mm |

| Pin top diameter (2R2) | 6 mm |

| Pin bottom diameter (2R3) | 4 mm |

| Pitch of threads | 0.1 |

| Height of pin (H) | 2.7 |

| Tool tilt angle (α) | 20.3° |

| Tool Rotation Speed (RPM) | Weld Speed (mm/min) | Probe Offset (mm) |

|---|---|---|

| 1400 | 65 | 1.0 |

| 1000 | 40 | 1.5 |

| 710 | 25 | 2.0 |

| Sample No. | Tool Rotation Sped (RPM) | Weld Speed (mm/min) |

|---|---|---|

| 1 | 1400 | 40 |

| 2 | 1000 | 40 |

| 3 | 710 | 40 |

| 4 | 1000 | 25 |

| 5 | 1400 | 25 |

| 6 | 1400 | 65 |

| 7 | 1000 | 65 |

| 8 | 710 | 25 |

| 9 | 710 | 65 |

| Sample No. | Tool Rotation Speed (RPM) | Weld Speed (mm/min) | YS (MPa) | UTS (MPa) | % E | Fracture Location |

|---|---|---|---|---|---|---|

| 6 | 1400 | 65 | 99.4 | 110.9 | 11 | SZ/TMAZ |

| 1 | 1400 | 40 | 95.1 | 110 | 9 | SZ/TMAZ |

| 5 | 1400 | 25 | 90.7 | 108.8 | 8.5 | SZ/TMAZ |

| 7 | 1000 | 65 | 90.1 | 108 | 8.8 | SZ/TMAZ |

| 2 | 1000 | 40 | 88.7 | 107.4 | 7.4 | HAZ |

| 4 | 1000 | 25 | 86.5 | 105.2 | 7 | HAZ |

| 9 | 710 | 65 | 87.2 | 106 | 7.2 | HAZ |

| 3 | 710 | 40 | 87 | 104.8 | 6.3 | HAZ |

| 8 | 710 | 25 | 85.4 | 102.1 | 5.4 | HAZ |

| Outcomes | DF | SS | MS | Calculated F Value | Tabulated F Value | Remarks | |||

|---|---|---|---|---|---|---|---|---|---|

| Regression | Residual | Regression | Residual | Regression | Residual | ||||

| YS | 2 | 6 | 146.371 | 20.438 | 73.185 | 73.185 | 21.48 | 5.14 | Adequate |

| UTS | 2 | 6 | 58.901 | 2.794 | 29.451 | 0.466 | 63.23 | 5.14 | Adequate |

| % E | 2 | 6 | 21.897 | 0.425 | 10.949 | 0.071 | 154.56 | 5.14 | Adequate |

| I For YS (MPa) | |||||

| Source | DF | SS | MS | F | P |

| Tool Rotation Speed | 2 | 120.429 | 60.2144 | 18.60 | 0.009 |

| Weld Speed | 2 | 33.429 | 16.7144 | 5.16 | 0.078 |

| Error | 4 | 12.951 | 3.2378 | ||

| Total | 8 | 166.809 | |||

| S = 1.799; R-Sq = 92.24%; R-Sq (adj) = 84.47% | |||||

| II For UTS (MPa) | |||||

| Source | DF | SS | MS | F | P |

| Tool Rotation Speed | 2 | 47.1489 | 23.5744 | 94.51 | 0.000 |

| Weld Speed | 2 | 13.5489 | 6.7744 | 27.16 | 0.005 |

| Error | 4 | 0.9978 | 0.2494 | ||

| Total | 8 | 61.6956 | |||

| S = 0.4994; R-Sq = 98.38%; R-Sq (adj) = 96.77% | |||||

| III For % Elongation | |||||

| Source | DF | SS | MS | F | P |

| Tool Rotation Speed | 2 | 15.4156 | 7.70778 | 86.17 | 0.001 |

| Weld Speed | 2 | 6.5489 | 3.27444 | 36.61 | 0.003 |

| Error | 4 | 0.3578 | 0.08944 | ||

| Total | 8 | 22.3222 | |||

| S = 0.2991; R-Sq = 98.40%; R-Sq (adj) = 96.79% | |||||

| Welding Variables | Values | Impact on Mechanical Properties |

|---|---|---|

| Tool probe offset (mm) (at constant tool rotational speed and weld speed) | 1.0 |  |

| 1.5 |  | |

| 2.0 |  | |

| Tool rotational speed (RPM) (at constant weld speed and tool probe offset) | 710 |  |

| 1000 |  | |

| 1400 |  | |

| Weld speed (mm/min) (at constant tool rotational speed and tool probe offset) | 25 |  |

| 40 |  | |

| 65 |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bora, B.; Kumar, R.; Chattopadhyaya, S.; Borucki, S. Analysis of Variance of Dissimilar Cu-Al Alloy Friction Stir Welded Joints with Different Offset Conditions. Appl. Sci. 2021, 11, 4604. https://doi.org/10.3390/app11104604

Bora B, Kumar R, Chattopadhyaya S, Borucki S. Analysis of Variance of Dissimilar Cu-Al Alloy Friction Stir Welded Joints with Different Offset Conditions. Applied Sciences. 2021; 11(10):4604. https://doi.org/10.3390/app11104604

Chicago/Turabian StyleBora, Bhabani, Ratnesh Kumar, Somnath Chattopadhyaya, and Sebastian Borucki. 2021. "Analysis of Variance of Dissimilar Cu-Al Alloy Friction Stir Welded Joints with Different Offset Conditions" Applied Sciences 11, no. 10: 4604. https://doi.org/10.3390/app11104604

APA StyleBora, B., Kumar, R., Chattopadhyaya, S., & Borucki, S. (2021). Analysis of Variance of Dissimilar Cu-Al Alloy Friction Stir Welded Joints with Different Offset Conditions. Applied Sciences, 11(10), 4604. https://doi.org/10.3390/app11104604