Mode Shape-Based Damage Detection Method (MSDI): Experimental Validation

Abstract

1. Introduction

2. Materials and Methods

2.1. The Mode Shape Damage Index (MSDI)

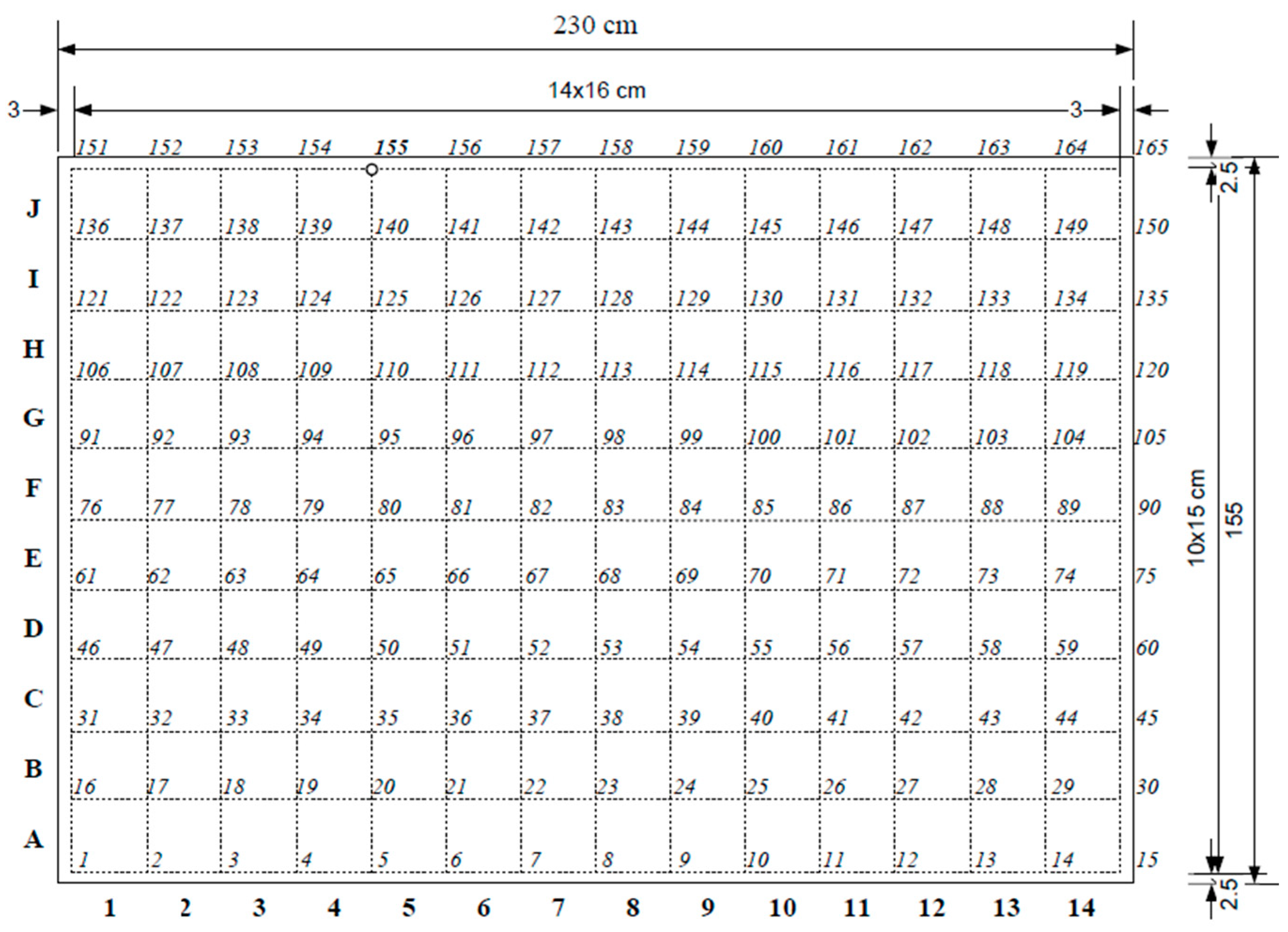

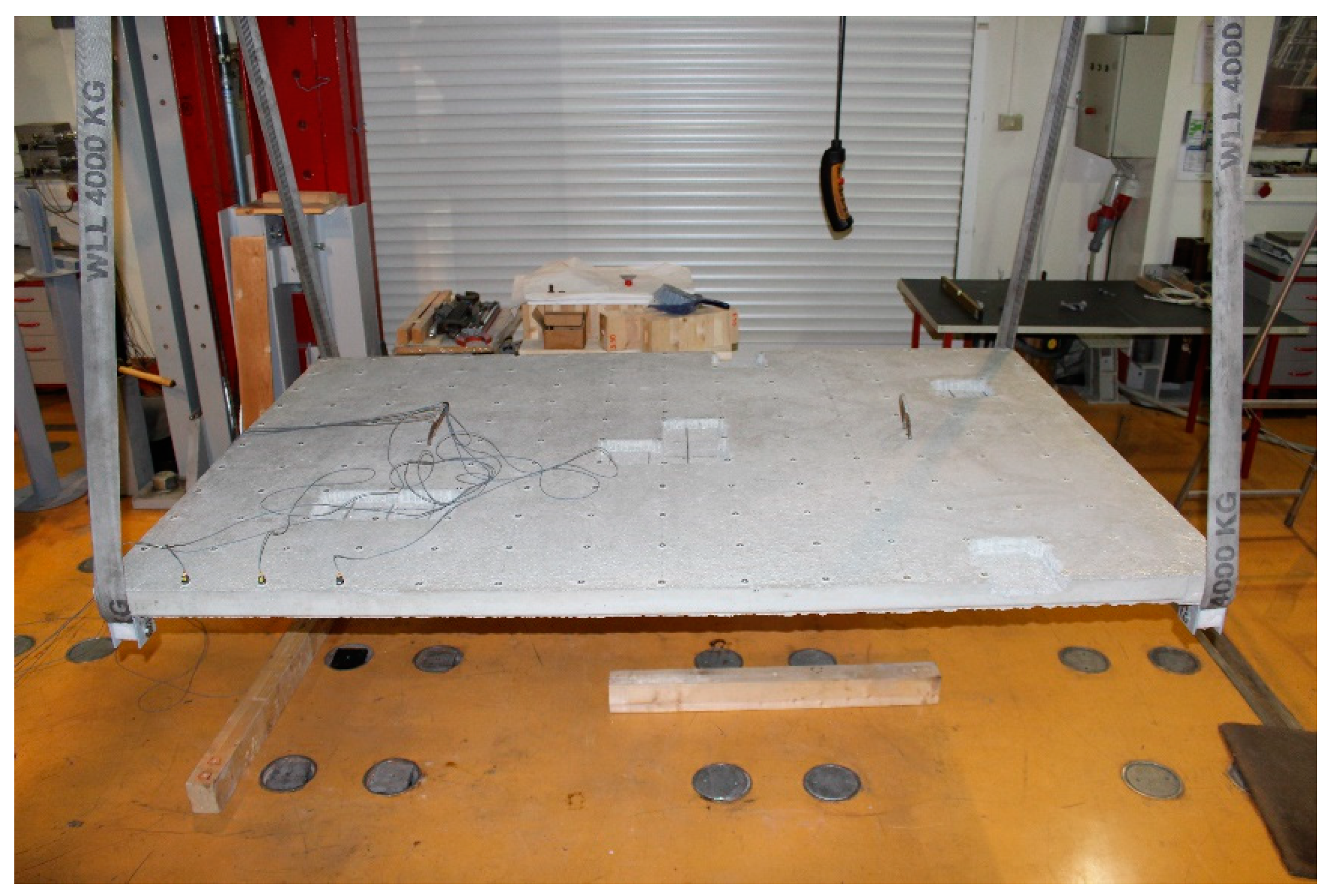

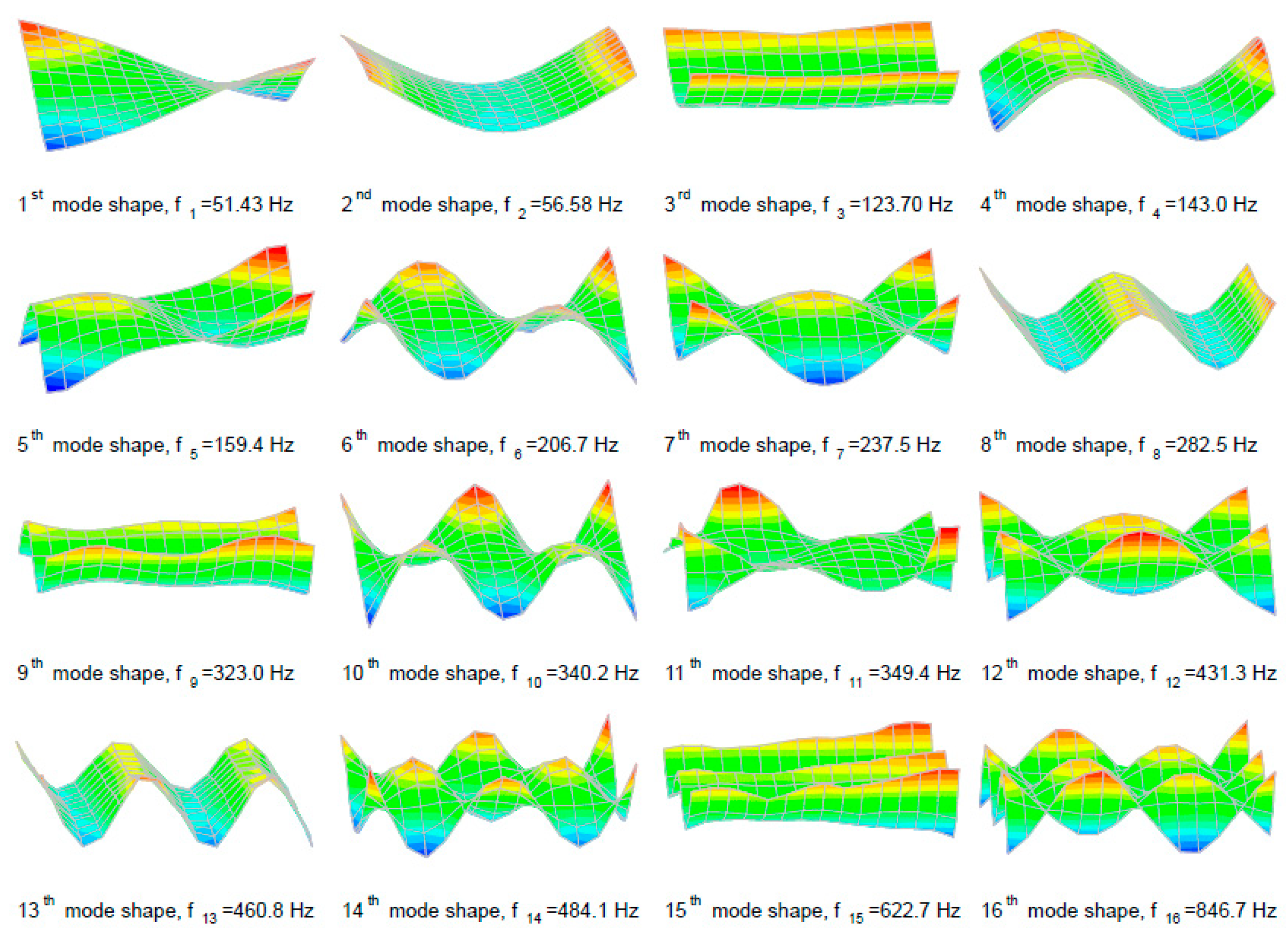

2.2. Dynamic Testing of the Plate Model

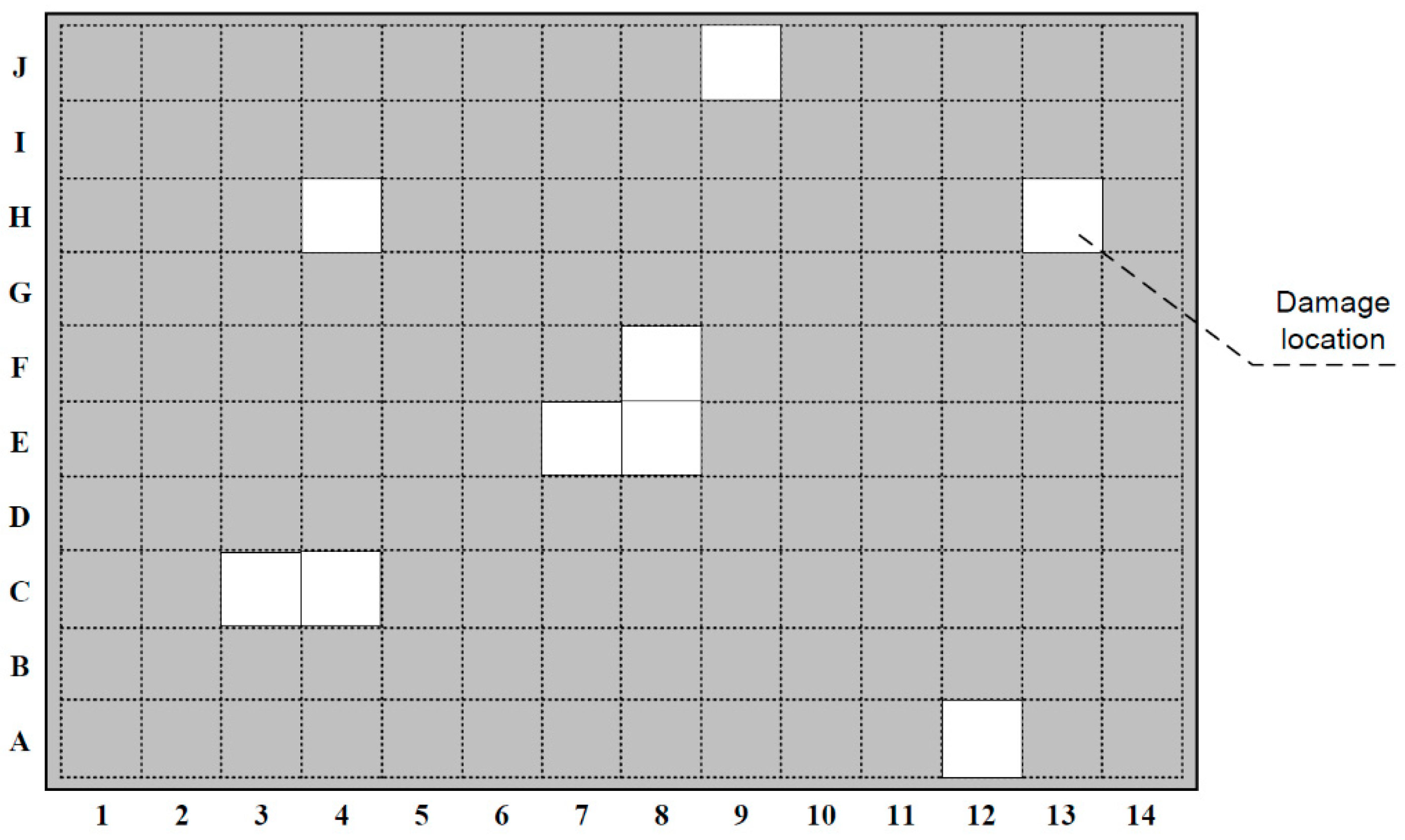

Simulation of Discrete Damages

3. Results and Discussion

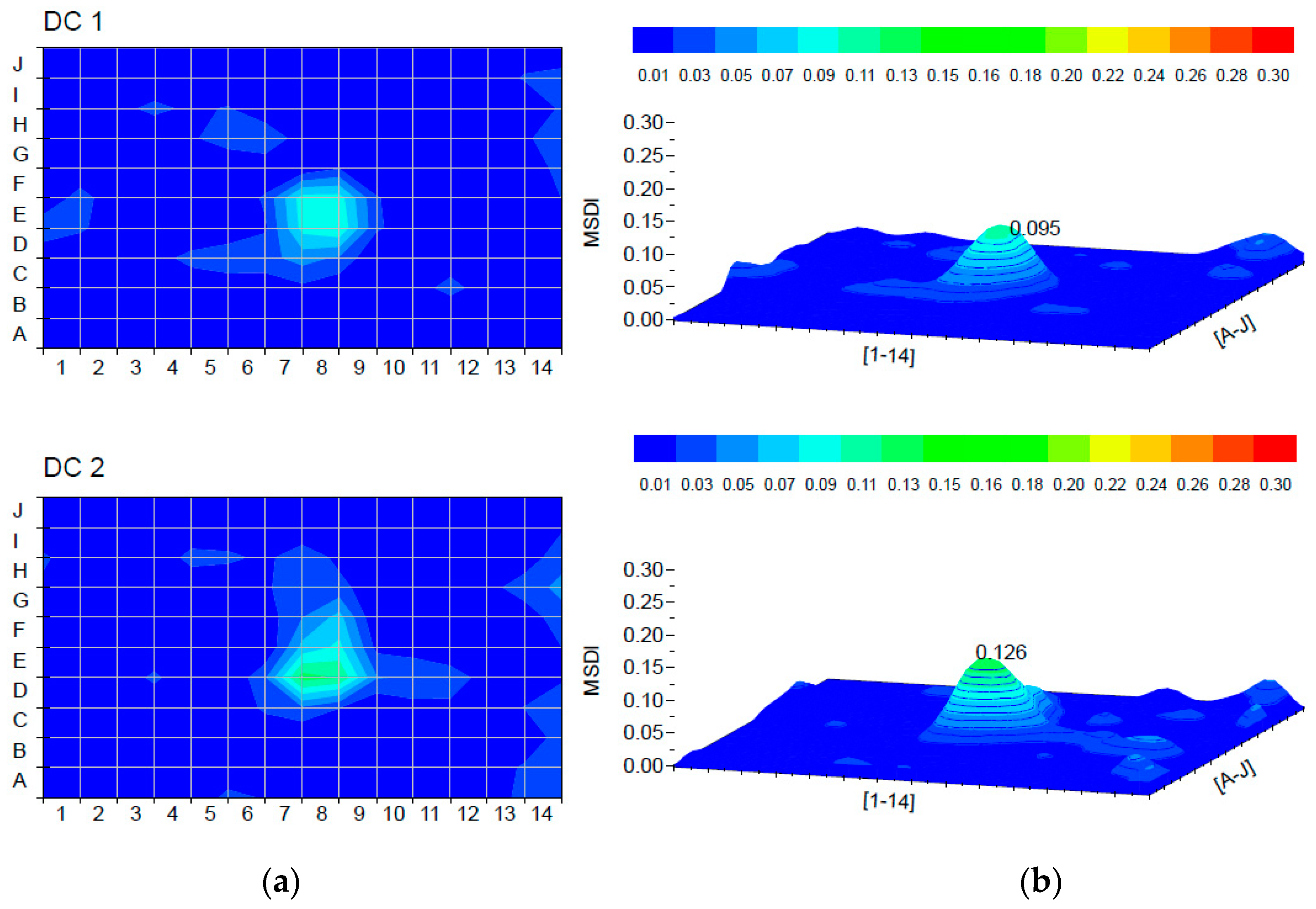

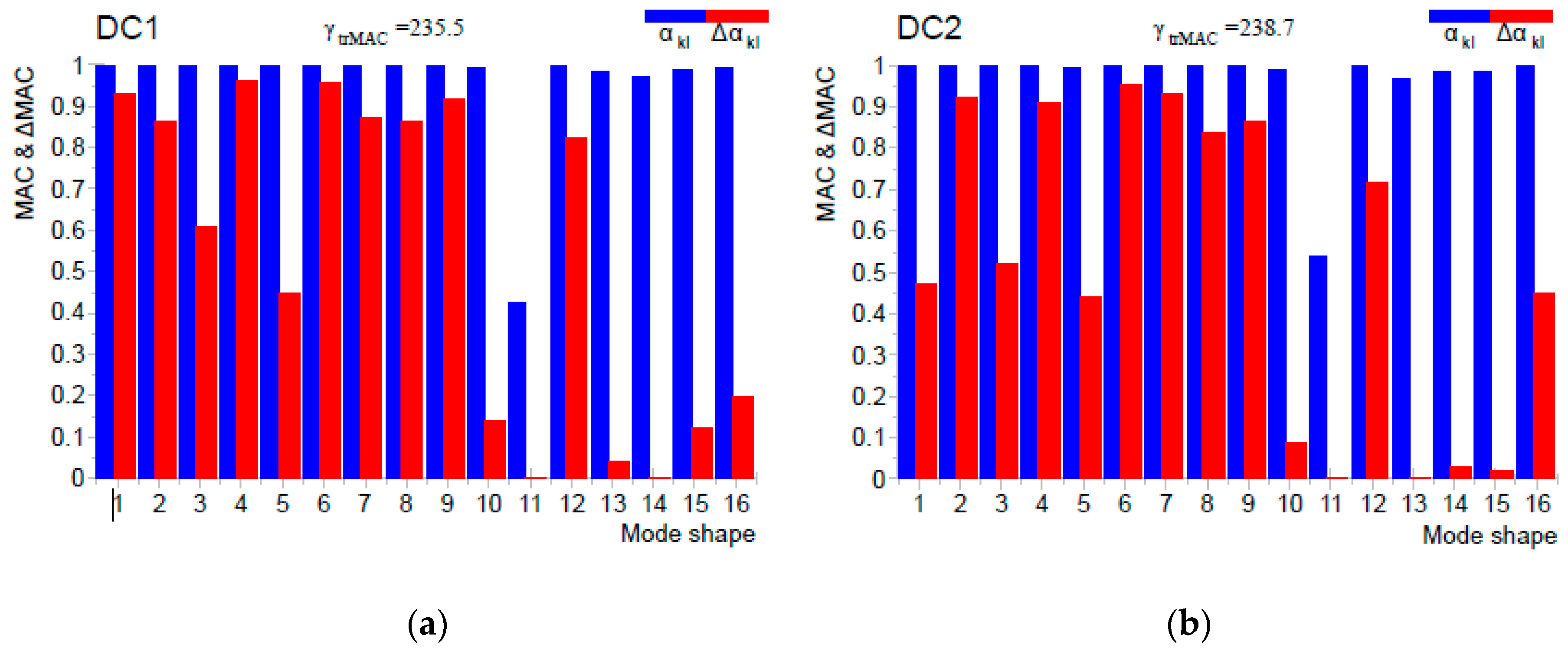

3.1. Effect of Damage Level at a Single Damage Location

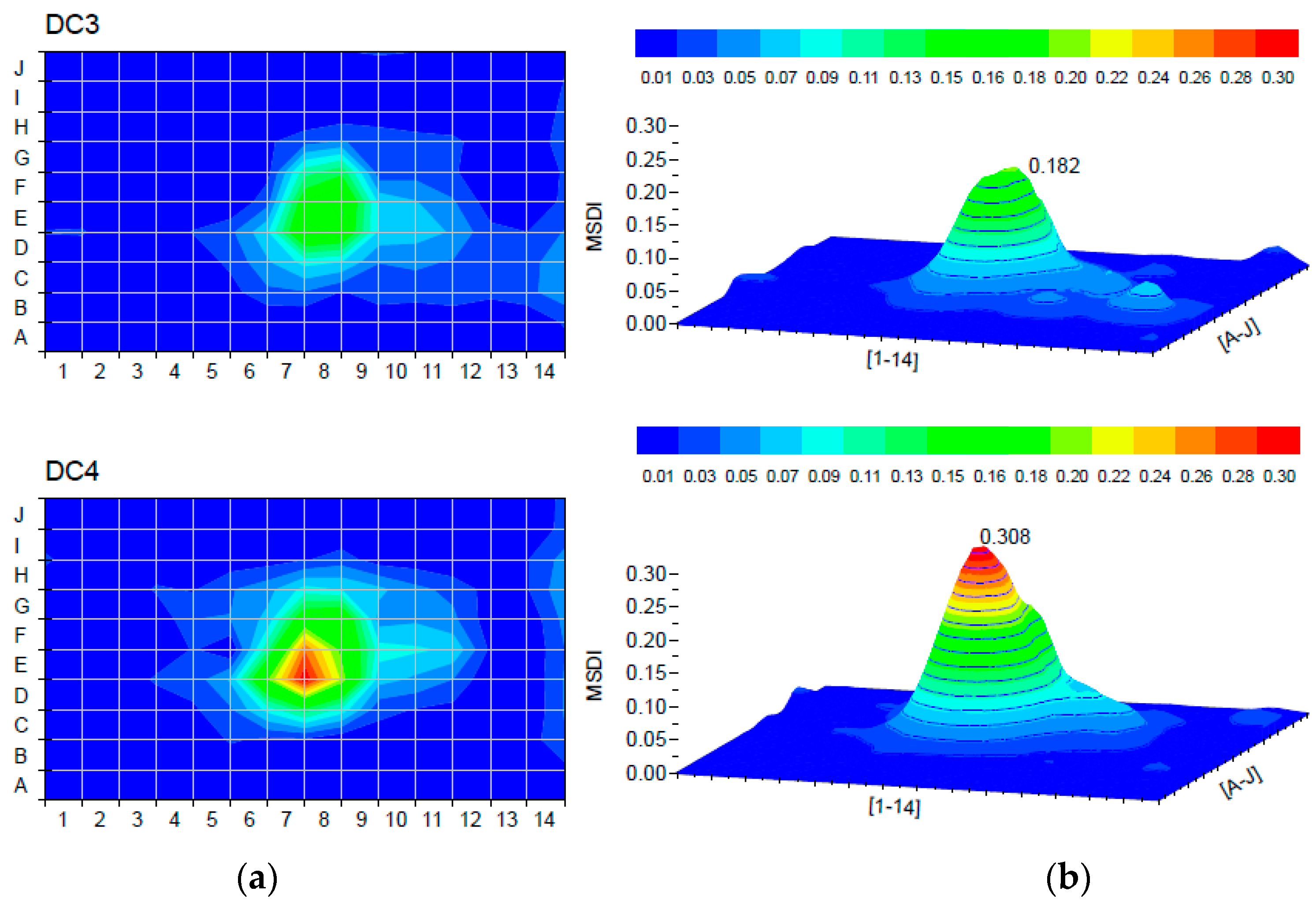

3.2. Effect of Damage Zone Size

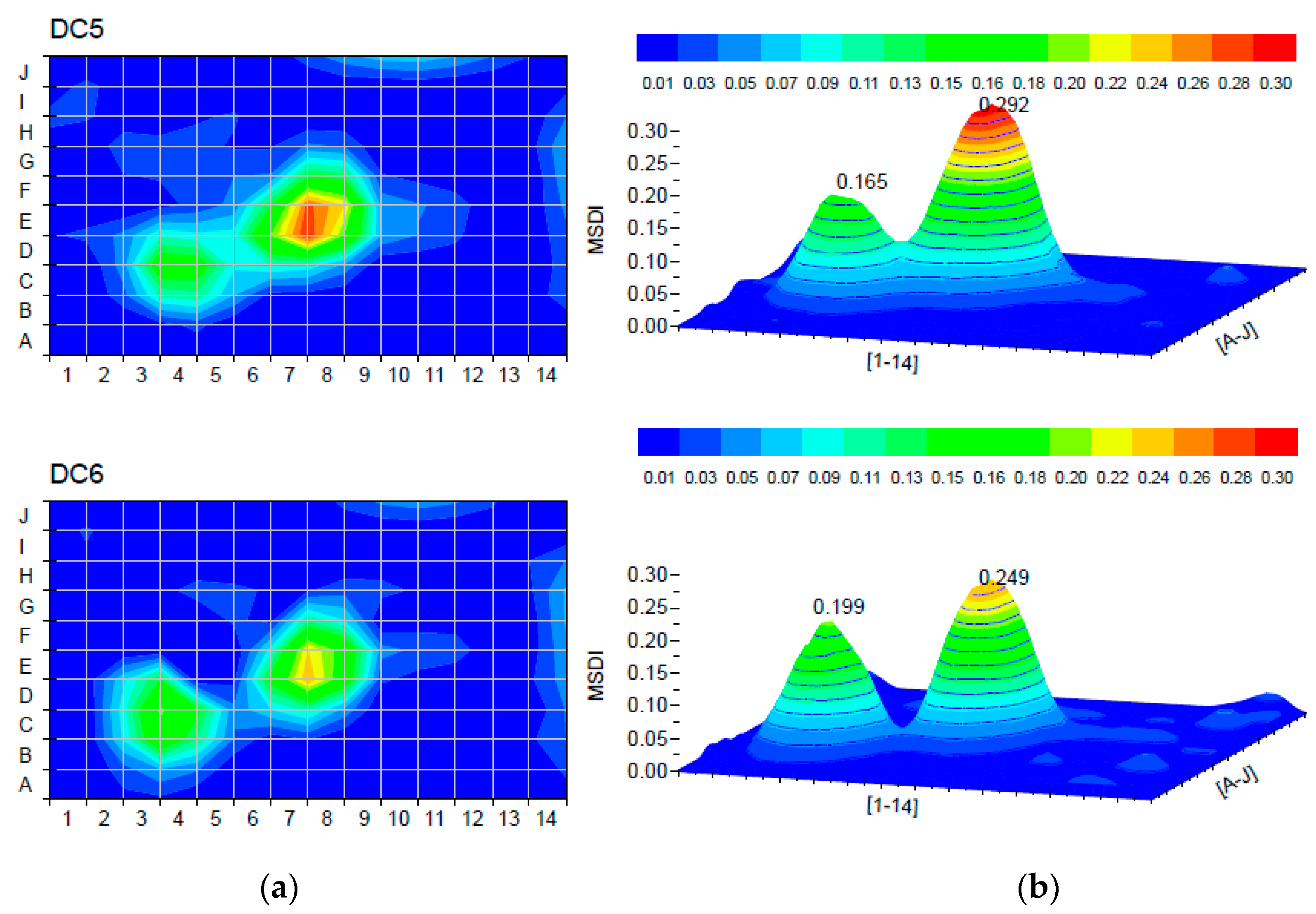

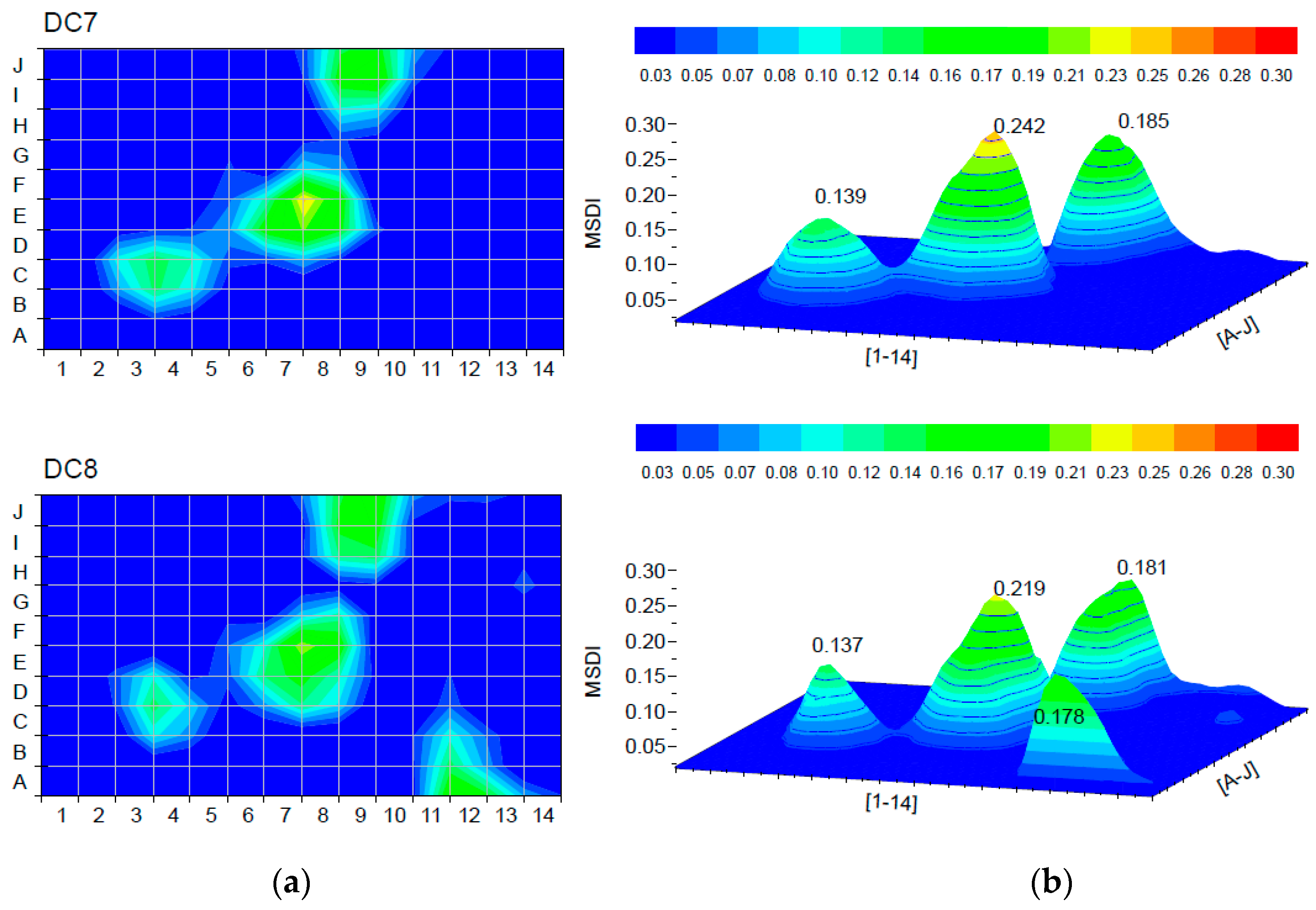

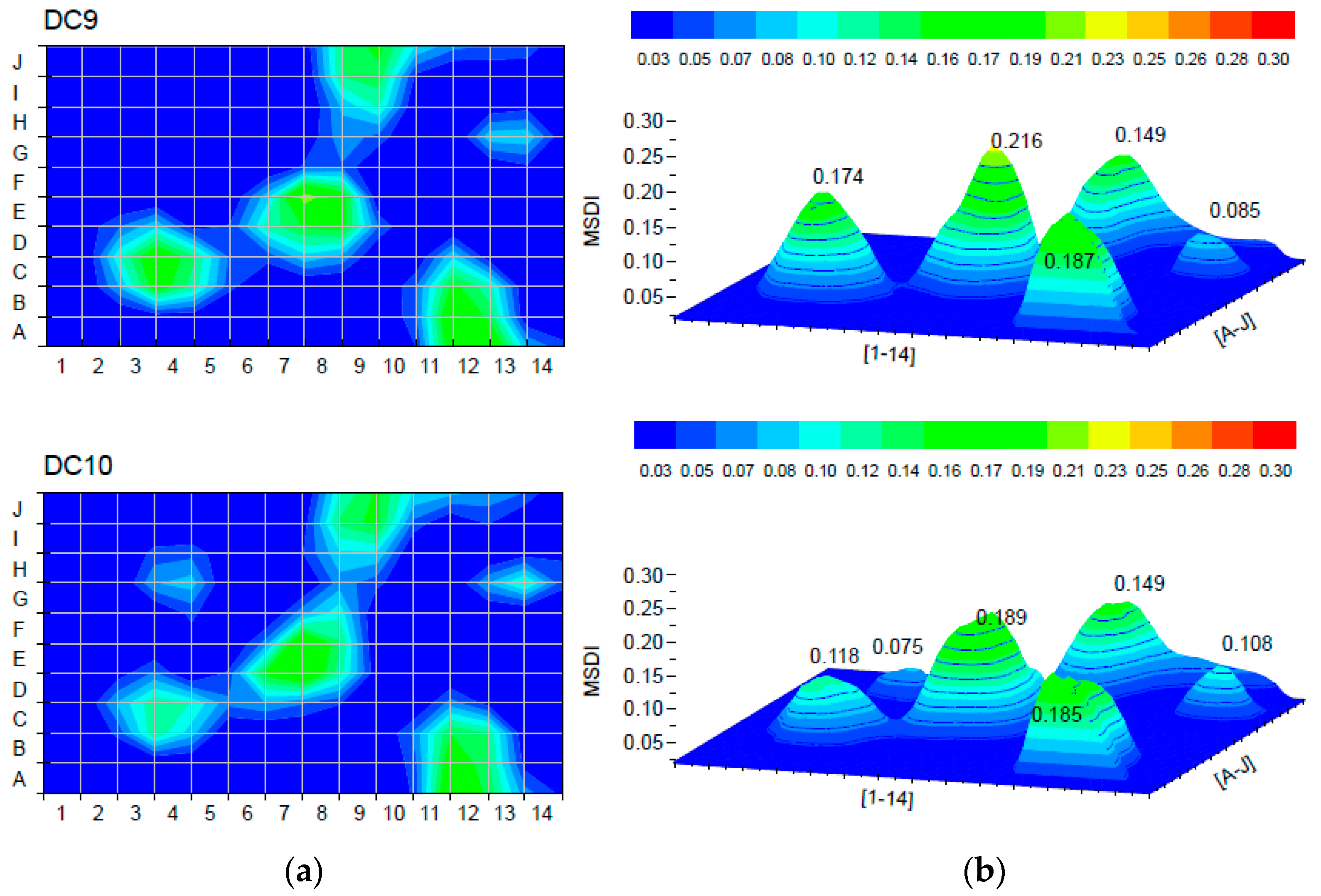

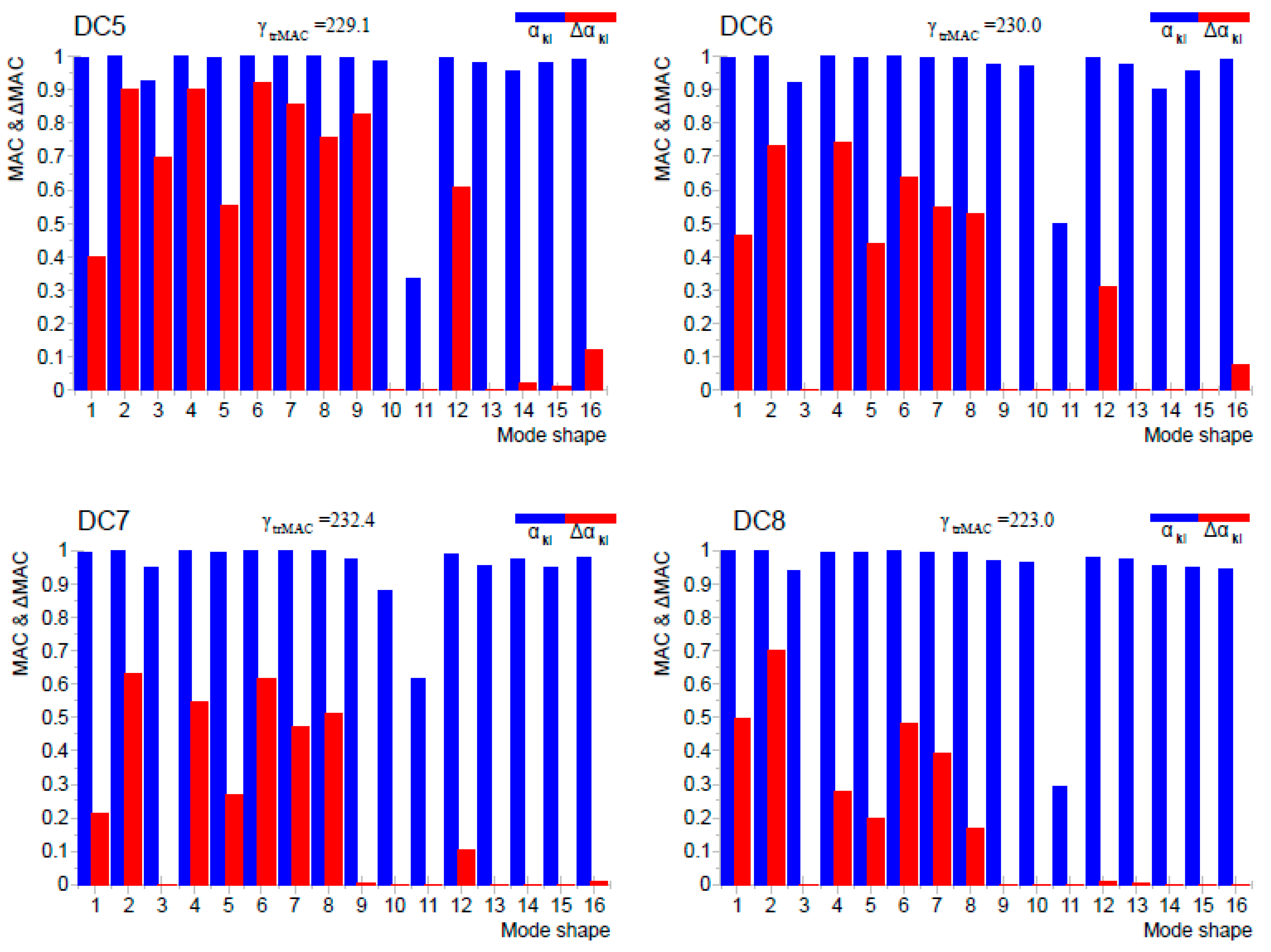

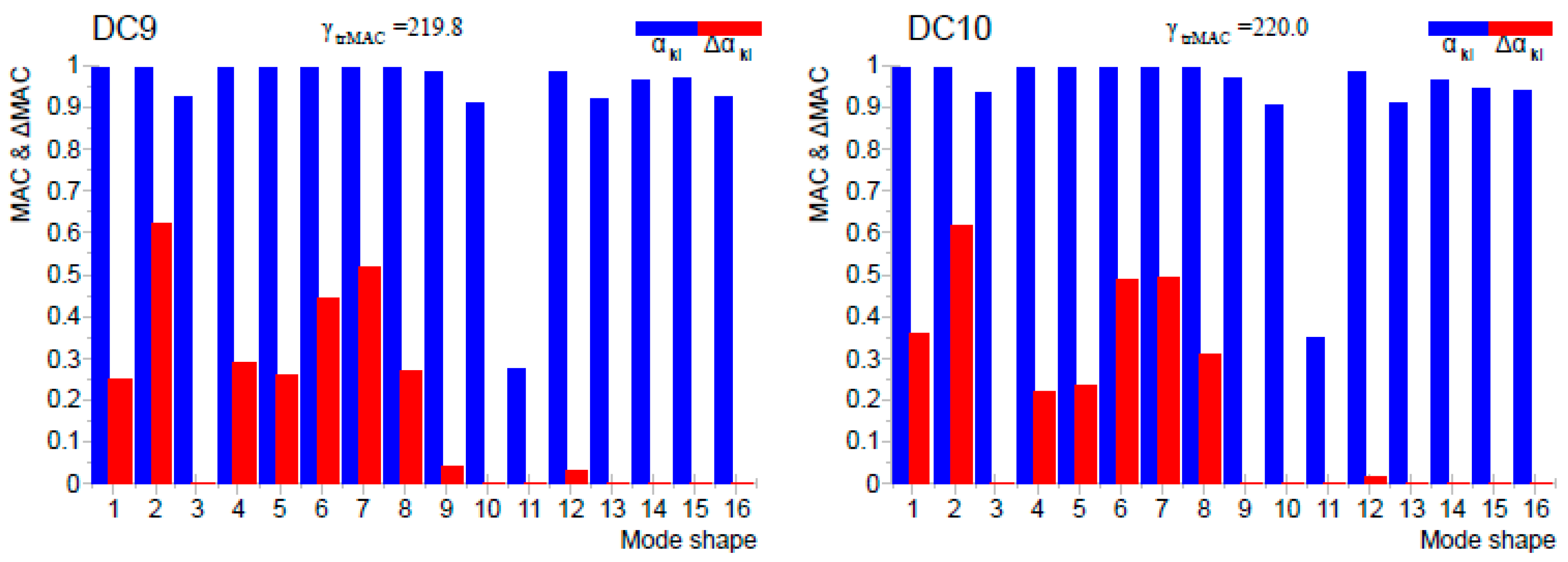

3.3. Effect of Multiple Damages

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cornwell, P.; Farrar, C.R.; Doebling, S.W.; Sohn, H. Environmental Variability of Modal Properties. Exp. Tech. 1999, 23, 45–48. [Google Scholar] [CrossRef]

- Wang, F.L.; Chan, T.H.T. Review of Vibration-Based Damage Detection and Condition Assessment of Bridge Structures Using Structural Health Monitoring. In The Second Infrastructure Theme Postgraduate Conference: Rethinking Sustainable Development: Planning, Engineering, Design and Managing Urban Infrastructure; Queensland University of Technology: Brisbane, Australia, 2009; pp. 35–47. [Google Scholar]

- Rytter, A. Vibrational Based Inspection of Civil Engineering Structures. Ph.D. Thesis, Department of Building Technology and Structural Engineering, Aalborg University, Aalborg, Denmark, 1993. [Google Scholar]

- Salawu, O.S. Detection of Structural Damage through Changes in Frequency: A Review. Eng. Struct. 1997, 19, 718–723. [Google Scholar] [CrossRef]

- Messina, A.; Williams, E.J.; Contursi, T. Structural Damage Detection by a Sensitivity and Statistical-Based Method. J. Sound Vib. 1998, 216, 791–808. [Google Scholar] [CrossRef]

- Morassi, A. Identification of a Crack in a Rod Based on Changes in a Pair of Natural Frequencies. J. Sound Vib. 2001, 242, 577–596. [Google Scholar] [CrossRef]

- Kim, J.T.; Stubbs, N. Crack Detection in Beam-Type Structures Using Frequency Data. J. Sound Vib. 2003, 259, 145–160. [Google Scholar] [CrossRef]

- Salehi, M.; Ziaei-Rad, S.; Ghayour, M.; Vaziri-Zanjani, M.A. A Structural Damage Detection Technique Based on Measured Frequency Response Functions. Contemp. Eng. Sci. 2010, 3, 215–226. [Google Scholar]

- Yang, Z.; Chen, X.; Yu, J.; Liu, R.; Liu, Z.; He, Z. A Damage Identification Approach for Plate Structures Based on Frequency Measurements. Nondestruct. Test. Eval. 2013, 28, 321–341. [Google Scholar] [CrossRef]

- Beskhyroun, S.; Wegner, L.D.; Sparling, B.F. New Methodology for the Application of Vibration-Based Damage Detection Techniques. Struct. Control Health Monit. 2012, 19, 632–649. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, W. Non-Model-Based Damage Identification of Plates Using Measured Mode Shapes. Struct. Health Monit. 2017, 16, 3–23. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M. Experimental Verification of Flexibility Difference Method for Locating Damage in Structures. J. Sound Vib. 1995, 184, 311–328. [Google Scholar] [CrossRef]

- Catbas, F.N.; Brown, D.L.; Aktan, A.E. Use of Modal Flexibility for Damage Detection and Condition Assessment: Case Studies and Demonstrations on Large Structures. J. Struct. Eng. 2006, 132, 1699–1712. [Google Scholar] [CrossRef]

- Abdel Wahab, M.M.; De Roeck, G. Damage Detection in Bridges Using Modal Curvatures: Application to a Real Damage Scenario. J. Sound Vib. 1999, 226, 217–235. [Google Scholar] [CrossRef]

- Maeck, J.; De Roeck, G. Damage Detection on a Prestressed Concrete Bridge and RC Beams Using Dynamic System Identification. Key Eng. Mater. 1999, 167, 320–327. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Law, S.S.; Zhang, L.M. Structural Damage Detection from Modal Strain Energy Change. J. Eng. Mech. 2000, 126, 1216–1223. [Google Scholar] [CrossRef]

- Hu, H.; Wang, B.T.; Lee, C.H.; Su, J.S. Damage Detection of Surface Cracks in Composite Laminates Using Modal Analysis and Strain Energy Method. Compos. Struct. 2006, 74, 399–405. [Google Scholar] [CrossRef]

- Meruane, V.; Lasen, M.; Droguett, E.L.; Ortiz-Bernardin, A. Modal Strain Energy-Based Debonding Assessment of Sandwich Panels Using a Linear Approximation with Maximum Entropy. Entropy 2017, 19, 619. [Google Scholar] [CrossRef]

- Fan, W.; Qiao, P. Vibration-Based Damage Identification Methods: A Review and Comparative Study. Struct. Health Monit. 2011, 10, 83–111. [Google Scholar] [CrossRef]

- Siow, P.Y.; Ong, Z.C.; Khoo, S.Y.; Lim, K.S. Damage Sensitive PCA-FRF Feature in Unsupervised Machine Learning for Damage Detection of Plate-Like Structures. Int. J. Struct. Stab. Dyn. 2021, 21. [Google Scholar] [CrossRef]

- Zhao, M.; Zhou, W.; Huang, Y.; Li, H. Sparse Bayesian Learning Approach for Propagation Distance Recognition and Damage Localization in Plate-like Structures Using Guided Waves. Struct. Health Monit. 2021, 20, 3–24. [Google Scholar] [CrossRef]

- Kahya, V.; Karaca, S.; Okur, F.Y.; Altunışık, A.C.; Aslan, M. Damage Localization in Laminated Composite Beams with Multiple Edge Cracks Based on Vibration Measurements. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 45, 75–87. [Google Scholar] [CrossRef]

- Limongelli, M.P. The Surface Interpolation Method for Damage Localization in Plates. Mech. Syst. Signal Process. 2019, 118, 171–194. [Google Scholar] [CrossRef]

- Catbas, F.N.; Gul, M.; Burkett, J.L. Conceptual Damage-Sensitive Features for Structural Health Monitoring: Laboratory and Field Demonstrations. Mech. Syst. Signal Process. 2008, 22, 1650–1669. [Google Scholar] [CrossRef]

- West, M.; West, W. Illustration of the Use of Modal Assurance Criterion to Detect Structural Changes in an Orbiter Test Specimen. Proc. Air Conf. Aircr. Struct. Integr. 1984, 1, 1–6. [Google Scholar]

- Doebling, S.W.; Farrar, C.R.; Prime, M.B. A Summary Review of Vibration-Based Damage Identification Methods. Shock Vib. Dig. 1998, 30, 91–105. [Google Scholar] [CrossRef]

- Allemang, R.J. The Modal Assurance Criterion—Twenty Years of Use and Abuse. In Proceedings of the IMAC-XX: Conference & Exposition on Structural Dynamics, Los Angeles, CA, USA, 4–7 February 2002; p. 9. [Google Scholar]

- Pastor, M.; Binda, M.; Harčarik, T. Modal Assurance Criterion. In Procedia Engineering; Elsevier: Amsterdam, The Netherlands, 2012; Volume 48, pp. 543–548. [Google Scholar] [CrossRef]

- Tatar, A.; Niousha, A.; Rofooei, F.R. Damage Detection in Existing Reinforced Concrete Building Using Forced Vibration Test Based on Mode Shape Data. J. Civ. Struct. Health Monit. 2017, 7, 123–135. [Google Scholar] [CrossRef]

- Duvnjak, I.; Rak, M.; Damjanović, D. A New Method for Structural Damage Detection and Localization Based on Modal Shapes. In Proceedings of the Fifth International Symposium on Life-Cycle Civil Engineering (IALCCE 2016), Delft, The Netherlands, 16–19 October 2016. [Google Scholar]

- Duvnjak, I.; Damjanović, D.; Sabourova, N.; Grip, N.; Ohlsson, U.; Elfgren, L.; Tu, Y. Damage Detection in Structures—Examples. In Proceedings of the IABSE Symposium 2019 Guimarães: Towards a Resilient Built Environment—Risk and Asset Management, Guimarães, Portugal, 27–29 March 2019. [Google Scholar]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of Bridge Structural Health Monitoring Aided by Big Data and Artificial Intelligence: From Condition Assessment to Damage Detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Hsieh, Y.-A.; Tsai, Y.J. Machine Learning for Crack Detection: Review and Model Performance Comparison. J. Comput. Civ. Eng. 2020, 34, 04020038. [Google Scholar] [CrossRef]

- Dang, H.V.; Raza, M.; Nguyen, T.V.; Bui-Tien, T.; Nguyen, H.X. Deep Learning-Based Detection of Structural Damage Using Time-Series Data. Struct. Infrastruct. Eng. 2020. [Google Scholar] [CrossRef]

- Zhang, L.; Brincker, R.; Andersen, P. An Overview of Operational Modal Analysis: Major Development and Issues. In Proceedings of the 1st International Operational Modal Analysis Conference (IOMAC 2005), Copenhagen, Denmark, 26–27 April 2005; pp. 149–160. [Google Scholar]

- Brincker, R.; Zhang, L.; Andersen, P. Modal Identification of Output-Only Systems Using Frequency Domain Decomposition. Smart Mater. Struct. 2001, 10, 441–445. [Google Scholar] [CrossRef]

- Gade, S.; Møller, N.B.; Herlufsen, H.; Konstantin-Hansen, H. Frequency Domain Techniques for Operational Modal Analysis. In Proceedings of the 1st International Operational Modal Analysis Conference (IOMAC 2005), Copenhagen, Denmark, 26–27 April 2005; p. 231. [Google Scholar]

- Khatibi, M.M.; Ashory, M.R.; Malekjafarian, A.; Brincker, R. Mass-Stiffness Change Method for Scaling of Operational Mode Shapes. Mech. Syst. Signal Process. 2012, 26, 34–59. [Google Scholar] [CrossRef]

| Damage Case | Elements | Depth (cm) |

|---|---|---|

| DC1 | E8 | 2 |

| DC2 | E8 | 3 |

| DC3 | E8 + F8 | 3 |

| DC4 | DC3 + E7 | 3 |

| DC5 | DC4 + C4 | 3 |

| DC6 | DC5 + C3 | 3 |

| DC7 | DC6 + J9 | 3 |

| DC8 | DC7 + A12 | 3 |

| DC9 | DC8 + H13 | 3 |

| DC10 | DC9 + H4 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duvnjak, I.; Damjanović, D.; Bartolac, M.; Skender, A. Mode Shape-Based Damage Detection Method (MSDI): Experimental Validation. Appl. Sci. 2021, 11, 4589. https://doi.org/10.3390/app11104589

Duvnjak I, Damjanović D, Bartolac M, Skender A. Mode Shape-Based Damage Detection Method (MSDI): Experimental Validation. Applied Sciences. 2021; 11(10):4589. https://doi.org/10.3390/app11104589

Chicago/Turabian StyleDuvnjak, Ivan, Domagoj Damjanović, Marko Bartolac, and Ana Skender. 2021. "Mode Shape-Based Damage Detection Method (MSDI): Experimental Validation" Applied Sciences 11, no. 10: 4589. https://doi.org/10.3390/app11104589

APA StyleDuvnjak, I., Damjanović, D., Bartolac, M., & Skender, A. (2021). Mode Shape-Based Damage Detection Method (MSDI): Experimental Validation. Applied Sciences, 11(10), 4589. https://doi.org/10.3390/app11104589