Flow Stress Modelling and 3D Processing Maps of Al4.5Zn4.5Mg1Cu0.12Zr Alloy with Different Scandium Contents

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

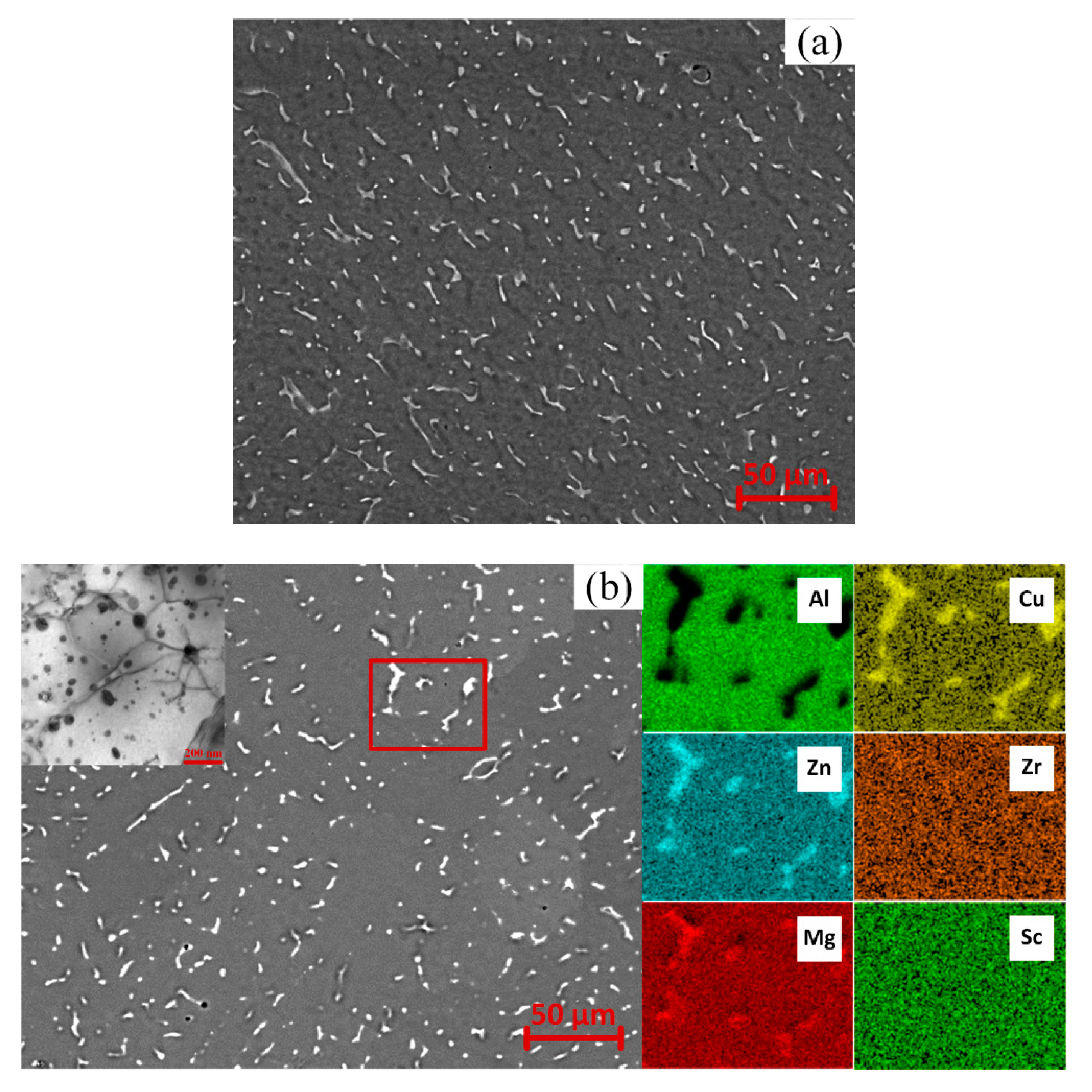

3.1. Initial Microstructure Investigation

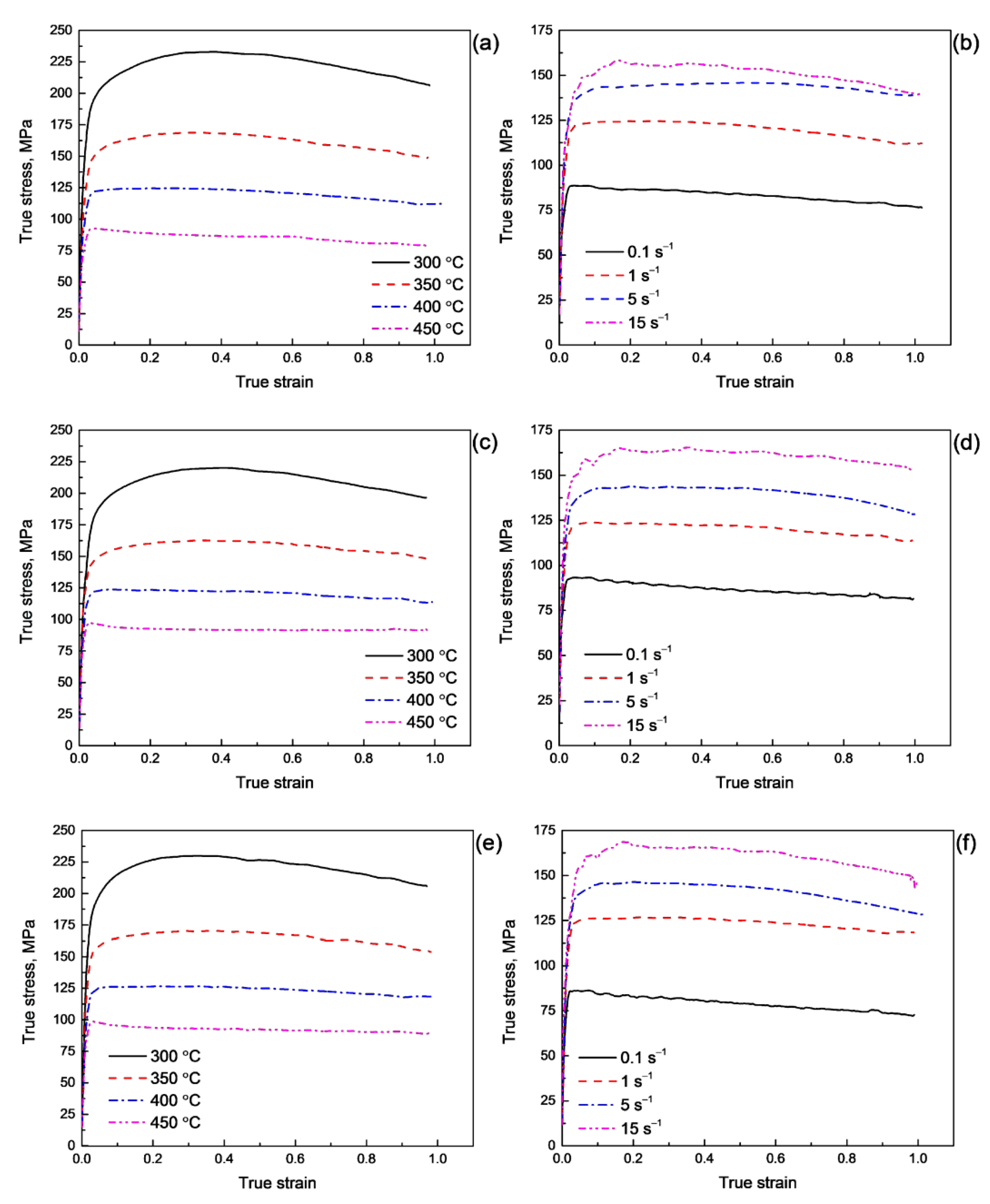

3.2. Hot Deformation Behaviour Modelling

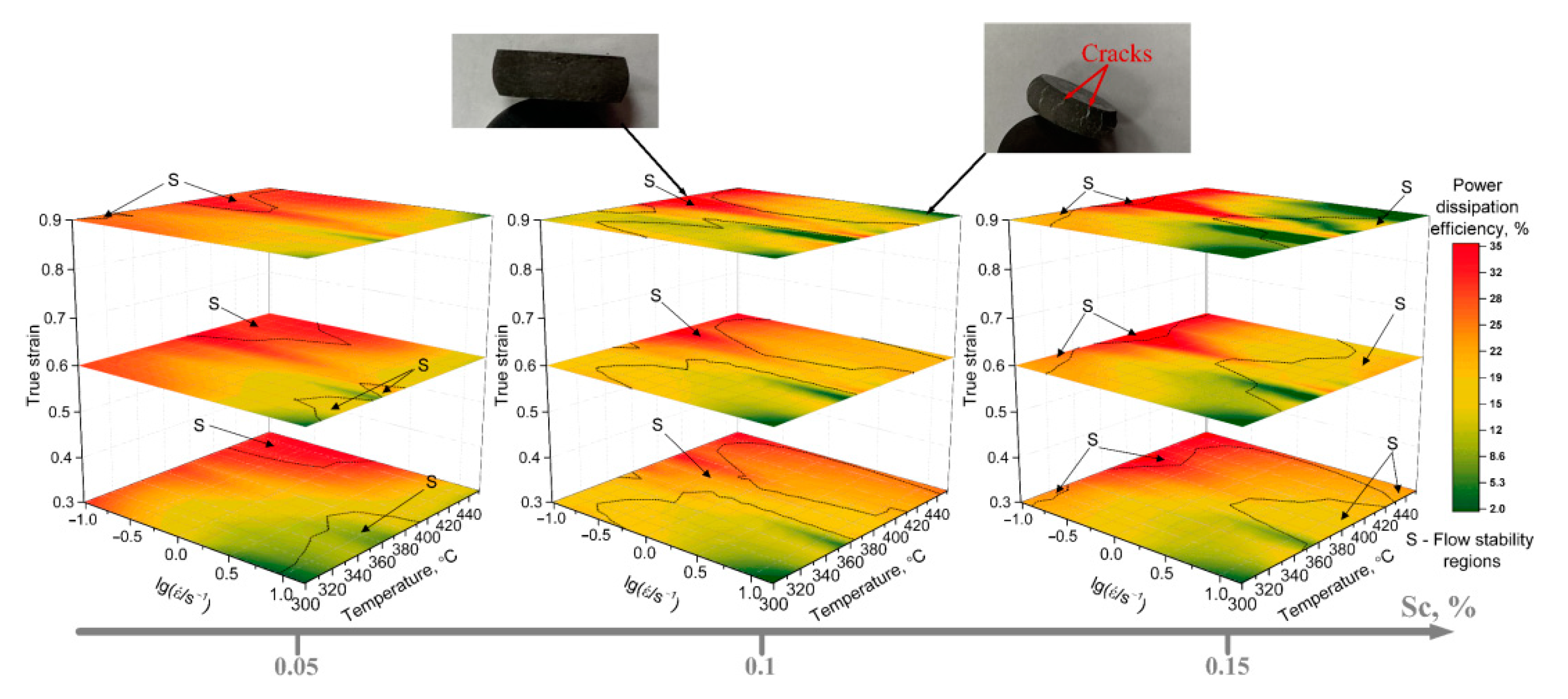

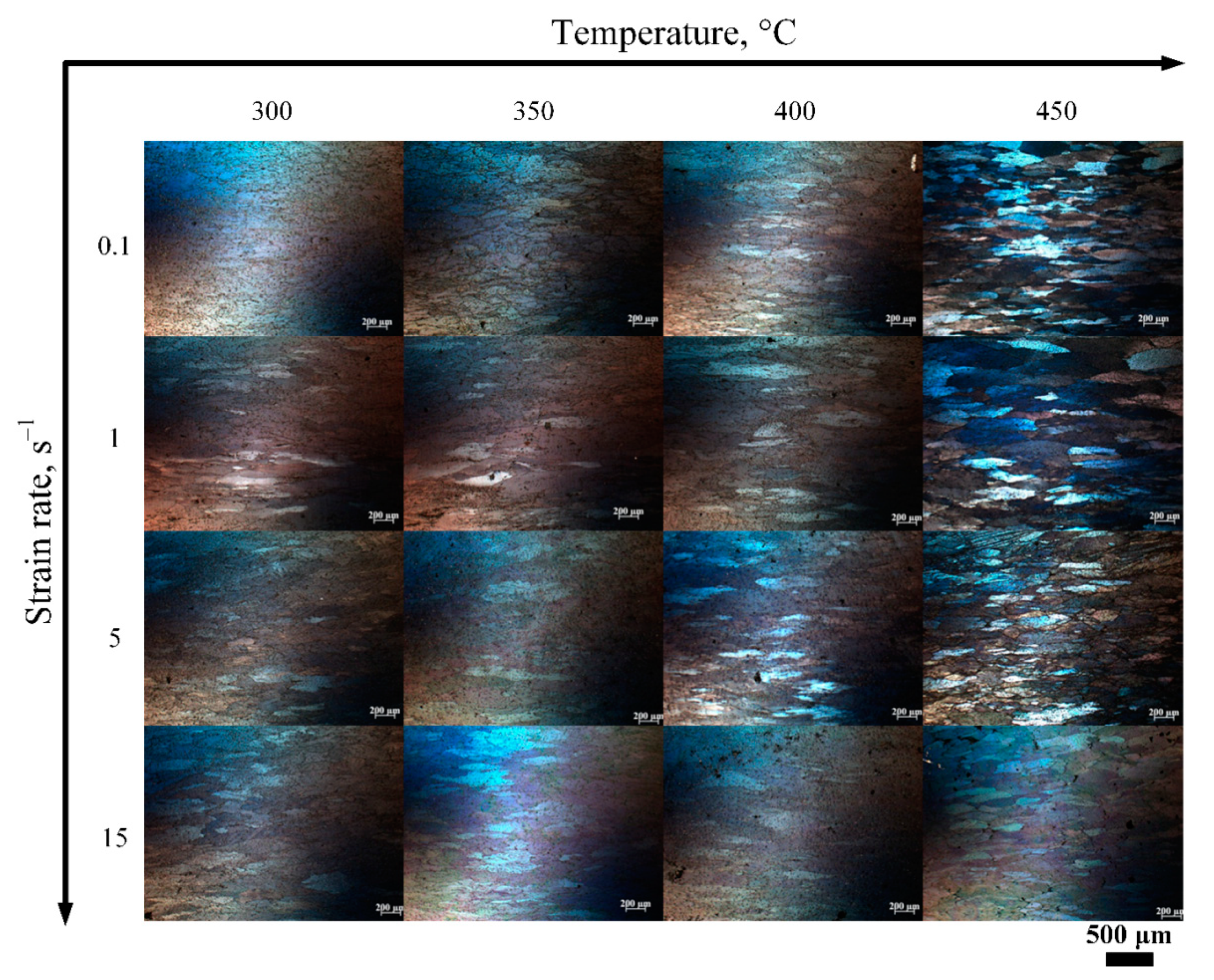

3.3. 3D Processing Maps Establishment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, P.; Chen, S.; Chen, K.; Jiao, H.; Huang, L.; Zhang, Z.; Yang, Z. Enhancing the stress corrosion cracking resistance of a low-Cu containing Al-Zn-Mg-Cu aluminum alloy by step-quench and aging heat treatment. Corros. Sci. 2019, 161, 108184. [Google Scholar] [CrossRef]

- Wang, P.; Li, H.C.; Prashanth, K.G.; Eckert, J.; Scudino, S. Selective laser melting of Al-Zn-Mg-Cu: Heat treatment, microstructure and mechanical properties. J. Alloys Compd. 2017, 707, 287–290. [Google Scholar] [CrossRef]

- Peng, X.; Guo, Q.; Liang, X.; Deng, Y.; Gu, Y.; Xu, G.; Yin, Z. Mechanical properties, corrosion behavior and microstructures of a non-isothermal ageing treated Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2017, 688, 146–154. [Google Scholar] [CrossRef]

- Chen, S.; Li, J.; Hu, G.Y.; Chen, K.; Huang, L. Effect of Zn/Mg ratios on SCC, electrochemical corrosion properties and microstructure of Al-Zn-Mg alloy. J. Alloys Compd. 2018, 757, 259–264. [Google Scholar] [CrossRef]

- Liu, J.; Hu, R.; Zheng, J.; Zhang, Y.; Ding, Z.; Liu, W.; Zhu, Y.; Sha, G. Formation of solute nanostructures in an Al–Zn–Mg alloy during long-term natural aging. J. Alloys Compd. 2020, 821, 153572. [Google Scholar] [CrossRef]

- Zolotorevskii, V.S.; Pozdnyakov, A.V.; Churyumov, A.Y. Search for promising compositions for developing new multiphase casting alloys based on Al-Zn-Mg matrix using thermodynamic calculations and mathematic simulation. Phys. Met. Metallogr. 2014, 115, 286–294. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, D.; Liu, H.; Zhuang, L.; Zhang, J. Precipitation hardening and intergranular corrosion behavior of novel Al–Mg–Zn(-Cu) alloys. J. Alloys Compd. 2021, 853, 157199. [Google Scholar] [CrossRef]

- Vlach, M.; Kodetova, V.; Cizek, J.; Leibner, M.; Kekule, T.; Lukáč, F.; Cieslar, M.; Bajtošová, L.; Kudrnová, H.; Sima, V.; et al. Role of Small Addition of Sc and Zr in Clustering and Precipitation Phenomena Induced in AA7075. Metals 2020, 11, 8. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, T.; He, C.; Ding, J.; Liu, E.; Shi, C.; Li, J.; Zhao, N. Evolution of microstructure and properties of Al-Zn-Mg-Cu-Sc-Zr alloy during aging treatment. J. Alloys Compd. 2016, 658, 946–951. [Google Scholar] [CrossRef]

- Li, B.; Pan, Q.; Zhang, Z.; Li, C. Characterization of flow behavior and microstructural evolution of Al-Zn-Mg-Sc-Zr alloy using processing maps. Mater. Sci. Eng. A 2012, 556, 844–848. [Google Scholar] [CrossRef]

- Xiao, Q.F.; Huang, J.W.; Jiang, Y.G.; Jiang, F.Q.; Wu, Y.F.; Xu, G.F. Effects of minor Sc and Zr additions on mechanical properties and microstructure evolution of Al−Zn−Mg−Cu alloys. Trans. Nonferrous Met. Soc. China 2020, 30, 1429–1438. [Google Scholar] [CrossRef]

- Li, H.; Cao, F.; Guo, S.; Ning, Z.; Liu, Z.; Jia, Y.; Scudino, S.; Gemming, T.; Sun, J. Microstructures and properties evolution of spray-deposited Al-Zn-Mg-Cu-Zr alloys with scandium addition. J. Alloys Compd. 2017, 691, 482–488. [Google Scholar] [CrossRef]

- Khomutov, M.; Chereshneva, A.; Petrovskiy, P.; Daubarayte, D.; Cheverikin, V.; Sova, A.; Travyanov, A.; Smurov, I. Microstructure of Al–Mg-Sc-Zr alloy cold spray deposits after heat treatment and hot isostatic pressing. J. Alloys Compd. 2020, 858, 157644. [Google Scholar] [CrossRef]

- Hou, Y.F.; Xiao, J.J.; Liu, C.Y.; Zhang, B. Effect of Heat Treatment on the Microstructure, Mechanical Properties, and Corrosion Resistance of Friction Stir Processed Al-Zn-Mg-Cu-Sc-Zr Alloy. J. Mater. Eng. Perform. 2021, 1–8. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.C.; Zhang, X.Y.; Huang, Y.C. Understanding grain refinement of Sc addition in a Zr containing Al-Zn-Mg-Cu aluminum alloy from experiments and first-principles. Intermetallics 2020, 123, 106823. [Google Scholar] [CrossRef]

- Wang, Y.; Xiong, B.; Li, Z.; Zhang, Y.; Teng, H. Precipitation Behavior of Al3(Sc,Zr) Particles in High-Alloyed Al–Zn–Mg–Cu–Zr–Sc Alloy During Homogenization. Arab. J. Sci. Eng. 2021, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Xiong, B.; Wen, K.; Huang, S.; Li, X.; Zhang, Y. Microstructure Evolution of High-Alloyed Al–Zn–Mg–Cu–Zr Alloy Containing Trace Amount of Sc During Homogenization. Met. Mater. Int. 2019, 25, 697–704. [Google Scholar] [CrossRef]

- Ke, B.; Ye, L.; Tang, J.; Zhang, Y.; Liu, S.; Lin, H.; Dong, Y.; Liu, X. Hot deformation behavior and 3D processing maps of AA7020 aluminum alloy. J. Alloys Compd. 2020, 845, 156113. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Z.; Wan, Z.; Hu, L.; Ye, W.; Li, N.; Fan, C. 3D processing map and hot deformation behavior of 6A02 aluminum alloy. J. Alloys Compd. 2018, 742, 356–368. [Google Scholar] [CrossRef]

- Shang, X.; Zhou, J.; Wang, X.; Luo, Y. Optimizing and identifying the process parameters of AZ31 magnesium alloy in hot compression on the base of processing maps. J. Alloys Compd. 2015, 629, 155–161. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Medvedeva, S.V.; Mamzurina, O.I.; Kazakova, A.A.; Churyumova, T.A. United Approach to Modelling of the Hot Deformation Behavior, Fracture, and Microstructure Evolution of Austenitic Stainless AISI 316Ti Steel. Appl. Sci. 2021, 11, 3204. [Google Scholar] [CrossRef]

- Lu, J.; Song, Y.; Hua, L.; Zheng, K.; Dai, D. Thermal deformation behavior and processing maps of 7075 aluminum alloy sheet based on isothermal uniaxial tensile tests. J. Alloys Compd. 2018, 767, 856–869. [Google Scholar] [CrossRef]

- Liu, Y.; Geng, C.; Lin, Q.; Xiao, Y.; Xu, J.; Kang, W. Study on hot deformation behavior and intrinsic workability of 6063 aluminum alloys using 3D processing map. J. Alloys Compd. 2017, 713, 212–221. [Google Scholar] [CrossRef]

- Li, P.W.; Li, H.Z.; Huang, L.; Liang, X.P.; Zhu, Z.X. Characterisation of hot deformation behavior of AA2014 forging aluminum alloy using processing map. Trans. Nonferrous Met. Soc. China 2017, 27, 1677–1688. [Google Scholar] [CrossRef]

- Jang, D.H.; Kim, W.J. Warm Temperature Deformation Behavior and Processing Maps of 5182 and 7075 Aluminum Alloy Sheets with Fine Grains. Met. Mater. Int. 2018, 24, 455–463. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, W.; Zhang, Z.; Huang, G.; Liu, X. Hot Deformation Behavior and Processing Maps of AA7085 Aluminum Alloy. Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng. 2018, 47, 409–415. [Google Scholar] [CrossRef]

- Zhou, P.; Deng, L.; Zhang, M.; Gong, P.; Wang, X.Y. Characterization of Hot Workability of 5052 Aluminum Alloy Based on Activation Energy-Processing Map. J. Mater. Eng. Perform. 2019, 28, 6209–6218. [Google Scholar] [CrossRef]

- Opěla, P.; Schindler, I.; Kawulok, P.; Kawulok, R.; Rusz, S.; Navrátil, H.; Jurča, R. Correlation among the power dissipation efficiency, flow stress course, and activation energy evolution in Cr-Mo low-alloyed steel. Materials 2020, 13, 3480. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, H.; Zhao, W.; Huang, M.; Wei, D.; Jiang, Z. Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network. Comput. Mater. Sci. 2014, 92, 47–56. [Google Scholar] [CrossRef]

- El Mehtedi, M.; Spigarelli, S.; Gabrielli, F.; Donati, L. Comparison Study of Constitutive Models in Predicting the Hot Deformation Behavior of AA6060 and AA6063 Aluminium Alloys. Mater. Today Proc. 2015, 2, 4732–4739. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Khomutov, M.G.; Tsar’Kov, A.A.; Pozdnyakov, A.V.; Solonin, A.N.; Efimov, V.M.; Mukhanov, E.L. Study of the structure and mechanical properties of corrosion-resistant steel with a high concentration of boron at elevated temperatures. Phys. Met. Metallogr. 2014, 115, 809–813. [Google Scholar] [CrossRef]

- Wan, Z.; Hu, L.; Sun, Y.; Wang, T.; Li, Z. Hot deformation behavior and processing workability of a Ni-based alloy. J. Alloys Compd. 2018, 769, 367–375. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, G.; Chen, Q.; Han, F.; Zhao, Z. A physically-based constitutive modelling of a high strength aluminum alloy at hot working conditions. J. Alloys Compd. 2018, 743, 283–293. [Google Scholar] [CrossRef]

- Bodunrin, M.O. Flow stress prediction using hyperbolic-sine Arrhenius constants optimised by simple generalised reduced gradient refinement. J. Mater. Res. Technol. 2020, 9, 2376–2386. [Google Scholar] [CrossRef]

- Lin, Y.C.; Dong, W.Y.; Zhou, M.; Wen, D.X.; Chen, D.D. A unified constitutive model based on dislocation density for an Al-Zn-Mg-Cu alloy at time-variant hot deformation conditions. Mater. Sci. Eng. A 2018, 718, 165–172. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Wu, X.L.; Gao, K.Y.; Wang, W.; Nie, Z.R. Hot deformation behavior and constitutive equation of a new type Al-Zn-Mg-Er-Zr alloy during isothermal compression. Mater. Sci. Eng. A 2016, 651, 415–424. [Google Scholar] [CrossRef]

- Yan, J.; Pan, Q.L.; Li, A.D.; Song, W.B. Flow behavior of Al–6.2Zn–0.70Mg–0.30Mn–0.17Zr alloy during hot compressive deformation based on Arrhenius and ANN models. Trans. Nonferrous Met. Soc. China 2017, 27, 638–647. [Google Scholar] [CrossRef]

- Churyumov, A.Y.; Khomutov, M.G.; Solonin, A.N.; Pozdniakov, A.V.; Churyumova, T.A.; Minyaylo, B.F. Hot deformation behaviour and fracture of 10CrMoWNb ferritic-martensitic steel. Mater. Des. 2015, 74, 44–54. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Narayana Murty, S.V.S.; Sarkar, A.; Narayanan, P.R.; Venkitakrishnan, P.V.; Mukhopadhyay, J. Development of Processing Maps and Constitutive Relationship for Thermomechanical Processing of Aluminum Alloy AA2219. J. Mater. Eng. Perform. 2017, 26, 2190–2203. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Rao, K.P.; Sasidhara, S. Hot Working Guide: A Compendium of Processing Maps, 2nd ed.; ASM International: Geauga County, OH, USA, 2015; ISBN 978-1-62708-091-0. [Google Scholar]

- Kim, Y.; Song, Y.B.; Lee, S.H.; Kwon, Y.S. Characterisation of the hot deformation behavior and microstructural evolution of Ti-6Al-4V sintered preforms using materials modeling techniques. J. Alloys Compd. 2016, 676, 15–25. [Google Scholar] [CrossRef]

| Alloy | Al | Zn | Mg | Cu | Zr | Sc |

|---|---|---|---|---|---|---|

| 0.05Sc | bal. | 4.5 | 4.5 | 1.0 | 0.12 | 0.05 |

| 0.1Sc | bal. | 4.5 | 4.5 | 1.0 | 0.12 | 0.1 |

| 0.15Sc | bal. | 4.5 | 4.5 | 1.0 | 0.12 | 0.15 |

| ε | 0.05Sc | 0.1Sc | 0.15Sc | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q, kJ·mol−1 | ln(A) | n2 | α | Q, kJ·mol−1 | ln(A) | n2 | α | Q, kJ·mol−1 | ln(A) | n2 | α | |

| 0.05 | 172 | 28.1 | 6.8 | 0.010 | 171 | 28.0 | 6.7 | 0.010 | 161 | 27.1 | 6.1 | 0.009 |

| 0.1 | 175 | 29.3 | 6.4 | 0.010 | 176 | 29.4 | 6.4 | 0.009 | 169 | 28.9 | 6.0 | 0.009 |

| 0.2 | 169 | 28.8 | 6.1 | 0.009 | 171 | 29.3 | 6.2 | 0.009 | 164 | 28.4 | 5.6 | 0.008 |

| 0.3 | 165 | 28.7 | 6.0 | 0.008 | 172 | 30.1 | 6.2 | 0.008 | 164 | 28.7 | 5.5 | 0.008 |

| 0.4 | 162 | 28.6 | 6.0 | 0.008 | 171 | 30.2 | 6.0 | 0.008 | 166 | 29.2 | 5.5 | 0.008 |

| 0.5 | 167 | 29.5 | 6.1 | 0.008 | 174 | 30.9 | 6.1 | 0.008 | 169 | 29.9 | 5.5 | 0.008 |

| 0.6 | 172 | 30.4 | 6.1 | 0.008 | 179 | 32.0 | 6.2 | 0.008 | 173 | 30.9 | 5.6 | 0.008 |

| 0.7 | 180 | 31.9 | 6.2 | 0.008 | 186 | 33.6 | 6.3 | 0.007 | 179 | 32.3 | 5.6 | 0.008 |

| 0.8 | 184 | 32.5 | 6.2 | 0.009 | 189 | 34.5 | 6.4 | 0.007 | 185 | 33.5 | 5.6 | 0.008 |

| 0.9 | 186 | 32.8 | 6.2 | 0.009 | 192 | 35.1 | 6.4 | 0.007 | 183 | 33.0 | 5.3 | 0.008 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khomutov, M.G.; Pozdniakov, A.V.; Churyumov, A.Y.; Barkov, R.Y.; Solonin, A.N.; Glavatskikh, M.V. Flow Stress Modelling and 3D Processing Maps of Al4.5Zn4.5Mg1Cu0.12Zr Alloy with Different Scandium Contents. Appl. Sci. 2021, 11, 4587. https://doi.org/10.3390/app11104587

Khomutov MG, Pozdniakov AV, Churyumov AY, Barkov RY, Solonin AN, Glavatskikh MV. Flow Stress Modelling and 3D Processing Maps of Al4.5Zn4.5Mg1Cu0.12Zr Alloy with Different Scandium Contents. Applied Sciences. 2021; 11(10):4587. https://doi.org/10.3390/app11104587

Chicago/Turabian StyleKhomutov, Maxim G., Andrey V. Pozdniakov, Alexander Yu. Churyumov, Ruslan Yu. Barkov, Alexey N. Solonin, and Maria V. Glavatskikh. 2021. "Flow Stress Modelling and 3D Processing Maps of Al4.5Zn4.5Mg1Cu0.12Zr Alloy with Different Scandium Contents" Applied Sciences 11, no. 10: 4587. https://doi.org/10.3390/app11104587

APA StyleKhomutov, M. G., Pozdniakov, A. V., Churyumov, A. Y., Barkov, R. Y., Solonin, A. N., & Glavatskikh, M. V. (2021). Flow Stress Modelling and 3D Processing Maps of Al4.5Zn4.5Mg1Cu0.12Zr Alloy with Different Scandium Contents. Applied Sciences, 11(10), 4587. https://doi.org/10.3390/app11104587