Solution-Processed NiO as a Hole Injection Layer for Stable Quantum Dot Light-Emitting Diodes

Abstract

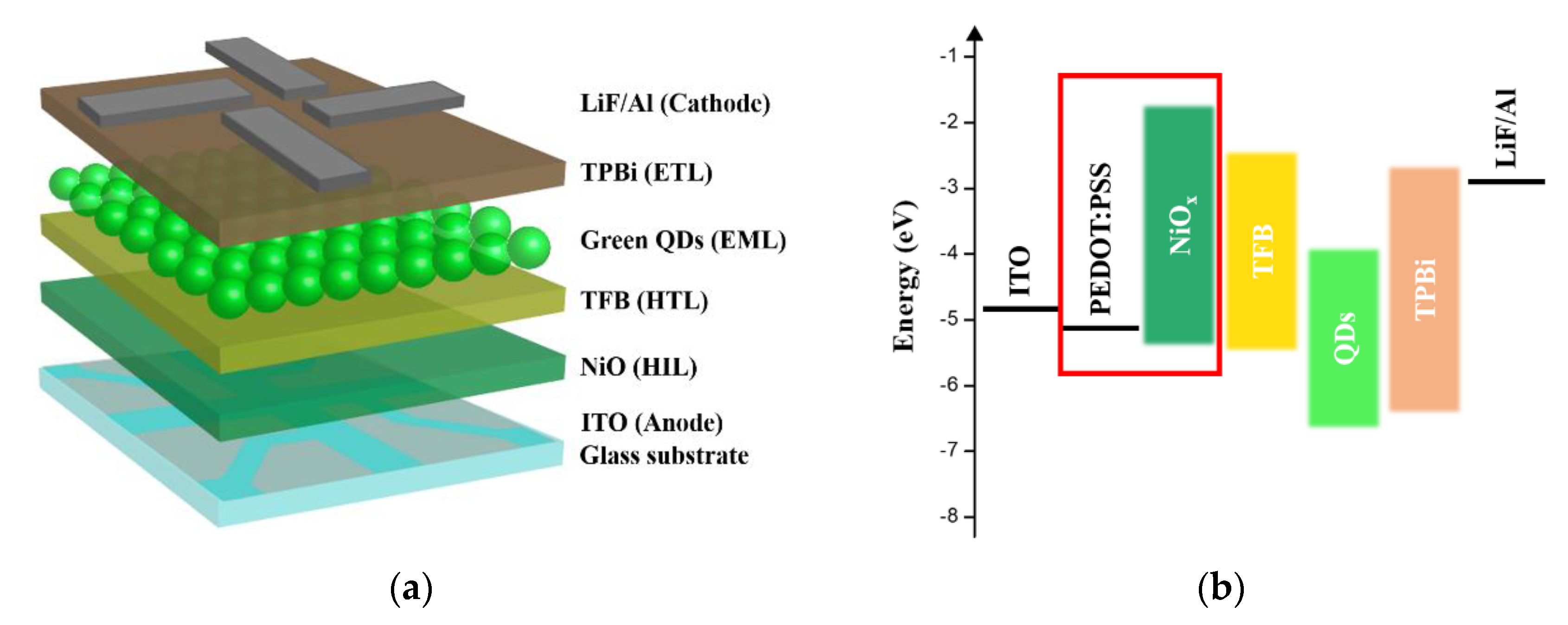

1. Introduction

2. Experiment

2.1. Synthesis of NiO Precursor

2.2. Synthesis of Green QDs

2.3. Fabrication of QLEDs

2.4. Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Shirasaki, Y.; Supran, G.J.; Bawendi, M.G.; Bulović, V. Emergence of colloidal quantum-dot light-emitting technologies. Nat. Photonics 2013, 7, 13–23. [Google Scholar] [CrossRef]

- Caruge, J.M.; Halpert, J.E.; Wood, V.; Bulović, V.; Bawendi, M.G. Colloidal quantum-dot light-emitting diodes with metal-oxide charge transport layers. Nat. Photonics 2008, 2, 247–250. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Q.; Chen, S. Recent progress in the device architecture of white quantum-dot light-emitting diodes. J. Inf. Disp. 2019, 20, 169–180. [Google Scholar] [CrossRef]

- Colvin, V.L.; Schlamp, M.C.; Alivisatos, A.P. Light-emitting diodes made from cadmium selenide nanocrystals and a semiconducting polymer. Nature 1994, 370, 354–357. [Google Scholar] [CrossRef]

- Shen, H.; Gao, Q.; Zhang, Y.; Lin, Y.; Lin, Q.; Li, Z.; Chen, L.; Zeng, Z.; Li, X.; Jia, Y.; et al. Visible quantum dot light-emitting diodes with simultaneous high brightness and efficiency. Nat. Photonics 2019, 13, 192–197. [Google Scholar] [CrossRef]

- Saatsakis, G.; Michail, C.; Fountzoula, C.; Kalyvas, N.; Bakas, A.; Ninos, K.; Fountos, G.; Sianoudis, I.; Kandarakis, I.; Panayiotakis, G.S.; et al. Fabrication and Luminescent Properties of Zn–Cu–In–S/ZnS Quantum Dot Films under UV Excitation. Appl. Sci. 2019, 9, 2367. [Google Scholar] [CrossRef]

- Won, Y.H.; Cho, O.; Kim, T.; Chung, D.Y.; Kim, T.; Chung, H.; Jang, H.; Lee, J.; Kim, D.; Jang, E. Highly efficient and stable InP/ZnSe/ZnS quantum dot light-emitting diodes. Nature 2019, 575, 634–638. [Google Scholar] [CrossRef]

- Cao, F.; Wang, H.; Shen, P.; Li, X.; Zheng, Y.; Shang, Y.; Zhang, J.; Ning, Z.; Yang, X. High-efficiency and stable quantum dot light-emitting diodes enabled by a solution-processed metal-doped nickel oxide hole injection interfacial layer. Adv. Funct. Mater. 2017, 27, 1704278. [Google Scholar] [CrossRef]

- Ding, T.; Yang, X.; Bai, L.; Zhao, Y.; Fong, K.E.; Wang, N.; Demir, H.V.; Sun, X.W. Colloidal quantum-dot LEDs with a solution-processed copper oxide (CuO) hole injection layer. Org. Electron. 2015, 26, 245–250. [Google Scholar] [CrossRef]

- Vu, H.T.; Su, Y.K.; Chiang, R.K.; Huang, C.Y.; Chen, C.J.; Yu, H.C. Solution-processable MoOx for efficient light-emitting diodes based on giant quantum dots. IEEE Photon. Technol. Lett. 2016, 28, 2156–2159. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, S.; Sun, X.; Chen, S. Solution-processed vanadium oxide as an efficient hole injection layer for quantum-dot light-emitting diodes. J. Mater. Chem. C 2017, 5, 817–823. [Google Scholar] [CrossRef]

- Wang, J.; Yang, P.; Wei, X.; Zhou, Z. Preparation of NiO two-dimensional grainy films and their high performance gas sensors for ammonia detection. Nanoscale Res. Lett. 2015, 10, 119. [Google Scholar] [CrossRef] [PubMed]

- Betancur, R.; Maymó, M.; Elias, X.; Vuong, L.T.; Martorell, J. Sputtered NiO as electron blocking layer in P3HT:PCBM solar cells fabricated in ambient air. Sol. Energy Mater. Sol. Cells 2011, 95, 735–739. [Google Scholar] [CrossRef]

- Manders, J.R.; Tsang, S.W.; Hartel, M.J.; Lai, T.H.; Chen, S.; Amb, C.M.; Reynolds, J.R.; So, F. Solution-processed nickel oxide hole transport layers in high efficiency polymer photovoltaic cells. Adv. Funct. Mater. 2016, 23, 2993–3001. [Google Scholar] [CrossRef]

- Meyer, J.; Winkler, T.; Hamwi, S.; Schmale, S.; Johannes, H.-H.; Weimann, T.; Hinze, P.; Kowalsky, W.; Riedl, T. Transparent inverted organic light-emitting diodes with a tungsten oxide buffer layer. Adv. Mater. 2008, 20, 3839–3843. [Google Scholar] [CrossRef]

- Hajakbari, F.; Afzali, M.T.; Hojabri, A. Nanocrystalline nickel oxide (NiO) thin films grown on quartz substrates: Influence of annealing temperatures. Acta Phys. Pol. A 2017, 131, 417–419. [Google Scholar] [CrossRef]

- Yin, Z.; Sun, S.; Salim, T.; Wu, S.; Huang, X.; He, Q.; Lam, Y.M.; Zhang, H. Organic photovoltaic devices using highly flexible reduced graphene oxide films as transparent electrodes. ACS Nano 2010, 4, 5263–5268. [Google Scholar] [CrossRef]

- Li, Y.; Fung, M.K.; Xie, Z.; Lee, X.-T.; Hung, L.-S.; Shi, J. An efficient pure blue organic light-emitting device with low driving voltages. Adv. Mater. 2002, 14, 1317–1321. [Google Scholar] [CrossRef]

- Redecker, M.; Bradley, D.D.C.; Inbasekaran, M.; Wu, W.W.; Woo, E.P. High mobility hole transport fluorene-triarylamine copolymers. Adv. Mater. 1999, 11, 241–246. [Google Scholar] [CrossRef]

- Kerkache, L.; Layadi, A.; Dogheche, E.; Remiens, D. Physical properties of RF sputtered ITO thin films and annealing effect. J. Phys. D. Appl. Phys. 2005, 39, 184. [Google Scholar] [CrossRef]

- Hikmet, R.A.M.; Talapin, D.V.; Weller, H. Study of conduction mechanism and electroluminescence in CdSe/ZnS quantum dot composites. J. Appl. Phys. 2003, 93, 3509–3514. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, W.; Wu, Y.; He, Z.; Zhang, S.; Chen, S. A low-temperature-annealed and UV-ozone-enhanced combustion derived nickel oxide hole injection layer for flexible quantum dot light-emitting diodes. Nanoscale 2019, 11, 1021–1028. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, Y.; Kim, J. Solution-Processed NiO as a Hole Injection Layer for Stable Quantum Dot Light-Emitting Diodes. Appl. Sci. 2021, 11, 4422. https://doi.org/10.3390/app11104422

Lee S, Kim Y, Kim J. Solution-Processed NiO as a Hole Injection Layer for Stable Quantum Dot Light-Emitting Diodes. Applied Sciences. 2021; 11(10):4422. https://doi.org/10.3390/app11104422

Chicago/Turabian StyleLee, Sangwon, Youngjin Kim, and Jiwan Kim. 2021. "Solution-Processed NiO as a Hole Injection Layer for Stable Quantum Dot Light-Emitting Diodes" Applied Sciences 11, no. 10: 4422. https://doi.org/10.3390/app11104422

APA StyleLee, S., Kim, Y., & Kim, J. (2021). Solution-Processed NiO as a Hole Injection Layer for Stable Quantum Dot Light-Emitting Diodes. Applied Sciences, 11(10), 4422. https://doi.org/10.3390/app11104422