1. Introduction

Elastomeric bearings for FPSO are located at the interfaces between topside modules and support stools on the deck of the offshore platform. Their major function is to minimize the structural interactions of the two bodies. Particularly, they shall reduce the shear loads and bending moments in the module plate girders supported on the stools. These bearings are manufactured by intersecting an elastomer made of neoprene and reinforcing steel plates in the same way as for land use [

1,

2]. Land elastomeric bearings are used in bridges and buildings so that they support high-frequency repetitive loads caused by earthquakes [

3,

4,

5]. Unlike those land elastomeric bearings subjected to repeated loads, the offshore elastomeric bearings are to firmly support the heavy upper module from the wind load and motion of hull in various sea environments including towing, operating, and extreme conditions [

6,

7,

8]. So, an offshore elastomeric bearing is larger in size and stronger in rigidity than that for land use, and it tends to have a square block shape to effectively support the translational and rotational movements of upper topside modules caused by 6DOF (degree of freedom) hull motions (surge, sway, heave, roll, pitch, yaw) [

9]. In addition, since loads vary with types of modules on the platform, offshore elastomer bearings should have adequate shear stiffness to minimize their horizontal movements while elastically supporting the vertical loads [

10].

The most important item when indicating the mechanical properties of such offshore elastomeric bearings is the shear modulus, and the method of measuring this is shown in EN 1337-3 [

11], a regulation related to offshore elastomeric bearings. In the previous study [

12] that analyzed the effect of reinforcing plate on the stiffness of elastomer bearing, the influence of reinforcing plate was dominant on compressive stiffness and bending stiffness. It was confirmed that the height ratio to the cross-sectional area mainly is affected. In addition, according to the EN 1337-3 regulation, it can be seen that the shore hardness of the elastomer is closely related to the shear modulus of the bearing. Many experimental and numerical studies have been reported on the effect of various parameters on the mechanical behavior of elastomeric bearings [

13,

14,

15,

16,

17]. Konstantinidis et al. [

13] performed an experimental analysis on the seismic response of three types of steel-reinforced elastomeric bearings (SREBs) used in bridges. They concluded that all SREBs they analyzed performed exceptionally well under seismic loading. Steelman et al. [

14] conducted experiments on SREBs attached to a concrete layer on one side and bounded on the other side. They observed that shear strain increases nonlinearly with vertical load (compressive pressure). Li and Wu [

15] experimentally studied the ultimate state of shear failure and the friction sliding performance of SREBs in bridges. Peng et al. [

16] performed experimental tests on natural rubber-laminated bearings for bridges to investigate the effects of vertical load and peak acceleration of ground motion. They also performed numerical simulations using a finite element method and proposed an accurate method for calculating seismic responses of bridges with laminated bearings. Recently, Kaloo et al. [

17] investigated the effect of various parameters on the mechanical properties of SREBs under large shear deformations numerically and experimentally. In all the literature mentioned above, experimental and/or numerical studies were conducted on elastomeric bridge-bearings only. However, till now, there have been no studies on finding the shear modulus of an offshore elastic bearing by using the EN 1337-3 regulation procedure to the authors’ knowledge. The reason is that the size of marine elastomer bearings is significantly larger than that for land use, and the applied load reaches thousands of tons, so experiments cannot be carried out with existing equipment. In addition, the method and regulations for measuring the shear modulus of elastomeric bearings for land and offshore are different, so the results of existing studies on bridge bearings cannot be applied to offshore applications. Therefore, the necessity of this research work is to analyze the shear modulus of offshore elastomeric bearings according to the procedure mentioned in EN 1337-3 regulation.

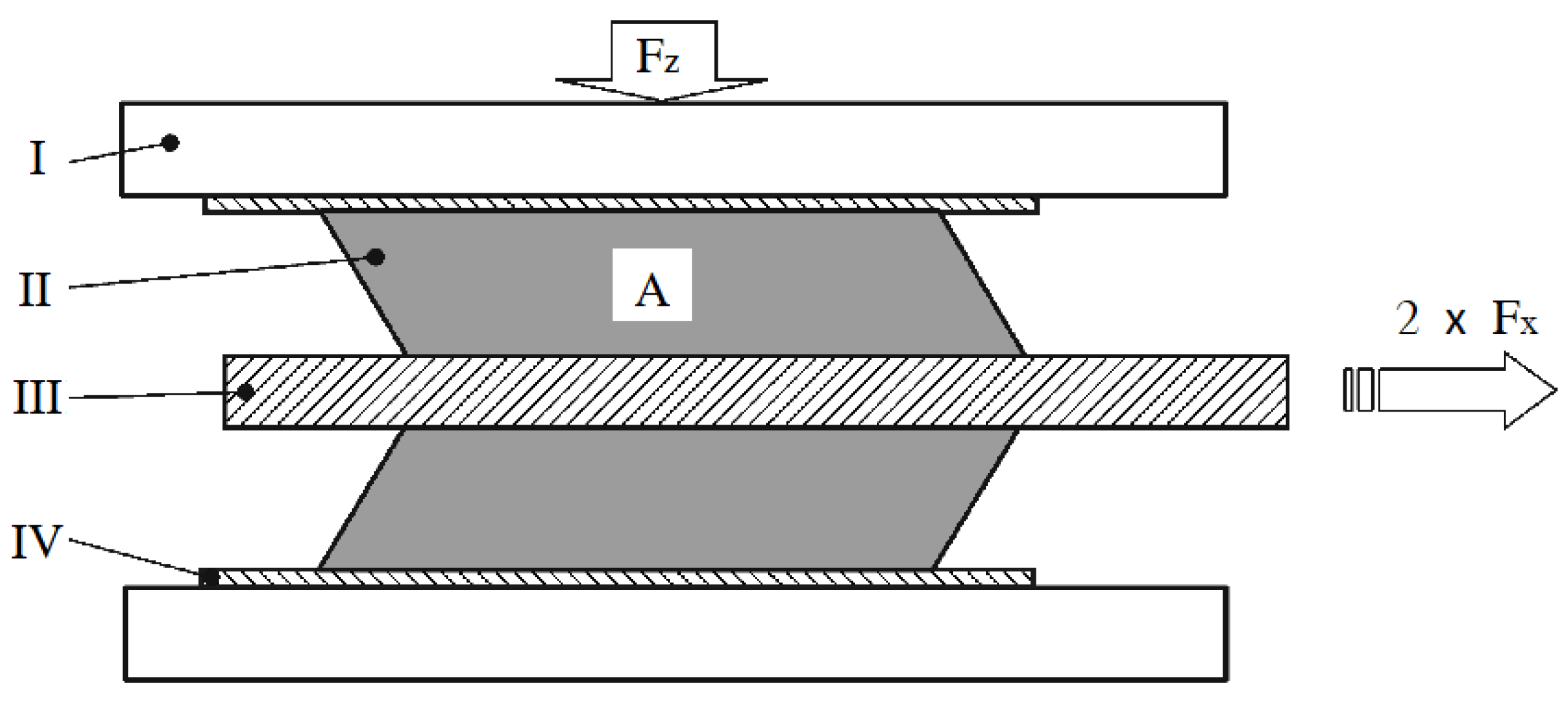

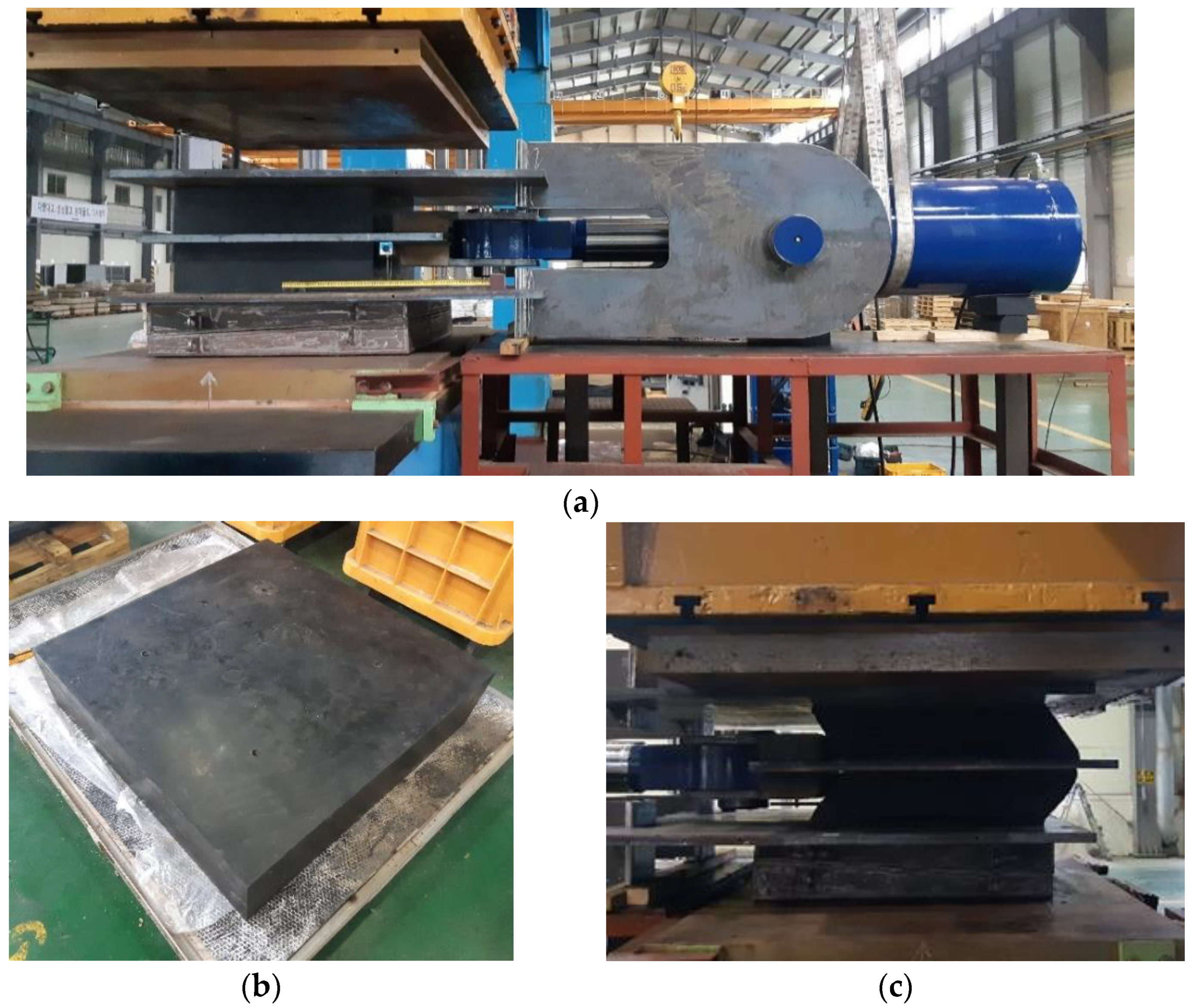

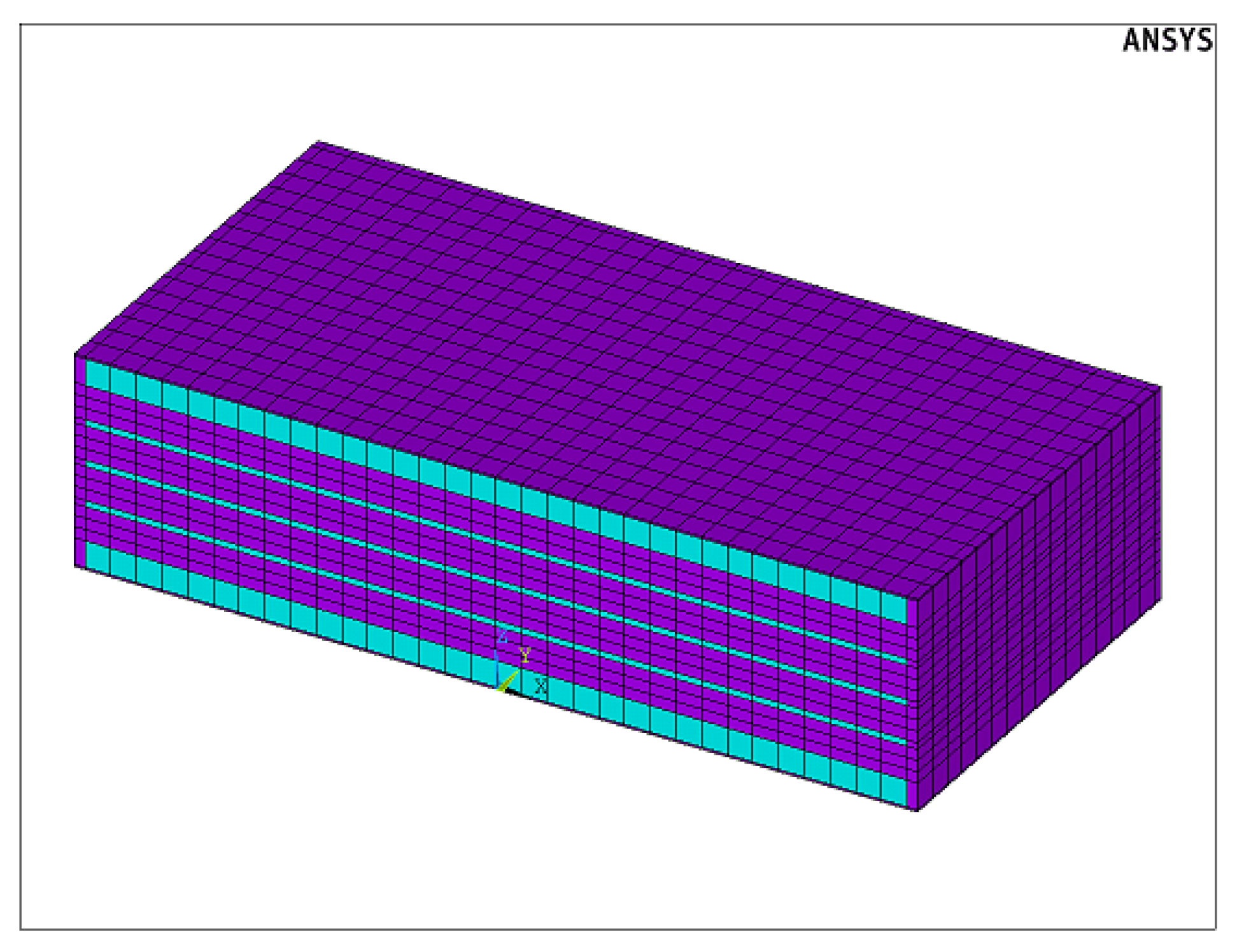

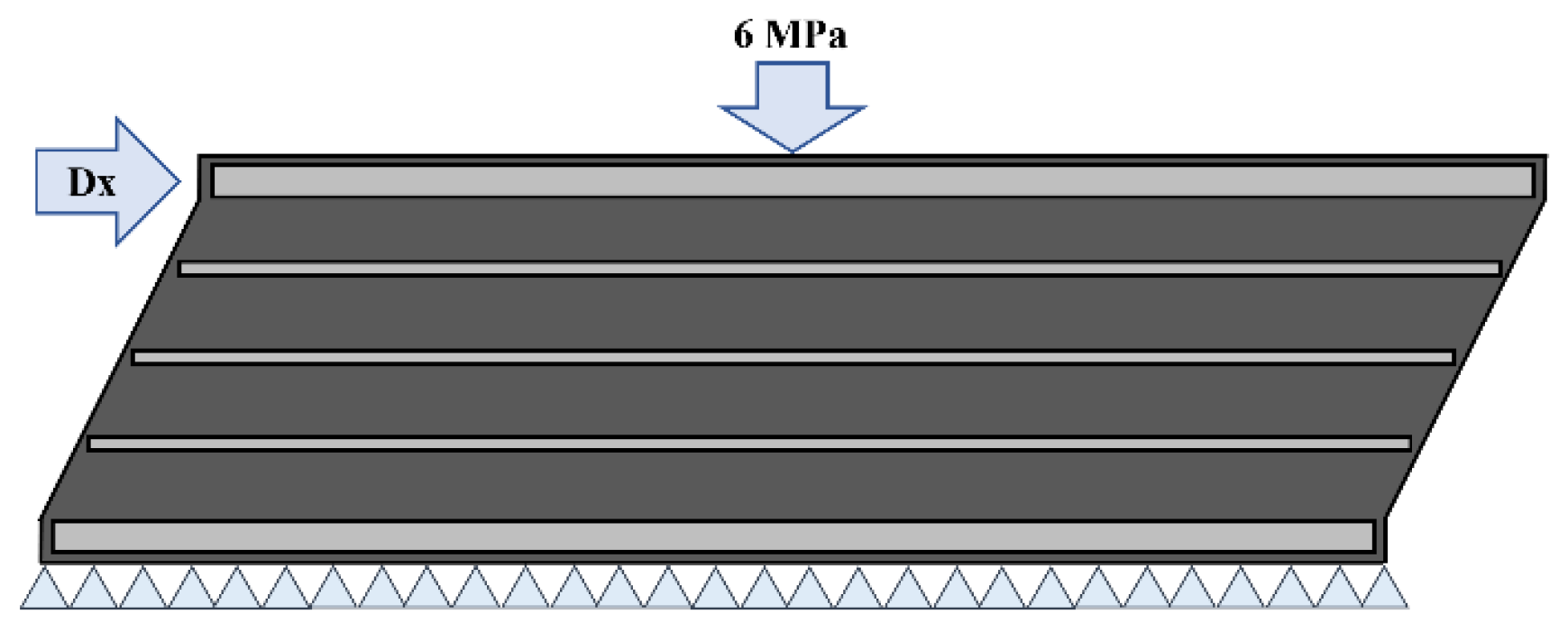

Offshore elastomeric bearings must be physically tested with full-size products in accordance with EN 1337-3 regulation. However, the experimental set-up incurs high cost due to large capacity of the test equipment and a dedicated shear test device. On the other hand, the numerical simulation can analyze various conditions at low cost, but in order to accurately analyze elastomers, which are hyperelastic (nonlinear) materials, it is necessary to find suitable analysis conditions. Therefore, finding the optimum analysis conditions for the numerical simulation technique that reproduce corresponding experimental results is necessary. The most crucial step in predicting the nonlinear behavior of a hyperelastic material through numerical simulations is considering the correct nonlinear model. When performing numerical simulations for hyperelastic materials such as rubber, the first-order, two-parameter (2P) Mooney–Rivlin (M-R) model is mainly used, which has a good response in compression within 30% and tension within 200%. On the contrary, the error is substantial in tensions of 200% or more. In this case, the responsiveness can be improved by using the 5P and 9P M-R models for the material behavior [

18,

19,

20]. In this study, three types of M-R models, such as 2P (first-order), 5P (second-order), and 9P (third-order), are used to increase the reliability of numerical simulation for offshore elastomeric bearings. The main objective of this research work is to propose a suitable M-R model for simulating the behavior of an elastomeric bearing under compression and shear tests by comparing and analyzing load-displacement graphs obtained with 2P, 5P, and 9P models with the experiment. Overall aim is to match the simulation results of elastomeric bearing’s shear modulus values with the experimental results. The research procedure for this is as follows: First, actual-sized offshore elastomeric bearing specimens are fabricated, and the experiment was conducted according to the procedure specified in EN 1337-3 Annex F: Shear Modulus Test. Second, the numerical simulation of the elastomeric bearing with respect to the behavior model of hyperelastic material was performed for the same conditions as the experiment. Third, after obtaining a shear force-displacement graph in both the experiment and the numerical simulation, the shear modulus is calculated and compared by using the slope of the graph. Last, the shear modulus of the elastomeric bearing with respect to the shore hardness was verified by comparing the numerical simulation values with the values presented in EN 1337-3 Annex D. A 2500-ton press equipped with a shear test device with a capacity of 300-tons is used for the experiment, and ANSYS Mechanical APDL [

21], a general-purpose finite element analysis program, is used for numerical simulation.

5. Conclusions

The most important item when indicating the mechanical properties of offshore elastomeric bearings is the shear modulus, but the experiment incurs a high cost due to a large capacity test equipment and a dedicated shear test device. As an alternative, a method for designing offshore elastomeric bearings through numerical simulation is proposed. In this study, the relationship between the experiment and the numerical simulation on the shear force of the bearing was analyzed to improve the accuracy of the numerical simulation. The conclusions are as follows:

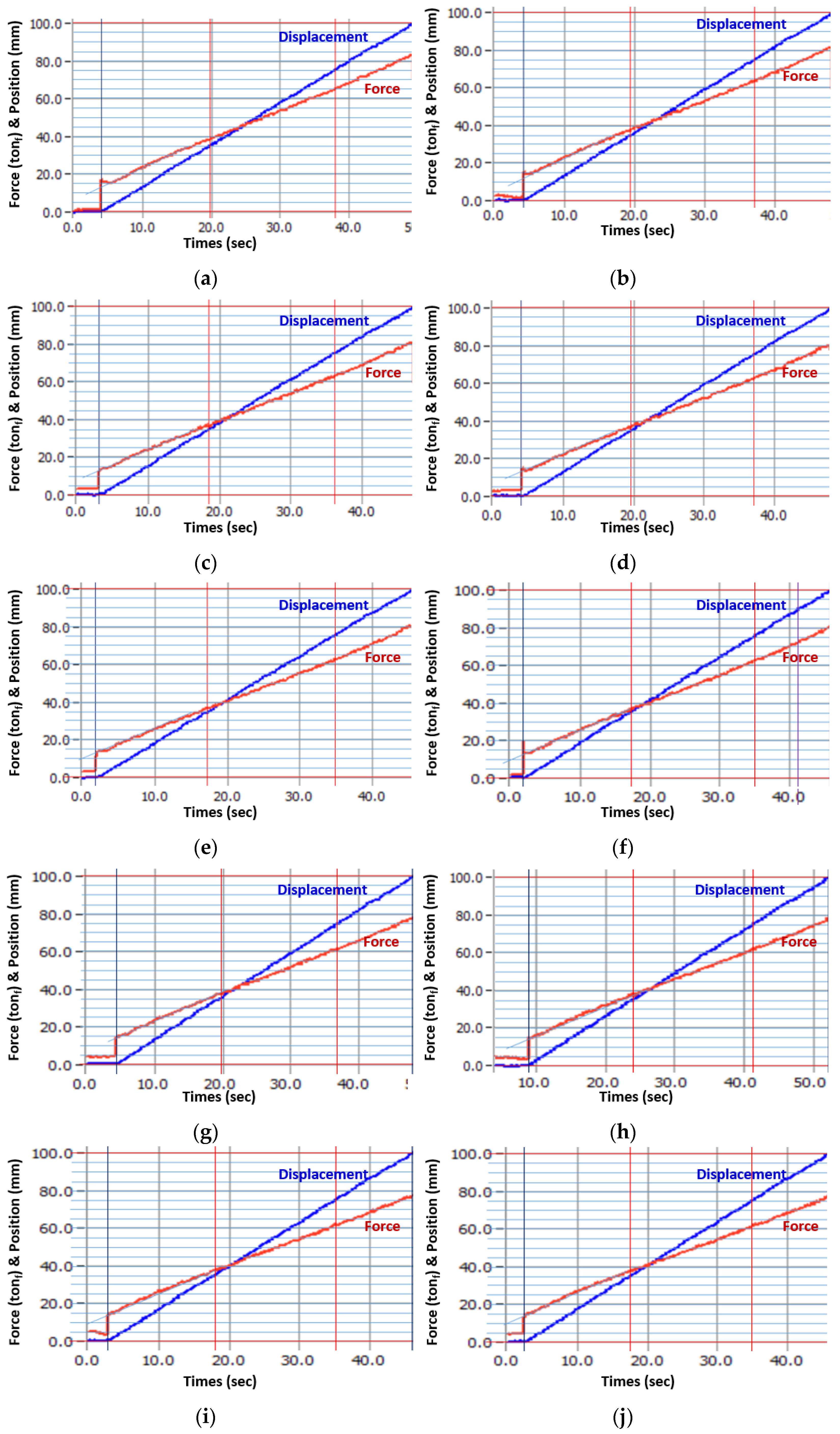

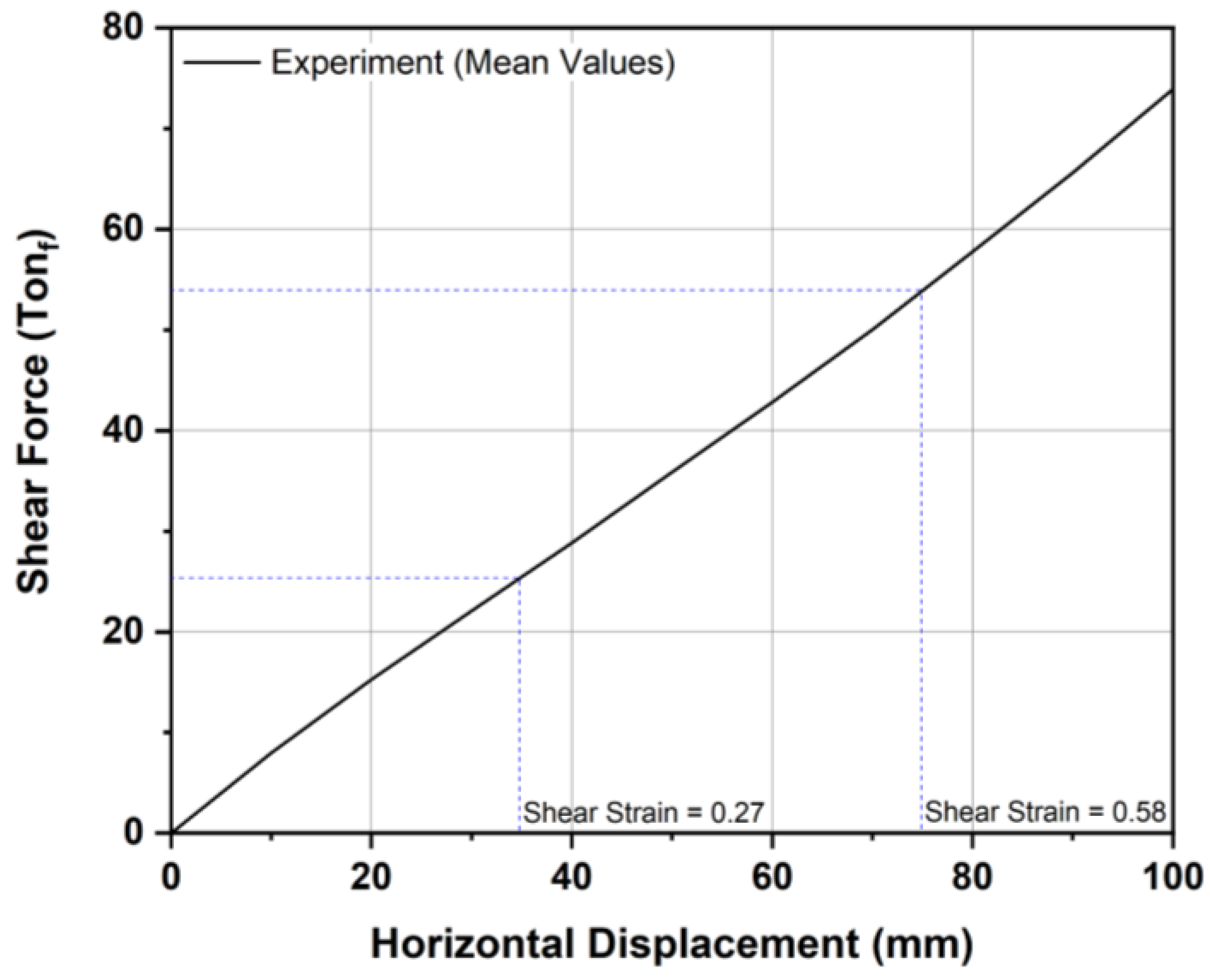

(1) In the experiment according to EN 1337-3 Annex F: Shear Modulus Test, 10 tests for the bearing specimen (800 × 800 × 200 mm) were performed with a shear strain of 0.77 (shear displacement of 100 mm). The measured average shear modulus of the bearing specimen is 0.707 MPa, which corresponds to a Shore A hardness of 50 + 5 grade with reference to EN 1337-3: Annex D.

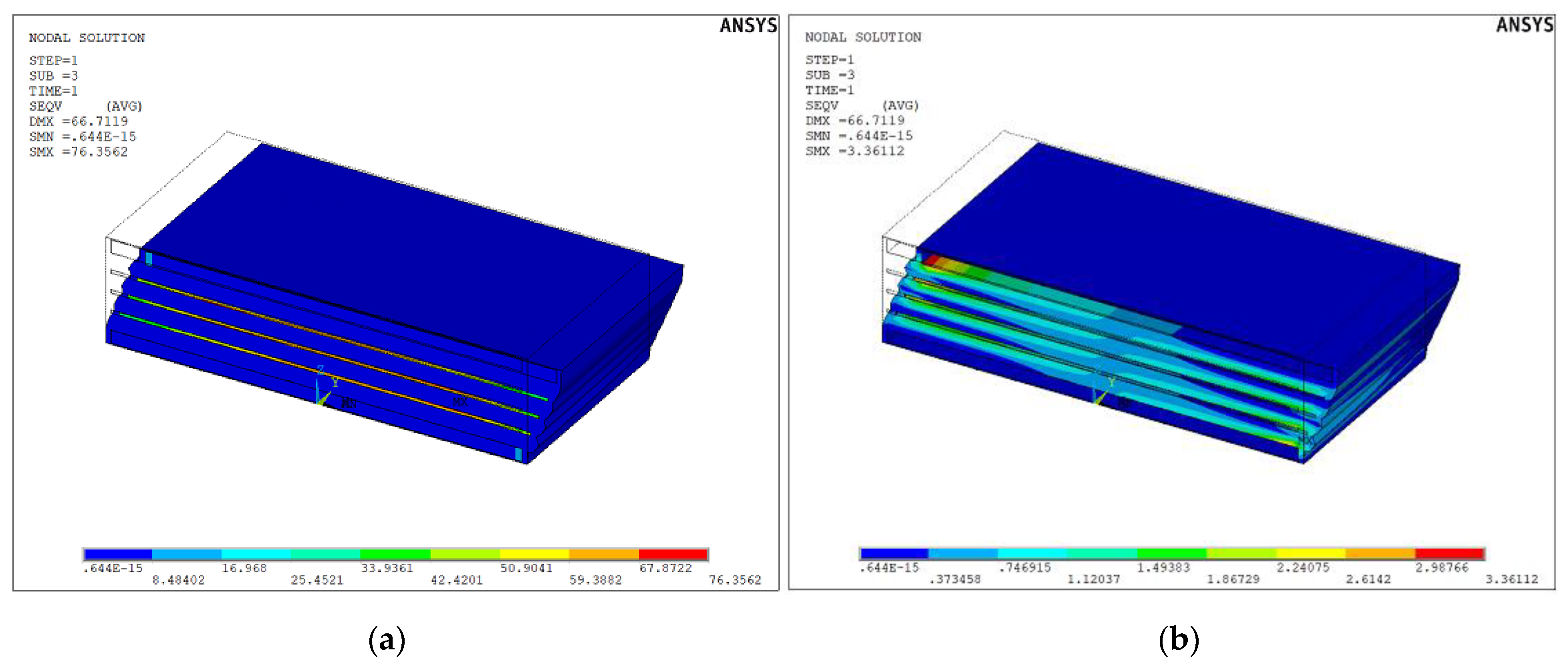

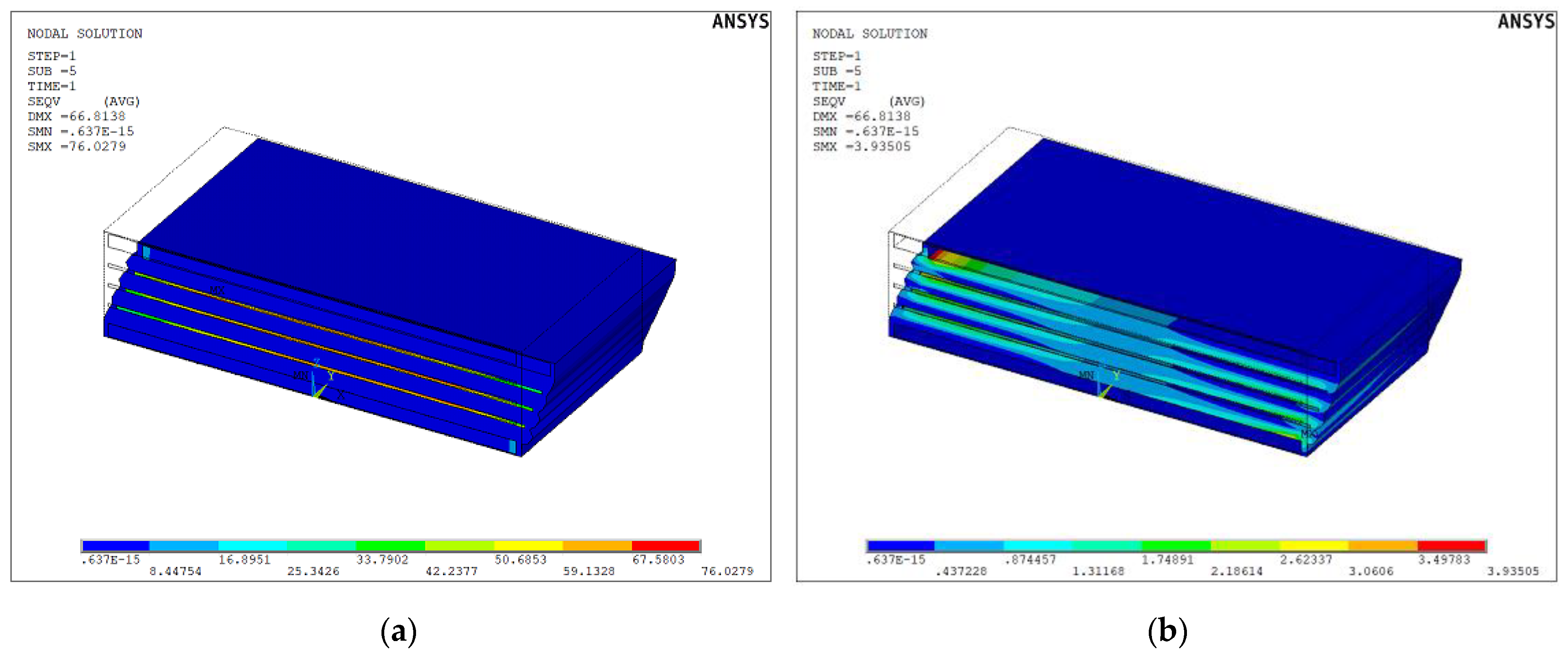

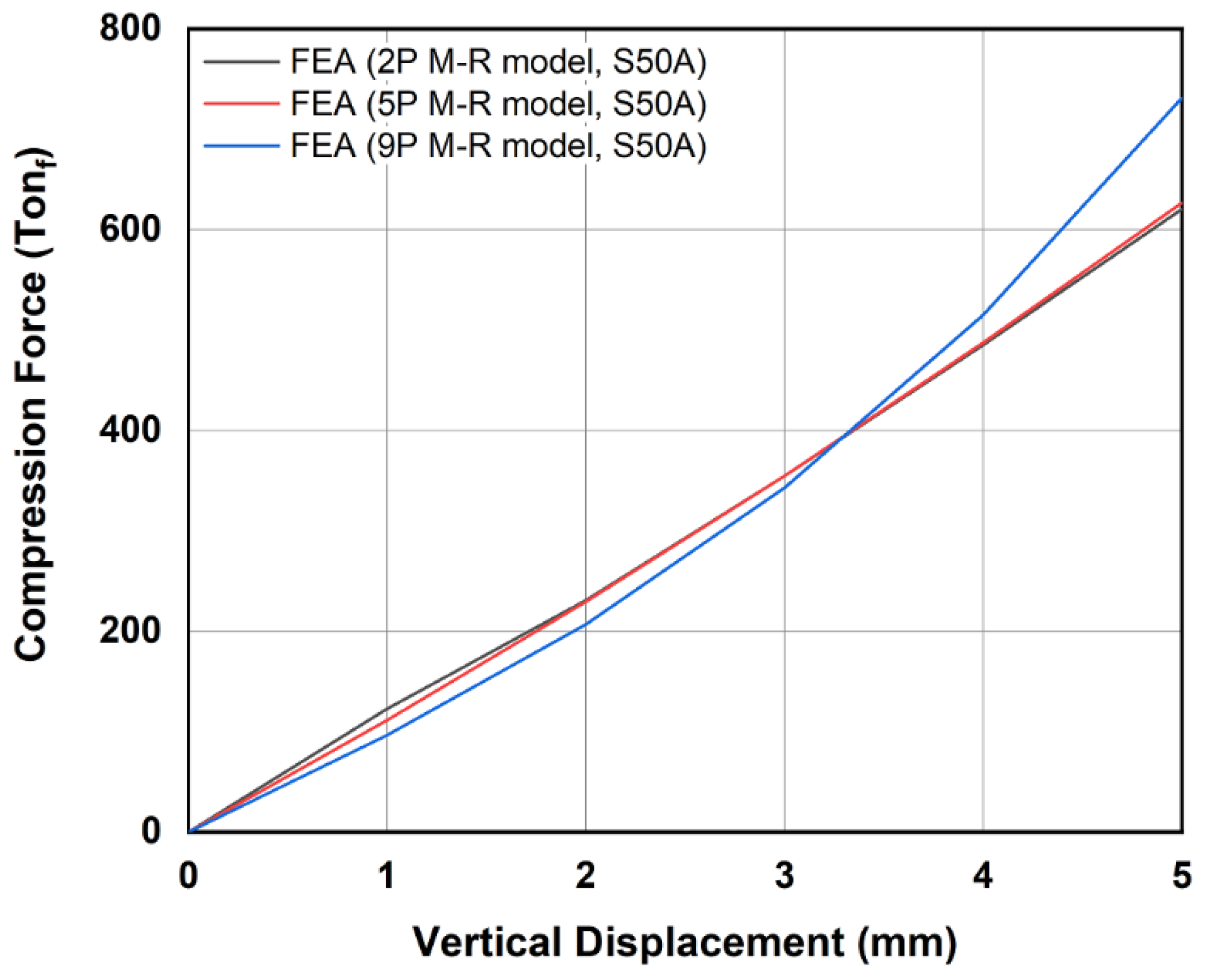

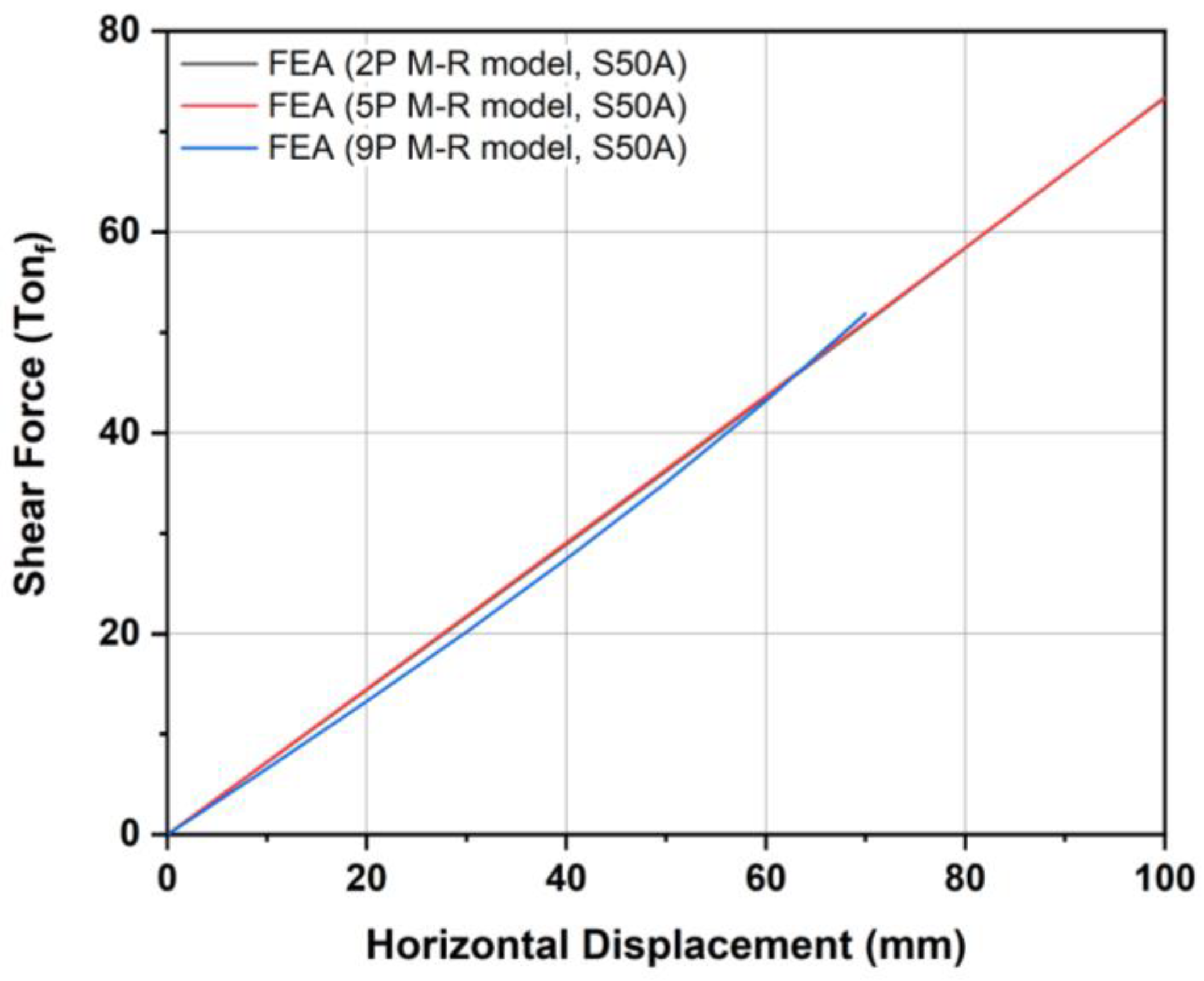

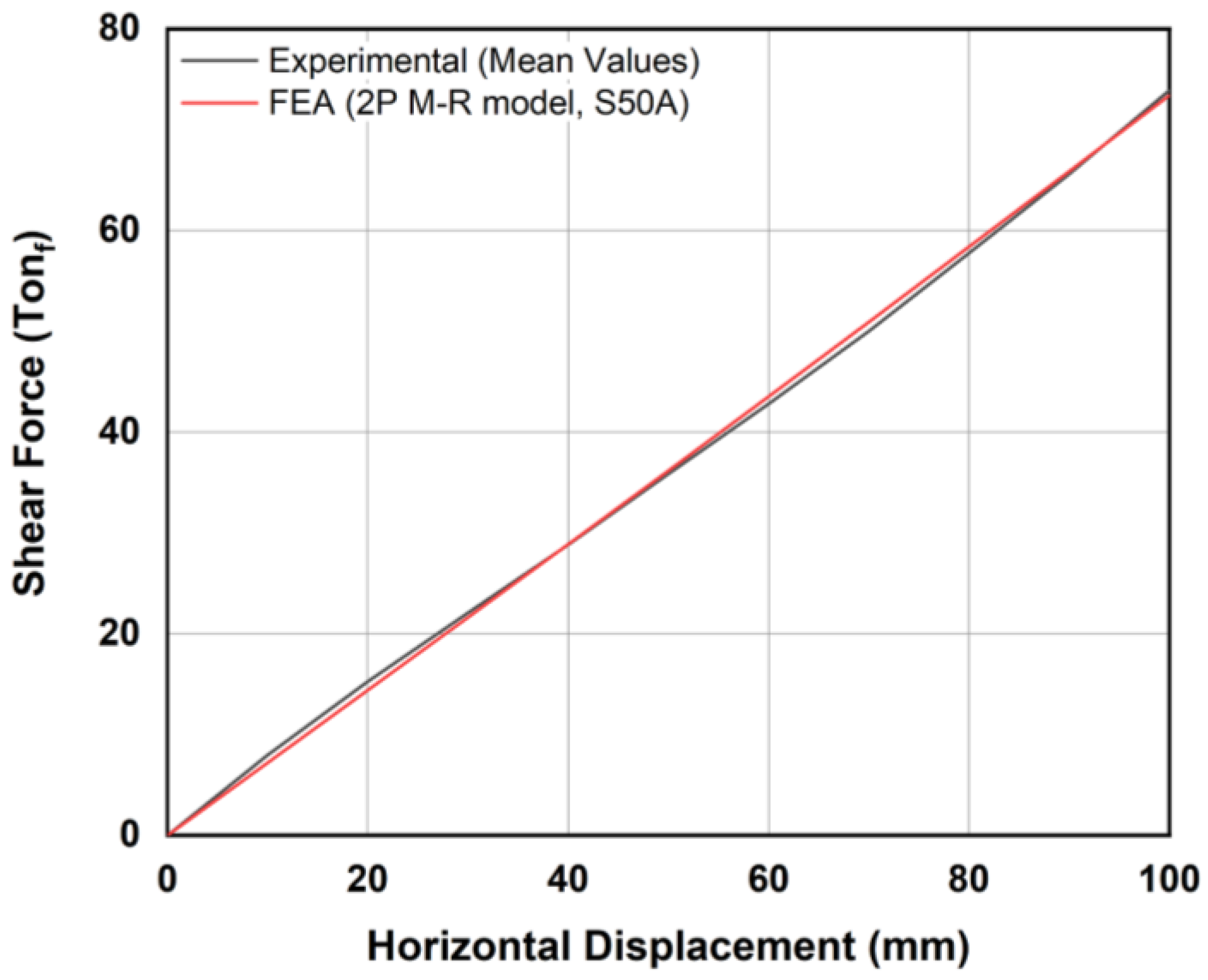

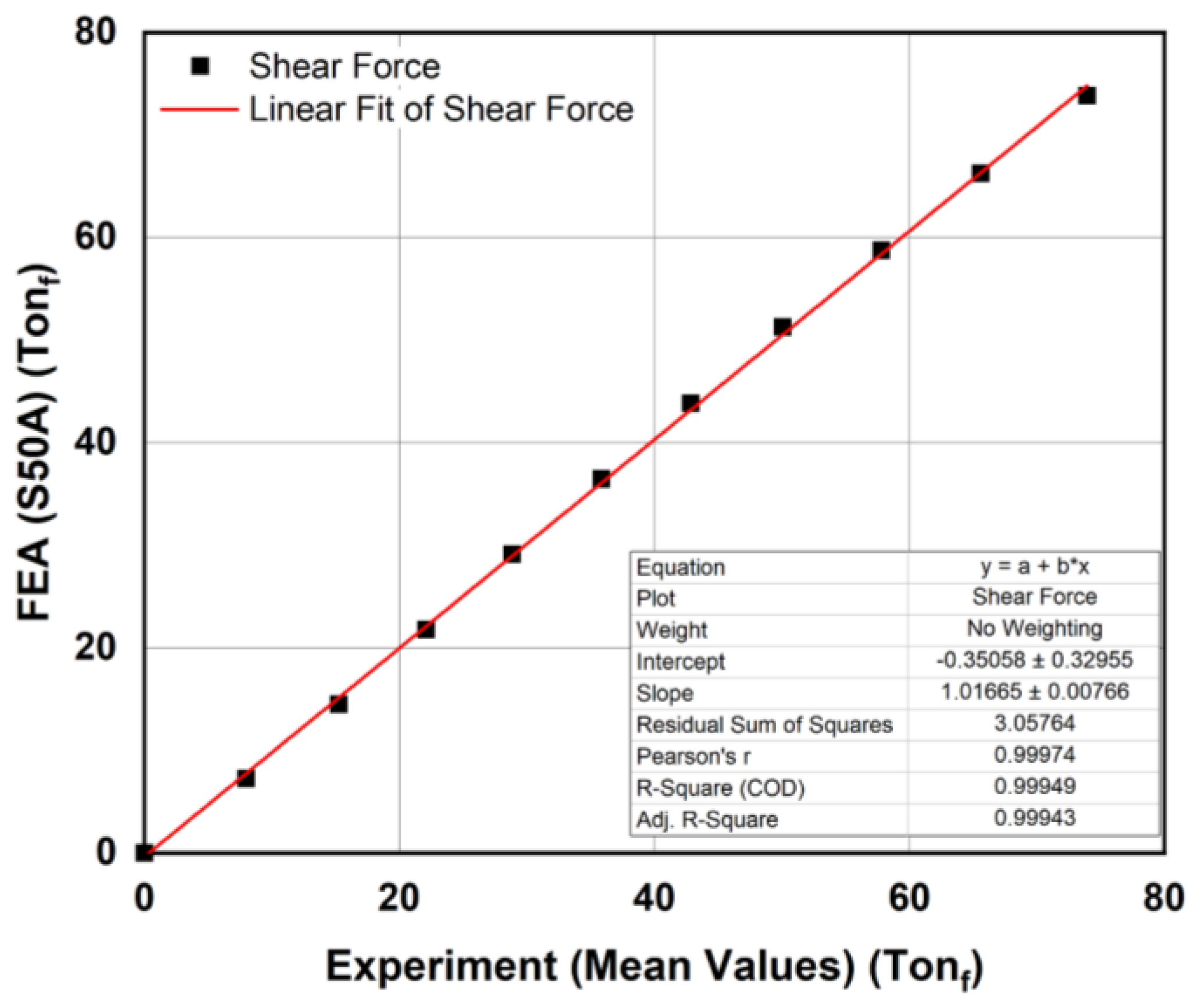

(2) In the numerical simulation, the Mooney–Rivlin (M-R) model is generally used for the hyperelastic materials, and there are three types of M-R models, such as 2P, 5P, and 9P based on the number of the terms in the series. The results of the compressive load-displacement from 2P and 5P M-R models are almost linear, and the difference between the two values is 2.23% on average, but in the case of 9P model, showing a difference of 11.83% from the 2P model. On the other hand, the shear-force displacement results obtained from the 5P model showed negligible difference with the 2P model, with an average error of 0.38%, and 9P showed an average error of 4.82%. In addition, the correlation coefficient (R2) for a regression model for the linear relationship between the experiment and the numerical simulation (for 2P M-R model) results is 0.99949, indicating a very good fit. Therefore, it can be seen that the nonlinear behavior model suitable for numerical simulation of marine elastomer bearings is the 2P M-R model.

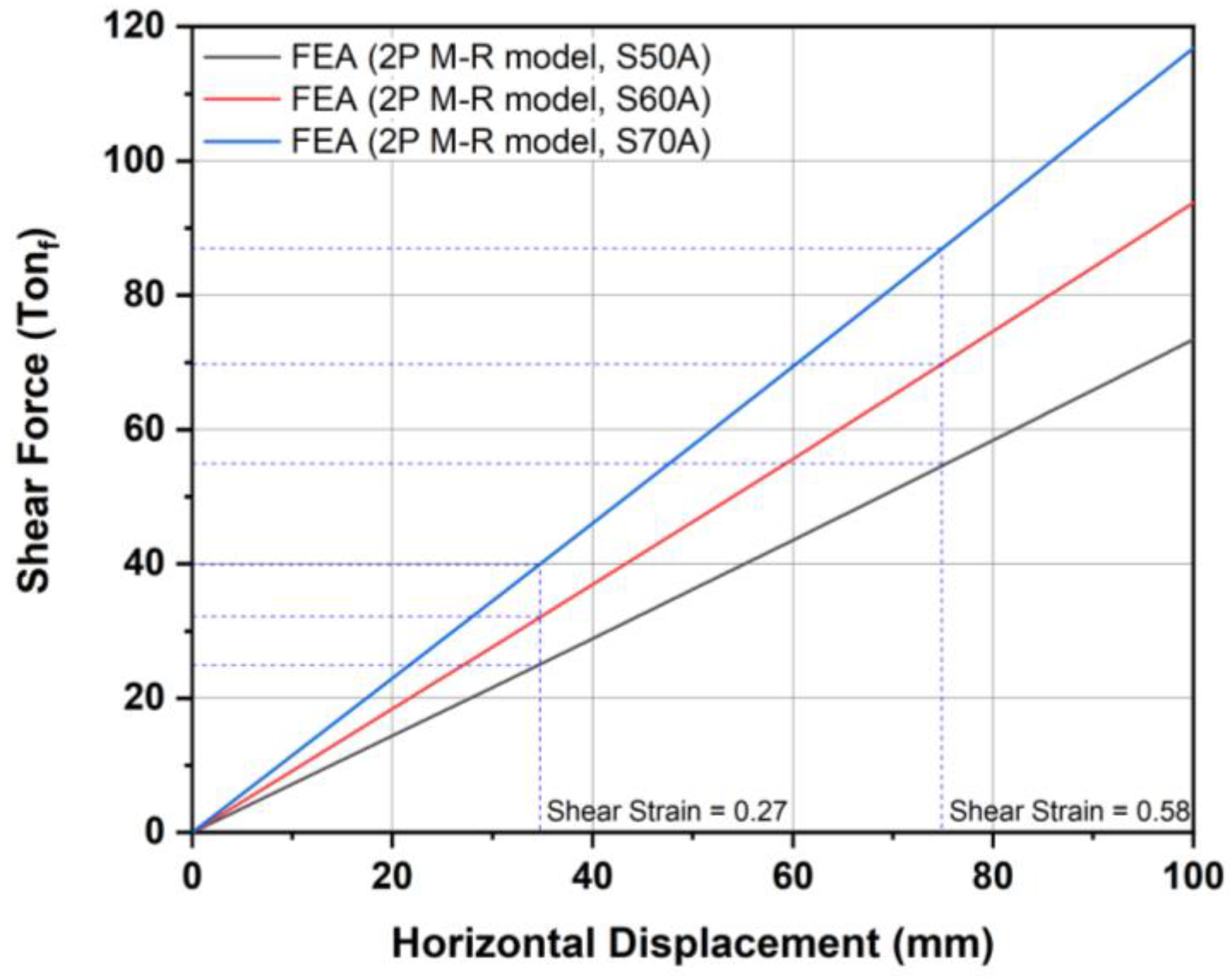

(3) In order to verify the analysis conditions suggested in this study for the numerical simulation, the shear force according to the horizontal displacement of the analytical model was obtained through numerical simulations at 60A and 70A as well as the hardness of the elastomer 50A. The shear modulus of the bearing through the numerical simulation (FEA) is 0.731 MPa (when shore hardness is 50A), 0.935 MPa (when 60A), and 1.165 MPa (when 70A). This indicates that the shear modulus of the bearing through the numerical simulation is corresponding to the values in EN 1337-3 Annex D: Shear Modulus Comments.

(4) Therefore, it is confirmed that the analysis conditions suggested in this study for the numerical simulation of the elastomeric bearing are capable of reproducing the experimental results for the shear modulus.