2.1. Fabrication of Full-Scale BH Girder Bridge and Installation of OSPC Strand

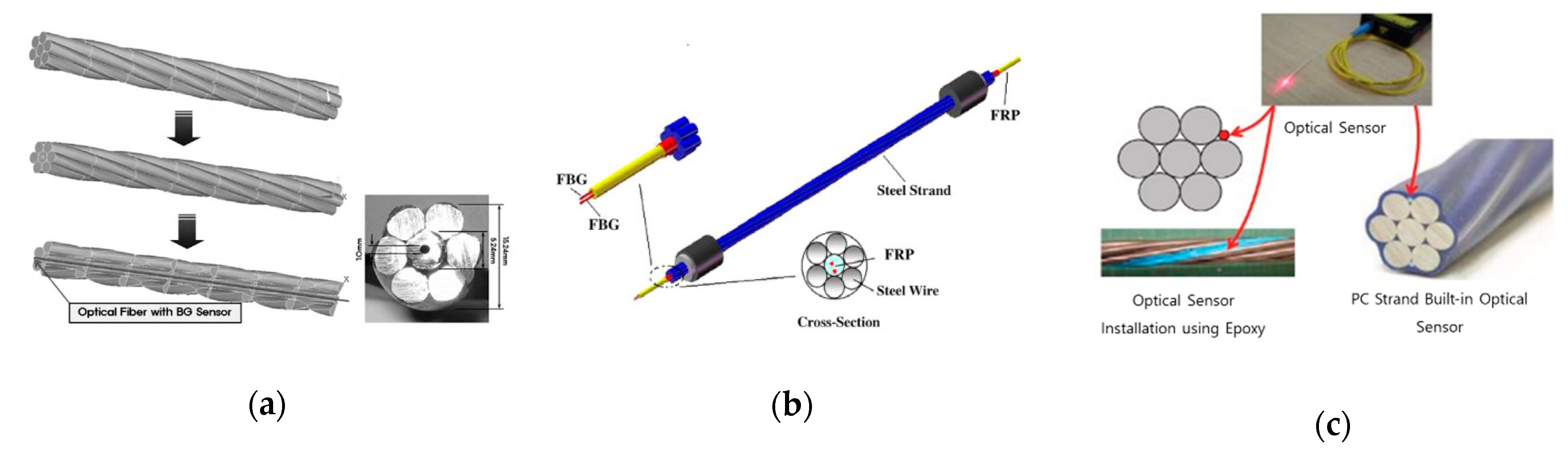

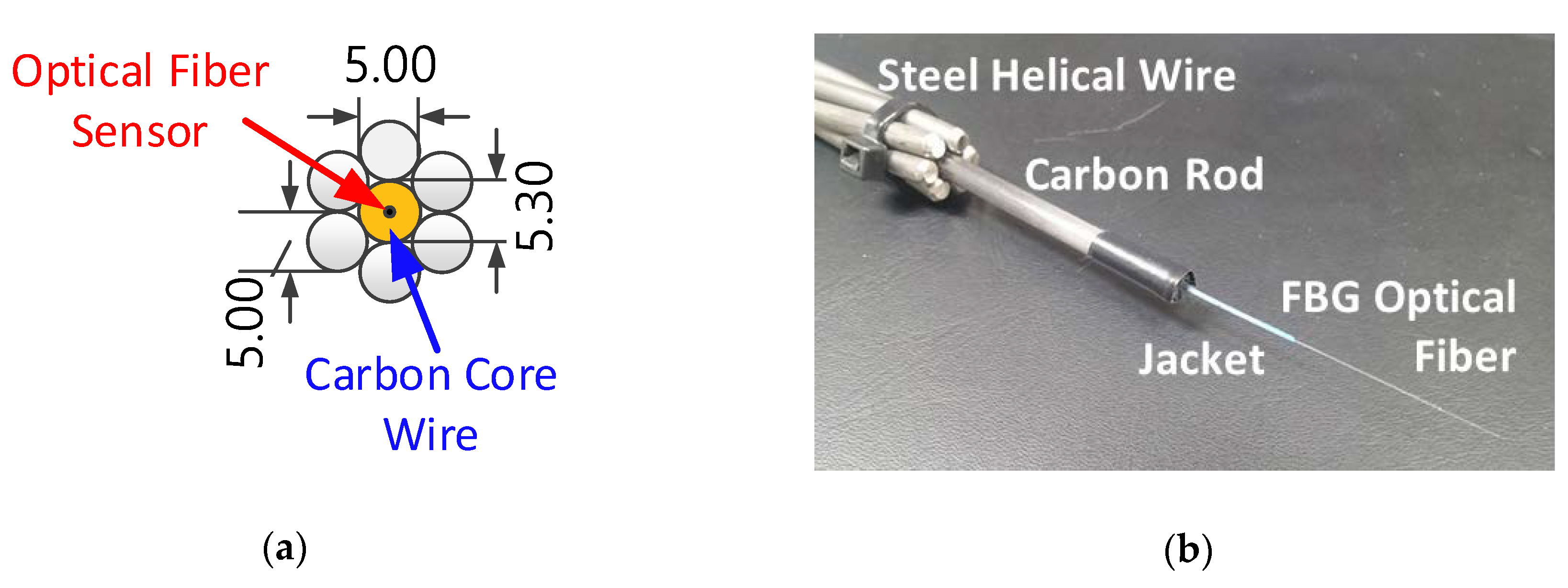

Figure 3 shows the conceptual drawing and a photograph of the manufactured OSPC strand. Since the OSPC strand had shapes and dimensions identical to a conventional steel strand, the same anchoring device could be used. In addition, considering that the OSPC strand exhibits performance equivalent or superior to that of the conventional steel strand, the OSPC strand offers the advantage of being able to play both roles of sensor and reinforcing member.

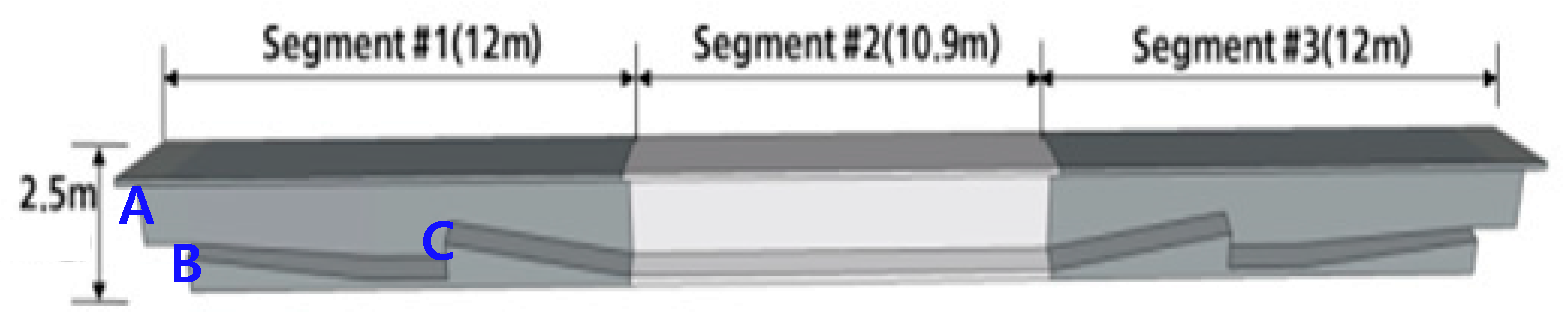

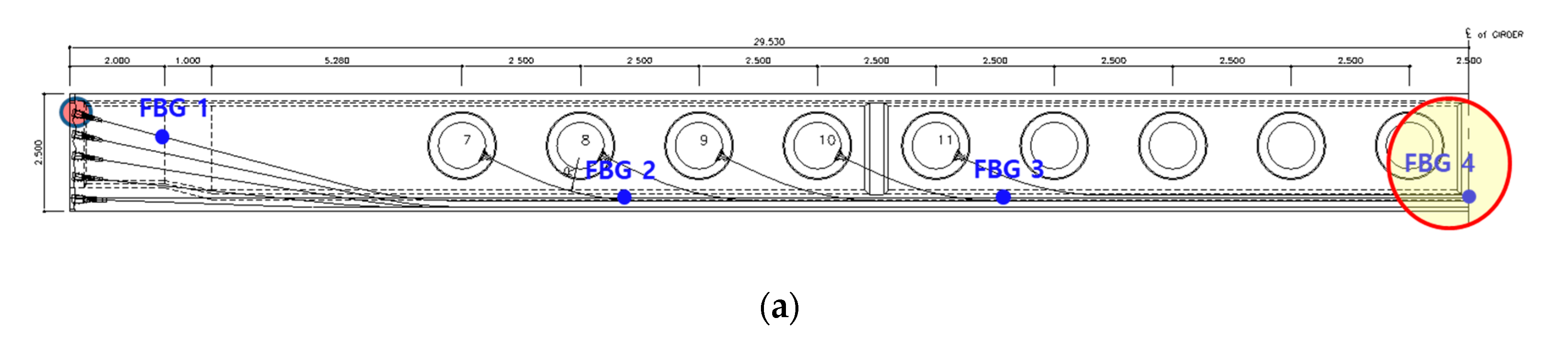

The full-scale BH girder bridge prototype constructed for the test had a length of 35 m and a deck depth of 2.5 m (

Figure 4). The anchorages were disposed at the top and bottom of the cross-section and near the connections between the segments. To observe the overall state of the prestressing force in the bridge, one OSPC strand was installed at each anchorage. Considering the profile of the tendon involving straight and curved parts, each sensor was set to have three to seven sensing points.

Figure 4 depicts the shape and dimensions of the BH girder bridge applying the OSPC strand and indicates the locations of the anchors (A, B, C).

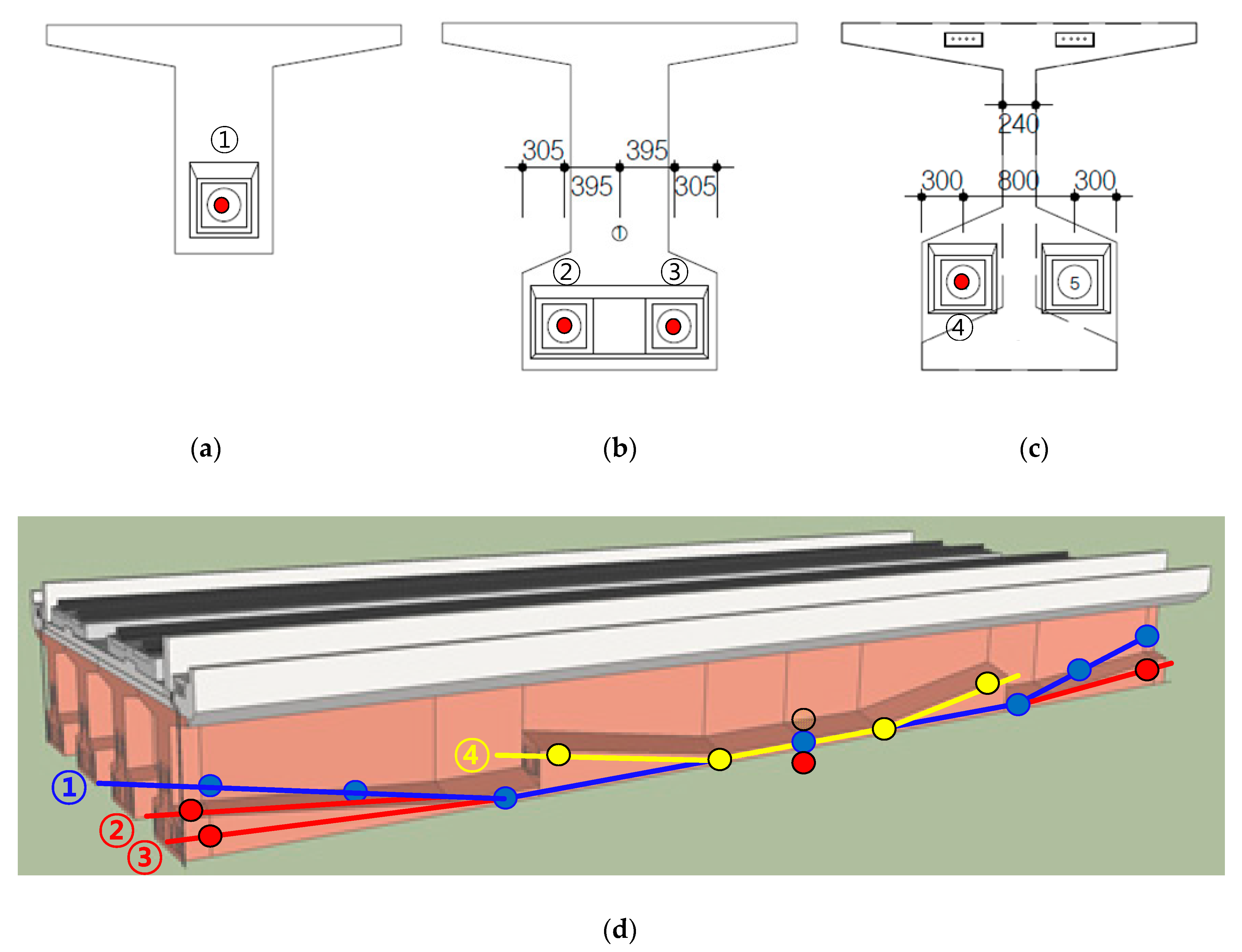

Figure 5 shows the position of the OSPC strand in the cross-section for each of the anchors, A, B, and C, of

Figure 4, as well as the numbering of the tendons.

Table 1 provides the details of the tendons one, two, three, and four, like the profile and length, the number of sensing points, and the prestressing method.

Table 2 shows the specification of the FBG sensor and measurement equipment used for manufacturing the OSPC. The FBG sensor used in OSPC fabrication distinguished the wavelength intervals so that the wavelengths did not overlap when a tension force was applied. Data was acquired once per second using an interrogator, and then the change in wavelength was converted to strain using the wavelength-strain formula from Equation (1)

where

is the reference wavelength before tension force is introduced, and

is the change in wavelength from the measurement.

is the elastic strain.

is effective photoelastic constant for the fiber and generally 0.22 is applied. Although the FBG sensor was sensitive to temperature, the temperature change was not considered. This is because the tension force as introduced for a short time, and the wavelength change by the tension force was quite large [

14]. In this paper, after converting the measured wavelength into strain, the tension force was estimated by applying the elastic modulus (195 GPa) from the basic tensile test of OSPC and the cross-sectional area.

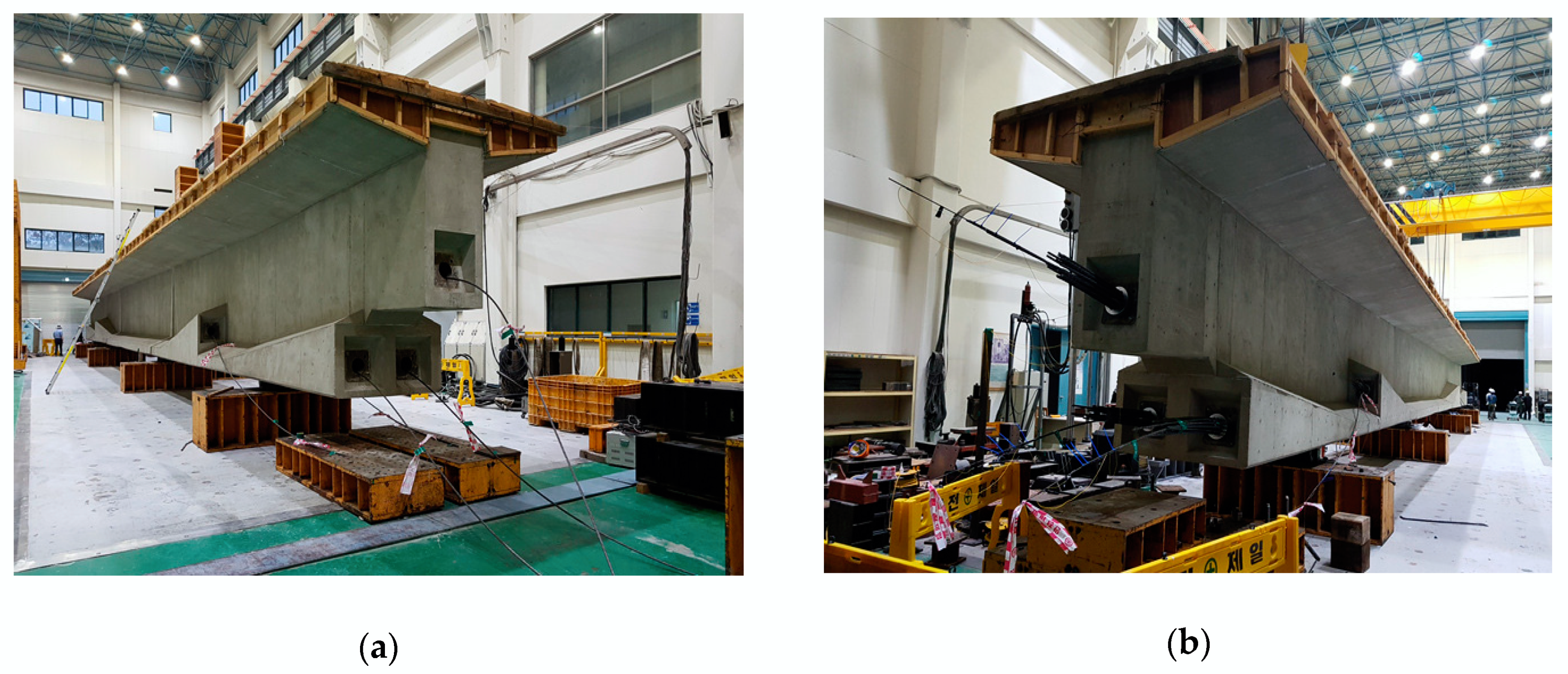

Figure 6 shows pictures of the fabricated full-scale BH girder bridge prototype installed with the OSPC strand.

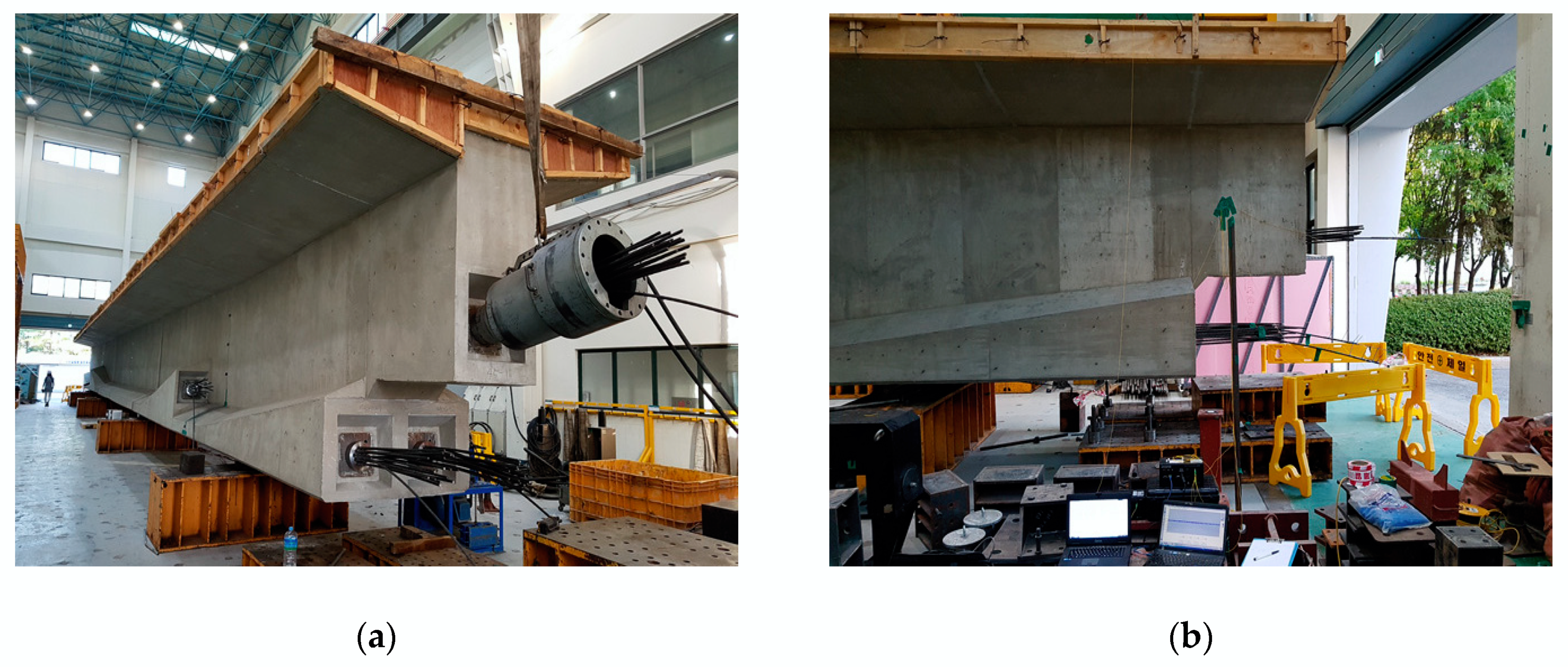

Figure 7 presents the tensioning process of the girder bridge and the measurement of the prestressing force during the process.

2.2. Prestressing of Full-Scale BH Girder Bridge Prototype

The prestressing of the BH girder bridge was executed by tensioning the tendons sequentially with respect to their number, as given in

Figure 5 and

Table 1. The process was performed in six steps by introducing prestress in tendons one to three of up to 3200 kN and, then, tensioning tendon four up to 2100 kN. The calculation provided an average prestressing force of 177.8 kN in the strands of tendons one to three and of 175.0 kN in the strands of tendon four. The prestressing force measured by the OSPC strand installed in each tendon was 173.1 kN for tendon one, 164.0 kN for tendon two, 165.7 kN for tendon three, and 168.5 kN for tendon four. These values were slightly lower than the target prestressing force and about 92.3% to 97.4% to the target values. However, if prestressing is conducted simultaneously using multiple hydraulic jacks for several strands, the resulting prestressing force for each individual strand would naturally exhibit a slight difference. This situation was reported in 2005 by Chandoga and Jaroševič [

15] through actual measurements. Moreover, Cho et al. [

16] analyzed the distribution of the prestressing force in the strands of the tendon and revealed that this distribution was normal with a variation of about ±4% around the mean value. Accordingly, even if the prestressing force measured by the OSPC strand is slightly lower than the target value, the measurement can be assumed to be correct.

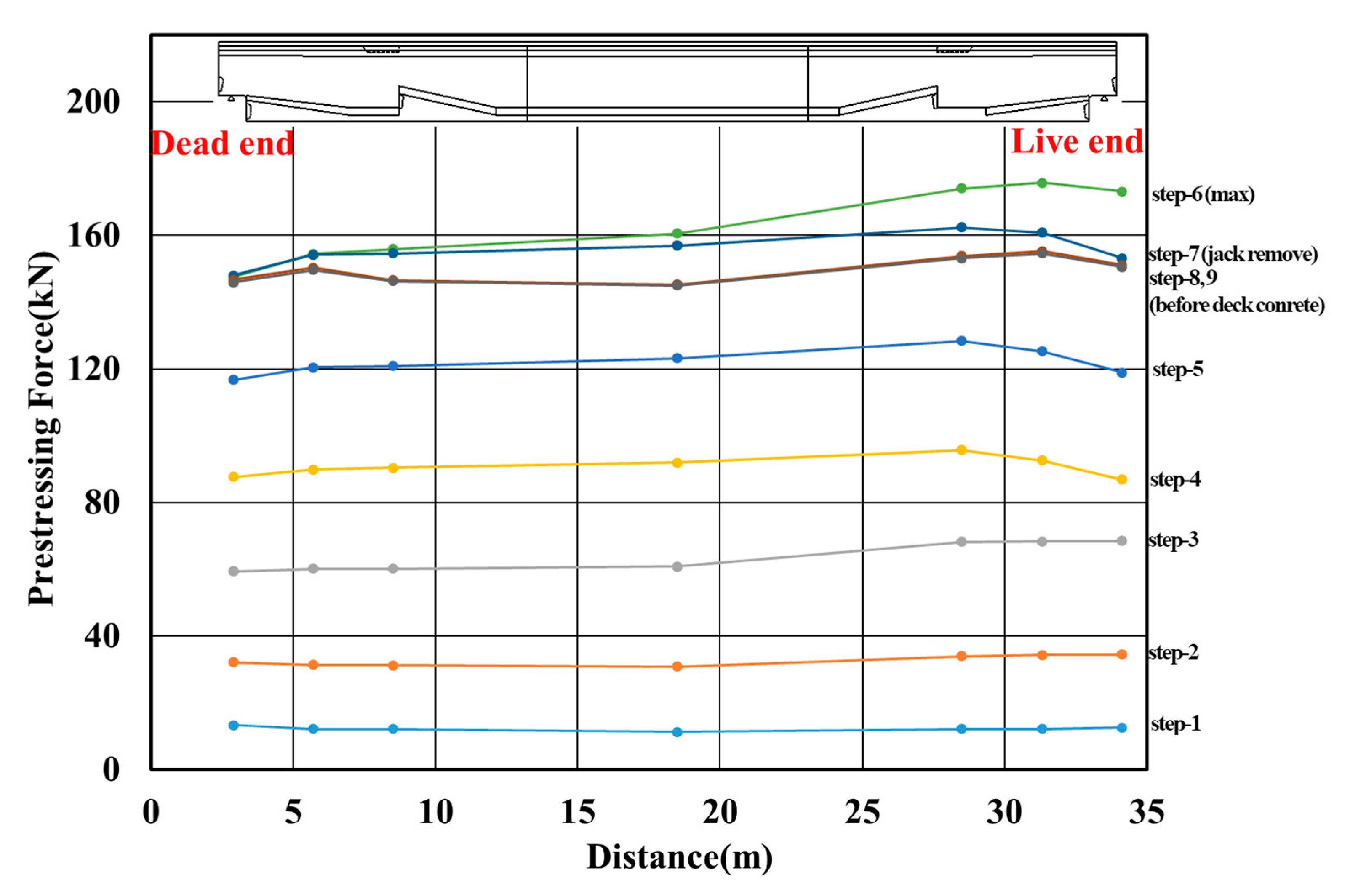

Figure 8 plots the change of the prestressing force measured in tendon one by the OPSC strand at each tensioning step. It could be observed that the prestressing force presents different distributions along the longitudinal direction. It is well known that the prestressing force generally exhibits its largest value at the end that is tensioned (live end), but

Figure 8 revealed that one sensor measured a slightly lower value near the hydraulic jack when the maximum tensioning force was attained. This discrepancy can be credited to the helical arrangement of the strands inside the tendon.

Besides, the loss of prestressing occurring during the removal of the hydraulic jack after the tensioning process could also be measured. This loss is called the immediate loss and is arranged per anchor in

Table 2. Assuming a loss of 5 mm due to the slip of the wedge in the anchor, the immediate loss that may occur in the anchors runs between 2.3% and 3.9%. However, the values of the immediate loss in

Table 2 fell slightly beyond this range. This greater immediate loss can be explained by some imprecision in the relative arrangement of the wedge and strands and in the fixation of the wedge of the hydraulic jack. Nevertheless, these higher values for the loss are acceptable considering that the loss of the prestress force generally ranged between 15% and 30% by accounting for the immediate loss as well as the loss according to time.

In addition, the anchor set length that is the distance over which the difference in the prestressing force due to the slip of the wedge at the removal of the hydraulic jack (step-7) and the maximum tensioning force (step-6) had an effect that was seen to be longer than 20 m in

Figure 8. This length was significantly longer than the value of 13.9 m obtained by calculation for the anchor set length. This calculated value is usually adopted in studies related to the anchor set length because of the difficulty to acquire actual data all along the tendon in the PSC structure. Note that KICT is currently developing an OSPC strand with distributed sensing to improve the present OSPC strand with a finite number of sensing points. The future application of this new OSPC strand to PSC structures will make it possible to compute the anchor set length more accurately.

The so-prestressed BH girder bridge prototype was finally completed by injecting grout and placing the top concrete. The performance of the completed full-scale BH girder bridge was verified via static test through four-point loading and dynamic test using an actuator.

Figure 9 presents the placing of top concrete and the completed bridge in place for testing.

2.3. Test and Measurement of Full-Scale BH Girder Bridge

For the measurement of the dynamic properties, accelerometers and displacement sensors were disposed vertically at the center on the bottom of each segment. As presented in

Table 3, the values measured by the FBG sensor at mid-length of the OSPC strand in tendon one were used. Consequently, the accelerometers measured the vertical vibration, and the OSPC strand measured the transversal vibration.

Figure 10 illustrates an installed accelerometer and the actuators used to load the bridge.

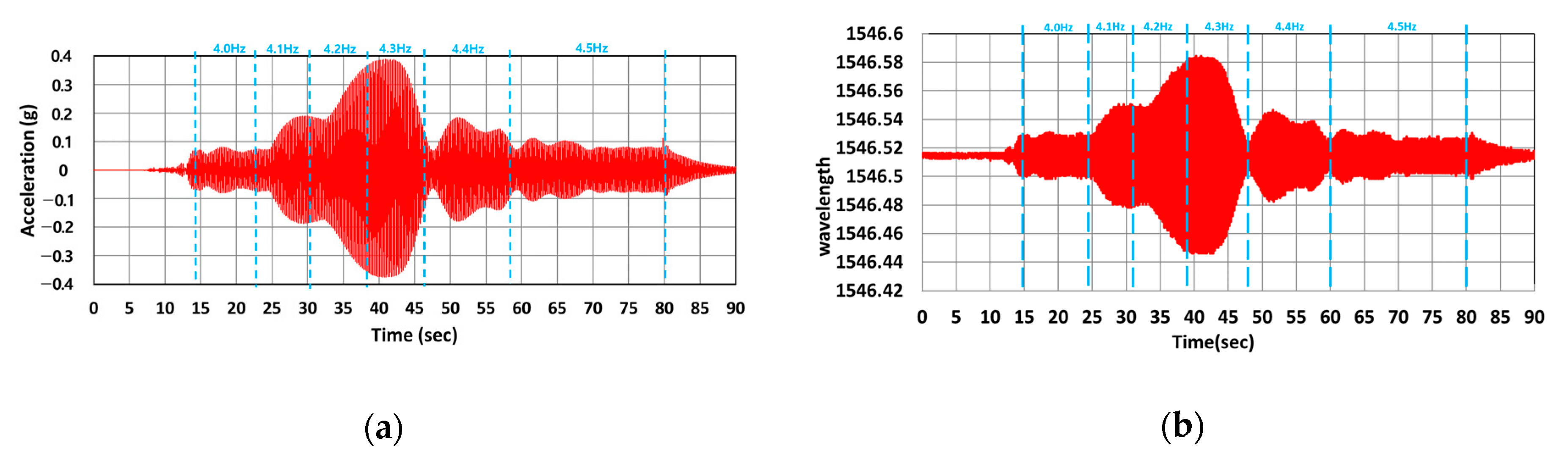

The forced vibration test using the actuators applied loading with gradual increase of the exciting frequency from 1 Hz to 5 Hz, and the corresponding responses of the bridge were observed. The observation revealed that the largest amplitude of vibration occurred around 4 Hz. As shown in

Figure 11, resonance happened between 4.2 Hz and 4.3 Hz in both data from the accelerometers and FBG sensor.

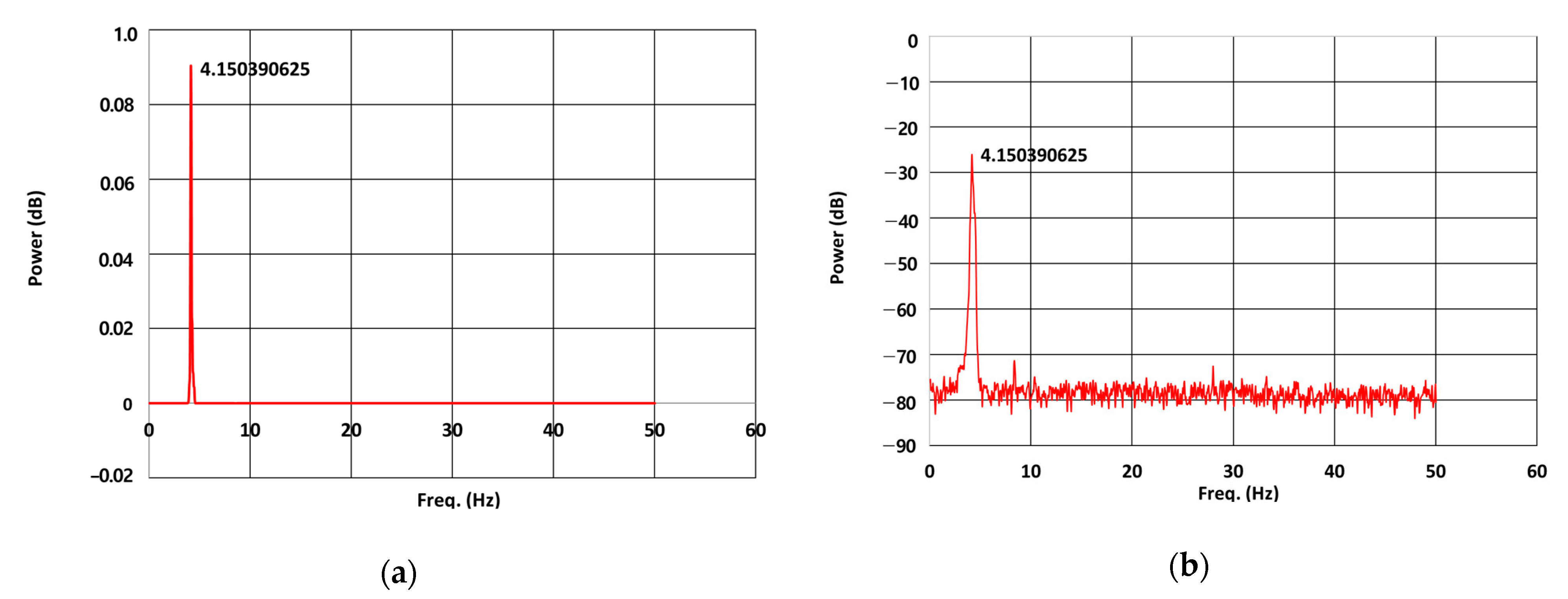

In order to analyze the frequency contents of the vibration test data from the accelerometers and FBG sensor, the Welch method [

17] was adopted to estimate the averaged periodograms of the overlapping segments in the signals, and these averaged periodograms were used to perform the analysis of the two different data in the frequency domain. Since the resonant frequency occurred below 30 Hz for the bridge, the sampling frequency was set to 100 Hz to secure a sufficient margin. The frequency band computed by the Welch method fell within the Nyquist frequency between 0 and 50 Hz. The Hanning function was used as the window function needed to conduct the segmental averaging of Welch and minimize the leakage effect. The window function involved a total of 4095 data, and the segments were generated by moving the window according to the time sequence. Fast Fourier transform (FFT) was executed for each segment to compute the power in the frequency domain, which was averaged to provide the final value.

Figure 12 plots the natural frequencies of the accelerometer data and FBG sensor data obtained by this method. The computed natural frequency of the first mode appears to be identical for both types of data. This result indicates that the FBG sensor embedded in the OSPC strand that was arranged transversally in the bridge could accurately measure the acceleration of the structure.

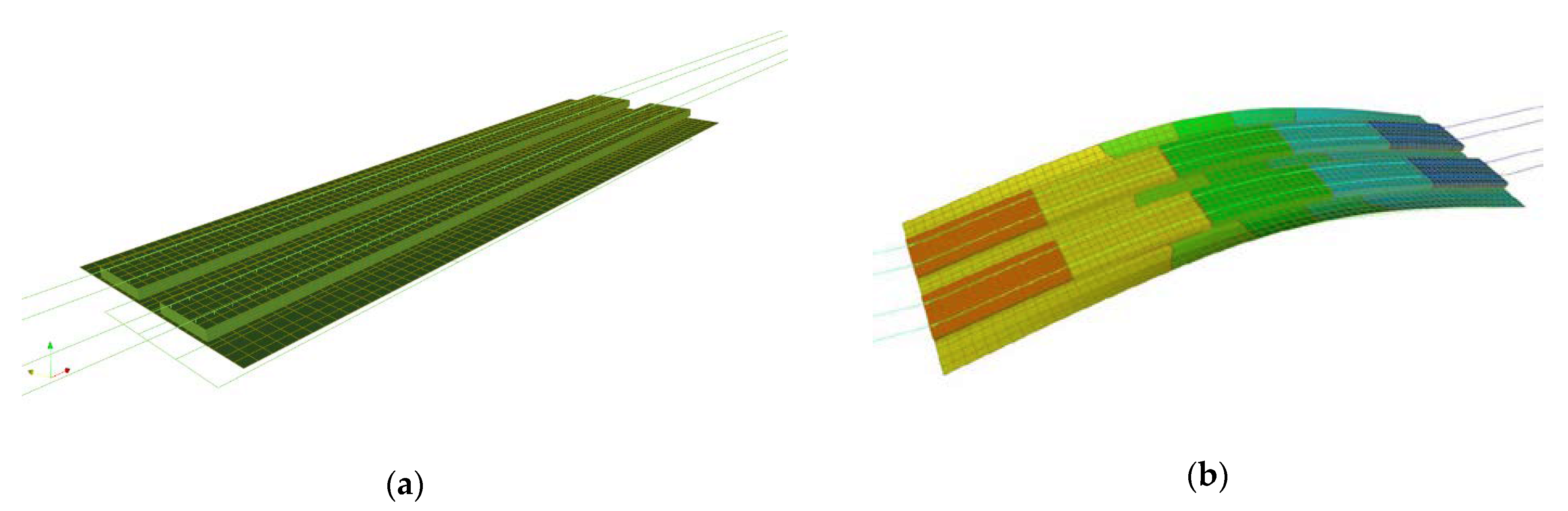

The dynamic analysis of the bridge structure was performed. To that goal, a three-dimensional model was established and reflected the track structure to achieve precise analysis. Two-node beam elements were used for the girder and cross beams, and four-node shell elements were adopted for the deck. The natural frequency analysis was executed using an in-house program developed at KICT in 2008.

Figure 13 depicts the analytic model and the first-mode shape of the structure [

13].

From the analysis, a natural frequency of 4.2783 Hz was computed for the first mode, which is slightly smaller by about 0.1279 Hz compared to the frequency of 4.1504 Hz obtained from the test. This small difference can be credited to the boundary conditions, which assumed simple supports (hinge and roller) in the analysis, whereas the prototype was supported actually by two rollers at its ends. Moreover, some differences in the material properties adopted in the analysis might also possibly have caused this discrepancy.

The data above are those obtained by vibrating the structure sufficiently using the actuator and allowed clear identification of the natural frequency. In general, data related to the longitudinal direction along the girder in bridge structures present poor sensitivity compared to the vertical acceleration response of the bridge, which made them improper for identifying the natural frequency. However, Lee et al. [

18] determined the impact factor of an actual in-service railway bridge structure based upon data measured by electrical resistance gages installed longitudinally in the girder near a FBG sensor during the crossing of train convoys. Moreover, prior to the test presented in this study, the OSPC strand was already installed inside the girder of a road bridge with a span length of 60 m and in operation.

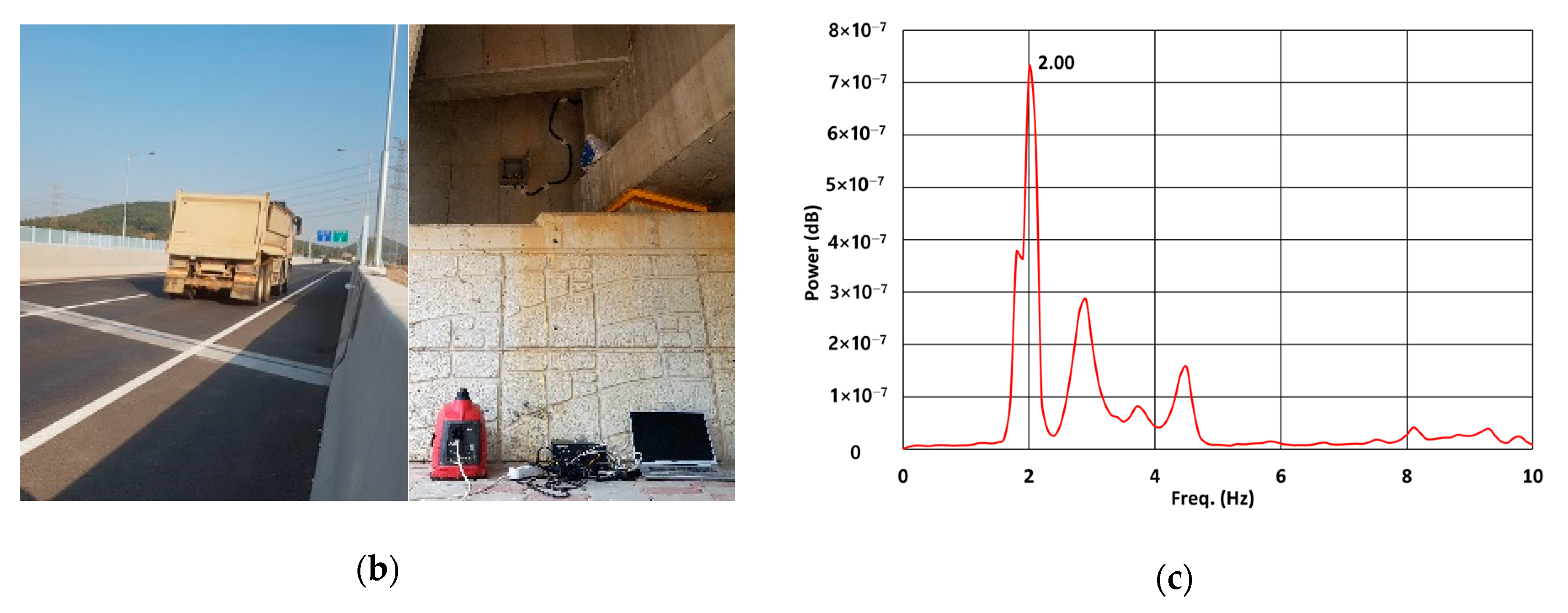

Figure 14 shows the layout and a photograph of this bridge together with its natural frequencies extracted from dynamic acceleration data acquired during the crossing of a truck.

Several months after the completion of the bridge shown in

Figure 14, the wavelength variation in the structure was measured by the OSPC strand under the crossing of a truck.

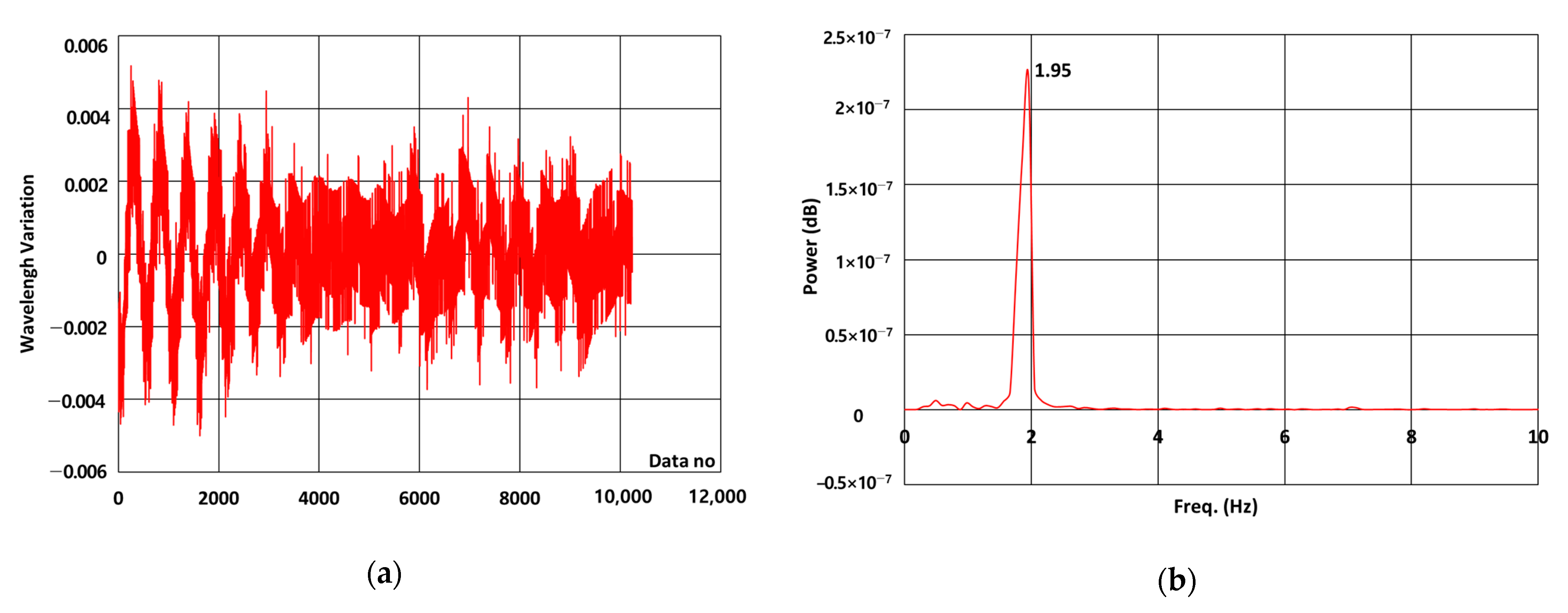

Figure 15 plots the dynamic data obtained during the measurement and the identified natural frequency.

The wavelength variation plotted in

Figure 15a was obtained by removing the Direct Current (DC) content from the raw data and applying a high pass filter. The natural frequency in

Figure 15b was computed by FFT. The natural frequency obtained from the OSPC data differed slightly from that of the acceleration response in

Figure 14c, but this difference was probably due to the effects of the time elapsed between the two measurements like temperature and change in the state of the bridge in operation.

In view of such results, installing semi-permanently the OSPC strand in the railway BH girder bridge appears to offer a fair and sufficient solution enabling to observe and evaluate the change in the prestressing force as well as the natural frequencies of the structure without other accelerometers nor electrical resistance gages. These features will allow effective maintenance since it is possible to detect any abnormal change of the structure.

Furthermore, the flexural performance of the BH girder bridge was evaluated through the four-point bending test, as shown in

Figure 16.

Figure 17 shows the comparison of the strain measured during the four-point bending test by the optical sensor located at the center of tendon one among the OSPC strands and by the electrical resistance strain gage bonded on the closest reinforcement in the cross-section. Linearly varying strains were measured by both types of sensor at early loading until the plastic zone. Beyond a value of about 3600 με, the strain provided by the electric resistance gage showed a steep increase, which indicated yielding of the steel reinforcement arranged at the bottom of the girder bridge. On the other hand, the OSPC strand continued to behave normally and measure the strain even after the yield of the reinforcement and until the final loading stage at approximately 6000 kN. A deflection of about 350 mm was finally observed at mid-span.

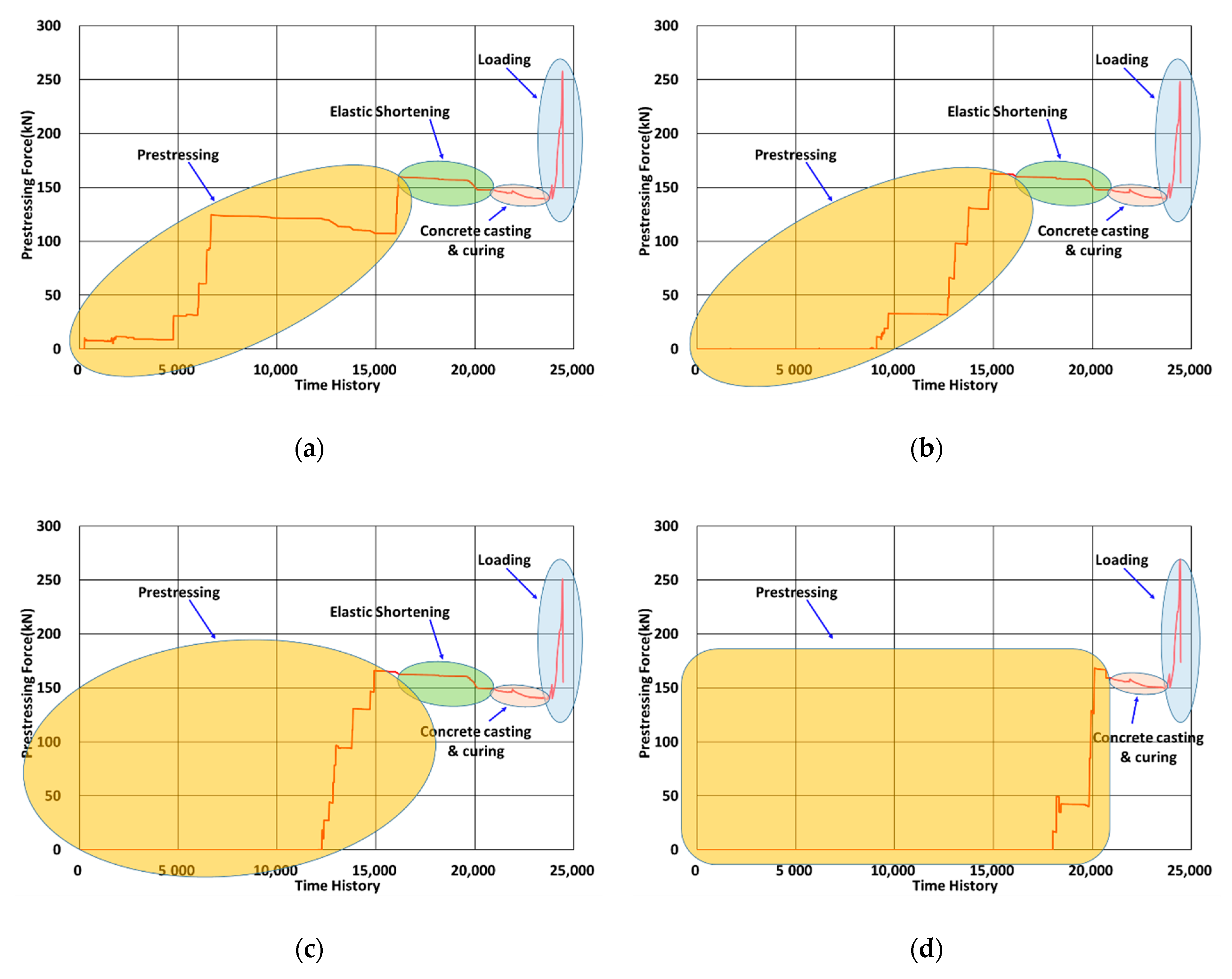

Figure 18 shows a plot of the change of the prestressing force measured by the OSPC strand in each tendon of the BH girder bridge at each stage from the start of tensioning during the fabrication of the specimen to the end of the bending test. The prestressing force was seen to undergo change since early prestress, and the elastic shortening could be clearly distinguished by the OSPC strand in the next prestressing stage. The partial increase of the prestressing force caused by the increase of the load following the placing of the top deck could also be observed. The large changes in the prestressing force due to the four-point bending are also clearly indicated in the graphs. Consequently, the OSPC strand could reliably measure the change of the prestressing force at major locations of the structure from construction to failure.

Considering its material characteristics, the optical sensor presents the disadvantage of being difficult to install without specific protection in civil structures for which steel or concrete are usually as construction materials. However, the embedment of the optical sensor in the strand endows it with semi-permanent durability in such an environment and will allow accurately measuring the change in the prestressing force all along the lifetime of the structure. For civil structures, such a possibility enables the OSPC strand to provide reliable and accurate data compared to the conventional electrical resistance gage and will allow more efficient maintenance of the structure.