A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in an Indoor Vertical Farm. Part 2: Rainwater Harvesting

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

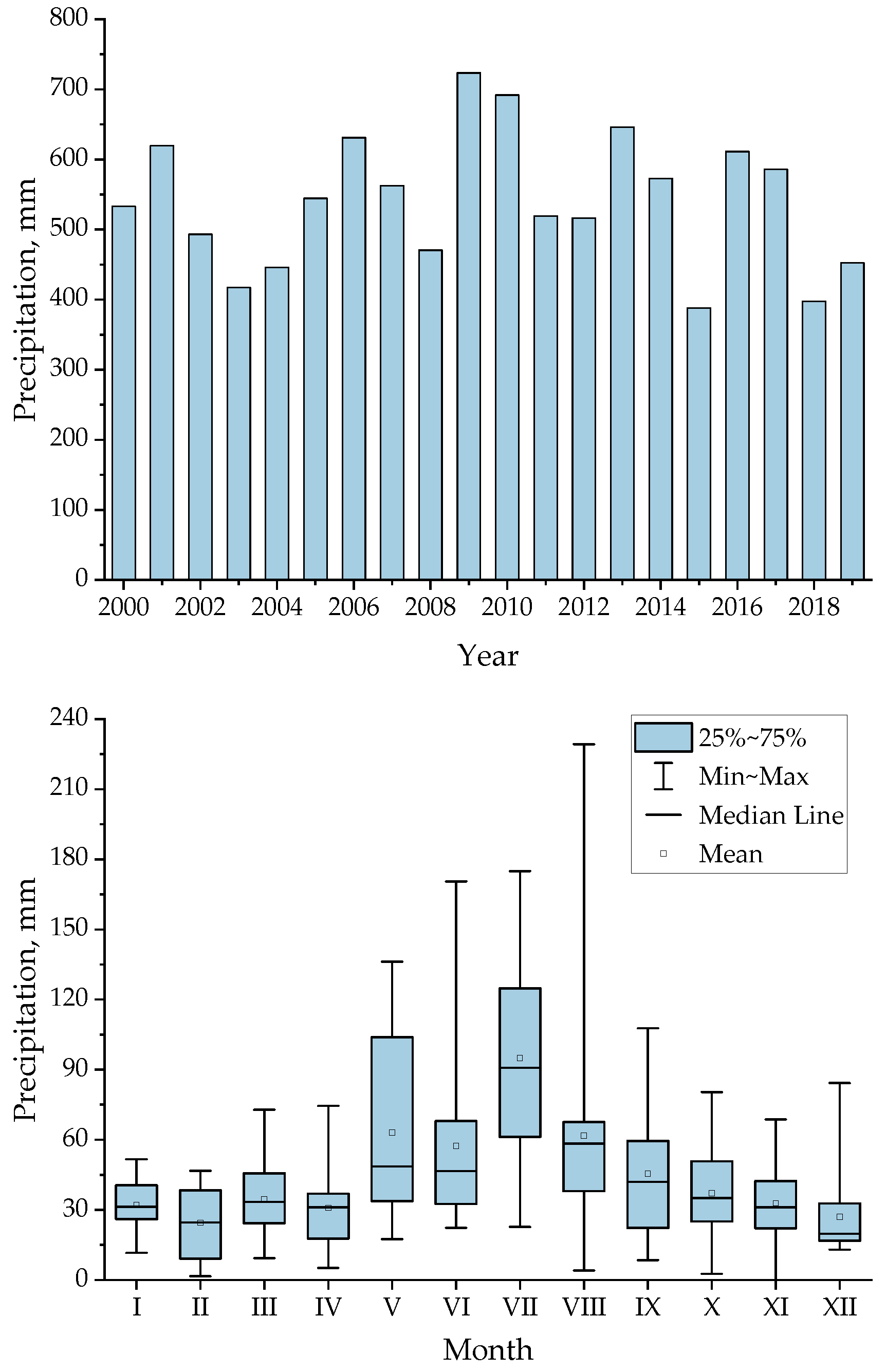

2.1. Meteorological Data

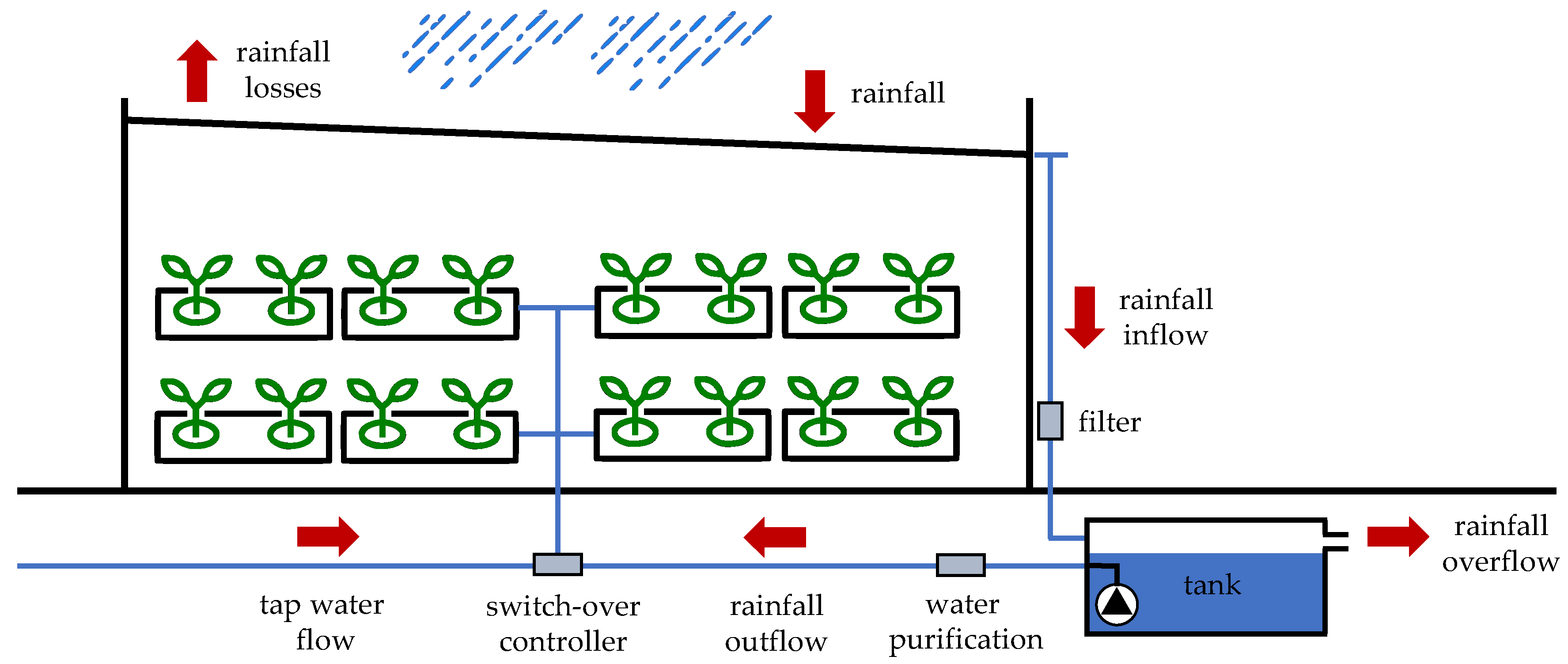

2.2. Description of the Vertical Indoor Farming Facility and Set-Up Parameters of the Growing Plants

2.3. Tank Capacity and Water Balance Model

3. Results

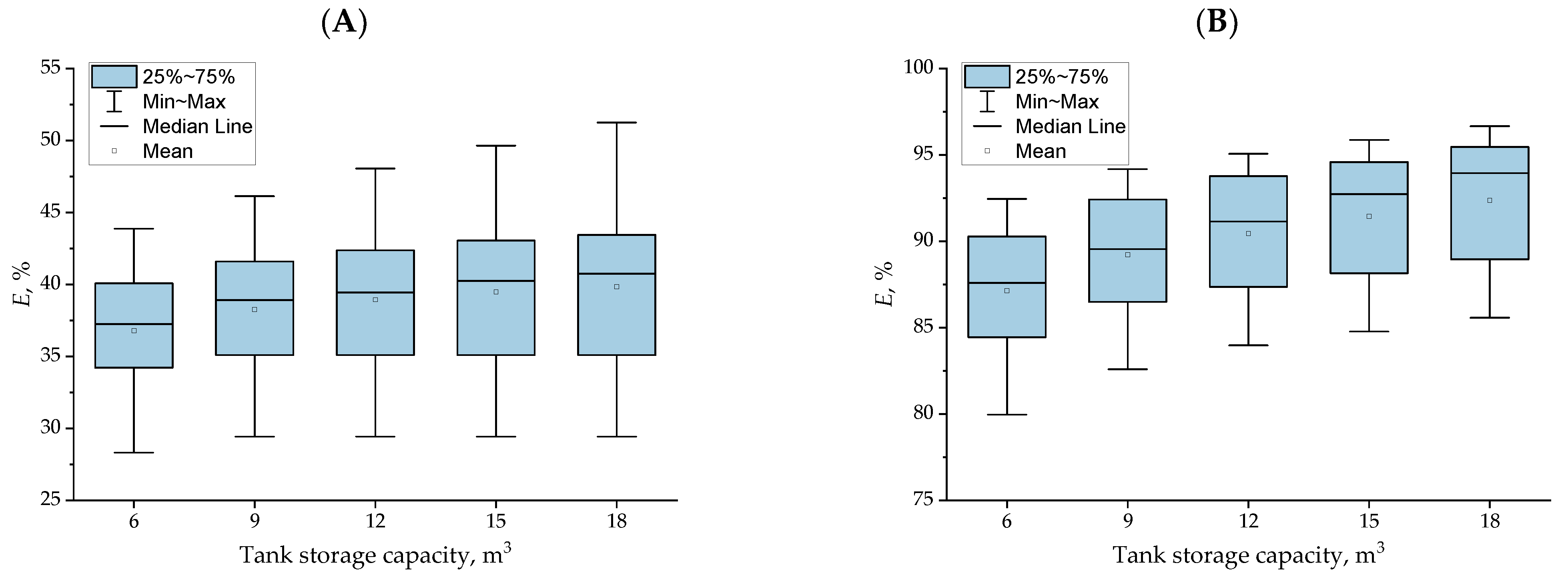

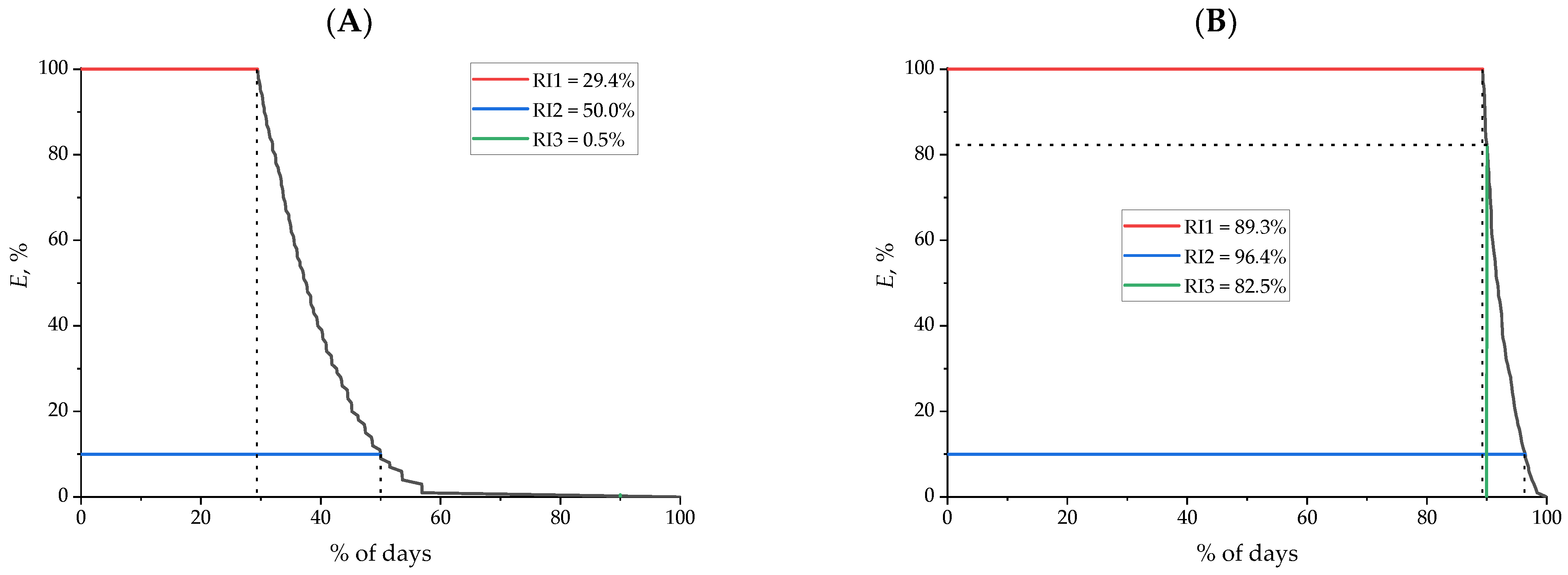

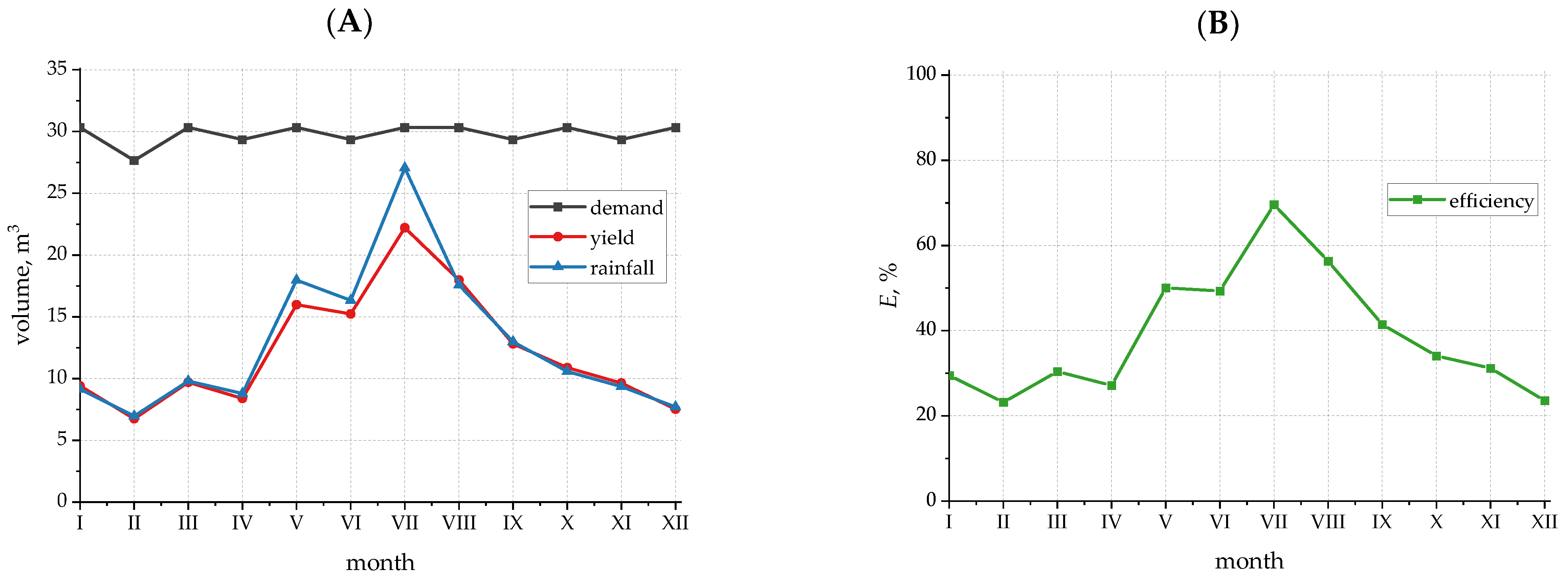

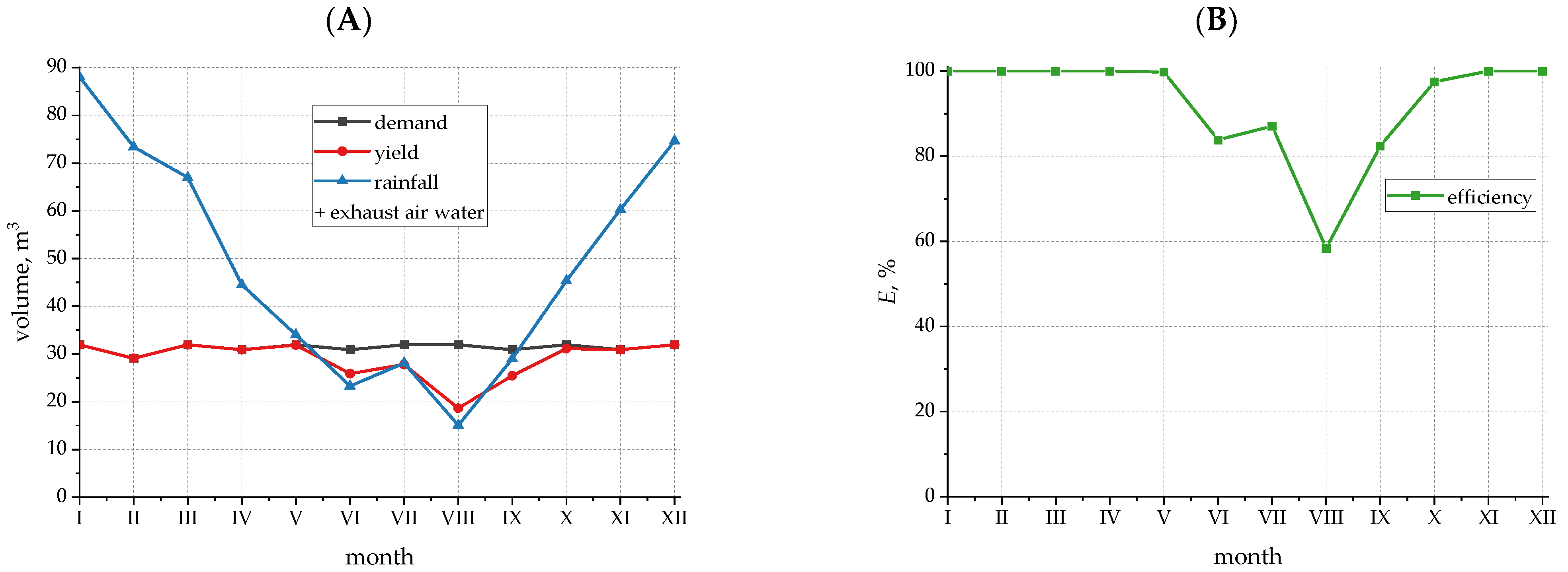

3.1. Analysis of Efficiency

3.2. Cost-Benefit Analysis

- according to [30], a discount rate of 5% had been assumed;

- the inflation rate had been assumed equal to 4.5% (on the basis of the inflation rate of potable water price in Wrocław in recent years);

- the actual price for potable water had been set equal to 1.2 €/m3 (the actual prices adopted by water utilities operating in Wrocław).

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Avgoustaki, D.D.; Xydis, G. Plant factories in the water-food-energy Nexus era: A systematic bibliographical review. Food Secur. 2020, 12, 253–268. [Google Scholar] [CrossRef]

- Jones, J.B., Jr. Complete Guide for Growing Plants Hydroponically, 1st ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Boca Raton, FL, USA, 2014; pp. 1–206. [Google Scholar]

- Kalantari, F.; Tahir, O.M.; Lahijani, A.M.; Kalantari, S. A Review of Vertical Farming Technology: A Guide for Implementation of Building Integrated Agriculture in Cities. Adv. Eng. Forum 2017, 24, 76–91. [Google Scholar] [CrossRef]

- Pacak, A.; Jurga, A.; Drąg, P.; Pandelidis, D.; Kaźmierczak, B. A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in Indoor Vertical Farm. Part 1: Water Recovery from Exhaust Air. Appl. Sci. 2020, 10, 8907. [Google Scholar] [CrossRef]

- Canales, F.A.; Gwoździej-Mazur, J.; Jadwiszczak, P.; Struk-Sokołowska, J.; Wartalska, K.; Wdowikowski, M.; Kaźmierczak, B. Long-Term Trends in 20-Day Cumulative Precipitation for Residential Rainwater Harvesting in Poland. Water 2020, 12, 1932. [Google Scholar] [CrossRef]

- Orlińska-Woźniak, P.; Wilk, P.; Gębala, J. Water availability in reference to water needs in Poland. Meteorol. Hydrol. Water Manag. 2014, 1, 45–50. [Google Scholar] [CrossRef][Green Version]

- Lam, K.L.; Kenway, S.J.; Lant, P.A. Energy use for water provision in cities. J. Clean. Prod. 2017, 143, 699–709. [Google Scholar] [CrossRef]

- Torregrossa, D.; Capitanescu, F. Optimization models to save energy and enlarge the operational life of water pumping systems. J. Clean. Prod. 2019, 213, 89–98. [Google Scholar] [CrossRef]

- Hofmann, J.; Schüttrumpf, H. Risk-Based Early Warning System for Pluvial Flash Floods: Approaches and Foundations. Geosciences 2019, 9, 127. [Google Scholar] [CrossRef]

- Kron, W.; Eichner, J.; Kundzewicz, Z. Reduction of flood risk in Europe–Reflections from a reinsurance perspective. J. Hydrol. 2019, 576, 197–209. [Google Scholar] [CrossRef]

- Ri, S.D.; Favargiotti, S.; Albatici, R. The role of vertical farming in re-thinking and re-designing cities within a circular perspective. Riv. Tema 2020, 6, 96–106. [Google Scholar] [CrossRef]

- Amos, C.C.; Rahman, A.; Karim, F.; Gathenya, J.M. A scoping review of roof harvested rainwater usage in urban agriculture: Australia and Kenya in focus. J. Clean. Prod. 2018, 202, 174–190. [Google Scholar] [CrossRef]

- Ngigi, S.N.; Savenije, H.H.; Rockström, J.; Gachene, C.K. Hydro-economic evaluation of rainwater harvesting and management technologies: Farmers’ investment options and risks in semi-arid Laikipia district of Kenya. Phys. Chem. Earth Parts A/B/C 2005, 30, 772–782. [Google Scholar] [CrossRef]

- Stout, D.T.; Walsh, T.C.; Burian, S.J. Ecosystem services from rainwater harvesting in India. Urban Water J. 2017, 14, 561–573. [Google Scholar] [CrossRef]

- Lupia, F.; Pulighe, G. Water Use and Urban Agriculture: Estimation and Water Saving Scenarios for Residential Kitchen Gardens. Agric. Agric. Sci. Procedia 2015, 4, 50–58. [Google Scholar] [CrossRef]

- Cook, S.; Sharma, A.; Chong, M. Performance Analysis of a Communal Residential Rainwater System for Potable Supply: A Case Study in Brisbane, Australia. Water Resour. Manag. 2013, 27, 4865–4876. [Google Scholar] [CrossRef]

- Woltersdorf, L.; Liehr, S.; Doell, P. Rainwater Harvesting for Small-Holder Horticulture in Namibia: Design of Garden Variants and Assessment of Climate Change Impacts and Adaptation. Water 2015, 7, 1402–1421. [Google Scholar] [CrossRef]

- Parsons, D.; Goodhew, S.; Fewkes, A.; De Wilde, P. The perceived barriers to the inclusion of rainwater harvesting systems by UK house building companies. Urban Water J. 2010, 7, 257–265. [Google Scholar] [CrossRef]

- Liuzzo, L.; Notaro, V.; Freni, G. A Reliability Analysis of a Rainfall Harvesting System in Southern Italy. Water 2016, 8, 18. [Google Scholar] [CrossRef]

- Campisano, A.; Butler, D.; Ward, S.; Burns, M.J.; Friedler, E.F.; DeBusk, K.; Fisher-Jeffes, L.N.; Ghisi, E.; Rahman, A.; Furumai, H.; et al. Urban rainwater harvesting systems: Research, implementation and future perspectives. Water Res. 2017, 115, 195–209. [Google Scholar] [CrossRef]

- Campisano, A.; Gnecco, I.; Modica, C.; Palla, A. Designing domestic rainwater harvesting systems under different climatic regimes in Italy. Water Sci. Technol. 2013, 67, 2511–2518. [Google Scholar] [CrossRef]

- Sørup, H.J.D.; Lerer, S.M.; Arnbjerg-Nielsen, K.; Mikkelsen, P.S.; Rygaard, M. Efficiency of stormwater control measures for combined sewer retrofitting under varying rain conditions: Quantifying the Three Points Approach (3PA). Environ. Sci. Policy 2016, 63, 19–26. [Google Scholar] [CrossRef]

- Anderson, M.S.; Ewert, M.K.; Keener, J.F.; Wagner, S.A. Life Support Baseline Values and Assumptions Document; National Aero-nautics and Space Administration: Houston, TX, USA, 2018; pp. 1–233. [Google Scholar]

- Struk-Sokołowska, J.; Gwoździej-Mazur, J.; Jadwiszczak, P.; Butarewicz, A.; Ofman, P.; Wdowikowski, M.; Kaźmierczak, B. The Quality of Stored Rainwater for Washing Purposes. Water 2020, 12, 252. [Google Scholar] [CrossRef]

- Gires, A.; De Gouvello, B. Consequences to water suppliers of collecting rainwater on housing estates. Water Sci. Technol. 2009, 60, 543–553. [Google Scholar] [CrossRef] [PubMed]

- Fewkes, A.; Butler, D. Simulating the performance of rainwater collection and reuse systems using behavioural models. Build. Serv. Eng. Res. Technol. 2000, 21, 99–106. [Google Scholar] [CrossRef]

- Khastagir, A.; Jayasuriya, N. Investment Evaluation of Rainwater Tanks. Water Resour. Manag. 2011, 25, 3769–3784. [Google Scholar] [CrossRef]

- Matos, C.; Bentes, I.; Santos, C.; Alam Imteaz, M.; Pereira, S. Economic Analysis of a Rainwater Harvesting System in a Commercial Building. Water Resour. Manag. 2015, 29, 3971–3986. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, D.; Chen, L.; Ashbolt, S. Potential for rainwater use in high-rise buildings in Australian cities. J. Environ. Manag. 2009, 91, 222–226. [Google Scholar] [CrossRef]

- European Commission, Directorate General Regional Policy. Guide to Cost-Benefit Analysis of Investment projects—Structural Funds, Cohesion Fund and Instrument for Pre-Accession. Available online: http://ec.europa.eu/regional_policy/sources/docgener/guides/cost/guide2008_en.pdf (accessed on 12 November 2015).

- O’Donnell, E.; Thorne, C.; Ahilan, S.; Arthur, S.; Birkinshaw, S.; Butler, D.; Dawson, D.; Everett, G.; Fenner, R.; Glenis, V.; et al. The blue-green path to urban flood resilience. Blue-Green Syst. 2019, 2, 28–45. [Google Scholar] [CrossRef]

- Jegatheesan, V.; Goonetilleke, A.; van Leeuwen, J.; Kandansamy, J.; Warner, D.; Myers, B.; Bhuiyan, M.; Spence, K.; Parker, G. Urban Stormwater and Flood Management: Enhancing the Liveability of Cities-Google Books; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Jamali, B.; Bach, P.M.; Deletic, A. Rainwater harvesting for urban flood management—An integrated modelling framework. Water Res. 2020, 171, 115372. [Google Scholar] [CrossRef]

| Tank Volume, m3 | Costs, € | Water-Saving, m3/Year | Annual E, % | NPV (20 Years), € | PBP, Year |

|---|---|---|---|---|---|

| 6 | 2654 | 106 (min.) | 28.3 | 1150 | 16 |

| 138 (av.) | 36.8 | 2292 | 13 | ||

| 165 (max.) | 43.9 | 3240 | 11 | ||

| 9 | 2863 | 111 (min.) | 29.4 | 1092 | 16 |

| 144 (av.) | 38.3 | 2279 | 13 | ||

| 173 (max.) | 46.1 | 3335 | 12 | ||

| 12 | 3017 | 111 (min.) | 29.4 | 938 | 17 |

| 147 (av.) | 38.9 | 2219 | 14 | ||

| 181 (max.) | 48.0 | 3438 | 12 | ||

| 15 | 3362 | 111 (min.) | 29.4 | 593 | 18 |

| 149 (av.) | 39.5 | 1945 | 15 | ||

| 187 (max.) | 49.6 | 3308 | 12 | ||

| 18 | 3516 | 111 (min.) | 29.4 | 439 | 19 |

| 150 (av.) | 39.8 | 1841 | 15 | ||

| 193 (max.) | 51.2 | 3368 | 13 |

| Tank Volume, m3 | Costs, € | Water-Saving, m3/Year | Annual E, % | NPV (20 Years), € | PBP, Year |

|---|---|---|---|---|---|

| 6 | 3099 | 301 (min.) | 80.0 | 7644 | 8 |

| 328 (av.) | 87.1 | 8615 | 7 | ||

| 349 (max.) | 92.5 | 9356 | 7 | ||

| 9 | 3307 | 311 (min.) | 82.6 | 7789 | 8 |

| 336 (av.) | 89.2 | 8686 | 8 | ||

| 355 (max.) | 94.2 | 9379 | 7 | ||

| 12 | 3461 | 316 (min.) | 84.0 | 7820 | 8 |

| 340 (av.) | 90.4 | 8698 | 8 | ||

| 358 (max.) | 95.1 | 9346 | 8 | ||

| 15 | 3806 | 319 (min.) | 84.8 | 7583 | 9 |

| 344 (av.) | 91.4 | 8488 | 8 | ||

| 361 (max.) | 95.9 | 9108 | 8 | ||

| 18 | 3960 | 322 (min.) | 85.6 | 7536 | 9 |

| 348 (av.) | 92.4 | 8458 | 9 | ||

| 364 (max.) | 96.7 | 9061 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jurga, A.; Pacak, A.; Pandelidis, D.; Kaźmierczak, B. A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in an Indoor Vertical Farm. Part 2: Rainwater Harvesting. Appl. Sci. 2021, 11, 310. https://doi.org/10.3390/app11010310

Jurga A, Pacak A, Pandelidis D, Kaźmierczak B. A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in an Indoor Vertical Farm. Part 2: Rainwater Harvesting. Applied Sciences. 2021; 11(1):310. https://doi.org/10.3390/app11010310

Chicago/Turabian StyleJurga, Anna, Anna Pacak, Demis Pandelidis, and Bartosz Kaźmierczak. 2021. "A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in an Indoor Vertical Farm. Part 2: Rainwater Harvesting" Applied Sciences 11, no. 1: 310. https://doi.org/10.3390/app11010310

APA StyleJurga, A., Pacak, A., Pandelidis, D., & Kaźmierczak, B. (2021). A Long-Term Analysis of the Possibility of Water Recovery for Hydroponic Lettuce Irrigation in an Indoor Vertical Farm. Part 2: Rainwater Harvesting. Applied Sciences, 11(1), 310. https://doi.org/10.3390/app11010310