Multi-Field Models of Fiber Reinforced Concrete for Structural Applications

Abstract

1. Introduction

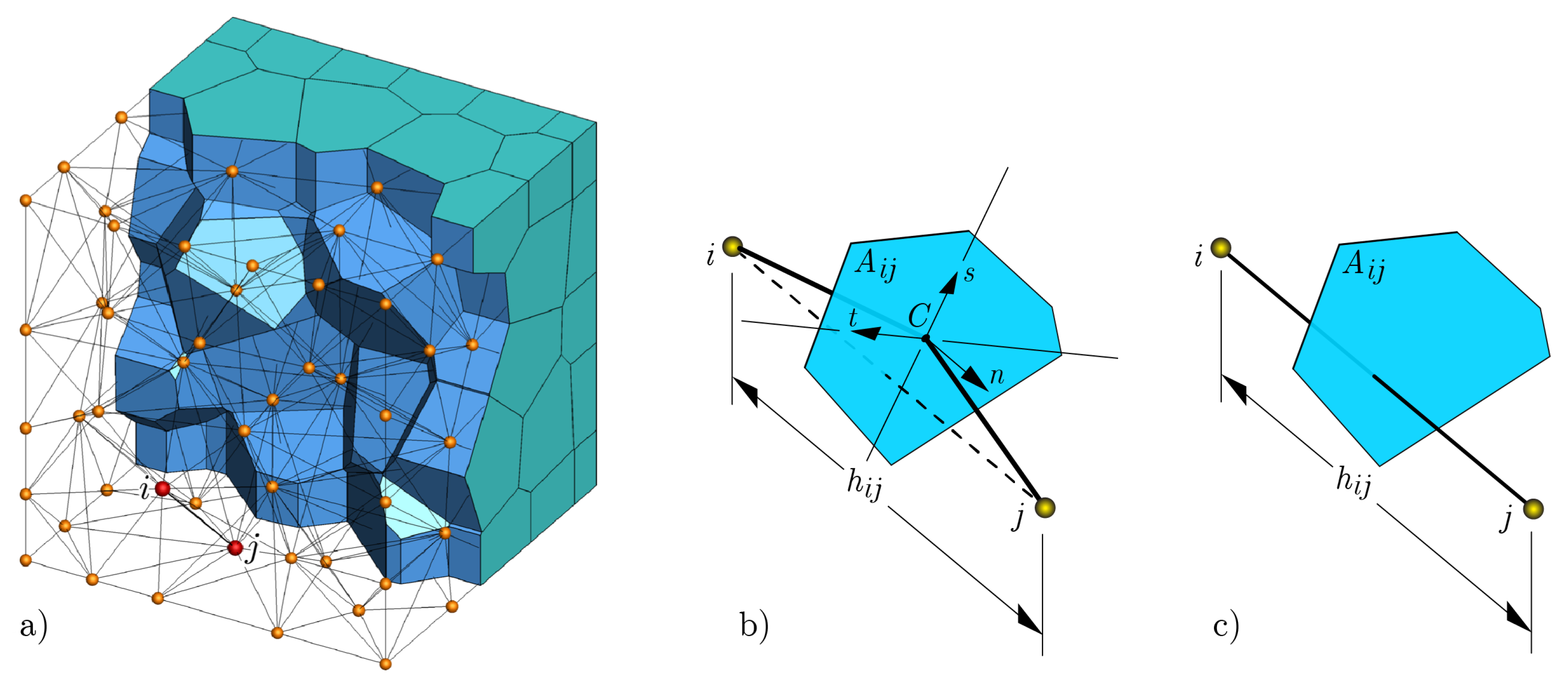

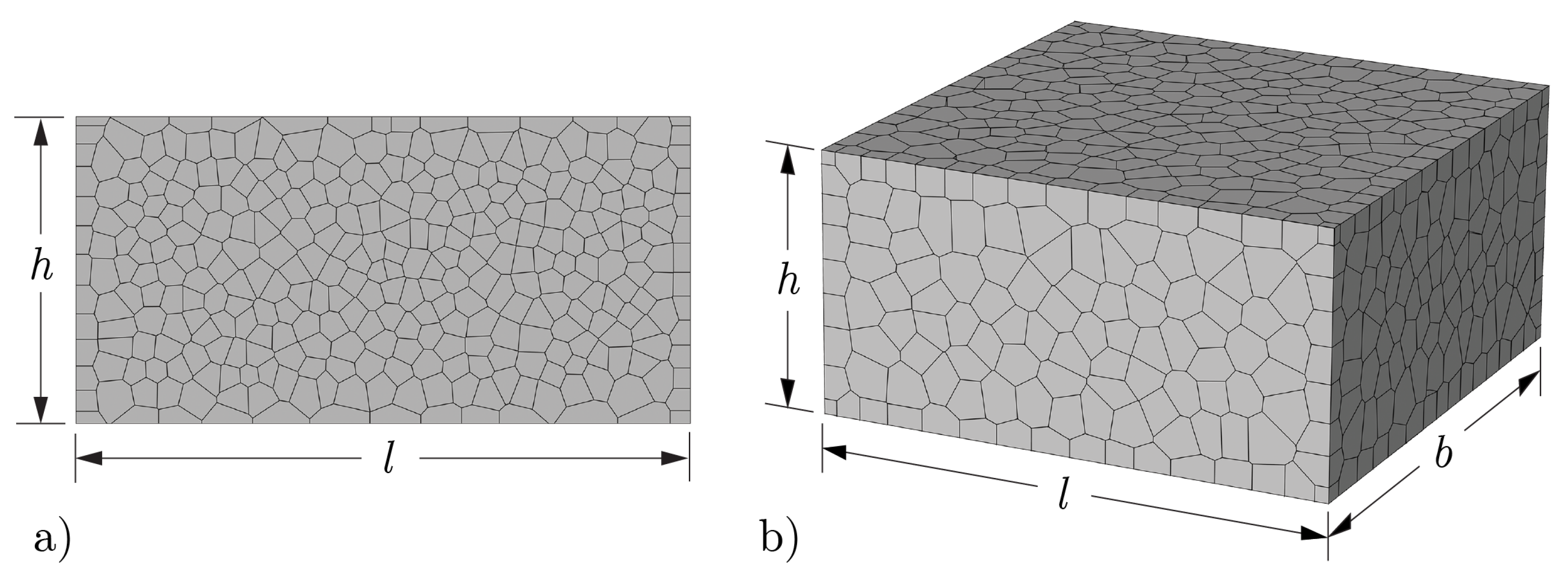

2. Voronoi-Cell Lattice Model

2.1. Mechanical Behavior

2.2. Transport Behavior

3. Models of Fiber Reinforcement

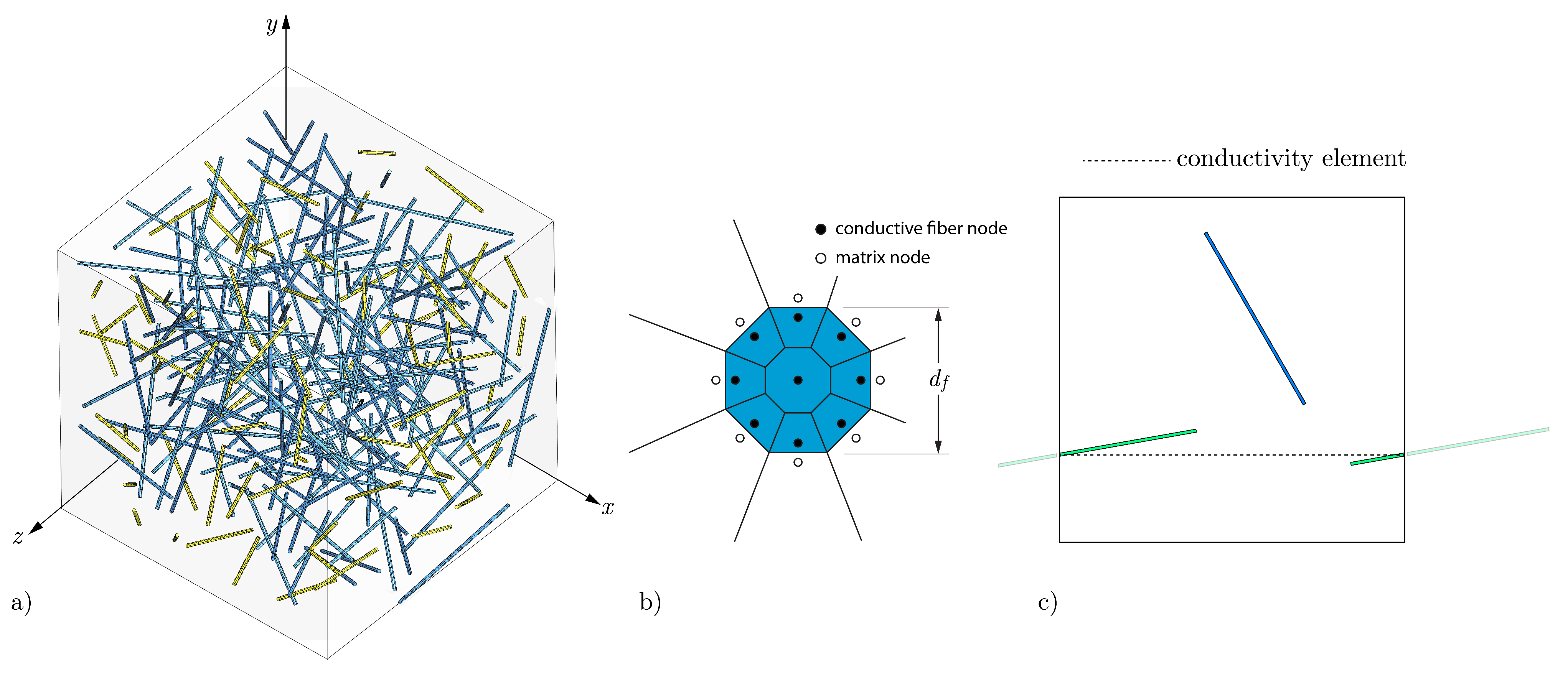

3.1. Volumetric Representation of Fibers

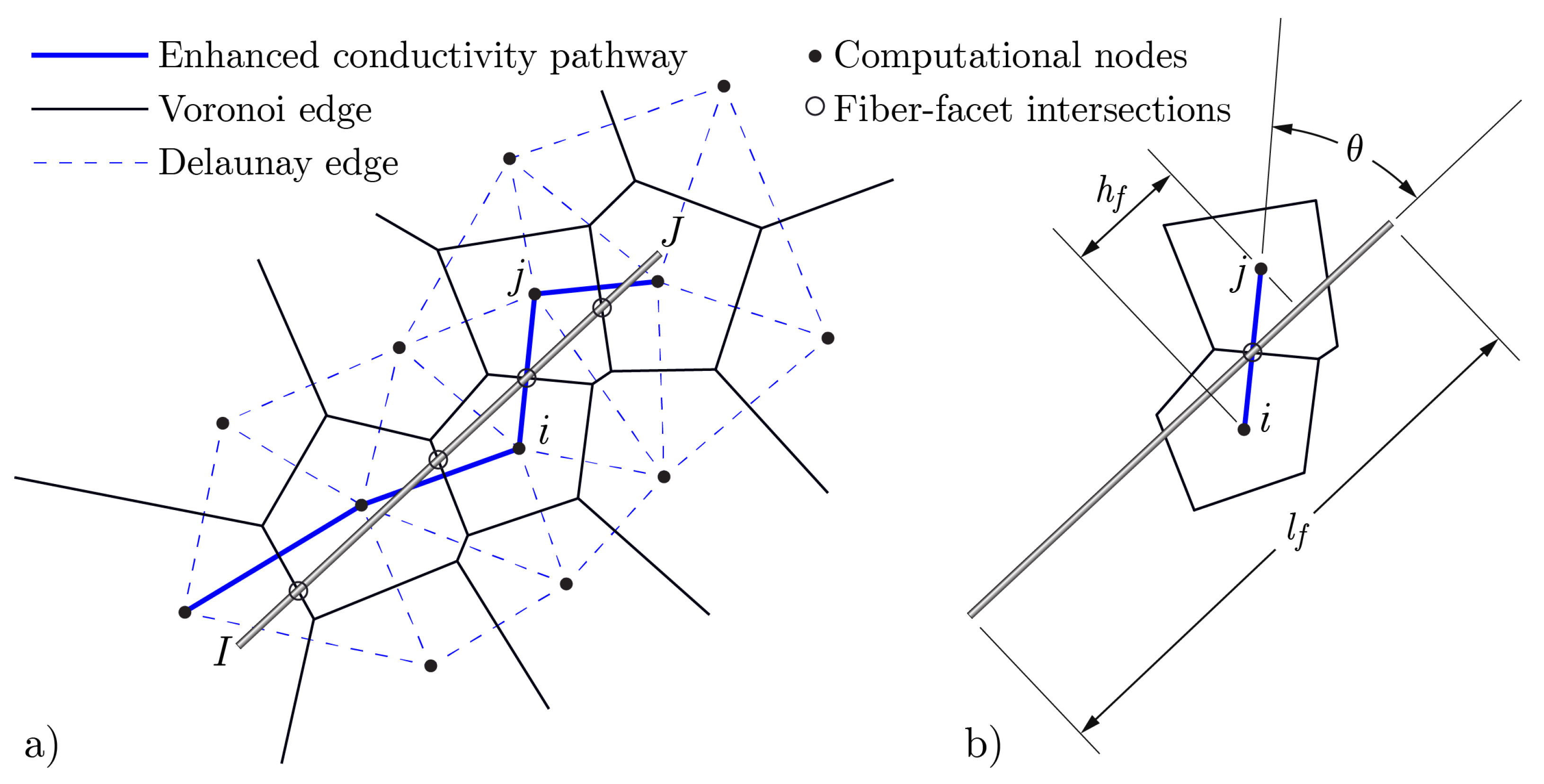

3.2. Semi-Discrete Representation of Fibers

3.2.1. Mechanical Behavior

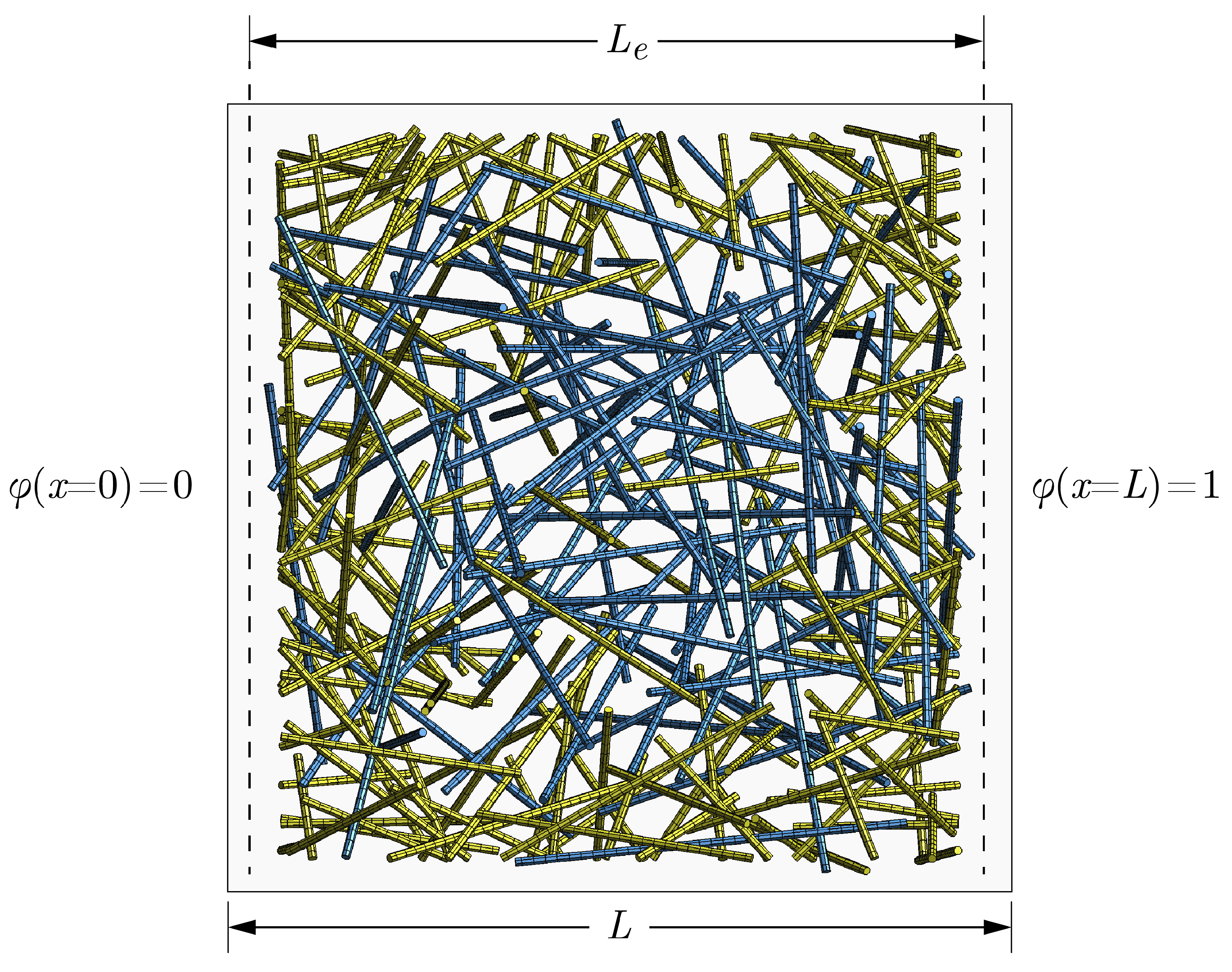

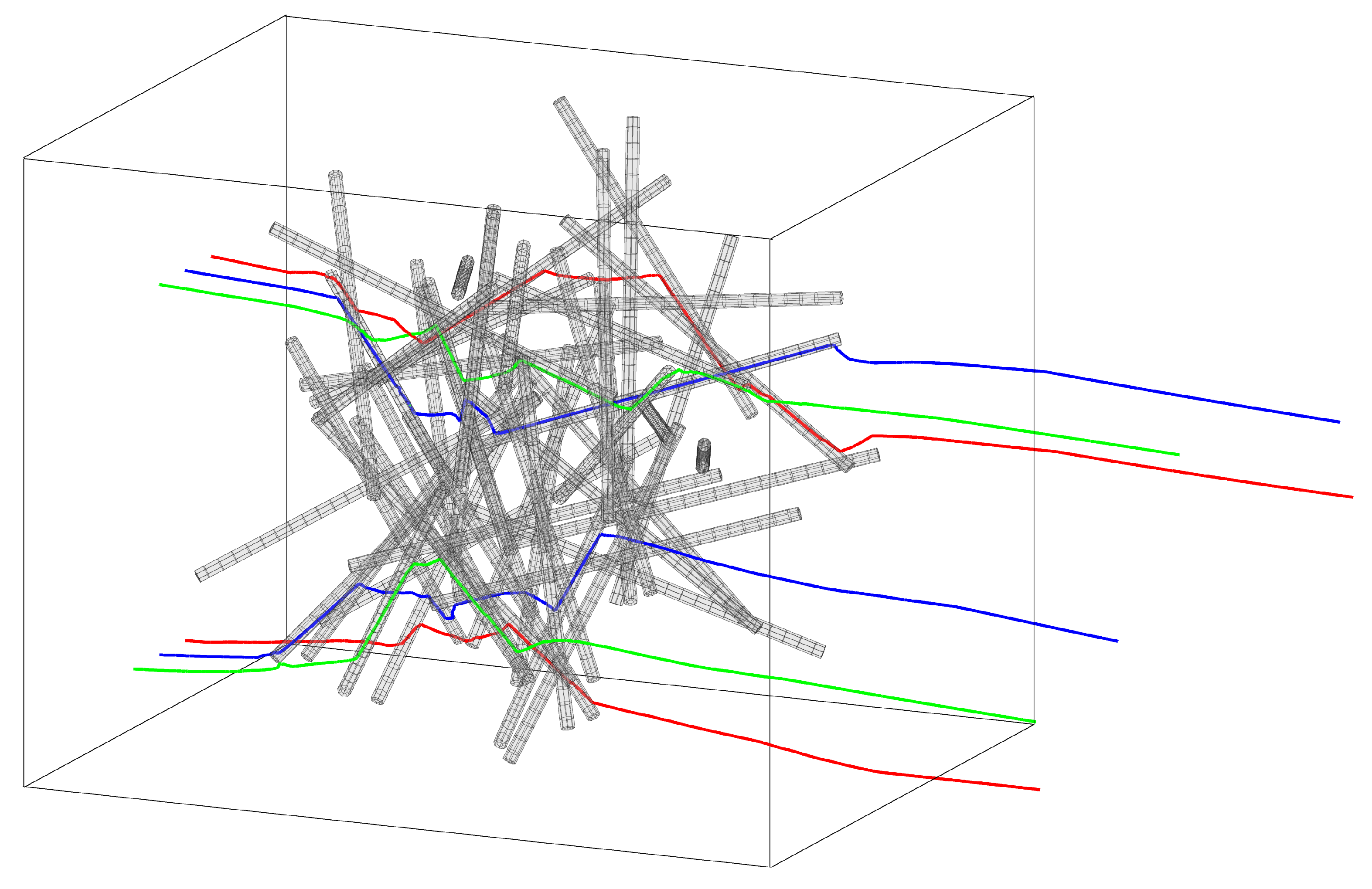

3.2.2. Transport Behavior

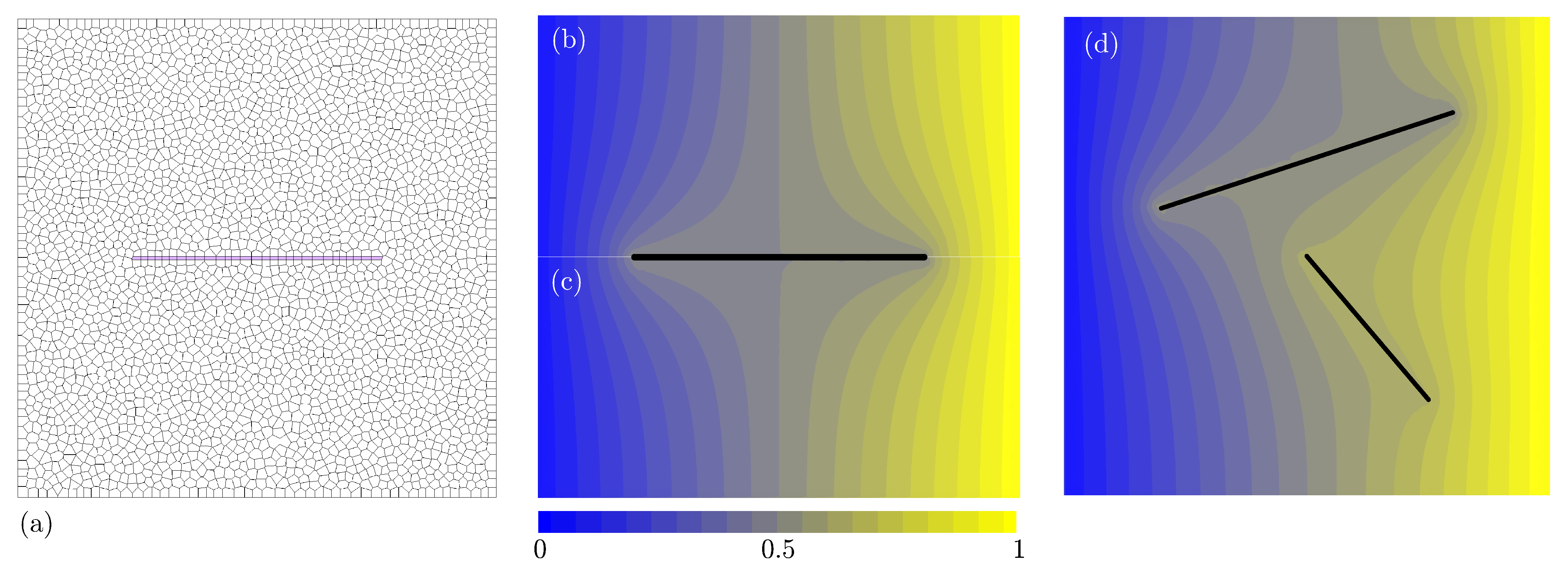

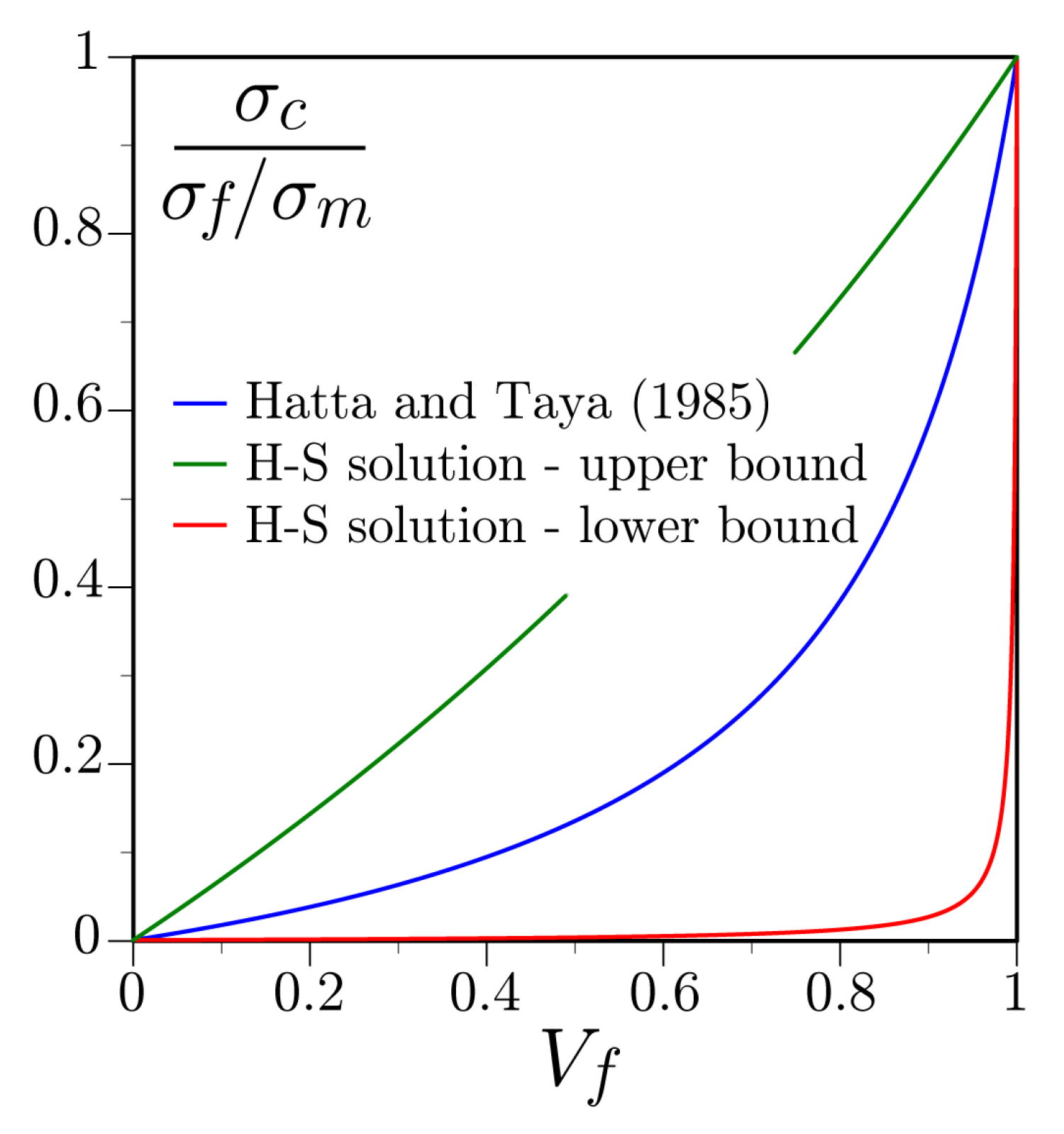

3.2.3. Transport Behavior: Model Verification

4. Electro-Mechanical Analyses with Applications to Self-Sensing

4.1. Background

4.2. Solution Scheme

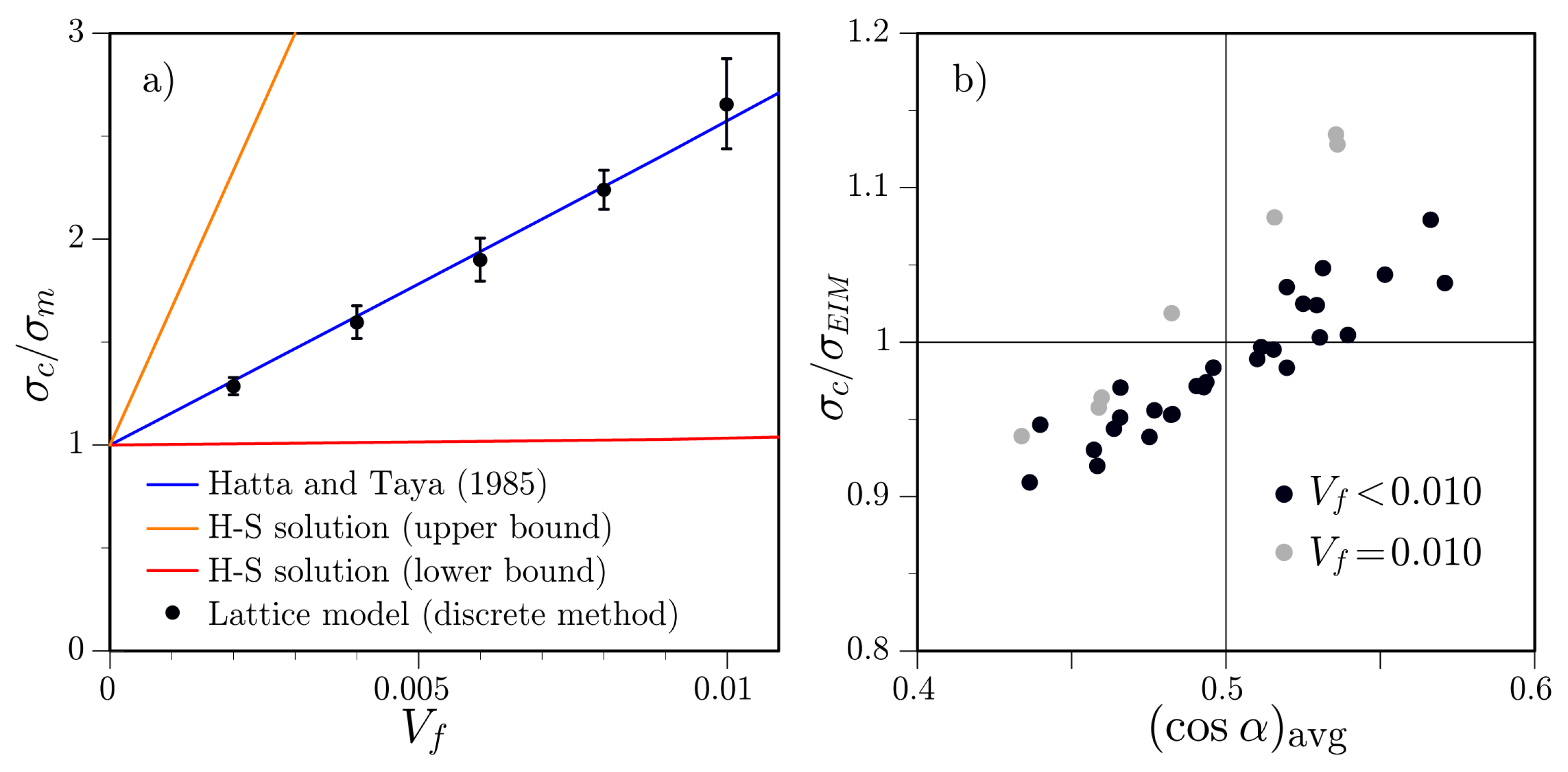

4.3. Verification of Conductivity Simulations

4.4. Analyses and Results

5. Hygro-Mechanical Analyses of Plastic Settlement

5.1. Background

5.2. Formulation of the Matrix Phase Model

- The load–deformation behavior of the mixture follows small-strain elastic theory.

- No hydration takes place during the time period covered by the analyses, such that heat generation, chemical shrinkage, or hardening do not occur.

- The material is isothermal and isolated from ambient conditions.

- The surface of the formwork is considered to be frictionless and no wall effect is considered.

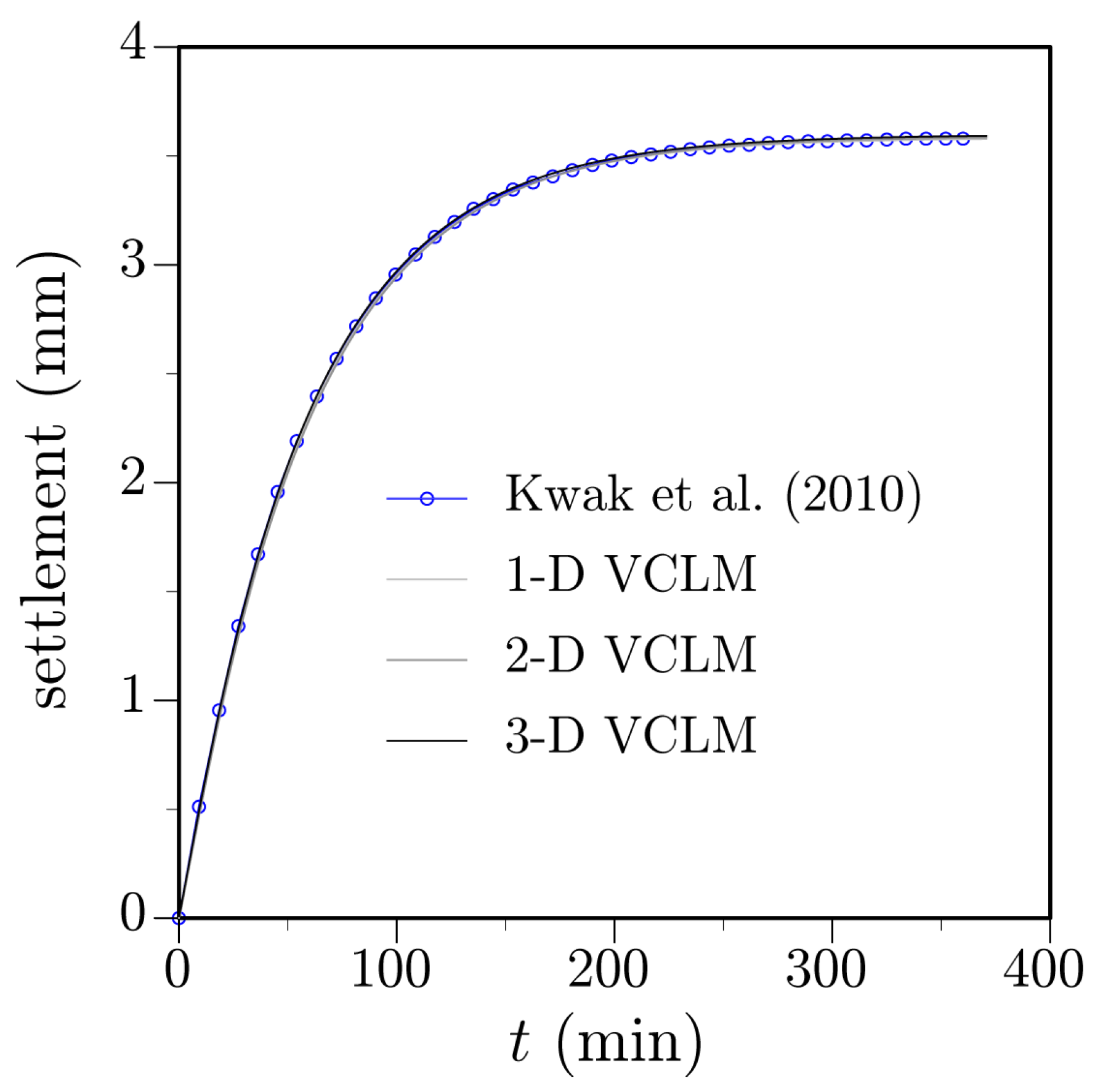

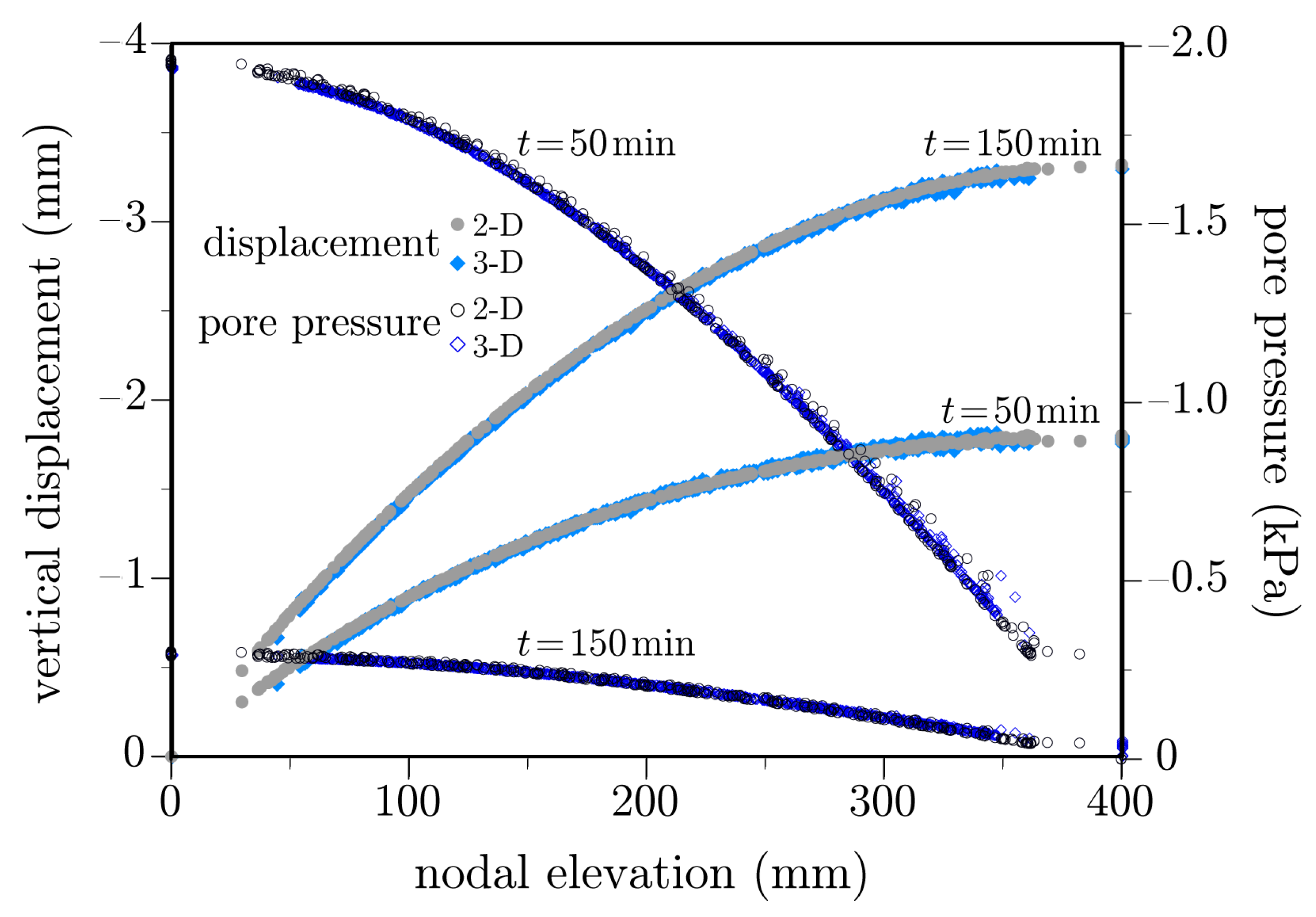

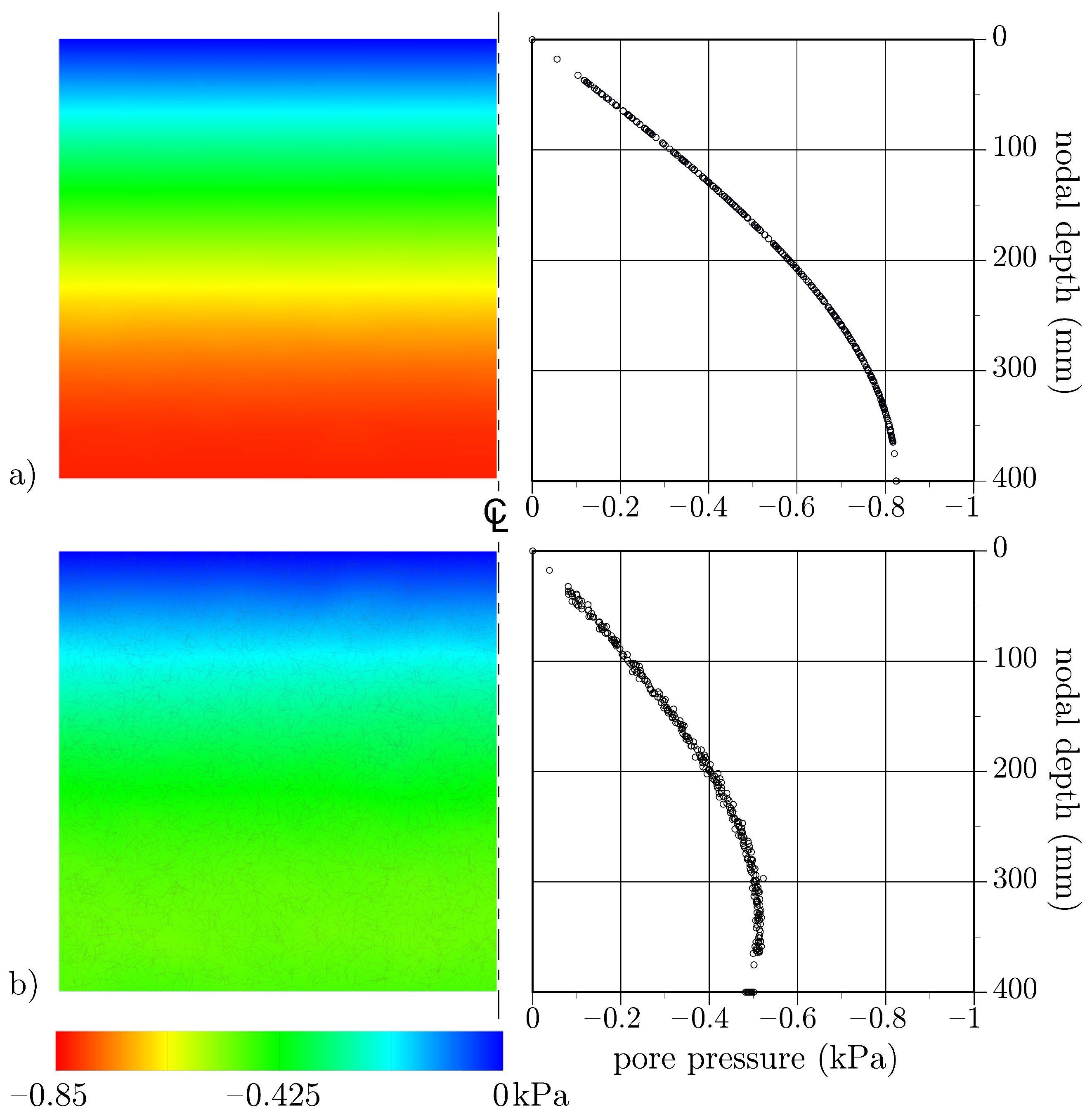

5.3. Verification of the Matrix Phase Model

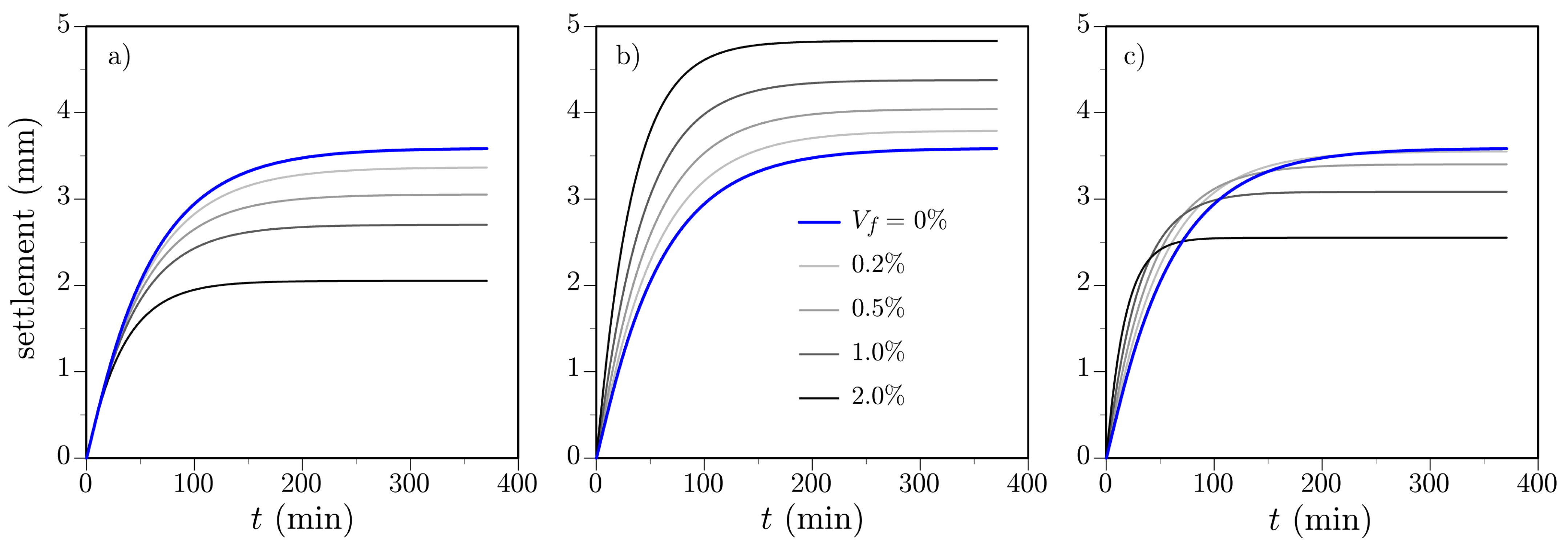

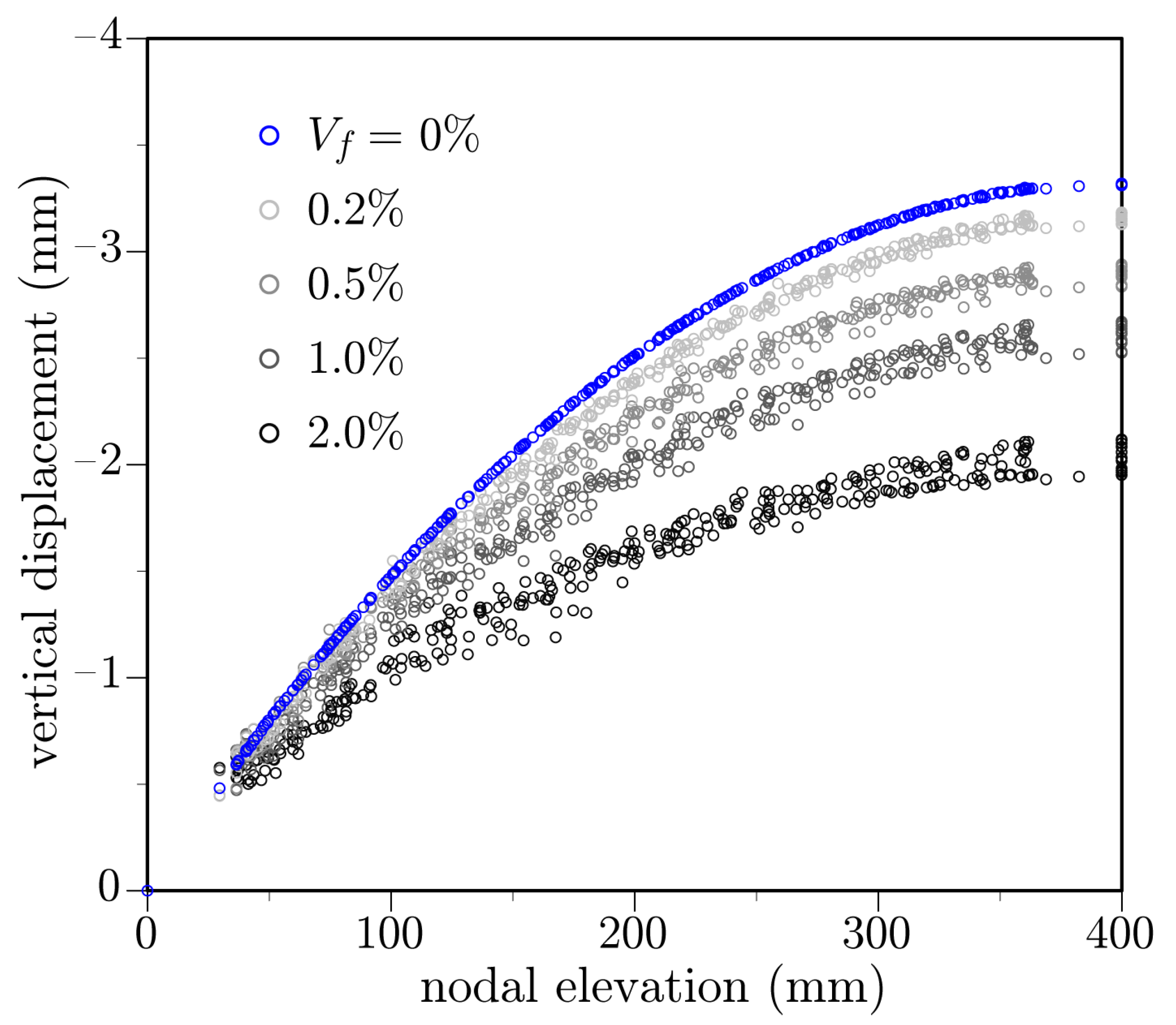

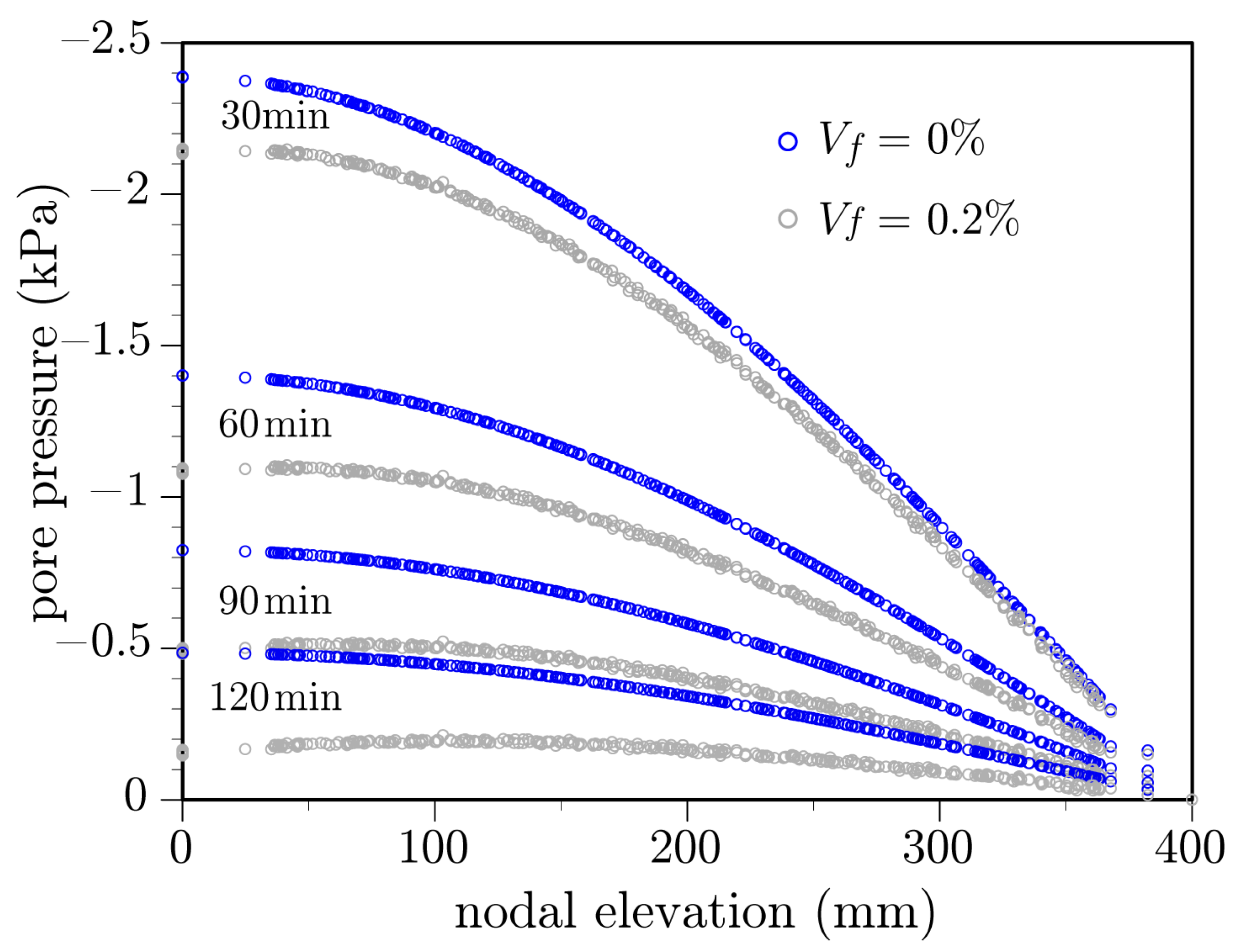

5.4. Influences of Short-Fiber Reinforcement: Parametric Study

6. Conclusions

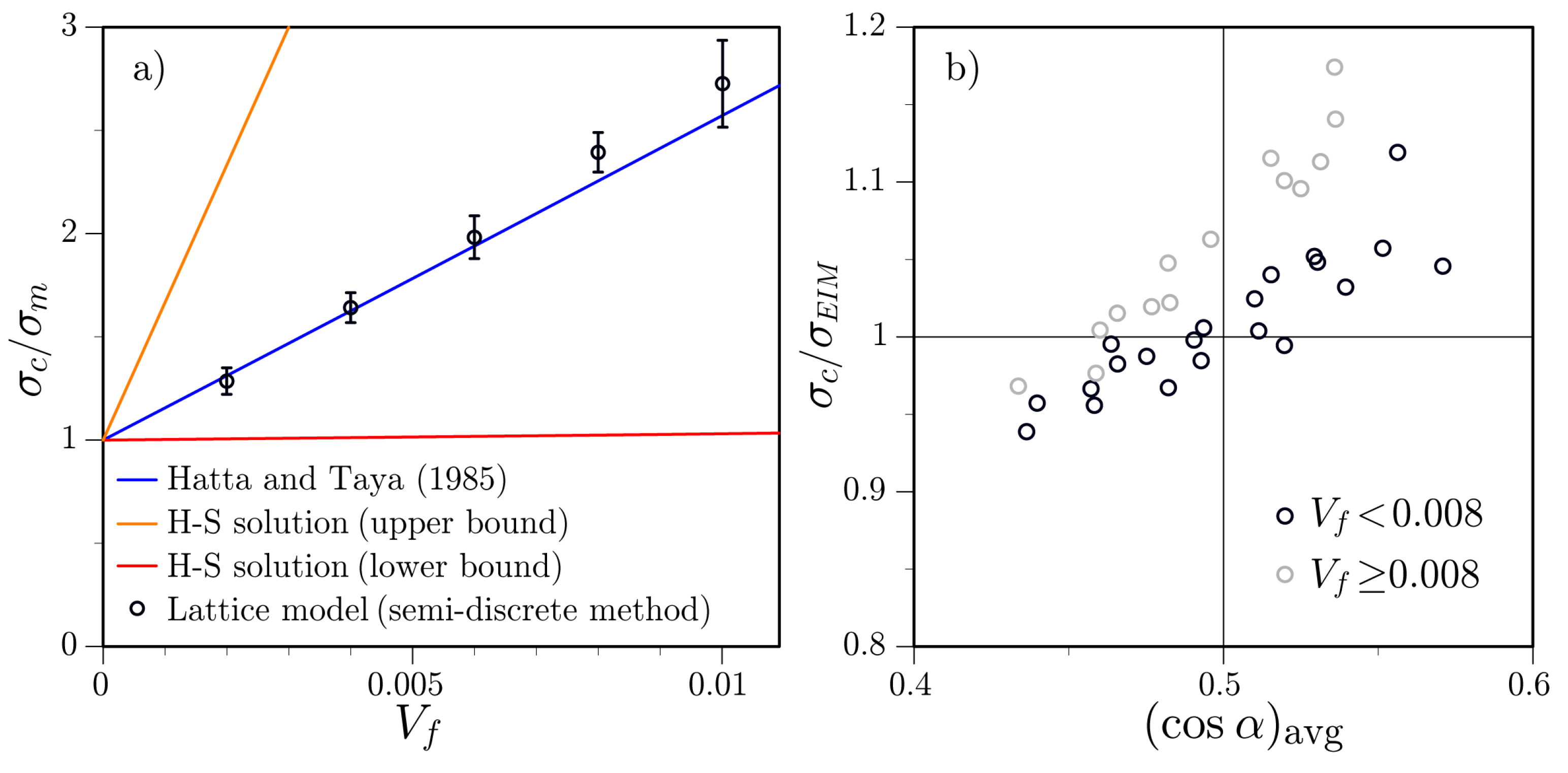

- At low fiber dosages, both the discrete and semi-discrete approaches to modeling conductive fibers offer precise estimates of conductivity of the composite material, in comparison with the equivalent inclusion method (EIM) of Hatta and Taya.

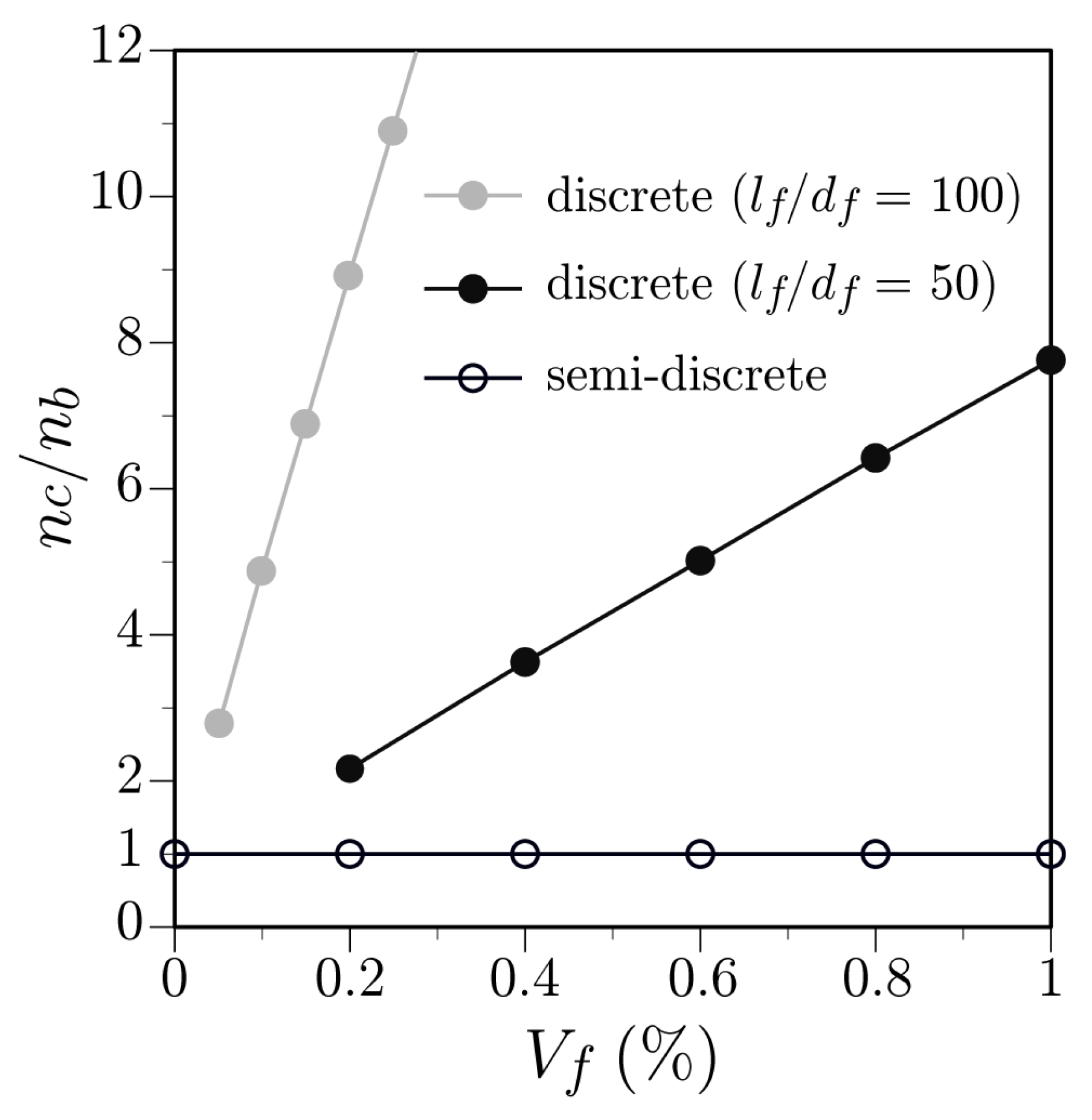

- The semi-discrete approach is computationally efficient in its representation of the conductivity contributions of individual fibers. Fiber additions do not increase the number of computational degrees of freedom of the model. For = 0.01, which is one of the fiber dosages considered herein, the number of computational nodes was nearly one order of magnitude smaller, relative to the number of nodes used for modeling the composite with discrete (volumetric) fibers. The computational savings would be even more dramatic when considering higher fiber dosages or aspect ratios.

- When comparing with the EIM results, the semi-discrete approach requires sufficient resolution of the background lattice such that the fibers are electrically isolated from one another by matrix material. Increasing , while keeping nodal density constant, eventually causes composite conductivity estimates of the semi-discrete model to be higher than the corresponding EIM values.

- For a given fiber content, conductivity of the composite varies with directionality of the fiber distribution. The discrete and semi-discrete models capture the expected result: conductivity of the composite material increases with preferential orientation of fibers with respect to the electrical field. This capability should enable the study of fiber distribution effects in actual members, where boundary effects and other sources of fiber distribution non-uniformity are present.

- The coupled electro-mechanical model captures the changes in composite resistance due to axial loading. An updating of nodal point positions leads to a composite gauge factor of unity. Other composite gauge factors can be simulated by introducing a parameter associated with the sensitivity of fiber conductivity to applied strain.

- With respect to the simulations of plastic settlement of an unreinforced matrix, the results are in agreement with previously published results based on finite element analysis. Moreover, the results are shown to be equivalent, regardless of the dimensionality of the VCLM.

- The proposed model enables study of the relative benefits of introducing short fibers to reduce plastic settlement of concrete. Both the mechanical and transport modifications of the material are considered. The simulation results support some experimental observations that higher fiber content leads to reduced settlement and increased amounts of bleed water due to the stiffness and conductivity enhancements of the fibers, respectively.

- Model extensions and validation efforts, through comparisons with physical test data, are needed to address a variety of practical simulation needs. With respect to the validation efforts, it is difficult to measure some of the model input parameters (e.g., the mechanical and hydraulic conductivity properties of individual fibers within fresh concrete). Such quantities need to be determined, either experimentally or through inverse calculations.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EIM | Equivalent inclusion method |

| RBSN | Rigid-body-spring network |

| VCLM | Voronoi-cell lattice model |

Appendix A

References

- Naaman, A.E. Fiber Reinforced Cement and Concrete Composites; Techno Press 3000: Sarasota, FL, USA, 2017. [Google Scholar]

- Naaman, A.E.; Wongtanakitcharoen, T.; Hauser, G. Influence of different fibers on plastic shrinkage cracking of concrete. ACI Mater. J. 2005, 102, 49–58. [Google Scholar]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Bentz, D.P. A review of early-age properties of cement-based materials. Cem. Concr. Res. 2008, 38, 196–204. [Google Scholar] [CrossRef]

- Kalifa, P.; Chéné, G.; Gallé, C. High-temperature behaviour of HPC with polypropylene fibres—From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Liu, X.; Ye, G.; De Schutter, G.; Yuan, Y.; Taerwe, L. On the mechanism of polypropylene fibres in preventing fire spalling in self-compacting and high-performance cement paste. Cem. Concr. Res. 2008, 38, 487–499. [Google Scholar] [CrossRef]

- Far, B.K.; Zanotti, C. Concrete-concrete bond in Mode-I: A study on the synergistic effect of surface roughness and fiber reinforcement. Appl. Sci. 2019, 9, 2556. [Google Scholar] [CrossRef]

- Moreno, D.M.; Trono, W.; Jen, G.; Ostertag, C.; Billington, S.L. Tension stiffening in reinforced high performance fiber reinforced cement-based composites. Cem. Concr. Compos. 2014, 50, 36–46. [Google Scholar] [CrossRef]

- Roy, M.; Hollmann, C.; Wille, K. Influence of fiber volume fraction and fiber orientation on the uniaxial tensile behavior of rebar-reinforced ultra-high performance concrete. Fibers 2019, 7, 67. [Google Scholar] [CrossRef]

- Nguyen, W.; Bandelt, M.J.; Trono, W.; Billington, S.L.; Ostertag, C.P. Mechanics and failure characteristics of hybrid fiber-reinforced concrete (HyFRC) composites with longitudinal steel reinforcement. Eng. Struct. 2019, 183, 243–254. [Google Scholar] [CrossRef]

- Xie, P.; Gu, P.; Beaudoin, J.J. Electrical percolation phenomena in cement composites containing conductive fibers. J. Mater. Sci. 1996, 31, 4093–4097. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Hornbostel, K.; Geiker, M.R.; Lofgren, I.; Lundgren, K.; Bekas, D.G. Electrical resistivity measurements in steel fibre reinforced cementitious materials. Cem. Concr. Compos. 2018, 89, 216–229. [Google Scholar] [CrossRef]

- Hatta, H.; Taya, M. Effective thermal conductivity of a misoriented short fiber composite. J. Appl. Phys. 1985, 58, 2478–2486. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H.; Roesler, J. Cohesive fracture model for functionally graded fiber reinforced concrete. Cem. Concr. Res. 2010, 40, 956–965. [Google Scholar] [CrossRef]

- Kozicki, J.; Tejchman, J. Effect of steel fibres on concrete behavior in 2D and 3D simulations using lattice model. Arch. Mech. 2010, 62, 465–492. [Google Scholar]

- Smith, J.; Cusatis, G.; Pelessone, D.; Landis, E.; O’Daniel, J.; Baylot, J. Discrete modeling of ultra-high performance concrete with application to projectile penetration. Int. J. Impact Eng. 2014, 65, 13–32. [Google Scholar] [CrossRef]

- Kang, J.; Bolander, J.E. Event-based lattice modeling of strain-hardening cementitious composites. Int. J. Fract. 2017, 206, 245–261. [Google Scholar] [CrossRef]

- Ogura, H.; Kunieda, M.; Nakamura, H. Tensile fracture analysis of fiber reinforced cement-based composites with rebar focusing on the contribution of bridging forces. J. Adv. Concr. Technol. 2019, 17, 216–231. [Google Scholar] [CrossRef]

- Bolander, J.E.; Berton, S. Simulation of shrinkage induced cracking in cement composite overlays. Cem. Concr. Compos. 2004, 26, 861–871. [Google Scholar] [CrossRef]

- Bolander, J.E.; Saito, S. Discrete modeling of short-fiber reinforcement in cementitious composites. Adv. Cem. Based Mater. 1997, 6, 76–86. [Google Scholar] [CrossRef]

- Kawai, T. New discrete models and their application to seismic response analysis of structures. Nucl. Eng. Des. 1978, 48, 207–229. [Google Scholar] [CrossRef]

- Bolander, J.E.; Saito, S. Fracture analyses using spring networks with random geometry. Eng. Fract. Mech. 1998, 61, 569–591. [Google Scholar] [CrossRef]

- Nagai, K.; Sato, Y.; Ueda, T. Mesoscopic simulation of failure of mortar and concrete by 3D RBSM. J. Adv. Concr. Technol. 2005, 3, 385–402. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Tabbara, M.R.; Kazemi, M.T.; Pijaudier-Cabot, G. Random Particle Model for Fracture of Aggregate or Fiber Composites. J. Eng. Mech. 1990, 116, 1686–1705. [Google Scholar] [CrossRef]

- Schlangen, E.; van Mier, J.G.M. Experimental and numerical analysis of micro-mechanisms of fracture of cement-based composites. Cem. Concr. Compos. 1992, 14, 105–118. [Google Scholar] [CrossRef]

- Jirásek, M.; Bažant, Z.P. Particle model for quasibrittle fracture and application to sea ice. J. Eng. Mech. ASCE 1995, 121, 1016–1025. [Google Scholar] [CrossRef]

- Cusatis, G.; Pelessone, D.; Mencarelli, A. Lattice Discrete Particle Model (LDPM) for failure behavior of concrete. I: Theory. Cem. Concr. Compos. 2011, 33, 881–890. [Google Scholar] [CrossRef]

- Alnaggar, M.; Cusatis, G.; di Luzio, G. Lattice Discrete Particle Modeling (LDPM) of Alkali Silica Reaction (ASR) deterioration of concrete structures. Cem. Concr. Compos. 2013, 41, 45–59. [Google Scholar] [CrossRef]

- Šavija, B.; Pacheco, J.; Schlangen, E. Lattice modeling of chloride diffusion in sound and cracked concrete. Cem. Concr. Compos. 2013, 42, 30–40. [Google Scholar] [CrossRef]

- Eliáš, J.; Vořechovský, M.; Skoček, J.; Bažant, Z.P. Stochastic discrete meso-scale simulations of concrete fracture: Comparison to experimental data. Eng. Fract. Mech. 2015, 135, 1–16. [Google Scholar] [CrossRef]

- Boumakis, I.; di Luzio, G.; Marcon, M.; Vorel, J.; Wan-Wendner, R. Discrete element framework for modeling tertiary creep of concrete in tension and compression. Eng. Fract. Mech. 2018, 200, 263–282. [Google Scholar] [CrossRef]

- Asahina, D.; Bolander, J.E. Voronoi-based discretizations for fracture analysis of particulate materials. Powder Technol. 2011, 213, 92–99. [Google Scholar] [CrossRef]

- Berton, S.; Bolander, J.E. Crack band model of fracture in irregular lattices. Comput. Methods Appl. Mech. Eng. 2006, 195, 7172–7181. [Google Scholar] [CrossRef]

- Asahina, D.; Aoyagi, K.; Kim, K.; Birkholzer, J.T.; Bolander, J.E. Elastically-homogeneous lattice models of damage in geomaterials. Comput. Geotech. 2017, 81, 195–206. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Isaji, Y.; Nakamura, H.; Miura, T. Collapse simulation of reinforced concrete including localized failure and large rotation using extended RBSM. In Proceedings of the 10th International Conference on Fracture Mechanics of Concrete and Concrete Structure (FraMCoS X), Bayonne, France, 24–26 June 2019. [Google Scholar]

- Hwang, Y.K.; Bolander, J.E.; Hong, J.W.; Lim, Y.M. Irregular lattice model for geometrically nonlinear dynamics of structures. Mech. Res. Commun. 2020, 107, 103554. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. Mater. Struct. 1983, 16, 155–177. [Google Scholar] [CrossRef]

- Červenka, J.; Červenka, V.; Laserna, S. On crack band model in finite element analysis of concrete fracture in engineering practice. Eng. Fract. Mech. 2019, 197, 27–47. [Google Scholar] [CrossRef]

- Pan, Y.; Prado, A.; Porras, R.; Hafez, O.; Bolander, J.E. Lattice modeling of early-age behavior of structural concrete. Materials 2017, 10, 231. [Google Scholar] [CrossRef]

- Nakamura, H.; Srisoros, W.; Yashiro, R.; Kunieda, M. Time-dependent structural analysis considering mass transfer to evaluate deterioration processes of RC structures. J. Adv. Concr. Technol. 2006, 4, 147–158. [Google Scholar] [CrossRef]

- Grassl, P.; Fahy, C.; Gallipoli, D.; Wheeler, S. On a 2D hydro-mechanical lattice approach for modelling hydraulic fracture. J. Mech. Phys. Solids 2015, 75, 104–118. [Google Scholar] [CrossRef]

- Grassl, P.; Bolander, J.E. Three-dimensional network model for coupling of fracture and mass transport in quasi-brittle geomaterials. Mater. J. 2016, 9, 782. [Google Scholar] [CrossRef] [PubMed]

- Fascetti, A.; Oskay, C. Dual random lattice modeling of backward erosion piping. Comput. Geotech. 2019, 105, 265–276. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Najjar, L.J. Drying of concrete as a nonlinear diffusion problem. Cem. Concr. Res. 1971, 1, 461–473. [Google Scholar] [CrossRef]

- Lewis, R.W.; Morgan, K.; Thomas, H.R.; Seetharamu, K.N. The Finite Element Method in Heat Transfer Analysis; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1996. [Google Scholar]

- Montero-Chacón, F.; Schlangen, E.; Cifuentes, H.; Medina, F. A numerical approach for the design of multiscale fibre-reinforced cementitious composites. Philos. Mag. 2015, 95, 3305–3327. [Google Scholar] [CrossRef]

- Radtke, F.K.F.; Simone, A.; Sluys, L.J. A partition of unity finite element method for simulating nonlinear debonding and matrix failure in thin fibre composites. Int. J. Numer. Methods Eng. 2011, 86, 453–476. [Google Scholar] [CrossRef]

- Schauffert, E.A.; Cusatis, G. Lattice Discrete Particle Model for fiber-reinforced concrete. I: Theory. J. Eng. Mech. 2012, 138, 826–833. [Google Scholar] [CrossRef]

- Caner, F.C.; Bažant, Z.; Wendner, R. Microplane model M7f for fiber reinforced concrete. Eng. Fract. Mech. 2013, 105, 41–57. [Google Scholar] [CrossRef]

- Luković, M.; Dong, H.; Šavija, B.; Schlangen, E.; Ye, G.; Breugel, K.V. Tailoring strain-hardening cementitious composite repair systems through numerical experimentation. Cem. Concr. Compos. 2014, 53, 200–213. [Google Scholar] [CrossRef]

- Zhan, Y.; Meschke, G. Multilevel computational model for failure analysis of steel-fiber–reinforced concrete structures. J. Eng. Mech. 2016, 142, 04016090. [Google Scholar] [CrossRef]

- Kunieda, M.; Ogura, H.; Ueda, N.; Nakamura, H. Tensile fracture process of strain hardening cementitious composites by means of three-dimensional meso-scale analysis. Cem. Concr. Compos. 2011, 33, 956–965. [Google Scholar] [CrossRef]

- Eddy, L.; Nagai, K. Numerical simulation of beam-column knee joints with mechanical anchorages by 3D rigid body spring model. Eng. Struct. 2016, 126, 547–558. [Google Scholar] [CrossRef]

- Kuntal, V.S.; Jiradilok, P.; Bolander, J.E.; Nagai, K. Estimation of internal corrosion degree from observed surface cracking of concrete using mesoscale simulation with Model Predictive Control. Comput. Aided Civ. Infrastruct. Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Fu, L.; Nakamura, H.; Yamamoto, Y.; Miura, T. Effect of various structural factors on shear strength degradation after yielding of RC members under cyclic loads. J. Adv. Concr. Technol. 2020, 18, 211–226. [Google Scholar] [CrossRef]

- Ferrara, L.; Ozyurt, N.; di Prisco, M. High mechanical performance of fibre reinforced cementitious composites: The role of “casting-flow induced” fibre orientation. Mater. Struct. 2011, 44, 109–128. [Google Scholar] [CrossRef]

- Lee, B.Y.; Kang, S.T.; Yun, H.B.; Kim, Y.Y. Improved sectional image analysis technique for evaluating fiber orientations in fiber-reinforced cement-based materials. Materials 2016, 9, 42. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.S.; Kang, S.T.; Lee, B.Y.; Koh, K.T.; Ryu, G.S. Improvement in predicting the post-cracking tensile behavior of ultra-high performance cementitious composites based on fiber orientation distribution. Materials 2016, 9, 829. [Google Scholar] [CrossRef]

- Stahli, P.; Custer, R.; van Mier, J.G.M. On flow properties, fibre distribution, fibre orientation and flexural behaviour of FRC. Mater. Struct. 2008, 41, 189–196. [Google Scholar] [CrossRef]

- Svec, O.; Zirgulis, G.; Bolander, J.E.; Stang, H. Influence of formwork surface on the orientation of steel fibres within self-compacting concrete and on the mechanical properties of cast structural elements. Cem. Concr. Compos. 2014, 50, 60–72. [Google Scholar] [CrossRef]

- Oesch, T.; Landis, E.; Kuchma, D. A methodology for quantifying the impact of casting A methodology for quantifying the impact of casting procedure on anisotropy in fiber-reinforced concrete using X-ray CT. Mater. Struct. 2018, 51, 1–13. [Google Scholar] [CrossRef]

- Knop, R.E. Random vectors uniform in solid angle. Commun. ACM 1970, 13, 326–327. [Google Scholar] [CrossRef]

- Lumelsky, V.J. On fast computation of distance between line segments. Inf. Process. Lett. 1985, 21, 55–61. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Naaman, A.E.; Namur, G.G.; Alwan, J.M.; Najm, H.S. Fiber Pullout and Bond Slip. I: Analytical Study. J. Struct. Eng. 1991, 117, 2769–2790. [Google Scholar] [CrossRef]

- Kang, J.; Kim, K.; Lim, Y.M.; Bolander, J.E. Modeling of fiber-reinforced cement composites: Discrete representation of fiber pullout. Int. J. Solids Struct. 2014, 51, 1970–1979. [Google Scholar] [CrossRef]

- Loh, K.J.; Hou, T.C.; Lynch, J.P.; Kotov, N.A. Carbon nanotube sensing skins for spatial strain and impact damage identification. J. Nondestruct. Eval. 2009, 28, 9–25. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. 1957, A241, 376–396. [Google Scholar]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the effective magnetic permeability of multiphase materials. J. Appl. Phys. 1962, 33, 3125. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: Berkshire, UK, 2014. [Google Scholar]

- Kang, S.T.; Lee, B.Y.; Kim, J.K.; Kim, Y.Y. The effect of fibre distribution characteristics on the flexural strength of steel fibre-reinforced ultra high strength concrete. Constr. Build. Mater. 2011, 25, 2450–2457. [Google Scholar] [CrossRef]

- Kang, J.; Rypl, R.; Bolander, J.E. Lattice modeling of strain-hardeningcement composites with spatially correlated random fiber distributions. In Proceedings of the 9th RILEM International Symposium on Fiber Reinforced Concrete (BEFIB 2016), Vancouver, BC, Canada, 19–21 September 2016; Banthia, N., di Prisco, M., Eds.; The University of British Columbia: Vancouver, BC, Canada, 2016. [Google Scholar]

- Powers, T. The Properties of Fresh Concrete; Wiley: New York, NY, USA, 1968. [Google Scholar]

- Wittmann, F. On the action of capillary pressure in fresh concrete. Cem. Concr. Res. 1976, 6, 49–56. [Google Scholar] [CrossRef]

- Slowik, V.; Schmidt, M.; Fritzsch, R. Capillary pressure in fresh cement-based materials and identification of the air entry value. Cem. Concr. Compos. 2008, 30, 557–565. [Google Scholar] [CrossRef]

- Combrinck, R. Cracking of Plastic Concrete in Slab-Like Elements. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2016. [Google Scholar]

- Slowik, V.; Schmidt, M. Kapillare Schwindrissbildung in Beton: Forschungsbericht zu Ursachen und Auswirkungen sowie zur Vermeidung von Frühschwindrissen; Beuth Verlag GmbH: Berlin, Germany, 2010. [Google Scholar]

- Combrinck, R.; Boshoff, W.P. Typical plastic shrinkage cracking behaviour of concrete. Mag. Concr. Res. 2013, 65, 486–493. [Google Scholar] [CrossRef]

- Wang, K.; Shah, S.P.; Phuaksuk, P. Plastic shrinkage cracking in concrete materials—Influence of fly ash and fibers. ACI Mater. J. 2001, 98, 458–464. [Google Scholar]

- Qi, C.; Weiss, J.; Olek, J. Characterization of plastic shrinkage cracking in fiber reinforced concrete using image analysis and a modified Weibull function. Mater. Struct. 2003, 36, 386–395. [Google Scholar] [CrossRef]

- Wongtanakitcharoen, T.; Naaman, A.E. Unrestrained early age shrinkage of concrete with polypropylene, PVA, and carbon fibers. Mater. Struct. 2006, 40, 289–300. [Google Scholar] [CrossRef]

- Fontana, P.; Pirskawetz, S.; Lura, P. Plastic shrinkage cracking risk of concrete–Evaluation of test methods. In Proceedings of the 7th RILEM International Conference on Cracking in Pavements, Delft, The Netherlands, 20–22 June 2012; Springer: Dordrecht, The Netherlands, 2012; pp. 591–600. [Google Scholar]

- Sivakumar, A.; Santhanam, M. A quantitative study on the plastic shrinkage cracking in high strength hybrid fibre reinforced concrete. Cem. Concr. Compos. 2007, 29, 575–581. [Google Scholar] [CrossRef]

- Kronlöf, A.; Leivo, M.; Sipari, P. Experimental study on the basic phenomena of shrinkage and cracking of fresh mortar. Cem. Concr. Res. 1995, 25, 1747–1754. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley and Sons: Hoboken, NJ, USA, 1943. [Google Scholar]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Lewis, R.W.; Schrefler, B.A. The Finite Element Method in the Static and Dynamic Deformation and Consolidation of Porous Media; John Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Tan, T.S.; Wee, T.H.; Tan, S.A.; Tam, C.T.; Lee, S.L. A consolidation model for bleeding of cement paste. Adv. Cem. Res. 1987, 1, 18–26. [Google Scholar] [CrossRef]

- Kwak, H.G.; Ha, S. Plastic shrinkage cracking in concrete slabs. Part I: A numerical model. Mag. Concr. Res. 2006, 58, 505–516. [Google Scholar] [CrossRef]

- Kwak, H.G.; Ha, S. Plastic shrinkage cracking in concrete slabs. Part II: Numerical experiment and prediction of occurrence. Mag. Concr. Res. 2006, 58, 517–532. [Google Scholar] [CrossRef]

- Kwak, H.G.; Ha, S.; Weiss, W.J. Experimental and numerical quantification of plastic settlement in fresh cementitious systems. J. Mater. Civ. Eng. 2010, 22, 951–966. [Google Scholar] [CrossRef]

- di Luzio, G.; Cusatis, G. Solidification-microprestress-microplane (SMM) theory for concrete at early age: Theory, validation and application. Int. J. Solids Struct. 2013, 50, 957–975. [Google Scholar] [CrossRef]

- Yu, P.; Duan, Y.H.; Chen, E.; Tang, S.W.; Hanif, A.; Fan, Y.L. Microstructure-based homogenization method for early-age creep of cement paste. Constr. Build. Mater. 2018, 188, 1193–1206. [Google Scholar] [CrossRef]

- Zhou, W.; Duan, L.; Tang, S.W.; Chen, E.; Hanif, A. Modeling the evolved microstructure of cement pastes governed by diffusion through barrier shells of C-S-H. J. Mater. Sci. 2019, 54, 4680–4700. [Google Scholar] [CrossRef]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Hygro-thermo-chemo-mechanical modelling of concrete at early ages and beyond. Part I: Hydration and hygro-thermal phenomena. Int. J. Numer. Methods Eng. 2006, 67, 299–331. [Google Scholar] [CrossRef]

- Kim, J.M.; Parizek, R.R. A mathematical model for the hydraulic properties of deforming porous media. Groundwater 1999, 37, 546–554. [Google Scholar] [CrossRef]

- Kang, J.; Bolander, J.E. Flow in fibrous composite materials: Numerical simulations. In Proceedings of the Computational Modeling of Concrete and Concrete Structures (EURO-C 2018), Bad Hofgastein, Austria, 26 February–1 March 2018. [Google Scholar]

- Pan, Y. Lattice Modeling of Volumetric Variation of Cementitious Materials at very Early Age. Ph.D. Thesis, Department of Civil and Environmental Engineering, University of California, Davis, CA, USA, 2018. [Google Scholar]

| Material Parameter | Value |

|---|---|

| Elastic Modulus E (MPa) | 0.2778 |

| Density of Solid Skeleton (kg/m3) | 2691 |

| Density of Pore Water (kg/m3) | 1000 |

| Initial Porosity | 0.25 |

| Initial Hydraulic Conductivity (mm/s) | 5.1 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Y.; Kang, J.; Ichimaru, S.; Bolander, J.E. Multi-Field Models of Fiber Reinforced Concrete for Structural Applications. Appl. Sci. 2021, 11, 184. https://doi.org/10.3390/app11010184

Pan Y, Kang J, Ichimaru S, Bolander JE. Multi-Field Models of Fiber Reinforced Concrete for Structural Applications. Applied Sciences. 2021; 11(1):184. https://doi.org/10.3390/app11010184

Chicago/Turabian StylePan, Yaming, Jingu Kang, Sonoko Ichimaru, and John E. Bolander. 2021. "Multi-Field Models of Fiber Reinforced Concrete for Structural Applications" Applied Sciences 11, no. 1: 184. https://doi.org/10.3390/app11010184

APA StylePan, Y., Kang, J., Ichimaru, S., & Bolander, J. E. (2021). Multi-Field Models of Fiber Reinforced Concrete for Structural Applications. Applied Sciences, 11(1), 184. https://doi.org/10.3390/app11010184