A Coordination Space Model for Assemblability Analysis and Optimization during Measurement-Assisted Large-Scale Assembly

Abstract

Featured Application

Abstract

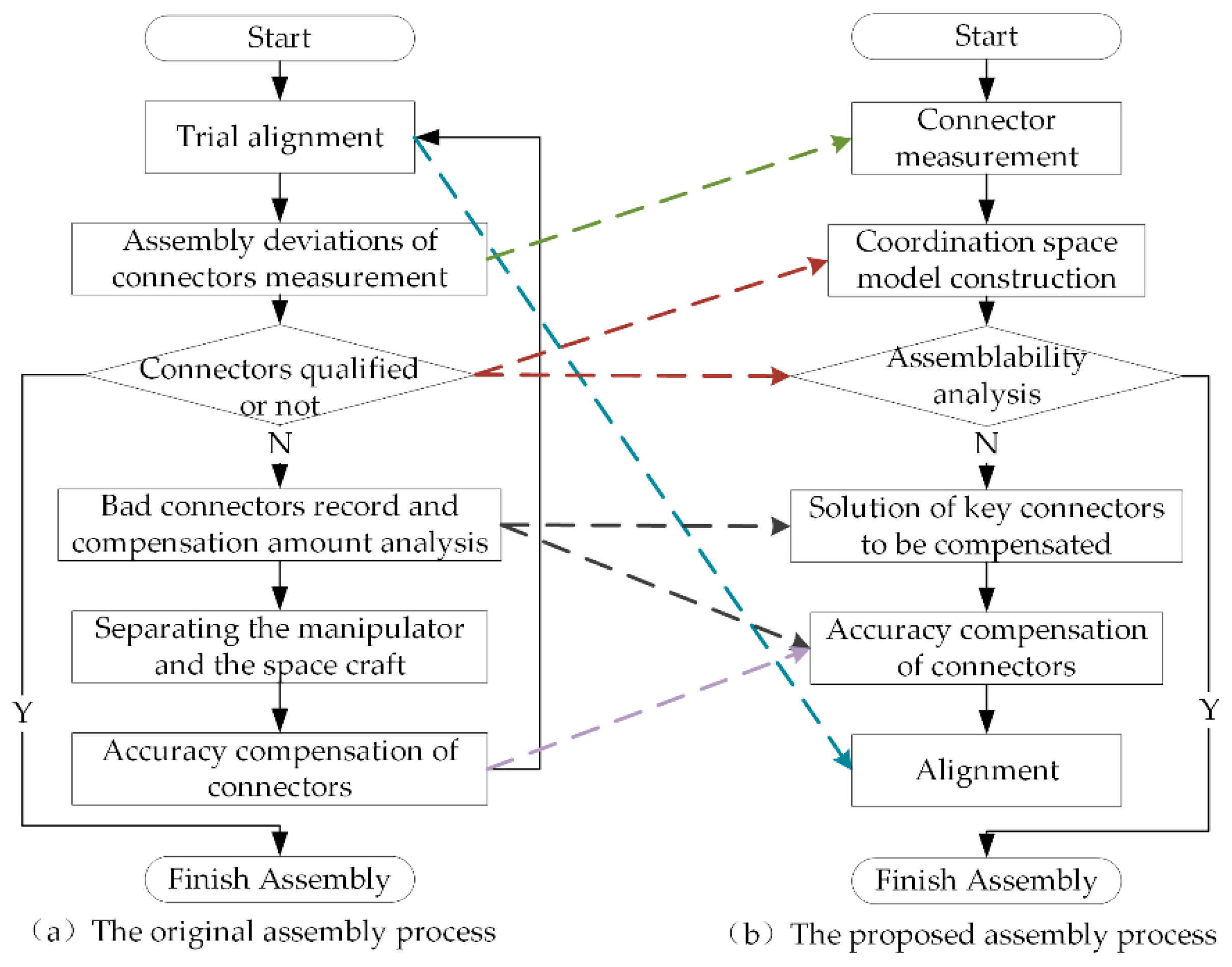

1. Introduction

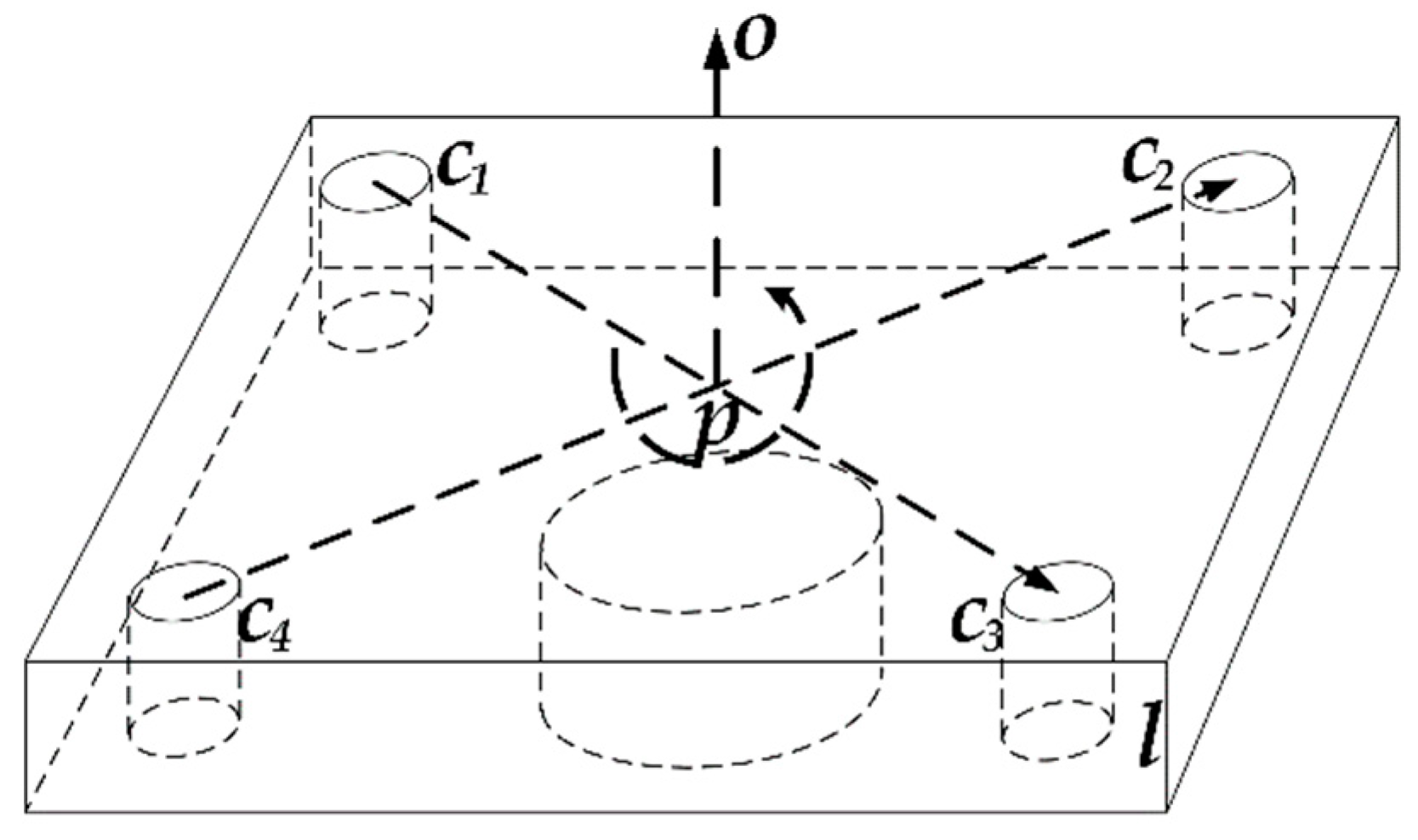

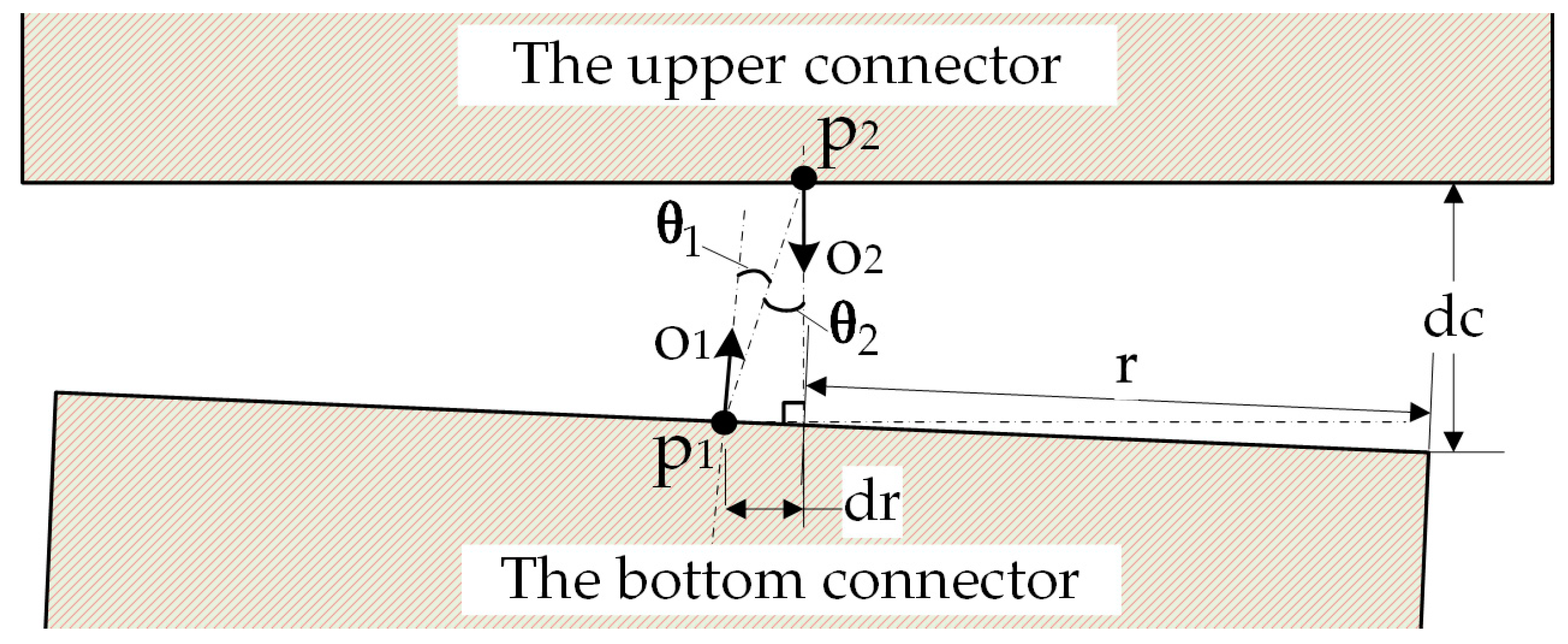

2. Coordination Space Model Based on Small Displacement Torsor

3. Assemblability Analysis Based on Coordination Space Model

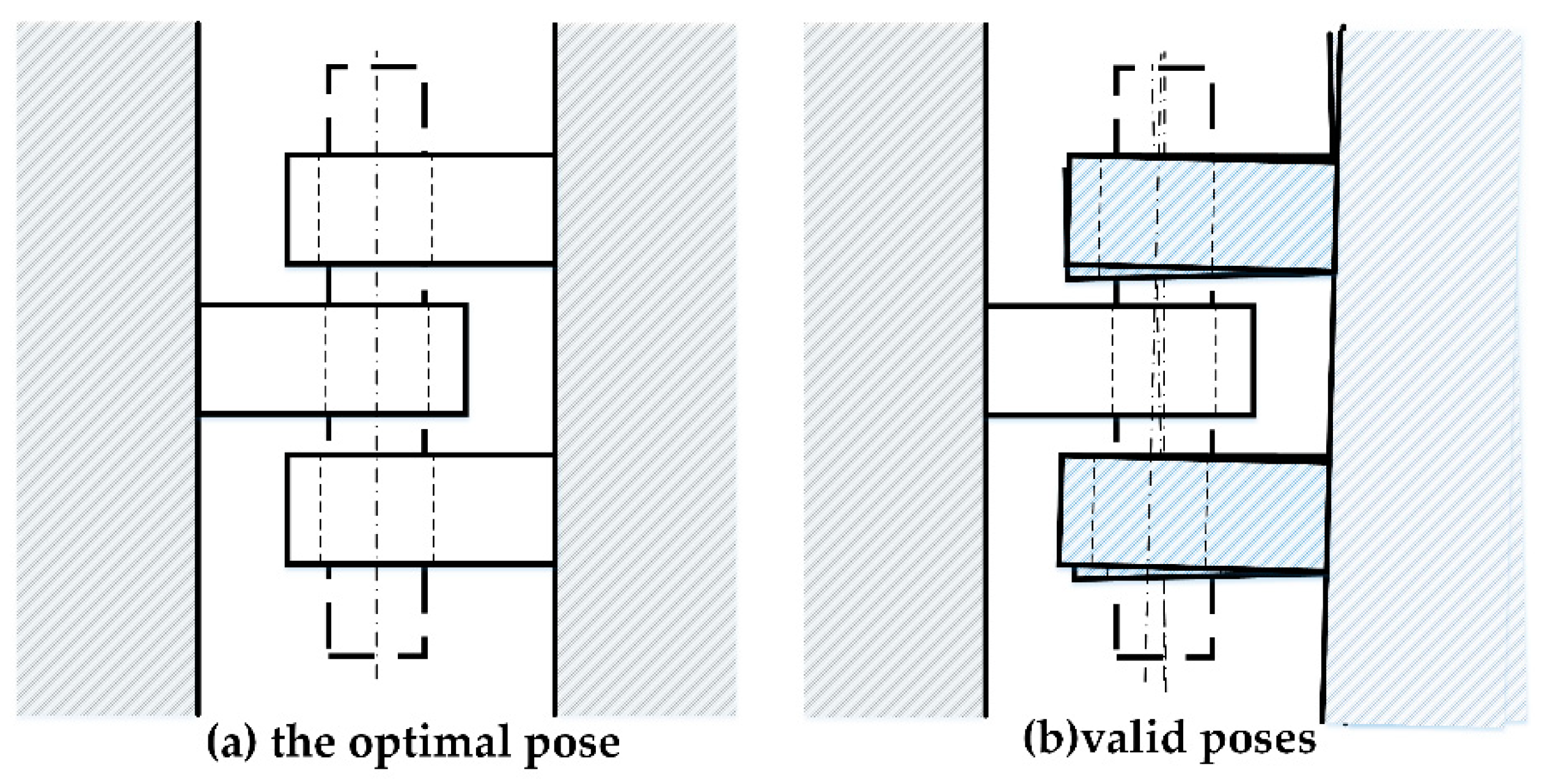

- Calculate the optimal pose based on the least-squares method.

- According to the dimensions and assembly accuracy requirements, a maximum pose space is assumed, as Equation (16) shows. All poses out of the space are not valid for any assembly accuracy requirements.

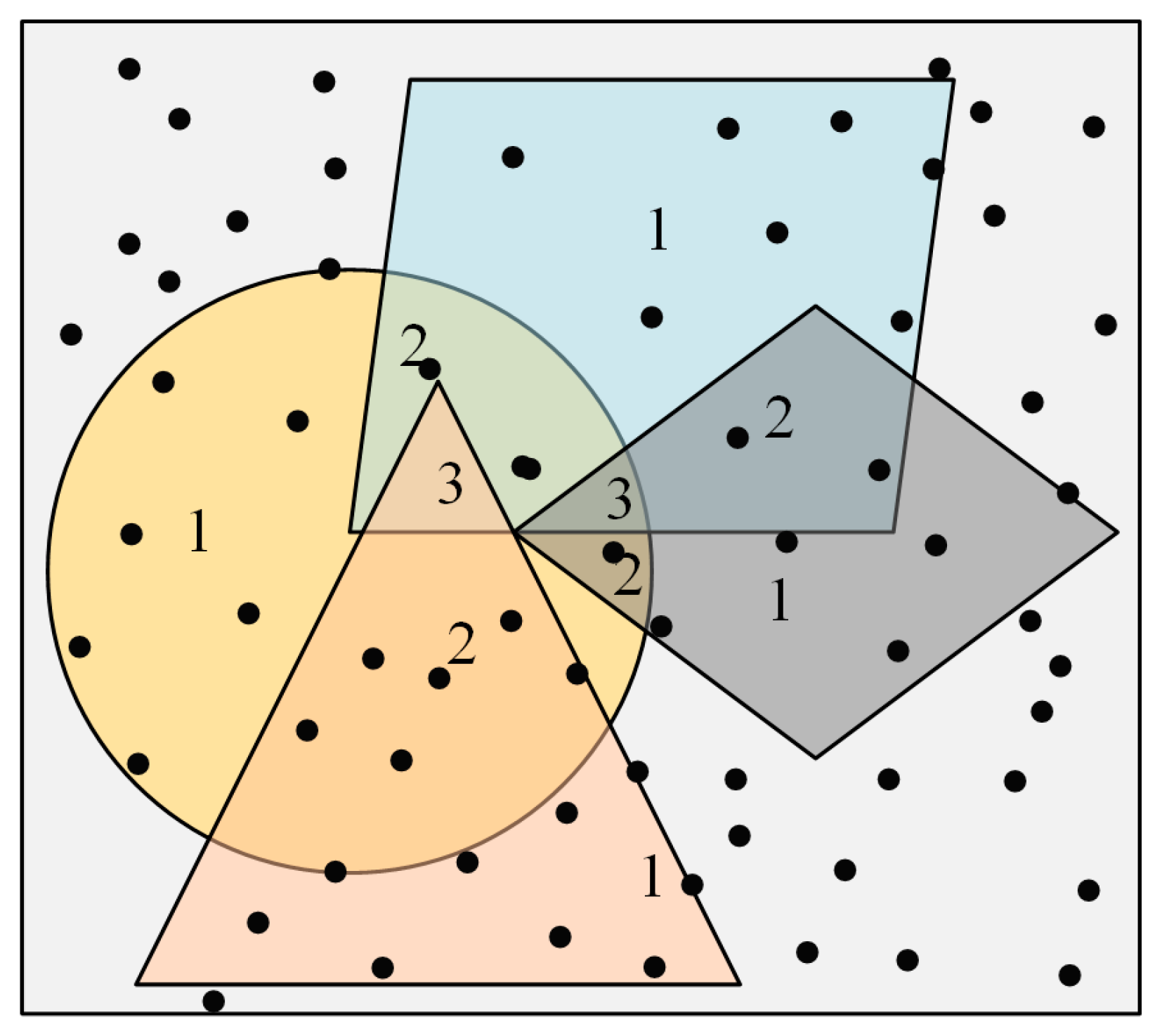

- Generate a random SDT uniformly for times and check the SDTs by Equation (15).

- If of SDTs are valid, the coordination space is

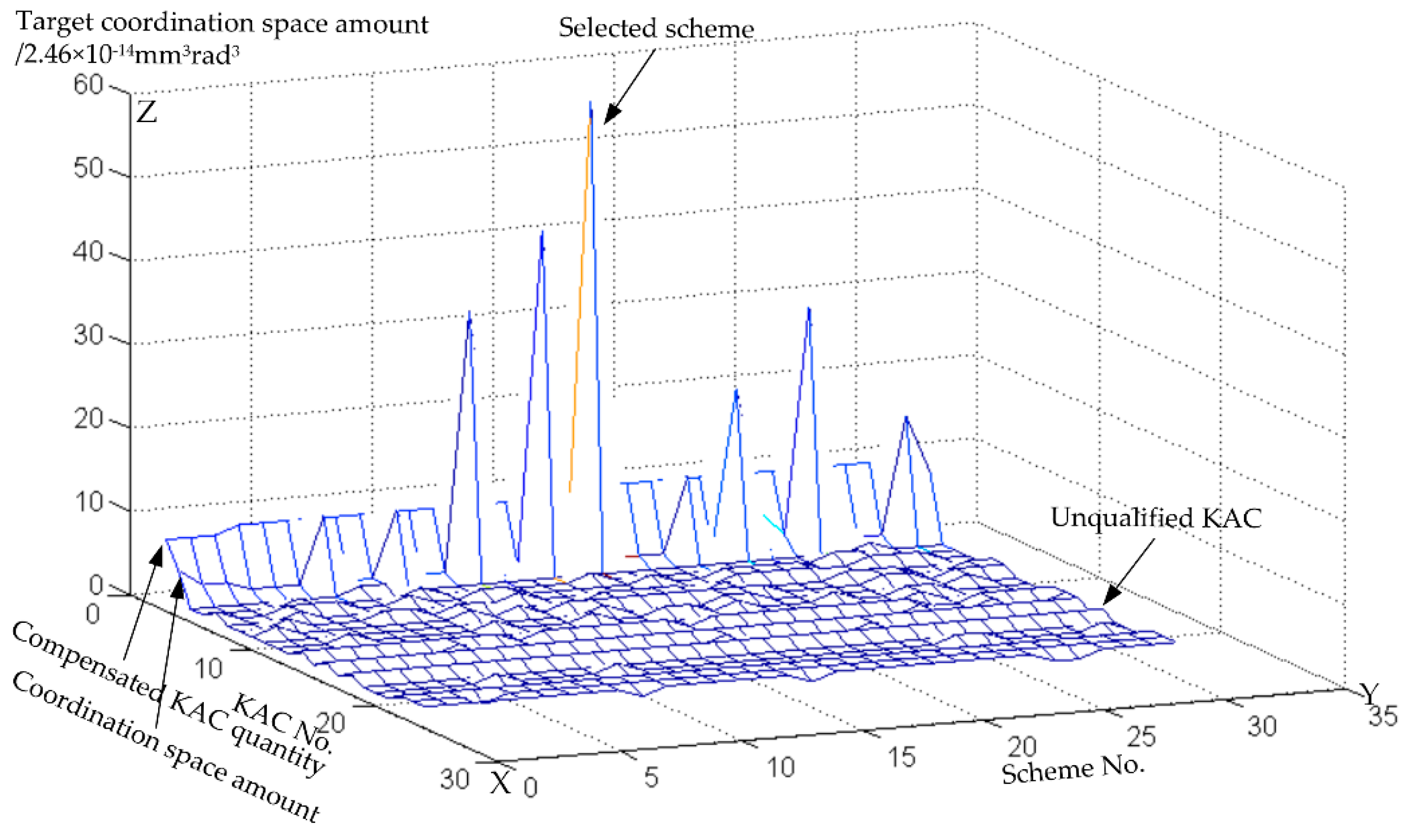

4. Assemblability Optimization Based on the Union Coordination Space

- Solve the optimal pose of the align part;

- Set a pose space as the pose boundary as shown by the square box of Figure 8;

- Generate a random SDT in the pose space;

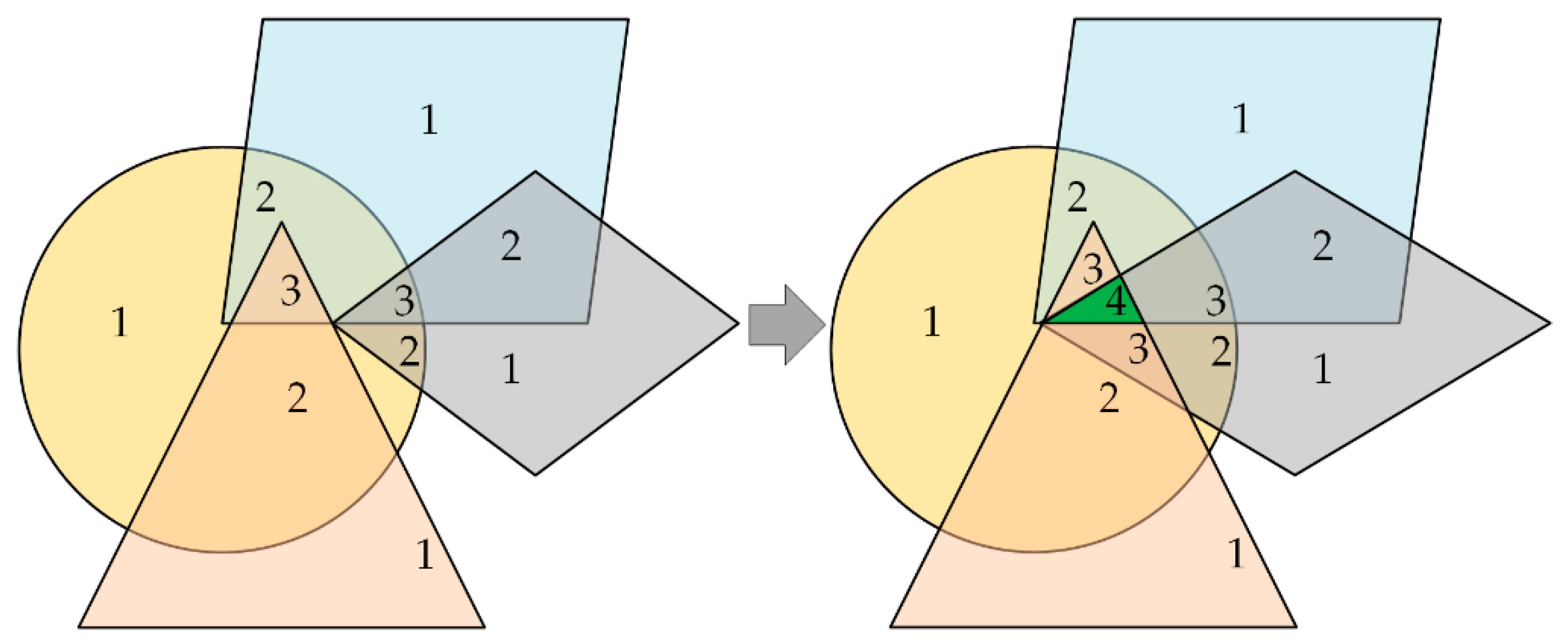

- According to Equation (19), judge which KAC equations are satisfied (coordination zone index) and which are not (incoordination zone index);

- Cluster the analysis results of each SDT. The SDTs in the same coordination zone are clustered together;

- Put the clustered results into the data structure of Equation (23). The KAC number to be compensated is the incoordination zone index. Select the scheme with a better KAC number and space volume of the coordination zone.where is the ith scheme, is the incoordination zone index, is the space amount of the coordination zone, is the information of uncoordinated KACs, is the SDT set, and is the max number of the schemes.

- Calculate the center SDT of the SDTs in the selected scheme. The assembly deviation of target features under the SDT is analyzed and the accuracy compensation is carried out.where is the center SDT, is the SDT number of , and is an SDT of . All assembly accuracies on are calculated. Then, the deviations on the excessive KACs will be compensated.

5. Case Study

5.1. Space Manipulator Assembly

5.2. Coordination Space Model

5.3. Assemblability Analysis

5.4. Assemblability Optimization

6. Discussion

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Spacecraft | Spacecraft | Manipulator | Manipulator | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| x/mm | y/mm | z/mm | x/mm | y/mm | z/mm | x/mm | y/mm | z/mm | x/mm | y/mm | z/mm |

| 26.060 | 26.037 | −192.674 | 2525.979 | 25.966 | −192.595 | 222.509 | 2274.256 | 403.730 | 2722.472 | 2274.418 | 403.607 |

| 25.941 | −25.881 | −192.645 | 2525.879 | −26.066 | −192.588 | 222.471 | 2222.338 | 403.647 | 2722.406 | 2222.370 | 403.680 |

| −25.972 | −25.945 | −192.558 | 2473.905 | −25.939 | −192.634 | 170.389 | 2222.349 | 403.666 | 2670.395 | 2222.418 | 403.611 |

| −25.973 | 26.032 | −192.581 | 2473.927 | 26.032 | −192.648 | 170.520 | 2274.362 | 403.722 | 2670.399 | 2274.318 | 403.725 |

| 25.964 | −1103.891 | −192.620 | 2525.886 | −1103.863 | −192.642 | 222.163 | 1144.197 | 403.734 | 2722.221 | 1144.019 | 403.649 |

| 25.995 | −1155.853 | −192.533 | 2525.963 | −1155.983 | −192.687 | 222.172 | 1092.171 | 403.594 | 2722.191 | 1092.064 | 403.681 |

| −26.108 | −1155.891 | −192.633 | 2473.910 | −1155.938 | −192.617 | 170.261 | 1092.242 | 403.670 | 2670.236 | 1092.093 | 403.632 |

| −26.138 | −1103.914 | −192.600 | 2473.997 | −1103.946 | −192.532 | 170.240 | 1144.209 | 403.636 | 2670.134 | 1144.022 | 403.682 |

| 526.046 | 26.182 | −192.691 | 25.984 | 371.512 | −292.868 | 722.540 | 2274.127 | 403.704 | 222.310 | 2619.620 | 303.466 |

| 526.032 | −25.859 | −192.578 | 26.082 | 328.937 | −322.879 | 722.525 | 2222.138 | 403.647 | 222.406 | 2577.169 | 273.462 |

| 474.044 | −25.874 | −192.632 | −25.948 | 328.968 | −322.927 | 670.477 | 2222.107 | 403.660 | 170.271 | 2577.228 | 273.409 |

| 473.999 | 26.048 | −192.660 | −25.989 | 371.392 | −292.860 | 670.519 | 2274.160 | 403.749 | 170.259 | 2619.691 | 303.502 |

| 525.926 | −1103.994 | −192.665 | 26.306 | 779.693 | −581.183 | 722.553 | 1144.152 | 403.622 | 222.373 | 3028.126 | 15.112 |

| 525.941 | −1156.028 | −192.670 | 26.328 | 737.195 | −611.193 | 722.582 | 1092.046 | 403.733 | 222.475 | 2985.706 | −14.926 |

| 473.906 | −1155.956 | −192.534 | −25.677 | 737.131 | −611.127 | 670.483 | 1092.007 | 403.687 | 170.440 | 2985.796 | −14.932 |

| 474.001 | −1103.938 | −192.549 | −25.718 | 779.531 | −581.201 | 670.468 | 1144.107 | 403.701 | 170.438 | 3028.159 | 15.042 |

| 1025.900 | 25.892 | −192.696 | 526.057 | 371.467 | −292.910 | 1222.170 | 2274.325 | 403.687 | 722.232 | 2619.736 | 303.446 |

| 1025.991 | −26.042 | −192.675 | 525.980 | 329.046 | −322.917 | 1222.300 | 2222.253 | 403.652 | 722.264 | 2577.274 | 273.375 |

| 973.956 | −26.131 | −192.596 | 473.953 | 329.017 | −322.836 | 1170.188 | 2222.222 | 403.641 | 670.255 | 2577.165 | 273.441 |

| 973.988 | 25.990 | −192.571 | 473.989 | 371.499 | −292.943 | 1170.178 | 2274.330 | 403.697 | 670.274 | 2619.662 | 303.464 |

| 1026.139 | −1104.097 | −192.694 | 526.004 | 779.757 | −581.219 | 1222.329 | 1144.177 | 403.676 | 722.338 | 3027.977 | 14.999 |

| 1026.085 | −1156.050 | −192.740 | 525.882 | 737.293 | −611.181 | 1222.380 | 1092.031 | 403.649 | 722.348 | 2985.465 | −14.896 |

| 974.124 | −1156.044 | −192.605 | 474.011 | 737.365 | −611.149 | 1170.291 | 1092.073 | 403.617 | 670.334 | 2985.461 | −14.882 |

| 974.105 | −1104.011 | −192.634 | 474.022 | 779.818 | −581.198 | 1170.331 | 1144.076 | 403.725 | 670.270 | 3028.053 | 15.054 |

| 1525.925 | 26.129 | −192.717 | 25.959 | −1458.921 | −322.909 | 1722.341 | 2274.278 | 403.722 | 222.442 | 789.300 | 273.358 |

| 1525.908 | −25.848 | −192.628 | 26.022 | −1501.395 | −292.846 | 1722.343 | 2222.377 | 403.704 | 222.364 | 746.770 | 303.402 |

| 1473.914 | −25.921 | −192.601 | −26.061 | −1501.356 | −292.887 | 1670.349 | 2222.277 | 403.637 | 170.403 | 746.817 | 303.352 |

| 1473.942 | 26.171 | −192.663 | −25.980 | −1458.862 | −322.971 | 1670.315 | 2274.352 | 403.667 | 170.462 | 789.233 | 273.423 |

| 1526.063 | −1104.006 | −192.639 | 26.112 | −1867.403 | −611.275 | 1722.264 | 1144.106 | 403.701 | 222.487 | 380.493 | −14.929 |

| 1525.951 | −1155.886 | −192.590 | 25.999 | −1909.862 | −581.157 | 1722.267 | 1092.232 | 403.641 | 222.479 | 338.017 | 15.121 |

| 1473.970 | −1155.991 | −192.610 | −25.945 | −1909.883 | −581.133 | 1670.247 | 1092.136 | 403.697 | 170.454 | 337.946 | 15.019 |

| 1474.029 | −1103.917 | −192.536 | −25.952 | −1867.415 | −611.214 | 1670.338 | 1144.104 | 403.578 | 170.502 | 380.501 | −15.022 |

| 2026.006 | 25.807 | −192.610 | 525.901 | −1459.048 | −322.918 | 2222.301 | 2274.138 | 403.623 | 722.541 | 789.350 | 273.516 |

| 2026.008 | −26.174 | −192.602 | 525.980 | −1501.511 | −292.844 | 2222.194 | 2222.153 | 403.685 | 722.525 | 746.885 | 303.481 |

| 1974.072 | −26.202 | −192.597 | 474.025 | −1501.571 | −292.828 | 2170.273 | 2222.082 | 403.688 | 670.449 | 746.930 | 303.374 |

| 1973.940 | 25.758 | −192.615 | 473.983 | −1459.106 | −322.849 | 2170.301 | 2274.070 | 403.707 | 670.465 | 789.270 | 273.409 |

| 2025.839 | −1103.981 | −192.592 | 525.886 | −1867.434 | −611.169 | 2222.555 | 1144.297 | 403.746 | 722.630 | 380.599 | −14.830 |

| 2025.808 | −1155.974 | −192.526 | 525.806 | −1909.943 | −581.114 | 2222.521 | 1092.226 | 403.623 | 722.554 | 338.263 | 15.129 |

| 1973.868 | −1155.897 | −192.571 | 473.872 | −1909.917 | −581.157 | 2170.597 | 1092.349 | 403.654 | 670.639 | 338.232 | 15.073 |

| 1973.894 | −1103.986 | −192.651 | 473.840 | −1867.343 | −611.211 | 2170.608 | 1144.349 | 403.683 | 670.507 | 380.619 | −14.907 |

References

- Zhou, F.; Xue, H.; Zhou, W.; Xu, G. Key technology and its improvement of aircraft digital flexible assembly. Aeronaut. Manuf. Technol. 2006, 9, 30–35. (In Chinese) [Google Scholar]

- Maropoulos, P.G.; Muelaner, J.E.; Summers, M.D.; Martin, O.C. A new paradigm in large-scale assembly—Research priorities in measurement assisted assembly. Int. J. Adv. Manuf. Technol. 2014, 70, 621–633. [Google Scholar] [CrossRef]

- Marguet, B.; Ribere, B. Measurement-assisted assembly applications on airbus final assembly lines. SAE Tech. Pap. 2003, 1, 2950. [Google Scholar]

- Chen, Z.; Du, F.; Tang, X. Position and orientation best-fitting based on deterministic theory during large scale assembly. J. Intell. Manuf. 2015, 29, 827–837. [Google Scholar] [CrossRef]

- Li, S.; Deng, Z.; Zeng, Q.; Huang, X. A coaxial alignment method for large aircraft component assembly using distributed monocular vision. Assem. Autom. 2018, 38, 437–449. [Google Scholar] [CrossRef]

- Wang, Q.; Dou, Y.; Li, J.; Ke, Y.; Keogh, P.; Maropoulos, P.G. An assembly gap control method based on posture alignment of wing panels in aircraft assembly. Assem. Autom. 2017, 37, 422–433. [Google Scholar] [CrossRef]

- Sukhan, L.; Chunsik, Y. Assemblability evaluation based on tolerance propagation. In Proceedings of the 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995. [Google Scholar]

- Sanderson, A.C. Assemblability based on maximum likelihood configuration of tolerances. IEEE Trans. Robot. Autom. 1999, 15, 568–572. [Google Scholar] [CrossRef][Green Version]

- Cui, Z.; Du, F. Assessment of large-scale assembly coordination based on pose feasible space. Int. J. Adv. Manuf. Technol. 2019, 104, 4465–4474. [Google Scholar] [CrossRef]

- Yuan, L.; Zhang, L.; Wang, Y. An optimal method of posture adjustment in aircraft fuselage joining assembly with engineering constraints. Chin. J. Aeronaut. 2017, 30, 222–229. [Google Scholar]

- Wu, D.; Du, F. A Multi-constraints Based Pose Coordination Model for Large Volume Components Assembly. Chin. J. Aeronaut. 2019. [Google Scholar] [CrossRef]

- Ma, H.; Jin, Y.; Zhang, X.; Zhou, H. Complex shape product tolerance and accuracy control method for virtual assembly. Proc. SPIE Int. Soc. Opt. Eng. 2015, 9446, 94462E. [Google Scholar]

- Du, Q.; Zhai, X.; Wen, Q. Study of the Ultimate Error of the Axis Tolerance Feature and Its Pose Decoupling Based on an Area Coordinate System. Appl. Sci. 2018, 8, 435. [Google Scholar] [CrossRef]

- Davis, B.; Jones, T.M.; Darrell, D.Z.; Tracy, E. Digitally Designed Shims for Joining Parts of an Assembly. European Patents EP 2533167A2, 5 June 2012. [Google Scholar]

- Fabian, S.; Nathapon, O.L.; Jorg, W. Automated assembly of large CFRP structures: Adaptive filling of joining gaps with additive manufacturing. In Proceedings of the 2016 IEEE International Symposium on Assembly and Manufacturing, Fort Worth, TX, USA, 21–22 August 2016; pp. 126–132. [Google Scholar]

- Wang, Q.; Dou, Y.; Cheng, L.; Ke, Y.; Qiao, H.; Zhao, X. Shimming design and optimal selection for non-uniform gaps in wing assembly. Assem. Autom. 2017, 37, 471–482. [Google Scholar] [CrossRef]

- Muelaner, J.; Kayani, A.; Martin, O.; Maropoulos, P.G. Measurement assisted assembly and the roadmap to part-to-part assembly. In Proceedings of the DET2011 7th International Conference on Digital Enterprise Technology, Athens, Greece, 27–30 September 2011; pp. 11–19. [Google Scholar]

- Cui, Z.; Du, F.; Xiong, T. Analysis and coordination on assembly deviation of multi plane-and-holes assembly based on orientation points groups. Acta Aeronaut. Astronaut. Sin. 2018, 38, 248–257. (In Chinese) [Google Scholar]

- Yang, J.L.; Huang, X.; Li, L.; Xiong, T.; Zhao, Z. Method for extracting repair amount of skin seam based on scan line point cloud. Aeronaut. Manuf. Technol. 2019, 62, 73–77. (In Chinese) [Google Scholar]

- Yu, A.; Liu, Z.; Duan, G.; Tan, J.; Che, L.; Chen, X. Geometric design model and object scanning mode based virtual assembly and repair analysis. Procedia CIRP 2016, 44, 144–150. [Google Scholar] [CrossRef]

- Manohar, K.; Hogan, T.; Buttrick, J.; Banerjee, A.G.; Kutz, J.N.; Brunton, S.L. Predicting shim gaps in aircraft assembly with machine learning and sparse sensing. J. Manuf. Syst. 2018, 48, 87–95. [Google Scholar] [CrossRef]

- Lei, P.; Zheng, L. An automated insitu alignment approach for finish machining assembly interfaces of large-scale components. Robot. Comput. Integr. Manuf. 2017, 46, 130–143. [Google Scholar] [CrossRef]

- Cheng, B. Aircraft Manufacturing Coordination Accuracy and Tolerance Allocation, 1st ed.; Aviation Industry Press: Beijing, China, 1987; pp. 1–16. (In Chinese) [Google Scholar]

- Arun, K.S. Least-squares fitting of two 3-D point sets. IEEE Trans. Pattern Anal. Mach. Intell. 1987, 9, 698–700. [Google Scholar] [CrossRef]

- Liu, J.; Wang, T.; Zou, C. A blending control aircraft assembly quality method using key assembly characteristic. Adv. Mater. Res. 2011, 314–316, 2469–2473. [Google Scholar]

- Bourdet, P.; Mathieu, L.; Lartigue, C.; Ballu, A. The concept of small displacement torsor in metrology. Adv. Math. Tools Metrol. 1996, 40, 110–122. [Google Scholar]

| Spacecraft | Manipulator | ||||

|---|---|---|---|---|---|

| x/mm | y/mm | z/mm | x/mm | y/mm | z/mm |

| 26.060 | 26.037 | −192.674 | 222.509 | 2274.256 | 403.730 |

| 25.941 | −25.881 | −192.645 | 222.471 | 2222.338 | 403.647 |

| −25.972 | −25.945 | −192.558 | 170.389 | 2222.349 | 403.666 |

| −25.973 | 26.032 | −192.581 | 170.520 | 2274.362 | 403.722 |

| No. | dr/mm | dc/mm | No. | dr/mm | dc/mm |

|---|---|---|---|---|---|

| 1 | 0.154 | 0.043 | 11 | 0.171 | −0.012 |

| 2 | 0.150 | −0.027 | 12 | 0.338 | 0.002 |

| 3 | 0.205 | 0.072 | 13 | 0.286 | −0.010 |

| 4 | 0.196 | 0.042 | 14 | 0.530 | −0.274 |

| 5 | 0.191 | 0.012 | 15 | 0.247 | 0.033 |

| 6 | 0.209 | 0.083 | 16 | 0.165 | −0.029 |

| 7 | 0.066 | 0.045 | 17 | 0.188 | 0.033 |

| 8 | 0.195 | −0.025 | 18 | 0.402 | −0.154 |

| 9 | 0.118 | −0.006 | 19 | 0.086 | 0.183 |

| 10 | 0.298 | −0.010 | 20 | 0.386 | −0.028 |

| No. | dr/mm | dc/mm | No. | dr/mm | dc/mm |

|---|---|---|---|---|---|

| 1 | 0.145 | 0.034 | 11 | 0.150 | −0.036 |

| 2 | 0.188 | −0.031 | 12 | 0.351 | −0.013 |

| 3 | 0.169 | 0.064 | 13 | 0.142 | −0.022 |

| 4 | 0.151 | 0.031 | 14 | 0.391 | −0.286 |

| 5 | 0.230 | 0.004 | 15 | 0.133 | 0.016 |

| 6 | 0.249 | 0.070 | 16 | 0.031 | −0.039 |

| 7 | 0.025 | 0.037 | 17 | 0.056 | 0.032 |

| 8 | 0.222 | −0.034 | 18 | 0.204 | −0.145 |

| 9 | 0.162 | −0.021 | 19 | 0.204 | 0.179 |

| 10 | 0.255 | −0.029 | 20 | 0.233 | −0.027 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Z.; Du, F. A Coordination Space Model for Assemblability Analysis and Optimization during Measurement-Assisted Large-Scale Assembly. Appl. Sci. 2020, 10, 3331. https://doi.org/10.3390/app10093331

Cui Z, Du F. A Coordination Space Model for Assemblability Analysis and Optimization during Measurement-Assisted Large-Scale Assembly. Applied Sciences. 2020; 10(9):3331. https://doi.org/10.3390/app10093331

Chicago/Turabian StyleCui, Zhizhuo, and Fuzhou Du. 2020. "A Coordination Space Model for Assemblability Analysis and Optimization during Measurement-Assisted Large-Scale Assembly" Applied Sciences 10, no. 9: 3331. https://doi.org/10.3390/app10093331

APA StyleCui, Z., & Du, F. (2020). A Coordination Space Model for Assemblability Analysis and Optimization during Measurement-Assisted Large-Scale Assembly. Applied Sciences, 10(9), 3331. https://doi.org/10.3390/app10093331