Verifying the Test Methods and Certification Criteria for New Technological Convergence Products: Using Living Labs as a Methodology

Abstract

1. Introduction

2. Literature Review

2.1. Challenges for New Technological Convergence Products (NCPs)

2.2. Certification of Compliance with New Products of Industrial Convergence

2.3. Verification of Test Methods and Certification Criteria

2.4. Living Labs as a Methodology

3. The Conceptual Framework Proposed

3.1. The Five-Step Process of Verification Using Living Labs

3.2. Analyzing the Real-Use Environments and Implementing Living Labs

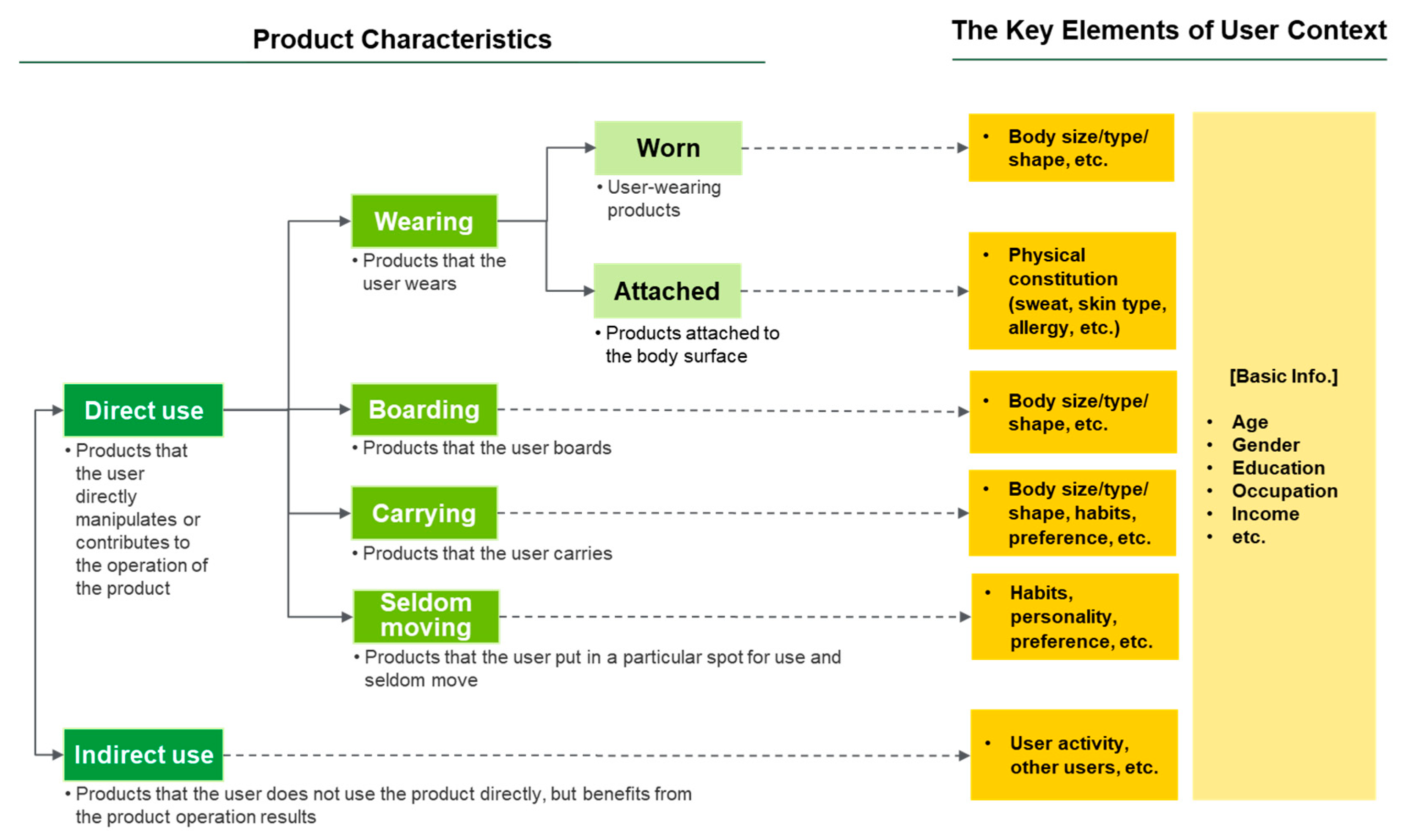

3.2.1. User Context

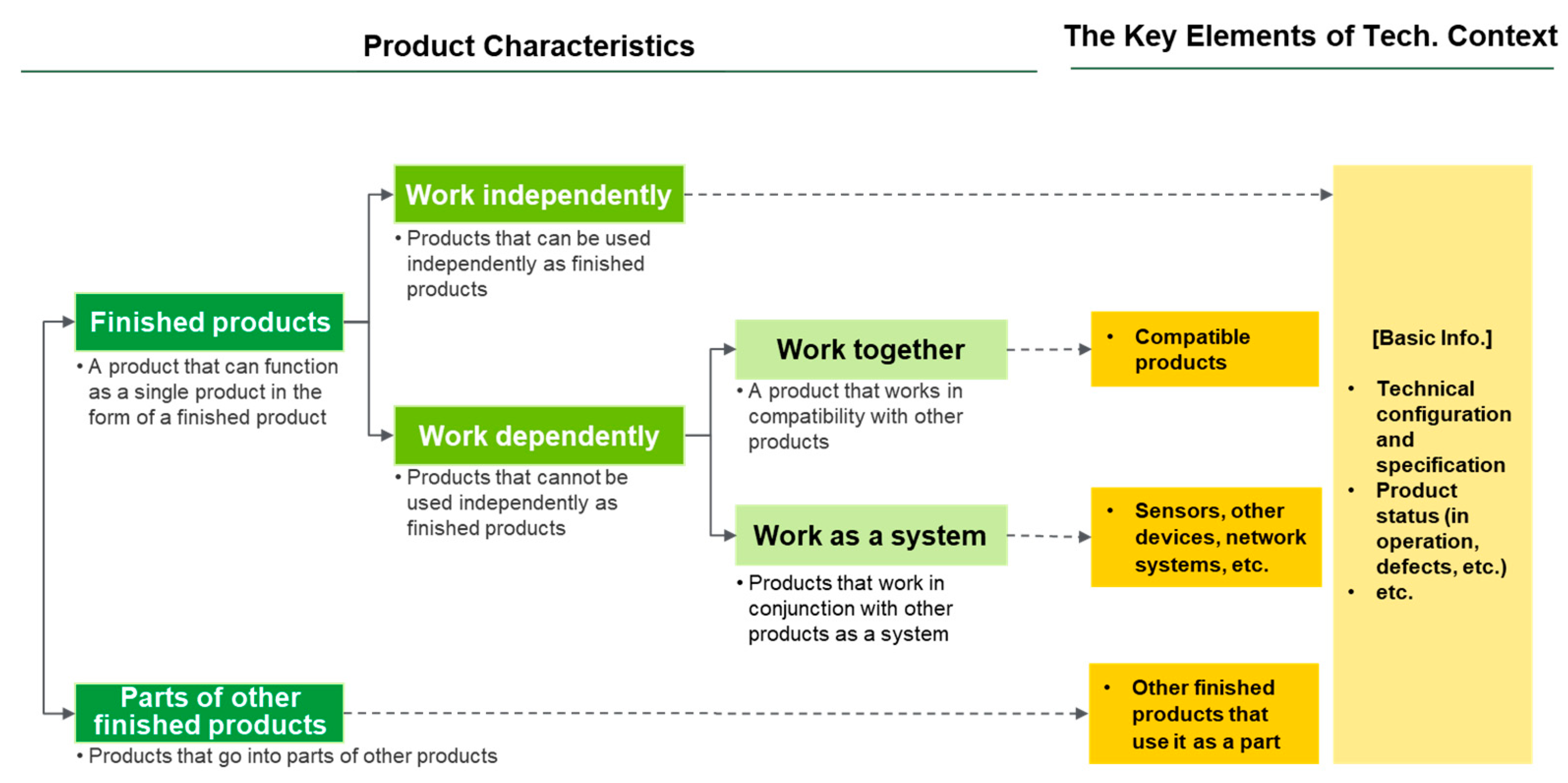

3.2.2. Technological Context

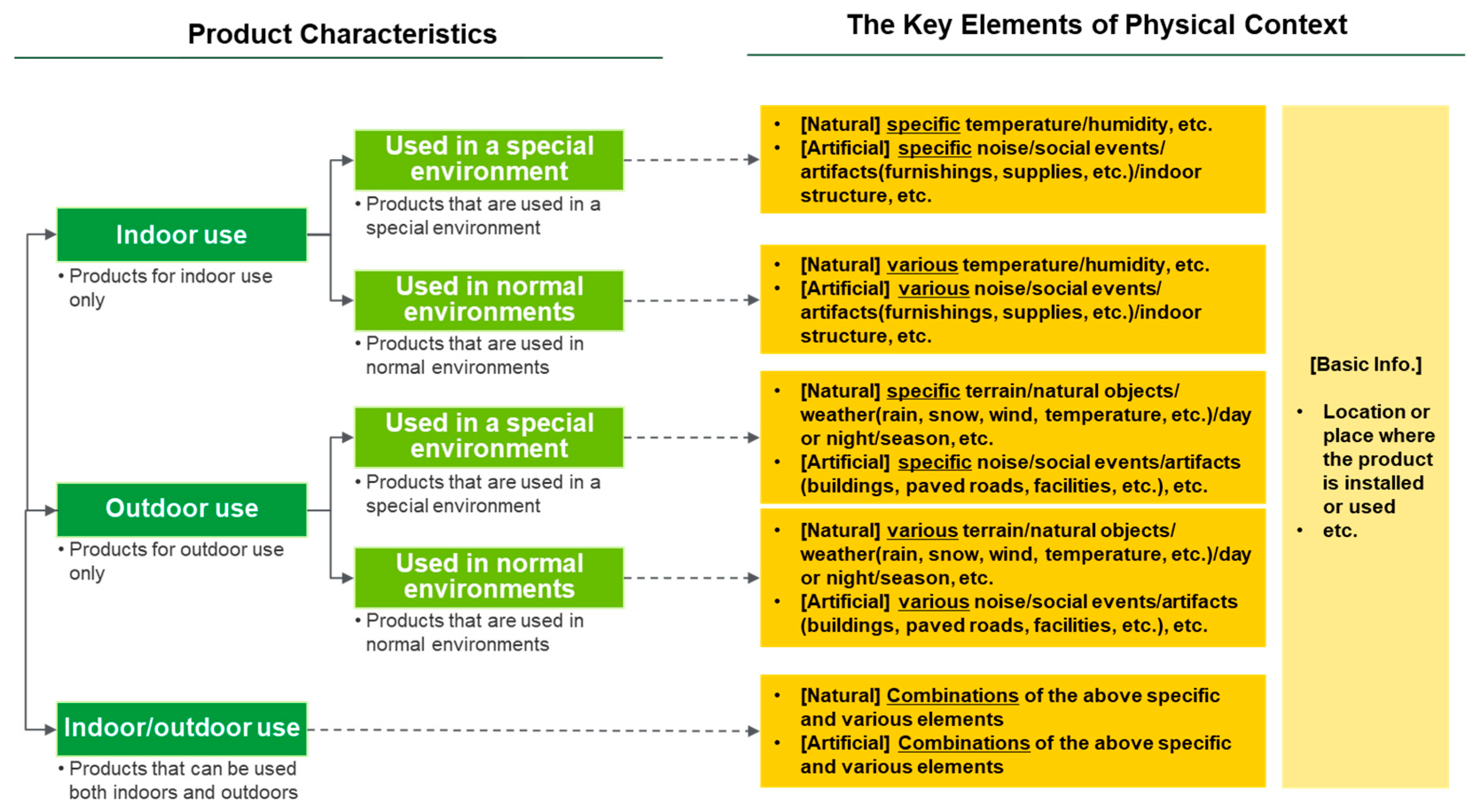

3.2.3. Physical Context

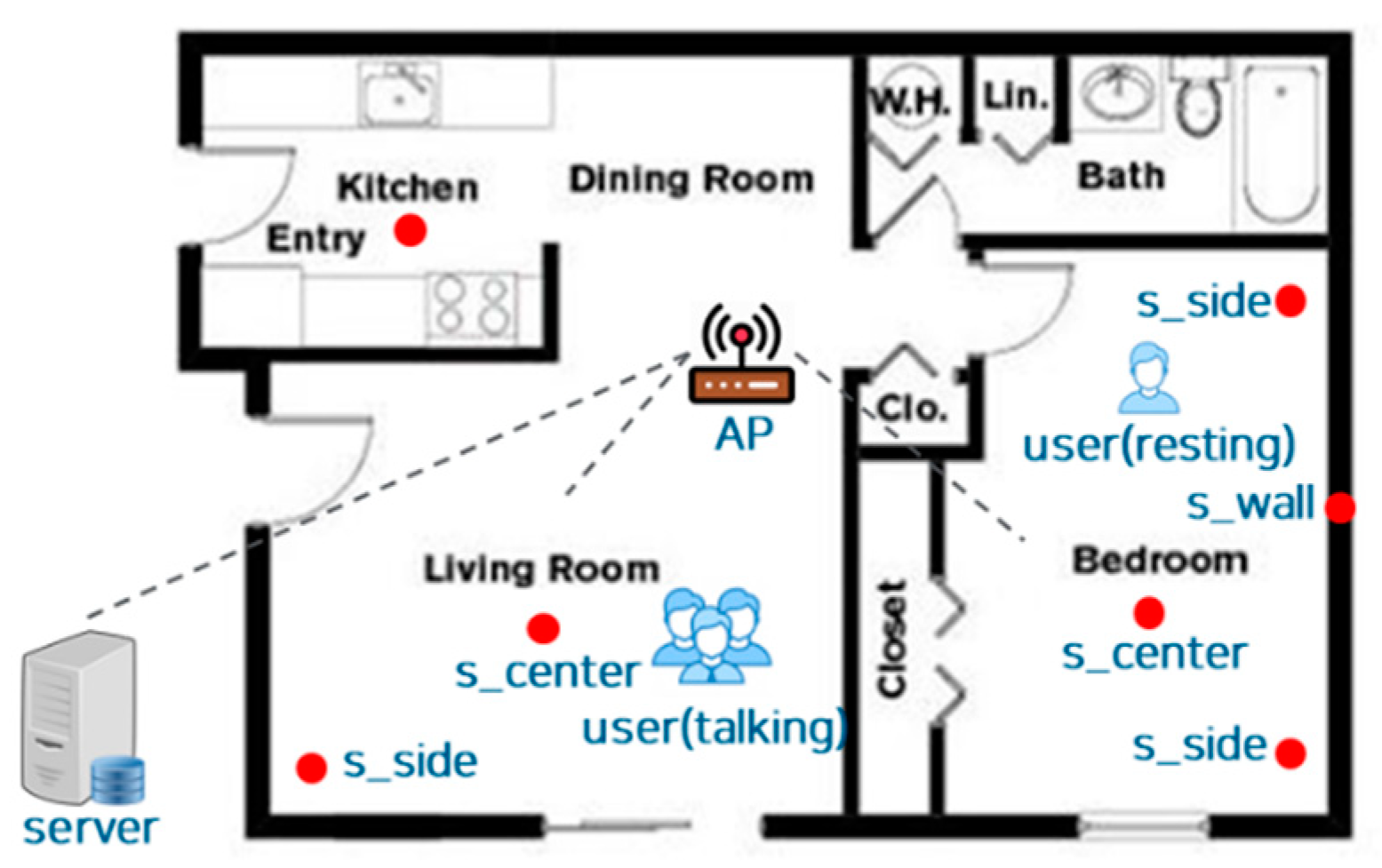

3.2.4. Living Lab Components

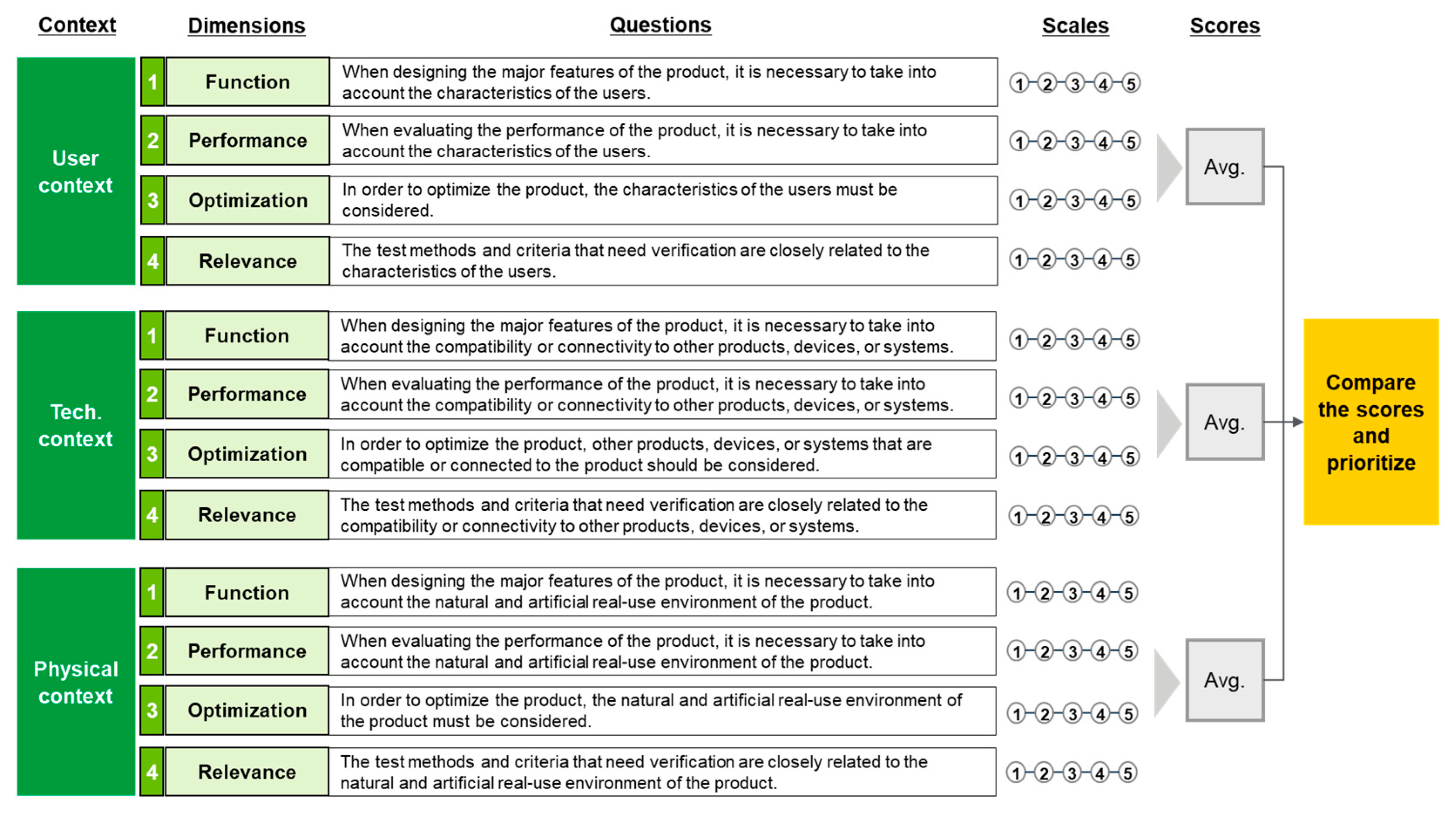

3.2.5. Prioritization

3.2.6. Implementation

4. Case Analysis: Validity Check for the Framework

5. Concluding Remarks

Funding

Acknowledgments

Conflicts of Interest

References

- Frank, A.G.; Mendes, G.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Geissbauer, R.; Vedso, J.; Schrauf, S. Industry 4.0: Building the Digital Enterprise. 2016 Global Industry 4.0 Survey; PWC: London, UK, 2016. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Nunes, M.L.; Pereira, A.C.; Alves, A.C. Smart products development approaches for Industry 4.0. Procedia Manuf. 2017, 13, 1215–1222. [Google Scholar] [CrossRef]

- Zulu-Chisanga, S.; Boso, N.; Adeola, O.; Oghazi, P. Investigating the Path from Firm Innovativeness to Financial Performance: The Role of New Product Success, Market Responsiveness, and Environment Turbulence. J. Small Bus. Strategy 2016, 26, 51–67. [Google Scholar]

- Hernandez-Vivanco, A.; Domingues, P.; Sampaio, P.; Bernardo, M.; Cruz-Cazares, C. Do Multiple Certifications Leverage Firm Performance? A Dynamic Approach. Int. Journal Prod. Econ. 2019, 218, 386–399. [Google Scholar] [CrossRef]

- Park, H.S.; Cho, C.H. Practice of KS Certification According to the Revision of Industry Standardization Act; Korean Standards Association Media: Seoul, Korea, 2019. [Google Scholar]

- The 3rd Public-Private Consultation for New Industries Held (MOTIE Press 2016). Available online: http://www.motie.go.kr/common/download.do?fid=bbs&bbs_cd_n=81&bbs_seq_n=158754&file_seq_n=1 (accessed on 21 June 2018).

- Ungerman, O.; Dědková, J. Marketing Innovations in Industry 4.0 and Their Impacts on Current Enterprises. Appl. Sci. 2019, 9, 3685. [Google Scholar] [CrossRef]

- Boiral, O.; Gendron, Y. Sustainable Development and Certification Practices: Lessons Learned and Prospects. Bus. Strat. Environ. 2010, 20, 331–347. [Google Scholar] [CrossRef]

- What is the Certification Systems? Korean Standards and Certification. Available online: https://standard.go.kr/KSCI/crtfcPotIntro/crtfcSystemIntro.do?menuId=540&topMenuId=536&upperMenuId=539 (accessed on 24 June 2018).

- Zhang, J.; Jiang, J.; Noorderhaven, N. Is certification an effective legitimacy strategy for foreign firms in emerging markets? Int. Bus. Rev. 2019, 28, 252–267. [Google Scholar] [CrossRef]

- Delimatsis, P. Into the Abyss of Standard-Setting: An Analysis of Procedural and Substantive Guarantees within the International Organization for Standardization (ISO); European University Institute: Badia Fiesolana, Italy, 2015. [Google Scholar]

- Stages of the Development of International Standards. International Organization for Standardization. Available online: https://web.archive.org/web/20071005165948/http://www.iso.org/iso/standards_development/processes_and_procedures/stages_description.htm (accessed on 18 April 2020).

- Introduction to Standards. International Renewable Energy Agency (IRENA). Available online: https://www.irena.org/inspire/Standards/Introduction (accessed on 21 April 2020).

- Industrial Convergence Promotion Act. National Law Information Center. Available online: http://www.law.go.kr/LSW/eng/engLsSc.do?menuId=2§ion=lawNm&query=INDUSTRIAL+CONVERGENCE+PROMOTION+ACT&x=17&y=12#liBgcolor0 (accessed on 20 January 2020).

- The Certification of Compliance with New Products of Industrial Convergence. Available online: http://www.knicc.re.kr/pages/suitability_certification_01.html (accessed on 24 June 2018).

- Announcement of 2017 2nd Industrial Convergence Promotion Projects. Available online: http://www.keit.re.kr/article.do?psStep=view&psPage=3&bbsCD=ann_bor&shSearch=&shKeyword=&shUserID=&gbn=03_12&shGonggoStatus=&shYY=2017&shMM=&shBizCate=&BIdx=113578 (accessed on 25 June 2018).

- Various Operating Performances of the Certification of Compliance with New Products of Industrial Convergence. SBSCNBC. Available online: https://cnbc.sbs.co.kr/article/10000907748 (accessed on 13 July 2018).

- Park, K.J.; Koh, J. Exploring the relationship between perceived pace of technology change and adoption resistance to convergence products. Comput. Hum. Behav. 2017, 69, 142–150. [Google Scholar] [CrossRef]

- Ruiz, A.; Juez, G.; Espinoza, H.; De La Vara, J.L.; Larrucea, X. Reuse of safety certification artefacts across standards and domains: A systematic approach. Reliab. Eng. Syst. Saf. 2017, 158, 153–171. [Google Scholar] [CrossRef]

- Hossain, M.; Leminen, S.; Westerlund, M. A Systermatic Review of Living Lab Literature. J. Clean. Prod. 2019, 213, 976–988. [Google Scholar] [CrossRef]

- Yoon, I. User-Driven Innovation Platform, Living Lab. Wkly. Tip 2017, 72, 1–10. [Google Scholar]

- Seong, J.; Song, W.; Kim, J.; Jung, S.; Han, K. A Study on the Construction of Living Lab for the Promotion of Technological Commercialization. Stepi Insight 2016, 198, 1–39. [Google Scholar]

- Leminen, S. Coordination and Participation in Living Lab Networks. Technol. Innov. Manag. Rev. 2013, 3, 5–14. [Google Scholar] [CrossRef]

- Citizen-led R&SD, Solving Life Problems. Sciencetimes. Available online: https://www.sciencetimes.co.kr/news/%ec%8b%9c%eb%af%bc%ec%a3%bc%eb%8f%84%ed%98%95-rsd-%ec%83%9d%ed%99%9c%eb%ac%b8%ec%a0%9c-%ed%95%b4%ea%b2%b0/ (accessed on 11 July 2018).

- Almirall, E.; Wareham, J. Living Labs: Arbiters of mid- and ground-level innovation. Technol. Anal. Strat. Manag. 2011, 23, 87–102. [Google Scholar] [CrossRef]

- Leminen, S. Living Labs as Open Innovation Networks: Networks, Roles, and Innovation Outcomes. Ph.D. Thesis, Alto University, Espoo, Finland, 2015. [Google Scholar]

- Leminen, S.; Nyström, A.-G.; Westerlund, M. A typology of creative consumers in living labs. J. Eng. Technol. Manag. 2015, 37, 6–20. [Google Scholar] [CrossRef]

- Seong, J.; Song, W.; Jung, B.; Choi, C.; Youn, C.; Jung, S.; Han, K. Current Status of Korean Living Labs and Its Development Plan. Policy Res. 2017, 9, 1–194. [Google Scholar]

- Opened “Smart Safety Living Lab” in Hwaseong City: Convergence New Product Demonstration. Asia Today. Available online: http://www.asiatoday.co.kr/view.php?key=20191224010014602 (accessed on 17 February 2020).

- Leminen, S.; Westerlund, M. A Framework for Understanding the Different Research Avenues of Living Labs. Int. J. Technol. Mark. 2016, 1, 399–420. [Google Scholar] [CrossRef]

- CoreLabs. Living Labs Roadmap 2007-2010: Recommendations on Networked Systems for Open User-Driven Research, Development and Innovation. Available online: http://ec.europa.eu/information_society/events/cf/ict2008/document.cfm (accessed on 12 July 2018).

- Bergvall-Kåreborn, B.; Eriksson, C.; Ståhlbröst, A.; Svensson, J. A Milieu for Innovation: Defining Living Labs. In Proceedings of the 2nd ISPIM Innovation Symposium: Simulating Recovery—The Role of Innovation Management, New York City, NY, USA, 6–9 December 2009. [Google Scholar]

- Dey, A.K.; Abowd, G. Towards a Better Understanding of Context and Context-Awareness. In Proceedings of the CHI 2000 Workshop on the What, Who, Where, and How of Context-Awareness, Hague, Netherlands, 3 April 2000. [Google Scholar]

- Kofod-Petersen, A.; Aamodt, A. Case-Based Situation Assessment in a Mobile Context-Aware System. In Proceedings of the AIMS2003, Workshop on Artificial Intelligence for Mobile Systems, Seattle, WA, USA, 12 October 2003. [Google Scholar]

- Suh, K.S.; Lee, Y.E. The Effects of Virtual Reality on Consumer Learning: An Empirical Investigation. Mis Q. 2005, 29, 673. [Google Scholar] [CrossRef]

- Li, Z.; Rau, P.-L.P.; Huang, D. Self-Disclosure to an IoT Conversational Agent: Effects of Space and User Context on Users’ Willingness to Self-Disclose Personal Information. Appl. Sci. 2019, 9, 1887. [Google Scholar] [CrossRef]

- Merrouni, Z.A.; Frikh, B.; Ouhbi, B. Toward Contextual Information Retrieval: A Review And Trends. Procedia Comput. Sci. 2019, 148, 191–200. [Google Scholar] [CrossRef]

- Jung, K.; Kim, J.; Jeon, K.; Hong, J.; Hong, J.; Bae, K.; Min, S. Design Guidelines of the Pelvic Airbag Cushion Systems for Absorbing Falling Impact Energy at Falling of the Elderly and Disables. Ergon. Soc. Korea 2013, 10, 216–219. [Google Scholar]

- Moreno, A.; Segura, Á.; Zlatanova, S.; Posada, J.; García-Alonso, A. Benefit of the integration of semantic 3D models in a fire-fighting VR simulator. Appl. Geomat. 2012, 4, 143–153. [Google Scholar] [CrossRef]

- Moreno, A.; Posada, J.; Segura, Á.; Arbelaiz, A.; Garcia-Alonso, A. Interactive fire spread simulations with extinguishment support for Virtual Reality training tools. Fire Saf. J. 2014, 64, 48–60. [Google Scholar] [CrossRef]

- Lee, S.; Choi, J.; Hwang, I.; Song, K. A Study on Eye Point and Field of View of Older Drivers. J. Ergon. Soc. Korea 2010, 29, 67–71. [Google Scholar] [CrossRef]

- Zhao, S.; Han, G.; Zhao, Q.; Wei, A.P. Zhao Prediction of Driver’s Attention Points Based on Attention Model. Appl. Sci. 2020, 10, 1083. [Google Scholar] [CrossRef]

- Petter, S.; Rai, A. Specifying Formative Constructs in Information Systems Research. Mis Q. 2007, 31, 623. [Google Scholar] [CrossRef]

- Curley, M.; Salmelin, B. Open Innovation 2.0: The Big Picture. In Open Innovation Yearbook 2014; European Commission: Brussels, Belgium, 2014. [Google Scholar]

| Steps | Contents | |

|---|---|---|

| Recognition of the need for verification | Step 1 | Selecting the product item and its test methods and certification criteria that need verification |

| - Analyzing the features of the product in terms of the quality and safety concerns | ||

| - Analyzing the appropriateness of specific test methods and criteria and the need for verification in the real-use environments | ||

| - Analyzing the feasibility of the verification using living labs | ||

| Development of verification methodology using living labs | Step 2 (the focus of this study) | Analyzing the real-use environment of the product |

| - Analyzing user context, technological context, and physical context of the product use | ||

| - Eliciting the key components of living labs in terms of the three real-use environments of the product | ||

| - Prioritizing the key components of living labs | ||

| Step 3 | Implementing living labs for verification purposes | |

| - Analyzing the implications elicited in step 2 and designing living labs accordingly | ||

| Verification and analysis | Step 4 | Conducting tests or experiments for verification |

| Step 5 | Analyzing the results and concluding the verification process | |

| - Analyzing the results of the tests or experiments to see whether the test methods and criteria are valid or need to be improved | ||

| - Discussing how to utilize the results to improve the current test methods and criteria, if necessary | ||

| Context | The Characteristics of NCPs | Air-ventilated welding helmet | Heating curtain | Floor noise level meter | Internet of Things (IoT)-based Manhole tops | Fiber-optic LED Pad | ||

|---|---|---|---|---|---|---|---|---|

|  |  |  |  | ||||

| User context | Direct use | Wearing | Worn | √ | ||||

| Attached | ||||||||

| Boarding | - | |||||||

| Carrying | - | |||||||

| Seldom moving | - | √ | ||||||

| Indirect use | - | - | √ | √ | √ | |||

| Tech. context | Finished products | Work independently | √ | √ | √ | |||

| Work dependently | Work together | |||||||

| Work as a system | √ | √ | ||||||

| Parts of other finished products | - | - | ||||||

| Physical context | Indoor use | Used in a special environment | - | √ | ||||

| Used in normal environments | - | √ | √ | |||||

| Outdoor use | Used in a special environment | - | ||||||

| Used in normal environments | - | √ | √ | |||||

| In/outdoor use | - | - | ||||||

| Context | Dimension | Questions | Scores | ||||

|---|---|---|---|---|---|---|---|

| NCP#1 | NCP#2 | NCP#3 | NCP#4 | NCP#5 | |||

| User context | Function | When designing the major features of the product, it is necessary to take into account the characteristics of the users. | 5 | 2 | 1 | 5 | 5 |

| Performance | When evaluating the performance of the product, it is necessary to take into account the characteristics of the users. | 4 | 3 | 3 | 2 | 4 | |

| Optimization | In order to optimize the product, the characteristics of the users must be considered. | 4 | 3 | 2 | 2 | 3 | |

| Relevance | The test methods and criteria that need verification are closely related to the characteristics of the users. | 5 | 4 | 3 | 3 | 5 | |

| Tech. context | Function | When designing the major features of the product, it is necessary to take into account the compatibility or connectivity to other products, devices, or systems. | 1 | 1 | 5 | 5 | 1 |

| Performance | When evaluating the performance of the product, it is necessary to take into account the compatibility or connectivity to other products, devices, or systems. | 1 | 1 | 5 | 5 | 1 | |

| Optimization | In order to optimize the product, other products, devices, or systems that are compatible or connected to the product should be considered. | 1 | 1 | 5 | 4 | 1 | |

| Relevance | The test methods and criteria that need verification are closely related to the compatibility or connectivity to other products, devices, or systems. | 1 | 1 | 4 | 2 | 1 | |

| Physical context | Function | When designing the major features of the product, it is necessary to take into account the natural and artificial real-use environment of the product. | 5 | 3 | 3 | 5 | 4 |

| Performance | When evaluating the performance of the product, it is necessary to take into account the natural and artificial real-use environment of the product. | 5 | 3 | 2 | 4 | 3 | |

| Optimization | In order to optimize the product, the natural and artificial real-use environment of the product must be considered. | 4 | 2 | 2 | 3 | 3 | |

| Relevance | The test methods and criteria that need verification are closely related to the natural and artificial real-use environment of the product. | 4 | 3 | 4 | 3 | 4 | |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.J. Verifying the Test Methods and Certification Criteria for New Technological Convergence Products: Using Living Labs as a Methodology. Appl. Sci. 2020, 10, 3269. https://doi.org/10.3390/app10093269

Kim HJ. Verifying the Test Methods and Certification Criteria for New Technological Convergence Products: Using Living Labs as a Methodology. Applied Sciences. 2020; 10(9):3269. https://doi.org/10.3390/app10093269

Chicago/Turabian StyleKim, Hyung Jin. 2020. "Verifying the Test Methods and Certification Criteria for New Technological Convergence Products: Using Living Labs as a Methodology" Applied Sciences 10, no. 9: 3269. https://doi.org/10.3390/app10093269

APA StyleKim, H. J. (2020). Verifying the Test Methods and Certification Criteria for New Technological Convergence Products: Using Living Labs as a Methodology. Applied Sciences, 10(9), 3269. https://doi.org/10.3390/app10093269