Improvement of Laser Beam Fusion Cutting of Mild and Stainless Steel Due to Longitudinal, Linear Beam Oscillation

Abstract

1. Introduction

2. Materials and Methods

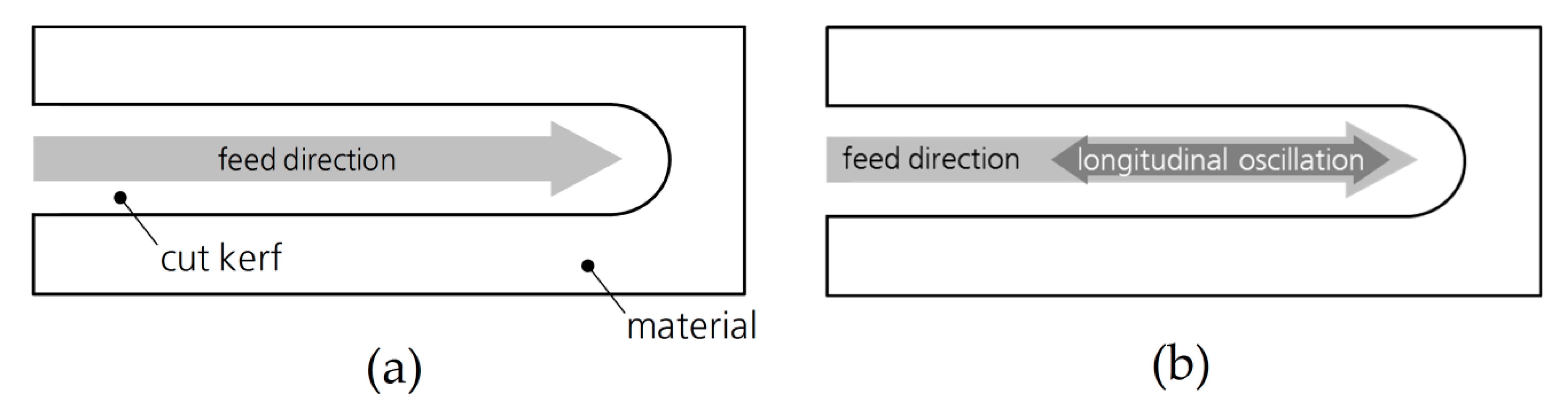

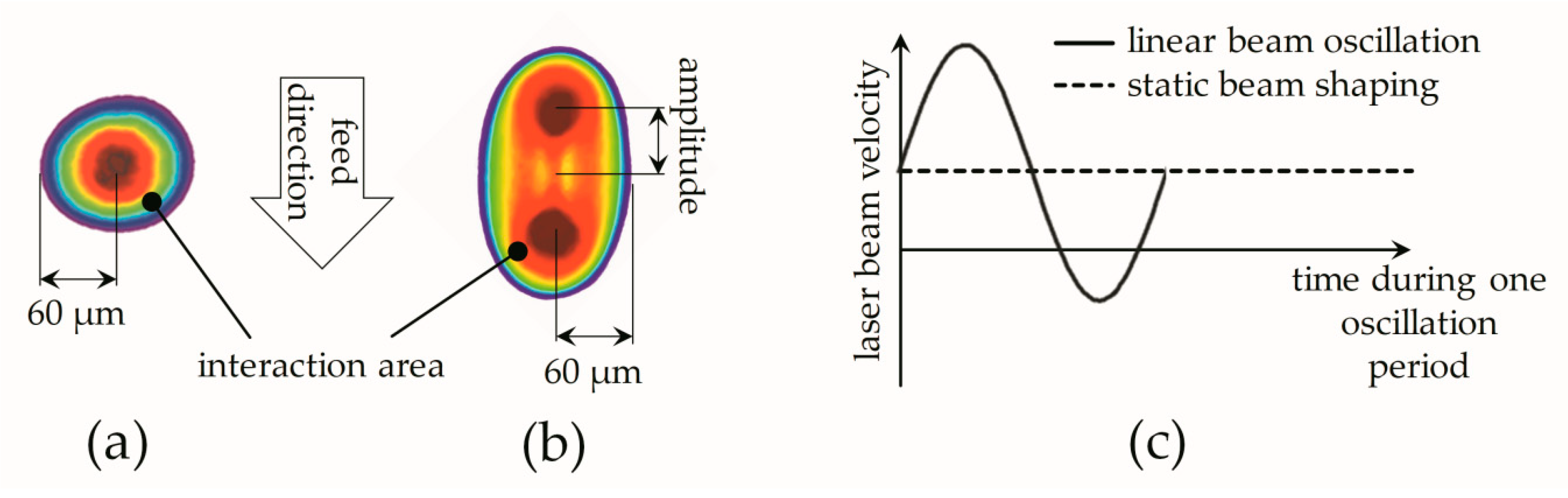

2.1. Experimental Setup

2.2. Determination of the Cutting Parameters

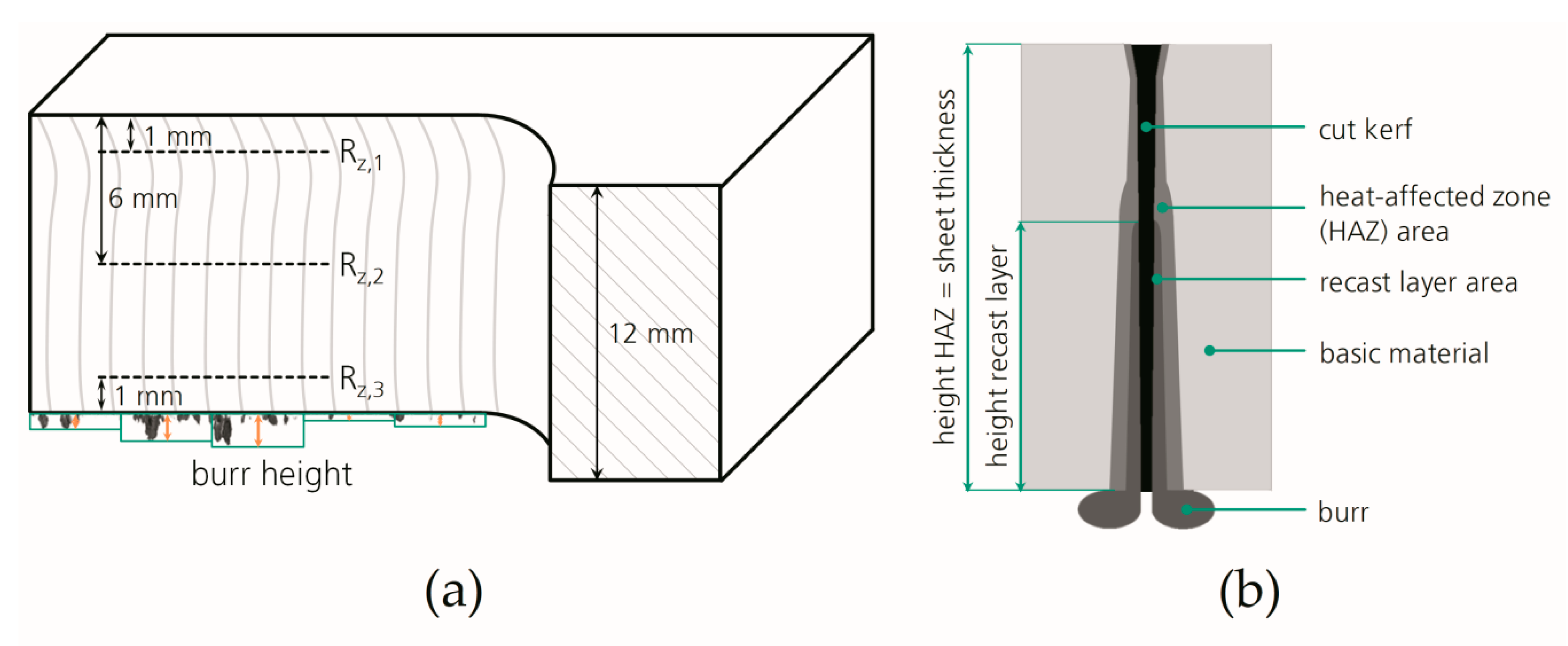

2.3. Characterization of the Cutting Result

3. Results and Discussion

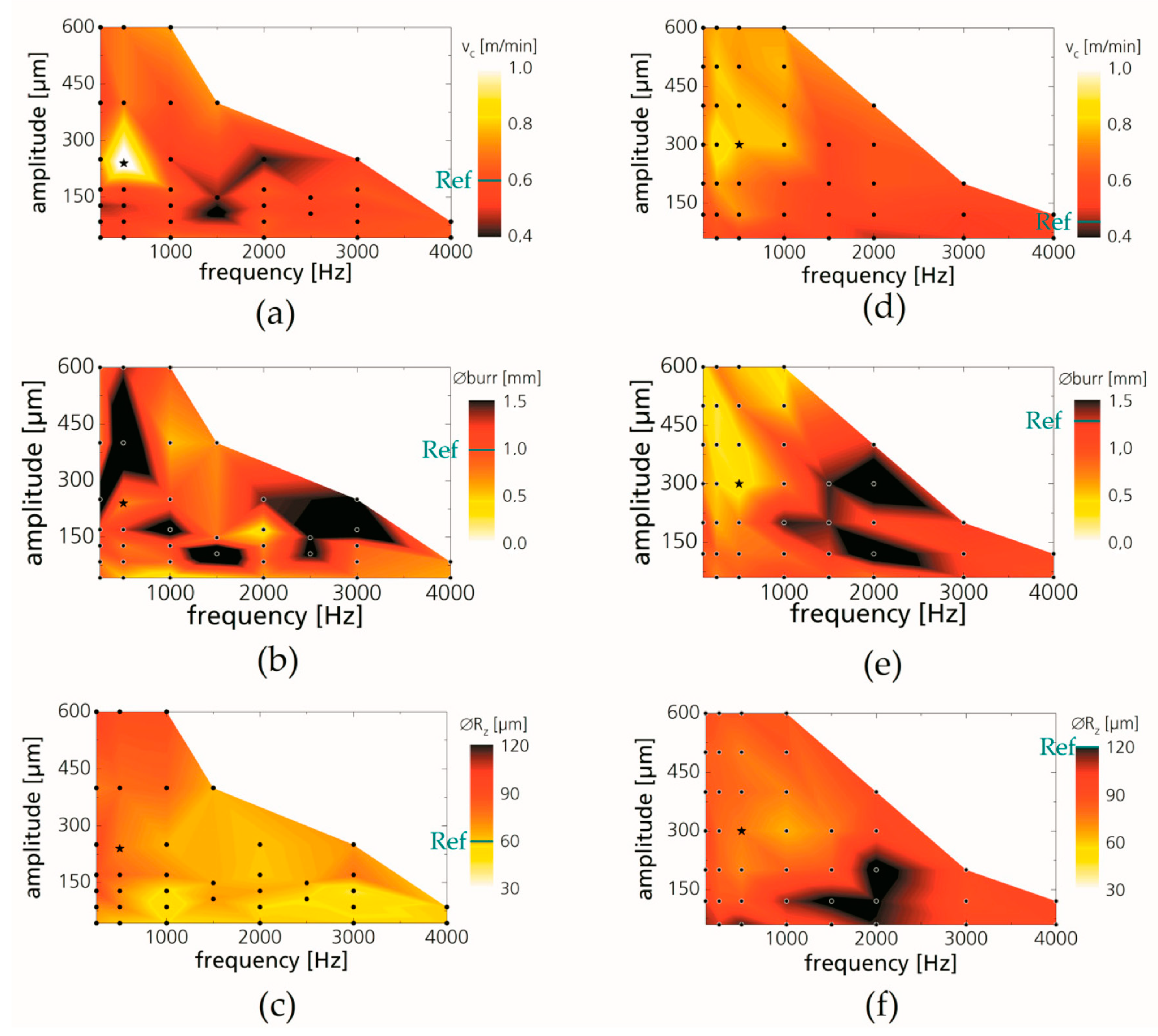

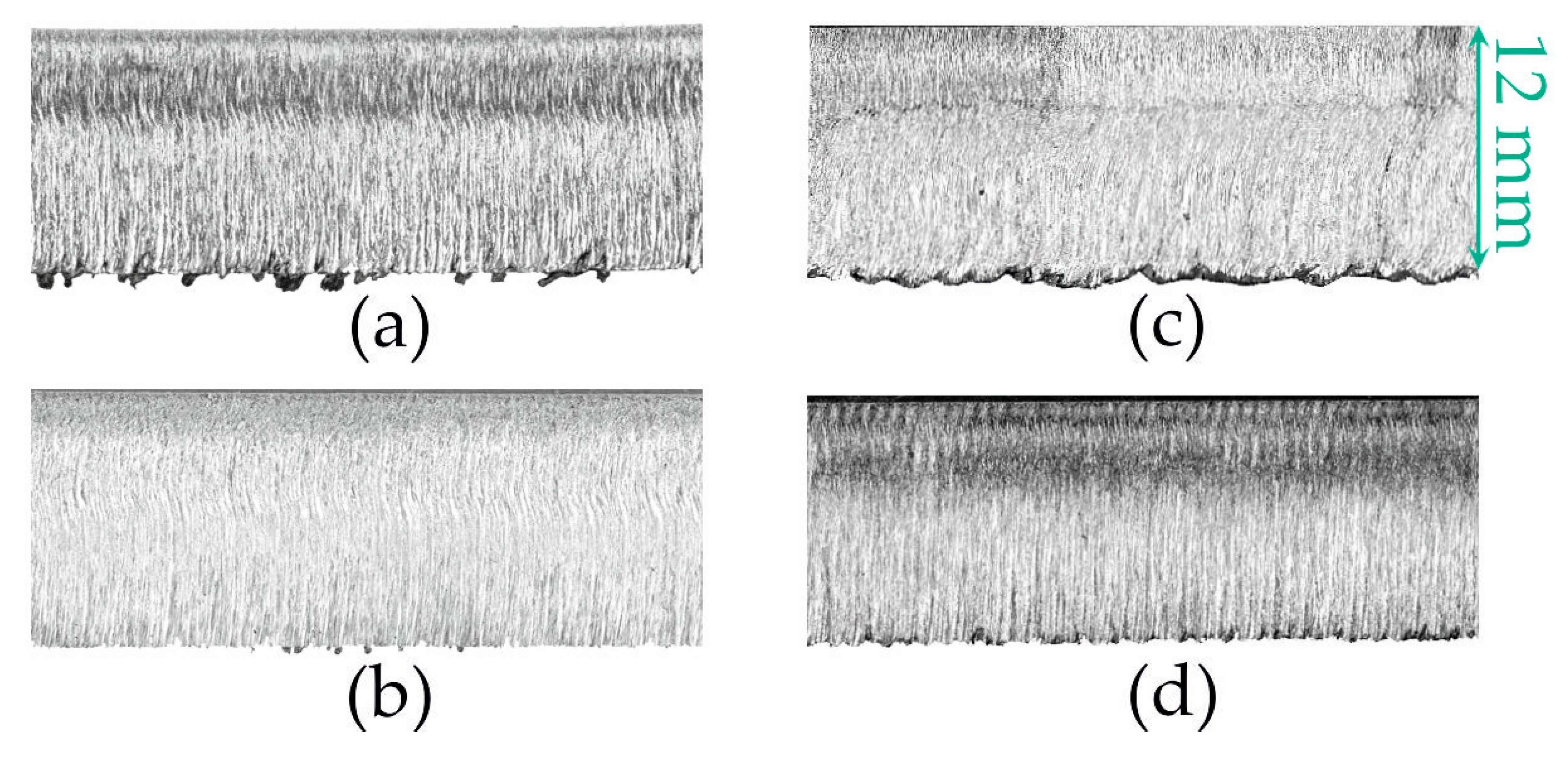

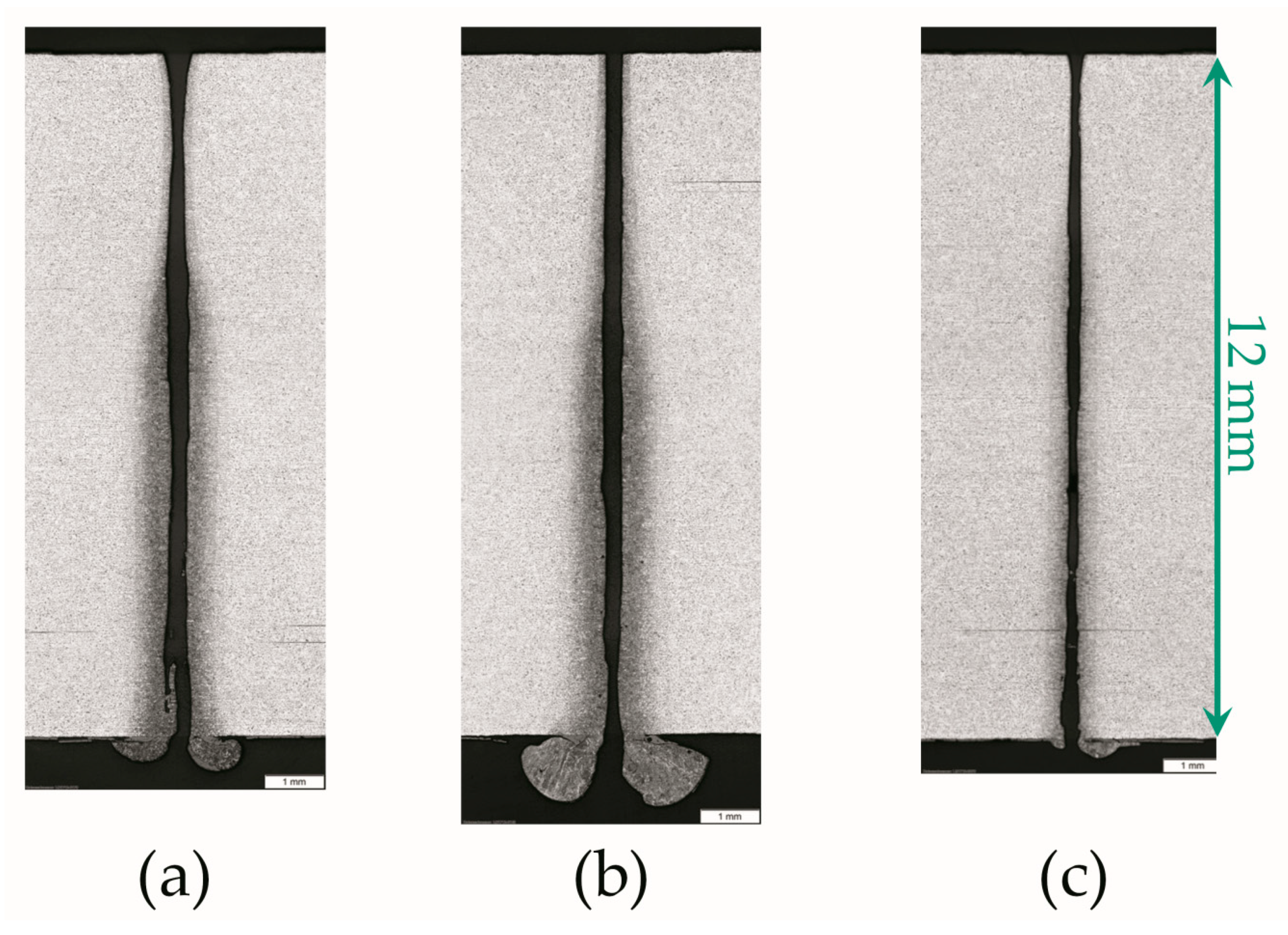

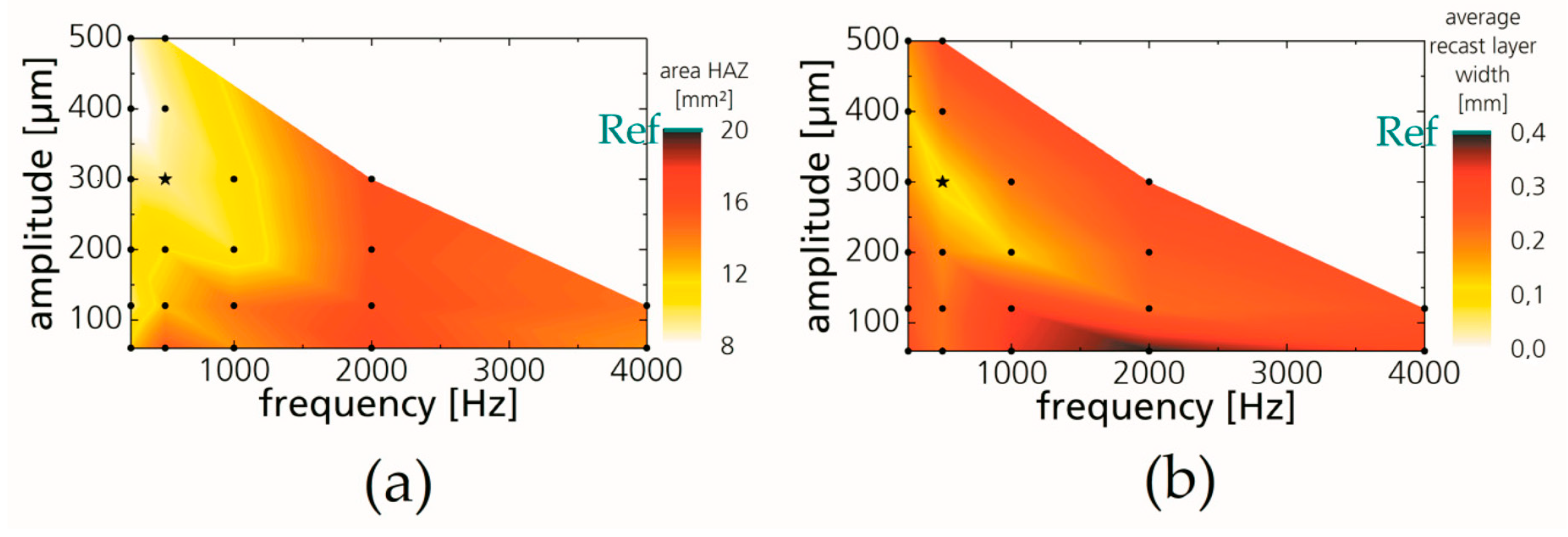

3.1. Improvement of the LBFC Due to Longitudinal, Linear Beam Oscillation

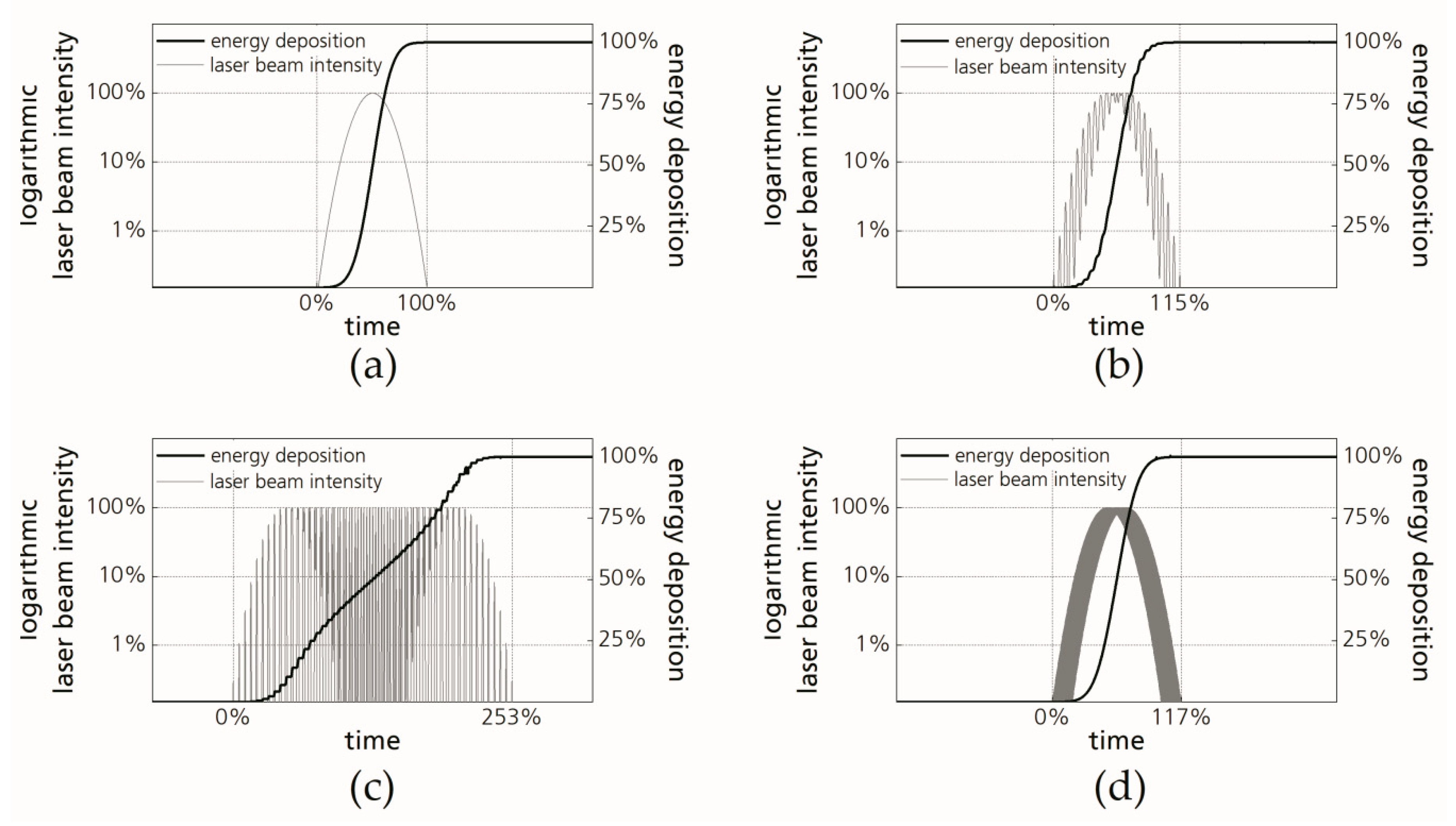

3.2. Metallographic Analysis of Mild Steel to Reveal the Thermal Energy Deposition

3.3. Explanatory Approach of the Process Improvements Due to Beam Oscillation Based on an Energetic Consideration

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Olsen, F.O. Fundamental mechanisms of cutting front formation in laser cutting. Proc. SPIE 1994, 2207, 402–413. [Google Scholar] [CrossRef]

- Mahrle, A.; Bartels, F.; Beyer, R.E. Theoretical aspects of the process efficiency in laser beam cutting with fiber lasers. LIA Publ. 2008, 611, 703–712. [Google Scholar] [CrossRef]

- Wandera, C.; Kujanpää, V. Characterization of the melt removal rate in laser cutting of thick-section stainless steel. J. Laser Appl. 2010, 22, 62–70. [Google Scholar] [CrossRef]

- Hügel, H.; Graf, T. Laser in der Fertigung: Grundlagen der Strahlquellen, Systeme, Fertigungsverfahren, 3rd ed.; Springer Vieweg: Wiesbaden, Germany, 2014; pp. 218–259. [Google Scholar]

- Powell, J.; Petring, D.; Pocorni, J.; Kaplan, A.F.H. LIA Guide to High Power Laser Cutting; LIA: Orlando, FL, USA, 2017; pp. 1–75. [Google Scholar]

- Hilton, P.A. Cutting stainless steel with disc and CO2 lasers. In Proceedings of the 5th International Congress on Laser Advanced Materials Processing, LAMP, Kobe, Japan, 29 June–2 July 2009; pp. 1–6. [Google Scholar]

- Wandera, C.; Salminen, A.; Kujanpää, V. Inert gas cutting of thick-section stainless steel and medium-section aluminum using a high power fiber laser. J. Laser Appl. 2009, 21, 154–161. [Google Scholar] [CrossRef]

- Wandera, C.; Kujanpää, V. Optimization of parameters for fibre laser cutting of a 10 mm stainless steel plate. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 641–649. [Google Scholar] [CrossRef]

- Orishich, A.M.; Malikov, A.G.; Shulyatyev, V.B.; Golyshev, A.A. Experimental comparison of laser cutting of steel with fiber and CO2 lasers on the basis of minimal roughness. Phys. Procedia 2014, 56, 875–884. [Google Scholar] [CrossRef]

- Amara, E.H.; Kheloufi, K.; Tamsaout, T.; Fabbro, R.; Hirano, K. Numerical investigations on high-power laser cutting of metals. Appl. Phys. A 2015, 119, 1245–1260. [Google Scholar] [CrossRef]

- Kheloufi, K.; Amara, E.H.; Benzaoui, A. Numerical simulation of transient three-dimensional temperature and kerf formation in laser fusion cutting. J. Heat Transf. 2015, 137, 112101. [Google Scholar] [CrossRef]

- Petring, D.; Arntz, D.; Stoyanov, S.; Schneider, F. Effects of beam power and power density distribution on process and quality issues during fiber laser cutting of stainless steel sheet metal. In Proceedings of the 10th Proceeding LiM, Munich, Germany, 24–27 June 2019; WLT: Munich, Germany, 2019; Volume 215, pp. 1–10. [Google Scholar]

- Sparkes, M.; Gross, M.; Celotto, S.; Zhang, T.; O’Neill, W. Practical and theoretical investigations into inert gas cutting of 304 stainless steel using a high brightness fiber laser. J. Laser Appl. 2008, 20, 59–67. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Zaitsev, A.V. Modeling of the free-surface shape in laser cutting of metals. 2. model of multiple reflection and absorption of radiation. J. Appl. Mech. Tech. Phys. 2005, 46, 9–13. [Google Scholar] [CrossRef]

- Scintilla, L.D.; Tricarico, L.; Wetzig, A.; Beyer, R.E. Investigation on disk and CO2 laser beam fusion cutting differences based on power balance equation. IJMTM 2013, 69, 30–37. [Google Scholar] [CrossRef]

- Tani, G.; Tomesani, L.; Campana, G.; Fortunato, A. Quality factors assessed by analytical modelling in laser cutting. Thin Solid Films 2004, 453, 486–491. [Google Scholar] [CrossRef]

- Zhang, C.; Wen, P.; Yao, Z.; Yuan, Y.; Fan, X. Visualization of flow separation inside cut kerf during laser cutting of thick sections. J. Laser Appl. 2016, 28, 022204. [Google Scholar] [CrossRef]

- Schulz, W.; Kostrykin, V.; Niessen, M.; Michel, J.; Petring, D.; Kreutz, E.W.; Poprawe, R. Dynamics of ripple formation and melt flow in laser beam cutting. J. Phys. D Appl. Phys. 1999, 32, 1219–1228. [Google Scholar] [CrossRef]

- Hirano, K.; Fabbro, R. Possible explanations for different surface quality in laser cutting with 1 and 10 µm beams. J. Laser Appl. 2012, 24, 012006. [Google Scholar] [CrossRef]

- Halm, U.; Niessen, M.; Arntz, D.; Gillner, A.; Schulz, W. Simulation of the temperature profile on the cutting edge in laser fusion cutting. In Proceedings of the 10th Proceeding LiM, Munich, Germany, 24–27 June 2019; WLT: Munich, Germany, 2019; Volume 244, pp. 1–6. [Google Scholar]

- Laskin, A.; Williams, G.; Demidovich, A. Applying refractive beam shapers in creating spots of uniform intensity and various shapes. Proc. SPIE 2010, 7579, 75790N. [Google Scholar] [CrossRef]

- Doan, H.D.; Noaki, I.; Kazuyoshi, F. Laser processing by using fluidic laser beam shaper. Int. J. Heat Mass Transf. 2013, 64, 263–268. [Google Scholar] [CrossRef]

- Fuse, K. Beam shaping for advanced laser materials processing. Laser Tech. J. 2015, 12, 19–22. [Google Scholar] [CrossRef]

- Goppold, C.; Zenger, K.; Herwig, P.; Wetzig, A.; Mahrle, A.; Beyer, E.R. Experimental analysis for improvements of process efficiency and cut edge quality of fusion cutting with 1 µm laser radiation. Phys. Procedia 2014, 56, 892–900. [Google Scholar] [CrossRef]

- Hilton, P.A.; Lloyd, D.; Tyrer, J.R. Use of a diffractive optic for high power laser cutting. J. Laser Appl. 2016, 28, 012014. [Google Scholar] [CrossRef]

- Kaakkunen, J.J.J.; Laakso, P.; Kujanpää, V. Adaptive multibeam laser cutting of thin steel sheets with fiber laser using spatial light modulator. J. Laser Appl. 2014, 26, 032008. [Google Scholar] [CrossRef]

- Powell, J.; Tan, W.K.; Maclennan, P.; Rudd, D.; Wykes, C.; Engstrom, H. Laser cutting stainless steel with dual focus lenses. J. Laser Appl. 2000, 12, 224–231. [Google Scholar] [CrossRef]

- Haas, G.J. Adaptive optics. Ind. Laser Solut. 2002, 17, 1–5. [Google Scholar]

- Laskin, A.; Volp, J.; Laskin, V.; Ostrun, A. Refractive multi-focus optics for material processing. In Proceedings of the 35th Proceeding ICALEO, San Diego, CA, USA, 16–20 October 2016; LIA: Orlando, FL, USA, 2016; Volume 1402, pp. 1–6. [Google Scholar] [CrossRef]

- Goppold, C.; Pinder, T.; Herwig, P.; Mahrle, A.; Wetzig, A.; Beyer, E.R. Beam oscillation—Periodic modification of the geometrical beam properties. In Proceedings of the 8th Proceeding LiM, Munich, Germany, 22–25 June 2015; WLT: Munich, Germany, 2015; Volume 112, pp. 1–8. [Google Scholar]

- Goppold, C.; Pinder, T.; Herwig, P. Transient beam oscillation with a highly dynamic scanner for laser beam fusion cutting. Adv. Opt. Technol. 2016, 5, 61–70. [Google Scholar] [CrossRef]

- Mahrle, A.; Beyer, R.E. Theoretical aspects of fibre laser cutting. J. Phys. D Appl. Phys. 2009, 42, 175507. [Google Scholar] [CrossRef]

- Von Dobeneck, D.; Löwer, T.; Adam, V. Elektronenstrahlschweißen. Das Verfahren und Seine Industrielle Anwendung für Höchste Produktivität; Verlag Moderne Industrie: Landsberg/Lech, Germany, 2001; pp. 1–70. [Google Scholar]

- Matthes, K.J.; Richter, E. Schweißtechnik. Schweißen von Metallischen Konstruktionswerkstoffen, 4th ed; Carl Hanser: Munich, Germany, 2008; pp. 366–382. [Google Scholar]

- Mahrle, A.; Beyer, R.E. Modeling and simulation of the energy deposition in laser beam welding with oscillatory beam deflection. In Proceedings of the 26th Proceeding ICALEO, Orlando, FL, USA, 29 October–1 November 2007; Lu, Y., Ed.; LIA: Orlando, FL, USA, 2007; Volume 1805, pp. 1–10. [Google Scholar] [CrossRef]

- Schweier, M.; Heins, J.F.; Haubold, M.W.; Zaeh, M.F. Spatter formation in laser welding with beam oscillation. Phys. Procedia 2013, 41, 20–30. [Google Scholar] [CrossRef]

- Müller, A.; Goecke, S.-F.; Sievi, P.; Albert, F.; Rethmeier, M. Laser beam oscillation strategies for fillet welds in lap joints. Phys. Procedia 2014, 56, 458–466. [Google Scholar] [CrossRef]

- Keßler, B.; Dittrich, D.; Brenner, B.; Standfuß, J.; Beyer, R.E. Laserstrahl-Mehrlagen-Engstspalt-Schweißen von Alloy 617occ—Fertigen von Schlüsselkomponenten zukünftiger energieeffizienter und ressourcensparender Hochtemperatur-Prozesse. DVS Berichte 2016, 327, 333–339. [Google Scholar]

- Arai, T.; Riches, S. Thick plate cutting with spinning laser beam. Proc. ICALEO 1997, 83, 19–26. [Google Scholar] [CrossRef]

- Morimoto, Y.; He, D.; Hijikata, W.; Shinshi, T.; Nakai, T.; Nakamura, N. Effect of high-frequency orbital and vertical oscillations of the laser focus position on the quality of the cut surface in a thick plate by laser beam machining. Precis. Eng. 2015, 40, 112–123. [Google Scholar] [CrossRef]

- Harris, J.; Brandt, M. Cutting 50 mm thick mild steel plate with a Nd:YAG laser. In Proceedings of the 22th Proceeding ICALEO, Jacksonville, FL, USA, 13–16 October 2003; LIA: Orlando, FL, USA, 2003; Volume 1102, pp. 1–13. [Google Scholar] [CrossRef]

- Aggoune, S.; Amara, E.H.; Debiane, M. Effects of the velocity and the nature of the inert gas on the stainless steel laser cut quality. FDMP 2013, 9, 61–75. [Google Scholar] [CrossRef]

- Adrian, H.A.L.; Ascari, A.; Fortunato, A.; Romoli, L. Long-pulse quasi-CW laser cutting of metals. Int. J. Adv. Manuf. Technol. 2017, 94, 155–162. [Google Scholar] [CrossRef]

- Scintilla, L.D.; Sorgente, D.; Tricarico, L. Experimental investigation on fiber laser cutting of Ti6Al4V thin sheet. Adv. Mater. Res. 2011, 264, 1281–1286. [Google Scholar] [CrossRef]

- Miraoui, I.; Boujelbene, M.; Zaied, M. High-power laser cutting of steel plates: Heat affected zone analysis. Adv. Mater. Sci. Eng. 2016, 2016, 1–8. [Google Scholar] [CrossRef]

- Jarosz, K.; Löschner, P.; Nieslony, P. Effect of cutting speed on surface quality and heat-affected zone in laser cutting of 316L stainless steel. Procedia Eng. 2016, 149, 155–162. [Google Scholar] [CrossRef]

| Characteristic | Data |

|---|---|

| laser power | 3 kW |

| wavelength | 1070 nm |

| focus radius | 60 µm |

| Rayleigh length | 1.1 mm |

| oscillation amplitude | 0–600 µm |

| oscillation frequency | 0–4 kHz |

| oscillation type | longitudinal, linear |

| assist gas | nitrogen |

| gas pressure | 1.8 MPa |

| nozzle diameter | 3 mm |

| stand-off distance | 0.7 mm |

| material | mild steel 1.0038 stainless steel 1.4301 |

| plate thickness | 12 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goppold, C.; Pinder, T.; Schulze, S.; Herwig, P.; Lasagni, A.F. Improvement of Laser Beam Fusion Cutting of Mild and Stainless Steel Due to Longitudinal, Linear Beam Oscillation. Appl. Sci. 2020, 10, 3052. https://doi.org/10.3390/app10093052

Goppold C, Pinder T, Schulze S, Herwig P, Lasagni AF. Improvement of Laser Beam Fusion Cutting of Mild and Stainless Steel Due to Longitudinal, Linear Beam Oscillation. Applied Sciences. 2020; 10(9):3052. https://doi.org/10.3390/app10093052

Chicago/Turabian StyleGoppold, Cindy, Thomas Pinder, Susanne Schulze, Patrick Herwig, and Andrés Fabián Lasagni. 2020. "Improvement of Laser Beam Fusion Cutting of Mild and Stainless Steel Due to Longitudinal, Linear Beam Oscillation" Applied Sciences 10, no. 9: 3052. https://doi.org/10.3390/app10093052

APA StyleGoppold, C., Pinder, T., Schulze, S., Herwig, P., & Lasagni, A. F. (2020). Improvement of Laser Beam Fusion Cutting of Mild and Stainless Steel Due to Longitudinal, Linear Beam Oscillation. Applied Sciences, 10(9), 3052. https://doi.org/10.3390/app10093052