Review on Development of High-Static–Low-Dynamic-Stiffness Seat Cushion Mattress for Vibration Control of Seating Suspension System

Abstract

1. Introduction

2. Passive Vibration Isolation Designs

3. Identified Research Gaps, Issues, and New Directions

3.1. Research Gaps and New Directions

3.2. Research Questions

3.3. Aim of the Research

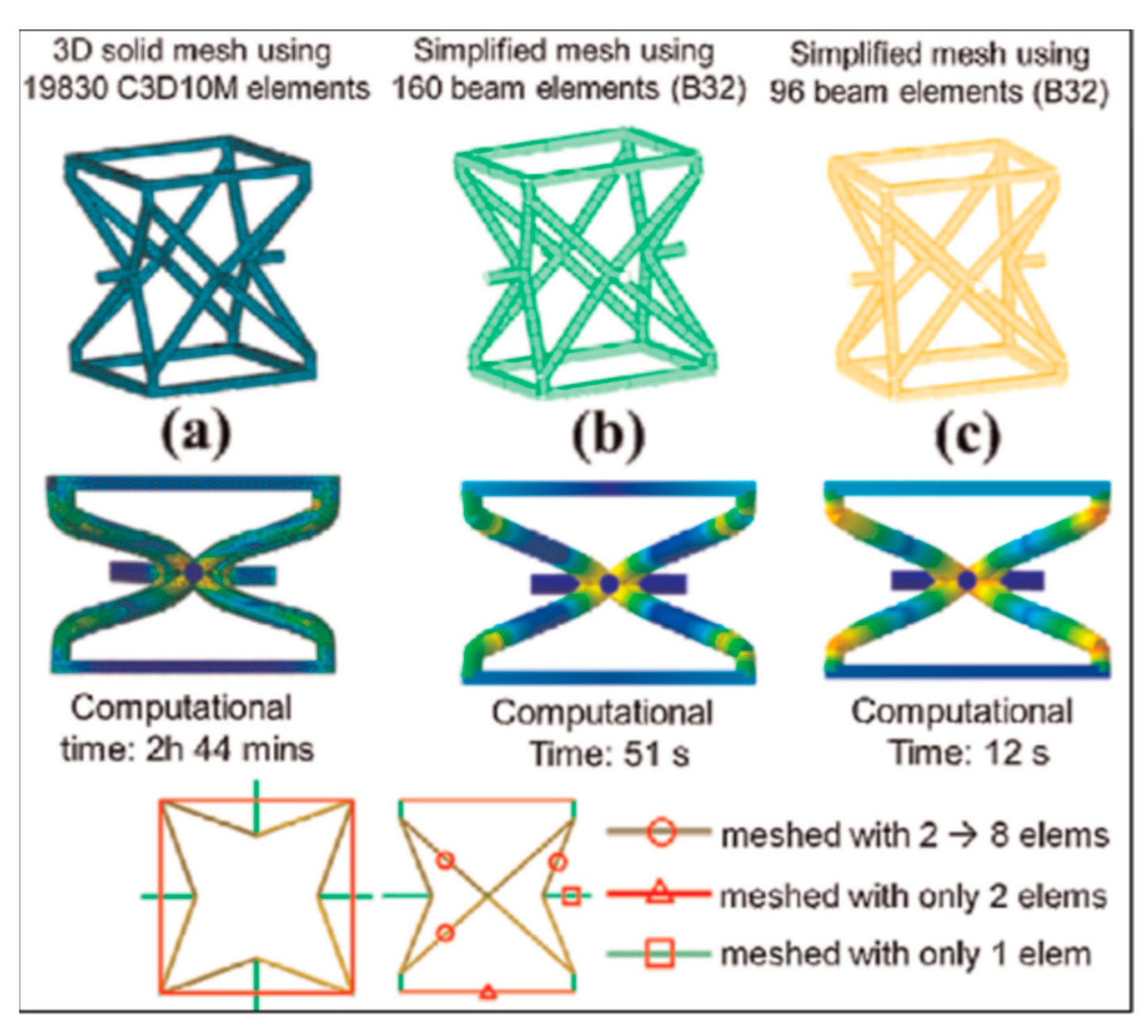

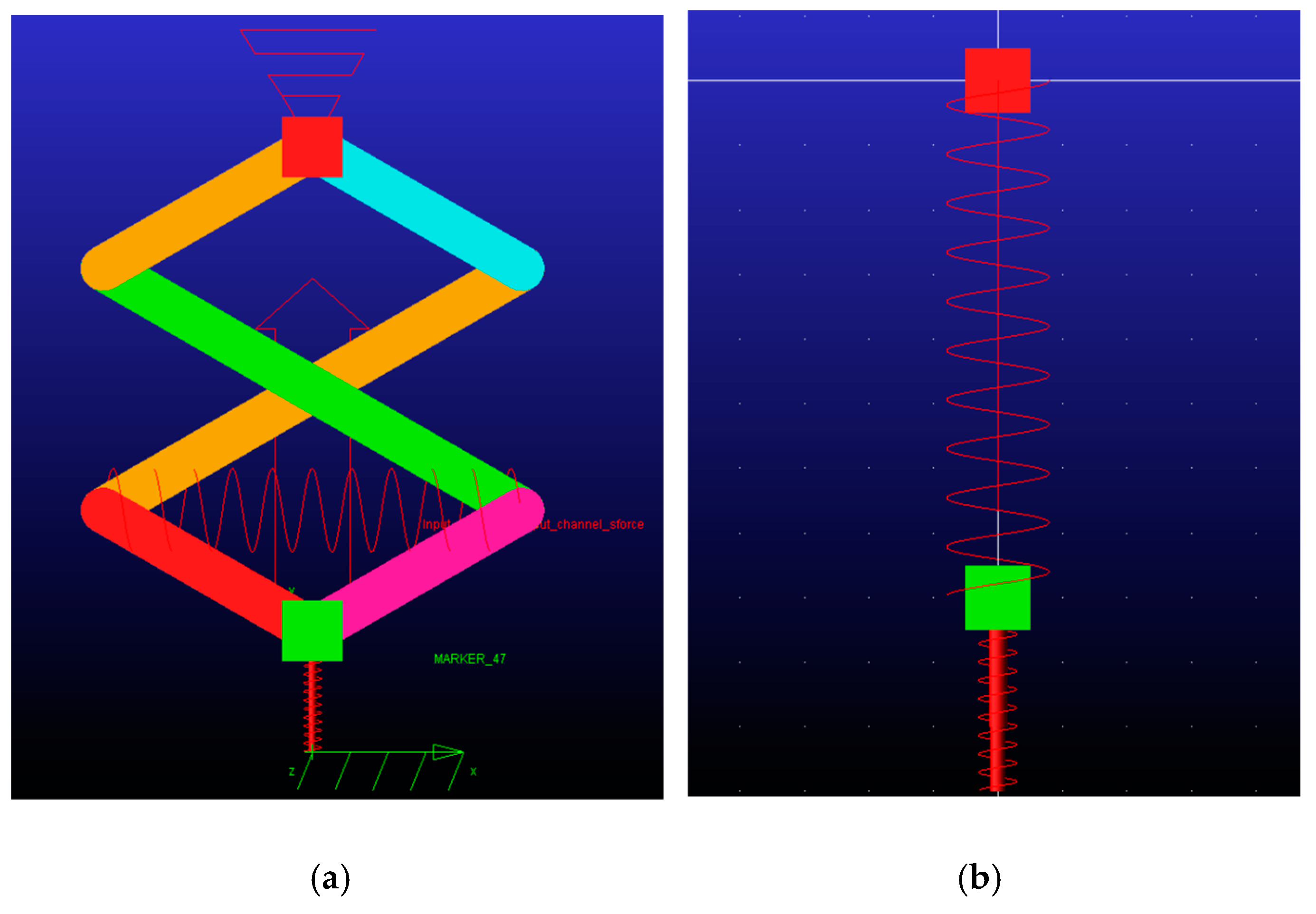

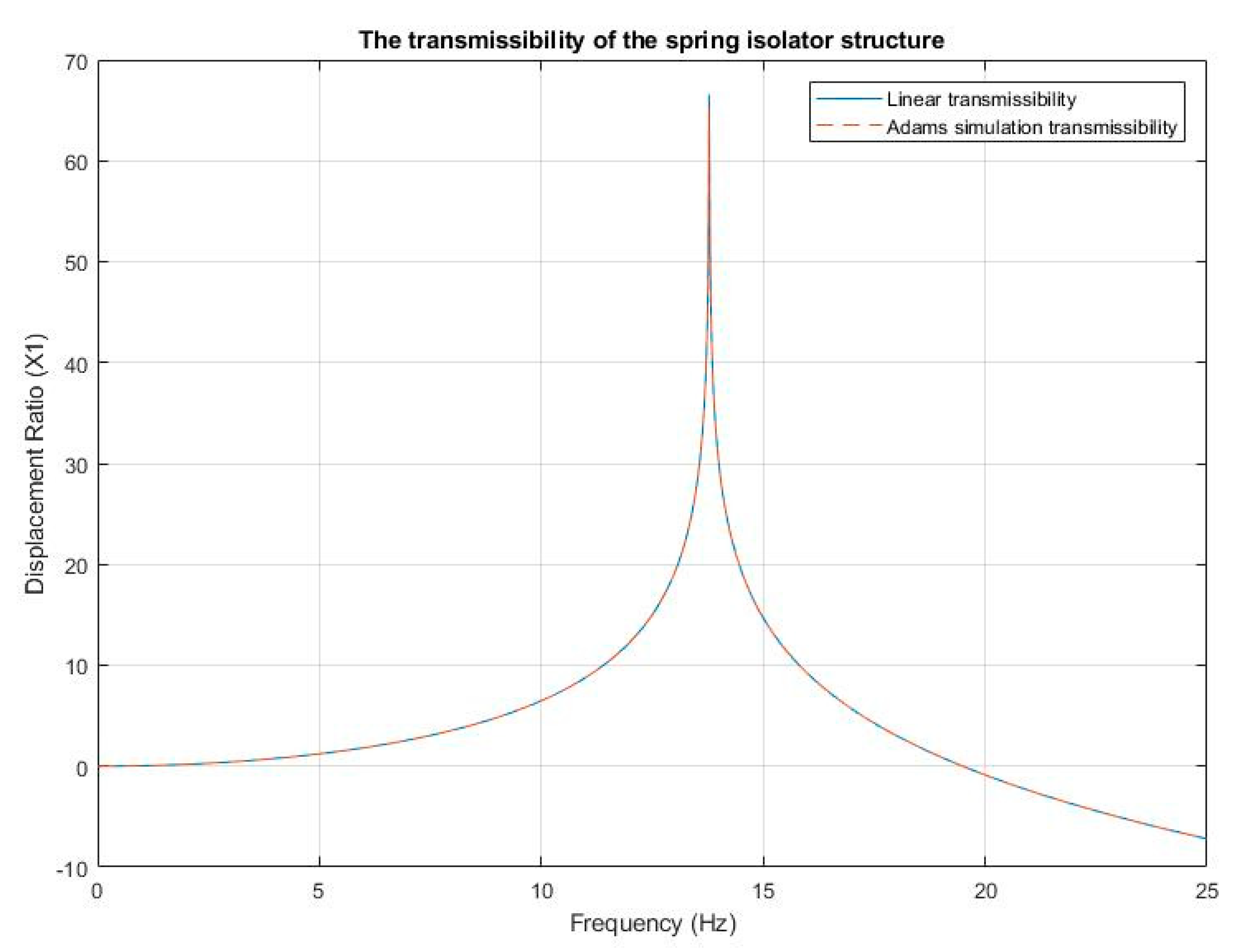

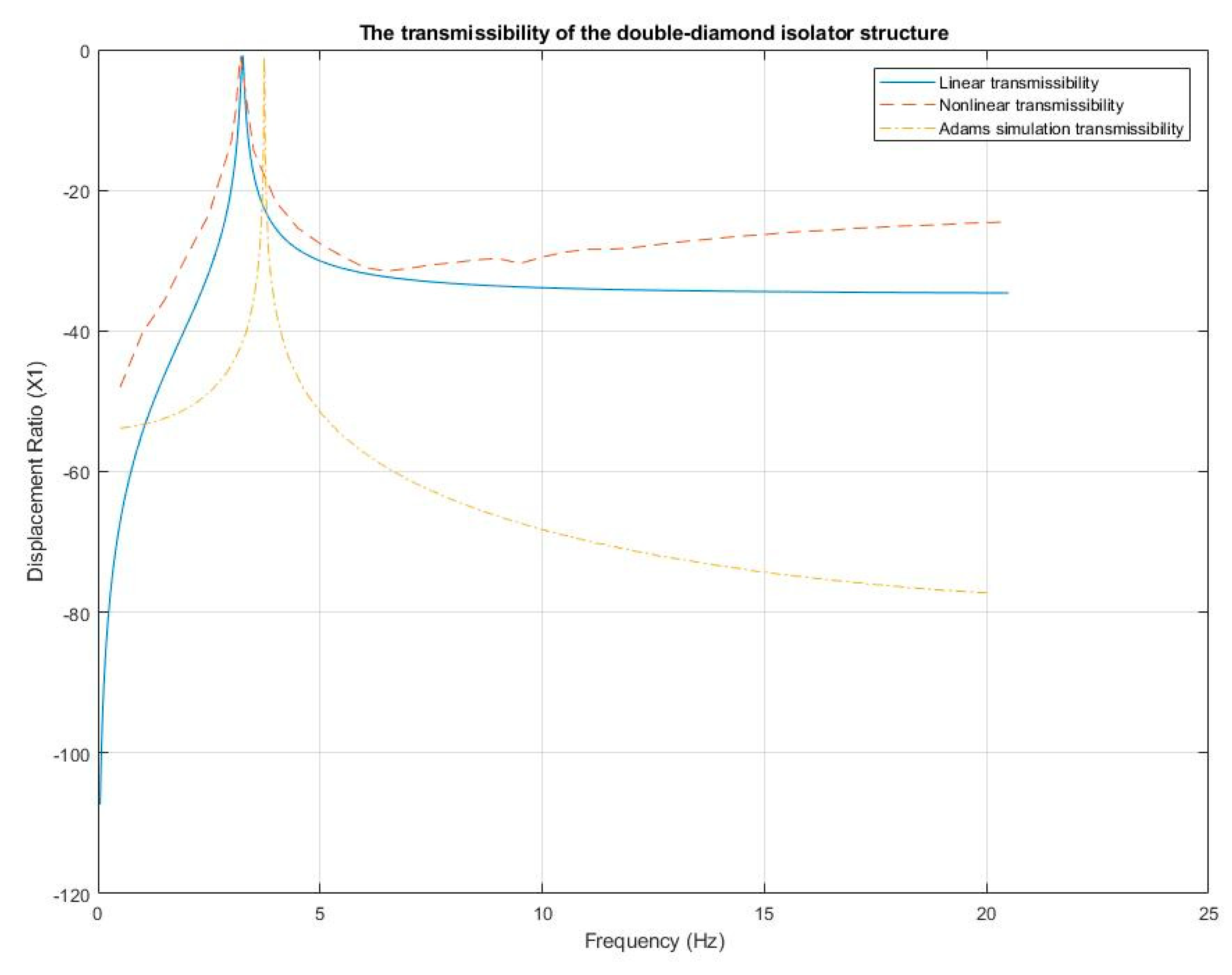

4. Our Current Work and Contributions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mabbott, N.; Foster, G.; McPhee, B. Heavy Vehicle Seat Vibration and Driver Fatigue; Australian Transport Safety Bureau: Canberra, Australia, 2002; Volume 203.

- Nadalin, V.; Kreiger, N.; Parent, M.-E.; Salmoni, A.; Sass-Kortsak, A.; Siemiatycki, J.; Sloan, M.; Purdham, J. Prostate cancer and occupati:nal whole-body vibration exposure. Ann. Occup. Hyg. 2012, 56, 968–974. [Google Scholar] [CrossRef] [PubMed]

- Bovenzi, M.; Hulshof, C.T.J. An updated review of epidemiologic studies on the relationship between exposure to whole-body vibration and low back pain (1986–1997). Int. Arch. Occup. Environ. Health 1999, 72, 351–365. [Google Scholar] [CrossRef] [PubMed]

- McPhee, B.; Foster, G.; Long, L. Bad Vibrations: A Handbook on Whole-Body Vibration Exposure in Mining; Coal Serv. Health Safety Trust, Queensland Min. Safety: Sydney, NSW, Australia, 2009. [Google Scholar]

- Newell, G.S.; Mansfield, N.J. Evaluation of reaction time performance and subjective workload during whole-body vibration exposure while seated in upright and twisted postures with and without armrests. Int. J. Ind. Ergon. 2008, 38, 499–508. [Google Scholar] [CrossRef]

- Özkaya, N.; Goldsheyder, D.; Willems, B. Effect of operator seat design on vibration exposure. Am. Ind. Hyg. Assoc. J. 1996, 57, 837–842. [Google Scholar] [CrossRef]

- Beranek, L.L.; Ver, I.L. Noise and vibration control engineering principles and applications. In Noise and Vibration Control Engineering Principles and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1992; 814p. [Google Scholar]

- Mitra, A.C.; Desai, G.J.; Patwardhan, S.R.; Shirke, P.H.; Kurne, W.M.H.; Banerjee, N. Optimization of passive vehicle suspension system by genetic algorithm. Procedia Eng. 2016, 144, 1158–1166. [Google Scholar] [CrossRef]

- Mead, D.J.; Meador, D.J. Passive Vibration Control; Wiley: Chichester, UK, 1998. [Google Scholar]

- Franchek, M.A.; Ryan, M.W.; Bernhard, R.J. Adaptive passive vibration control. J. Sound Vib. 1996, 189, 565–585. [Google Scholar] [CrossRef]

- Karnopp, D.; Crosby, M.J.; Harwood, R.A. Vibration control using semi-active force generators. J. Eng. Ind. 1974, 96, 619–626. [Google Scholar] [CrossRef]

- Fuller, C.C.; Elliott, S.; Nelson, P.A. Active Control of Vibration; Academic Press: Cambridge, MA, USA, 1996. [Google Scholar]

- Karnopp, D. Active and semi-active vibration isolation. In Current Advances in Mechanical Design and Production VI. Pergamon; ASME: New York, NY, USA, 1995; pp. 409–423. [Google Scholar]

- Denoyer, K.K.; Johnson, C.D. Recent achievements in vibration isolation systems for space launch and on-orbit applications. In Proceedings of the 52nd IAF, International Astronautical Congress, Toulouse, France, 1–5 October 2001. [Google Scholar]

- Sun, W.; Gao, H.; Kaynak, O. Adaptive backstepping control for active suspension systems with hard constraints. IEEE/ASME Trans. Mechatron. 2012, 18, 1072–1079. [Google Scholar] [CrossRef]

- Ning, D.; Sun, S.; Zhang, J.; Du, H.; Li, W.; Wang, X. An active seat suspension design for vibration control of heavy-duty vehicles. J. Low Freq. Noise Vib. Act. Control 2016, 35, 264–278. [Google Scholar] [CrossRef]

- Alanoly, J.; Sankar, S. A new concept in semi-active vibration isolation. J. Mech. Transm. Autom. Des. 1987, 109, 242–247. [Google Scholar] [CrossRef]

- Liu, Y.; Waters, T.P.; Brennan, M.J. A comparison of semi-active damping control strategies for vibration isolation of harmonic disturbances. J. Sound Vib. 2005, 280, 21–39. [Google Scholar] [CrossRef]

- Ver, I.L.; Beranek, L.L. Noise and Vibration Control Engineering-Principles and Applications, Wiley, 2006: Noise and Vibration Control Engineering-Principles and Applications; Bukupedia: New York, NY, USA, 2006. [Google Scholar]

- Zhou, N.; Liu, K. A tunable high-static–low-dynamic stiffness vibration isolator. J. Sound Vib. 2010, 329, 1254–1273. [Google Scholar] [CrossRef]

- Mayton, A.G.; DuCarme, J.P.; Jobes, C.C.; Matty, T.J. Laboratory Investigation of Seat Suspension Performance during Vibration Testing. In Proceedings of the ASME 2006 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers, Chicago, IL, USA, 5–10 November 2006; pp. 177–183. [Google Scholar]

- Jalili, N. A comparative study and analysis of semi-active vibration-control systems. J. Vib. Acoust. 2002, 124, 593–605. [Google Scholar] [CrossRef]

- Platus, D.L. Negative-stiffness-mechanism vibration isolation systems. In Proceedings of the Vibration Control in Microelectronics, Optics, and Metrology. International Society for Optics and Photonics, San Jose, CA, USA, 1 February 1992; Volume 1619, pp. 44–55. [Google Scholar]

- Maciejewski, I.; Meyer, L.; Krzyzynski, T. Modelling and multi-criteria optimisation of passive seat suspension vibro-isolating properties. J. Sound Vib. 2009, 324, 520–538. [Google Scholar] [CrossRef]

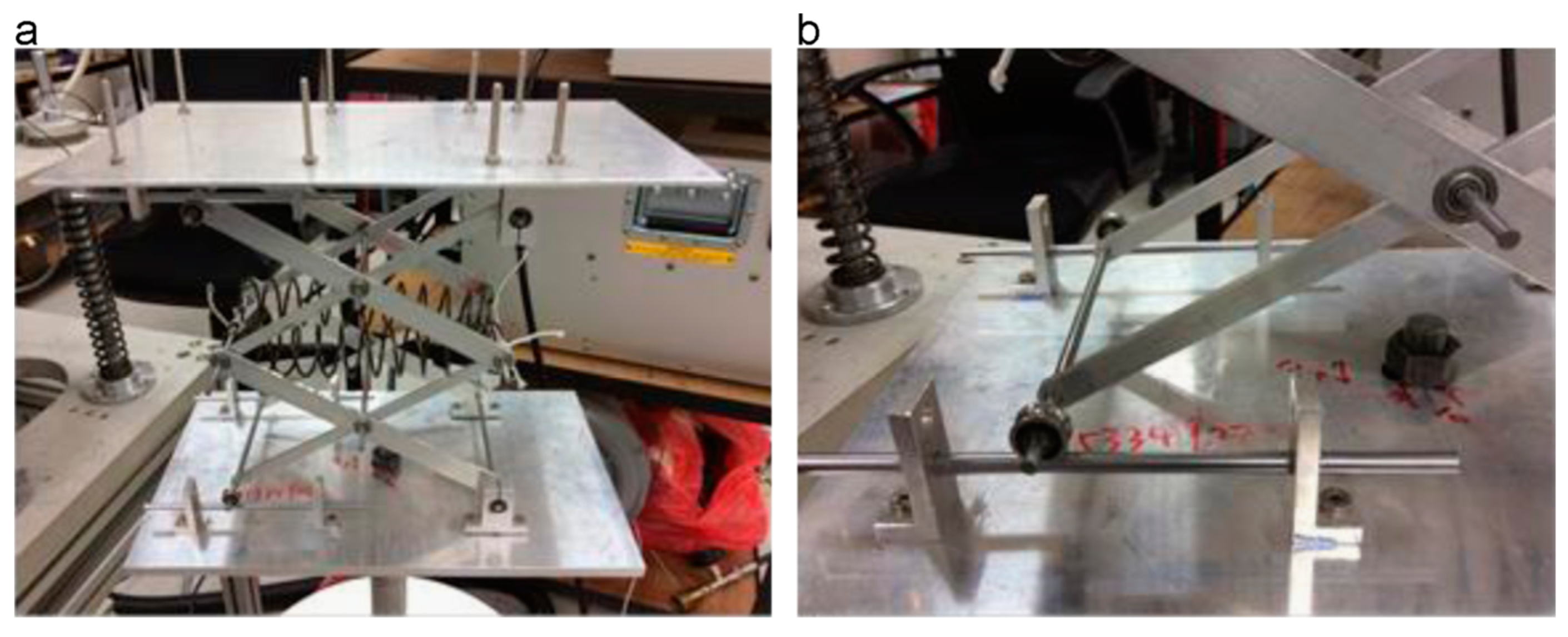

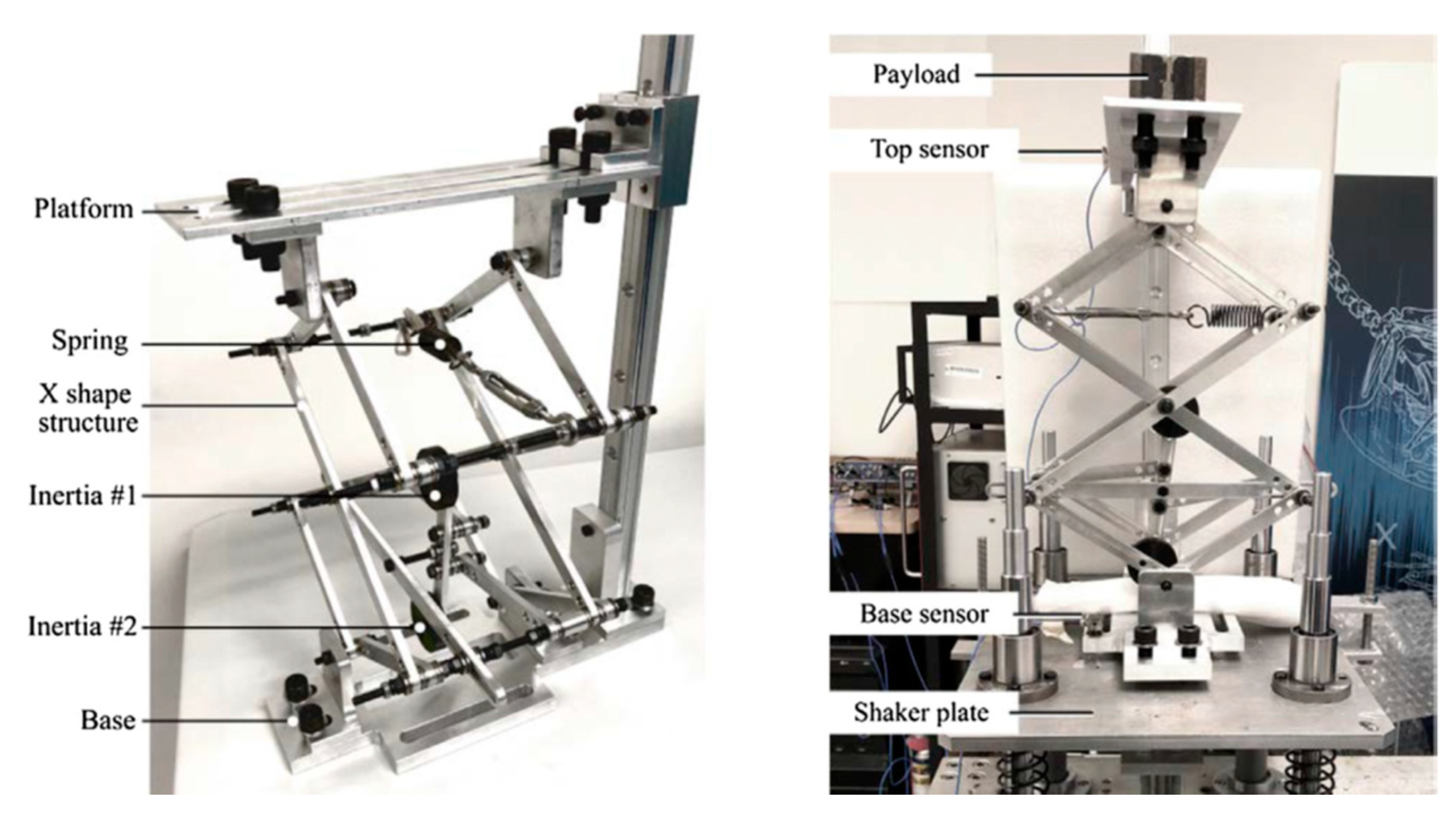

- Ning, D.; Du, H.; Sun, S.; Li, W.; Zhang, B. An innovative two-layer multiple-DOF seat suspension for vehicle whole-body vibration control. IEEE/ASME Trans. Mechatron. 2018, 23, 1787–1799. [Google Scholar] [CrossRef]

- Zhang, L.; Helander, M.G.; Drury, C.G. Identifying factors of comfort and discomfort in sitting. Hum. Factors 1996, 38, 377–389. [Google Scholar] [CrossRef]

- Andersson, B.J.G.; Ortengren, R.; Nachemson, A.; Elfstrom, G. Lumbar disc pressure and myoelectric back muscle activity during sitting.IV. Studies on a car driver’s seat. Scand. J. Rehab. Med. 1974, 6, 128–133. [Google Scholar]

- Ebe, K.; Griffin, M.J. Qualitative models of seat discomfort including static and dynamic factors. Ergonomics 2000, 43, 771–790. [Google Scholar] [CrossRef]

- Kamijo, K.; Tsujimura, H.; Obara, H.; Katsumata, M. Evaluation of Seating Comfort; Technical Paper No. 820761; Society of Automotive Engineers, Inc.: Warrendale, PA, USA, 1982. [Google Scholar]

- Hertzberg, H.T.E. The Human Buttocks in Sitting: Pressures, Patterns, and Palliatives; Technical Paper No.72005; Society of Automotive Engineers, Inc.: New York, NY, USA, 1972. [Google Scholar]

- Diebschlag, W.; Heidinger, F.; Kuurz, B.; Heiberger, R. Recommendation for Ergonomic and Climatic Physiological Vehicle Seat Design; Technical Paper No.880055; Society of Automotive Engineers, Inc.: Warrendale, PA, USA, 1988. [Google Scholar]

- Levrat, E.; Voisin, A.; Bombardier, S.; Brémont, J. Subjective evaluation of car seat comfort with fuzzy set techniques. Int. J. Intell. Syst. 1997, 12, 891–913. [Google Scholar] [CrossRef]

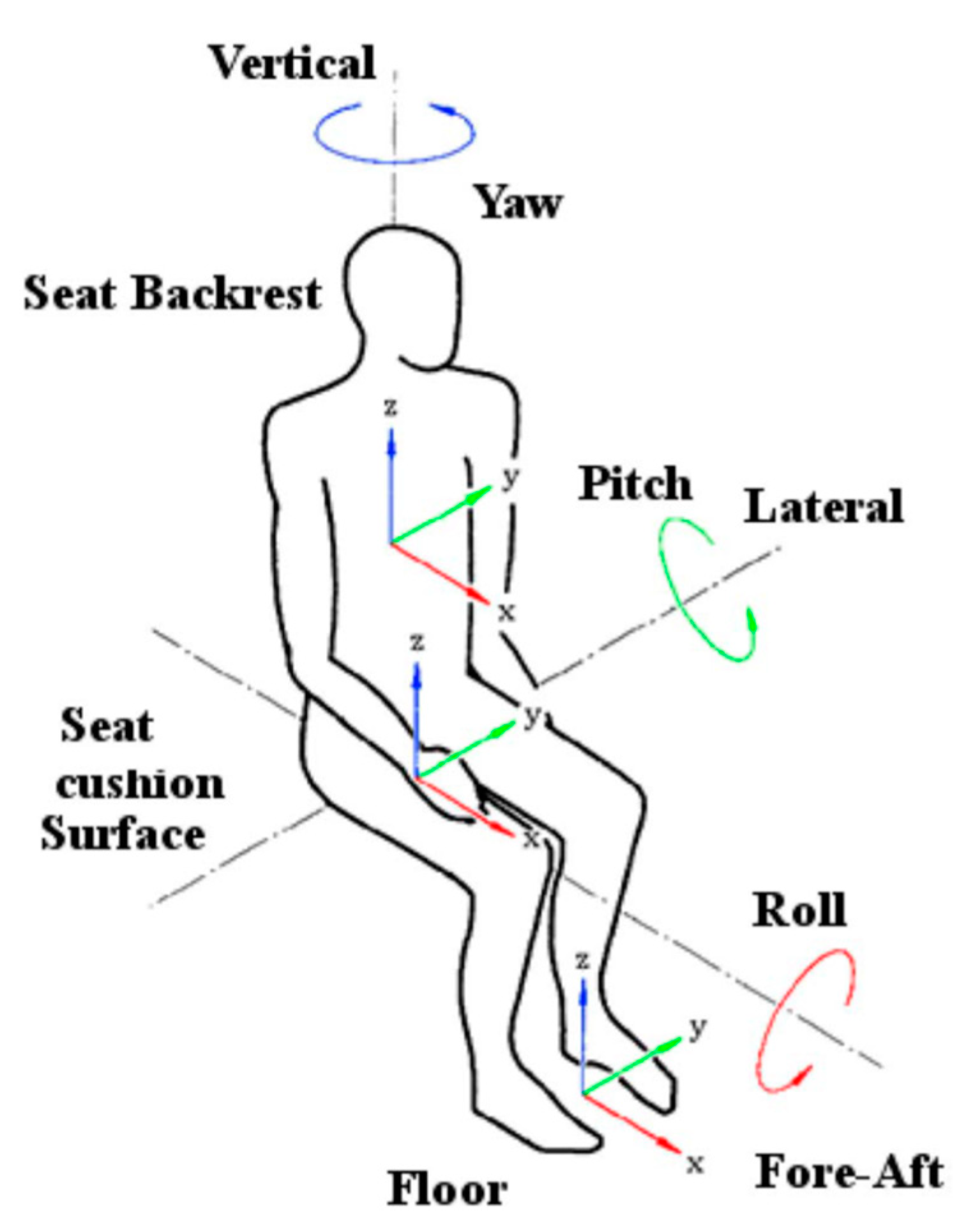

- Coyte, J.L.; Stirling, D.; Du, H.; Ros, M. Seated whole-body vibration analysis, technologies, and modeling: A survey. IEEE Trans. Syst. Man Cybern. Syst. 2015, 46, 725–739. [Google Scholar] [CrossRef]

- Picu, L.; Picu, M.; Rusu, E.V.C. Evaluation of Human Exposure to Whole-Body Vibration Verification Method of Stevens’s Power Law. In Proceedings of the 18th International Multidisciplinary Scientific Geo Conference, Albena, Bulgaria, 30 June–9 July 2018. [Google Scholar]

- Mechanical Vibration and Shock—Evaluation of Human Exposure to Whole-Body Vibration—Part 1: General Requirements; ISO Standard 2631-1; International Organization for Standardization (ISO): Geneva, Switzerland, 1997.

- Mechanical Vibration and Shock. Evaluation of Human Exposure to Whole-Body Vibration. General Requirements; BS ISO 2631-1; BSI: London, UK, 1997.

- Giaime, J.; Saha, P.; Shoemaker, D. A passive vibration isolation stack for LIGO: Design, modeling, and testing. Rev. Sci. Instrum. 1996, 67, 208–214. [Google Scholar] [CrossRef][Green Version]

- Friswell, M.I.; Flores, E.I.S.; Xia, Y. Vibration isolation using nonlinear springs. Proc. ISMA2012-USD 2012, 2012, 2333–2342. [Google Scholar]

- Carrella, A.; Brennan, M.J.; Waters, T.P. Static analysis of a passive vibration isolator with quasi-zero-stiffness characteristic. J. Sound Vib. 2007, 301, 678–689. [Google Scholar] [CrossRef]

- Le, T.D.; Ahn, K.K. A vibration isolation system in low frequency excitation region using negative stiffness structure for vehicle seat. J. Sound Vib. 2011, 330, 6311–6335. [Google Scholar] [CrossRef]

- Holtz, M.W.; Van Niekerk, J.L. Modelling and design of a novel air-spring for a suspension seat. J. Sound Vib. 2010, 329, 4354–4366. [Google Scholar] [CrossRef]

- Valeev, A.; Zotov, A.; Kharisov, S. Designing of compact low frequency vibration isolator with quasi-zero-stiffness. J. Low Freq. Noise Vib. Act. Control 2015, 34, 459–473. [Google Scholar] [CrossRef]

- Xu, D.; Zhang, Y.; Zhou, J.; Lou, J. On the analytical and experimental assessment of the performance of a quasi-zero-stiffness isolator. J. Vib. Control 2014, 20, 2314–2325. [Google Scholar] [CrossRef]

- Gan, Z.; Hillis, A.J.; Darling, J. Adaptive control of an active seat for occupant vibration reduction. J. Sound Vib. 2015, 349, 39–55. [Google Scholar] [CrossRef]

- Earnshaw, S. On the nature of the molecular forces which regulate the constitution of the luminferous ether. Trans. Camb. Phil. Soc. 1842, 7, 97–112. [Google Scholar]

- Van der Westhuizen, A.; van Niekerk, J.L. Verification of seat effective amplitude transmissibility (SEAT) value as a reliable metric to predict dynamic seat comfort. J. Sound Vib. 2006, 295, 1060–1075. [Google Scholar] [CrossRef]

- Sun, X.; Jing, X. Analysis and design of a nonlinear stiffness and damping system with a scissor-like structure. Mech. Syst. Signal Process. 2016, 66, 723–742. [Google Scholar] [CrossRef]

- Le, T.D.; Ahn, K.K. Experimental investigation of a vibration isolation system using negative stiffness structure. Int. J. Mech. Sci. 2013, 70, 99–112. [Google Scholar] [CrossRef]

- Sun, X.; Jing, X. Multi-direction vibration isolation with quasi-zero stiffness by employing geometrical nonlinearity. Mech. Syst. Signal Process. 2015, 62–63, 149–163. [Google Scholar] [CrossRef]

- Alabuzhev, P.M. Vibration Protection and Measuring Systems with Quasi-Zero Stiffness; CRC Press: Boca Raton, FL, USA, 1989. [Google Scholar]

- Lan, C.C.; Yang, S.A.; Wu, Y.S. Design and experiment of a compact quasi-zero-stiffness isolator capable of a wide range of loads. J. Sound Vib. 2014, 333, 4843–4858. [Google Scholar] [CrossRef]

- Ibrahim, R.A. Recent advances in nonlinear passive vibration isolators. J. Sound Vib. 2008, 314, 371–452. [Google Scholar] [CrossRef]

- Molyneux, W.G. The support of an aircraft for ground resonance tests: A survey of available methods. Aircr. Eng. Aerosp. Technol. 1958, 30, 160–166. [Google Scholar] [CrossRef]

- Xu, D.; Yu, Q.; Zhou, J.; Bishop, S.R. Theoretical and experimental analyses of a nonlinear magnetic vibration isolator with quasi-zero-stiffness characteristic. J. Sound Vib. 2013, 332, 3377–3389. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, X.; Xu, D.; Bishop, S. Nonlinear dynamic characteristics of a quasi-zero stiffness vibration isolator with cam–roller–spring mechanisms. J. Sound Vib. 2015, 346, 53–69. [Google Scholar] [CrossRef]

- Kovacic, I.; Brennan, M.J.; Waters, T.P. A study of a nonlinear vibration isolator with a quasi-zero stiffness characteristic. J. Sound Vib. 2008, 315, 700–711. [Google Scholar] [CrossRef]

- Carrella, A.; Brennan, M.J.; Kovacic, I.; Waters, T.P. On the force transmissibility of a vibration isolator with quasi-zero-stiffness. J. Sound Vib. 2009, 322, 707–717. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, D.; Bishop, S. A torsion quasi-zero stiffness vibration isolator. J. Sound Vib. 2015, 338, 121–133. [Google Scholar] [CrossRef]

- Li, Q.; Zhu, Y.; Xu, D.; Hu, J.; Min, W.; Pang, L. A negative stiffness vibration isolator using magnetic spring combined with rubber membrane. J. Mech. Sci. Technol. 2013, 27, 813–824. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, X.; Luo, Y.; Yan, B.; Ma, C. Design and experiment of a high-static–low-dynamic stiffness isolator using a negative stiffness magnetic spring. J. Sound Vib. 2016, 360, 31–52. [Google Scholar] [CrossRef]

- Zhou, J.; Xiao, Q.; Xu, D.; Ouyang, H.; Li, Y. A novel quasi-zero-stiffness strut and its applications in six-degree-of-freedom vibration isolation platform. J. Sound Vib. 2017, 394, 59–74. [Google Scholar] [CrossRef]

- Dong, G.; Zhang, X.; Luo, Y.; Zhang, Y.; Xie, S. Analytical study of the low frequency multi-direction isolator with high-static-low-dynamic stiffness struts and spatial pendulum. Mech. Syst. Signal Process. 2018, 110, 521–539. [Google Scholar] [CrossRef]

- Dong, G.; Zhang, X.; Xie, S.; Yan, B.; Luo, Y. Simulated and experimental studies on a high-static-low-dynamic stiffness isolator using magnetic negative stiffness spring. Mech. Syst. Signal Process. 2017, 86, 188–203. [Google Scholar] [CrossRef]

- Wang, X.; Liu, H.; Chen, Y.; Gao, P. Beneficial stiffness design of a high-static-low-dynamic-stiffness vibration isolator based on static and dynamic analysis. Int. J. Mech. Sci. 2018, 142, 235–244. [Google Scholar] [CrossRef]

- Feng, X.; Jing, X.; Xu, Z.; Gao, Y. Bio-inspired anti-vibration with nonlinear inertia coupling. Mech. Syst. Signal Process. 2019, 124, 562–595. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Q.; Yan, B.; Luo, Y.; Zhang, X. A Stewart isolator with high-static-low-dynamic stiffness struts based on negative stiffness magnetic springs. J. Sound Vib. 2018, 422, 390–408. [Google Scholar] [CrossRef]

- Imbalzano, G.; Tran, P.; Ngo, T.D.; Lee, P.V.S. A numerical study of auxetic composite panels under blast loadings. Compos. Struct. 2016, 135, 339. [Google Scholar] [CrossRef]

- Qiao, J.; Chen, C.Q. Analyses on the in-plane impact resistance of auxetic double arrowhead honeycombs. J. Appl. Mech. 2015, 82, 051007. [Google Scholar] [CrossRef]

- Wang, X.; Bi, F.; Du, H. Reduction of low-frequency vibration of a truck driver and seating system through system parameter identification, sensitivity analysis, and active control. Mech. Syst. Signal Process. 2018, 105, 16–35. [Google Scholar] [CrossRef]

- Heidarian, A. and Wang X. Review on Seat Suspension System Technology Development. Appl. Sci. 2019, 9, 2834. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X. A Review of Low-Frequency Active Vibration Control of Seat Suspension Systems. Appl. Sci. 2019, 9, 3326. [Google Scholar] [CrossRef]

- Alashmoriand, M.; Wang, X. A Systematic Literature Review of Various Control Techniques for Active Seat Suspension Systems. Appl. Sci. 2020, 10, 1148. [Google Scholar] [CrossRef]

| Type of Structure | Geometry | Key Features and Novelty | Advantage | Disadvantage | Performance Criterion | Performance |

|---|---|---|---|---|---|---|

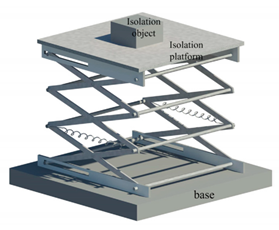

| (6-DOF) X-shaped support legs quasi-zero-stiffness (QZS) Stewart platform isolator [38] |  | (1) Three layers; (2) Each layer consists of connecting rods and corresponding rotating joints. (3) Support joints of the left bottom and top layer sliding along horizontal tracks. (4) Additional springs for extra stiffness. (5) High-static–low-dynamic stiffness (6) Double-diamond isolator structure in place of X-shape structure. | (1) A very flexible and versatile scissor-like structure. (2) It can be independent of or combined with other vibration isolators, to provide damping and stiffness as the passive or semi-active isolator. (3) Flexible structure size for different application situations. (4) Good vibration isolation performance. | (1) Complex structure and many components. | Displacement transmissibility Equivalent stiffness | The peak values of the transmissibility ratios of the mass-spring-damper vibration isolator (MSD-VI), scissor-like structure vibration isolator (SLS-VI), and quasi-zero-stiffness vibration isolator (QZS-VI) are 20, 8, and 4, respectively |

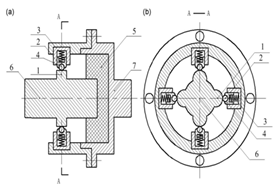

| (6-DOF) Stewart platform with high-static–low-dynamic stiffness (HSLDS) passive vibration isolator [60] |  | (1) Both the inner magnet and the outer magnet are composed of several tile magnets that are magnetized uniformly along the radial direction. (2) The inner magnet and the outer magnet are in a repulsive configuration. (3) The configuration is unstable in the axial direction and can produce negative stiffness. | (1) Stewart platform can have lower resonance frequencies (2) Compact configuration of the presented negative-stiffness magnetic spring (NSMS). | (1) Complex structure and many components. (2) High cost | Displacement transmissibility Force transmissibility | Compare to the system without negative stiffness magnetic spring, frequency-sweeping results is improved. |

| (6-DOF) Pyramidal 3-quasi-zero-stiffness (QZS) strut isolator [61] |  | (1) Four pyramidal 3-QZS-strut isolators hold the platform (2) Four pyramidal 3-QZS-struts are identical to each other (3) The vertical inclination angles are the same at the static equilibrium (4) Both the platform and machine are mounted rigidly and located symmetrically. | (1) The proposed isolator has the QZS characteristics in all six DOFs (2) The QZS struts provided good vibration isolation effectiveness (3) Broadened the bandwidth of vibration isolation into lower-frequency (4) jumping phenomenon reduced | (1) Complex structure and many components. (2) High cost | Force transmissibility | Natural frequency Ωx = Ωy = 0.4082 Ωz = 1 |

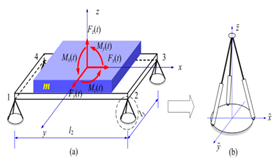

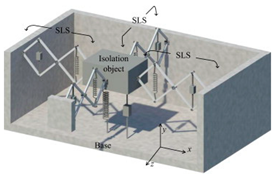

| (3-DOF) Multi-direction quasi-zero-stiffness (MSQZS) vibration isolator [49] |  | (1) Four n-layer scissor-like structures assembled symmetrically (2) Linear spring and damper are used in the vertical direction (3) Isolation object connected with four scissor-like structures and linear spring and damper | (1) Excellent vibration isolation in three directions simultaneously (2) Adjustable structural parameters in the QZS system with scissors-like structure (SLS) | (1) Complex structure | Displacement transmissibility | Compare to multi-direction quasi-zero-stiffness displacement transmissibility, reduces from 11.5 to 0.5. |

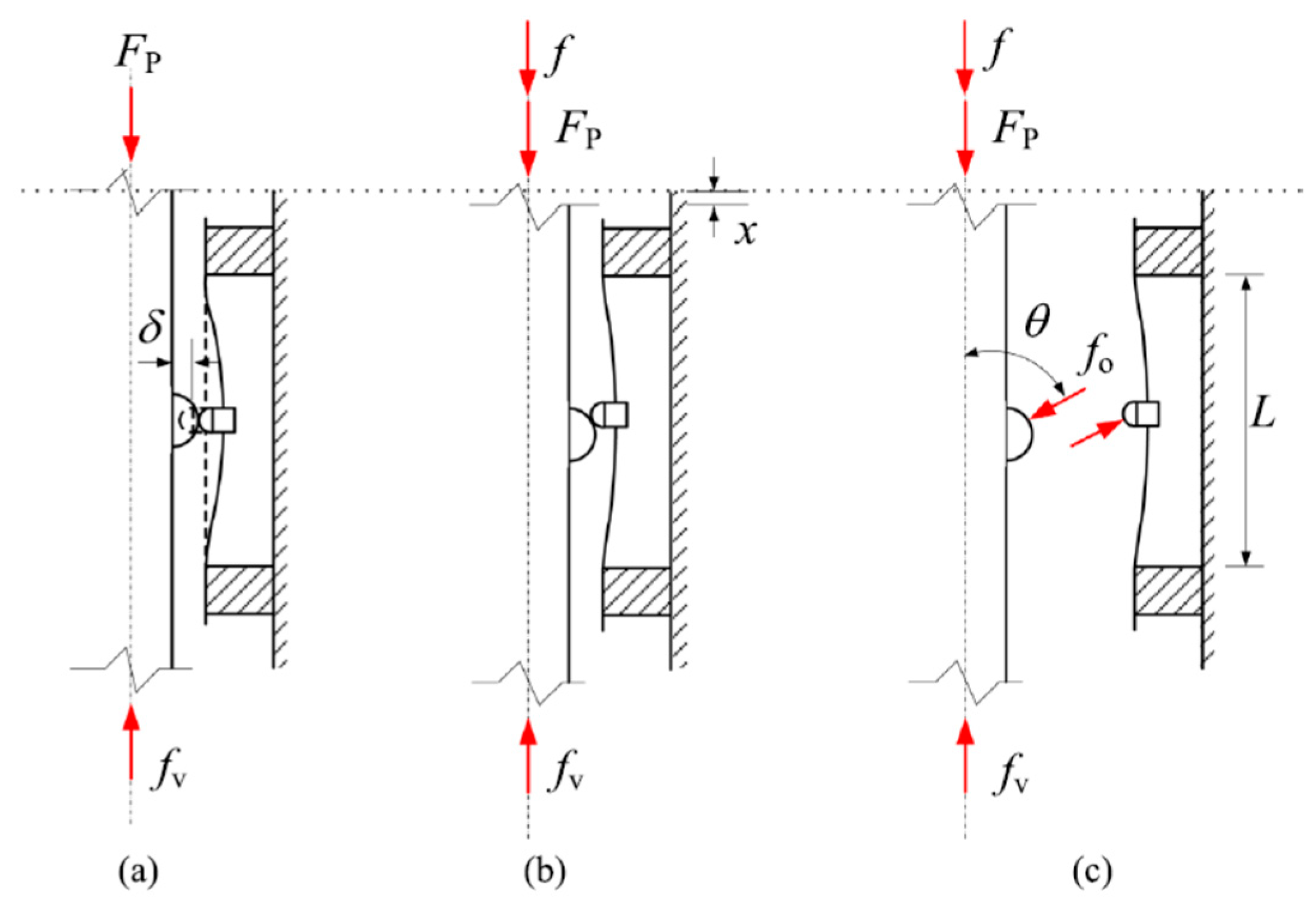

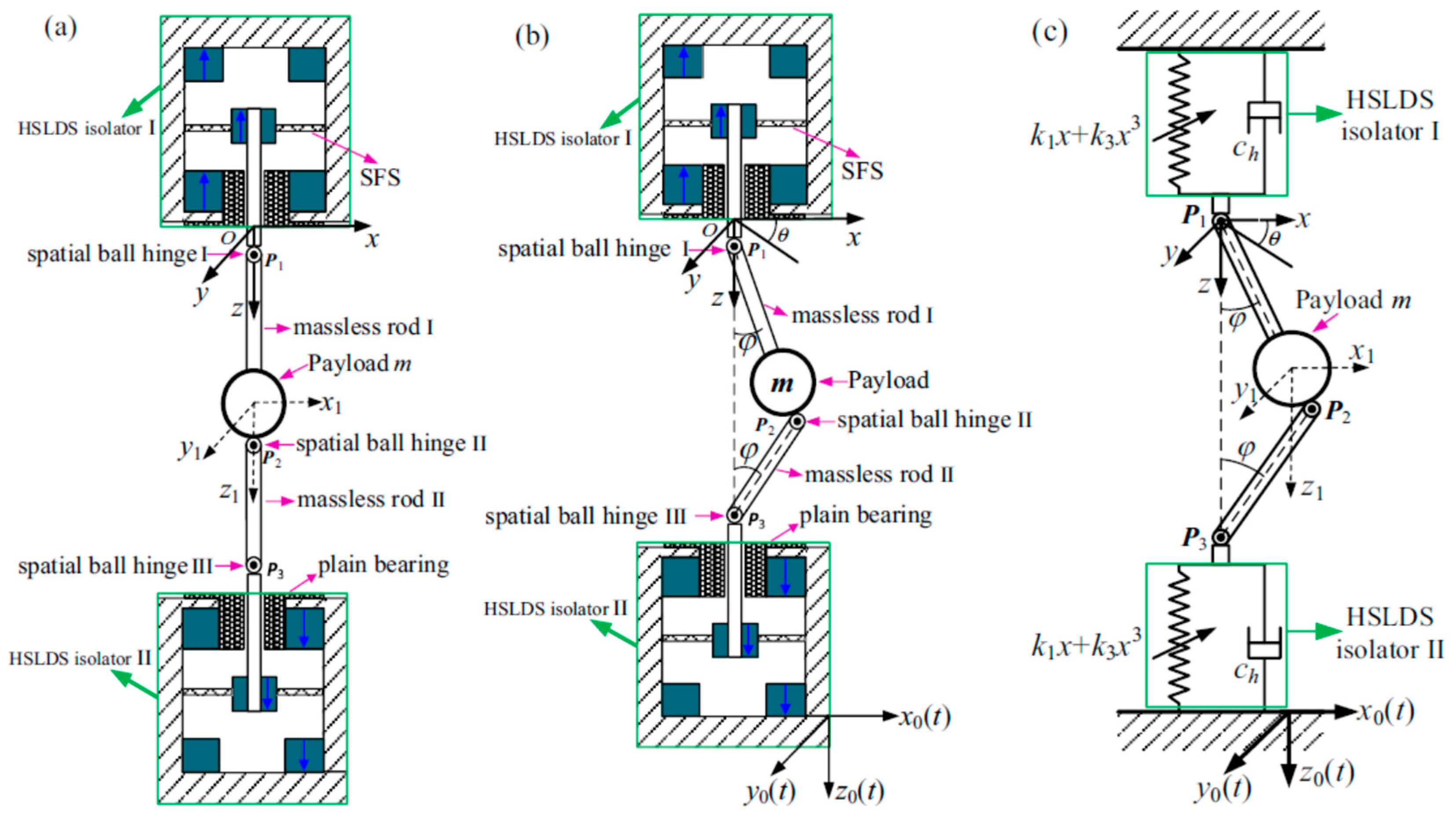

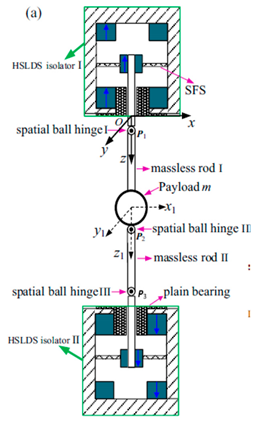

| (3-DOF) High-static–low-dynamic stiffness (HSLDS) struts and spatial pendulum passive isolator [62] |  | (1) The isolator composed of two HSLDS struts, preload m, three spatial ball hinges, and two massless rods. (2) Without external excitation, the isolator would stay at a static equilibrium position (3) The length of two massless rods is l. (4) Payload m absolute motion is , and two horizontal directions are . (5) Two HSLDS struts are identical and symmetrically fixed on the ground. (6) HSLDS struts with magnetic negative stiffness spring (MNSS) and spiral flexure spring (SFS) | (1) High-static–low-dynamic stiffness in the vertical direction and quasi-zero stiffness in two horizontal directions (2) Expanded low-frequency isolation bandwidth in each direction (3) No resonance phenomenon occurring in two horizontal directions | (1) Complex structure and many components. (2) High cost (3) Large packaging space. | Displacement transmissibility | Except for the small rise in the range from 5 to 12 Hz, displacement transmissibility in x and y directions are good. |

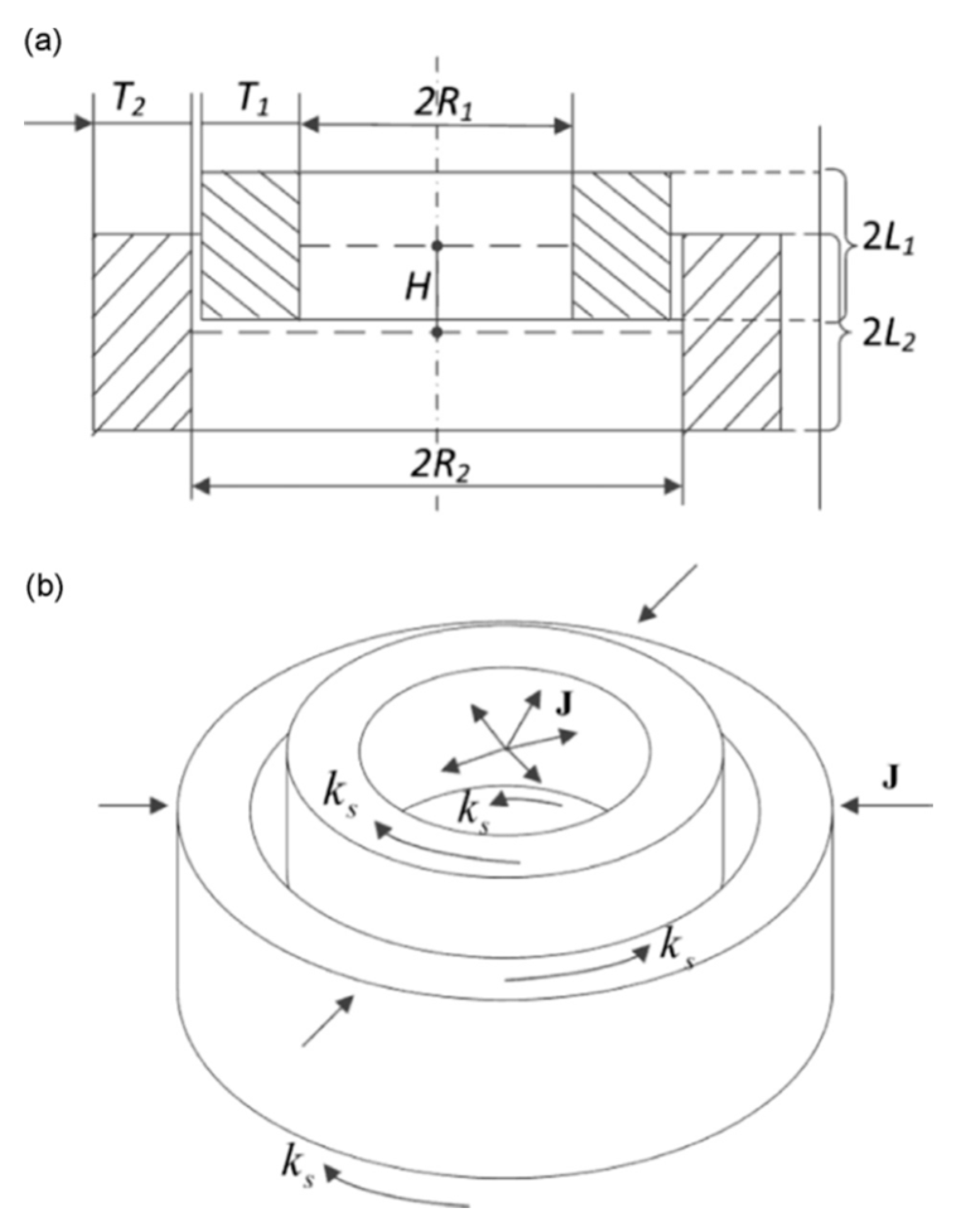

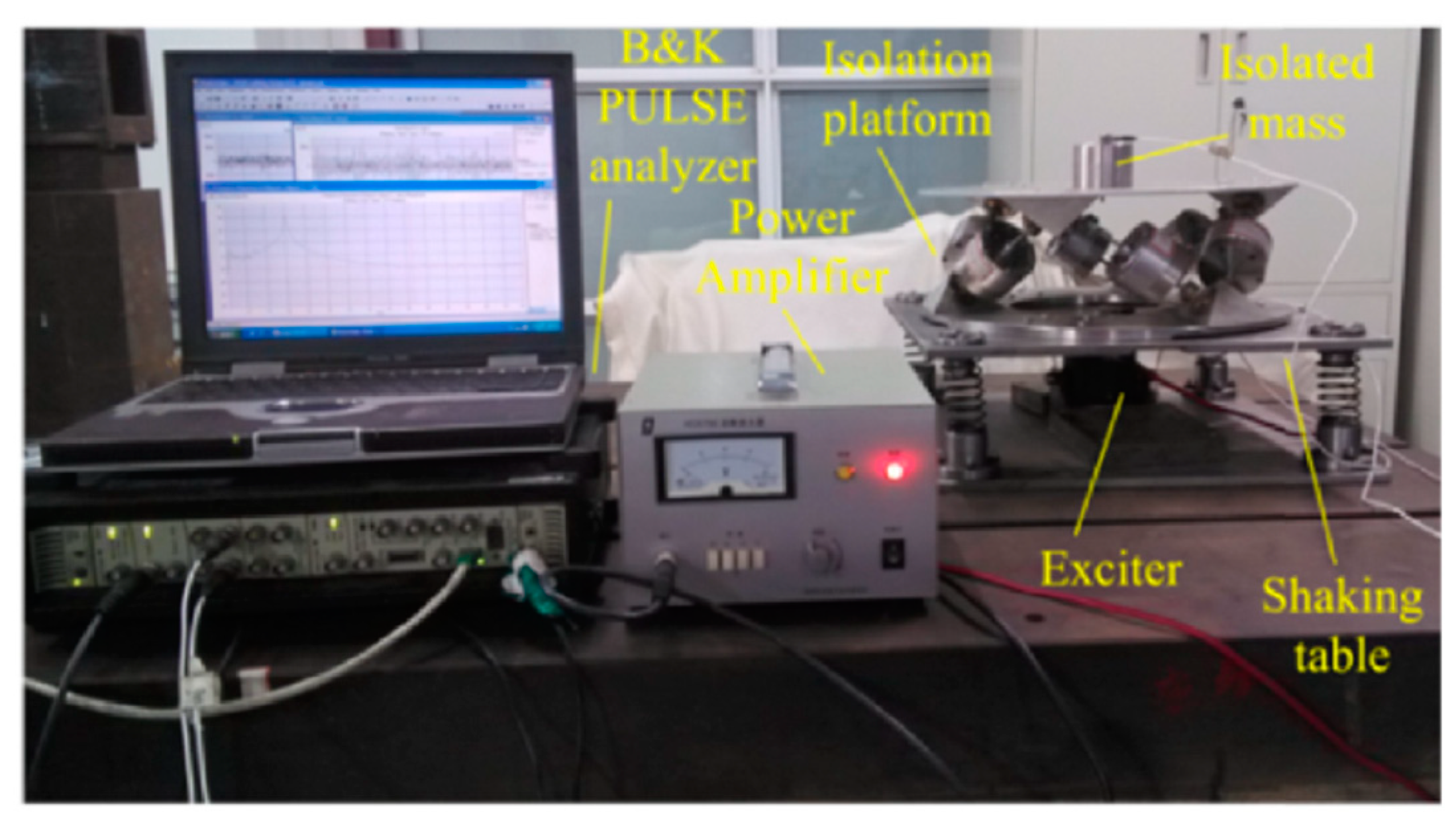

| (3-DOF) High-static–low-dynamic stiffness (HSLDS) magnetic vibration isolator system [63] |  | (1) The isolator combines a positive-stiffness spring with a negative-stiffness in parallel. (2) A special device spiral flexure spring (SFS) is applied to provide positive stiffness (3) A magnetic negative-stiffness spring (MNSS) is applied to provide negative magnetic stiffness (MNS) (4) Positive stiffness and negative stiffness cancel each other for reducing the resonance frequency of the isolator. | (1) Good load capacity under a small static deformation (2) Large and flattened magnitude of MNS near the equilibrium position (3) Damping property is improved considerably. | (1) Complex structure and many components. (2) High cost | Vibration transmissibility | Compare to the system without magnetic negative-stiffness spring, the vibration transmissibility has been reduced by 22.25. |

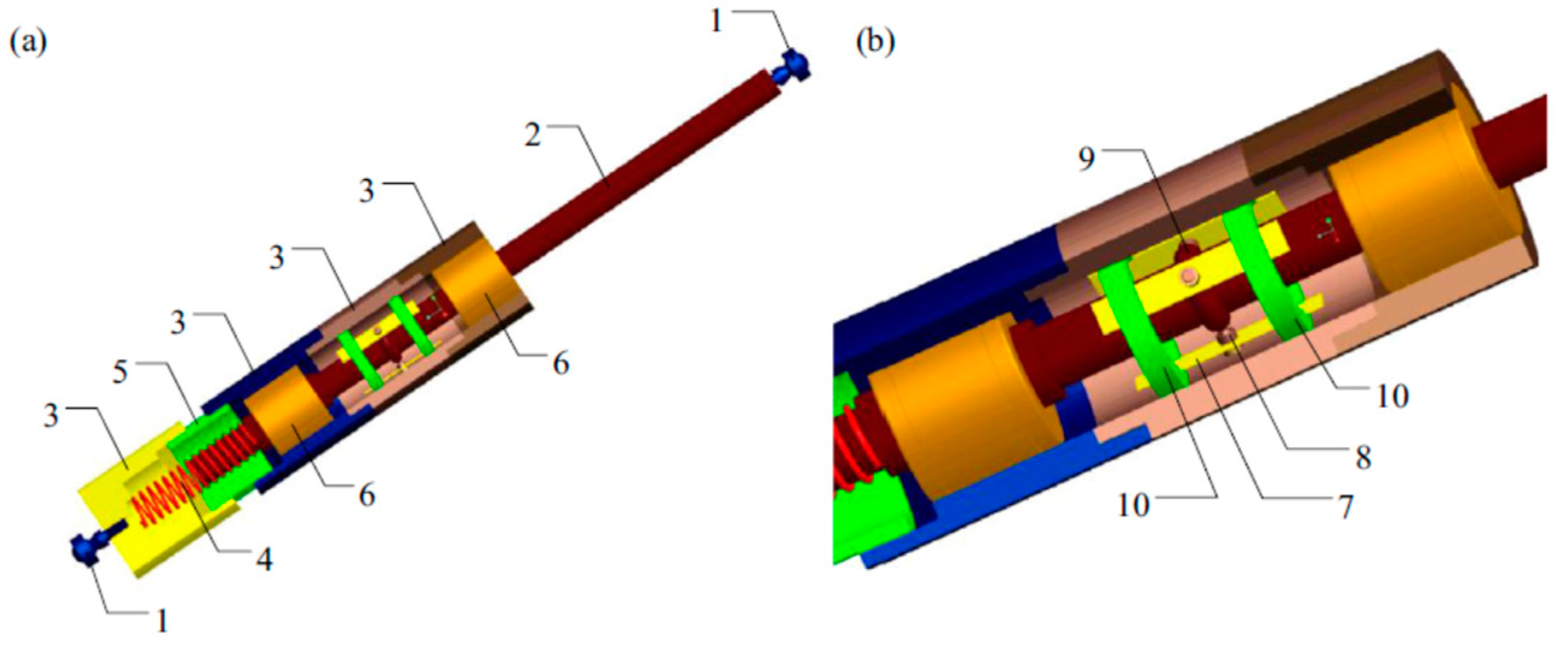

| (2-DOF) Torsion QZS vibration isolator [58] |  | (1) Shafts connected two ends of the isolator (2) The right (7) and left (6) shaft connector are connected (3) The rubber is a linear vibration isolator (4) Four cylindrical cams (1) contact with four rollers (2) (5) Roller (2) is held by slider (4), and sliders are supported by a spring (3) (6) As for rolling contact, the friction between the cylindrical cam (1) and the roller (2) is neglected | (1) The QZS isolator has a good sensibility to a deviation of output torque. | (1) Limited application range where the designed transmission torque is constant. (2) Complex structure and many components. | Dimensionless torque–torsion Dimensionless stiffness | Compare to linear system torque transmissibility, reduced from 23 to 18 |

| (2-DOF) High-static–low-dynamic stiffness (HSLDS) vibration isolator system [64] |  | (1) The mass M is connected to the base through two horizontal springs and a connecting bar and a vertical spring (2) Horizontal springs are connected between the base and two rollers, and are able to slide in the horizontal direction freely (3) The connecting bar is linked between the roller and mass at point P. Thus, the mass can move vertically. | (1) Good isolation performance in low-frequency vibration and micro-vibration isolation. (2) By reduction in the stiffness in the static equilibrium position and by an increase in the dimensionless spring deformation range. The vibration isolation region has been increased, and the force transmissibility ratio has been reduced. | (1) Limited installation space (2) Limited maximum vibration displacement responses | Dimensionless-displacement and force transmissibility and dimensionless stiffness | |

| (2-DOF) Human body-inspired anti-vibration structure with nonlinear inertia (HBIAV-NI) [65] |  | (1) The structure contains an X-shaped supporting structure with a nonlinear rotating inertia passive vibration isolation system. (2) The isolator contains a large X-shaped structure supporting the mass , a rotational unit, and a small embedded X-shaped structure. | (1) Adjustable structural parameters (2) Designable nonlinear properties (3) Nonlinear inertia (4) A small embedded X-shaped structure to mimic muscle functions. | (1) Large packaging space. (2) Complex structure | Displacement transmissibility | Compare to linear system and X-shaped structure system, the displacement transmissibility has a slight reduction. |

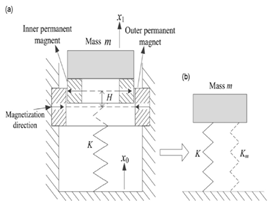

| (1-DOF) Negative-stiffness magnetic spring (NSMS) vibration isolator system [60] |  | (1) The structure contains a mechanical spring in parallel with a negative-stiffness magnetic spring (NSMS). (2) The isolated mass moves only in the vertical direction. (3) The NSMS is composed of two opposite-direction ring permanent magnets (4) The outer magnet is fixed on the base, and the inner magnet is fixed with mass m. The mechanical spring is connected between the inner magnet and base. | (1) The proposed NSMS isolator can effectively reduce the peak transmissibility and resonance frequency | The jump-down frequency would increase under excessive base excitation | Displacement transmissibility | Compare to the system without negative-stiffness magnetic spring, the displacement transmissibility has reduced from 23 to 15. |

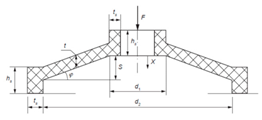

| Vibration isolator with quasi-zero stiffness [42] |  | d1 represents the diameter of the inner wall; d2 the diameter of the outer wall; t the wall thickness; s the height of the outer wall; ϕ the angle of the wall inclination; hs the height of the outer wall; ts the thickness of the outer wall; F the load, and x the compression. | (1) Low cost and high speed of manufacture (2) A low natural frequency, which is excellent for vibration isolators | (1) Low load capacity | Natural frequency | The natural frequency of the vibration isolator with a clamp is less than 0.5. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.; Wang, X.; Fan, R.-L.; Bi, F. Review on Development of High-Static–Low-Dynamic-Stiffness Seat Cushion Mattress for Vibration Control of Seating Suspension System. Appl. Sci. 2020, 10, 2887. https://doi.org/10.3390/app10082887

Guo L, Wang X, Fan R-L, Bi F. Review on Development of High-Static–Low-Dynamic-Stiffness Seat Cushion Mattress for Vibration Control of Seating Suspension System. Applied Sciences. 2020; 10(8):2887. https://doi.org/10.3390/app10082887

Chicago/Turabian StyleGuo, Linchuan, Xu Wang, Rang-Lin Fan, and Fengrong Bi. 2020. "Review on Development of High-Static–Low-Dynamic-Stiffness Seat Cushion Mattress for Vibration Control of Seating Suspension System" Applied Sciences 10, no. 8: 2887. https://doi.org/10.3390/app10082887

APA StyleGuo, L., Wang, X., Fan, R.-L., & Bi, F. (2020). Review on Development of High-Static–Low-Dynamic-Stiffness Seat Cushion Mattress for Vibration Control of Seating Suspension System. Applied Sciences, 10(8), 2887. https://doi.org/10.3390/app10082887