1. Introduction

Soil erosion has environmental and socioeconomic significances. In arid areas, soil erosion by wind leads to dust emission to the atmosphere that increase air pollution and risk exposure to human health [

1,

2,

3]. Current global estimates of dust-related particulate matter (PM10), which is less than 10 µm in diameter, loading varies widely from ~6 to 30 million tons [

4]. There is uncertainty regarding the relative dust contribution of disturbed soils in non-desert areas, which are subjected to human activities. The continuous population growth increases the land uses of agriculture, mining, and vehicles traveling on unpaved roads in these areas. Such activities change the topsoil properties, reduce the soil stability, and thus increase soil erosion and dust emission [

5,

6,

7].

There is a growing interest in soil stabilization to reduce soil erosion and dust emission from disturbed soil in arid and semi-arid regions. There are various dust-control materials commonly used to reduce dust emission from soils. These products are based on natural and synthetic polymers such as lignin, resin, bitumen, and polyvinyl acetate (PVA). The typical application of these products is by spraying the solution on the soil surface at certain concentration (liter per square meter). Among the common dust-control materials, the hydrous-magnesium chloride (brine) is one of the most efficient application in preventing dust emission [

8]. The adverse soil pollution and environmental footprint resulting from the use of the common dust-control materials are still unclear. Moreover, typical applications for dust control do not provide a reinforcement of the topsoil, and thereby stabilization against physical pressures due to vehicle traveling.

One of the most common materials that is used for soil stabilization is PVA. When the PVA solution is absorbed in the soil, the polymers enveloping the soil particles that remain aggregated after the evaporation processes. PVA is especially efficient in soils with granular texture and with small specific surface area, in which it creates a stable crust with strong tensile strength. However, the environmental impacts of this synthetic polymer and its efficiency in fine-grained soils with high content of dust are still unclear. This raises the need to develop an effective material from the perspectives of dust control, soil stabilization, and environmental footprint. Geopolymers are a group of mineral-based materials that commonly used in the building industry [

9]. Geopolymer can be synthesized by mixing calcined kaolin and strongly alkaline solutions (such as NaOH or KOH) and then curing at a room temperature [

10]. Several studies have examined the use of various geopolymers for loess soil stabilization, including fly ash, lime, and cement, etc., [

11,

12,

13,

14,

15,

16]. However, the use of the anhydrous calcined form of the clay mineral kaolinite (metakaolin) was given less attention in loess stabilization. Loess is a widespread surface deposit in many parts of the world. There is a strong need for loess stabilization in construction requirements and geohazard mitigation due to its propensity to collapse and subsidence after loading and wetting [

11,

12]. Moreover, unpaved roads in loess are associated with strong erosion by wind and water, which leads to soil disintegration [

7]. This study examined the use of a metakaolin-based geopolymer with different compounds and concentrations for the reinforcement of the topsoil of a semi-arid loess soil.

2. Materials and Methods

The experiments conducted on a typical loess soil of the northern Negev, Israel. The semi-arid region of the northern Negev is characterized by annual average rainfall of ~200 mm. Most of the loess soils in northern Negev are a secondary material that reworked under pedogenic and geomorphological processes after investment of aeolian and/or pluvial materials [

17]. Currently, the northern Negev loess is subjected to intense human activities and related soil erosion and dust emission, e.g., [

6,

18].

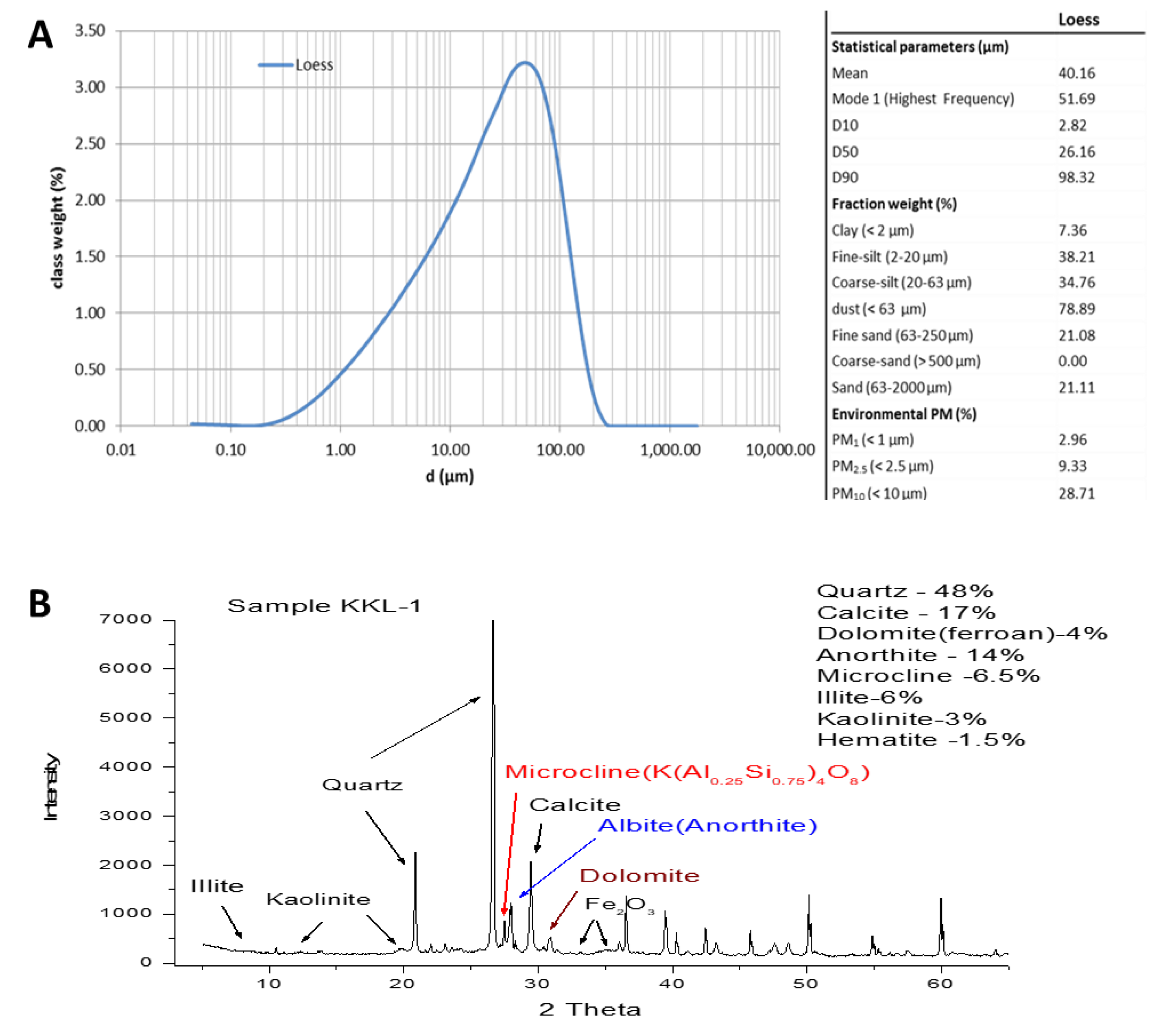

The texture of the soil is silt-loam with a relatively high content of silt and clay particles. Particle size distribution was obtained by the ANALYSETTE 22 MicroTec Plus (Fritsch, Idar-Oberstein, Germany) laser diffraction, which measures particles in the size range of 0.08–2000 μm [

19,

20]. Replicas (100 mg) were dispersed in Na-hexamvetaphosphate solution (0.5%) by sonication (38 kHz). The data was calculated using the Fraunhofer diffraction model with a size resolution of 1 μm using MasControl software (

Figure 1a). Mineralogical analysis, which was obtained by the X-ray power diffraction (XRPD) method, shows typical loess composition with high content of quartz, clays (illite, kaolinite), as well as Ca-based components that are found in arid loess (

Figure 1b).

For the dust control experiment, the soil was placed in trays that fit the wind tunnel dimensions (0.5 × 1.0 m, with height of 0.02 m). Three trays (replicas) were prepared for each soil treatment/product.

Table 1 presents the products used for the laboratory experiment and their application on the soil. The composition of the solution of each substance and the concentration of the solution to be applied by spraying on the soil surface were provided by the suppliers of the products and are typical in dust control. The soil samples were left outside for a drying process of several days before the experiment to avoid the impact of the amount of the solution (water content) on wind erosion and dust emission. The geopolymer for the dust control experiment was composed of metakaolin (MK) with an activation solution containing NaOH and sodium silicate in a constant ratio. The activation solution was added to the soil mixture in over-saturated until reaching a shed state of the mixture. The MK amount added to the soil sample was 30% of the soil sample weight. The geopolymer was mixed in the soil sample and tested after a drying process of 28 days.

The soils were tested in a wind tunnel for dust emission—overall 30 runs were performed by the wind tunnel (5 samples, 3 replicates, 2 wind velocities). These experiments were performed in the portable boundary-layer wind tunnel of the Aeolian Simulation Laboratory at BGU [

8]. Boundary-layer wind tunnels enable simulations under standardized quasi-natural wind conditions and provide quantitative information on dust emission rates from the soils. The wind tunnel has a cross sectional area in the order of 0.5 × 0.5 m with open-floored working sections of up to 10 m length. Air push or air suction flow in the tunnel is generated by an axial fan up to a maximum velocity of 18 m s

−1. Instruments installed in the test section of the tunnel enable quantification of wind characteristics and dust (PM) concentrations.

The tunnel was operated under two wind velocities, 6.5, and 9.5 m s

−1, which represent medium and strong natural winds that are associated with dust emission in semi-arid loess soils [

13]. Each run of specific wind velocity lasted 30 s to record the trend of dust emission. Dust concentrations (µg m

−3) PM10 were recorded by a light-scattering device, DustTrak DRX 8534 (TSI, Shoreview, MN, USA), in the range of 0.001–150 µg m

−3 (±0.1% of reading) at 1-s intervals, which was placed at 25 cm above the tunnel bed. The recorded PM10 concentrations were converted into mass flux emitted from the soil surface (mg m

−2 s

−1) based on the wind tunnel dimensions, the area of the soil bed, and the wind velocity (for in depth description refer to Katra et al. 2016 [

21]). The PM10 flux from the soil surface can be used in parameterization of dust emission and transport models [

7,

21].

The soil sample mixed with the geopolymer was examined also for soil stabilization by the tensile strength test. A 300 g quantity of soil was mixed with MK (with the activation solution) to form test sample in three replicates. The mixtures were then poured into a 3.5 cm diameter cylinder on a length of 7.5 cm. Each sample series was dried for 28 days until the bonding material stabilized before testing the strength of the stabilized soil sample. The tensile strength of the sample was measured using the Universal Testing Systems for Tensile, Compression, and Flexure Testing of Instron 5900 Series (Instron, Norwood, MA, USA) at a crosshead speed of 10 mm min

−1. This device is commonly used to measure the strength of samples in cement engineering and other materials. The soil sample was placed at the center of the lower surface of the pressure clamps for pressing small pulses until the graph stabilized after the collapse of the sample. The strength tests were conducted for two groups of geopolymer compositions (

Table 2). (1) Geopolymer with different MK percentage (0–30%) in the soil sample. (2) Metakaolin (MK) based geopolymer with an alternative activation solution, replacing the NaOH with lime (CaO). Different concentrations of CaO were tested, where the measured solubility level of lime at 20 °C (1.79 g L) was taken as a starting point. The amount of lime suspension (in water) used in the activation solution was the same as the NaOH in the origin activation solution, and up to 20-times. The content of the MK was 30% in this group.

3. Results and Discussion

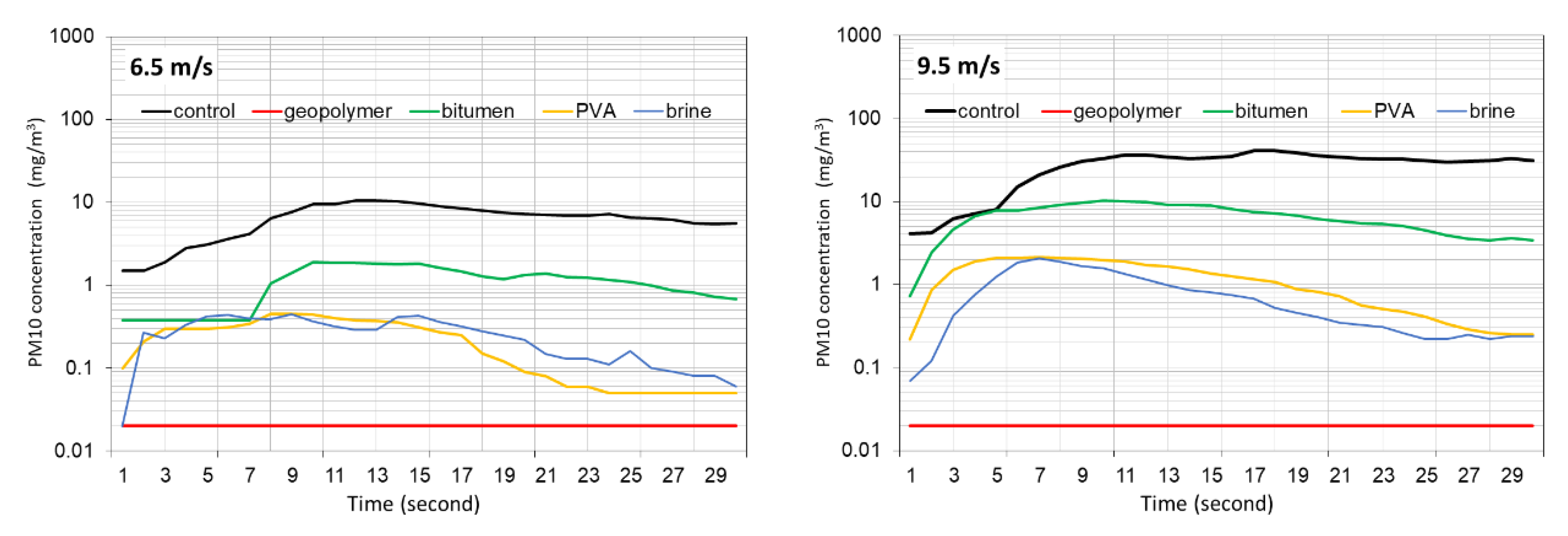

Figure 2 presents the results of the dust emission experiment. The recorded PM10 concentrations are a result of dust emission from the surface of the loess soil samples under two wind velocities. It is clearly shown that no dust emission and PM10 concertation was recorded in the application of the clay-based geolopyler. The “straight” line that was similarly recorded for the two wind velocities in the test of the geopolymer application is a representation of the background level (~20 µg m

−3) measured in the wind tunnel before the test. In all the other applications, bitumen, brine and PVA, the averaged PM10 concentrations were significantly (

p < 0.05) higher than the background level. In general, the PM10 concentrations received for the brine, PVA, and bitumen, were higher under 9 m s

−1 compared with 6.5 m s

−1. The wind velocity OF 9.5 m s

−1 was run promptly after the prior velocity (6.5 m s

−1), and since the amount of dust particles in the soil samples is limited, the dust emission in 9.5 m s

−1 could have been an underestimation for non-limited samples. The PM10 values of the control sample were significantly higher than those of all the other samples in both wind velocities, suggesting that all the applied products are efficient for dust suppression at a certain level. It is interesting to see that the brine, which was found to be very efficient by reducing > 90% of the dust emission in calcareous soils under the same experimental conditions [

8], is less effective in loess soils. The results of the brine are at the range of the PVA. However, the brine is not used for the purpose of soil stabilization as the PVA and the geopoylmers.

Tensile tests were conducted for the geopolymer as a soil stabilizer. The first test was to examine the effect of the MK amount at the range of 0–30% in the geopolymer composition (Group 1,

Table 2). The activation solution (sodium silicate and NaOH) remained in a constant ratio. The results in

Figure 3a show that the soil sample without MK (0%) resulted in resistant of less than 1000 N. Application of MK content at the range of 2.5–10% improved the soil resistant up to 6000 N. A significant change was obtained for samples with MK content at the range 20–30%. These samples resulted in a consistent increase in resistance to pressure when the peaks ranges from ~11,000 N (20% MK) to ~25,000 N (30% MK). Just for comparison, we tested also the PVA as soil stabilizer, which has been used extensively in soil stabilization [

22]. The PVA results after a curing time of 28 days were up to 4200 N. The drying time until significant strength is reached is an important factor when there is a need to stabilize an unpaved road. External factors, such as solar radiation and water regime, can have a great impact on the nature and duration of the soil stabilization. As such, this study examined the hardness of the geopolymer during a short seven-day cure. The geopolymer composition of 30% MK with the activation solution (sodium silicate and NaOH) yielded a result of 15,510 N.

A second tensile test was conducted for geopolymer with replacement of the NaOH with the base of lime (CaO) that is more “natural” soil material (Group 2,

Table 2). The addition of lime is used in applications of soil loess stabilization, e.g., [

23]. The lime improves the cation exchange of the soil and absorbs water, which lowers the pH. Adding lime also affects the structure of the soil through the soil ability to absorb water. The results of the test for soil samples stabilized by the geopolymer with different amounts of CaO in the activation solution are presented in

Figure 3b. The MK content of 30% was constant for all the samples. The resistance increased as the concentration of the lime was higher. This was true up to lime concentration that is 15 (X15) times that of the original concentration (X1). At the highest concentration (X20), the resistance was lower (peak at 6450 N) than in X15 (peak at 7400 N). This can be explained by a rapid and unsteady solidification of the material, which does not allow us to pour the soil mixture into the molds. However, the results of the NaOH in the activation solution (

Figure 3a) are significantly higher than those of the replacement base (CaO) with 30% MK (

Figure 3a).

The results in

Figure 2 and

Figure 3 show the potential of the clay-based geopolymer examined in this study to suppress dust emission and to stabilized loess soil. The application of the geopolymer for dust control in loess soil in comparison with common products (brine, bitumen, PVA) resulted in no dust emission. As a soil stabilizer, the geopolymer tested in this study provides remarkably good results in the tensile test. The most successful composition of the geopolymer, which is activation solution of sodium silicate and NaOH together with an addition of 30% MK, obtained soil strength of 23,900 N after 28 days. The attempt to replace NaOH with CaO in the activation solution was far inferior to the original composition. The factor of relatively rapid firming of the soil after seven days (strength of 15,510 N) is very important in stabilizing unpaved roads.