Ultrasonic VHCF Tests on Very Large Specimens with Risk-Volume Up to 5000 mm3

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Material

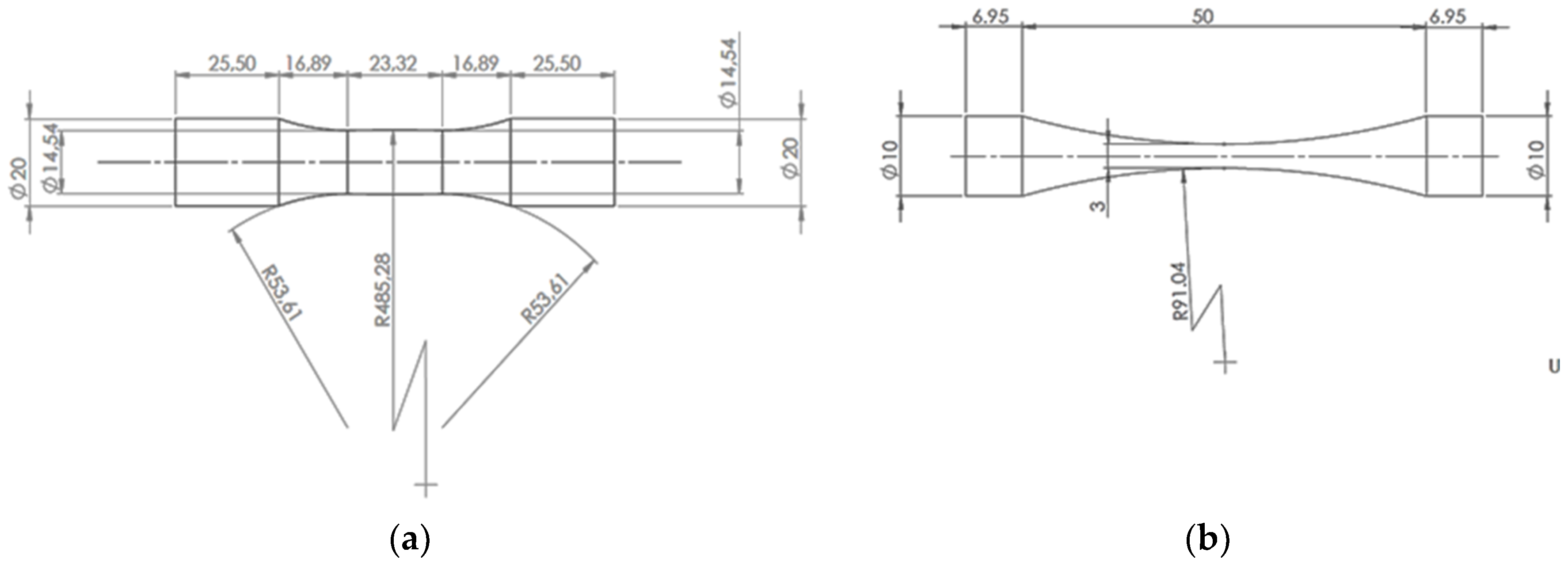

2.2. Gaussian Specimen Design

2.3. Ultrasonic Fatigue Tests

3. Results

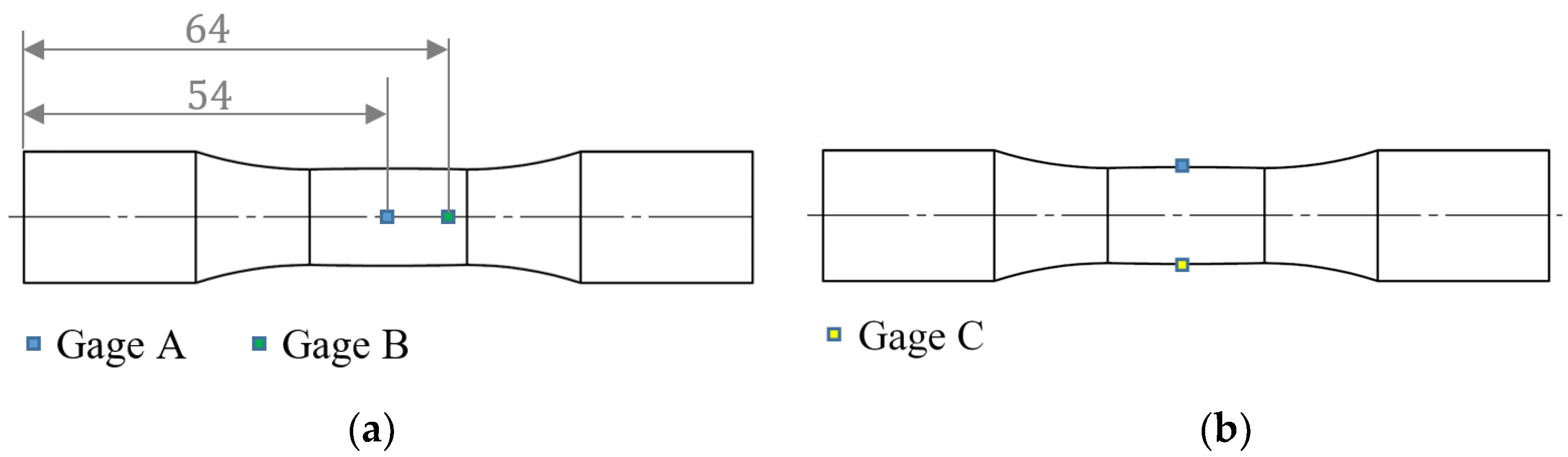

3.1. Experimental Calibration

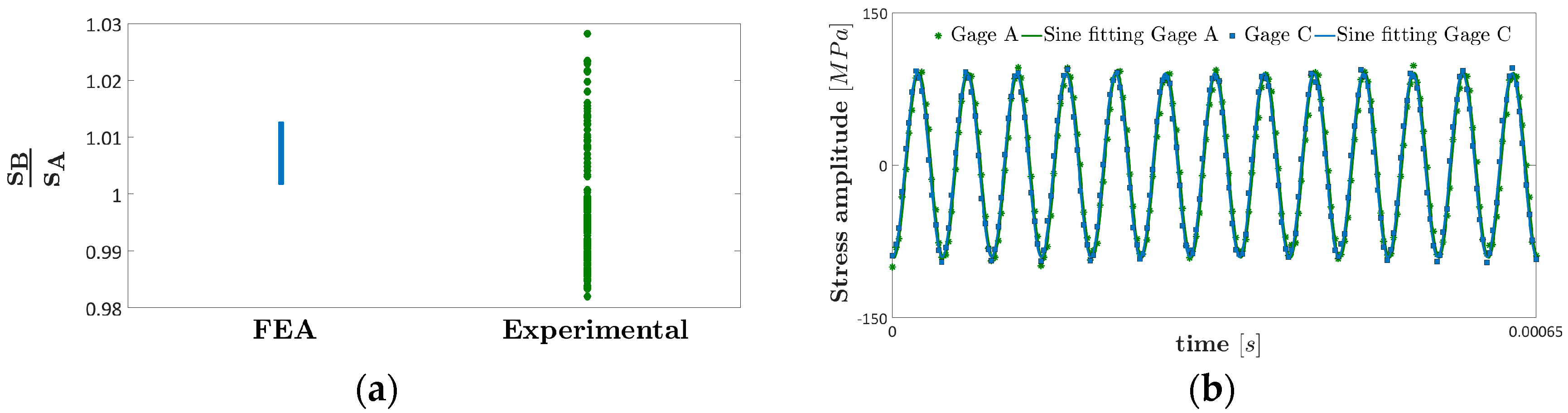

3.2. Experimental Results

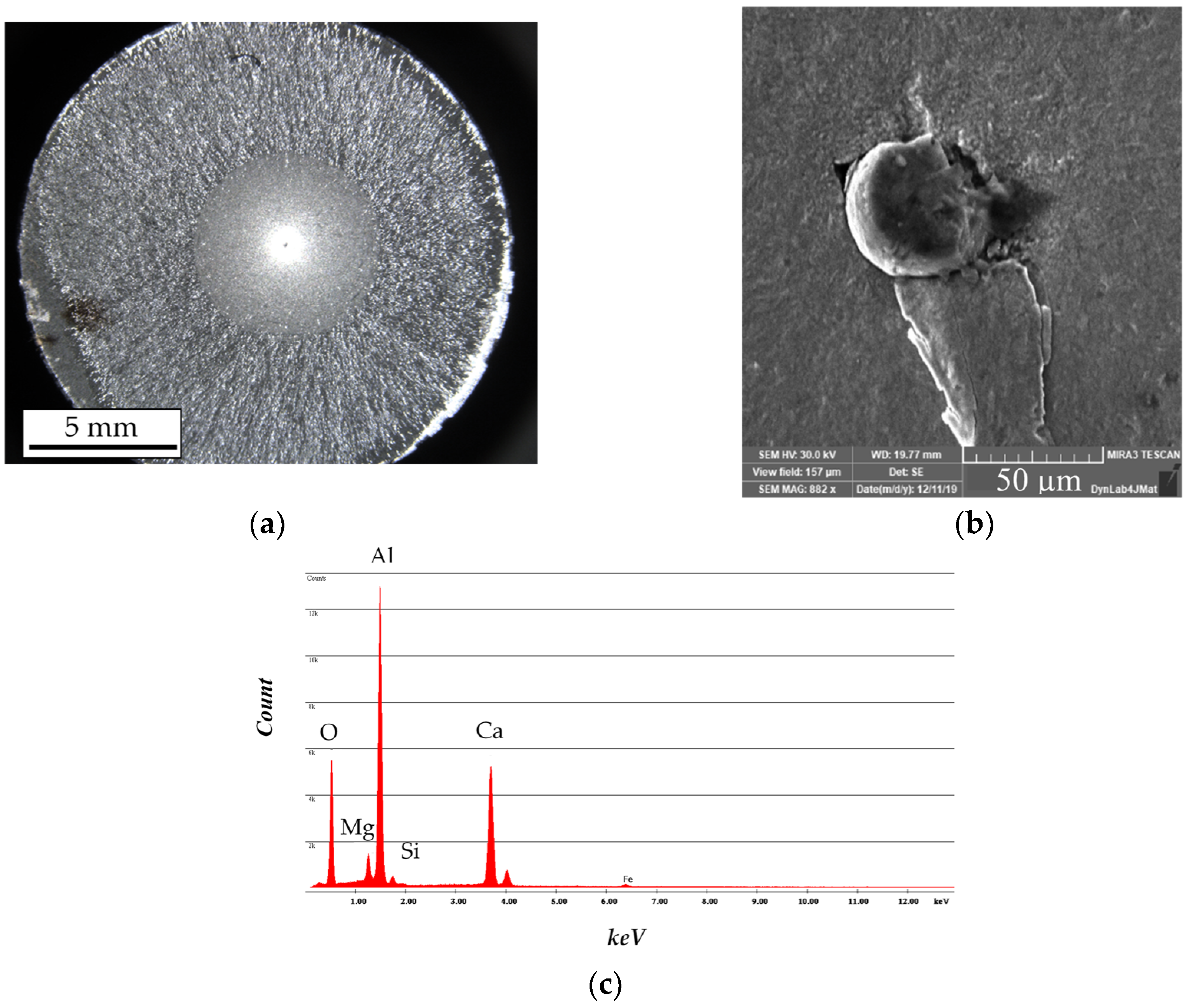

3.3. Fracture Surfaces and Defect Analysis

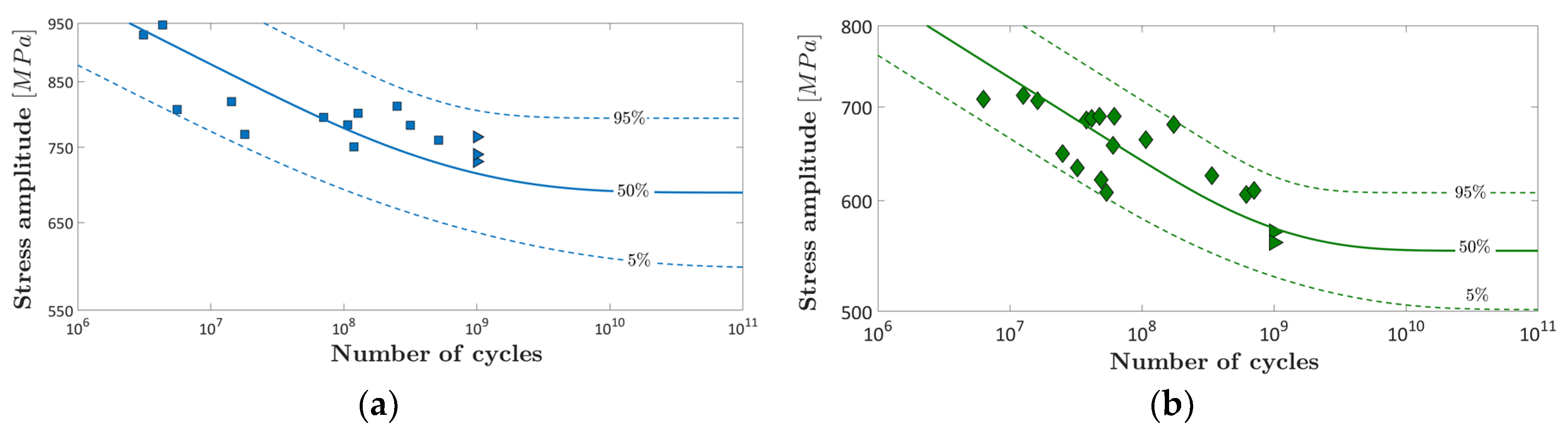

3.4. P–S–N Curves

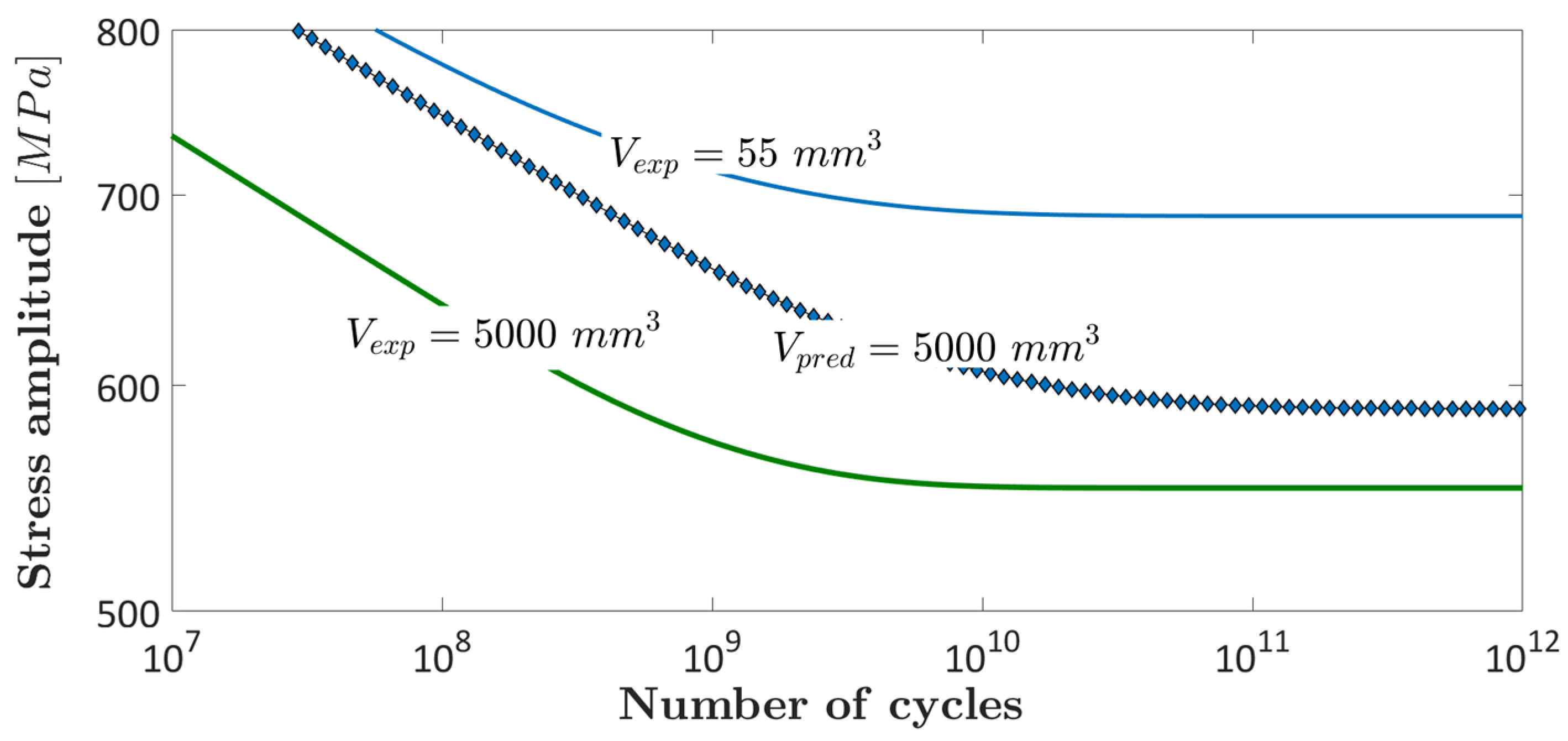

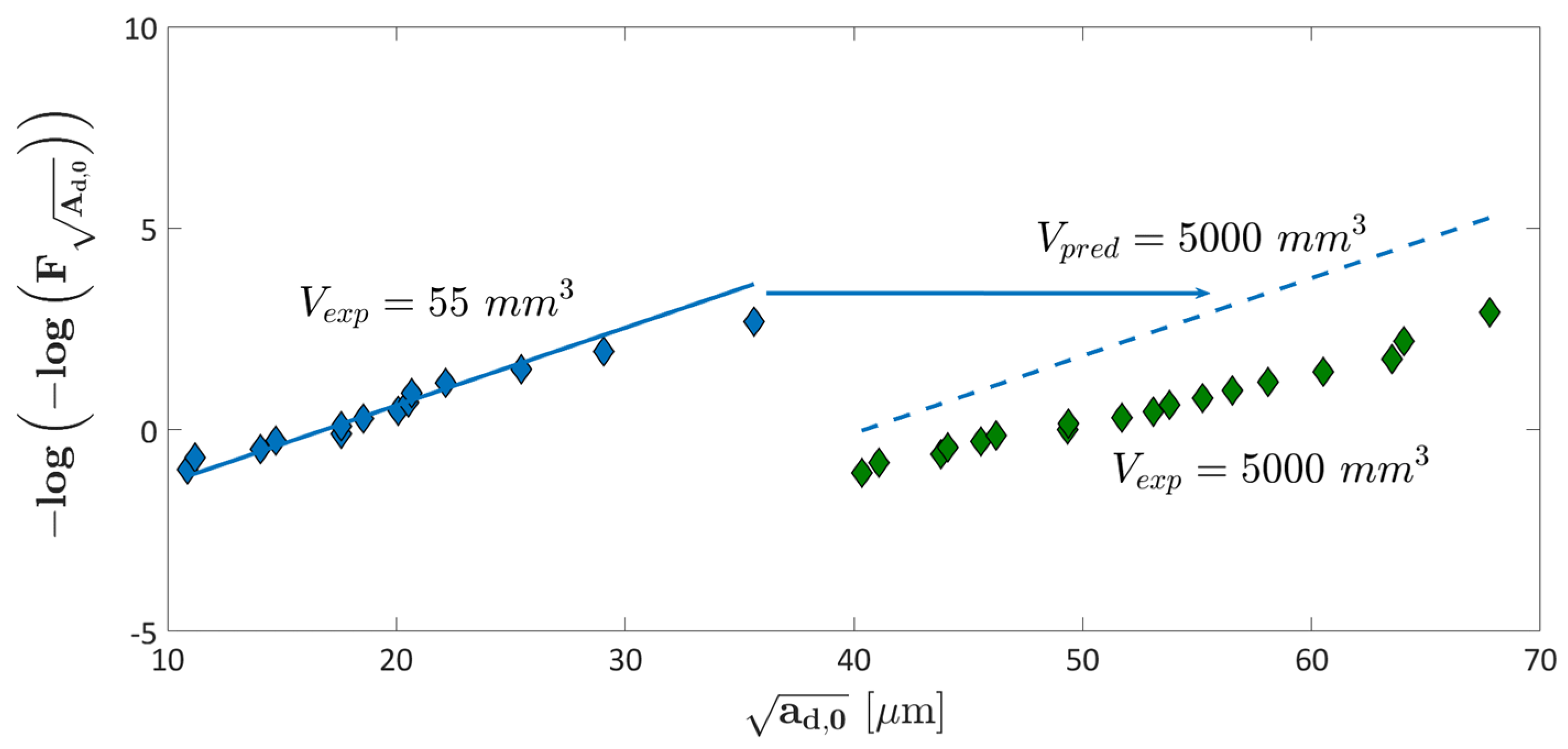

3.5. Size-Effect: Discussion

4. Conclusions

- (1)

- Ultrasonic VHCF tests on Gaussian specimens with very large risk-volumes above 5000 mm3 are feasible. The strain-gage calibration validated the stress distribution assessed through FEA and confirmed that no spurious bending loads are present, even by significantly enlarging the risk-volume.

- (2)

- Fatigue failures were uniformly distributed within the risk-volume in Gaussians specimens, whereas they were more concentrated close to the surface for small hourglass specimens, mainly due to the different stress gradients and stress distributions within the risk-volumes of the two specimen types.

- (3)

- The median P–S–N curve for a risk-volume of 5000 mm3 was predicted by considering the experimental results on hourglass specimens with a statistical model proposed by the authors. The predicted median curve was found to be above the experimental P–S–N curve. The main reason was that the distribution of defects size, assumed to follow a Largest Extreme Value Distribution (LEVD), was not capable of accurately predicting the largest defect for the risk-volume of Gaussian specimens. The prediction error was mainly due to the fact that the estimated LEVD did not take into account the stress gradient within the specimen risk-volume. A statistical distribution of defect size capable of considering the stress gradient would permit us to more properly predict the defect size within the component volume and, accordingly, the VHCF response.

- (4)

- Experimental results pointed out that larger tested risk-volumes lead to a more reliable design against VHCF failures. Very large tested risk-volumes allow for a more proper assessment of the critical defect size and of the P–S–N curves for components in service conditions.

Author Contributions

Funding

Conflicts of Interest

References

- Findley, W.N. An explanation of size effect in fatigue of metals. J. Mech. Eng. Sci. 1972, 14, 424–425. [Google Scholar] [CrossRef]

- Nishida, S. Failure Analysis in Engineering Applications, 1st ed.; Butterworth-Heinemann: Oxford, UK, 1992. [Google Scholar]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions Elsevier, 1st ed.; Elsevier: Oxford, UK, 2002. [Google Scholar]

- Furuya, Y. Notable size effects on very high cycle fatigue properties of high strength steel. Mater. Sci. Eng. 2011, 528, 5234–5240. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Chiandussi, G.; Rossetto, M. Comparison between dog-bone and Gaussian specimens for size effect evaluation in gigacycle fatigue. Frat. Integrità Strutt. 2013, 26, 49–56. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. On specimen design for size effect evaluation in ultrasonic gigacycle fatigue testing. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 570–579. [Google Scholar] [CrossRef]

- Tridello, A. VHCF response of two AISI H13 steels: Effect of manufacturing process and size-effect. Metals 2019, 9, 133. [Google Scholar] [CrossRef]

- Xue, H.; Sun, Z.; Zhang, X.; Gao, T.; Li, Z. Very High Cycle Fatigue of a Cast Aluminum Alloy: Size Effect and Crack Initiation. J. Mater. Eng. Perform. 2018, 27, 5406–5416. [Google Scholar] [CrossRef]

- Tridello, A. VHCF response of Gaussian specimens made of high-strength steels: Comparison between unrefined and refined AISI H13. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1676–1689. [Google Scholar] [CrossRef]

- Bathias, C.; Paris, P.C. Gigacycle Fatigue in Mechanical Practice, 1st ed.; CRC Dekker: New York, NY, USA, 2004. [Google Scholar]

- Lei, Z.; Hong, Y.; Xie, J.; Sun, C.; Zhao, A. Effects of inclusion size and location on very-high-cycle fatigue behavior for high strength steels. Mater. Sci. Eng. 2012, 558, 234–241. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S. Very high cycle fatigue measuring techniques. Int. J. Fatigue 2014, 60, 2–17. [Google Scholar] [CrossRef]

- Tridello, A.; Biffi, C.A.; Fiocchi, J.; Bassani, P.; Chiandussi, G.; Rossetto, M.; Tuissi, A.; Paolino, D.S. VHCF response of as-built SLM AlSi10Mg specimens with large loaded volume. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1918–1928. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. S-N curves in the very-high-cycle fatigue regime: Statistical modeling based on the hydrogen embrittlement consideration. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1319–1336. [Google Scholar] [CrossRef]

- Paolino, D.S.; Chiandussi, G.; Rossetto, M. A unified statistical model for S-N fatigue curves: Probabilistic definition. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 187–201. [Google Scholar] [CrossRef]

- Beretta, S.; Ghidini, A.; Lombardo, F. Fracture mechanics and scale effects in the fatigue of railway axles. Eng. Fract. Mech. 2005, 72, 195–208. [Google Scholar] [CrossRef]

- Sakai, T.; Sato, Y.; Oguma, N. Characteristic S–N properties of high-carbon–chromium–bearing steel under axial loading in long-life fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 765–773. [Google Scholar] [CrossRef]

- Qian, G.; Hong, Y.; Zhou, C. Investigation of high cycle and Very-High-Cycle Fatigue behaviors for a structural steel with smooth and notched specimens. Eng. Fail. Anal. 2010, 17, 1517–1525. [Google Scholar] [CrossRef]

- Spriestersbach, D.; Grad, P.; Kerscher, E. Influence of different non-metallic inclusion types on the crack initiation in high-strength steels in the VHCF regime. Int. J. Fatigue 2014, 64, 114–120. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Mo | V |

|---|---|---|---|---|---|---|

| wt.% | 0.39 | 1.00 | 0.40 | 0.40 | 5.30 | 0.90 |

| Specimen | ||

|---|---|---|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tridello, A.; Paolino, D.S.; Rossetto, M. Ultrasonic VHCF Tests on Very Large Specimens with Risk-Volume Up to 5000 mm3. Appl. Sci. 2020, 10, 2210. https://doi.org/10.3390/app10072210

Tridello A, Paolino DS, Rossetto M. Ultrasonic VHCF Tests on Very Large Specimens with Risk-Volume Up to 5000 mm3. Applied Sciences. 2020; 10(7):2210. https://doi.org/10.3390/app10072210

Chicago/Turabian StyleTridello, Andrea, Davide Salvatore Paolino, and Massimo Rossetto. 2020. "Ultrasonic VHCF Tests on Very Large Specimens with Risk-Volume Up to 5000 mm3" Applied Sciences 10, no. 7: 2210. https://doi.org/10.3390/app10072210

APA StyleTridello, A., Paolino, D. S., & Rossetto, M. (2020). Ultrasonic VHCF Tests on Very Large Specimens with Risk-Volume Up to 5000 mm3. Applied Sciences, 10(7), 2210. https://doi.org/10.3390/app10072210