Electric Vehicle Relay Lifetime Prediction Model Using the Improving Fireworks Algorithm–Grey Neural Network Model

Abstract

1. Introduction

- establish GM (1,5) model to test the temperature, dynamic contact voltage drop peak, static contact voltage drop, dynamic contact resistance duration, and contact bounce time for relay lifetime;

- test the IFWA and FWA by using standard functions; and

- establish the multi-dimensional IFWA-GNN model.

2. Model Establishment

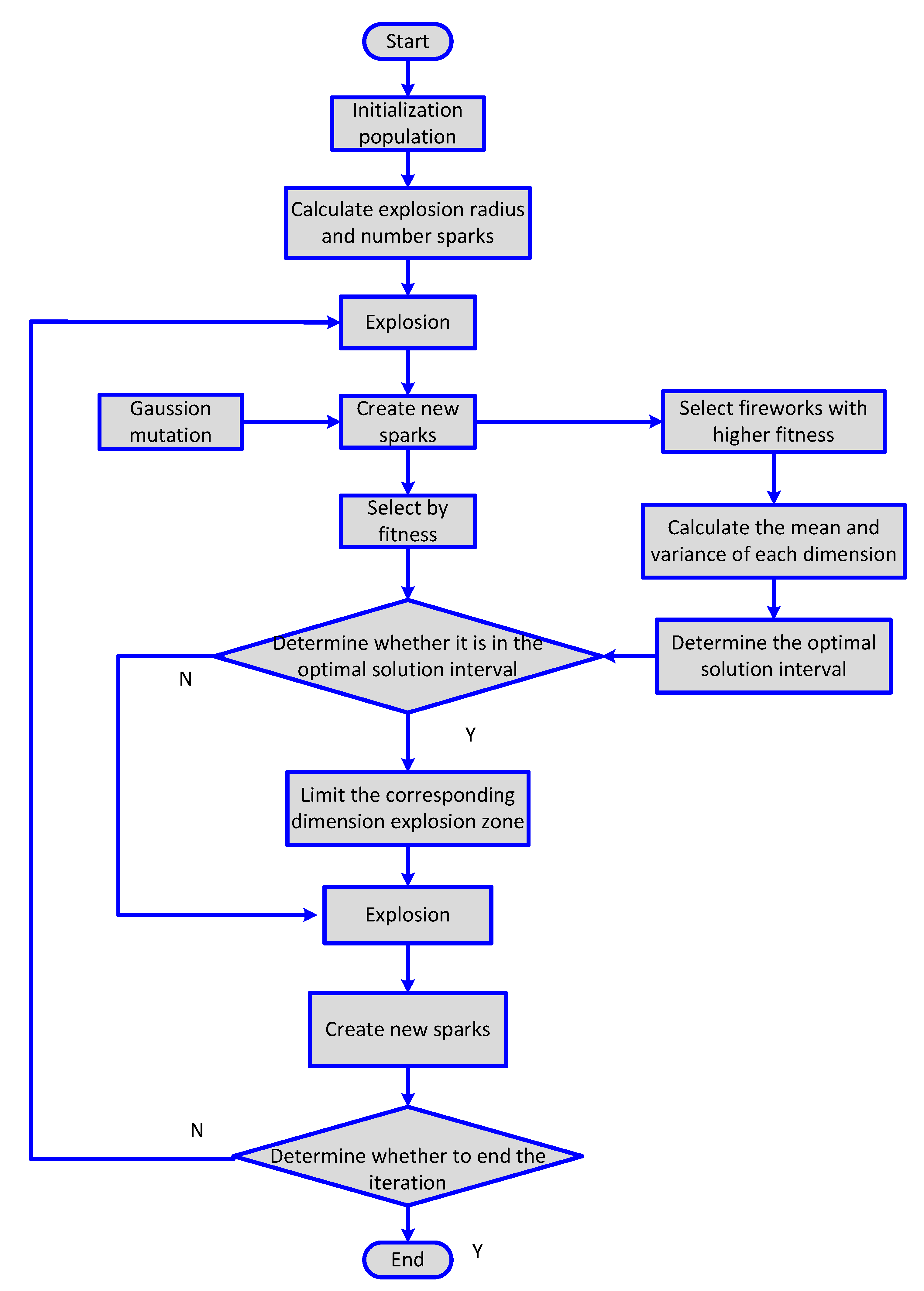

2.1. Fireworks Algorithm and Improved Fireworks Algorithm

- (1)

- The parameters of IFWA are initialized: the number of fireworks, the number of variant sparks, the maximum number of iterations, etc.

- (2)

- The number of sparks and the radius of fireworks explosion are calculated.

- (3)

- The sparks explode, their position is obtained, and the fitness value of sparks is calculated.

- (4)

- The Gauss variation sparks are generated and the fitness value of Gauss sparks is calculated.

- (5)

- The sparks satisfying the conditions are limited to the explosion range and the sparks that do not satisfy the conditions are exploded in the original way.

- (6)

- If the termination condition is not satisfied, go to Step 2. if the result is satisfied, the iteration is terminated.

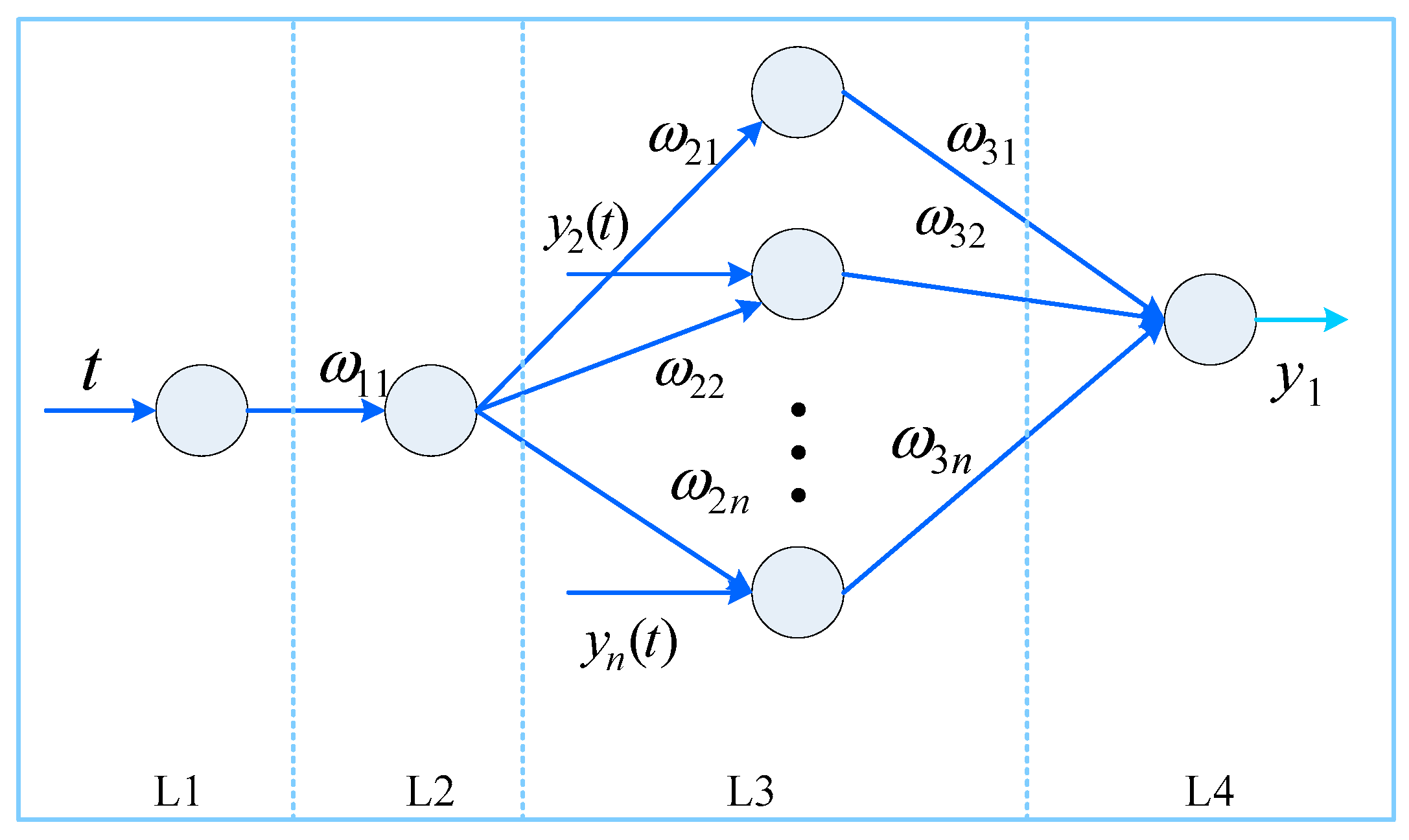

2.2. Multi-dimensional Grey Model and Grey Neural Network Model

2.3. Improved Fireworks Algorithm Optimization Grey Neural Network

- (1)

- The input and output parameters of the predictive model are determined.

- (2)

- The input and output of the model are normalized.

- (3)

- The basic parameters of the fireworks algorithm are initialized: the maximum number of iterations, the number of fireworks, etc.

- (4)

- The IFWA is used to optimize the parameters of GNN model.

- (5)

- The optimized parameters are entered into the GNN model.

- (6)

- The IFWA-GNN model is used to predict the life of relay, and the predicted results are inversely normalized.

- (7)

- The evaluation indicators are used to evaluate the prediction model.

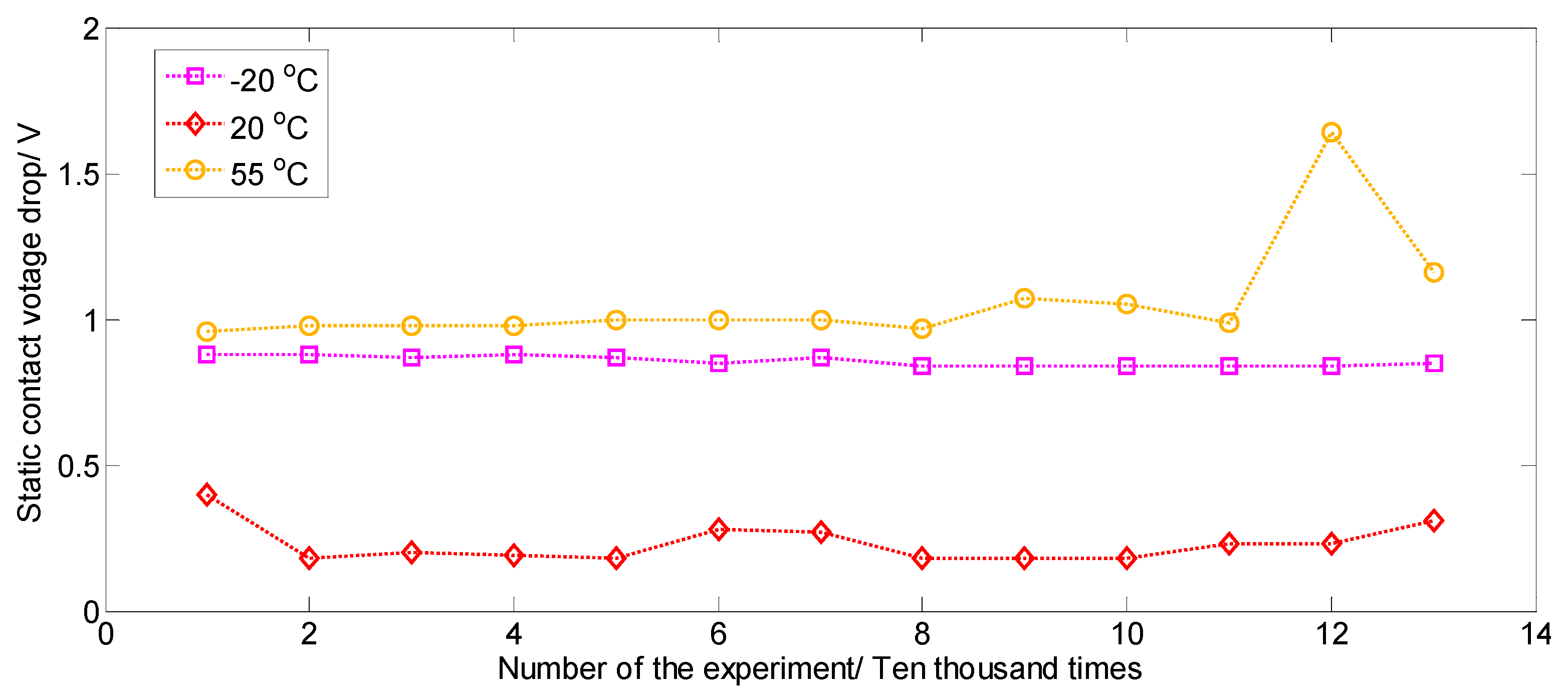

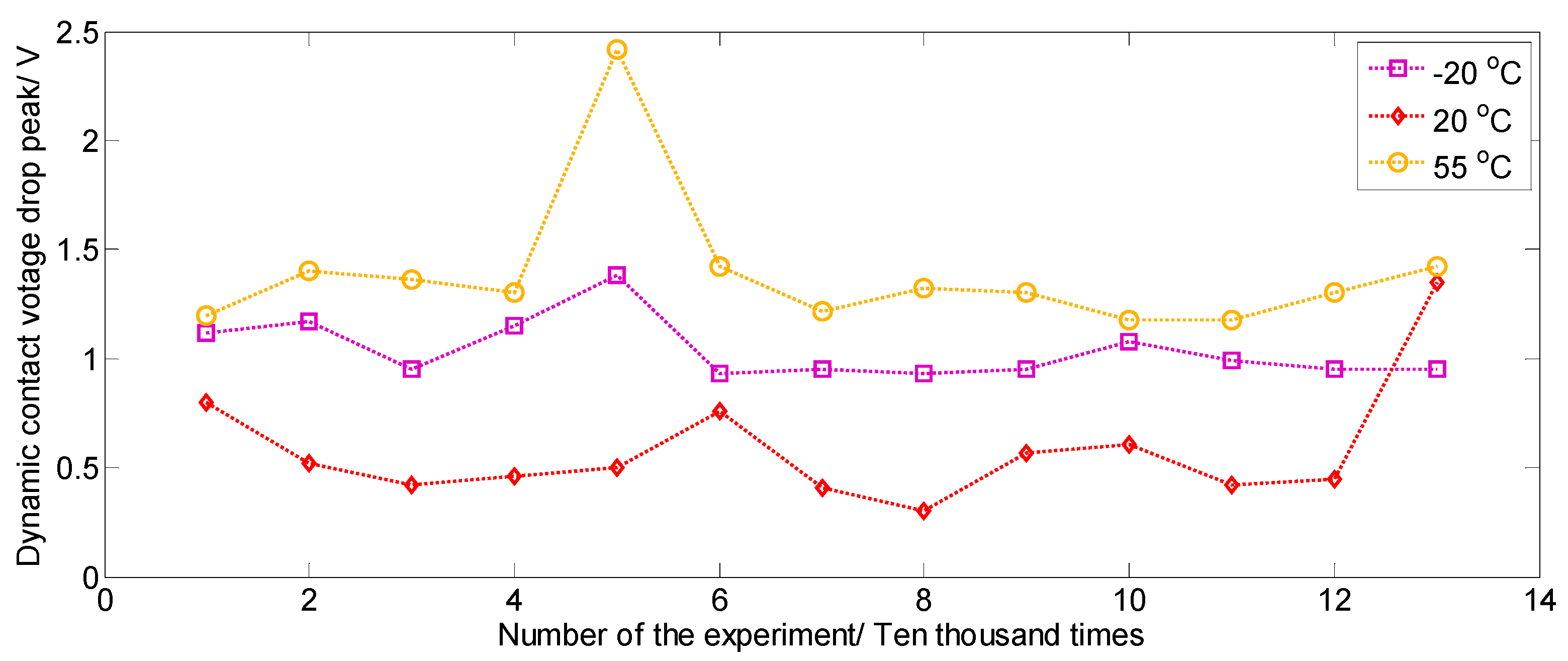

3. The Relay Experiment and Parameters Analysis

3.1. The Relay Experiment

3.2. Parameter Analysis

4. Experiment Results

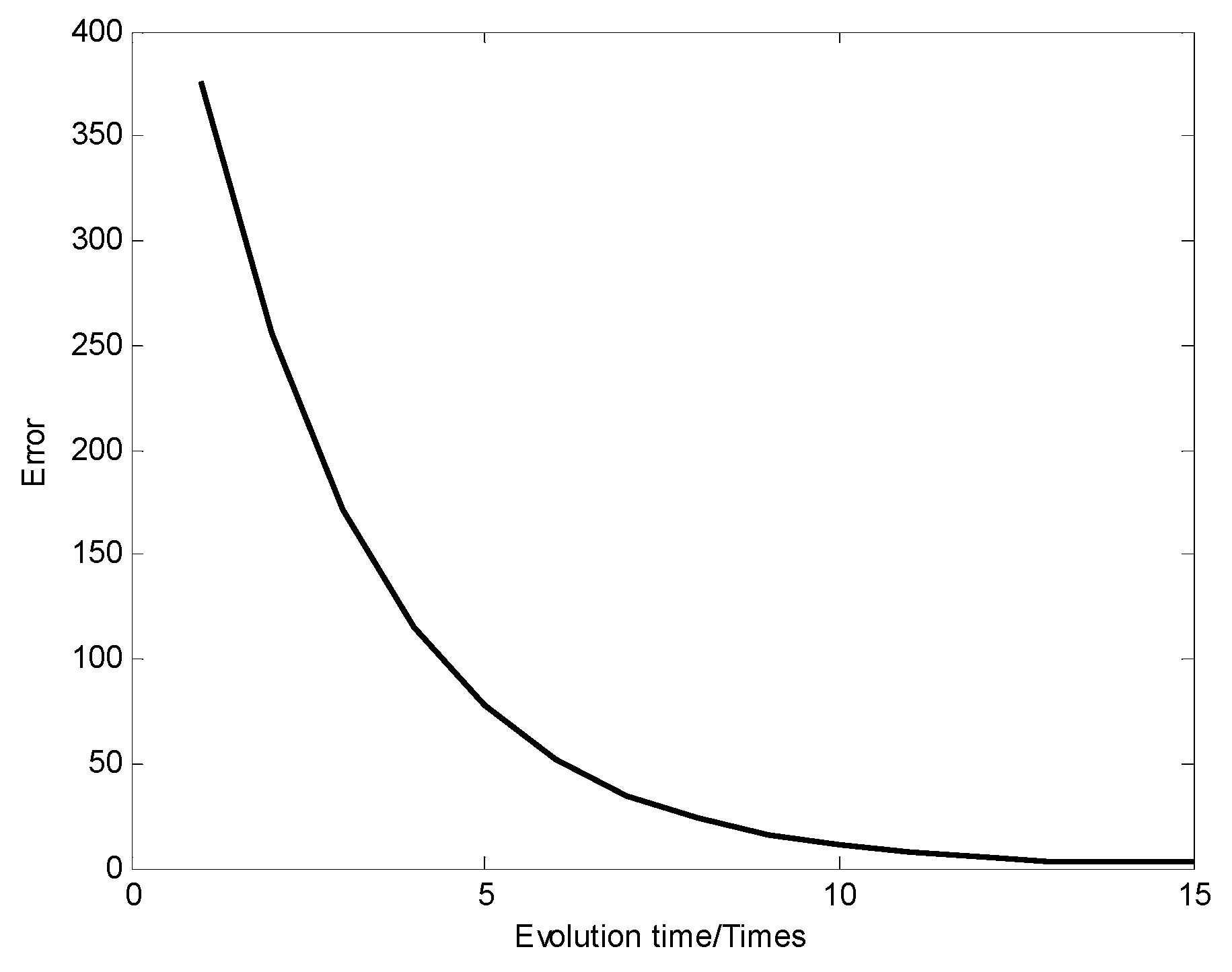

4.1. IFWA Performance Analysis

4.2. Simulation Test Data and Evaluation Index

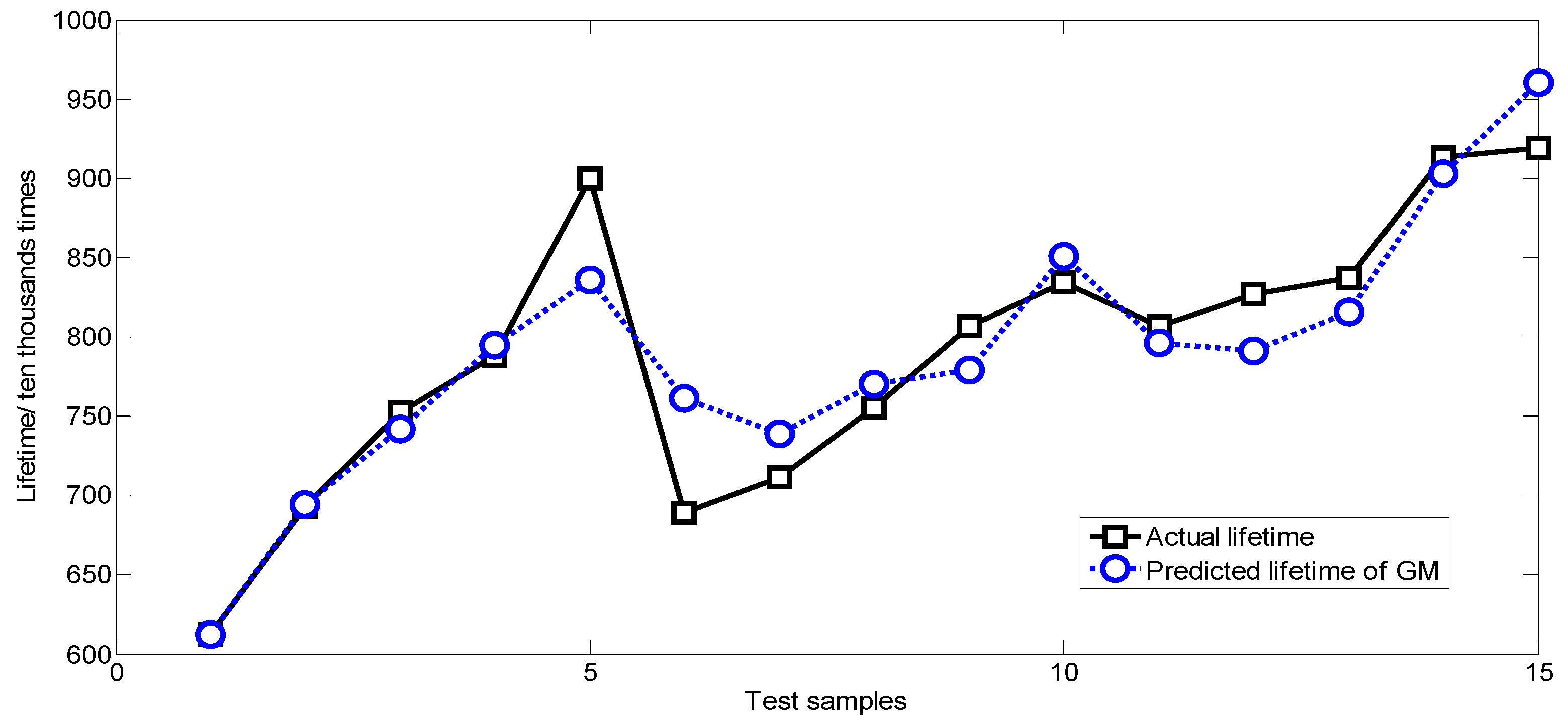

4.3. The Relay Lifetime Prediction Based on Multi-Dimensional GM

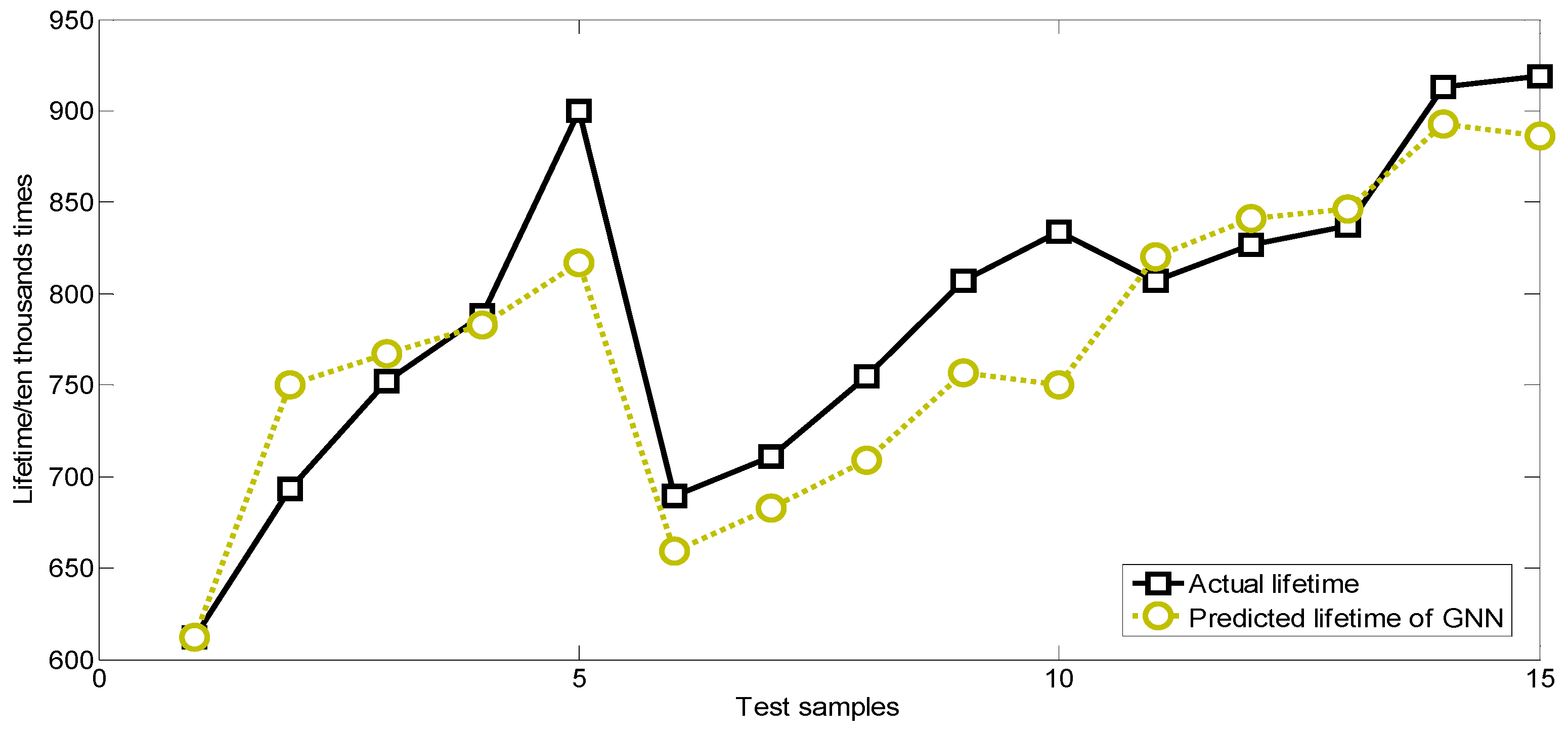

4.4. The Relay Lifetime Prediction Based on GNN Model

4.5. The Relay Lifetime Prediction Based on the IFWA Optimizing GNN Model

4.6. Prediction Effect Evaluation of Each Model

5. Concluding Remarks

- (1)

- The temperature is an important factor affecting the performance parameters of relay, and the parameters are various with the different temperatures. A multi-dimensional grey model is applied to predict the relay lifetime. The five parameters of temperature, contact bounce time , dynamic contact resistance duration , dynamic contact voltage drop peak , and static contact voltage drop are used as initial performance parameters.

- (2)

- IFWA and FWA are tested by three standard test functions. The test results show that the convergence performance of IFWA is better than FWA. IFWA has the shortest running time. For the three standard test functions, the total average run time of the IFWA is 22.04% faster than the FWA.

- (3)

- This paper proposes an IFWA-GNN model. The test results show that the prediction effect of FWA-GNN model is better than the three other models. The AD value of IFWA-GNN model is 14.73% smaller than the AD value of FWA-GNN model; the RMSE value of IFWA-GNN model is 6.75% smaller than the RMSE value of FWA-GNN model.

Author Contributions

Conflicts of Interest

References

- Fang, H.; Wang, B.X.; Song, W.Y. Analyzing the interrelationships among barriers to green procurement in photovoltaic industry: An integrated method. J. Clean. Prod. 2020, 249, 15. [Google Scholar] [CrossRef]

- Li, L.L.; Lin, G.Q.; Tseng, M.L.; Tan, K.H.; Lim, M.K. A Maximum Power Point Tracking Method for Pv System with Improved Gravitational Search Algorithm. Appl. Soft Comput. 2018, 65, 333–348. [Google Scholar] [CrossRef]

- Jeong, J.; Shim, M.; Maeng, J.; Park, I.; Kim, C. An Efficiency-Aware Cooperative Multicharger System for Photovoltaic Energy Harvesting Achieving 14 Efficiency Improvement. IEEE Trans. Power Electron. 2020, 35, 2253–2256. [Google Scholar] [CrossRef]

- Kagra, H.; Sonare, P. On-Line Automatic Measurement of Contact Resistance of Metal to Carbon Relays Used in Railway Signaling. Comput. Intell. Inf. Technol. 2011, 469, 2932–2940. [Google Scholar]

- Wang, Q.; Song, X.X.; Li, R.R. A Novel Hybridization of Nonlinear Grey Model and Linear Arima Residual Correction for Forecasting Us Shale Oil Production. Energy 2018, 165, 1320–1331. [Google Scholar] [CrossRef]

- Xu, Q.M.; Li, X.; Chan, C.Y. A Cost-Effective Vehicle Localization Solution Using an Interacting Multiple Model Unscented Kalman Filters (Imm-Ukf) Algorithm and Grey Neural Network. Sensors 2017, 17, 1431. [Google Scholar] [CrossRef]

- Zhou, J.; Ren, J.; Yao, C. Multi-objective optimization of multi-axis ball-end milling Inconel 718 via grey relational analysis coupled with RBF neural network and PSO algorithm. Measurement 2017, 102, 271–285. [Google Scholar] [CrossRef]

- Uygur, I.; Cicek, A.; Toklu, E.; Kara, R.; Saridemir, S. Fatigue Life Predictions of Metal Matrix Composites Using Artificial Neural Networks. Arch. Metall. Mater. 2014, 59, 97–103. [Google Scholar] [CrossRef]

- Liu, C.X.; Shu, T.; Chen, S.; Wang, S.; Lai, K.K.; Gan, L. An improved grey neural network model for predicting transportation disruptions. Expert Syst. Appl. 2016, 45, 331–340. [Google Scholar] [CrossRef]

- Guo, L.; Li, N.; Jia, F.; Lei, Y.; Lin, J. A recurrent neural network based health indicator for remaining useful life prediction of bearings. Neurocomputing 2017, 240, 98–109. [Google Scholar] [CrossRef]

- Drouillet, C.; Karandikar, J.; Nath, C.; Journeaux, A.C.; Mansori, M.E.; Kurfess, T. Tool life predictions in milling using spindle power with the neural network technique. J. Manuf. Process. 2016, 22, 161–168. [Google Scholar] [CrossRef]

- Xu, N.; Dang, Y.; Gong, Y. Novel grey prediction model with nonlinear optimized time response method for forecasting of electricity consumption in China. Energy 2017, 118, 473–480. [Google Scholar] [CrossRef]

- Zhou, K.P.; Lin, Y.; Deng, H.W.; Li, J.l.; Liu, C.J. Prediction of rock burst classification using cloud model with entropy weight. Trans. Nonferrous Met. Soc. China 2016, 26, 1995–2002. [Google Scholar] [CrossRef]

- Liu, J.Q.; Zhang, M.; Zhao, N.; Chen, A.F. A Reliability Assessment Method for High Speed Train Electromagnetic Relays. Energies 2018, 11, 652. [Google Scholar] [CrossRef]

- Sun, Y.K.; Zhang, Y.Z.; Xu, C.F.; Cao, Y. A Novel Life Prediction Method for Railway Safety Relays Using Degradation Parameters. IEEE Intell. Transp. Syst. Mag. 2018, 10, 48–56. [Google Scholar] [CrossRef]

- Wang, Z.B.; Fu, S.; Shang, S.; Zhai, G.F. Storage Degradation Testing and Life Prediction for Missile Electromagnetic Relay. J. Beijing Univ. Aeronaut. Astronaut. 2016, 42, 2610–2619. [Google Scholar]

- Zhao, Y.H.; Zio, E.; Fu, G.C. Remaining storage life prediction for an electromagnetic relay by a particle filtering-based method. Microelectron. Reliab. 2017, 79, 221–230. [Google Scholar] [CrossRef]

- Li, L.L.; Zhang, S.N.; Li, Z.G.; He, P.J. The Life Prediction Method of Relay Based on Rough Set Theory and Relays Initial Life Information. Trans. China Electrotech. Soc. 2016, 31, 46–53. [Google Scholar]

- Zhai, G.F.; Wang, S.J.; Xu, F.; Liu, M.K. Research on Double-Variable Life Forecasting Based on Model-Building of Super-Path Time and Pick-up Time for Relays. Proc. Chin. Soc. Electr. Eng. 2002, 22, 76–80. [Google Scholar]

- Sun, Y.K.; Zhang, Y.Z.; Xu, C.F.; Cao, Y. Failure Mechanisms Discrimination and Life Prediction of Safety Relay. J. Traffic Transp. Eng. 2018, 18, 138–147. [Google Scholar]

- Liu, Y.B.; He, B.; Liu, F.; Lu, S.L.; Zhao, Y.L.; Zhao, J.W. Remaining Useful Life Prediction of Rolling Bearings Using PSR, JADE, and Extreme Learning Machine. Math. Probl. Eng. 2016, 2016, 13. [Google Scholar] [CrossRef]

- Cheng, Y.; Lu, C.; Li, T.; Tao, L. Residual lifetime prediction for lithium-ion battery based on functional principal component analysis and Bayesian approach. Energy 2015, 90, 1983–1993. [Google Scholar] [CrossRef]

- Tan, Y.; Zhu, Y. Fireworks algorithm for optimization. Int. Conf. Adv. Swarm Intell. 2010, 2010, 355–364. [Google Scholar]

- Zhang, T.; Liu, Z. Fireworks algorithm for mean-VaR/CVaR models. Phys. A Stat. Mech. Appl. 2017, 483, 1–8. [Google Scholar] [CrossRef]

- Babu, T.S.; Ram, J.P.; Sangeetha, K.; Laudani, A.; Rajasekar, N. Parameter extraction of two diode solar PV model using Fireworks algorithm. Solar Energy 2016, 140, 265–276. [Google Scholar] [CrossRef]

- Ren, Y.T.; Qi, H.; He, M.J.; Ruan, S.T.; Ruan, L.M.; Tan, H.P. Application of an improved firework algorithm for simultaneous estimation of temperature-dependent thermal and optical properties of molten salt. Int. Commun. Heat. Mass. Transfer. 2016, 77, 33–42. [Google Scholar] [CrossRef]

- Li, J.M.; Tian, Q.; Zhang, G.Y.; Wu, W.F.; Xue, D.; Li, L.T.; Wang, J.X.; Chen, L. Task Scheduling Algorithm Based on Fireworks Algorithm. EURASIP J. Wirel. Commun. Netw. 2018, 2018, 256. [Google Scholar] [CrossRef]

- Li, J.Z.; Tan, Y. Loser-out Tournament-Based Fireworks Algorithm for Multimodal Function Optimization. IEEE Trans. Evol. Comput. 2018, 22, 679–691. [Google Scholar] [CrossRef]

- Li, B.W.; Zhang, J.; He, Y.; Wang, Y. Short-Term Load-Forecasting Method Based on Wavelet Decomposition with Second-Order Grey Neural Network Model Combined with ADF Test. IEEE Access. 2017, 5, 16324–16331. [Google Scholar] [CrossRef]

- Zhang, J.L.; Li, D.Z.; Hao, Y.; Tan, Z.F. A Hybrid Model Using Signal Processing Technology, Econometric Models and Neural Network for Carbon Spot Price Forecasting. J. Clean. Prod. 2018, 204, 958–964. [Google Scholar] [CrossRef]

- Li, L.L.; Liu, Z.F.; Tseng, M.L.; Chiu, A.S.F. Enhancing the Lithium-Ion Battery Life Predictability Using a Hybrid Method. Appl. Soft Comput. 2019, 74, 110–121. [Google Scholar] [CrossRef]

- Liu, Z.F.; Li, L.L.; Tseng, M.L.; Lim, M.K. Prediction short-term photovoltaic power using improved chicken swarm optimizer-Extreme learning machine model. J. Clean. Prod. 2020, 248, 14. [Google Scholar] [CrossRef]

| Model | HH52P |

|---|---|

| Contact rating | 5A |

| Contact form | 2H, 2D, 2Z |

| Coil power | 0.9W |

| Contact resistance | |

| Insulation resistance | |

| Contact material | Silver alloy |

| Temperature (°C) | Times (Ten Thousands Times) | ||||

|---|---|---|---|---|---|

| −20 | 10 | 0.71 | 0.20 | 1.12 | 0.88 |

| −20 | 50 | 0.44 | 0.69 | 1.17 | 0.88 |

| −20 | 100 | 1.49 | 0.22 | 0.95 | 0.87 |

| −20 | 150 | 0.91 | 0.62 | 1.15 | 0.88 |

| −20 | 200 | 0.57 | 0.69 | 1.38 | 0.87 |

| −20 | 250 | 0.50 | 0.76 | 0.93 | 0.85 |

| −20 | 300 | 0.51 | 1.39 | 0.95 | 0.87 |

| −20 | 350 | 1.06 | 0.75 | 0.93 | 0.84 |

| −20 | 400 | 0.69 | 1.28 | 0.95 | 0.84 |

| −20 | 450 | 0.54 | 1.08 | 1.08 | 0.84 |

| −20 | 500 | 0.49 | 1.12 | 0.99 | 0.84 |

| −20 | 550 | 0.69 | 1.28 | 0.95 | 0.84 |

| −20 | 600 | 0.82 | 0.67 | 0.95 | 0.85 |

| Temperature (°C) | Times (Ten Thousands Times) | ||||

|---|---|---|---|---|---|

| 20 | 10 | 1.01 | 0.88 | 0.80 | 0.4 |

| 20 | 50 | 0.35 | 1.24 | 0.52 | 0.18 |

| 20 | 100 | 0.42 | 0.60 | 0.42 | 0.20 |

| 20 | 150 | 0.43 | 0.94 | 0.46 | 0.19 |

| 20 | 200 | 0.41 | 0.65 | 0.50 | 0.18 |

| 20 | 250 | 0.55 | 1.96 | 0.76 | 0.28 |

| 20 | 300 | 0.82 | 0.55 | 0.41 | 0.27 |

| 20 | 350 | 0.78 | 0.57 | 0.30 | 0.18 |

| 20 | 400 | 0.42 | 0.76 | 0.57 | 0.18 |

| 20 | 450 | 0.76 | 0.31 | 0.61 | 0.18 |

| 20 | 500 | 0.85 | 3.34 | 0.42 | 0.23 |

| 20 | 550 | 0.81 | 1.29 | 0.45 | 0.23 |

| 20 | 600 | 0.88 | 2.00 | 1.35 | 0.31 |

| Temperature (°C) | Times (Ten Thousands Times) | ||||

|---|---|---|---|---|---|

| 55 | 10 | 0.34 | 0.86 | 1.20 | 0.96 |

| 55 | 50 | 0.53 | 0.55 | 1.40 | 0.98 |

| 55 | 100 | 0.55 | 0.23 | 1.36 | 0.98 |

| 55 | 150 | 0.49 | 0.32 | 1.30 | 0.98 |

| 55 | 200 | 1.54 | 0.65 | 2.42 | 1.00 |

| 55 | 250 | 0.41 | 0.42 | 1.42 | 1.00 |

| 55 | 300 | 0.49 | 0.26 | 1.22 | 1.00 |

| 55 | 350 | 0.57 | 2.38 | 1.32 | 0.97 |

| 55 | 400 | 0.46 | 1.38 | 1.30 | 1.07 |

| 55 | 450 | 0.36 | 1.39 | 1.18 | 1.05 |

| 55 | 500 | 0.36 | 0.69 | 1.18 | 0.99 |

| 55 | 550 | 0.46 | 1.38 | 1.30 | 1.64 |

| 55 | 600 | 0.36 | 0.62 | 1.42 | 1.16 |

| Test Function | Optimal Value | Range of Values |

|---|---|---|

| 0 | [−100, 100] | |

| 0 | [−10, 10] | |

| 0 | [−5.12, 5.12] |

| Algorithm | Parameters |

| FWA | Itera = 2000, D = 100, SeedN = 5, SonN = 50, MutaN = 5, Amp = 0.5, SparksmaxN = 40, SparksminN = 2 |

| IFWA | Itera = 2000, D = 100, SeedN = 5, SonN = 50, MutaN = 5, Amp = 0.5, SparksmaxN = 40, SparksminN = 2 |

| Y | Algorithm | Optimal Value | The Worst Value | Average Value | Average Running Time of Program (s) |

|---|---|---|---|---|---|

| Y1 | FWA | 4.51 × 10−21 | 2.88 × 10−6 | 2.11 × 10−7 | 1.14 |

| IFWA | 2.20 × 10−32 | 8.59 × 10−25 | 5.81 × 10−26 | 0.86 | |

| Y2 | FWA | 7.79 × 10−10 | 1.51 × 10−5 | 4.21 × 10−6 | 0.98 |

| IFWA | 1.74 × 10−16 | 1.69 × 10−13 | 2.07 × 10−14 | 0.77 | |

| Y3 | FWA | 1.77 × 10−15 | 5 × 10−2 | 3.8 × 10−3 | 1.01 |

| IFWA | 0 | 0 | 0 | 0.88 |

| Lifetime (Ten Thousands Times) | Temperature (°C) | ||||

|---|---|---|---|---|---|

| 612 | −20 | 0.54 | 0.63 | 0.67 | 0.90 |

| 693 | −20 | 0.71 | 0.20 | 0.91 | 0.88 |

| 752 | −20 | 0.43 | 0.69 | 1.12 | 0.88 |

| 788 | −20 | 0.92 | 0.69 | 1.61 | 0.88 |

| 900 | −20 | 1.89 | 0.69 | 2.58 | 0.91 |

| 689 | 20 | 0.95 | 0.20 | 1.15 | 0.04 |

| 711 | 20 | 0.71 | 0.48 | 1.19 | 0.13 |

| 755 | 20 | 0.55 | 0.84 | 1.39 | 0.18 |

| 807 | 20 | 1.01 | 0.88 | 1.89 | 0.40 |

| 834 | 20 | 0.73 | 1.30 | 2.03 | 0.22 |

| 807 | 55 | 0.50 | 0.25 | 0.75 | 1.02 |

| 827 | 55 | 0.40 | 0.62 | 1.02 | 1.02 |

| 837 | 55 | 0.34 | 0.86 | 1.20 | 0.96 |

| 913 | 55 | 0.36 | 1.39 | 1.75 | 1.05 |

| 919 | 55 | 0.59 | 1.29 | 1.88 | 1.00 |

| Dimension Variate | a | b1 | b2 | b3 | b4 | b5 |

|---|---|---|---|---|---|---|

| Standard deviation | 0.0610 | 0.0826 | 0.0378 | 0.0257 | 0.0718 | 0.0695 |

| Mean value | 0.4889 | 0.3674 | 0.4158 | 0.4418 | 0.4824 | 0.3645 |

| No | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| FWA | 2.45% | 2.41% | 3.68% | 2.31% | 2.89% | 2.69% | 2.48% | 2.41% | 3.09% | 2.61% |

| IFWA | 2.38% | 2.22% | 2.32% | 2.25% | 2.62% | 2.30% | 1.96% | 2.12% | 2.16% | 2.05% |

| Model | AD | RMSE | R2 |

|---|---|---|---|

| GM | 24.06 | 31.78 | 0.86 |

| GNN | 32.46 | 41.37 | 0.81 |

| FWA-GNN | 19 | 22.21 | 0.98 |

| IFWA-GNN | 16.2 | 20.71 | 0.98 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, X.; Li, Z.; Tseng, M.-L.; Liu, K.; Tan, K.; Li, H. Electric Vehicle Relay Lifetime Prediction Model Using the Improving Fireworks Algorithm–Grey Neural Network Model. Appl. Sci. 2020, 10, 1940. https://doi.org/10.3390/app10061940

Pang X, Li Z, Tseng M-L, Liu K, Tan K, Li H. Electric Vehicle Relay Lifetime Prediction Model Using the Improving Fireworks Algorithm–Grey Neural Network Model. Applied Sciences. 2020; 10(6):1940. https://doi.org/10.3390/app10061940

Chicago/Turabian StylePang, Xuelian, Zhuo Li, Ming-Lang Tseng, Kaihua Liu, Kimhua Tan, and Hengyi Li. 2020. "Electric Vehicle Relay Lifetime Prediction Model Using the Improving Fireworks Algorithm–Grey Neural Network Model" Applied Sciences 10, no. 6: 1940. https://doi.org/10.3390/app10061940

APA StylePang, X., Li, Z., Tseng, M.-L., Liu, K., Tan, K., & Li, H. (2020). Electric Vehicle Relay Lifetime Prediction Model Using the Improving Fireworks Algorithm–Grey Neural Network Model. Applied Sciences, 10(6), 1940. https://doi.org/10.3390/app10061940