1. Introduction

As the exploitation of offshore oil and gas expands into deep water and regions with strong ocean currents, the significance of vortex-induced vibration (VIV) has attracted the attention of engineers. However, some grave engineering problems are due mainly to VIV, similar to fatigue failure on submarine pipelines. Therefore, the prediction of the hydrodynamic forces on an oscillating cylinder is still paramount to the design of the structures. Numerical and experimental studies on the flow around a cylinder oscillating in the fluid have always been the focus of related studies for many years. However, it is still a significant primary task because of the complexity of flow characteristics. At present, one of the common methods to determine the VIV phenomenon is a circular cylinder that is forced to oscillate with a preset motion including an excitation amplitude (A) and a frequency (fe) approximating VIV. Given the richness of the research on VIV, only a forced oscillating cylinder problem is included in the following discussion.

Bishop et al. conducted an experimental study on the hydrodynamic forces acting on a circular cylinder and found that an abrupt jump existed in the phase angle between the cylinder motion and the lift force when the oscillation frequency (

fe) approximately equaled the natural shedding frequency (

fs) of the stationary cylinder [

1]. In addition, the average amplitude of the lift and drag increased when the frequency ratio satisfied

fe/

fs ≈ 1. This condition is also known as a “lock-in” phenomenon, which signifies that the vortex shedding frequency of the oscillating cylinder (

fv) primarily depends on the oscillation frequency

fe, i.e.,

fv =

fe. Additionally, it also means that the vortex shedding frequency

fv is no longer determined by the Strouhal number (

St).

Williamson and Rishko studied the flow characteristics of a circular cylinder at various Reynolds numbers (

Re),

Re = 300 to 1000 [

2] and obtained three main vortex shedding modes that existed in their experiments when meeting

fe/

fs ≈ 1, including 2S, 2P, and P + S modes. The 2S mode signifies two single vortices shed per oscillation cycle, which is also the natural Kármán mode of shedding. The 2P mode indicates two count-rotating vortex pairs formed per oscillation cycle, and the P + S asymmetric mode shows a vortex pair on one side and a single vortex on the other side. Moreover, the vortex shedding mode changes from 2P to 2S when

fe/

fs increased through unity. Morse and Willamson experimentally investigated the amplitude-response prediction of a forced oscillation with much higher resolution. In a high-amplitude regime, they found two vortex shedding modes overlap at

Re = 4000 and 12,000 [

3]. This vortex formation mode includes two vortex pairs per oscillation cycle. Importantly, the primary vortex in each vortex pair is stronger than the secondary, which also is recognized as a 2P overlap mode (2P

0) in the condition of

fe/

fs ≈ 1.

Carberry et al. researched the wake state by using controlled oscillation experiments based on amplitude-to-cylinder ratios (

A/

D) that increased from 0.25 to 0.6 at

Re = 2300, 4410, and 9100 [

4], where

D is the cylinder diameter. The high- and low-frequency wake states showed the 2S and 2P modes, respectively, which also impacted the near wake structure and the lift. The high- and low-frequency wake states were transited through an intermediate wake state. Pastrana et al. conducted a high-fidelity large-eddy simulation (LES) study to investigate the two-degree-of-freedom (2DOF) VIV phenomenon of a low mass ratio circular cylinder at

Re = 3900, 5300, and 11000 [

5,

6]. Their simulations presented that a 2T vortex formation mode, namely two triplets of vortices per cycle, was an inherent feature of the flow in the super-upper branch. Marble et al. experimentally studied the wake development of a stationary cylinder and the VIV of a pivoted cylinder with elliptical trajectories at a fixed

Re = 3027. Their experiments showed that the wake topology of a 2DOF VIV with different amplitudes significantly deviated from the shedding map of an one-degree-of-freedom (1DOF) forced VIV originated from Morse and Williamson [

7,

8].

Blackburn and Henderson adopted two-dimensional (2D) direct numerical simulations (DNSs) to study the hydrodynamic forces acting on a circular cylinder at

Re = 500 [

9]. They found that the lift exhibited a variation when the wake vortex changed. However, the state of the wake mode was not reported in their research. Dong and Karniadakis et al. performed a three-dimensional (3D) DNS of a forced oscillating cylinder at

Re = 10,000 [

10]. Their simulation effectively predicted the lift and drag coefficients through a comparison with the experimental results, but the wake structure was also not illustrated in their study. Although the 2D simulation has some limitations, it has been extensively employed in high Reynolds number VIV studies [

10]. Atluri et al. studied the effect of a modulated excitation frequency on a forced oscillating cylinder at

Re = 500 to 8000 by using an extensive 2D LES and qualitatively validated their conclusion through a comparison with the experimental data [

11]. To accurately simulated the VIV phenomenon, numerical simulation commonly was restricted to low Reynolds numbers. This was caused by the fact that a large number of computational resources and additional modeling works needed to be invested to reasonably describe the flow regime beyond the laminar flow [

12,

13,

14].

Significant improvements have been made to address the difficulties in numerical simulations of the VIV phenomenon. Currently LESs are increasingly applied to calculate the separation flows at subcritical, critical, and supercritical Reynolds numbers. [

5,

15,

16] The LES method can accurately solve the large-eddy structures, because the transient large-scale turbulent motions are explicitly calculated. However, the LES method is usually not computationally feasible, since it is sensitive to the grid resolution requirement near the wall when the global flow dynamics is significantly impacted by the attached boundary layers. Additionally, LES often requires more computing resources [

17]. To reduce the computational cost, hybrid turbulence modeling methods have been extensively developed, such as a very LES (VLES) method. The VLES method has also been used in an unsteady flow to handle the transient dynamics of a separated flow [

18].

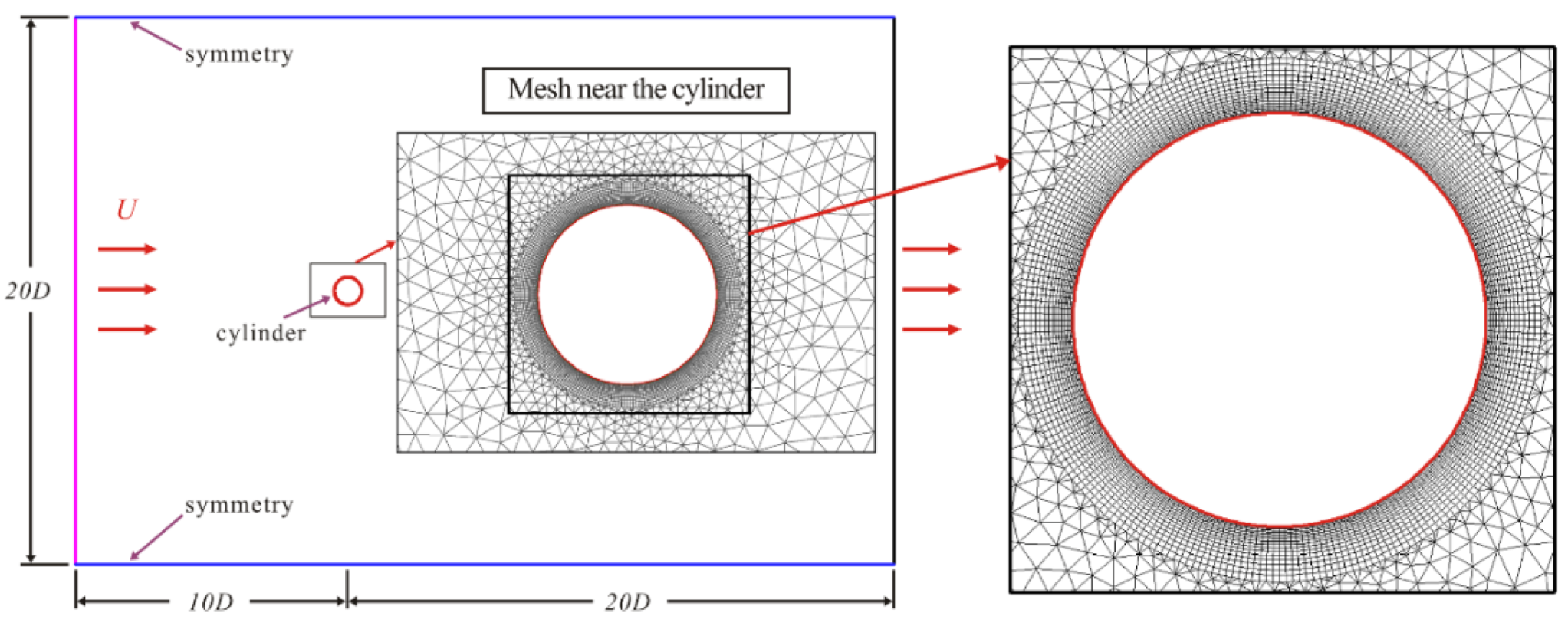

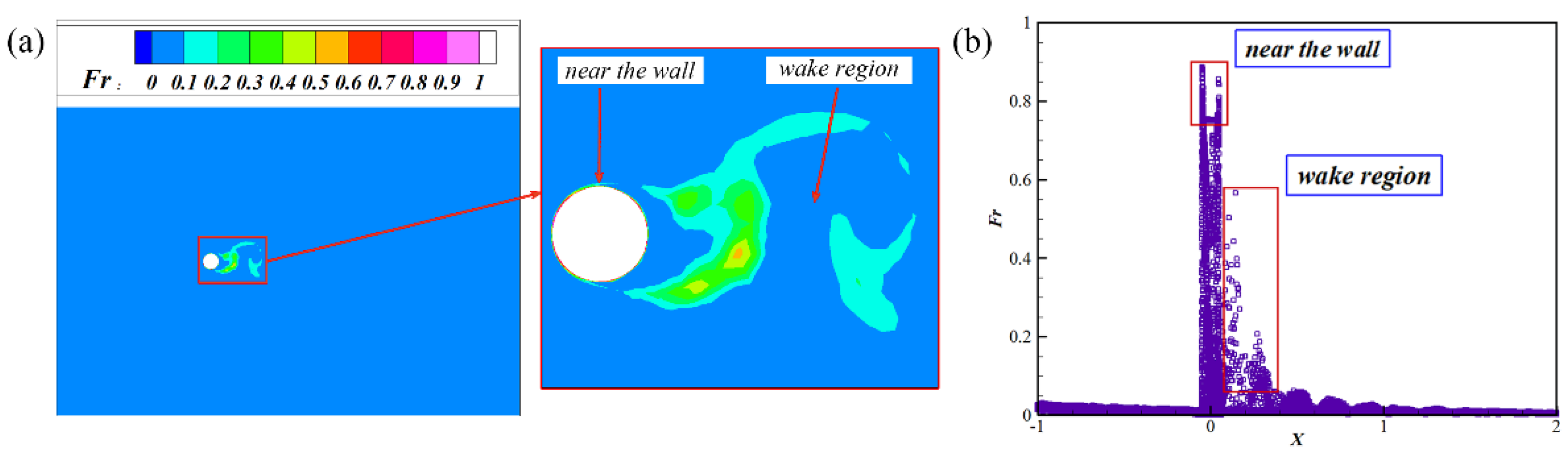

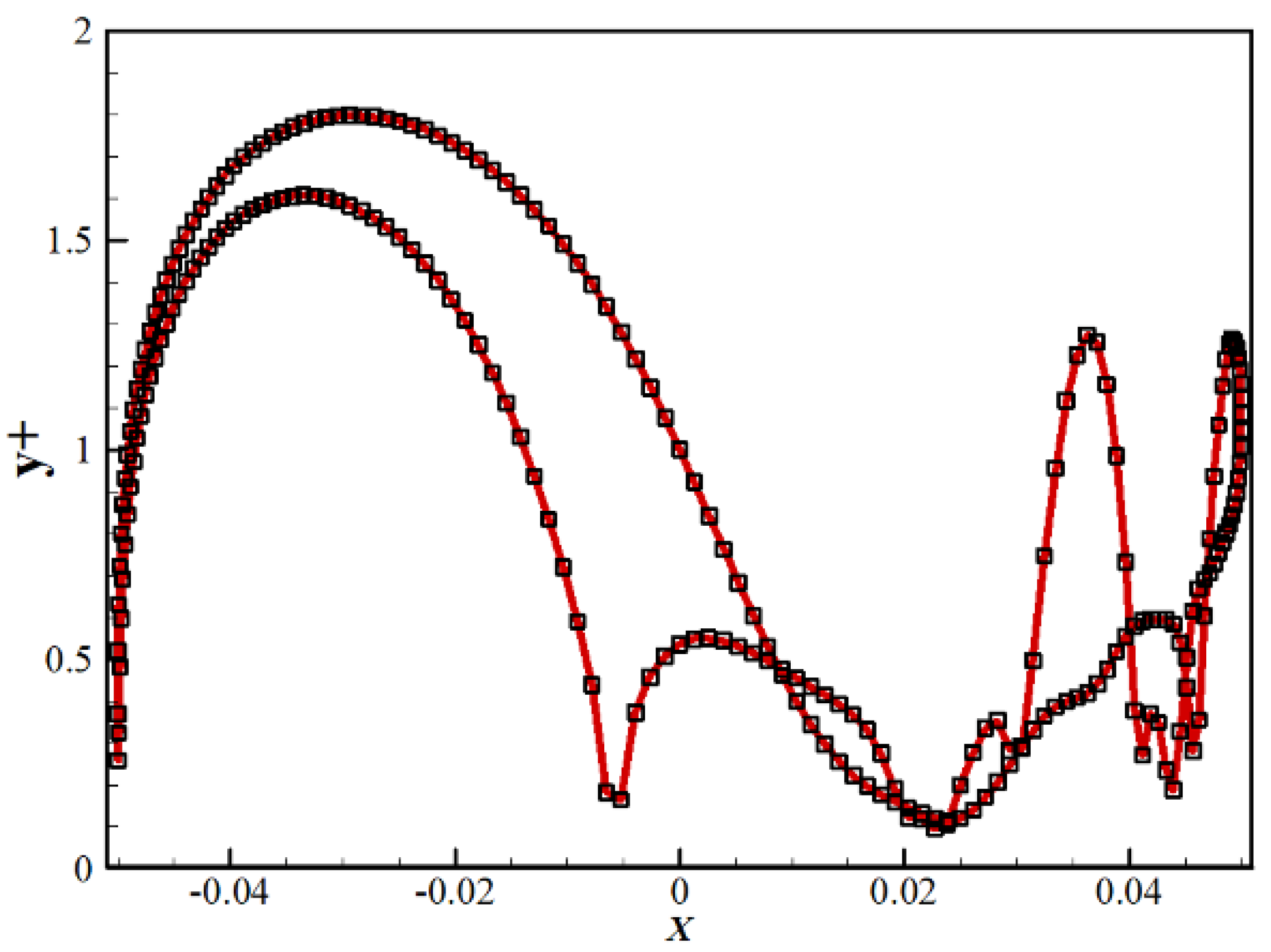

In this paper, a high-efficiency VLES method is used to simulate the VIV phenomenon of the oscillating cylinder at a subcritical Reynolds number Re = 4000 combined with the dynamic grid technique.

3. Results and Discussion

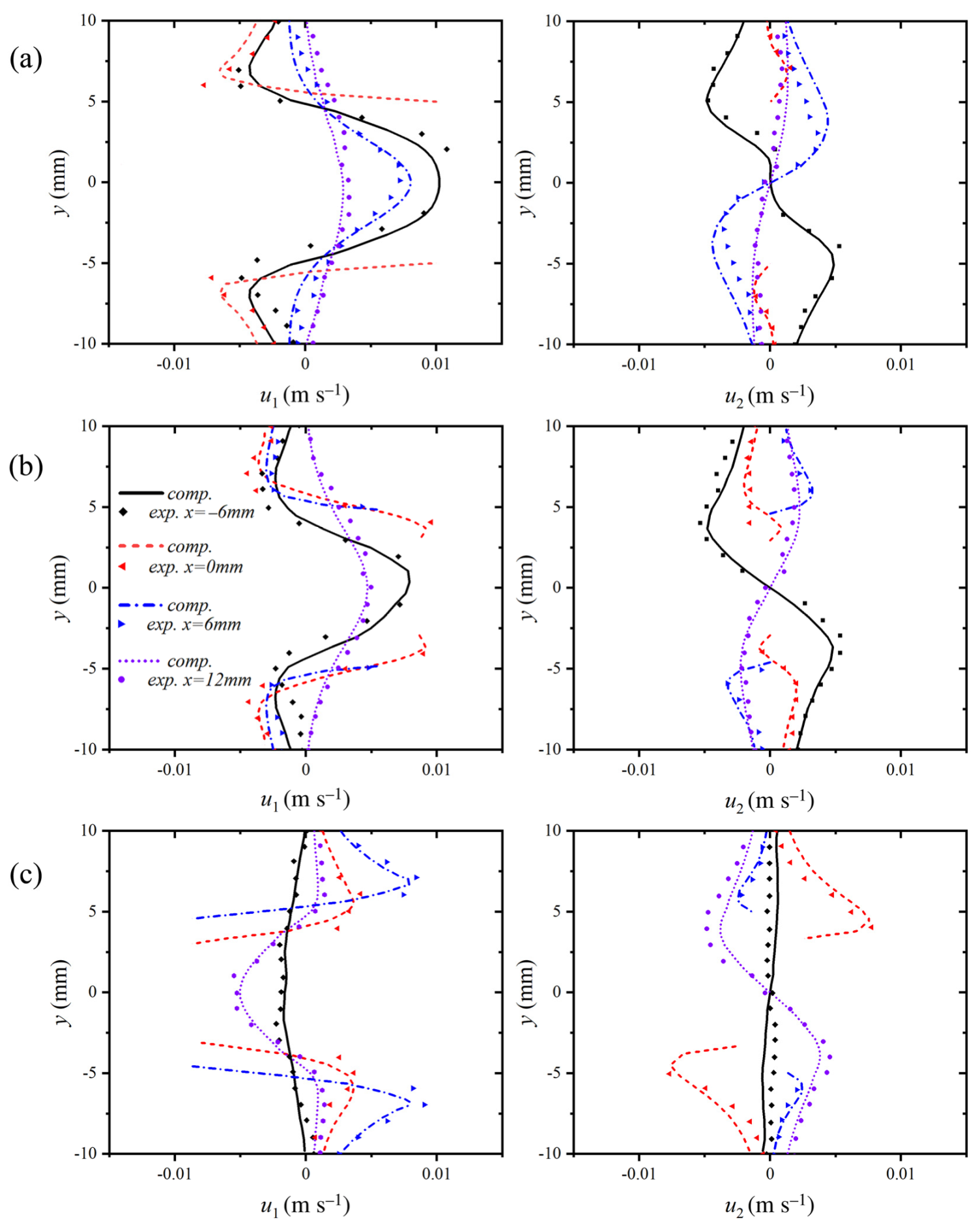

To illustrate the VIV characteristics of the oscillating cylinder at

Re = 4000, we conducted a series of simulations for

A/

D = 0.5 to 1.5 and

fe/

fs = 0.5 to 1.35 in this paper, and the specific parameter settings are shown in

Table 3. Additionally, the temporal evolutions of the lift and drag coefficients, and the frequency and mode of the vortex shedding is discussed in detail, respectively.

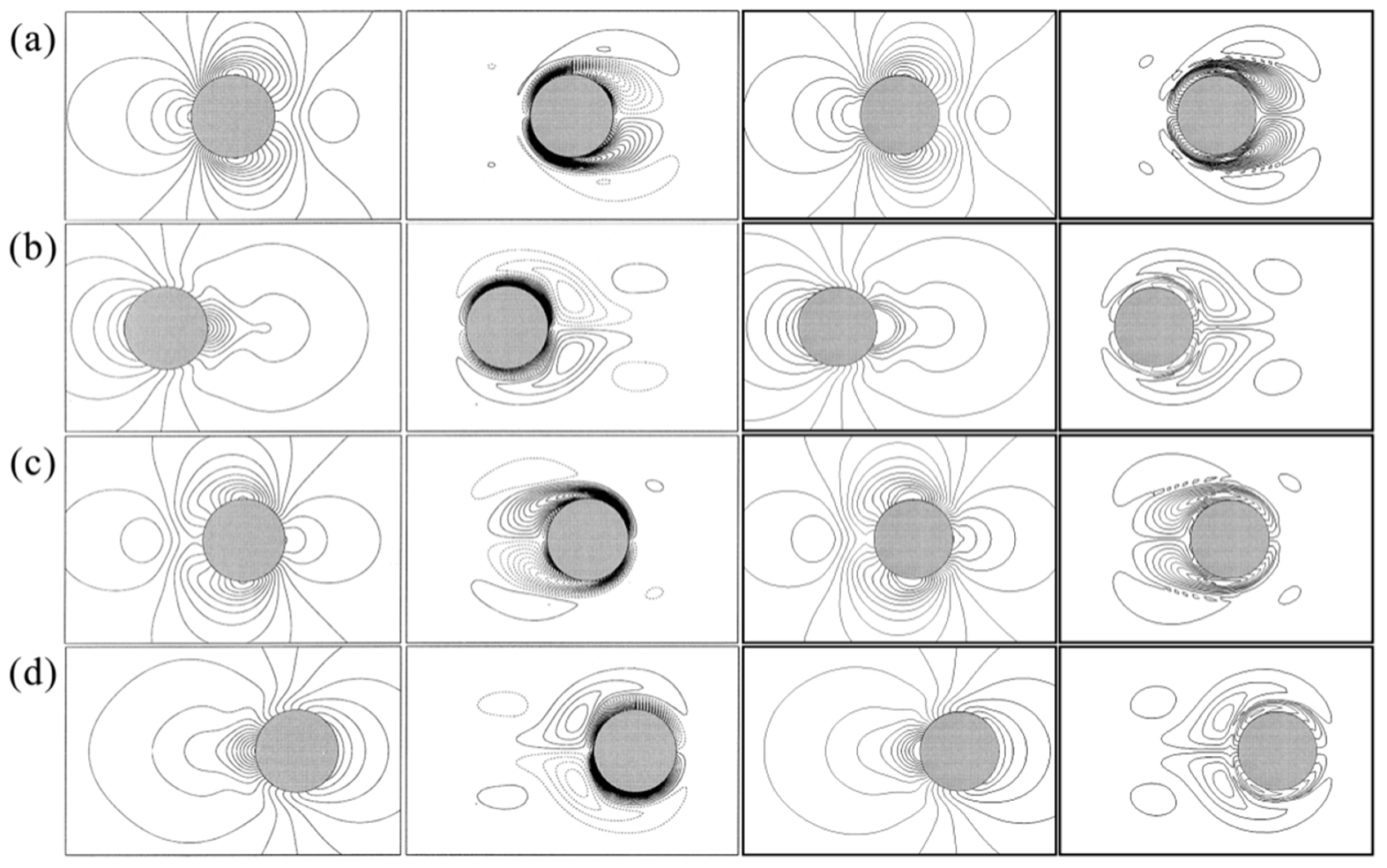

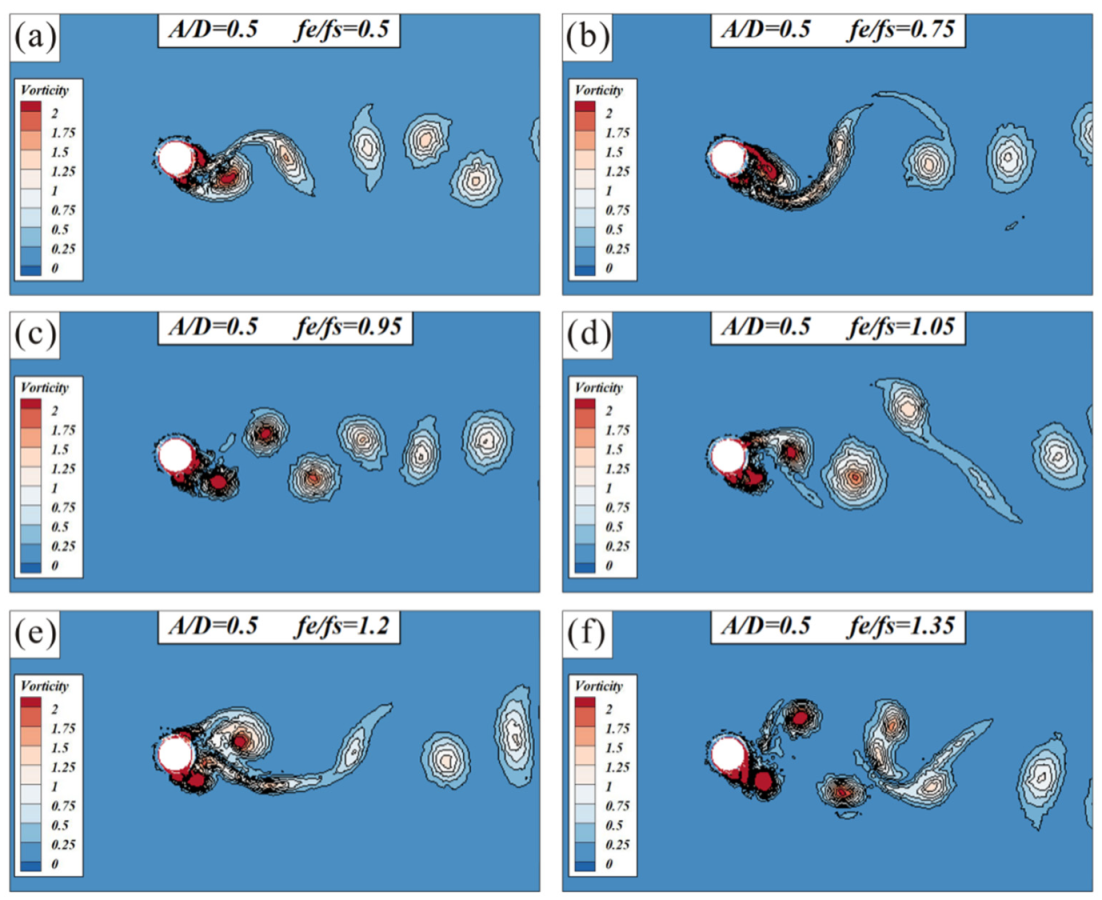

Figure 7 shows the vorticities around and behind the oscillating cylinder at

A/

D = 0.5 and

fe/

fs = 0.5 to 1.35.

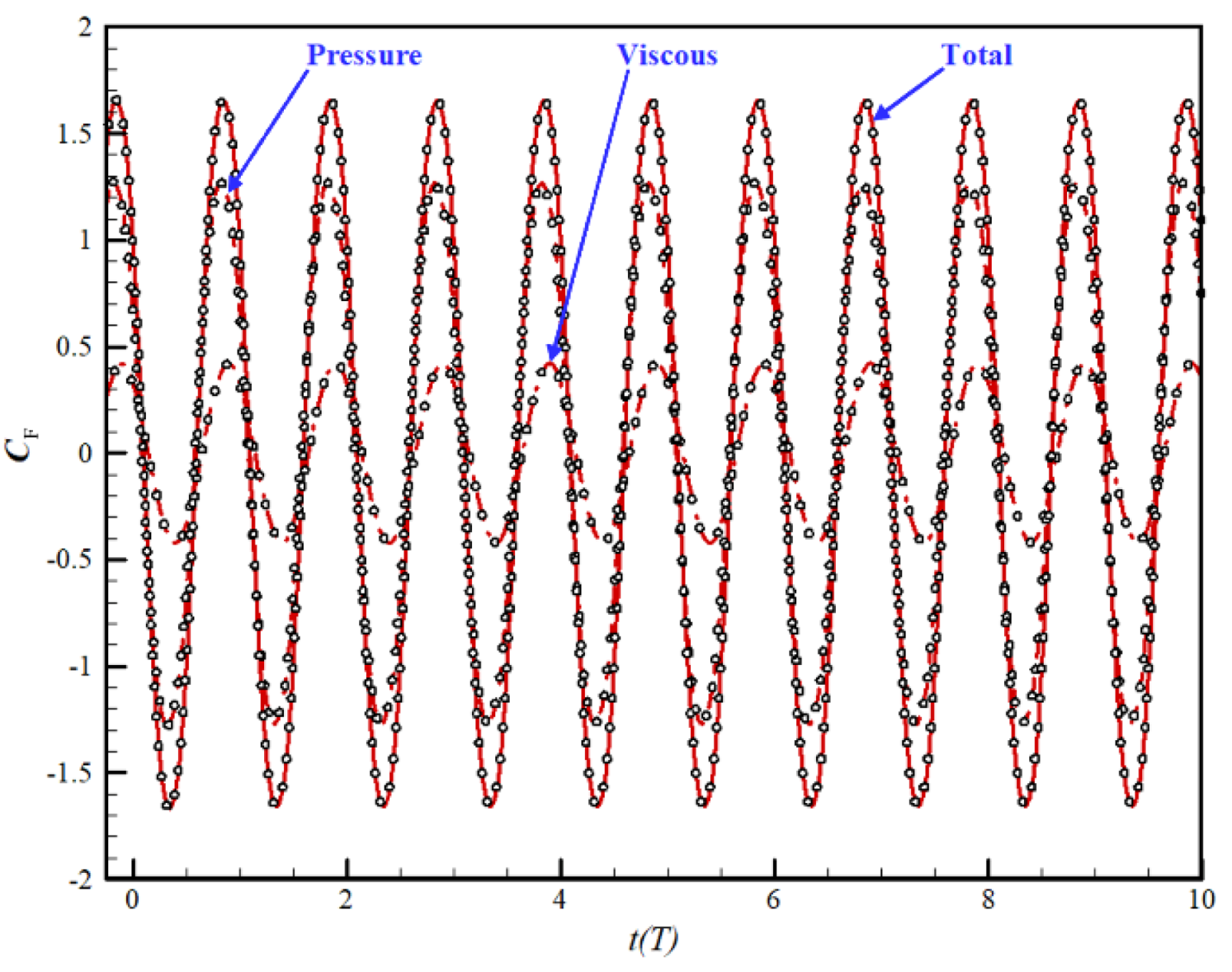

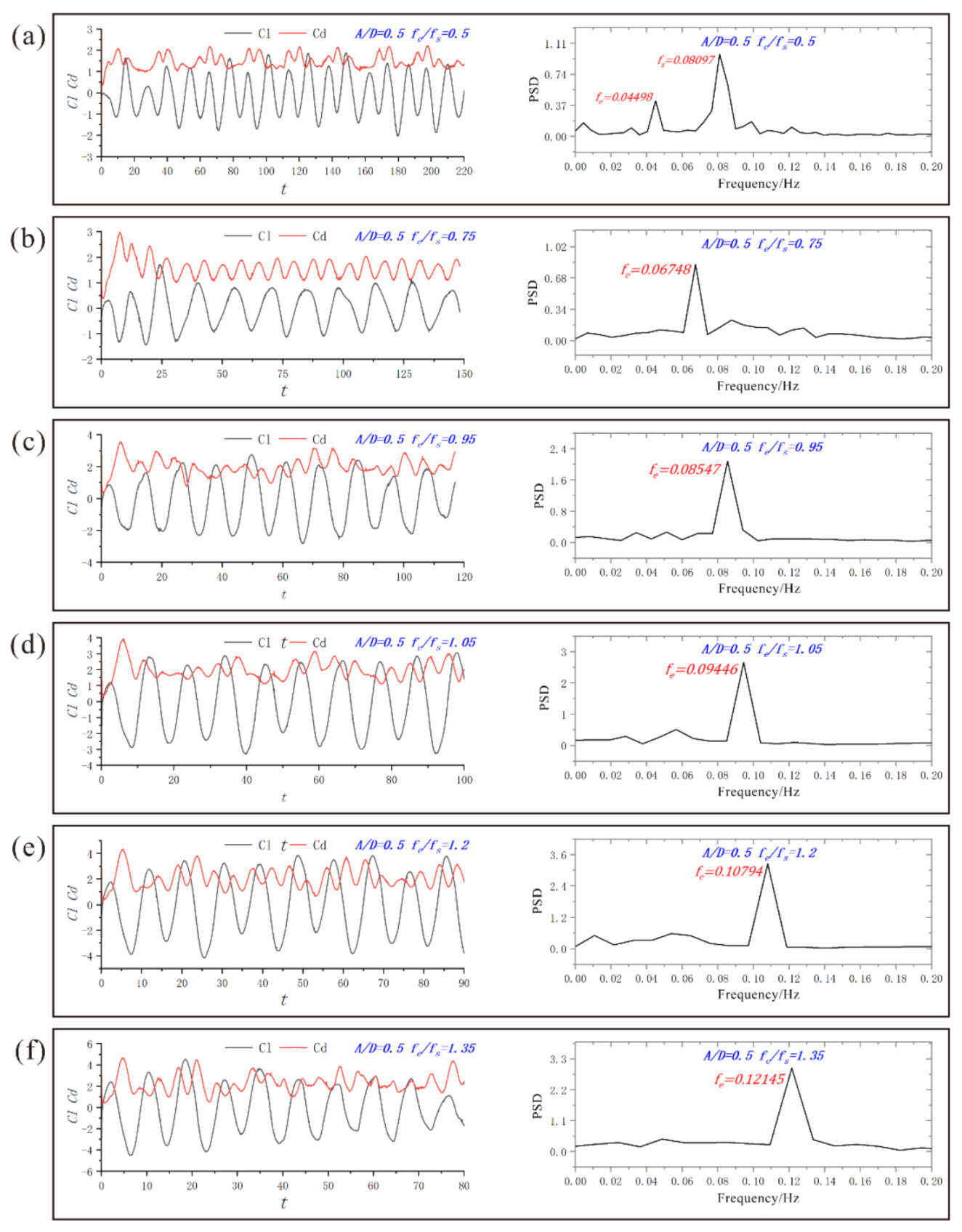

Figure 8 shows the temporal evolutions of the lift coefficient (

Cl) and drag coefficient (

Cd) (left) and the power spectral density (PSD) of the lift coefficient of the oscillating cylinder (right) in the corresponding parameters. The PSD distribution of the lift coefficient of an oscillating cylinder is obtained by a fast Fourier transform (FFT).

As per the Parseval’s identity, the lift coefficient can be expressed as follows by FFT:

The fluid force acting on the cylinder includes two contributing parts based on pressure and shear stress. Additionally, the lift (coefficient)

(

Cl) and drag (coefficient)

(

Cd) are defined as, respectively:

and

where

and

are obtained by a dimensionless transformation of the pressure and the axial vorticity on the surface of the oscillating cylinder, respectively.

In

Figure 7, the wake vortices are mainly distributed near the wake center line, showing no significant lateral deviation due to less excitation amplitude at

A/

D = 0.5. In addition, the number of the wake vortices at

fe/

fs = 0.5 obviously is greater than that at

fe/

fs = 0.75. This is caused by the fact that the vortex shedding is influenced by the excitation frequency

fe and, according to the PSD at

A/

D = 0.5 and

fe/

fs = 0.5 in

Figure 8, the Stroulhal frequency

fs also impacts the vortex shedding. Both of the two frequencies combine to determine the vortex shedding in the wake, causing an obvious ”beating” characteristic in the temporal evolutions of the lift and drag coefficients.

Additionally, the vortex shedding mode also verifies that the frequency ratio

fe/

fs = 0.5 is not within the range of the “lock-in” phenomenon at

Re = 4000. When

fe/

fs = 0.75, the scale and strength of the vortices shedding in the wake almost maintains the same level. The vortex shedding frequency is only impacted by the oscillation frequency

fe as per the PSD at

A/

D = 0.5 and

fe/

fs = 0.75 in

Figure 8, thereby being in the ”lock-in” range. With an increase in the frequency ratio

fe/

fs, the strength of the vortex shedding also increases. But the vortex shedding mode keeps a 2S mode in the range of 0.75 ≤

fe/

fs ≤ 1.35, and the dominant frequency is always the excitation frequency

fe. Additionally, the boundary of the cylinder moves faster as the excitation frequency increases, thereby accelerating the nearby fluid more and causing the wake vortices large lateral displacement in downstream. Along with an increase in the oscillating frequency ratio, the amplitudes of the lift and drag coefficients also increase. Additionally, the temporal evolutions of the lift and drag coefficients show different levels of fluctuation and no significant periodicity at

fe/

fs ≥ 0.95. It could be that the time of the vortex shedding is not consistent per cycle under the condition of small excitation amplitude or it could be that the vortex shedding is a lasting process, leading the lift and drag coefficients to fluctuate irregularly.

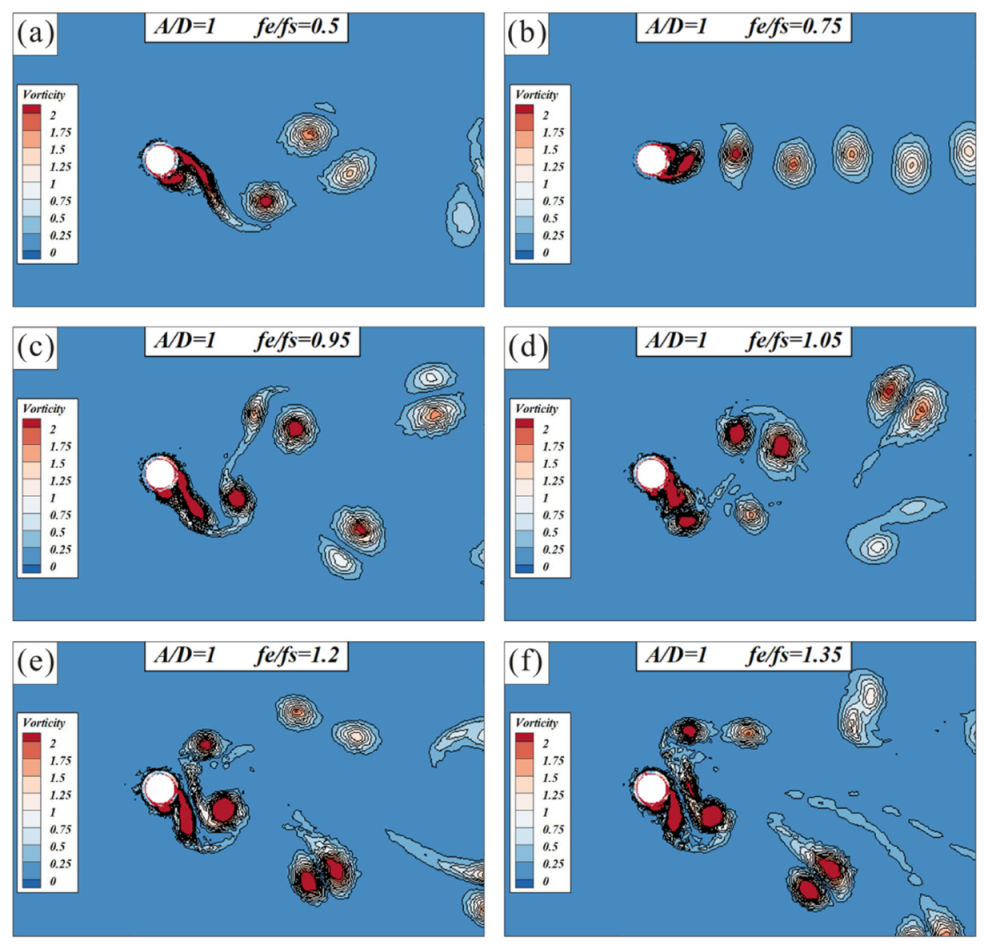

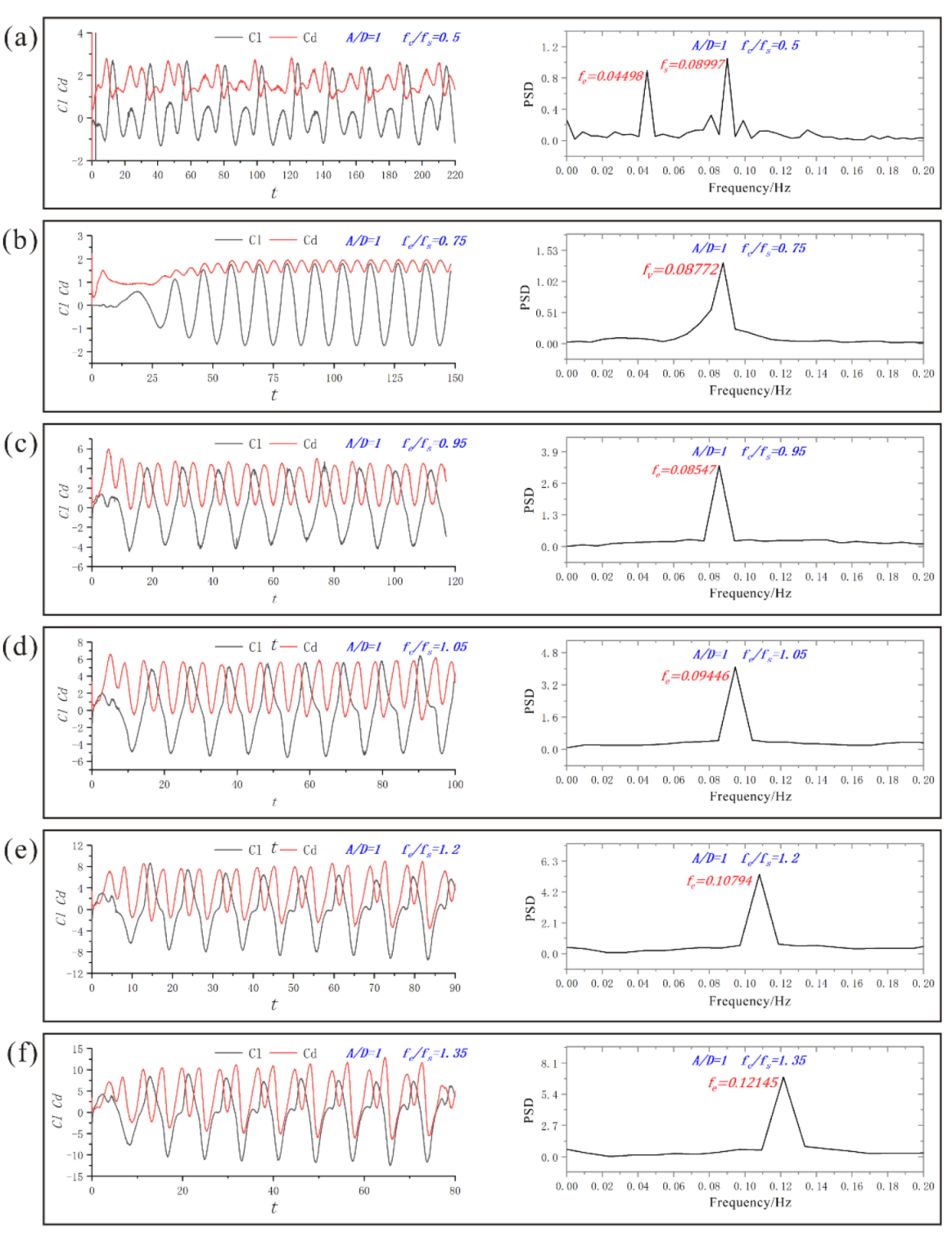

Similarly,

Figure 9 shows the vorticities around and behind the oscillating cylinder at

A/

D = 1 and

fe/

fs = 0.5 to 1.35.

Figure 10 shows the temporal evolutions of the lift and drag coefficients (left) and the PSD of the lift coefficient of the oscillating cylinder (right) in the corresponding parameters. However, the vortex shedding mode and the characteristics of the lift and drag coefficients at

A/

D = 1 are very different from that at

A/

D = 0.5.

When fe/fs = 0.5, the vortex shedding mode is a similar ”P + S” mode, and the lift and drag coefficients also show the ”beat” characteristics. However, its vortex shedding mode actually is a 2S mode placed out of the ”lock-in” range. This is due to the fact that the vortex shedding is also influenced by the excitation frequency and the Stroulhal frequency at A/D = 1 and fe/fs = 0.5, which is in line with the case at A/D = 0.5 and fe/fs = 0.5. The detachment of the vortices from the cylinder surface is dominated by a joint action of these two frequencies, leading to the complexity of the vortex shedding in the wake. The temporal evolutions of the lift and drag coefficients exhibit significant fluctuations, which correspond to the vortex shedding mode.

When A/D = 1 and fe/fs = 0.75, the vortex shedding exhibits a 2S mode, and the vortices shed behave regularly with a higher dominant frequency (0.08772) than that of its excitation frequency fe (0.06748). Thus, the vortices shed in the wake closely to the condition of the same excitation frequency. Additionally, the temporal evolutions of the lift and drag coefficients also perform periodicity. The case of fe/fs = 0.75 is an exception to the ”lock-in” range, which could be due to the fact that it is in an intermediate state from the 2S mode to the 2P0 mode or it could be that the dominant frequency is a fusion between the excitation frequency fe and the Stroulhal frequency fs.

In the case of

fe/

fs = 0.95, the vortex shedding mode is transformed into a 2P mode. Moreover, the secondary vortex of each vortex pair has lower strength than that of the primary vortex. This vortex shedding mode corresponds to a 2P overlap mode, 2P

0, which is consistent with the vortex shedding mode at

fe/

fs ≈ 1 obtained by Morse and Willamson [

3]. Additionally, the vortex shedding mode is within the range of the “lock-in” phenomenon as a stable state and the vortex shedding frequency of the oscillating cylinder approaches the natural shedding frequency, which can lead to the approximate symmetry of the wake vortices.

As the frequency ratio fe/fs increases to 1.05, the vortex shedding mode steps in an intermediate state from a 2P mode to a P + S mode. Two vortex pairs exist per cycle. The strength of one vortex pair is significantly stronger than that of the other, and the weak vortex pair dissipates faster when it moves downstream. The strong and weak vortex pairs are separated in the process of the downward and upward oscillation, respectively. More importantly, the asymmetry of the strength of the vortex shedding leads in the asymmetry of the temporal evolution of the lift coefficient per cycle. In other ways, an irregular ”jumping” phenomenon occurs at the right side of the temporal evolution of the lift coefficient per cycle when the cylinder moves to near a negative extreme displacement. However, the strong vortex pair is separated in the process of the upward oscillation at fe/fs ≈ 1.2, which is different from that at fe/fs ≈ 1.05, although they have the same vortex shedding modes. Accordingly, an irregular ”jumping” phenomenon occurs at the left side of the temporal evolution of the lift coefficient per cycle. From fe/fs = 1.05 to fe/fs = 1.2, the discrepancy in time of separation of the strong vortex pair mainly derives from the difference in the oscillation frequency. Additionally, the irregular ”jumping” occurs when the oscillating direction switches. When fe/fs = 1.35, its vortex shedding mode is in line with that at fe/fs = 1.2, but the lateral displacement of the vortex shedding is greater than that at fe/fs = 1.2. From fe/fs = 1.05 to fe/fs = 1.35, the temporal evolutions of the lift coefficient all show a periodic fluctuation, and locations of the irregular ”jumping’ on them mainly depend on the time of the separation of the vortices.

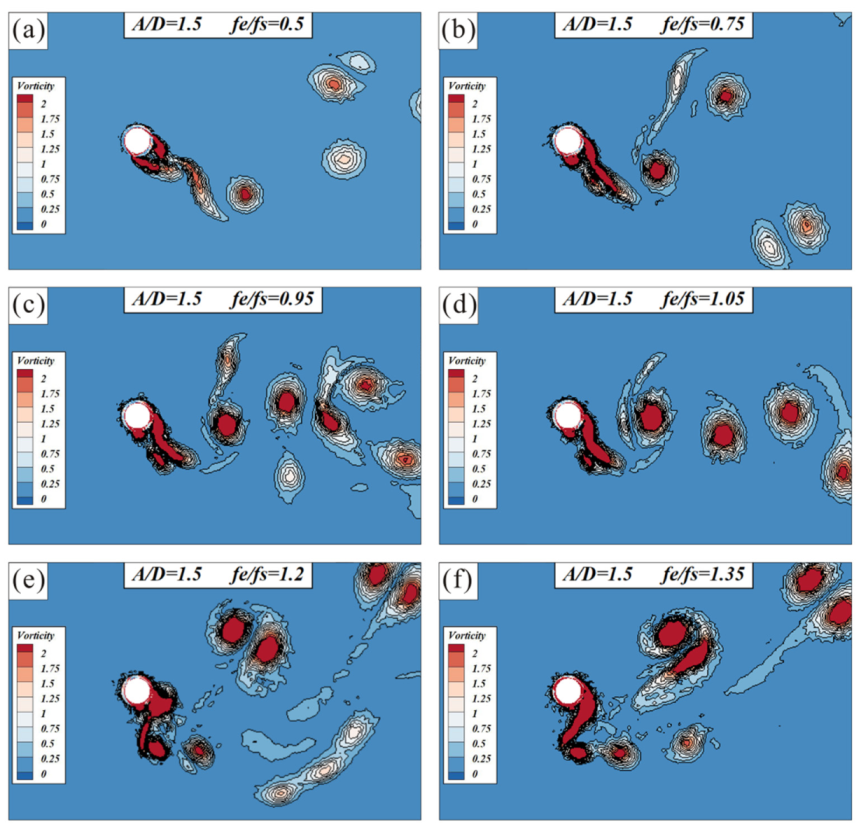

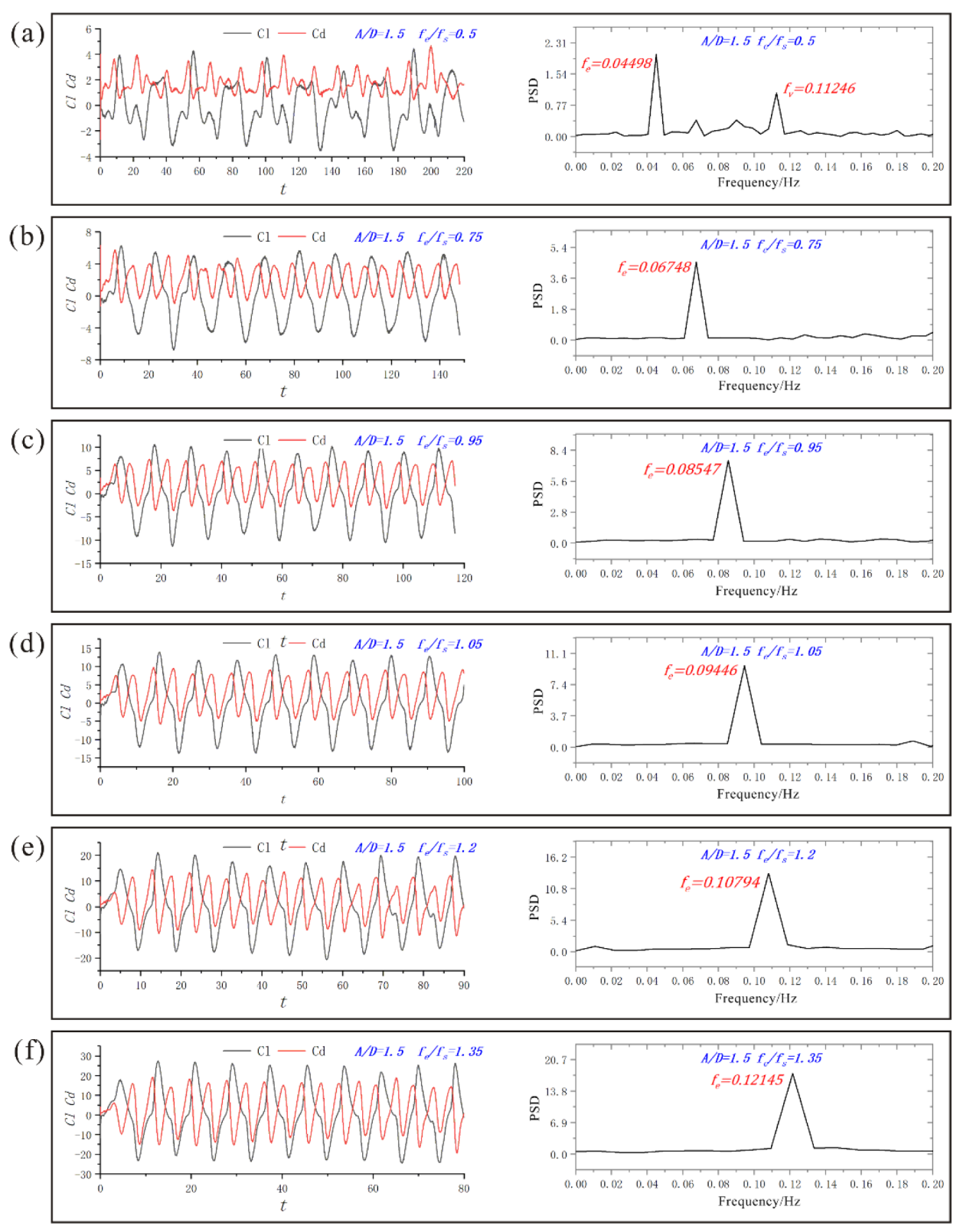

As above,

Figure 11 shows the vorticities around and behind the oscillating cylinder at

A/

D = 1.5 and

fe/

fs = 0.5 to 1.35.

Figure 12 shows the temporal evolutions of the lift and drag coefficients (left) and the PSD of the lift coefficient of the oscillating cylinder (right) in the corresponding parameters. As

A/

D further increases to 1.5, the lateral displacement of the vortex shedding is also increased.

Similarly, the vortex shedding mode also shows a similar ”P + S” model at

A/

D = 1.5 and

fe/

fs = 0.5, and the lift and drag coefficients also show the ”beat” characteristics. The temporal evolutions of the lift and drag coefficients also fluctuate drastically. The PSD of the lift coefficient at

fe/

fs = 0.5 shows that the vortex shedding frequency is affected not only by

fe and

fs, but also by other nondominant frequencies, as shown in

Figure 12a. The vortex shedding mode shows a 2P

0 mode placed out of the ”lock-in’ range, because the vortex shedding in the wake is either a single vortex or a vortex pair (including a strong vortex and a weak vortex). The phenomenon is also caused by the joint action of the excitation frequency and the Stroulhal frequency.

When fe/fs = 0.75, the vortex shedding mode has transformed into a 2P0 mode. The PSD of the lift coefficient at fe/fs = 0.75 also verifies that the vortex shedding frequency only rests with the excitation frequency fe. However, the vortex shedding has a larger lateral displacement in downstream as compared with the case at A/D = 1 and fe/fs =0.95, although the vortex shedding mode is the same. Additionally, this phenomenon also indicates that the transition of the vortex shedding mode is more likely to occur at high excitation amplitude.

In the case of fe/fs = 0.95 and fe/fs = 1.05, the vortex shedding modes are also in an intermediate state from the 2P0 mode to the P + S mode. However, the vortex shedding exhibits a small lateral displacement in downstream, converging towards the wake centerline. The temporal evolution of the lift coefficient at fe/fs = 0.95 shows a similar irregular ”jumping” in the process of the downward and upward oscillation, respectively, i.e., double ”jumpings”. The temporal evolution of the lift coefficient at fe/fs = 1.05 also exhibits the double ”jumpings”. Additionally, the strength of the vortex shedding remains the same in the process of the downward and upward oscillation, although the shedding vortex can be a single vortex or a vortex pair.

When fe/fs = 1.2 and fe/fs = 1.35, the vortex shedding modes keep a P + S mode. The single vortex is still weaker and is dissipated quickly in the downstream. However, the vortex pair enjoys stronger strength, and spreads upward. Therefore, the temporal evolution of the lift coefficient also shows an irregular ”jumping” on its right side per cycle.

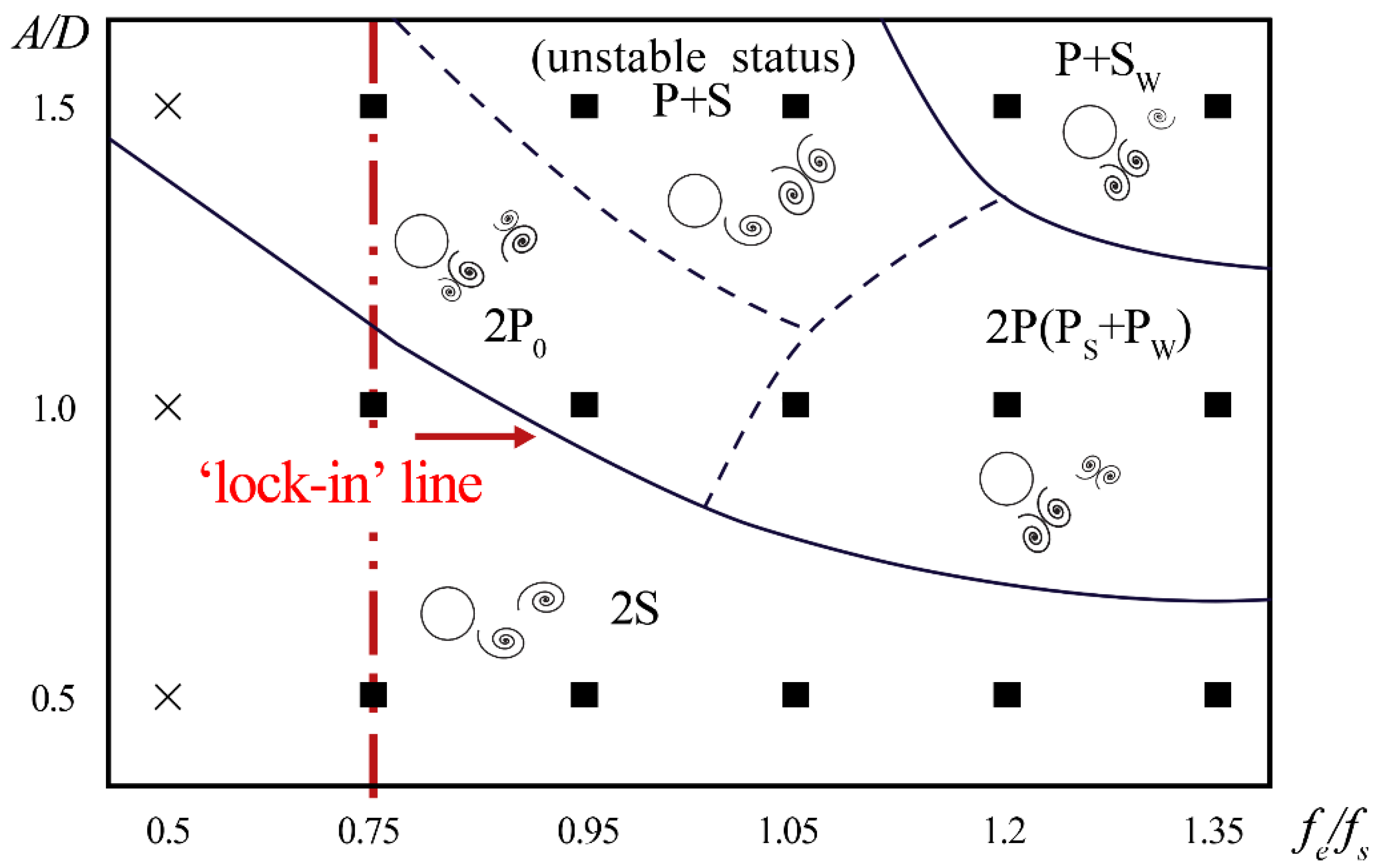

Figure 13 shows a diagram of the vortex formation modes in the above computed range at

Re = 4000. The results feature complex vortex formation transitions. A ”lock-in” line at

fe/

fs = 0.75 determines the components of the vortex shedding frequency for a series of simulations of

A/

D = 0.5 to 1.5 and

fe/

fs = 0.5 to 1.35. The vortex shedding is dominated by the excitation frequency and the Stroulhal frequency when

fe/

fs < 0.75, located in the left of the ”lock-in” line. However, the vortex shedding is only determined by a dominated vortex shedding frequency when

fe/

fs ≥ 0.75, which is within the range of the “lock-in” phenomenon. For a lower excitation amplitude, the vortex shedding mode shows a 2S mode. With an increase in the excitation amplitude, the vortex shedding mode turns into a 2P

0 or 2P mode, corresponding to lower oscillation frequency ratios and higher ones, respectively. The mentioned 2P mode characterizes a combined mode including a strong vortex pair and a weak one, which occur in higher oscillation frequency ratios. In addition, the strength of the vortex shedding also increases with the increase of the oscillation frequency ratio. As the excitation amplitude increase to

A/

D = 1.5, the vortex shedding mode exhibits a P + S mode in high oscillation frequency ratios. An unstable status exists in the mode transition from the 2P

0 mode to the P + S mode, which is also considered as an intermediate state. Additionally, the case of a higher excitation amplitude and oscillating frequency ratio has a vortex shedding mode featuring a strong vortex pair and a single weak vortex.