Bonding Characteristics of Single- and Joggled-Lap CFRP Specimens: Mechanical and Acoustic Investigations

Abstract

1. Introduction

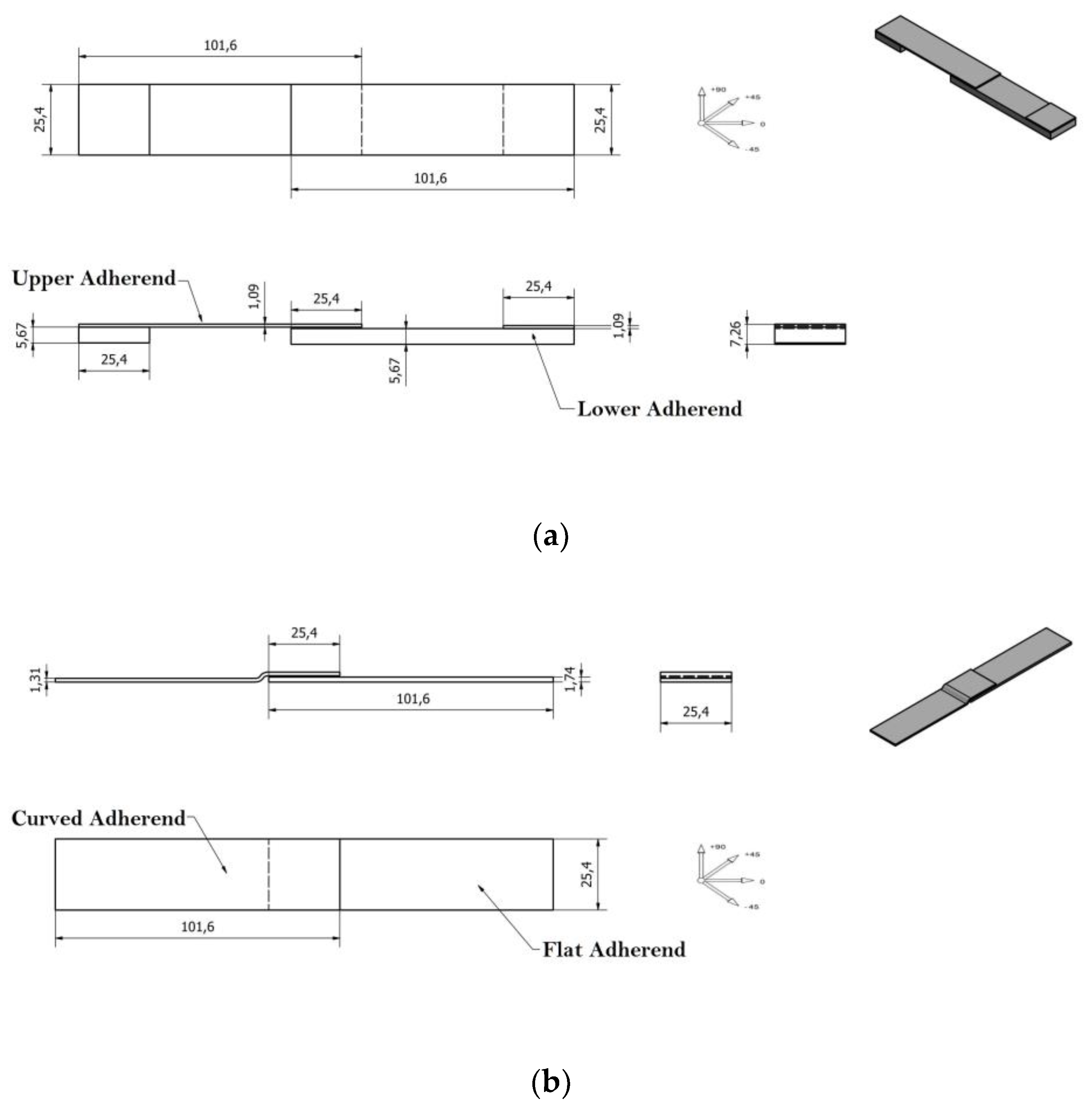

2. Materials and Methods

2.1. Materials

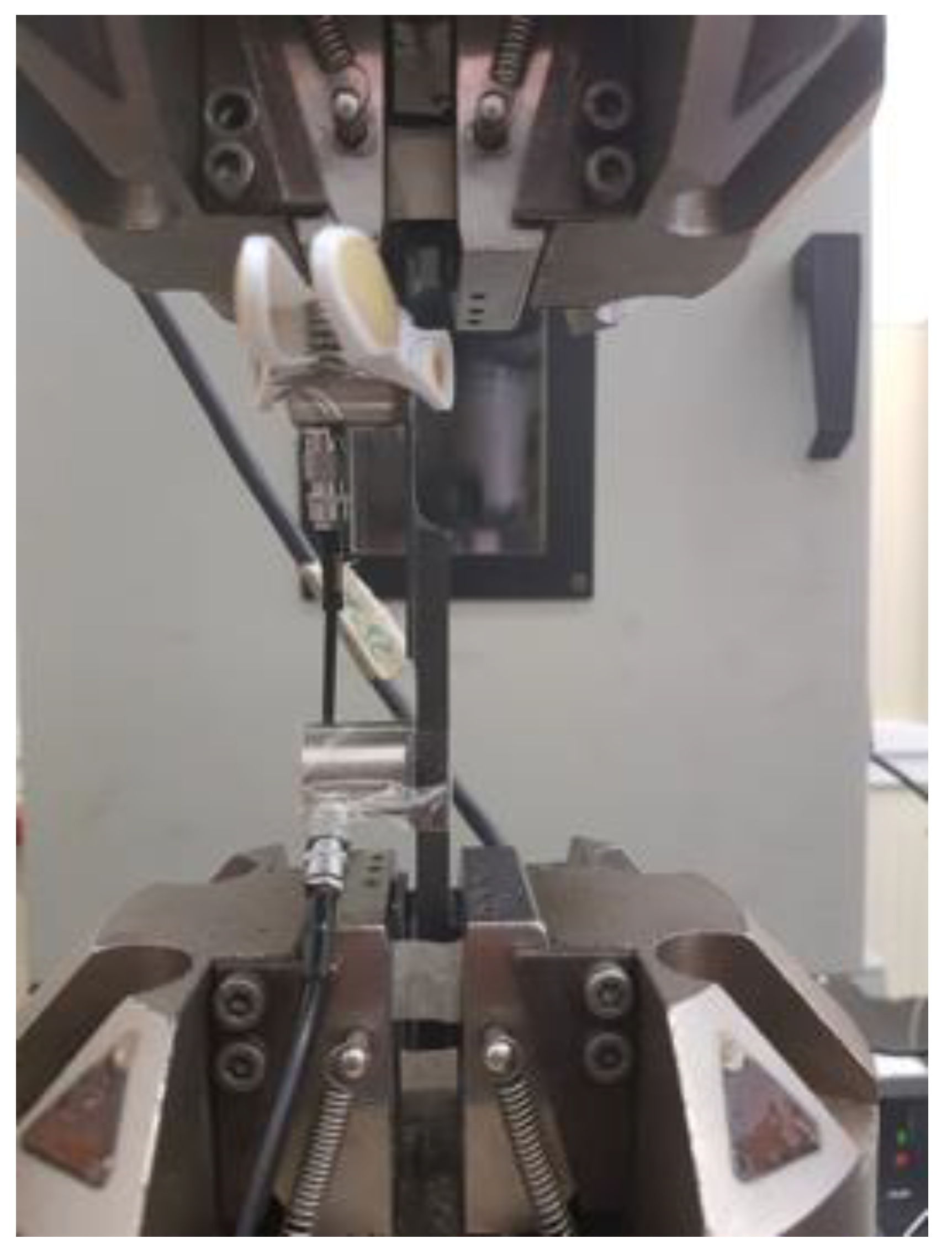

2.2. Testing Methods

2.3. Acoustic Emission (AE) Characterization

3. Results and Discussions

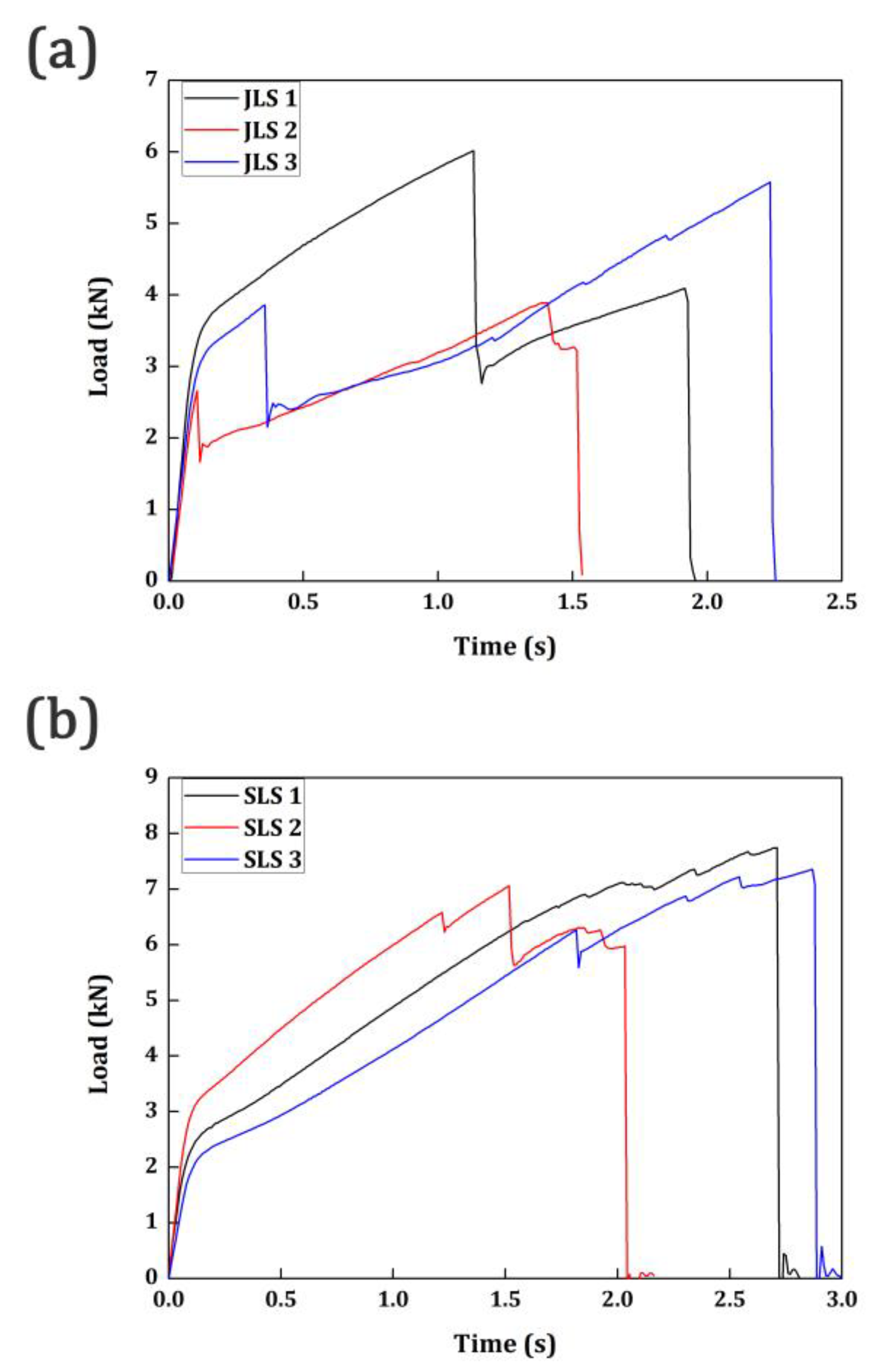

3.1. Mechanical Test Results

3.2. Acoustic Emission Results: Cumulative Counts and Cumulative Energy

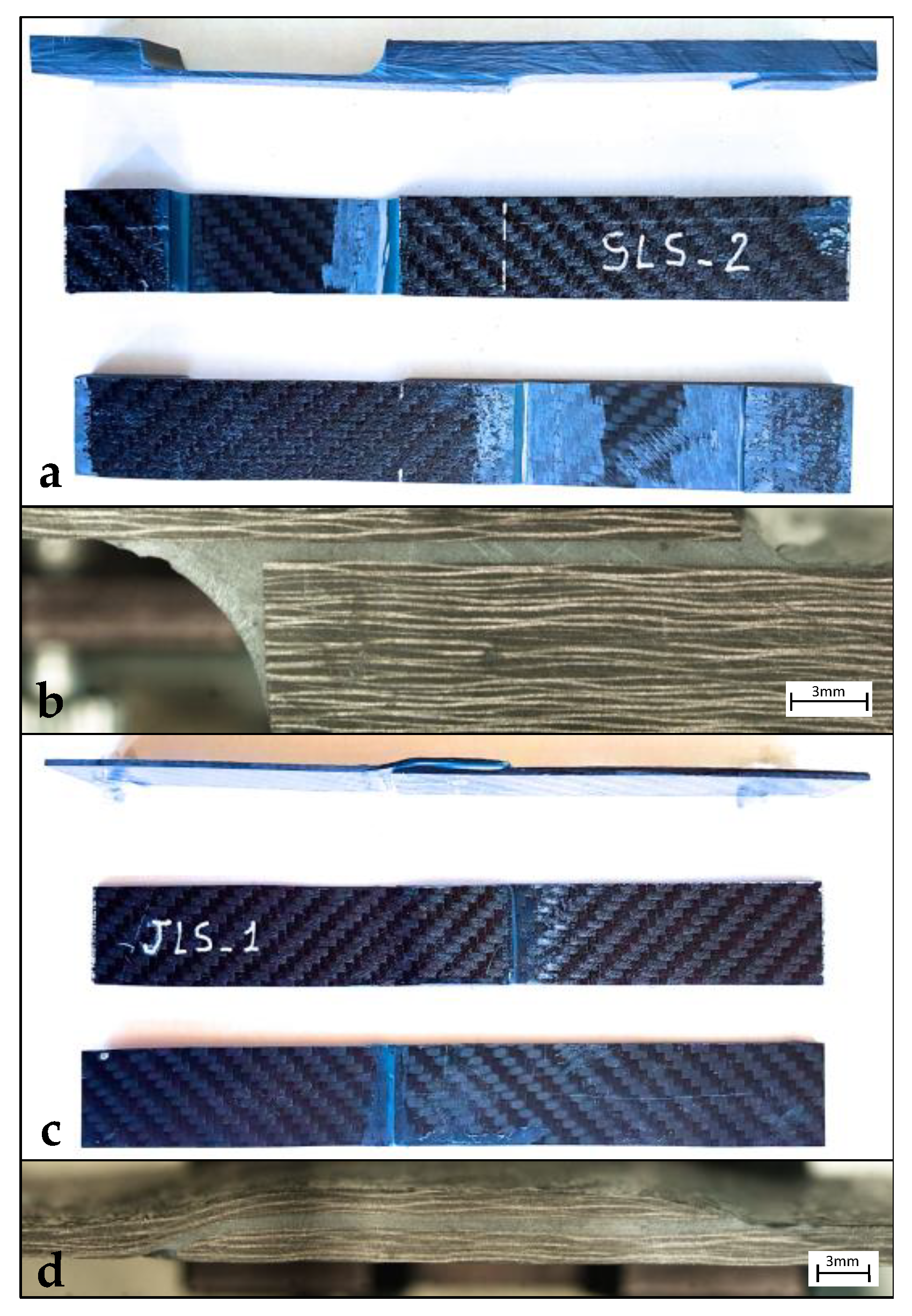

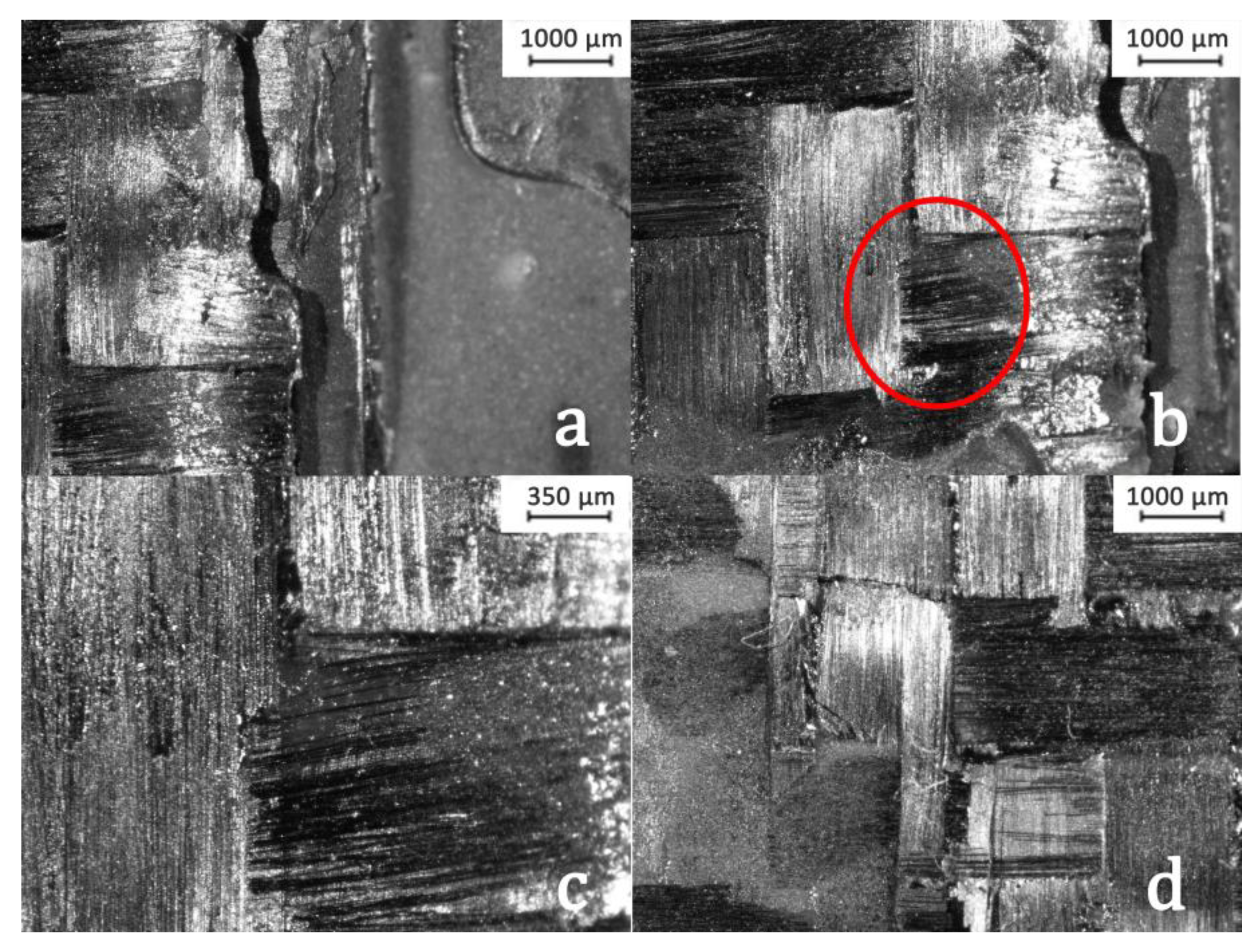

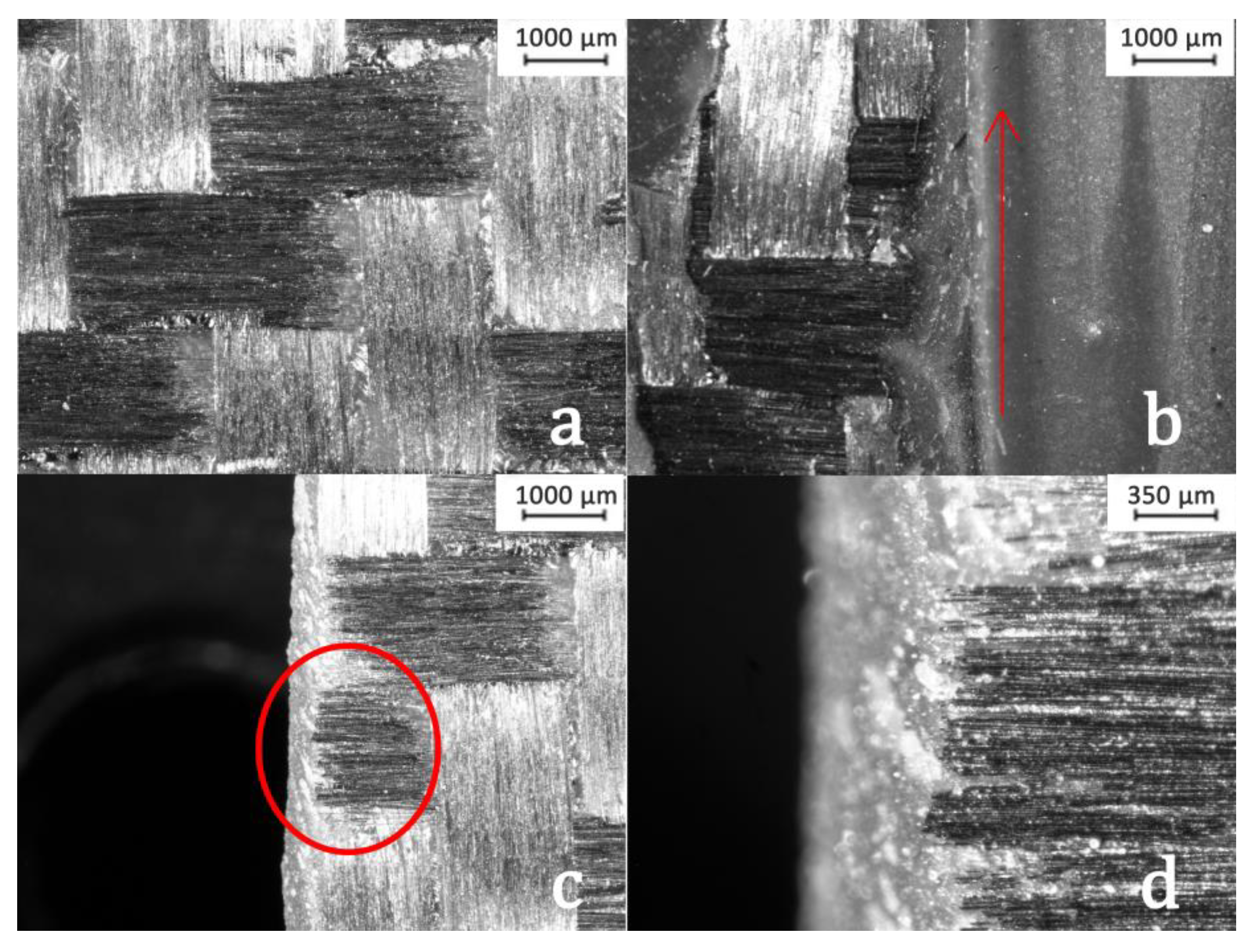

3.3. Fracture Surface Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sugita, Y.; Winkelmann, C.; La Saponara, V. Environmental and chemical degradation of carbon/epoxy lap joints for aerospace applications, and effects on their mechanical performance. Compos. Sci. Technol. 2010, 70, 829–839. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; de Moura, M.F.S.F.; Domingues, J.J.M.S. Using a cohesive damage model to predict the tensile behaviour of CFRP single-strap repairs. Int. J. Solids Struct. 2008, 45, 1497–1512. [Google Scholar] [CrossRef]

- Yu, Q.; Gao, R.; Gu, X.; Zhao, X.; Chen, T. Bond behavior of CFRP-steel double-lap joints exposed to marine atmosphere and fatigue loading. Eng. Struct. 2018, 15, 76–85. [Google Scholar] [CrossRef]

- Kucher, N.K.; Zemtsov, M.P.; Zarazovskii, M.N. Deformation behavior and strength of unidirectional carbon fiber laminates. Mech. Compos. Mater. 2006, 42, 407–418. [Google Scholar] [CrossRef]

- Tong, L.; Steven, G.P. Analysis and Design of Structural Bonded Joints; Kluwer Academic Publishers: Boston, MA, USA, 1999. [Google Scholar]

- Barile, C.; Casavola, C.; Gambino, B.; Mellone, A.; Spagnolo, M. Mode-I fracture behavior of CFRPs: Numerical model of the experimental results. Materials 2019, 12, 513. [Google Scholar] [CrossRef] [PubMed]

- Benatar, A.; Gillespie, J., Jr.; Kedward, K. Joining of composites. In Advanced Composites Manufacturing; Gutowski, T.G., Ed.; John Wiley: New York, NY, USA, 1997; pp. 487–512. [Google Scholar]

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor and Francis Publishers: New York, NY, USA, 1999. [Google Scholar]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Characterization of adhesive bonded CFRP laminates using full-field digital image stereo-correlation and finite element analysis. Compos. Sci. Technol. 2019, 169, 16–25. [Google Scholar] [CrossRef]

- Li, G.; Pang, S.S.; Woldesenbet, E.; Stubblefield, M.A.; Mensah, P.F.; Iberkwe, S.I. Investigation of prepreg bonded composite single lap joint. Compos. Part B Eng. 2001, 32, 651–658. [Google Scholar] [CrossRef]

- Taib, A.A.; Boukhili, R.; Achiou, S.; Gordon, S.; Boukehili, H. Bonded joints with composite adherends. Part I. Effect of specimen configuration, adhesive thickness, spew filler and adherend stiffness on fracture. Int. J. Adhes. Adhes. 2006, 26, 226–236. [Google Scholar] [CrossRef]

- Yang, C.; Tomblin, J.S. Investigation of Adhesive Behavior in Aircraft Applications; DOT/FAA/AR-01/57; US Department of Transportation Federal Aviation Administration, Office of Aviation Research: Washington, DC, USA, 2001.

- Grosse, C. Introduction. In Acoustic Emission Testing; Grosse, C., Ohtsu, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Balázs, G.L.; Grosse, C.; Koch, R.; Reinhardt, H.W. Damage accumulation on deformed steel bar to concrete interaction detected by acoustic emission technique. Mag. Concr. Res. 1996, 48, 311–320. [Google Scholar] [CrossRef]

- Grosse, C.; Linzer, L. Signal-based AE analysis. In Acoustic Emission Testing; Grosse, C., Ohtsu, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Barile, C.; Casavola, C.; Pappalettera, G. Acoustic emission waveform analysis in CFRP under Mode I test. Eng. Fract. Mech. 2018, 210, 408–413. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Damage characterization in composite materials using acoustic emission signal-based and parameter-based data. Compos. Part B-Eng. 2019. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Investigation of structural integrity of composite materials using wavelet packet transform. Procedia Eng. 2019, 17, 582–588. [Google Scholar] [CrossRef]

- Hamstad, M.A. Frequencies and Amplitudes of AE Signals in a Plate as a Function of Source Rise Time. In Proceedings of the 29th European Conference on Acoustic Emission Testing; Available online: https://www.ndt.net/events/EWGAE%202010/proceedings/papers/20_Hamstad.pdf (accessed on 4 March 2020).

- Oz, F.E.; Ersoy, N.; Lomov, S.V. Do high frequency acoustic emission events always represent fibre failure in CFRP laminates? Compos. Part A Appl. Sci. 2017, 103, 230–235. [Google Scholar] [CrossRef]

- Liu, P.F.; Chu, J.K.; Liu, Y.L.; Zheng, J.Y. A study on the failure mechanisms of carbon fiber/epoxy composite laminates using acoustic emission. Mater. Design 2012, 37, 228–235. [Google Scholar] [CrossRef]

- De Groot, P.J.; Wijnen, P.A.M.; Janssen, R.B.F. Real-time frequency determination of acoustic emission for different fracture mechanisms in carbon/epoxy composites. Compos. Sci. Technol. 1995, 55, 405–412. [Google Scholar] [CrossRef]

- Njuhovic, E.; Bräu, M.; Wolff-Fabris, F.; Starzynski, K.; Altstädt, V. Identification of failure mechanisms of metallised glass fibre reinforced composites under tensile loading using acoustic emission analysis. Compos. Part B-Eng. 2015, 81, 1–13. [Google Scholar] [CrossRef]

- Alia, A.; Fantozzi, G.; Godin, N.; Osmani, H.; Reynaud, P. Mechanical behaviour of jute fibre-reinforced polyester composite: Characterization of damage mechanisms using acoustic emission and microstructural observations. J. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- ASTM D5868-01(2014). Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding; ASTM International: West Conshohocken, PA, USA, 2014; Available online: www.astm.org (accessed on 4 March 2020).

- Mangalgiri, P.D.; Johnson, W.S.; Everett, R.A., Jr. Effect of adherend thickness and mixed mode loading on debond growth in adhesively bonded composite joints. J. Adhes. 1987, 23, 263–288. [Google Scholar] [CrossRef]

- Hsiao, K.T.; Alms, J.; Advani, S.G. Use of epoxy/multiwalled carbon nanotubes as adhesives to join graphite fibre reinforced polymer composites. Nanotechnology 2003, 14, 791–793. [Google Scholar] [CrossRef]

- Avila, A.F.; Bueno, P.O. An experimental and numerical study on adhesive joints for composites. Compos. Struct. 2004, 64, 531–537. [Google Scholar] [CrossRef]

- Liu, X.; Shao, X.; Li, Q.; Sun, G. Experimental study on residual properties of carbon fibre reinforced plastic (CFRP) and aluminum single-lap adhesive joints at different strain rates after transverse pre-impact. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105372. [Google Scholar] [CrossRef]

- Finkel, P.; Mitchell, J.R.; Carlos, M.F. Experimental study of ‘Auto Sensor Test-Self Test Mode’ for acoustic emission system performance verification. AIP. Conf. Proc. 2000, 509, 1995–2002. [Google Scholar]

- Harris, D.O.; Bell, R.L. The measurement and significance of energy in acoustic-emission testing. Exp. Mech. 1977, 17, 347–353. [Google Scholar] [CrossRef]

- Kishore, A.N.; Prasad, N.S. An experimental study of Flat-Joggle-Flat bonded joints in composite laminates. Int. J. Adhes. Adhes. 2012, 35, 55–58. [Google Scholar] [CrossRef]

- Taib, A.A.; Boukhili, R.; Achiou, S.; Boukhili, H. Bonded joints with composite adherends. Part II. Finite element analysis of joggle lap joints. Int. J. Adhes. Adhes. 2006, 26, 237–248. [Google Scholar] [CrossRef]

| Flat Adherend | ||||

| Length (mm) | Width (mm) | Thickness (mm) | No. of Plies | Stacking sequence |

| 101.6 ± 0.12 | 26.09 ± 0.07 | 2.0 ± 0.04 | 8 | [+45/−45]3/−45/+45 |

| Curved Adherend | ||||

| Length (mm) | Width (mm) | Thickness (mm) | No. of Plies | Stacking sequence |

| 101.6 ± 0.17 | 26.09 ± 0.05 | 1.5 ± 0.02 | 6 | [+45/+45/−45]S |

| Overlapping Region (Adhesive) | ||||

| Length (mm) | Width (mm) | Thickness (mm) | ||

| 26 ± 0.21 | 26.09 ± 0.06 | 3.67 ± 0.05 | ||

| Upper Adherend | ||||

| Length (mm) | Width (mm) | Thickness (mm) | No. of Plies | Stacking sequence |

| 101.6 ± 0.11 | 25.33 ± 0.12 | 1.3 ± 0.05 | 5 | +45/+45/+45/−45/+45 |

| Lower Adherend | ||||

| Length (mm) | Width (mm) | Thickness (mm) | No. of Plies | Stacking sequence |

| 101.6 ± 0.09 | 25.33 ± 0.14 | 6.4 ± 0.12 | 26 | +45/[+45/−45]12/+45 |

| Overlapping Region (Adhesive) | ||||

| Length (mm) | Width (mm) | Thickness (mm) | ||

| 26 ± 0.12 | 25.33 ± 0.25 | 8.5 ± 0.11 | ||

| Specimen | Peak Load (kN) | |

|---|---|---|

| Initial Rupture | Final Rupture | |

| JLS 1 | 6.02 | 4.09 |

| JLS 2 | 2.67 | 3.89 |

| JLS 3 | 3.86 | 5.57 |

| Mean | 4.18 | 4.52 |

| Std. Dev. | 1.70 | 0.92 |

| SLS 1 | 7.05 | 7.75 |

| SLS 2 | 7.06 | 5.96 |

| SLS 3 | 5.93 | 7.36 |

| Mean | 6.78 | 7.02 |

| Std. Dev. | 0.75 | 0.94 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barile, C.; Casavola, C.; Moramarco, V.; Pappalettere, C.; Vimalathithan, P.K. Bonding Characteristics of Single- and Joggled-Lap CFRP Specimens: Mechanical and Acoustic Investigations. Appl. Sci. 2020, 10, 1782. https://doi.org/10.3390/app10051782

Barile C, Casavola C, Moramarco V, Pappalettere C, Vimalathithan PK. Bonding Characteristics of Single- and Joggled-Lap CFRP Specimens: Mechanical and Acoustic Investigations. Applied Sciences. 2020; 10(5):1782. https://doi.org/10.3390/app10051782

Chicago/Turabian StyleBarile, Claudia, Caterina Casavola, Vincenzo Moramarco, Carmine Pappalettere, and Paramsamy Kannan Vimalathithan. 2020. "Bonding Characteristics of Single- and Joggled-Lap CFRP Specimens: Mechanical and Acoustic Investigations" Applied Sciences 10, no. 5: 1782. https://doi.org/10.3390/app10051782

APA StyleBarile, C., Casavola, C., Moramarco, V., Pappalettere, C., & Vimalathithan, P. K. (2020). Bonding Characteristics of Single- and Joggled-Lap CFRP Specimens: Mechanical and Acoustic Investigations. Applied Sciences, 10(5), 1782. https://doi.org/10.3390/app10051782