Simulation and Experimental Analysis on the Load Characteristics of a Temperature-Control Curtain in a Thermally-Stratified Reservoir

Abstract

1. Introduction

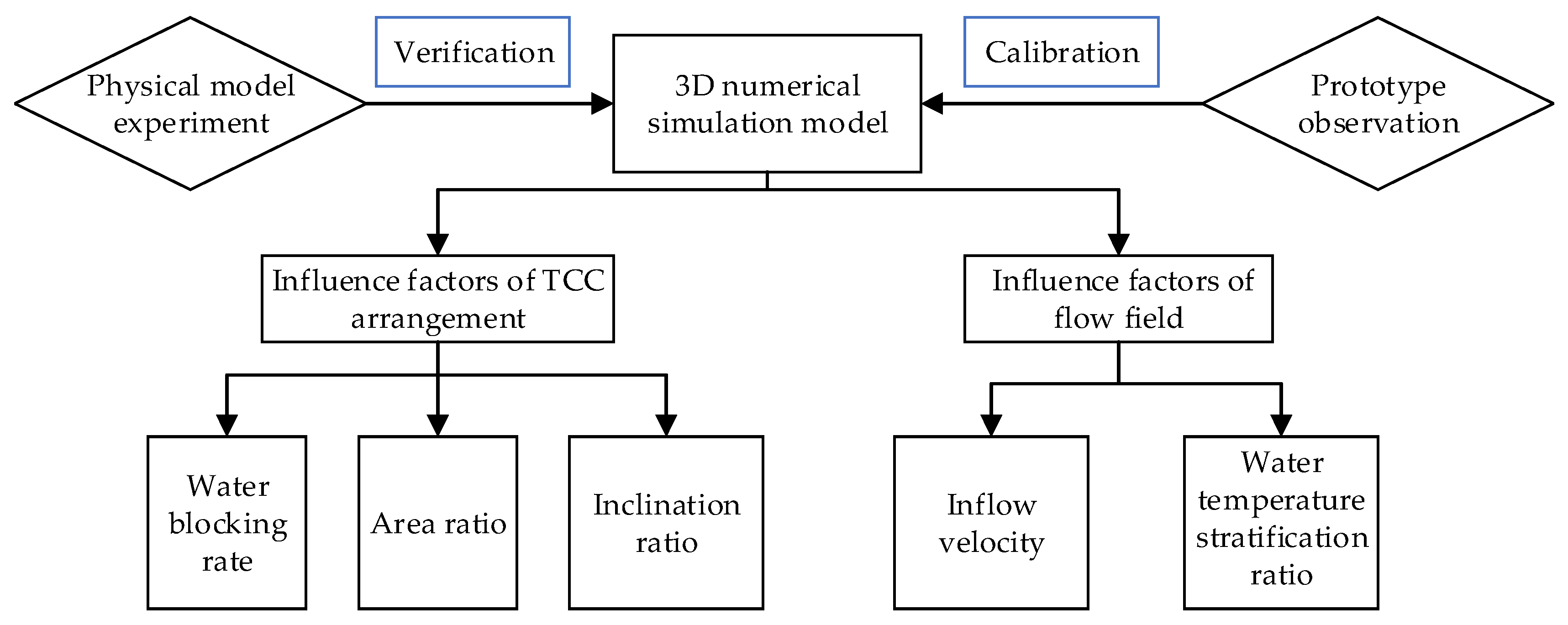

2. Materials and Methods

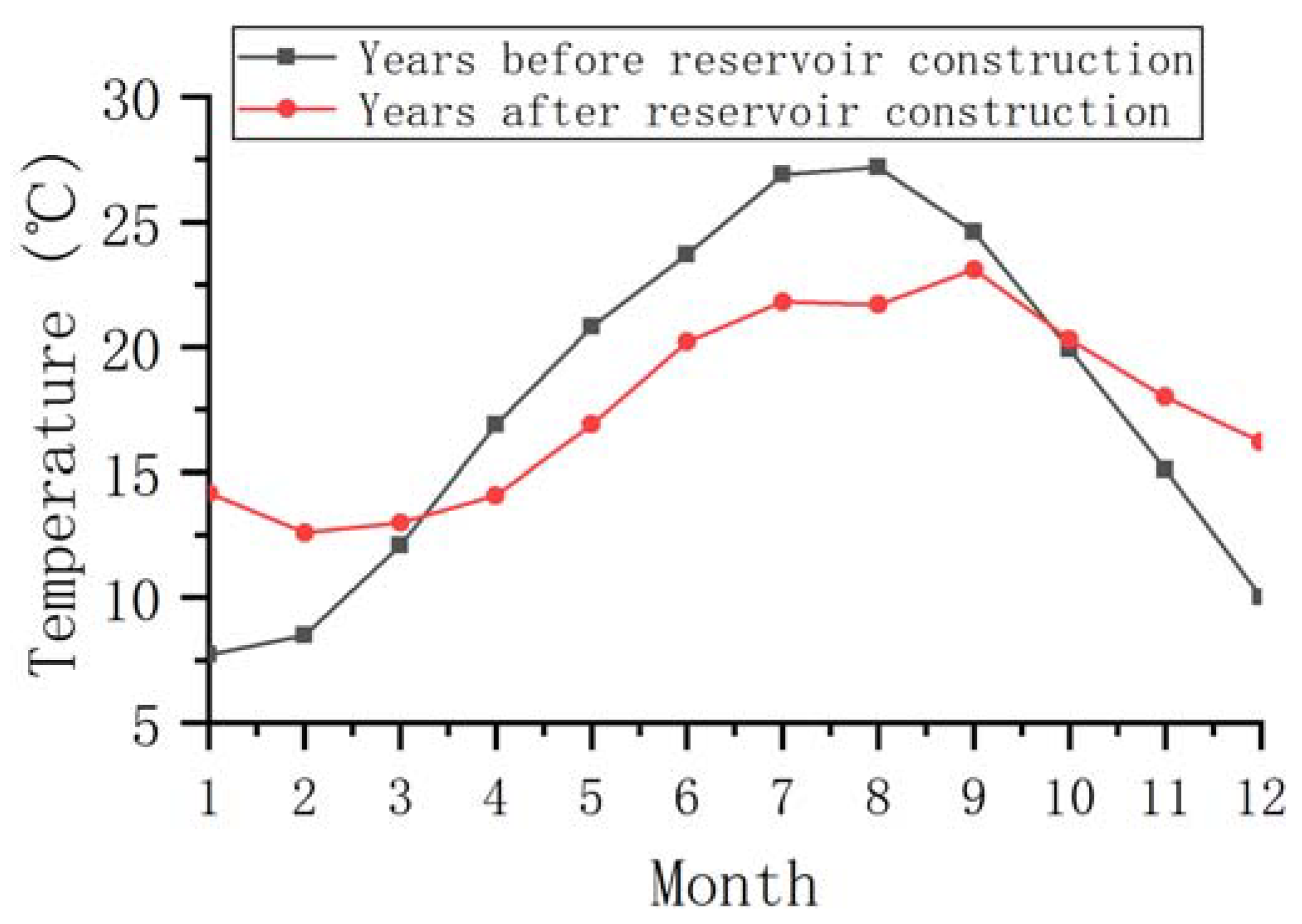

2.1. Case Study

2.2. Main Parameters

- (1)

- Water blocking rate (Prh): water blocking area divided by cross-sectional area.

- (2)

- Area ratio (Pra): total area divided by vertical projection area.

- (3)

- Inclination ratio (Prl): inclination distance divided by vertical height.

- (4)

- Water temperature stratification ratio (β): temperature difference between surface and bottom divided by water depth.

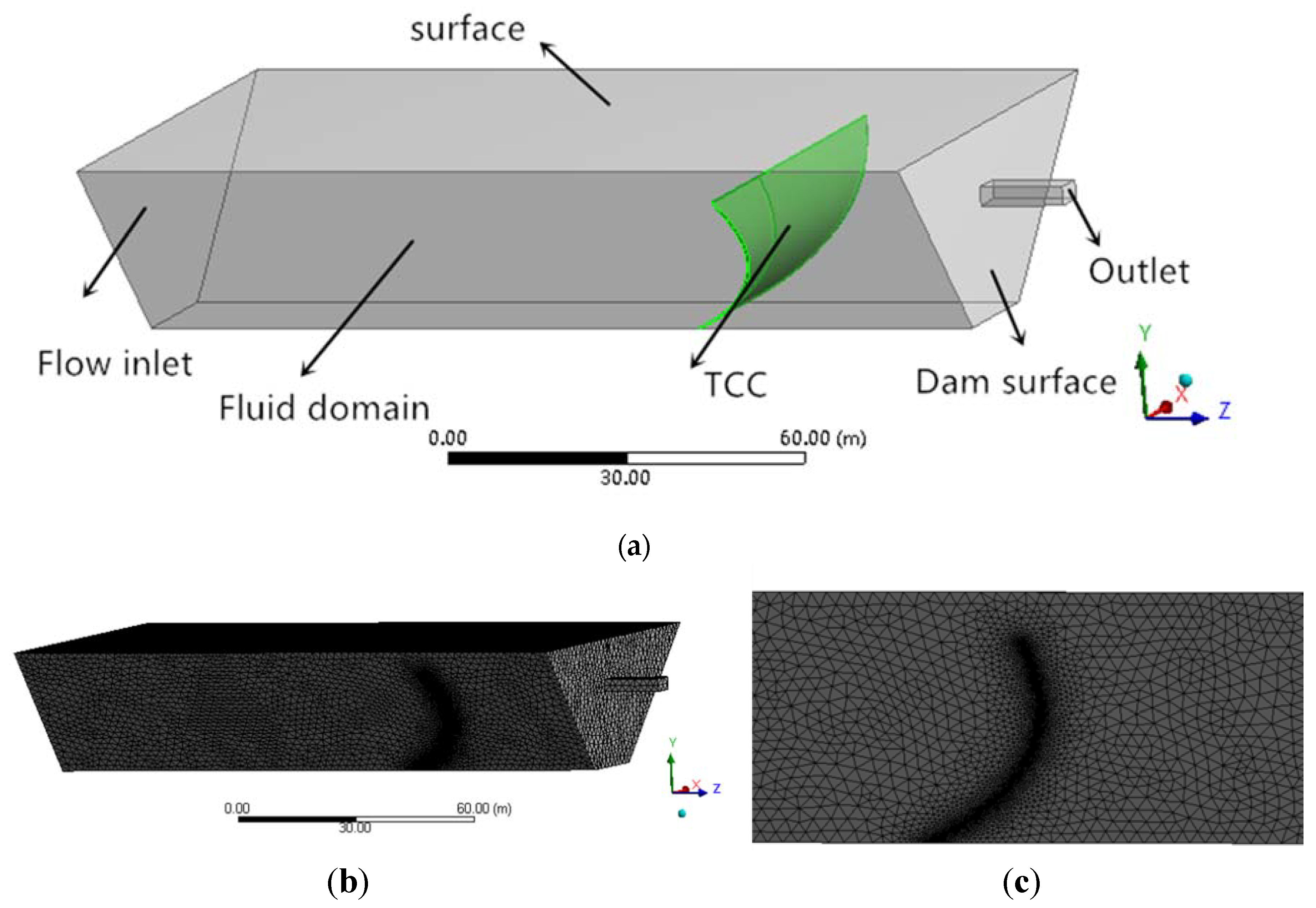

2.3. Numerical Simulation

2.3.1. Governing equations

2.3.2. Model establishment and boundary conditions

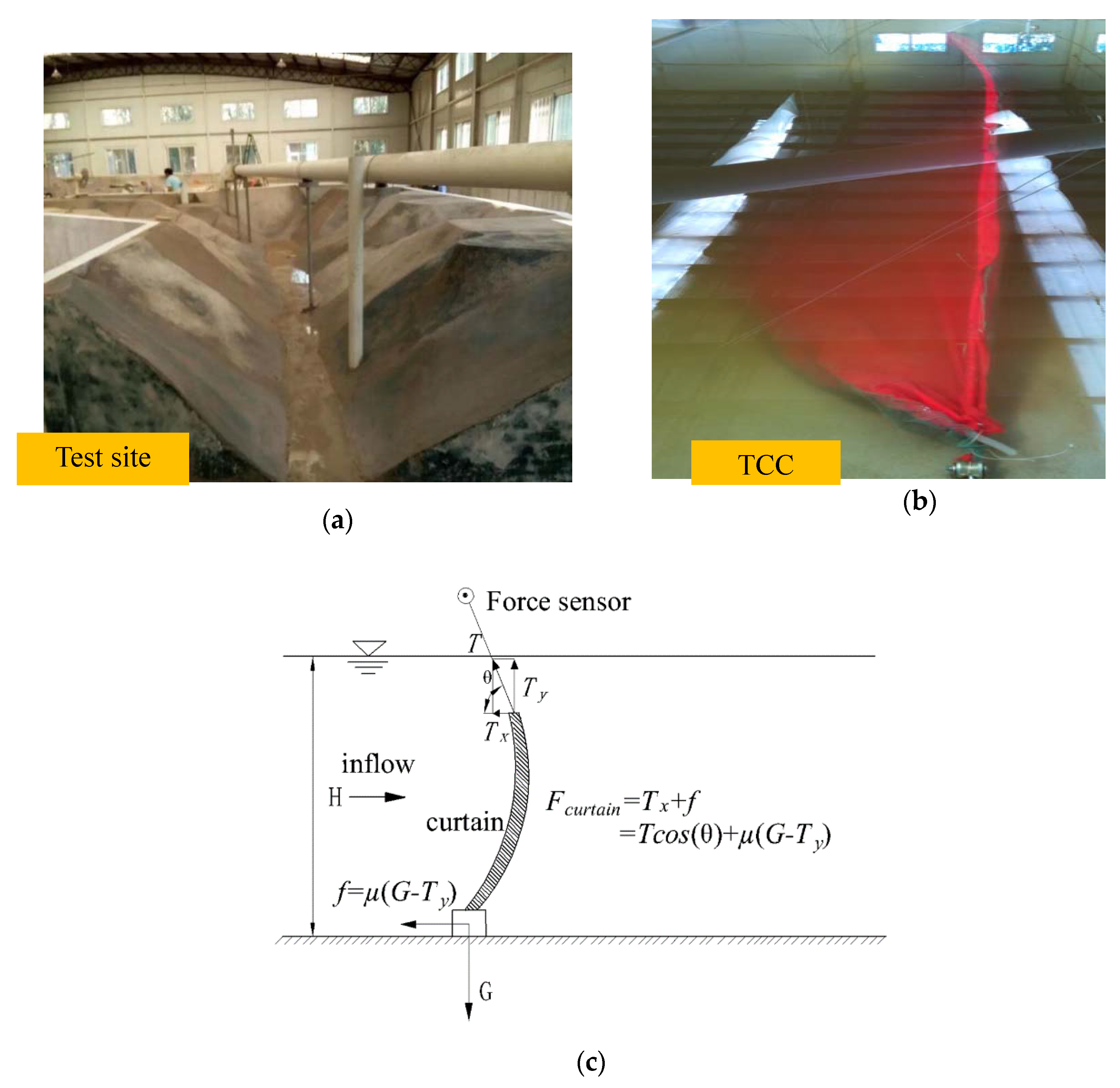

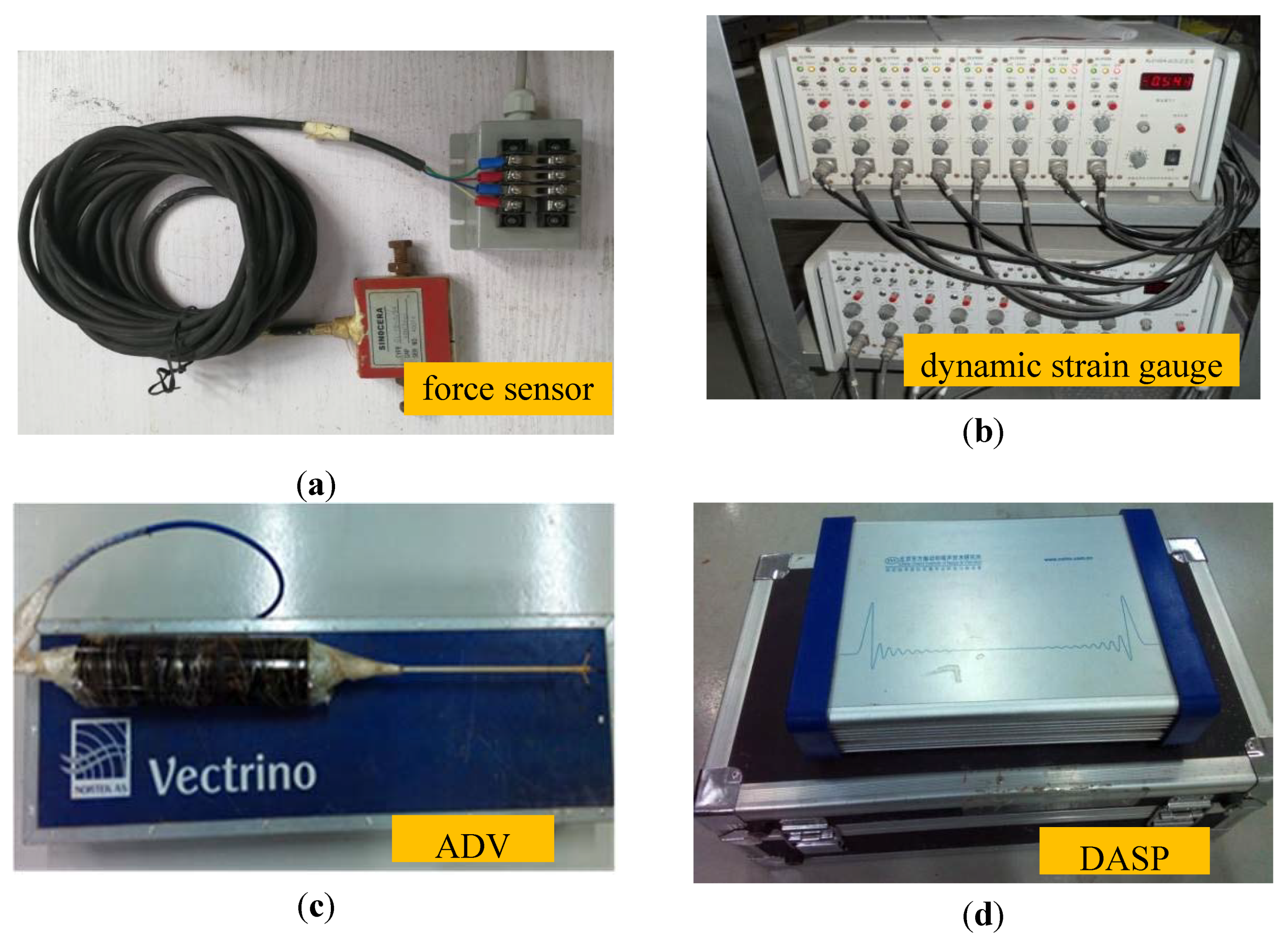

2.4. Physical Model Experiment

2.5. Numerical Simulation Model Scenarios

2.6. Resistance Equation

3. Results

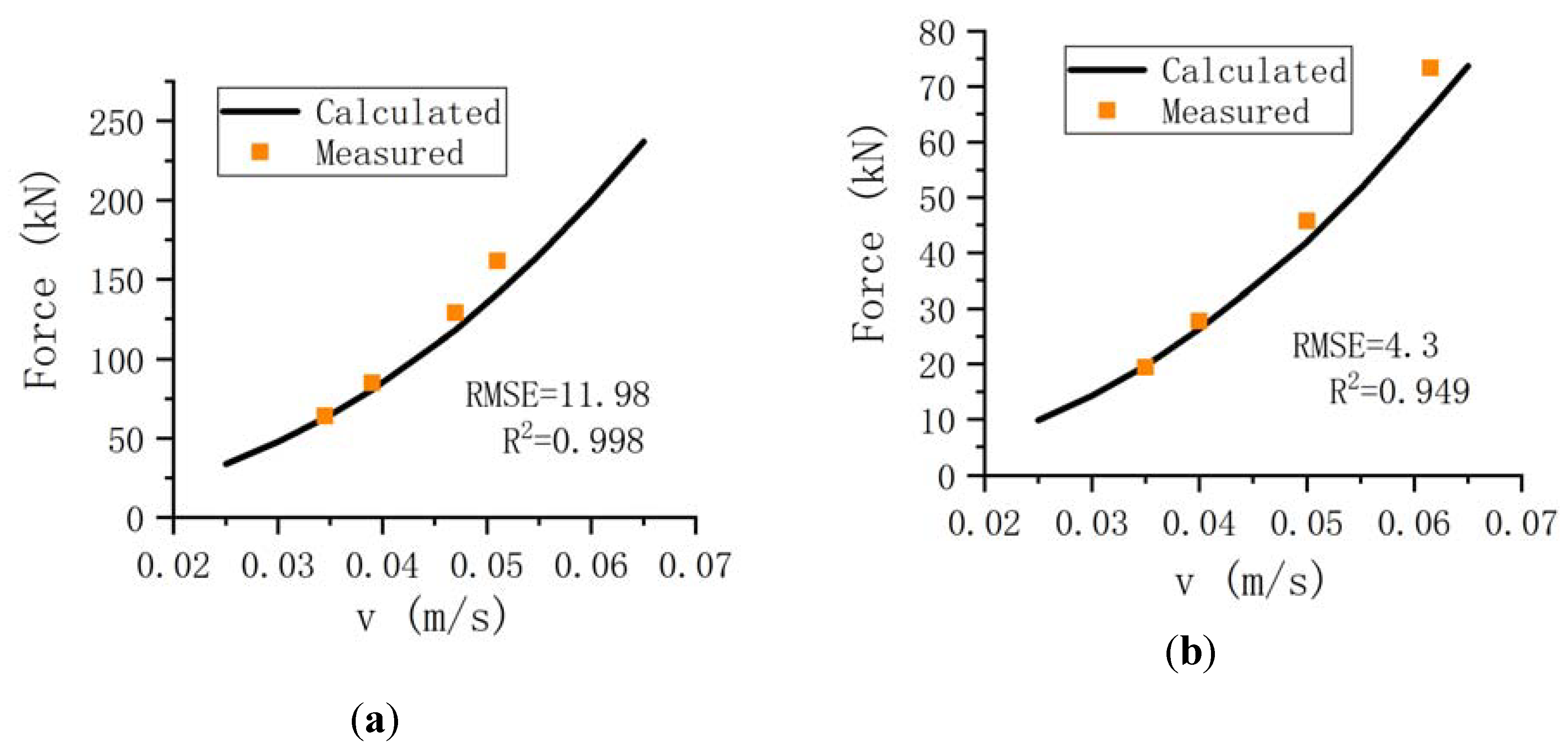

3.1. Model Validation

3.1.1. Physical model experiment verification

3.1.2. Prototype observation verification

3.2. Effect of Water Blocking Rate

3.3. Effect of Area Ratio

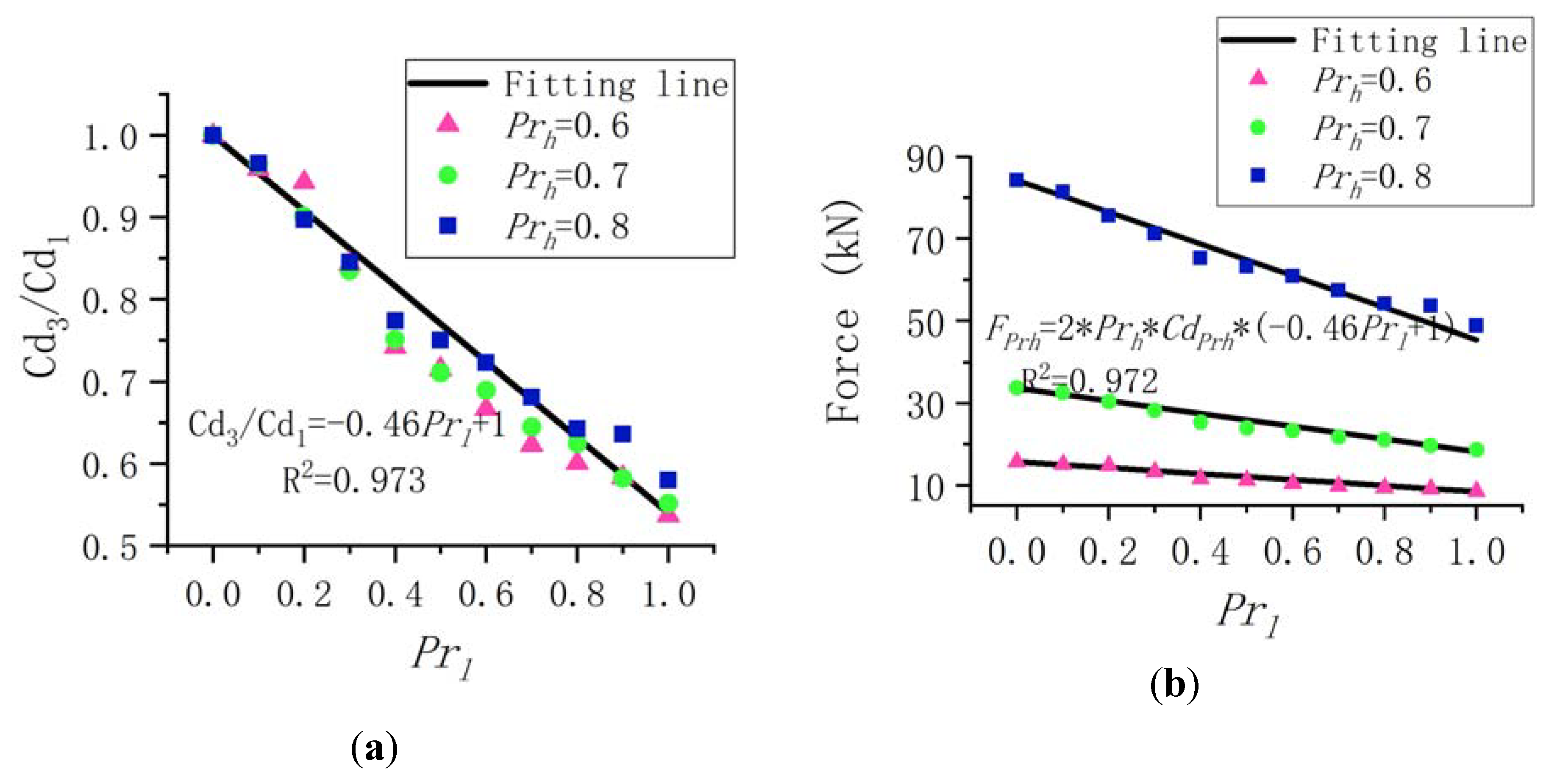

3.4. Effect of Inclination Ratio

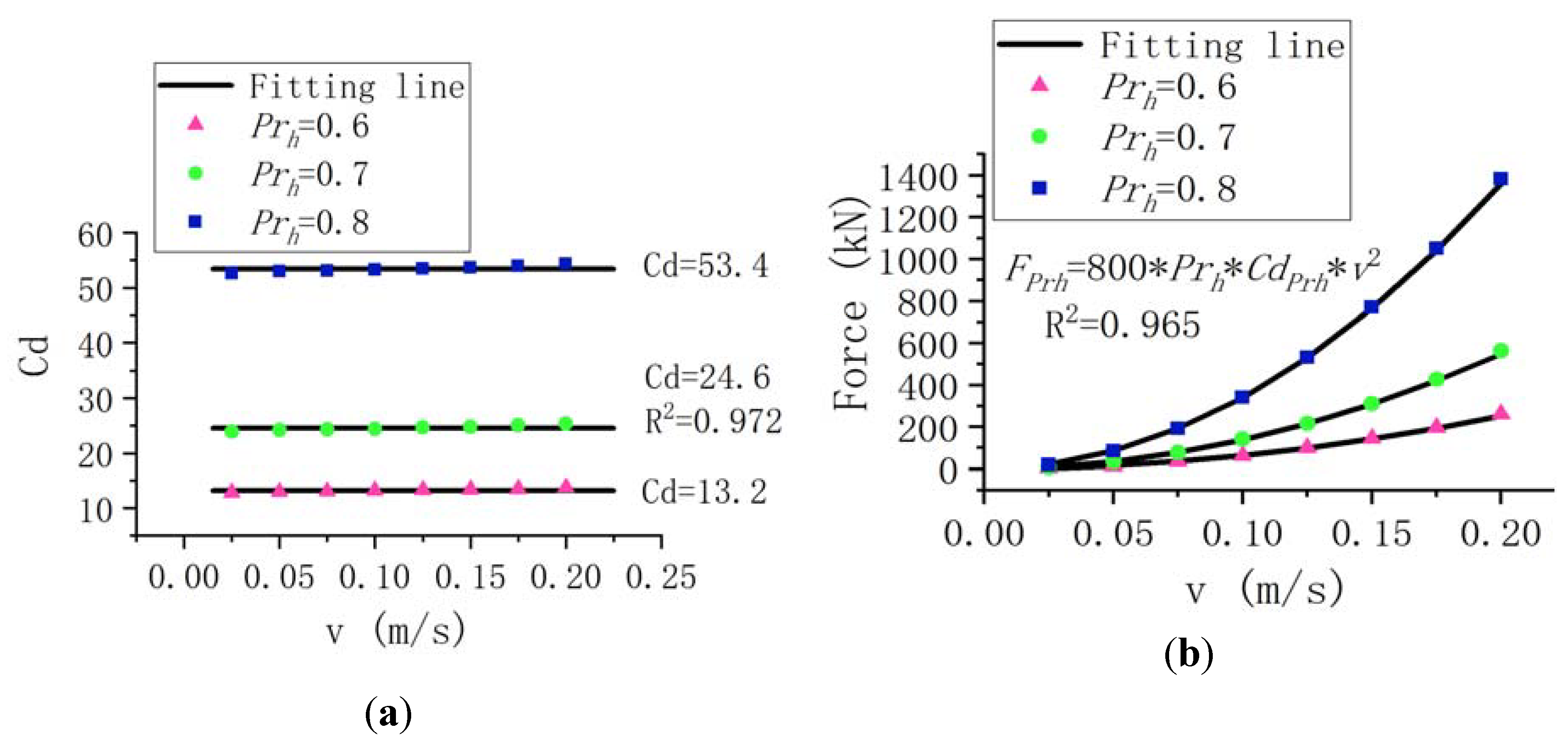

3.5. Effect of Inflow Velocity

3.6. Effect of Water Temperature Stratification Ratio

4. Discussion

4.1. Simulation Model

4.2. Engineering Applications

4.3. Limitations

4.4. Further Work

4.4.1. Flood condition

4.4.2. Various engineering applications

4.4.3. Implementation plan

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jamali, M.; Haddadzadegan, H. Effects of a sill on selective withdrawal through a point sink in a linearly stratified fluid. Adv. Water Resour. 2010, 33, 1517–1523. [Google Scholar] [CrossRef]

- Zouabi-Aloui, B.; Adelana, S.M.; Gueddari, M. Effects of selective withdrawal on hydrodynamics and water quality of a thermally stratified reservoir in the southern side of the Mediterranean Sea: A simulation approach. Environ. Monit. Assess 2015, 187, 292. [Google Scholar] [CrossRef]

- Lindim, C.; Pinho, J.L.; Vieira, J.M.P. Analysis of spatial and temporal patterns in a large reservoir using water quality and hydrodynamic modeling. Ecol. Model. 2011, 222, 2485–2494. [Google Scholar] [CrossRef]

- Dai, L.; Dai, H.; Jiang, D. Temporal and spatial variation of thermal structure in Three Gorges Reservoir: A simulation approach. J. Food Agric. Environ. 2012, 10, 1174–1178. [Google Scholar]

- Wang, S.; Qian, X.; Han, B.; Luo, L.; Hamilton, D.P. Effects of local climate and hydrological conditions on the thermal regime of a reservoir at Tropic of Cancer, in southern China. Water Res. 2012, 46, 2591–2604. [Google Scholar] [CrossRef]

- Ma, J.; Liu, D.; Wells, S.A.; Tang, H.; Ji, D.; Yang, Z. Modeling density currents in a typical tributary of the Three Gorges Reservoir, China. Ecol. Model. 2015, 296, 113–125. [Google Scholar] [CrossRef]

- Lian, J.; Yao, Y.; Ma, C.; Guo, Q. Reservoir Operation Rules for Controlling Algal Blooms in a Tributary to the Impoundment of Three Gorges Dam. Water 2014, 6, 3200–3223. [Google Scholar] [CrossRef]

- Shen, X.; Liu, S.; Li, R.; Ou, Y. Experimental study on the impact of temperature on the dissipation process of supersaturated total dissolved gas. J. Environ. Sci.-China 2014, 26, 1874–1878. [Google Scholar] [CrossRef] [PubMed]

- Bradford, S. Scoping Options for Mitigating Cold Water Discharges from Dams; CSIRO Land and Water: Canberra, Australia, 2000. [Google Scholar]

- Gao, X.; Chen, H.; Li, Y.; Xu, M. Flow Patter and Effect of Withdrawal Water from Stop Log Gate with Multi-Levels in Hydropower Station. J. Tianjin Univ. (Sci. Technol.) 2013, 46, 895–900. (In Chinese) [Google Scholar]

- Vermeyen, T. Application of Flexible Curtains to Control Mixing and Enable Selective Withdrawal in Reservoirs. In Proceedings of the 5th International Symposium on Stratified Flows, Vancouver, BC, Canada, 10–13 July 2000; IAHR: Madrid, Spain, 2000. [Google Scholar]

- Gao, X.; Li, G.; Han, Y. Effect of Flow Rate of Side-Type Orifice Intake on Withdrawn Water Temperature. Sci. World J. 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Asaeda, T.; Priyantha, D.G.N.; Saitoh, S.; Gotoh, K. A new technique for controlling algal blooms in the withdrawal zone of reservoirs using vertical curtains. Ecol. Eng. 1996, 7, 95–104. [Google Scholar] [CrossRef]

- Asaeda, T.; Pham, H.S.; Nimal Priyantha, D.G.; Manatunge, J.; Hocking, G.C. Control of algal blooms in reservoirs with a curtain: A numerical analysis. Ecol. Eng. 2001, 16, 395–404. [Google Scholar] [CrossRef]

- Park, C.; Park, M.; Kim, K.; Kim, N.; Kim, Y.; Gwon, E.; Kim, B.; Lim, B.; Hwang, S. A Physical Pre-Treatment Method (Vertical Weir Curtain) for Mitigating Cyanobacteria and Some of Their Metabolites in a Drinking Water Reservoir. Water 2017, 9, 775. [Google Scholar] [CrossRef]

- Lee, H.S.; Chung, S.W.; Choi, J.K.; Min, B.H. Feasibility of curtain weir installation for water quality management in Daecheong Reservoir. Desalin. Water Treat. 2012, 19, 164–172. [Google Scholar] [CrossRef]

- Lian, J.J.; Yan, X.; Peng, X.M.; Ma, C.; Liu, F.; Wang, H.J. A Kind of Floating and Hanging Flexible Water Blocking Curtain. Chinese Patent China CN 204753530U, 11 November 2015. (In Chinese). [Google Scholar]

- He, W.; Lian, J.; Yao, Y.; Wu, M.; Ma, C. Modeling the effect of temperature-control curtain on the thermal structure in a deep stratified reservoir. J. Environ. Manag. 2017, 202, 106–116. [Google Scholar] [CrossRef]

- Vermeyen, T. Use of Temperature Control Curtains to Control Reservoir Release Water Temperatures; Report 97-09; US Bureau of Reclamation: Denver, CO, USA, 1997.

- Shammaa, Y.; Zhu, D.Z. Experimental Study on Selective Withdrawal in a Two-Layer Reservoir Using a Temperature-Control Curtain. J. Hydraul. Eng. 2010, 136, 234–246. [Google Scholar] [CrossRef]

- Politano, M.; Haque, M.M.; Weber, L.J. A numerical study of the temperature dynamics at McNary Dam. Ecol. Model. 2008, 212, 408–421. [Google Scholar] [CrossRef]

- Lian, J.; Du, H.; Ma, C. Effects of temperature control curtain on water releases in deep water reservoirs. J. Hydraul. Eng. 2016, 47, 942–948. (In Chinese) [Google Scholar]

- He, W.; Lian, J.; Ma, C.; Wu, M.; Liu, F. Analysis of the Thrust Force on the Temperature-Control Curtain in a Large Stratified Reservoir. J. Hydraul. Eng. 2017, 143, 04017049. [Google Scholar] [CrossRef]

- Wang, H.; Si, F.; Lou, G.; Yang, W.; Yu, G. Hydrodynamic Characteristics of a Suspended Curtain for Sediment Trapping. J. Waterw. Port Coast. 2015, 141, 04014030. [Google Scholar] [CrossRef]

- ANSYS. ANSYS Fluent 16.0 Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2015. [Google Scholar]

- Wang, J.; Fan, H.; Zhu, L. Experimental study on mechanism and shape characteristics of suspended flexible dam. China Ocean Eng. 2014, 28, 869–878. [Google Scholar] [CrossRef]

- Sheng, C.; Lian, J.; Liu, F.; Xu, B. Force analysis on water barrier curtain for released flow with low temperature from deep reservoirs. J. Hydraul. Eng. 2016, 47, 1548–1557. (In Chinese) [Google Scholar]

- Lian, J.J.; He, J.L.; Liu, F.; Ran, D.J.; Wang, X.Q.; Wang, C. An Improved Empirical Model for Flood Discharge Atomization and Its Application to Optimize the Flip Bucket of the Nazixia Project. Int. J. Environ. Res. Public Health 2019, 16, 316. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Xu, Y.; Zhang, M.; Fu, S.; Meng, Y.; Huang, C. Distribution of drag coefficients along a flexible pipe with helical strakes in uniform flow. Ocean Eng. 2019, 184, 216–226. [Google Scholar] [CrossRef]

- Lou, X.; Zhou, T.; Cheng, L. Hydrodynamic coefficients of a yawed square cylinder in oscillatory flows. Ocean Eng. 2017, 130, 510–522. [Google Scholar] [CrossRef]

- Lian, J.J.; Li, P.Y.; Yao, Y.; He, W.; Shao, N. Experimental and Numerical Study on the Effect of the Temperature Control Curtain in Thermal Stratified Reservoirs. Appl. Sci. 2019, 9, 5354. [Google Scholar] [CrossRef]

| Similarity Criterion | Physical Quantity | Scale Relation | Scale |

|---|---|---|---|

| Gravity similarity theory | Length | λL | 25 |

| Velocity | λt = λL0.5 | 5 | |

| Force | λF = λL3 | 15,625 | |

| Time | λt = λL0.5 | 5 |

| Number | Depth (m) | Flow Depth Above TCC (m) | Water Blocking Rate | Average Velocity (m/s) | Load of TCC (N) |

|---|---|---|---|---|---|

| A1 | 1.44 | 0.16 | 0.828 | 0.0069 | 4.09 |

| A2 | 1.44 | 0.16 | 0.828 | 0.0078 | 5.44 |

| A3 | 1.44 | 0.16 | 0.828 | 0.0094 | 8.25 |

| A4 | 1.44 | 0.16 | 0.828 | 0.0102 | 10.35 |

| B1 | 1.30 | 0.25 | 0.716 | 0.007 | 1.40 |

| B2 | 1.30 | 0.25 | 0.716 | 0.008 | 2.00 |

| B3 | 1.30 | 0.25 | 0.716 | 0.01 | 3.30 |

| B4 | 1.30 | 0.25 | 0.716 | 0.0123 | 5.29 |

| Number | Description | Water Blocking Rate Prh | Area Ratio Pra | Inclination Ratio Prl | Inflow Velocity vin (m/s) | Water Temperature Stratification Ratio β |

|---|---|---|---|---|---|---|

| C1–C11 | Varying water blocking rates Prh (basic working condition) | Range: 0.3–0.8 step size 0.05 | 1.0 | 0 | 0.05 | 0 |

| D1–D6 | Varying area ratios Pra | 0.6 | Range: 1.0–1.5, step size: 0.1 | 0 | 0.05 | 0 |

| D6–D12 | 0.7 | 0 | 0.05 | 0 | ||

| D13–D18 | 0.8 | 0 | 0.05 | 0 | ||

| E1–E11 | Varying inclination ratios Prl | 0.6 | 1.0 | Range: 0–1.0, step size: 0.1 | 0.05 | 0 |

| E12–E22 | 0.7 | 1.0 | 0.05 | 0 | ||

| E23–E33 | 0.8 | 1.0 | 0.05 | 0 | ||

| F1–F8 | Varying inflow velocities vin | 0.6 | 1.0 | 0 | Range: 0.025–0.2, step size: 0.025 | 0 |

| F9–F16 | 0.7 | 1.0 | 0 | 0 | ||

| F17–F24 | 0.8 | 1.0 | 0 | 0 | ||

| G1–G11 | Varying water temperature stratification ratios β | 0.6 | 1.0 | 0 | 0.05 | Range: 0–1.0, step size: 0.1 |

| G12–G22 | 0.7 | 1.0 | 0 | 0.05 | ||

| G23–G33 | 0.8 | 1.0 | 0 | 0.05 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lian, J.; Liu, C.; Wang, H.; Liu, F.; Lu, W.; Zhao, Y. Simulation and Experimental Analysis on the Load Characteristics of a Temperature-Control Curtain in a Thermally-Stratified Reservoir. Appl. Sci. 2020, 10, 1461. https://doi.org/10.3390/app10041461

Lian J, Liu C, Wang H, Liu F, Lu W, Zhao Y. Simulation and Experimental Analysis on the Load Characteristics of a Temperature-Control Curtain in a Thermally-Stratified Reservoir. Applied Sciences. 2020; 10(4):1461. https://doi.org/10.3390/app10041461

Chicago/Turabian StyleLian, Jijian, Chunxi Liu, Haijun Wang, Fang Liu, Wenhe Lu, and Yue Zhao. 2020. "Simulation and Experimental Analysis on the Load Characteristics of a Temperature-Control Curtain in a Thermally-Stratified Reservoir" Applied Sciences 10, no. 4: 1461. https://doi.org/10.3390/app10041461

APA StyleLian, J., Liu, C., Wang, H., Liu, F., Lu, W., & Zhao, Y. (2020). Simulation and Experimental Analysis on the Load Characteristics of a Temperature-Control Curtain in a Thermally-Stratified Reservoir. Applied Sciences, 10(4), 1461. https://doi.org/10.3390/app10041461