The Use of Volcanic Powder as a Cement Replacement for the Development of Sustainable Mortars

Abstract

1. Introduction

2. Materials and Methods

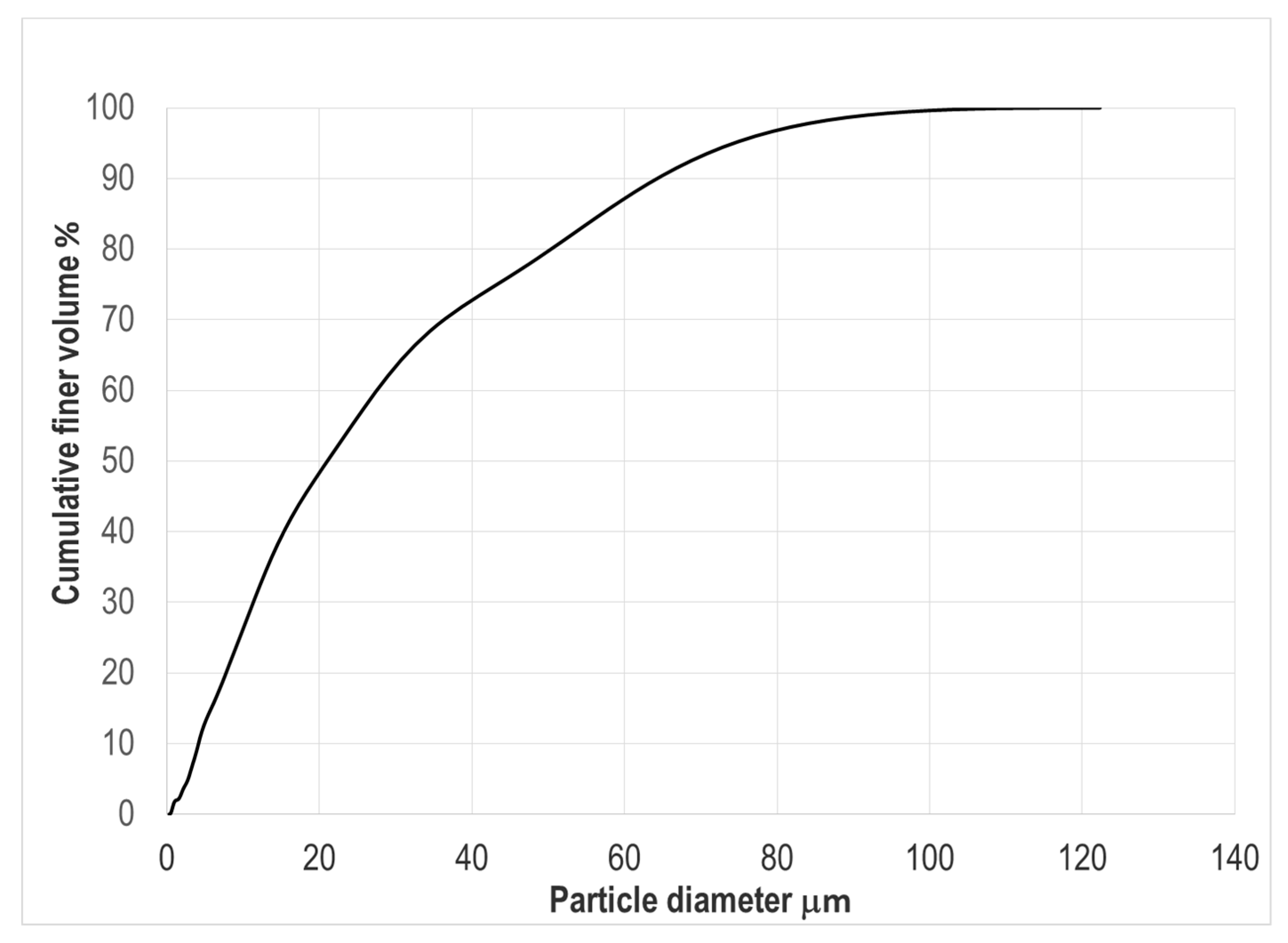

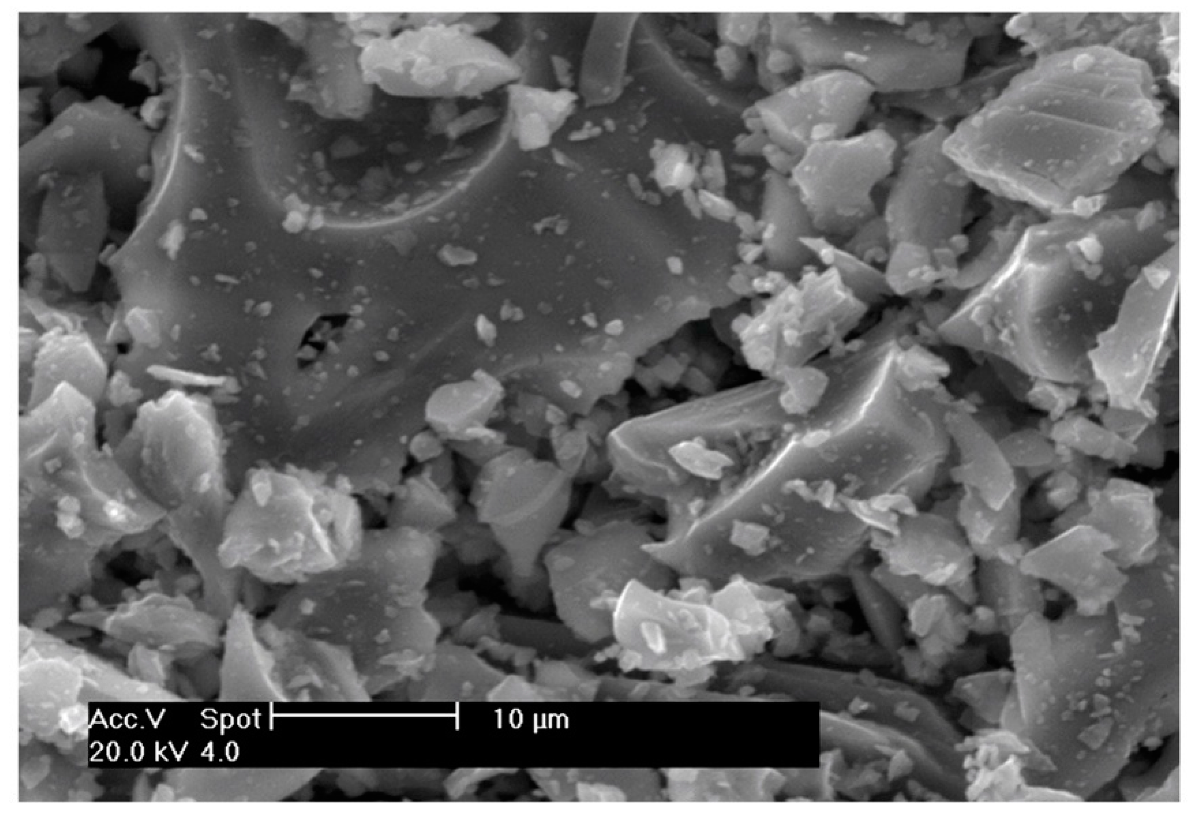

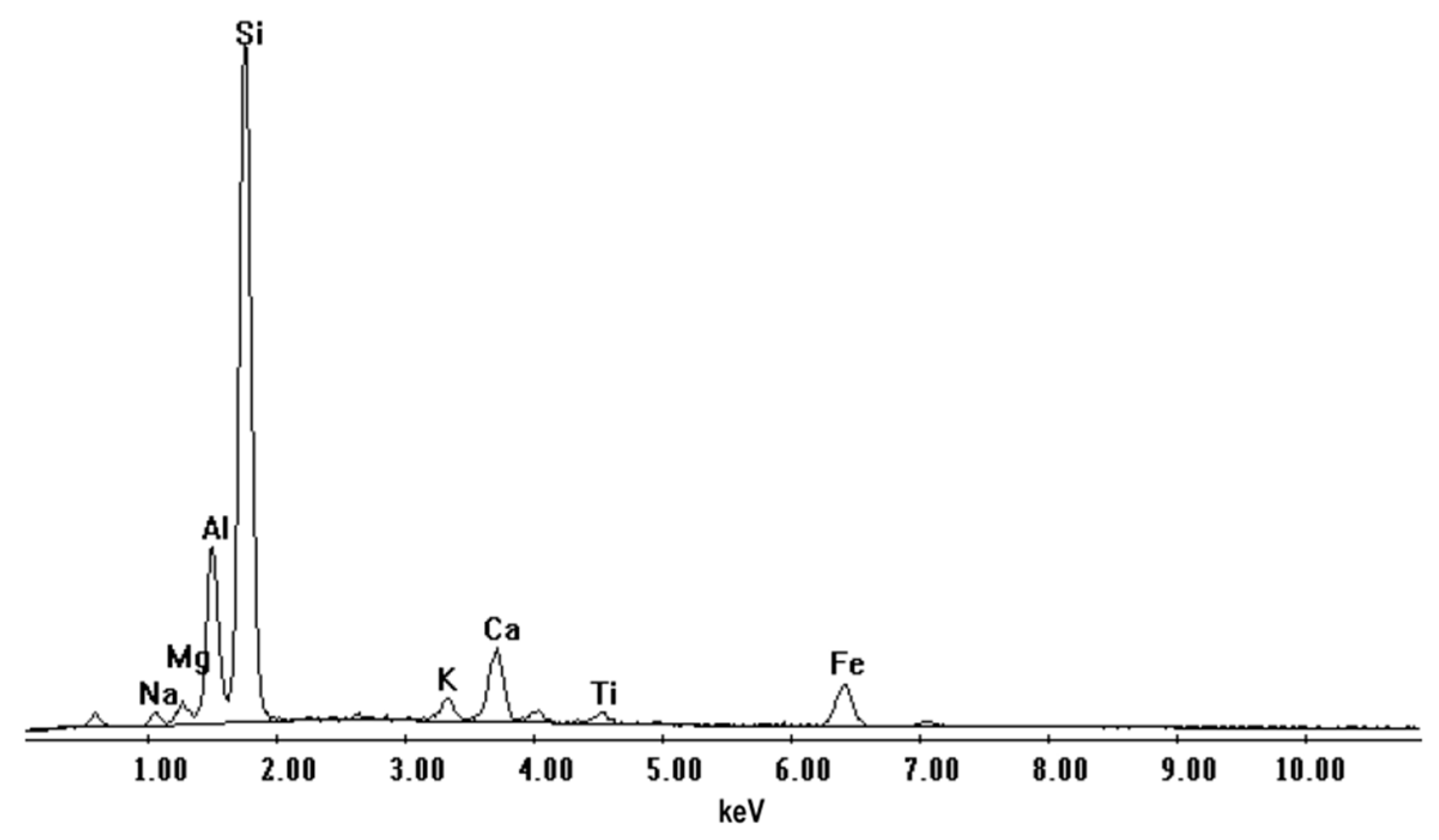

2.1. Volcanic Powder Characterization

2.2. Sample Preparation and Environmental Conditions

2.3. Mercury Intrusion Porosimetry

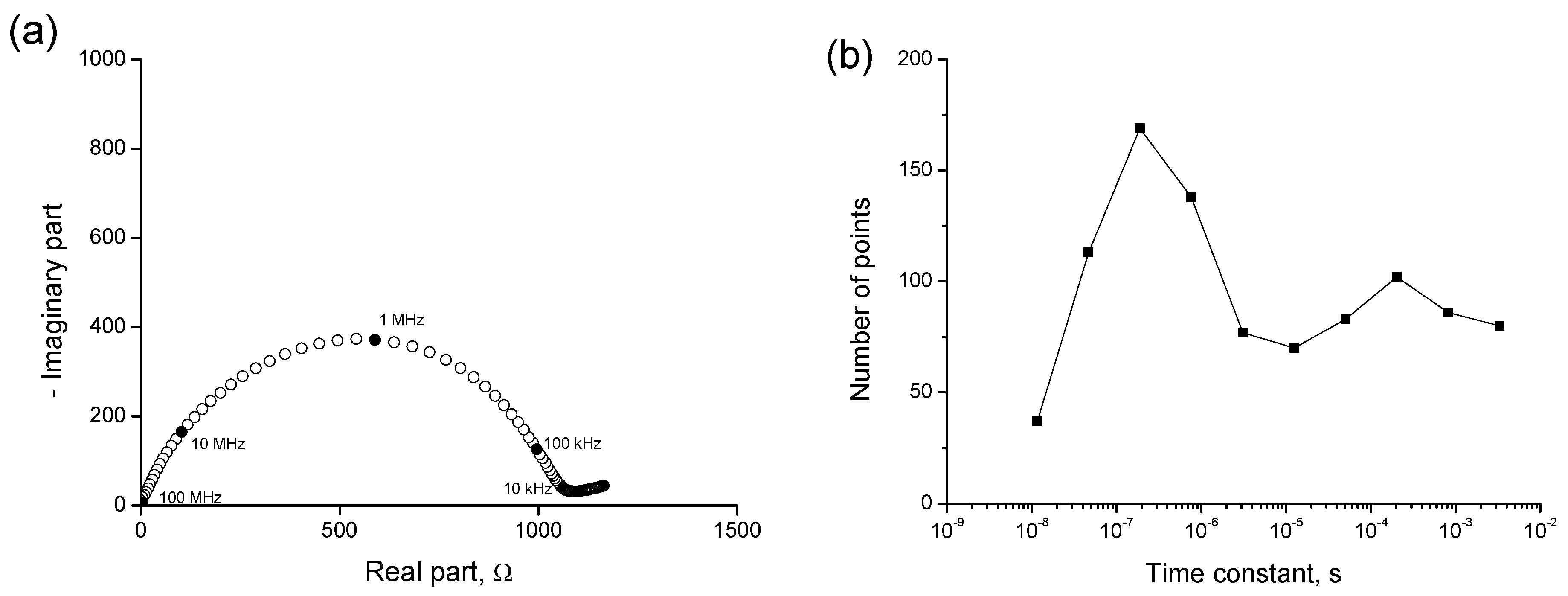

2.4. Impedance Spectroscopy

2.5. Capillary Absorption Test

2.6. Steady-State Diffusion Coefficient Obtained from the Resistivity of the Saturated Sample

2.7. Forced Migration Test

2.8. Mechanical Strength Test

2.9. Evaluation of Greenhouse Gas (GHG) Emissions

3. Results and Discussion

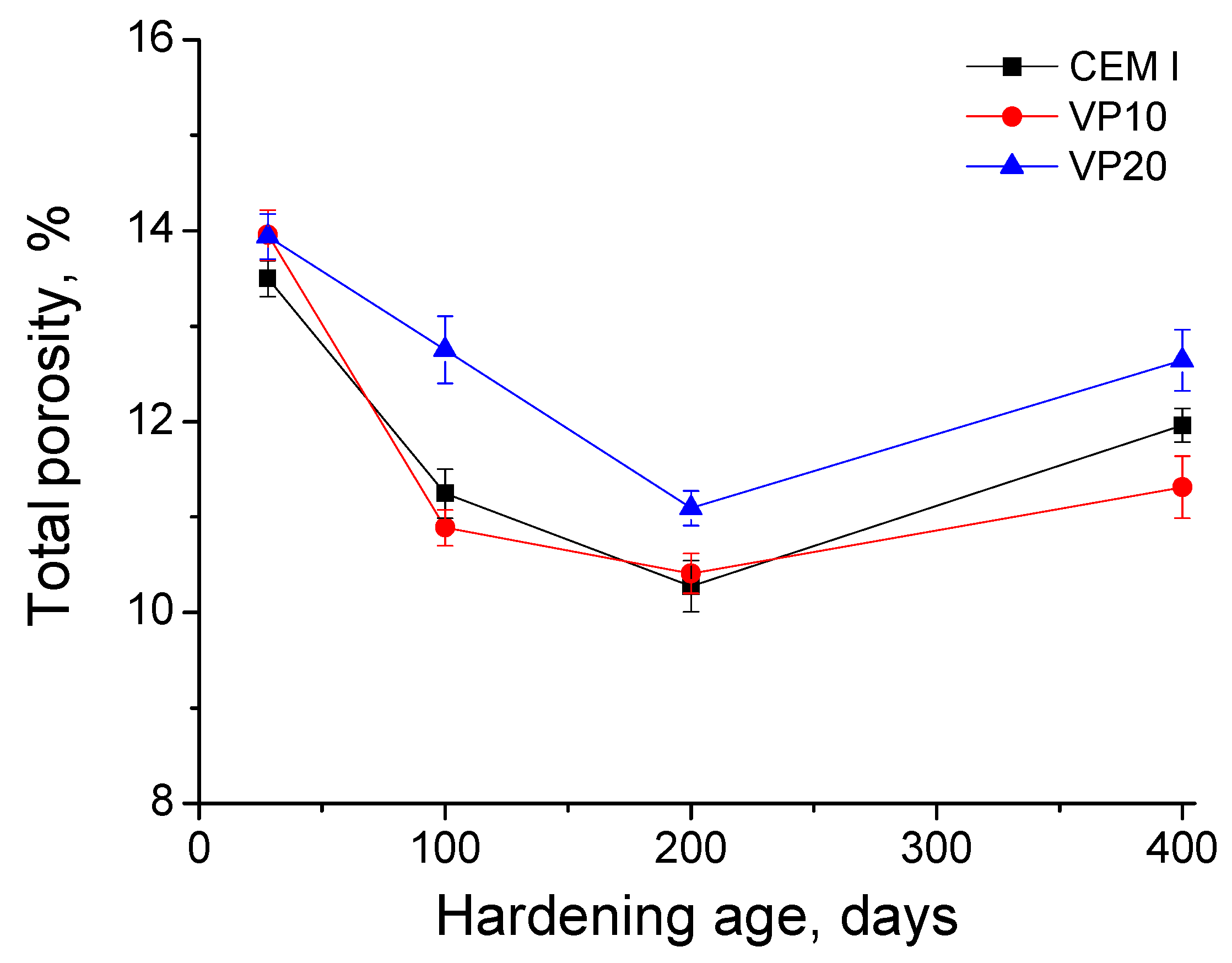

3.1. Mercury Intrusion Porosimetry

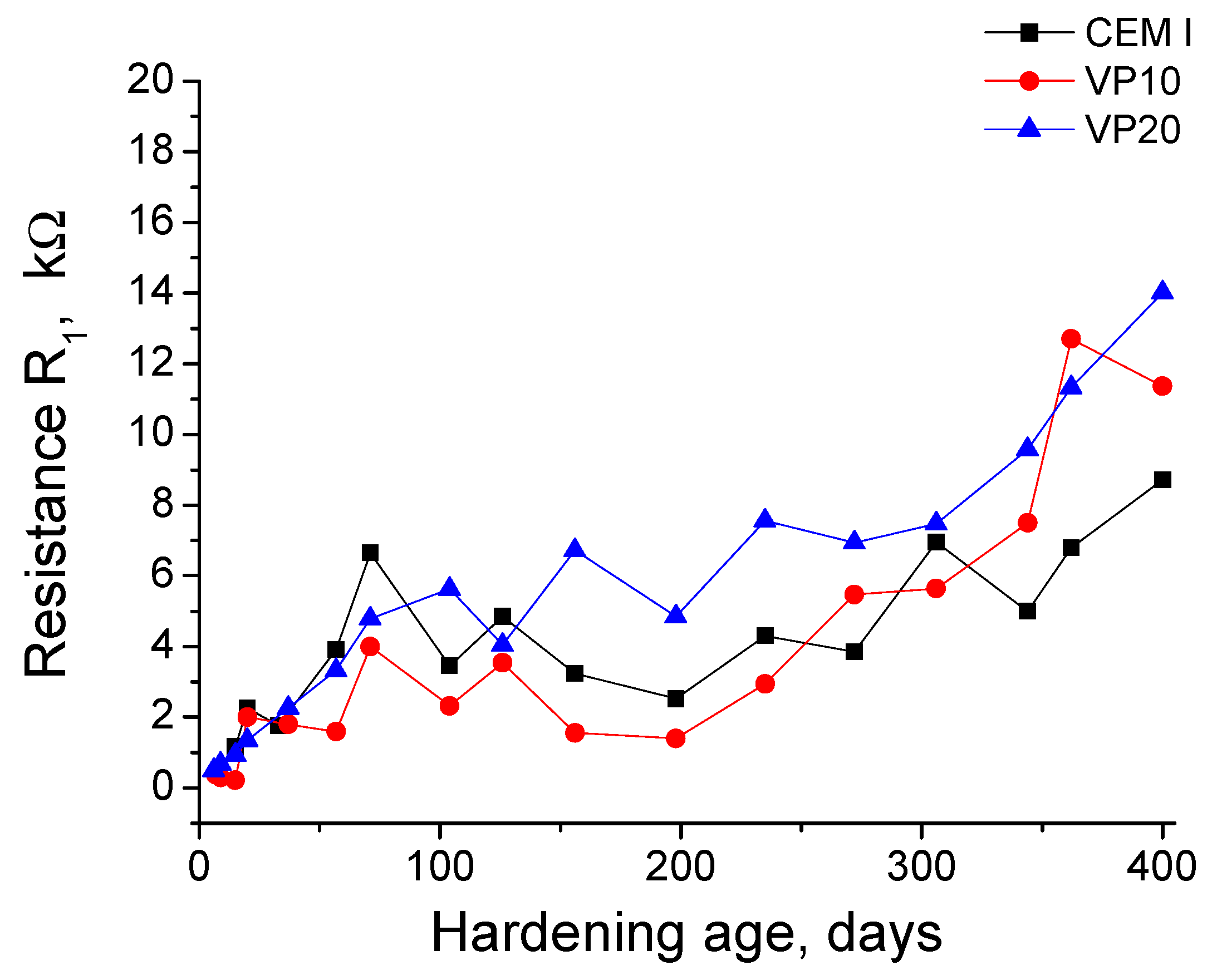

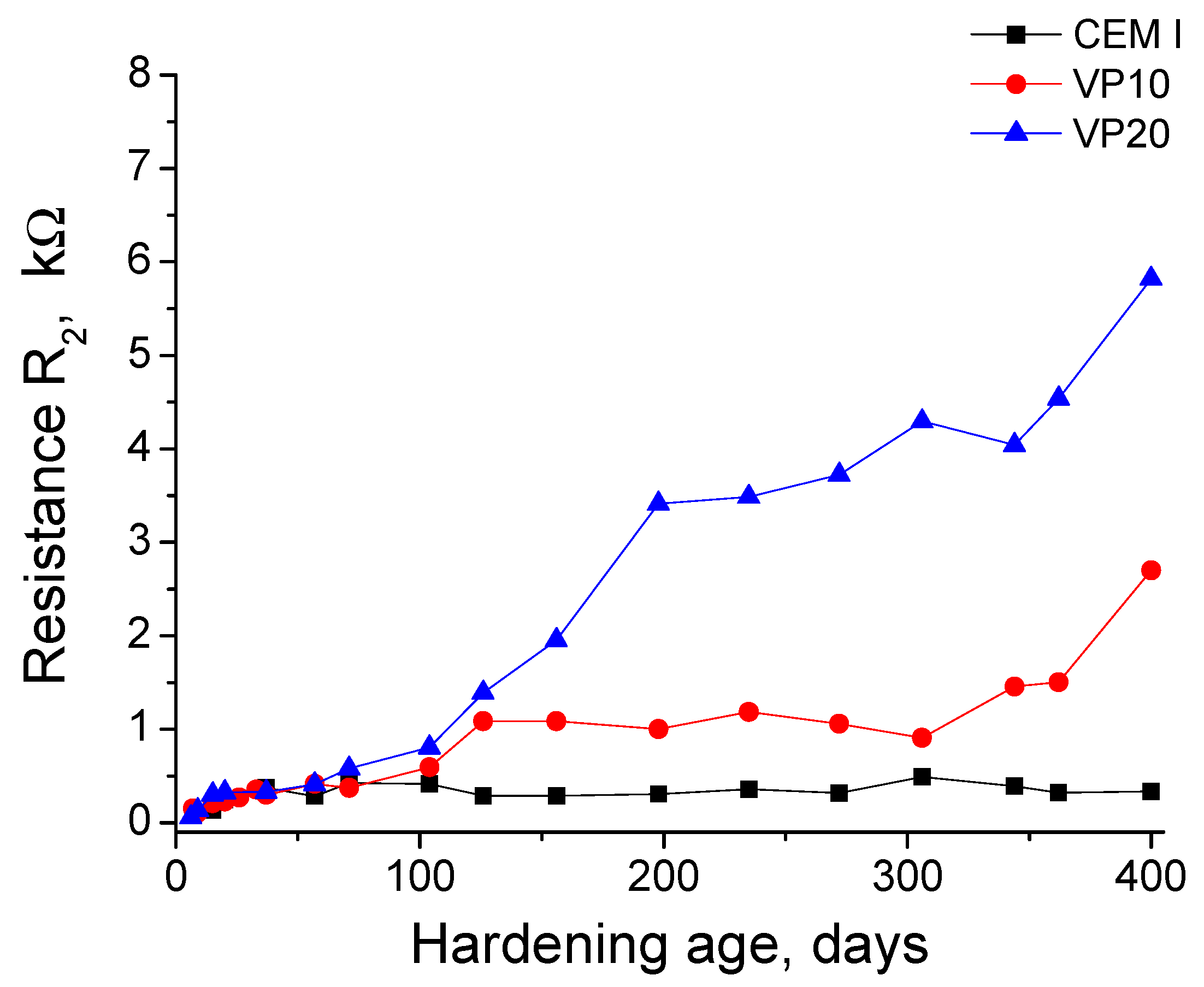

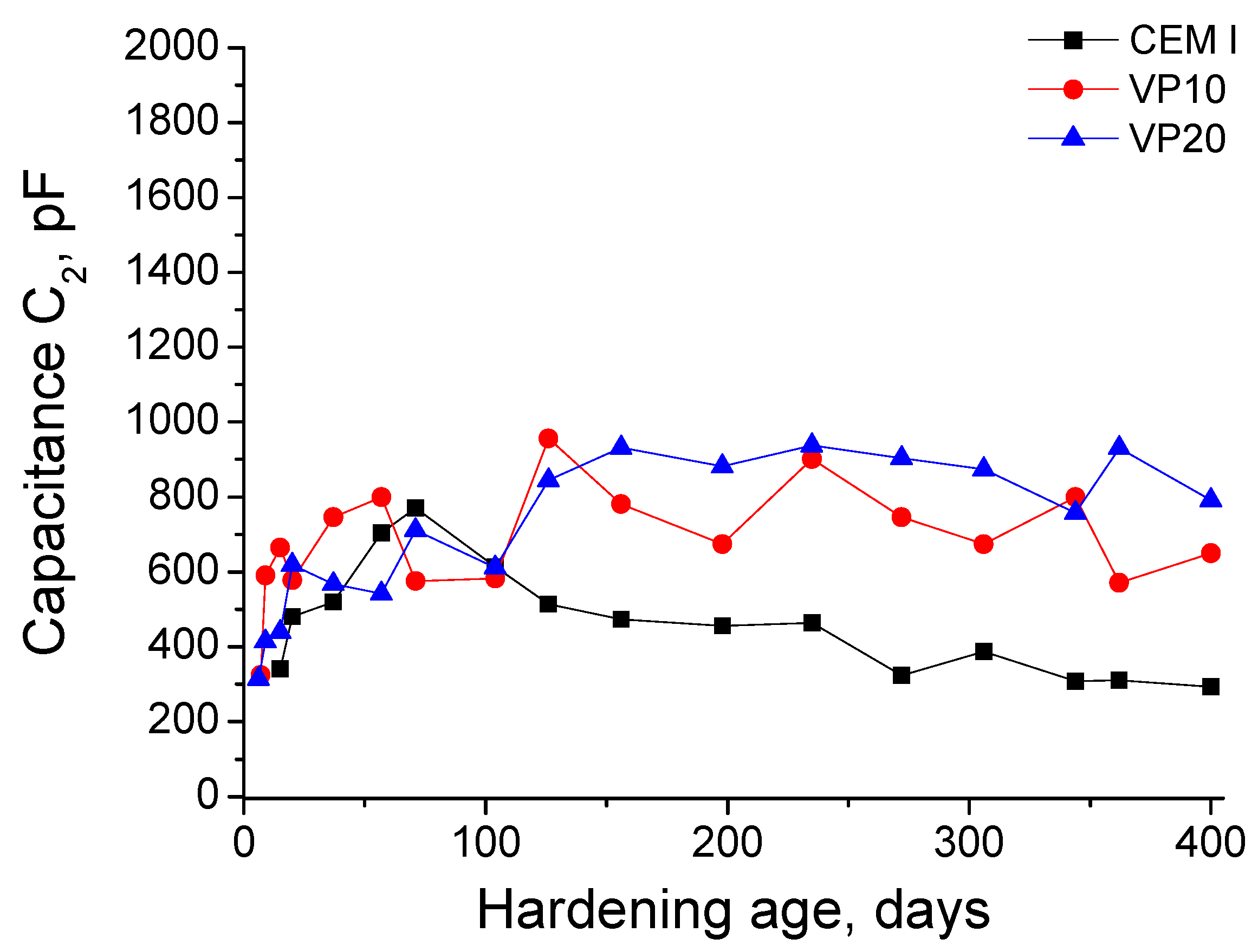

3.2. Impedance Spectroscopy

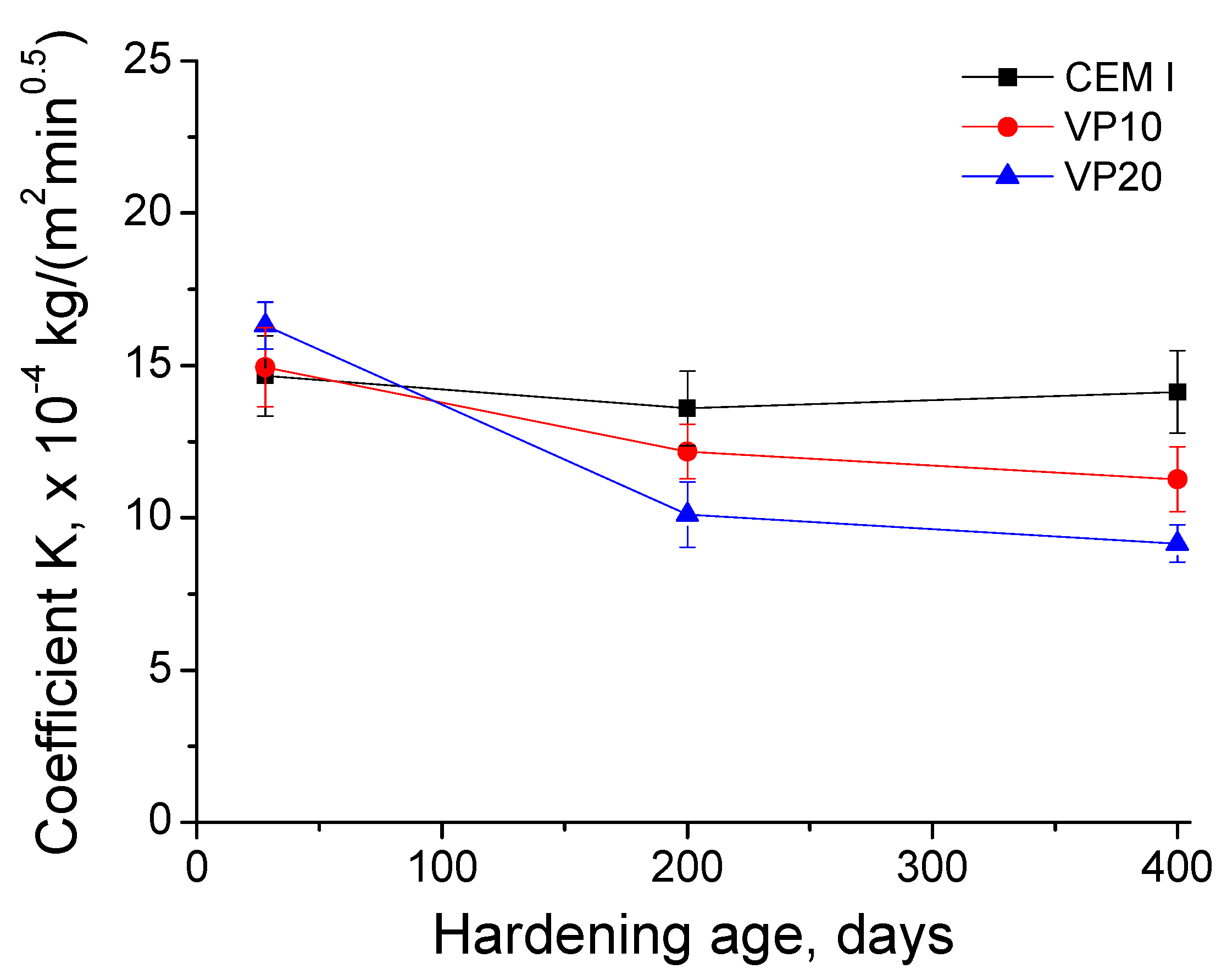

3.3. Capillary Absorption Test

3.4. Steady-State Diffusion Coefficient Obtained from the Resistivity of the Saturated Sample

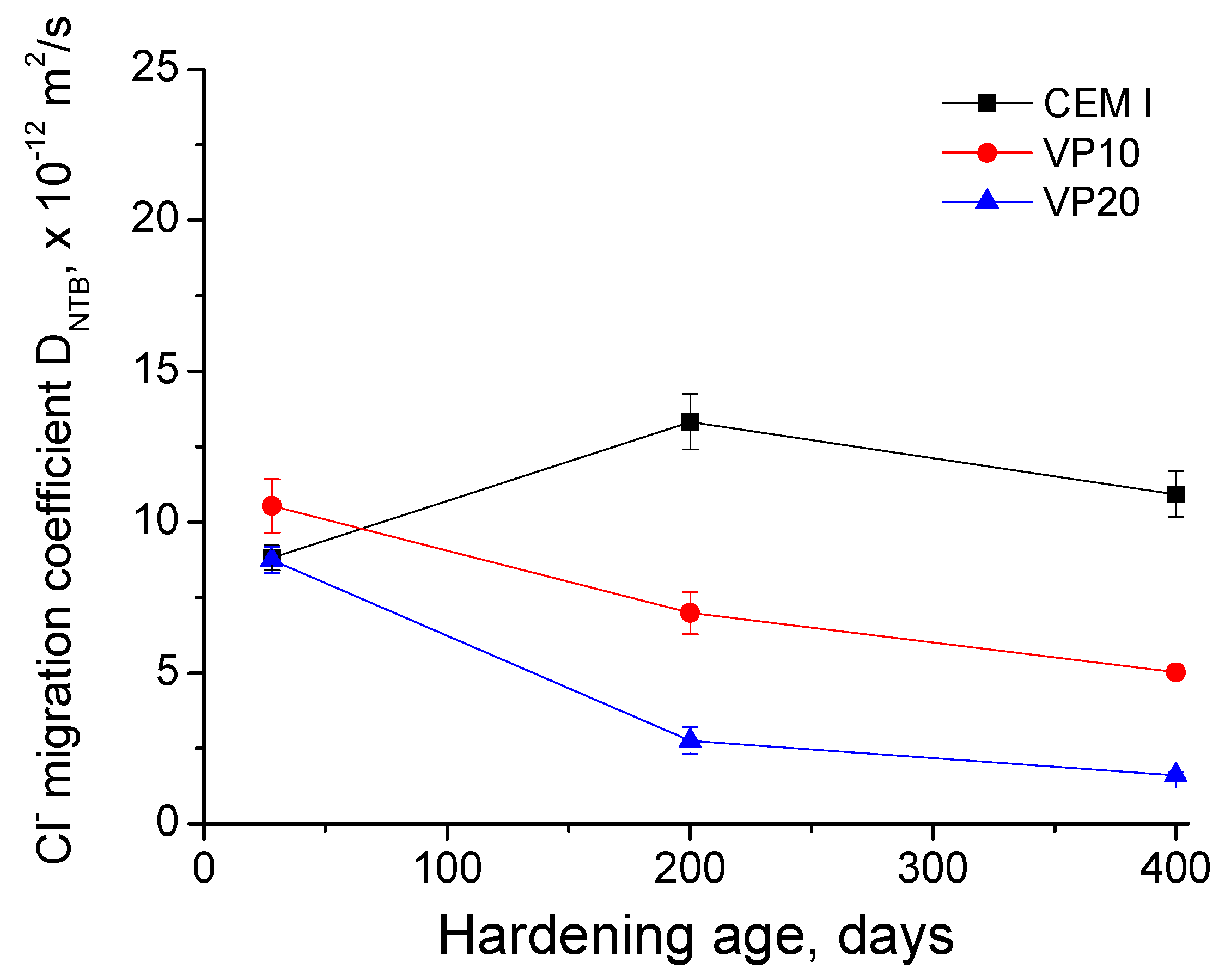

3.5. Forced Migration Test

3.6. Mechanical Properties

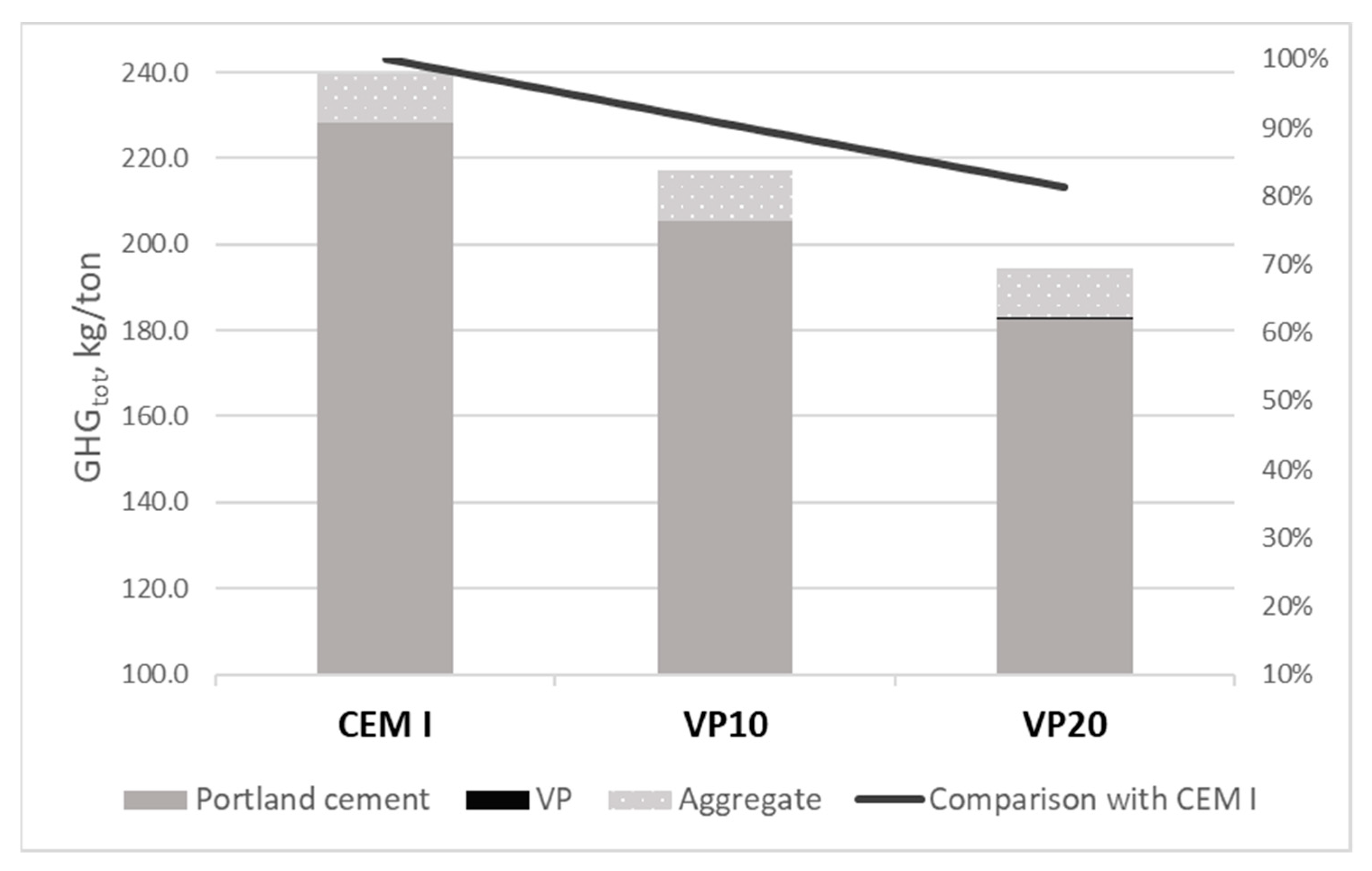

3.7. Evaluation of Greenhouse Gas (GHG) Emissions

4. Conclusions

- In all the mortars studied, the pore structure was probably refined as the curing days increased due to the progressive development of clinker hydration and the pozzolanic reactions of the VP;

- Compared to the CEM I mortar, in the mortars with VP a greater refinement of the microstructure was observed, which could be due to the formation of additional solid phases, a result of the pozzolanic reactions of the VP;

- The findings of the non-destructive impedance spectroscopy technique were generally compatible with those obtained with mercury intrusion porosimetry. It is possible to use impedance spectroscopy as a way to follow the development of the pore network in the mortars that incorporate VP as clinker replacement;

- The addition of VP, up to 20% of the binder, allowed the durability-related properties of the mortars to be improved. These improvements could be linked to the more refined microstructure produced by the pozzolanic activity of VP;

- The addition of 10% volcanic powder did not present losses in the compressive strength of the mortars, fulfilling the compressive strength requirements of the corresponding standard;

- From the results obtained in this study, it has been noted that the mortars that incorporate 10% or 20% VP as a clinker replacement showed good service properties at high hardening times (400 days), even exceeding the properties of the CEM I control mortars;

- From an environmental point of view, the proposed material is attractive since it makes use of VP, in this way, avoiding or reducing the harmful effects in the short term that VP could produce in the natural soil on which it is deposited. In addition, the potential of this replacement was shown to reduce the total greenhouse gas emissionsup to 18.66%, when 20% of CEM I is replaced by VP;

- Volcanic powder as a raw material reduces the energy costs related to mortar production, which in addition to reducing CO2 emissions, could also reduce costs. However, this must be proven in future studies.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hossain, M.U.; Xuan, D.; Poon, C.S. Sustainable management and utilisation of concrete slurry waste: A case study in Hong Kong. Waste Manag. 2017, 61, 397–404. [Google Scholar] [CrossRef]

- Labbaci, Y.; Labbaci, B.; Abdelaziz, Y.; Mekkaoui, A.; Alouani, A. The use of the volcanic powders as supplementary cementitious materials for environmental-friendly durable concrete. Constr. Build. Mater. 2017, 133, 468–481. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influence of environmental conditions on durability of slag cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010. [Google Scholar]

- Ghanbari, M.; MonirAbbasi, A.; Ravanshadnia, M. Economic and Environmental Evaluation and Optimal Ratio of Natural and Recycled Aggregate Production. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Ibanco, F.J.; Sánchez, I.; Climent, M.A. Influence of Silica Fume Addition in the Long-Term Performance of Sustainable Cement Grouts for Micropiles Exposed to a Sulphate Aggressive Medium. Materials 2017, 10, 890. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.Á.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Letelier, V.; Ortega, J.M.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of Waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Medina, C.; Banfill, P.F.G.; Sánchez de Rojas, M.I.; Frías, M. Rheological and calorimetric behaviour of cements blended with containing ceramic sanitary ware and construction/demolition waste. Constr. Build. Mater. 2013, 40, 822–831. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Cement & Concrete Composites Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Experimental characterization of binary and ternary blended-cement concretes containing ultrafine residual rice husk and sugar cane bagasse ashes. Constr. Build. Mater. 2012, 29, 641–646. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Stafford, F.N.; Raupp-pereira, F. Life cycle assessment of the production of cement: A Brazilian case study. J. Clean. Prod. 2016, 137, 1293–1299. [Google Scholar] [CrossRef]

- Rajamma, R.; Senff, L.; Ribeiro, M.J.; Labrincha, J.A.; Ball, R.J.; Allen, G.C.; Ferreira, V.M. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoǧlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos. Part B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Pastor, J.L.; Ortega, J.M.; Flor, M.; López, M.P.; Sánchez, I.; Climent, M.A. Microstructure and durability of fly ash cement grouts for micropiles. Constr. Build. Mater. 2016, 117. [Google Scholar] [CrossRef]

- Ortega, J.M.; Pastor, J.L.; Albaladejo, A.; Sánchez, I.; Climent, M.A. Durability and compressive strength of blast furnace slag-based cement grout for special geotechnical applications. Mater. Constr. 2014, 64. [Google Scholar] [CrossRef]

- Ortega, J.M.; Ferrandiz, V.; Antón, C.; Climent, M.A.; Sánchez, I. Influence of curing conditions on the mechanical properties and durability of cement mortars. In Materials Characterisation IV: Computational Methods and Experiments; Mammoli, A.A., Brebbia, C.A., Eds.; WIT Press: Southampton, UK, 2009; pp. 381–392. [Google Scholar] [CrossRef]

- Naceri, A.; Hamina, M.C. Use of waste brick as a partial replacement of cement in mortar. Waste Manag. 2009, 29, 2378–2384. [Google Scholar] [CrossRef]

- Siddique, R. Properties of concrete made with volcanic ash. Resour. Conserv. Recycl. 2012, 66, 40–44. [Google Scholar] [CrossRef]

- Habert, G.; Choupay, N.; Montel, J.M.; Guillaume, D.; Escadeillas, G. Effects of the secondary minerals of the natural pozzolans on their pozzolanic activity. Cem. Concr. Res. 2008, 38, 963–975. [Google Scholar] [CrossRef]

- SeddikMeddah, M. Durability performance and engineering properties of shale and volcanic ashes concretes. Constr. Build. Mater. 2015, 79, 73–82. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Lachemi, M. Strength, durability and micro-structural aspects of high performance volcanic ash concrete. Cem. Concr. Res. 2007, 37, 759–766. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Al-Aibani, A.F.; Abdulsalam, M.F.; Mao, C.; Bumajdad, A.; Palkovic, S.D.; Büyüköztürk, O. Microstructure of cement paste with natural pozzolanic volcanic ash and Portland cement at different stages of curing. Constr. Build. Mater. 2016, 113, 423–441. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Palkovic, S.D.; Bumajdad, A.; Soriano, C.; Büyüköztürk, O. Use of silica fume and natural volcanic ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr. Build. Mater. 2018, 158, 574–590. [Google Scholar] [CrossRef]

- Anwar Hossain, K.M. Performance of volcanic ash based precast and in situ blended cement concretes in marine environment. J. Mater. Civ. Eng. 2005, 17, 694–702. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Blended cement using volcanic ash and pumice. Cem. Concr. Res. 2003, 33, 1601–1605. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; de Wolf, C.; Chin, S.; Ochsendorf, J.; Hajiah, A.E.; Al-Mumin, A.; Büyüköztürk, O. Impact of Embodied Energy on materials/buildings with partial replacement of ordinary Portland Cement (OPC) by natural Pozzolanic Volcanic Ash. J. Clean. Prod. 2018, 177, 547–554. [Google Scholar] [CrossRef]

- Romero, J.E.; Morgavi, D.; Arzilli, F.; Daga, R.; Caselli, A.; Reckziegel, F.; Viramonte, J.; Díaz-Alvarado, J.; Polacci, M.; Burton, M.; et al. Eruption dynamics of the 22–23 April 2015 Calbuco Volcano (Southern Chile): Analyses of tephra fall deposits. J. Volcanol. Geotherm. Res. 2016, 317, 15–29. [Google Scholar] [CrossRef]

- Reckziegel, F.; Bustos, E.; Mingari, L.; Báez, W.; Villarosa, G.; Folch, A.; Collini, E.; Viramonte, J.; Romero, J.; Osores, S. Forecasting volcanic ash dispersal and coeval resuspension during the April–May 2015 Calbuco eruption. J. Volcanol. Geotherm. Res. 2016, 321, 44–57. [Google Scholar] [CrossRef]

- Asociación Española de Normalización y Certificación (AENOR). UNE-EN 197-1:2011. Composición, Especificaciones y Criterios de Conformidad de Los Cementos Comunes; AENOR: Madrid, Spain, 2011; p. 30. (In Spanish) [Google Scholar]

- Asociación Española de Normalización y Certificación (AENOR). UNE-EN 196-1:2005. Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias Mecánicas; AENOR: Madrid, Spain, 2005; p. 36. (In Spanish) [Google Scholar]

- Fraj, A.B.; Idir, R. Concrete based on recycled aggregates – Recycling and environmental analysis: A case study of paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- OECD Climate Change Mitigation Policies. Available online: http://www.compareyourcountry.org/climate-policies?cr=oecd{\&}lg=en{\&}page=2{\&}visited=1 (accessed on 28 July 2018).

- Williams, M.; Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.A. Non-Destructive Study of the Microstructural Effects of Sodium and Magnesium Sulphate Attack on Mortars Containing Silica Fume Using Impedance Spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Cabeza, M.; Merino, P.; Miranda, A.; Nóvoa, X.R.; Sanchez, I. Impedance spectroscopy study of hardened Portland cement paste. Cem. Concr. Res. 2002, 32, 881–891. [Google Scholar] [CrossRef]

- Cabeza, M.; Keddam, M.; Nóvoa, X.R.; Sánchez, I.; Takenouti, H. Impedance spectroscopy to characterize the pore structure during the hardening process of Portland cement paste. Electrochim. Acta 2006, 51, 1831–1841. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Macdonald, J.B.; Johnson, W. Impedance Spectroscopy: Theory, Experiment, and Applications. In Impedance Spectroscopy: Theory, Experiment, and Applications, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; pp. 1–26. ISBN 9780471716242. [Google Scholar]

- Vladikova, D.; Zoltowski1, P.; Makowska, E.; Stoynov1, Z. Selectivity study of the differential impedance analysis—Comparison with the complex non-linear least-squares method. Electrochim. Acta 2002, 47, 2943–2951. [Google Scholar] [CrossRef]

- Asociación Española de Normalización y Certificación (AENOR). UNE 83982:2008. Durabilidad del Hormigón. Métodos de Ensayo. Determinación de La Absorción de Agua Por Capilaridad del Hormigón Endurecido. Método Fagerlund; AENOR: Madrid, Spain, 2008; p. 8. (In Spanish) [Google Scholar]

- Ortega, J.M.; Sánchez, I.; Antón, C.; de Vera, G.; Climent, M.A. Influence of environment on durability of fly ash cement mortars. ACI Mater. J. 2012, 109, 647–656. [Google Scholar]

- Rilem recommendation TC 116-PCD. Permeability of concrete as a criterion of its durability. Mater. Struct. 1999, 32, 174–179. [Google Scholar]

- Andrade, C.; Alonso, C.; Arteaga, A.; Tanner, P. Methodology based on the electrical resistivity for the calculation of reinforcement service life. In Proceedings of the 5th CANMET/ACI International Conference on Durability of Concrete, Supplementary Papers, Barcelona, Spain, 4–9 June 2000; Malhotra, V.M., Ed.; American Concrete Institute: Farmington Hills, MI, USA, 2000; pp. 899–915. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C1202-12, Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2012; p. 8. [Google Scholar]

- Nordtest. NT Build 492. Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; Nordtest Espoo: Greater Helsinki, Finland, 1999; p. 8. [Google Scholar]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Letelier, V.; Ortega, M.; Tarela, E.; Muñoz, P.; Henríquez-Jara, B.I.; Moriconi, G. Mechanical Performance of Eco-Friendly Concretes with Volcanic Powder and Recycled Concrete Aggregates. Sustainability 2018, 10, 3036. [Google Scholar] [CrossRef]

- UK Government. Department for Business, E. & I. S. Government Emission Conversion Factors for Greenhouse Gas Company Reporting. Available online: https://www.gov.uk/government/collections/government-conversion-factors-for-company-reporting (accessed on 7 August 2018).

- Liu, Y.; Sidhu, K.S.; Chen, Z.; Yang, E.-H. Alkali-treated incineration bottom ash as supplementary cementitious materials. Constr. Build. Mater. 2018, 179, 371–378. [Google Scholar] [CrossRef]

| Composition | VP |

|---|---|

| SiO2 | 57.76% |

| Al2O3 | 14.54% |

| CaO | 8.27% |

| Fe2O3 | 11.00% |

| SO3 | - |

| MgO | 2.44% |

| Na2O | 2.41% |

| K2O | 2.14% |

| TiO2 | 1.42% |

| Density | 2450 kg/m3 |

| Blaine surface area | 285 m2/kg |

| Raw Material | Embodied Energy | ||||||

|---|---|---|---|---|---|---|---|

| % | |||||||

| Cement (k = c) | 0.273 | 0 | 830 | 0.142 | 50 | 7.089 | 4.6 |

| 10 | |||||||

| 20 | |||||||

| VP (k = VP) | 0.273 | 0 | 6 | 0.142 | 50 | 7.089 | 0.0045 |

| 10 | |||||||

| 20 | |||||||

| Sand (k = s) | 0.818 | 0 | 14 | 0.142 | 100 | 14.177 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Letelier, V.; Ortega, J.M.; Tremiño, R.M.; Henriquéz-Jara, B.I.; Fustos, I.; Real-Herraiz, T.; Moriconi, G.; Climent, M.Á.; Sánchez, I. The Use of Volcanic Powder as a Cement Replacement for the Development of Sustainable Mortars. Appl. Sci. 2020, 10, 1460. https://doi.org/10.3390/app10041460

Letelier V, Ortega JM, Tremiño RM, Henriquéz-Jara BI, Fustos I, Real-Herraiz T, Moriconi G, Climent MÁ, Sánchez I. The Use of Volcanic Powder as a Cement Replacement for the Development of Sustainable Mortars. Applied Sciences. 2020; 10(4):1460. https://doi.org/10.3390/app10041460

Chicago/Turabian StyleLetelier, Viviana, José Marcos Ortega, Rosa María Tremiño, Bastián I. Henriquéz-Jara, Ivo Fustos, Teresa Real-Herraiz, Giacomo Moriconi, Miguel Ángel Climent, and Isidro Sánchez. 2020. "The Use of Volcanic Powder as a Cement Replacement for the Development of Sustainable Mortars" Applied Sciences 10, no. 4: 1460. https://doi.org/10.3390/app10041460

APA StyleLetelier, V., Ortega, J. M., Tremiño, R. M., Henriquéz-Jara, B. I., Fustos, I., Real-Herraiz, T., Moriconi, G., Climent, M. Á., & Sánchez, I. (2020). The Use of Volcanic Powder as a Cement Replacement for the Development of Sustainable Mortars. Applied Sciences, 10(4), 1460. https://doi.org/10.3390/app10041460