Application of Organic-Inorganic Hybrids in Chemical Analysis, Bio- and Environmental Monitoring

Abstract

1. Introduction

2. Classification and Synthesis of Organic-Inorganic Hybrids (OIH)

2.1. Classification

2.2. Synthesis

2.2.1. Sol-Gel and Solvothermal Methods

2.2.2. (Self) Assembly Method

2.2.3. Supramolecular Template Method

2.2.4. Combined Method

3. Biosensors as a Targeted Class of OIH

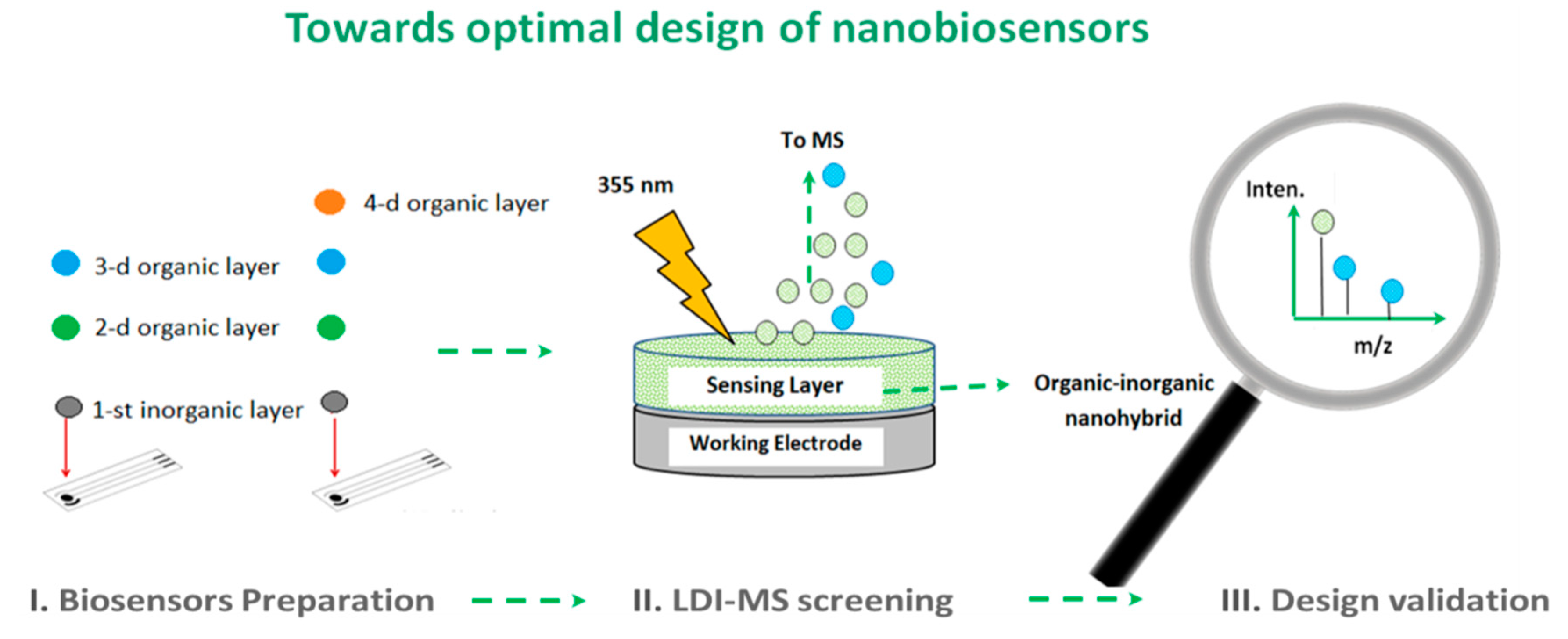

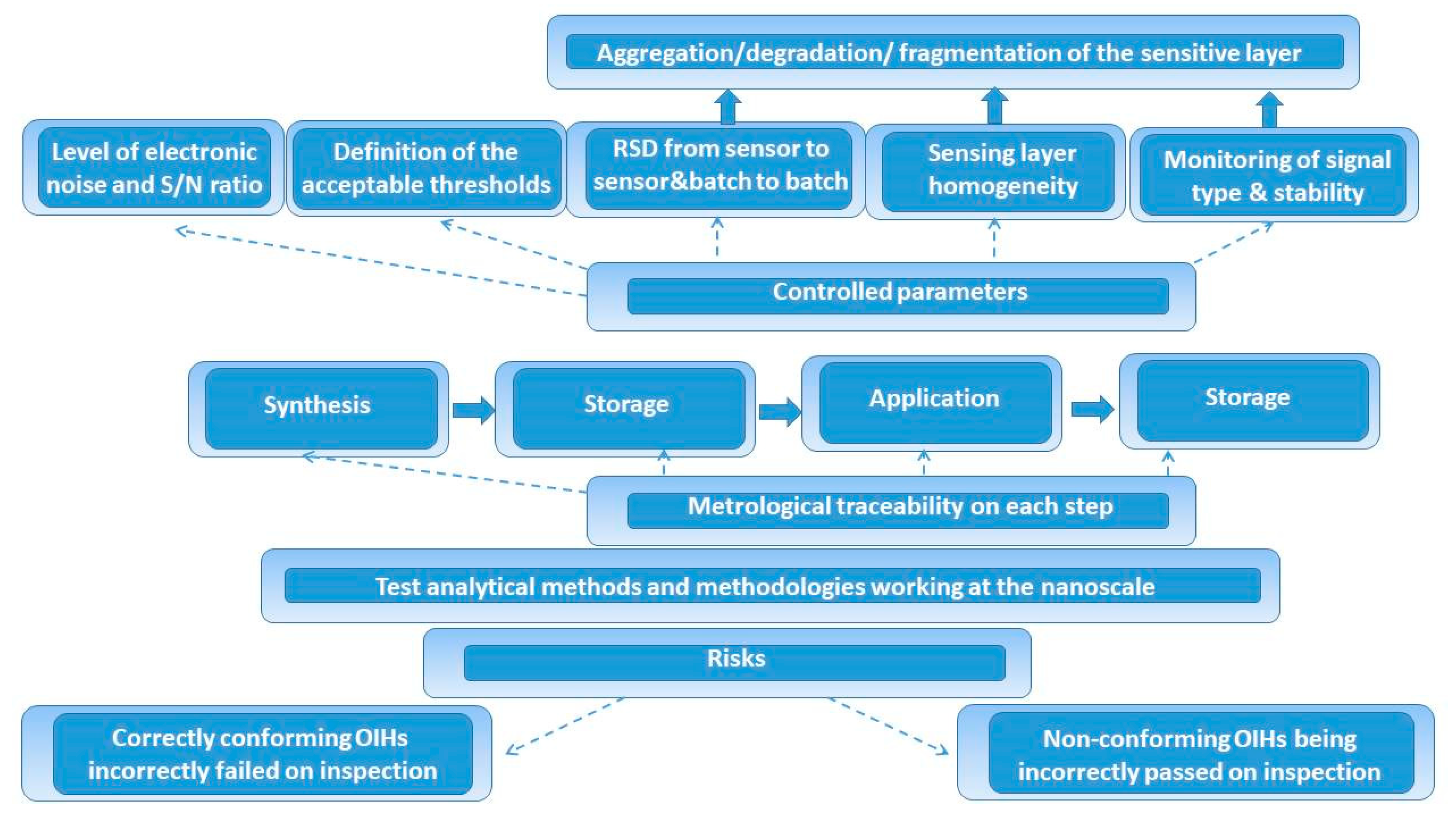

4. The Role of Nanoanalytics and Nanometrology in Biosensors/Nanobiosensors Development

5. Using Computational Intelligence and Mathematical Simulation and Modeling in OIH

6. Conclusions, Outlook, and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AA | ascorbic acid |

| AFM | atomic force microscopy |

| ALD | atomic layer deposition |

| Ap | Application |

| BN | boron nitrides |

| CV | cyclic voltammetry |

| DA | dopamine |

| EDX | energy dispersive X-ray microanalysis |

| EIS | electron impedance spectroscopy |

| ELISA | enzyme-linked immunosorbent assay |

| EFB | European Federation of Biotechnology |

| ESBES | European Society of Biochemical Engineering Science |

| FTIR | Fourier transform infrared spectroscopy |

| GO | graphene oxide |

| IEP | isoelectric point |

| LbL | layer-by-layer |

| LDPE | low-density polyethylene |

| LDI-MS | laser-desorption ionization mass spectrometry |

| MIPs | molecular imprinted polymers |

| MS | mass spectrometry |

| M3C | measurement, monitoring, modeling and control |

| NRs | nanorods |

| NPs | nanoparticles |

| NM | nanometrology |

| OIH | organic-inorganic hybrids |

| OInH | organic-inorganic nano-based hybrids |

| PLA | polylactic acid |

| PAN | polyacrylonitrile |

| PEDOT | poly(3,4-ethylenedioxythiophene) |

| PAN | polyacrylonitrile |

| PDA | polydopamine |

| QCMs | quartz crystal microbalances |

| QbD | quality by design |

| QC | quality control |

| RAMAN | RAMAN spectroscopy |

| SPAN | self-doped polyaniline |

| SPAN@UIO-66-NH2 | metal-organic framework (SPAN@UIO-66-NH2) |

| SERS | surface enhanced Raman spectroscopy |

| S/N | signal to noise |

| SU | improved scientific understanding on the object |

| SEM | scanning electron microscopy3D-OECT—3d organic electrochemical transistor |

References

- Pumera, M. Graphene in biosensing. Mater. Today 2011, 14, 308–315. [Google Scholar] [CrossRef]

- Viter, R.; Savchuk, M.; Starodub, N.; Balevicius, Z.; Tumenas, S.; Ramanaviciene, A.; Jevdokimovs, D.; Erts, D.; Iatsunskyi, I.; Ramanavicius, A. Photoluminescence immunosensor based on bovine leukemia virus proteins immobilized on the ZnO nanorods. Sens. Actuators B Chem. 2019, 285, 601–606. [Google Scholar] [CrossRef]

- Myndrul, V.; Viter, R.; Savchuk, M.; Koval, M.; Starodub, N.; Silamiķelis, V.; Smyntyna, V.; Ramanavicius, A.; Iatsunskyi, I. Gold coated porous silicon nanocomposite as a substrate for photoluminescence-based immunosensor suitable for the determination of Aflatoxin B1. Talanta 2017, 175, 297–304. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-H.; Orler, B.; Wilkes, G. Ceramers: Hybrid materials incorporating polymeric/oligomeric species with inorganic glasses by a sol-gel process. Polym. Bull. 1985, 14, 557–564. [Google Scholar] [CrossRef]

- Tamaki, R.; Chujo, Y. Synthesis of poly(vinyl alcohol)/silica gel polymer hybrids by in-situ hydrolysis method. Appl. Organomet. Chem. 1998, 12, 755–762. [Google Scholar] [CrossRef]

- Iyoku, Y.; Kakimoto, M.; Imai, Y. The preparation of poly(methylsilsesquioxane) network-polyimide hybrid materials by the sol-gel process and their properties. High Perform. Polym. 1994, 6, 43–52. [Google Scholar] [CrossRef]

- Judeinstein, P.; Sanchez, C. Hybrid organic–inorganic materials: a land of multidisciplinarity. J. Mater. Chem. 1996, 6, 511–525. [Google Scholar] [CrossRef]

- Shea, K.J.; Loy, D.A.; Small, J.H. Condensed aryl-bridged siliconates. New ladder and network ionomers. Chem. Mater. 1992, 4, 255–258. [Google Scholar] [CrossRef]

- Munch, E.; Launey, M.E.; Alsem, D.H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Tough, Bio-Inspired Hybrid Materials. Science 2008, 322, 1516–1520. [Google Scholar] [CrossRef]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The Chemistry and Applications of Metal-Organic Frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef] [PubMed]

- Kagan, C.R. Organic-Inorganic Hybrid Materials as Semiconducting Channels in Thin-Film Field-Effect Transistors. Science 1999, 286, 945–947. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.-S.; Xu, G.; Zhang, Z.-J.; Guo, G.-C. Inorganic–organic hybrid photochromic materials. Chem. Commun. 2010, 46, 361–376. [Google Scholar] [CrossRef]

- Faustini, M.; Nicole, L.; Ruiz-Hitzky, E.; Sanchez, C. History of Organic-Inorganic Hybrid Materials: Prehistory, Art, Science, and Advanced Applications. Adv. Funct. Mater. 2018, 28, 1704158. [Google Scholar] [CrossRef]

- Karyakin, A.A.; Karyakina, E.E.; Gorton, L. On the mechanism of H2O2 reduction at Prussian Blue modified electrodes. Electrochem. Commun. 1999, 1, 78–82. [Google Scholar] [CrossRef]

- Batool, R.; Rhouati, A.; Nawaz, M.H.; Hayat, A.; Marty, J.L. A Review of the Construction of Nano-Hybrids for Electrochemical Biosensing of Glucose. Biosensors 2019, 9, 46. [Google Scholar] [CrossRef] [PubMed]

- Follmann, H.D.M.; Naves, A.F.; Araujo, R.A.; Dubovoy, V.; Huang, X.; Asefa, T.; Silva, R.; Oliveira, O.N. Hybrid Materials and Nanocomposites as Multifunctional Biomaterials. Curr. Pharm. Des. 2017, 23. [Google Scholar] [CrossRef] [PubMed]

- Hosu, O.; Florea, A.; Cristea, C.; Sandulescu, R. Functionalized Advanced Hybrid Materials for Biosensing Applications. In Advanced Biosensors for Health Care Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 171–207. [Google Scholar]

- Wang, L.; Zhang, Z.; Geng, L.; Yuan, T.; Liu, Y.; Guo, J.; Fang, L.; Qiu, J.; Wang, S. Solution-printable fullerene/TiS 2 organic/inorganic hybrids for high-performance flexible n-type thermoelectrics. Energy Environ. Sci. 2018, 11, 1307–1317. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, X.; Fang, H.; Deng, W.; Xu, X.; Jie, J.; Zhang, X. Facile Assembly of High-Quality Organic-Inorganic Hybrid Perovskite Quantum Dot Thin Films for Bright Light-Emitting Diodes. Adv. Funct. Mater. 2018, 28, 1705189. [Google Scholar] [CrossRef]

- Silva, J.M.; Maturi, F.E.; Barud, H.S.; Constantino, V.R.L.; Ribeiro, S.J.L. New organic-inorganic hybrid composites based on cellulose nanofibers and modified Laponite. Adv. Opt. Technol. 2018, 7, 327–334. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Liu, Y.; Wang, B.; Fang, L.; Qiu, J.; Zhang, K.; Wang, S. Exceptional thermoelectric properties of flexible organic−inorganic hybrids with monodispersed and periodic nanophase. Nat. Commun. 2018, 9, 3817. [Google Scholar] [CrossRef] [PubMed]

- Kou, D.; Zhang, S.; Lutkenhaus, J.L.; Wang, L.; Tang, B.; Ma, W. Porous organic/inorganic hybrid one-dimensional photonic crystals for rapid visual detection of organic solvents. J. Mater. Chem. C 2018, 6, 2704–2711. [Google Scholar] [CrossRef]

- Zhan, Y.; Zhao, S.; Wan, X.; He, S. Hierarchical Fe3O4 -derived organic/inorganic hybrids constructed by modified bio-inspired functionalization: efficient adsorbents for water-soluble methylene blue and mechanism. J. Chem. Technol. Biotechnol. 2019, 94, 1638–1650. [Google Scholar] [CrossRef]

- Xue, M.-H.; Xu, Q.; Zhou, M.; Zhu, J.-J. In situ immobilization of glucose oxidase in chitosan–gold nanoparticle hybrid film on Prussian Blue modified electrode for high-sensitivity glucose detection. Electrochem. Commun. 2006, 8, 1468–1474. [Google Scholar] [CrossRef]

- Du, Y.; Luo, X.-L.; Xu, J.-J.; Chen, H.-Y. A simple method to fabricate a chitosan-gold nanoparticles film and its application in glucose biosensor. Bioelectrochemistry 2007, 70, 342–347. [Google Scholar] [CrossRef]

- Xian, Y.; Hu, Y.; Liu, F.; Xian, Y.; Wang, H.; Jin, L. Glucose biosensor based on Au nanoparticles–conductive polyaniline nanocomposite. Biosens. Bioelectron. 2006, 21, 1996–2000. [Google Scholar] [CrossRef]

- Pandey, G.; Chaudhari, R.; Joshi, B.; Choudhary, S.; Kaur, J.; Joshi, A. Fluorescent Biocompatible Platinum-Porphyrin–Doped Polymeric Hybrid Particles for Oxygen and Glucose Biosensing. Sci. Rep. 2019, 9, 5029. [Google Scholar] [CrossRef]

- Sinibaldi, A.; Danz, N.; Munzert, P.; Michelotti, F. Hybrid inorganic/organic photonic crystal biochips for cancer biomarkers detection. Opt. Laser Technol. 2018, 102, 227–232. [Google Scholar] [CrossRef]

- Myndrul, V.; Viter, R.; Savchuk, M.; Shpyrka, N.; Erts, D.; Jevdokimovs, D.; Silamiķelis, V.; Smyntyna, V.; Ramanavicius, A.; Iatsunskyi, I. Porous silicon based photoluminescence immunosensor for rapid and highly-sensitive detection of Ochratoxin A. Biosens. Bioelectron. 2018, 102, 661–667. [Google Scholar] [CrossRef]

- De Benedetto, G.; Di Masi, S.; Pennetta, A.; Malitesta, C. Response Surface Methodology for the Optimisation of Electrochemical Biosensors for Heavy Metals Detection. Biosensors 2019, 9, 26. [Google Scholar] [CrossRef]

- Çakıroğlu, B.; Demirci, Y.C.; Gökgöz, E.; Özacar, M. A photoelectrochemical glucose and lactose biosensor consisting of gold nanoparticles, MnO2 and g-C3N4 decorated TiO2. Sens. Actuators B Chem. 2019, 282, 282–289. [Google Scholar]

- Lu, Y.; Chen, Y.; Wang, Q.; Hao, X.; Liu, P.; Chu, X. Organic–Inorganic Hybrid Nanocomposites: A Novel Way to Immobilize l-Glutamate Oxidase with Manganese Phosphate. J. Inorg. Organomet. Polym. Mater. 2019. [Google Scholar] [CrossRef]

- Qiu, R.; Xu, Q.; Jiang, H.; Wang, X. A Novel Enzyme-Free Biosensor Based on Porous Core–Shell Metal Organic Frame Nanocomposites Modified Electrode for Highly Sensitive Detection of Uric Acid and Dopamine. J. Biomed. Nanotechnol. 2019, 15, 1443–1453. [Google Scholar] [CrossRef]

- Rathee, K.; Dhull, V.; Dhull, R.; Singh, S. Biosensors based on electrochemical lactate detection: A comprehensive review. Biochem. Biophys. Reports 2016, 5, 35–54. [Google Scholar] [CrossRef]

- Florescu, M.; David, M. Tyrosinase-Based Biosensors for Selective Dopamine Detection. Sensors 2017, 17, 1314. [Google Scholar] [CrossRef] [PubMed]

- Tavakolian-Ardakani, Z.; Hosu, O.; Cristea, C.; Mazloum-Ardakani, M.; Marrazza, G. Latest Trends in Electrochemical Sensors for Neurotransmitters: A Review. Sensors 2019, 19, 2037. [Google Scholar] [CrossRef]

- Sanchez, C.; Soler-Illia, G.J.; Ribot, F.; Lalot, T.; Mayer, C.R.; Cabuil, V. Designed Hybrid Organic−Inorganic Nanocomposites from Functional Nanobuilding Blocks. Chem. Mater. 2001, 13, 3061–3083. [Google Scholar] [CrossRef]

- Viter, R.; Savchuk, M.; Iatsunskyi, I.; Pietralik, Z.; Starodub, N.; Shpyrka, N.; Ramanaviciene, A.; Ramanavicius, A. Analytical, thermodynamical and kinetic characteristics of photoluminescence immunosensor for the determination of Ochratoxin A. Biosens. Bioelectron. 2018, 99, 237–243. [Google Scholar] [CrossRef]

- Pavlenko, M.; Coy, E.L.; Jancelewicz, M.; Załęski, K.; Smyntyna, V.; Jurga, S.; Iatsunskyi, I. Enhancement of optical and mechanical properties of Si nanopillars by ALD TiO 2 coating. RSC Adv. 2016, 6, 97070–97076. [Google Scholar] [CrossRef]

- Sessolo, M.; Bolink, H.J. Hybrid Organic-Inorganic Light-Emitting Diodes. Adv. Mater. 2011, 23, 1829–1845. [Google Scholar] [CrossRef]

- Sun, C.; Liu, J.; Gong, Y.; Wilkinson, D.P.; Zhang, J. Recent advances in all-solid-state rechargeable lithium batteries. Nano Energy 2017, 33, 363–386. [Google Scholar] [CrossRef]

- Arkas, M.; Allabashi, R.; Tsiourvas, D.; Mattausch, E.-M.; Perfler, R. Organic/Inorganic Hybrid Filters Based on Dendritic and Cyclodextrin “Nanosponges” for the Removal of Organic Pollutants from Water. Environ. Sci. Technol. 2006, 40, 2771–2777. [Google Scholar] [CrossRef]

- Manocha, L.M.; Yasuda, E.; Tanabe, Y.; Manocha, S.; Vashistha, D. Sol-gel processing of carbidic glasses. Bull. Mater. Sci. 2000, 23, 1–4. [Google Scholar] [CrossRef]

- Han, J.T.; Zheng, Y.; Cho, J.H.; Xu, X.; Cho, K. Stable Superhydrophobic Organic−Inorganic Hybrid Films by Electrostatic Self-Assembly. J. Phys. Chem. B 2005, 109, 20773–20778. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Chanthad, C.; Oh, H.; Ayhan, I.A.; Wang, Q. Organic–inorganic hybrid electrolytes from ionic liquid-functionalized octasilsesquioxane for lithium metal batteries. J. Mater. Chem. A 2017, 5, 18012–18019. [Google Scholar] [CrossRef]

- Jeronimo, P.; Araujo, A.; Conceicaobsmmontenegro, M. Optical sensors and biosensors based on sol–gel films. Talanta 2007, 72, 13–27. [Google Scholar] [CrossRef]

- Wang, D.; Bierwagen, G.P. Sol–gel coatings on metals for corrosion protection. Prog. Org. Coat. 2009, 64, 327–338. [Google Scholar] [CrossRef]

- Forster, P.M.; Thomas, P.M.; Cheetham, A.K. Biphasic Solvothermal Synthesis: A New Approach for Hybrid Inorganic−Organic Materials. Chem. Mater. 2002, 14, 17–20. [Google Scholar] [CrossRef]

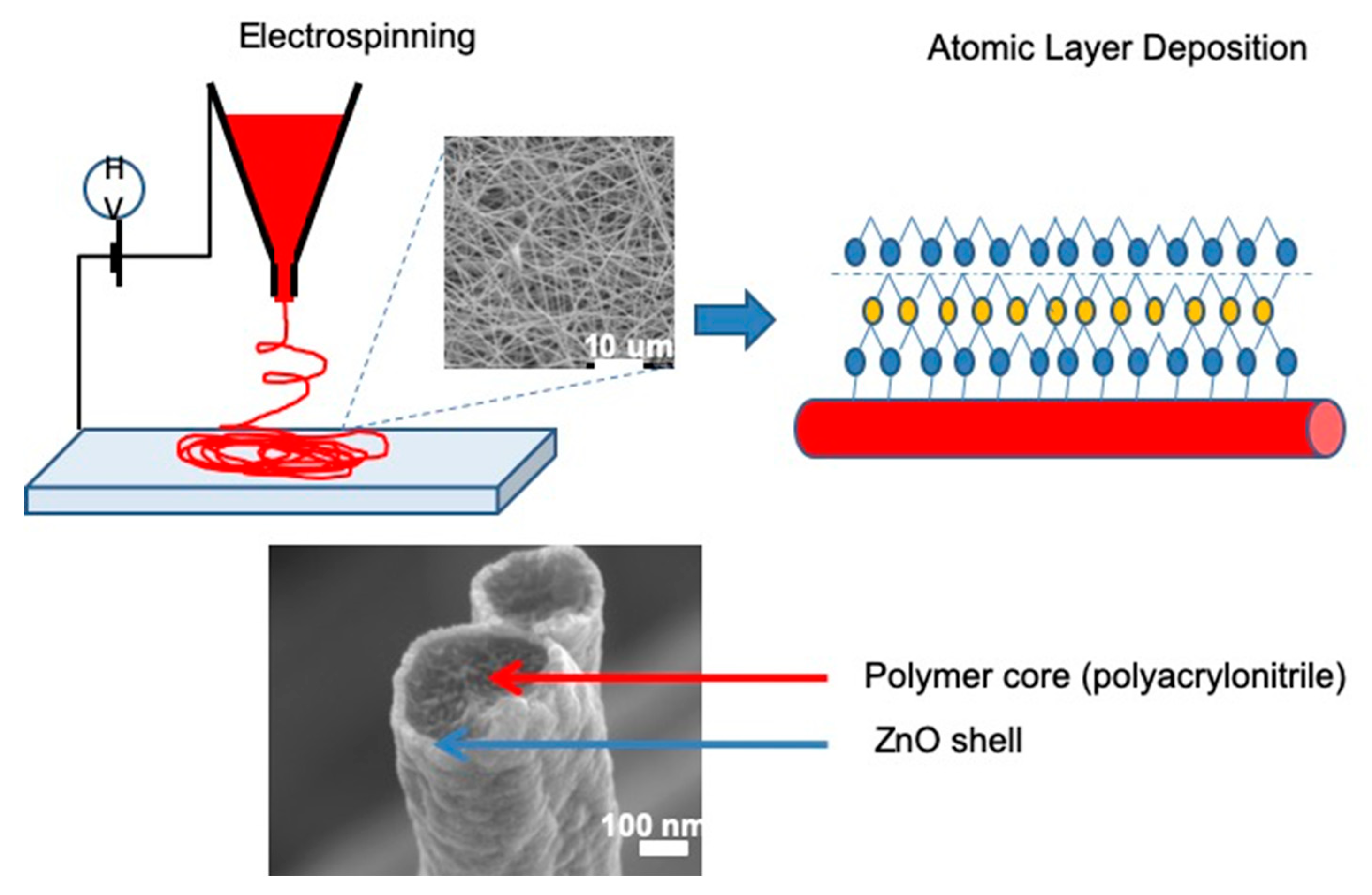

- Iatsunskyi, I.; Vasylenko, A.; Viter, R.; Kempiński, M.; Nowaczyk, G.; Jurga, S.; Bechelany, M. Tailoring of the electronic properties of ZnO-polyacrylonitrile nanofibers: Experiment and theory. Appl. Surf. Sci. 2017, 411, 494–501. [Google Scholar] [CrossRef]

- Dolbecq, A.; Mialane, P.; Lisnard, L.; Marrot, J.; Sécheresse, F. Hybrid Organic–Inorganic 1D and 2D Frameworks with ε-Keggin Polyoxomolybdates as Building Blocks. Chem. A Eur. J. 2003, 9, 2914–2920. [Google Scholar] [CrossRef]

- Shen, M.; Shi, X. Dendrimer-based organic/inorganic hybrid nanoparticles in biomedical applications. Nanoscale 2010, 2, 1596–1610. [Google Scholar] [CrossRef] [PubMed]

- Fattahi, P.; Yang, G.; Kim, G.; Abidian, M.R. A Review of Organic and Inorganic Biomaterials for Neural Interfaces. Adv. Mater. 2014, 26, 1846–1885. [Google Scholar] [CrossRef] [PubMed]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

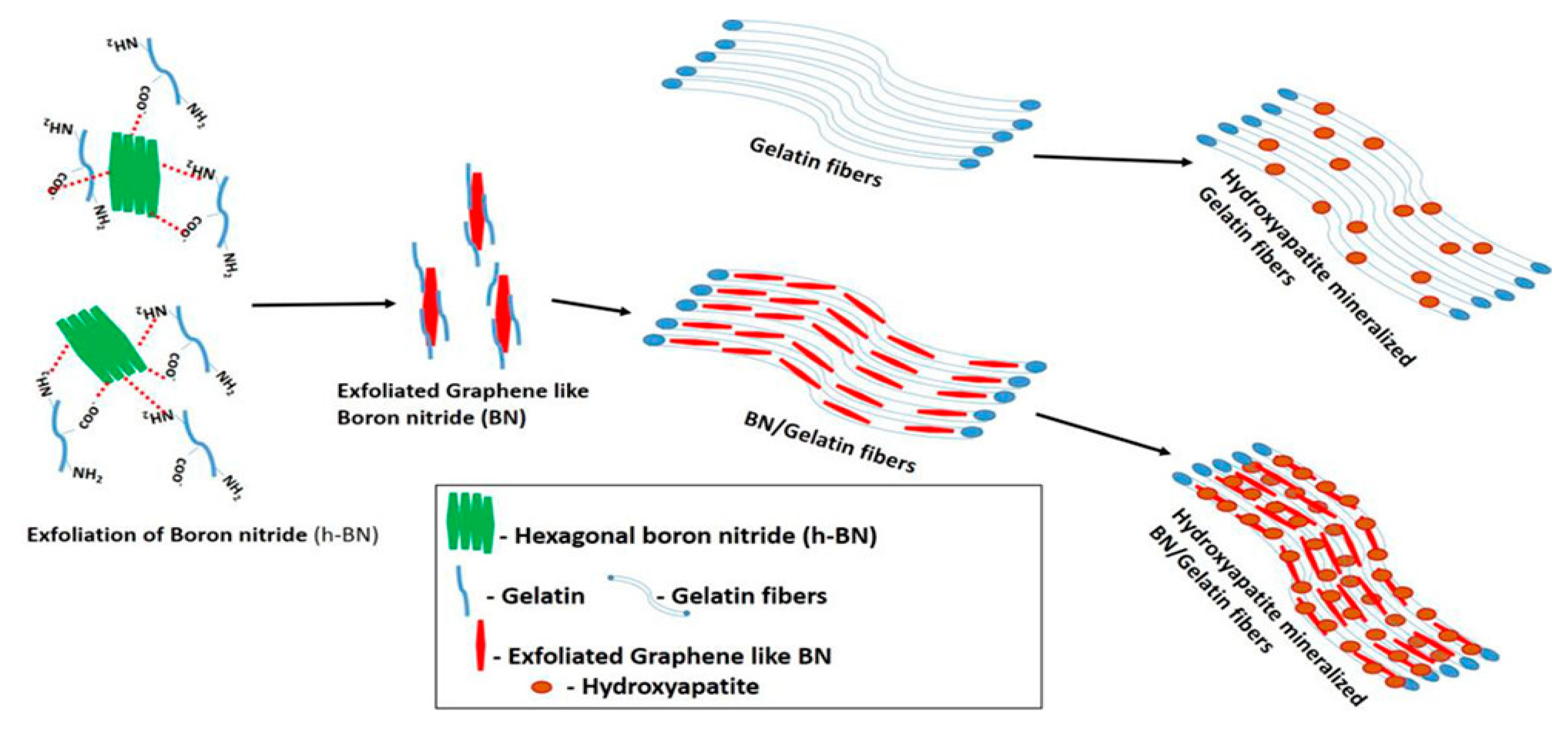

- Weber, M.; Tuleushova, N.; Zgheib, J.; Lamboux, C.; Iatsunskyi, I.; Coy, E.; Flaud, V.; Tingry, S.; Cornu, D.; Miele, P.; et al. Enhanced electrocatalytic performance triggered by atomically bridged boron nitride between palladium nanoparticles and carbon fibers in gas-diffusion electrodes. Appl. Catal. B Environ. 2019, 257, 117917. [Google Scholar] [CrossRef]

- Nagarajan, S.; Belaid, H.; Pochat-Bohatier, C.; Teyssier, C.; Iatsunskyi, I.; Coy, E.; Balme, S.; Cornu, D.; Miele, P.; Kalkura, N.S.; et al. Design of Boron Nitride/Gelatin Electrospun Nanofibers for Bone Tissue Engineering. ACS Appl. Mater. Interfaces 2017, 9, 33695–33706. [Google Scholar] [CrossRef]

- Viter, R.; Iatsunskyi, I.; Fedorenko, V.; Tumenas, S.; Balevicius, Z.; Ramanavicius, A.; Balme, S.; Kempiński, M.; Nowaczyk, G.; Jurga, S.; et al. Enhancement of Electronic and Optical Properties of ZnO/Al 2 O 3 Nanolaminate Coated Electrospun Nanofibers. J. Phys. Chem. C 2016, 120, 5124–5132. [Google Scholar] [CrossRef]

- Viter, R.; Abou Chaaya, A.; Iatsunskyi, I.; Nowaczyk, G.; Kovalevskis, K.; Erts, D.; Miele, P.; Smyntyna, V.; Bechelany, M. Tuning of ZnO 1D nanostructures by atomic layer deposition and electrospinning for optical gas sensor applications. Nanotechnology 2015, 26, 105501. [Google Scholar] [CrossRef]

- Graniel, O.; Iatsunskyi, I.; Coy, E.; Humbert, C.; Barbillon, G.; Michel, T.; Maurin, D.; Balme, S.; Miele, P.; Bechelany, M. Au-covered hollow urchin-like ZnO nanostructures for surface-enhanced Raman scattering sensing. J. Mater. Chem. C 2019, 7, 15066–15073. [Google Scholar] [CrossRef]

- Myndrul, V.; Iatsunskyi, I. Nanosilicon-Based Composites for (Bio)sensing Applications: Current Status, Advantages, and Perspectives. Materials (Basel) 2019, 12, 2880. [Google Scholar] [CrossRef]

- Pu, K. Biosensors and Bioimaging. ChemBioChem 2019, 20, 420–421. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Lee, S.H.; Lee, U.J.; Fermin, C.D.; Kim, M. Immobilized enzymes in biosensor applications. Materials (Basel) 2019, 12, 121. [Google Scholar] [CrossRef]

- Sassolas, A.; Blum, L.J.; Leca-Bouvier, B.D. Immobilization strategies to develop enzymatic biosensors. Biotechnol. Adv. 2012, 30, 489–511. [Google Scholar] [CrossRef] [PubMed]

- Unnikrishnan, B.; Palanisamy, S.; Chen, S.-M. A simple electrochemical approach to fabricate a glucose biosensor based on graphene–glucose oxidase biocomposite. Biosens. Bioelectron. 2013, 39, 70–75. [Google Scholar] [CrossRef]

- Vasylieva, N.; Barnych, B.; Meiller, A.; Maucler, C.; Pollegioni, L.; Lin, J.-S.; Barbier, D.; Marinesco, S. Covalent enzyme immobilization by poly(ethylene glycol) diglycidyl ether (PEGDE) for microelectrode biosensor preparation. Biosens. Bioelectron. 2011, 26, 3993–4000. [Google Scholar] [CrossRef] [PubMed]

- Richardson, J.J.; Cui, J.; Björnmalm, M.; Braunger, J.A.; Ejima, H.; Caruso, F. Innovation in Layer-by-Layer Assembly. Chem. Rev. 2016, 116, 14828–14867. [Google Scholar] [CrossRef] [PubMed]

- Semenova, D.; Gernaey, K.V.; Morgan, B.; Silina, Y.E. Towards one-step design of tailored enzymatic nanobiosensors. Analyst 2020, 145, 1014–1024. [Google Scholar] [CrossRef] [PubMed]

- Chou, J.-A.; Chung, C.-L.; Ho, P.-C.; Luo, C.-H.; Tsai, Y.-H.; Wu, C.-K.; Kuo, C.-W.; Hsiao, Y.-S.; Yu, H.; Chen, P. Organic Electrochemical Transistors/SERS-Active Hybrid Biosensors Featuring Gold Nanoparticles Immobilized on Thiol-Functionalized PEDOT Films. Front. Chem. 2019, 7, 281. [Google Scholar] [CrossRef]

- Mahadeva, S.K.; Nayak, J.; Kim, J. Biosensor made with organic-inorganic hybrid composite: Cellulose-tin oxide. In Nanosensors, Biosensors, and Info-Tech Sensors and Systems 2011; Varadan, V.K., Ed.; SPIE: Bellingham, WA, USA, 2011; Volume 7980, pp. 114–118. [Google Scholar]

- Zhao, X.; Bai, W.; Yan, Y.; Wang, Y.; Zhang, J. Core-Shell Self-Doped Polyaniline Coated Metal-Organic-Framework (SPAN@UIO-66-NH 2) Screen Printed Electrochemical Sensor for Cd 2+ Ions. J. Electrochem. Soc. 2019, 166, B873–B880. [Google Scholar] [CrossRef]

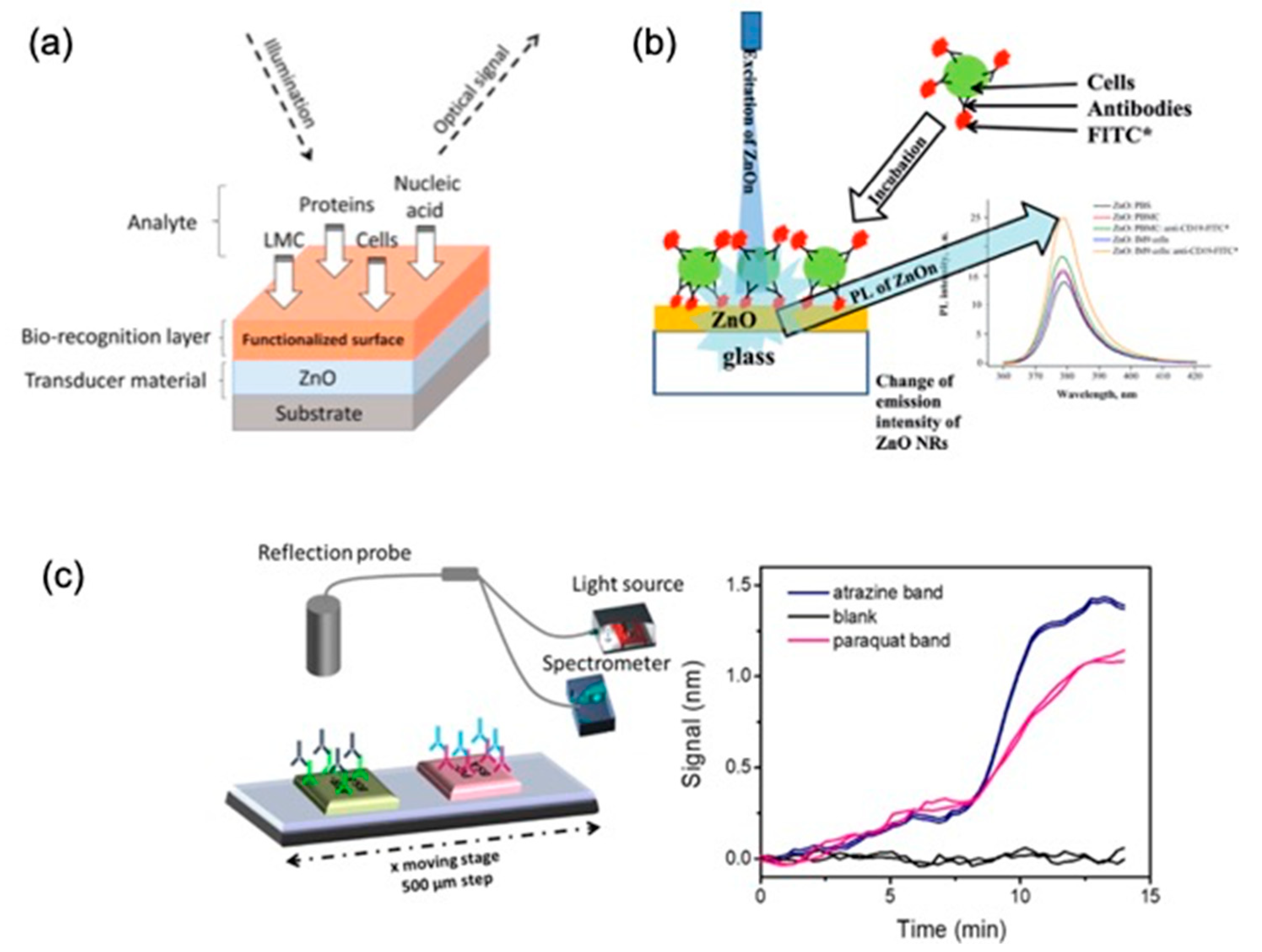

- Tereshchenko, A.; Bechelany, M.; Viter, R.; Khranovskyy, V.; Smyntyna, V.; Starodub, N.; Yakimova, R. Optical biosensors based on ZnO nanostructures: advantages and perspectives. A review. Sens. Actuators B Chem. 2016, 229, 664–677. [Google Scholar] [CrossRef]

- Tamashevski, A.; Harmaza, Y.; Viter, R.; Jevdokimovs, D.; Poplausks, R.; Slobozhanina, E.; Mikoliunaite, L.; Erts, D.; Ramanaviciene, A.; Ramanavicius, A. Zinc oxide nanorod based immunosensing platform for the determination of human leukemic cells. Talanta 2019, 200, 378–386. [Google Scholar] [CrossRef]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-Inspired Surface Chemistry for Multifunctional Coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef] [PubMed]

- Liebscher, J.; Mrówczyński, R.; Scheidt, H.A.; Filip, C.; Hădade, N.D.; Turcu, R.; Bende, A.; Beck, S. Structure of Polydopamine: A Never-Ending Story? Langmuir 2013, 29, 10539–10548. [Google Scholar] [CrossRef] [PubMed]

- Mrówczyński, R. Polydopamine-Based Multifunctional (Nano)materials for Cancer Therapy. ACS Appl. Mater. Interfaces 2018, 10, 7541–7561. [Google Scholar] [CrossRef] [PubMed]

- Stavra, E.; Petrou, P.S.; Koukouvinos, G.; Kiritsis, C.; Pirmettis, I.; Papadopoulos, M.; Goustouridis, D.; Economou, A.; Misiakos, K.; Raptis, I.; et al. Simultaneous determination of paraquat and atrazine in water samples with a white light reflectance spectroscopy biosensor. J. Hazard. Mater. 2018, 359, 67–75. [Google Scholar] [CrossRef]

- He, D.; He, X.; Yang, X.; Li, H.-W. A smart ZnO@polydopamine-nucleic acid nanosystem for ultrasensitive live cell mRNA imaging by the target-triggered intracellular self-assembly of active DNAzyme nanostructures. Chem. Sci. 2017, 8, 2832–2840. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, W. Bifunctional polydopamine thin film coated zinc oxide nanorods for label-free photoelectrochemical immunoassay. Talanta 2017, 166, 141–147. [Google Scholar] [CrossRef]

- Zapato, L. Lord Kelvin Quotations. Kelvin Libr. 2008. [Google Scholar]

- Fissell, W.H. What Is Nanotechnology? Adv. Chronic Kidney Dis. 2013, 20, 452–453. [Google Scholar] [CrossRef]

- BSI Nanotechnologies—Terminology and Definitions for Nano-Objects Nanofibre and Nanoplate (ISO/TS 27687:2008); NSAI: Dublin, Ireland.

- Dean, S.; Mansoori, G.; Fauzi Soelaiman, T. Nanotechnology—An Introduction for the Standards Community. J. ASTM Int. 2005, 2, 13110. [Google Scholar] [CrossRef]

- Joint Committee for Guides in Metrology International vocabulary of basic and general terms in metrology (VIM). Int. Organ. 2004.

- Kim, H.-A.; Seo, J.-K.; Kim, T.; Lee, B.-T. Nanometrology and its perspectives in environmental research. Environ. Health Toxicol. 2014, 29, e2014016. [Google Scholar] [CrossRef] [PubMed]

- Bich, W.; Cox, M.G.; Dybkaer, R.; Elster, C.; Estler, W.T.; Hibbert, B.; Imai, H.; Kool, W.; Michotte, C.; Nielsen, L.; et al. Revision of the ‘Guide to the Expression of Uncertainty in Measurement’. Metrologia 2012, 49, 702–705. [Google Scholar] [CrossRef]

- Roebben, G.; Emons, H.; Reiners, G.; Decker, J.E.; Steele, A.G. Nanotechnology Standards; Murashov, V., Howard, J., Eds.; Nanostructure Science and Technology; Springer: New York, NY, USA, 2011; ISBN 978-1-4419-7852-3. [Google Scholar]

- Simonet, B.M.; Valcárcel, M. Monitoring nanoparticles in the environment. Anal. Bioanal. Chem. 2009, 393, 17–21. [Google Scholar] [CrossRef] [PubMed]

- Yacoot, A.; Koenders, L. Recent developments in dimensional nanometrology using AFMs. Meas. Sci. Technol. 2011, 22, 122001. [Google Scholar] [CrossRef]

- Postek, M.T.; Vladár, A.; Archie, C.; Ming, B. Review of current progress in nanometrology with the helium ion microscope. Meas. Sci. Technol. 2011, 22, 024004. [Google Scholar] [CrossRef][Green Version]

- Borovikov, V.; Zangwill, A. Step-edge instability during epitaxial growth of graphene from SiC(0001). Phys. Rev. B 2009, 80, 121406. [Google Scholar] [CrossRef]

- Zangwill, A.; Vvedensky, D.D. Novel Growth Mechanism of Epitaxial Graphene on Metals. Nano Lett. 2011, 11, 2092–2095. [Google Scholar] [CrossRef]

- Birch, D.J.S.; Yip, P. Nanometrology. In Methods in Molecular Biology; Springer: Heidelberg, Germany, 2014; pp. 279–302. ISBN 9781627036481. [Google Scholar]

- Linsinger, T.P.J.; Roebben, G.; Solans, C.; Ramsch, R. Reference materials for measuring the size of nanoparticles. TrAC Trends Anal. Chem. 2011, 30, 18–27. [Google Scholar] [CrossRef]

- Zangwill, A. Modern Electrodynamics; Cambridge University Press: Cambridge, UK, 2012; ISBN 9781139034777. [Google Scholar]

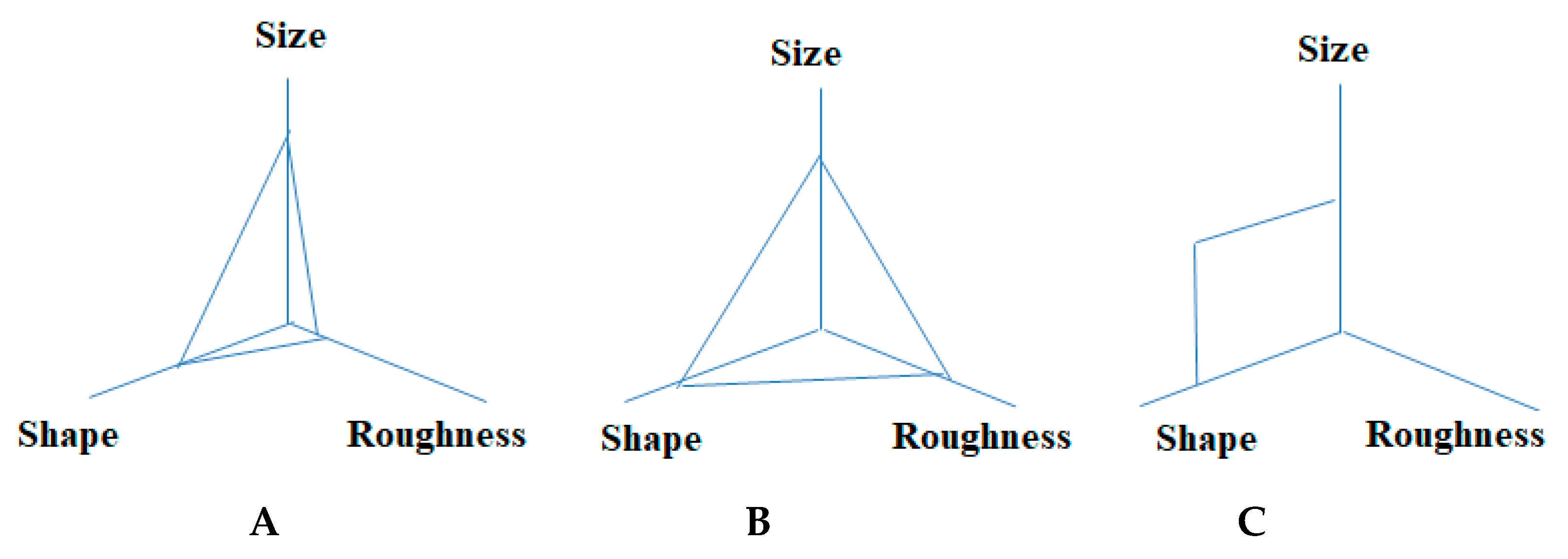

- Whitehouse, D.J. Handbook of Surface and Nanometrology. IOP Publishing Ltd., CRC press: Boca Raton, FL, USA, 2003; ISBN 0750305835. [Google Scholar]

- Whitehouse, D.J. Handbook of Surface and Nanometrology; CRC Press: Boca Raton, FL, USA, 2010; ISBN 9780429140693. [Google Scholar]

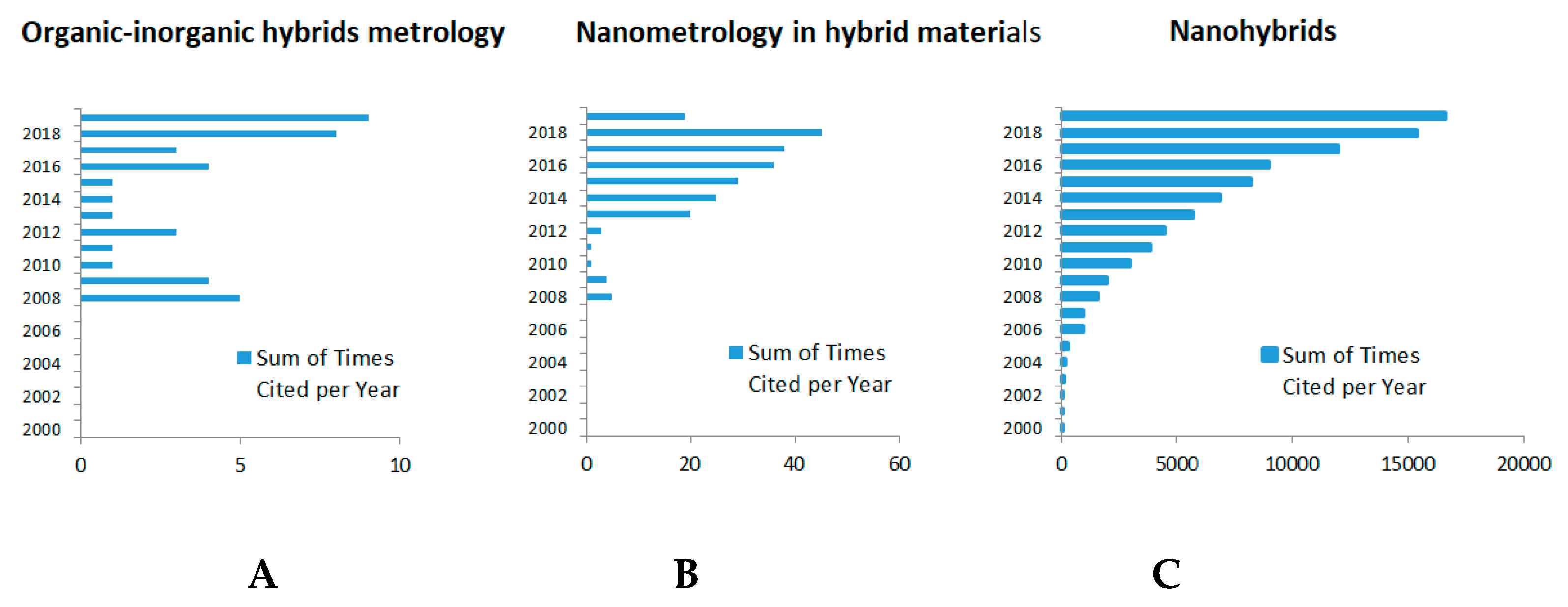

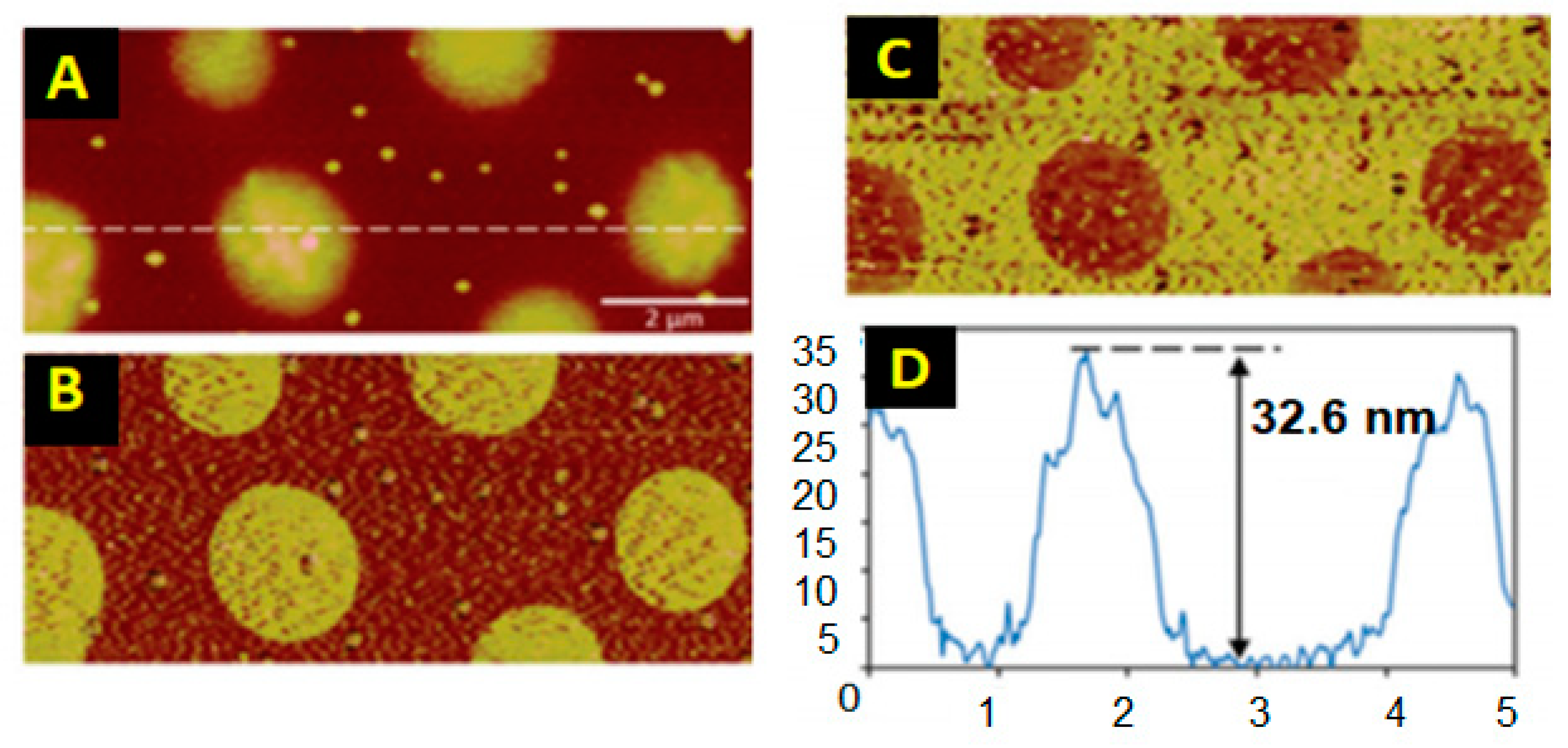

- Semenova, D.; Silina, Y.E. The Role of Nanoanalytics in the Development of Organic-Inorganic Nanohybrids—Seeing Nanomaterials as They Are. Nanomaterials 2019, 9, 1673. [Google Scholar] [CrossRef]

- Zolotov, Y.A. Analytical chemistry: The day today. J. Anal. Chem. 2007, 62, 912–917. [Google Scholar] [CrossRef]

- Zolotov, Y.A. Nanoanalytics. J. Anal. Chem. 2010, 65, 1207–1208. [Google Scholar] [CrossRef][Green Version]

- Shtykov, S. (Ed.) Nanoanalytics; Walter de Gruyter: Berlin, Germany, 2018; ISBN 9783110547207. [Google Scholar]

- Hansen, P.-E.; Roebben, G.; Babick, F.; Braun, A.; Dirscherl, K.; Hansen, P.-E.; Jennett, N.M. Introductory Guide to Nanometrology: Metrology for Dimensional Analysis of Thin Films; European Commission, Joint Research Centre: Belgium, Brussels, 2010; 64p, ISBN 978-0-9566809-1-4. [Google Scholar]

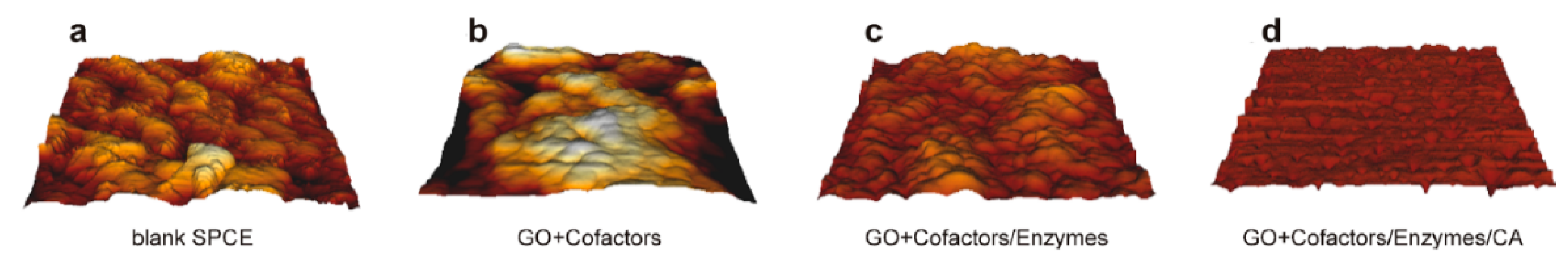

- Pilas, J.; Selmer, T.; Keusgen, M.; Schöning, M.J. Screen-Printed Carbon Electrodes Modified with Graphene Oxide for the Design of a Reagent-Free NAD + -Dependent Biosensor Array. Anal. Chem. 2019, 91, 15293–15299. [Google Scholar] [CrossRef] [PubMed]

- Ding, R.-F.; Yang, C.-W.; Huang, K.-Y.; Hwang, I.-S. High-sensitivity imaging with lateral resonance mode atomic force microscopy. Nanoscale 2016, 8, 18421–18427. [Google Scholar] [CrossRef]

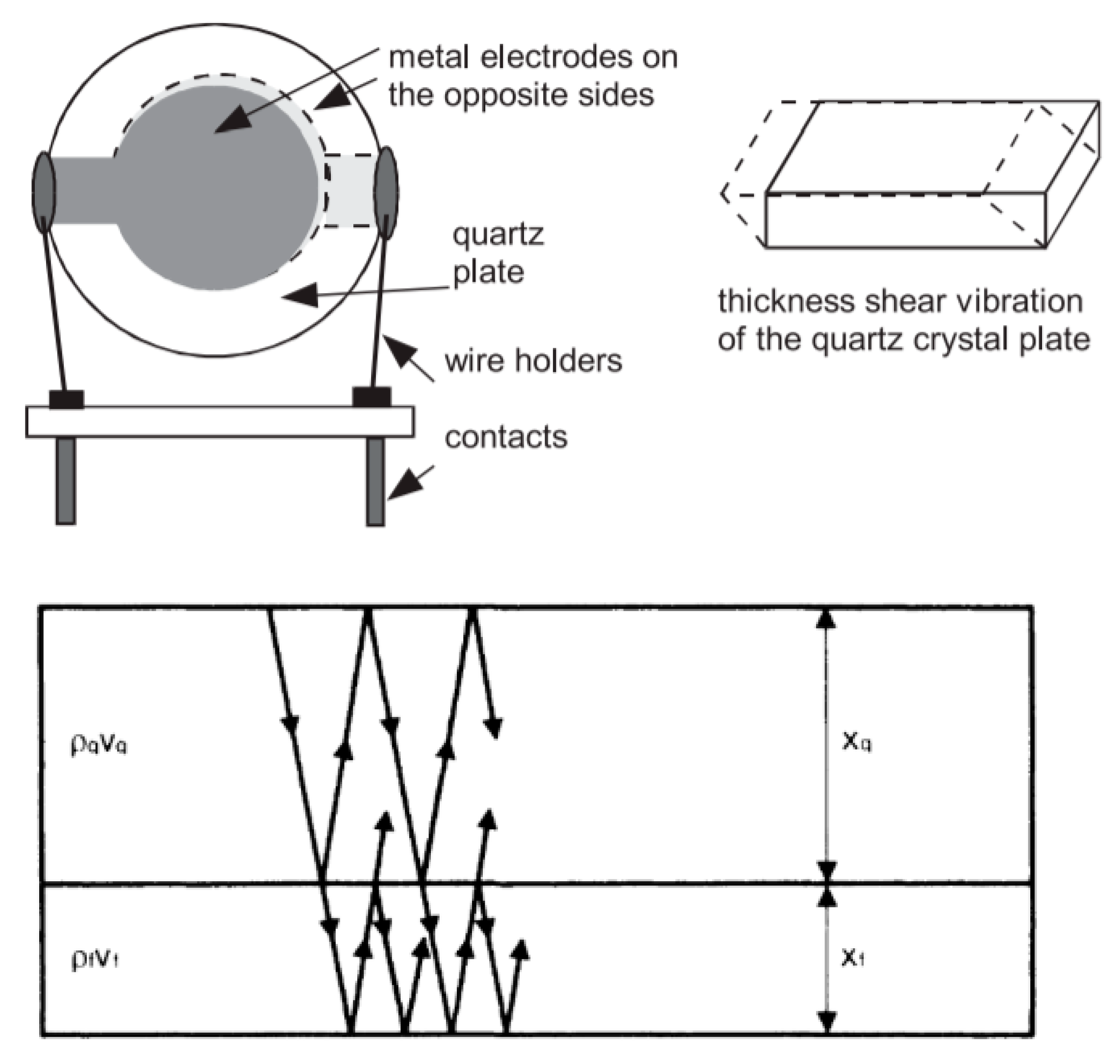

- Okahata, Y.; Enna, G.; Ebato, H. Synthetic chemoreceptive membranes. Sensing bitter or odorous substances on a synthetic lipid multibilayer film by using quartz-crystal microbalances and electric responses. Anal. Chem. 1990, 62, 1431–1438. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, H. Piezoelektrizität in zweidimensionalen Materialien. Angew. Chemie 2015, 127, 4508–4510. [Google Scholar] [CrossRef]

- Sauerbrey, G. Use of quartz vibration for weighing thin films on a microbalance. Z. Fur. Phys. 1959, 155, 206–222. [Google Scholar] [CrossRef]

- Kurosawa, S.; Hirokawa, T.; Kashima, K.; Aizawa, H.; Han, D.-S.; Yoshimi, Y.; Okada, Y.; Yase, K.; Miyake, J.; Yoshimoto, M.; et al. Detection of deposition rate of plasma-polymerized films by quartz crystal microbalance. Thin Solid Films 2000, 374, 262–267. [Google Scholar] [CrossRef]

- Pohanka, M. Overview of Piezoelectric Biosensors, Immunosensors and DNA Sensors and Their Applications. Materials (Basel) 2018, 11, 448. [Google Scholar] [CrossRef]

- Skládal, P. Piezoelectric quartz crystal sensors applied for bioanalytical assays and characterization of affinity interactions. J. Braz. Chem. Soc. 2003, 14, 491–502. [Google Scholar] [CrossRef]

- Lu, C.; Czanderna, A.W.; Townshend, A. Applications of piezoelectric quartz crystal microbalances. Anal. Chim. Acta 1987, 199, 279. [Google Scholar] [CrossRef]

- Logothetidis, S. Nanostructured Materials and Their Applications; Logothetidis, S., Ed.; NanoScience and Technology; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-22226-9. [Google Scholar]

- Leach, R. Front-matter. In Fundamental Principles of Engineering Nanometrology; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9781455777532. [Google Scholar]

- Bell, S. Good Practice Guide No. 11—Introductory Guide to Uncertainty of Measurement; NPL: Teddington, UK, 2001; ISBN 1368-6550. [Google Scholar]

- Allen, D. Good Practice in Physical Interventions. A Guide for Staff and Managers; BILD Code of Practice for the Use of Physical Interventions. A Guide for Trainers and Commissioners of Training. J. Appl. Res. Intellect. Disabil. 2007, 20, 586–587. [Google Scholar] [CrossRef]

- Nicoletti, M.C.; Jain, L.C.; Giordano, R.C. Computational Intelligence Techniques as Tools for Bioprocess Modelling, Optimization, Supervision and Control. In Studies in Computational Intelligence; Springer: Berlin, Germany, 2009; pp. 1–23. ISBN 9783642018879. [Google Scholar]

- Sin, G.; Woodley, J.M.; Gernaey, K. V Application of modeling and simulation tools for the evaluation of biocatalytic processes: A future perspective. Biotechnol. Prog. 2009, 25, 1529–1538. [Google Scholar] [CrossRef] [PubMed]

- Baronas, R.; Ivanauskas, F.; Kulys, J. Mathematical Modeling of Biosensors; Springer: Heidelberg, Germany, 2010; ISBN 978-90-481-3243-0. [Google Scholar]

- HOFMANN, O.T.; ZOJER, E. Modelling Organic-Inorganic Hybrid Interfaces. In World Scientific Reference of Hybrid Materials; World Scientific Series in Nanoscience and Nanotechnology; World Scientific Publishing Company: Singapore, 2019; pp. 3–40. ISBN 978-981-327-053-4. [Google Scholar]

- Van Daele, T.; Gernaey, K.V.; Ringborg, R.H.; Börner, T.; Heintz, S.; Van Hauwermeiren, D.; Grey, C.; Krühne, U.; Adlercreutz, P.; Nopens, I. Application of iterative robust model-based optimal experimental design for the calibration of biocatalytic models. Biotechnol. Prog. 2017, 33, 1278–1293. [Google Scholar] [CrossRef] [PubMed]

- Ringborg, R.H.; Woodley, J.M. The application of reaction engineering to biocatalysis. React. Chem. Eng. 2016, 1, 10–22. [Google Scholar] [CrossRef]

- Roldan, A. Frontiers in first principles modelling of electrochemical simulations. Curr. Opin. Electrochem. 2018, 10, 1–6. [Google Scholar] [CrossRef]

- Semenova, D.; Zubov, A.; Silina, Y.E.; Micheli, L.; Koch, M.; Fernandes, A.C.; Gernaey, K.V. Mechanistic modeling of cyclic voltammetry: A helpful tool for understanding biosensor principles and supporting design optimization. Sens. Actuators B Chem. 2018, 259, 945–955. [Google Scholar] [CrossRef]

- Nabaei, V.; Chandrawati, R.; Heidari, H. Magnetic biosensors: Modelling and simulation. Biosens. Bioelectron. 2018, 103, 69–86. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silina, Y.E.; Gernaey, K.V.; Semenova, D.; Iatsunskyi, I. Application of Organic-Inorganic Hybrids in Chemical Analysis, Bio- and Environmental Monitoring. Appl. Sci. 2020, 10, 1458. https://doi.org/10.3390/app10041458

Silina YE, Gernaey KV, Semenova D, Iatsunskyi I. Application of Organic-Inorganic Hybrids in Chemical Analysis, Bio- and Environmental Monitoring. Applied Sciences. 2020; 10(4):1458. https://doi.org/10.3390/app10041458

Chicago/Turabian StyleSilina, Yuliya E., Krist V. Gernaey, Daria Semenova, and Igor Iatsunskyi. 2020. "Application of Organic-Inorganic Hybrids in Chemical Analysis, Bio- and Environmental Monitoring" Applied Sciences 10, no. 4: 1458. https://doi.org/10.3390/app10041458

APA StyleSilina, Y. E., Gernaey, K. V., Semenova, D., & Iatsunskyi, I. (2020). Application of Organic-Inorganic Hybrids in Chemical Analysis, Bio- and Environmental Monitoring. Applied Sciences, 10(4), 1458. https://doi.org/10.3390/app10041458