1. Introduction

Facing environmental degradation and a decrease in resources, eco-efficiency has been proposed as one of the main tools to promote sustainable development. Eco-efficiency means that a system provides an affordable service while satisfying human needs and reducing the intensity of consumption of inputs and environmental impacts [

1]. Consumers are looking for better quality products through environmentally friendly production. Thus, producers are obliged to increase or maintain a level of production while reducing their environmental impact, without compromising either the quality of performance of their processes [

2,

3].

Animal husbandry is one of the production processes necessary for world food security [

4]; dairy farming, meat poultry, and aquaculture are the most representative. These processes are the world’s primary industries that transforms vegetable protein into animal protein. This production process maintains an intensive specialized egg production sector, which consists of separating chicken meat and shelf egg production. The hatching egg sector is not taken into account in this work. Shelf egg production demands food and water inputs due to the biological need for birds and environmental conditions [

5,

6]. The energy consumption is a consequence of the farm operations and their level of automation. It has been reported that the most energy-demanding processes in the poultry industry are climate control and lighting, with variable energy consumption of 3 to 4.4 kWh/bird/m

2/year [

7]. The analysis of egg production is gaining importance, which is why studies have been carried out in countries such as Germany, Australia, Canada, the United Kingdom, and Switzerland to create a history of the consumption of energy inputs and materials to estimate the carbon footprint for each kilogram of egg produced according to its housing system (

Table 1).

Mexico is the world’s leading egg consumer, with an estimated annual per capita consumption of 23.3 kg [

15]. There is a high demand in the national diet, so the poultry sector has considerable participation in the production of shelf eggs and gross domestic product (GDP). In 2018, the poultry sector represented 63.3% of the country’s agricultural activities, of which 28.2% corresponded to the generation of egg products. According to the Mexican National Union of Poultry Producers [

15], shelf egg production in 2019 reached 2.88 × 10

6 t. Expectations for growth in this field are 1.45% per annum [

16,

17]. Despite the importance of shelf egg production in Mexico, as it represents 17% of the protein contribution by the livestock sector, there is no national data reporting on environmental assessments. As part of the contribution to food sovereignty, the aim is for agricultural production to be carried out under eco-efficient production schemes. Therefore, it is essential to identify significant environmental issues and opportunities for improvement in this sector.

There are tools such as life cycle assessment (LCA) that allow us to estimate potential environmental impacts within a supply chain, and that can integrate improvement strategies into the process [

18]. Globally, LCA has been applied to the study of egg production, considering inputs such as diets, electricity, water expenditure, and land-use change [

14]. Value stream mapping (VSM) is one of the techniques that can be integrated into LCA. This tool allows visualization of the flow of information in terms of the unitary productivity, efficiency, and reduction of process wastage [

19,

20]. The solution obtained through the integration of these instruments reduces waste by 20%–50%, understood as being due to reducing problems in the supply chains of a process [

21]. For example, [

20] reported a 25% decrease in material consumption, 19% decrease in energy consumption, and 7% decrease in the carbon footprint of an automotive production line in India. To the best of the author’s knowledge, there are no reports on the integration of LCA and VSM for shelf egg production. There is a lack of studies on eco-efficient scenarios that integrate the environmental impacts derived from inefficiency into the use of inputs. This study aimed to design an eco-efficient scheme for a semi-technified poultry farm.

2. Methodology

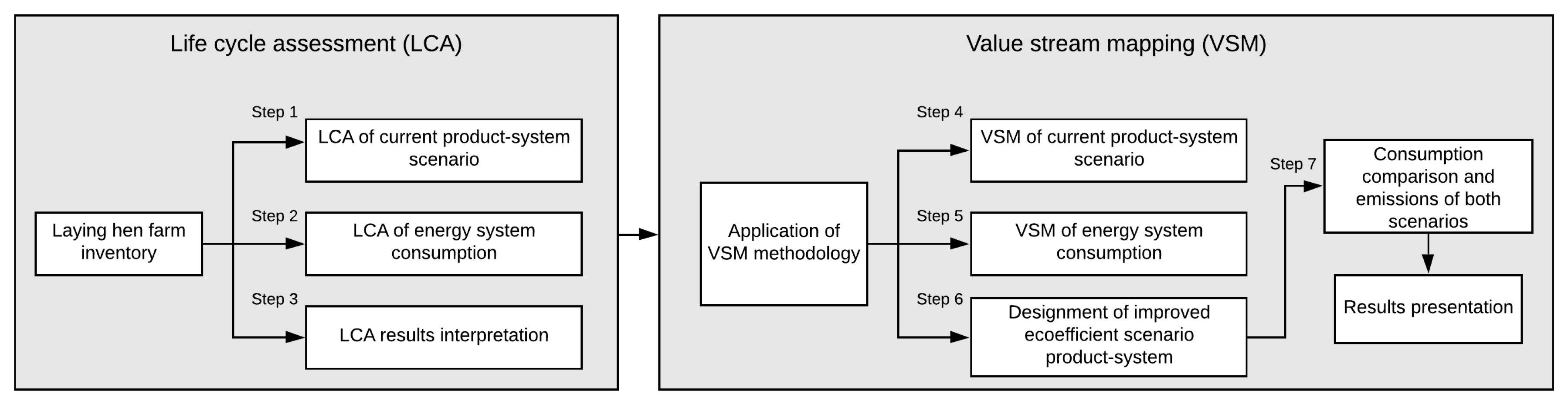

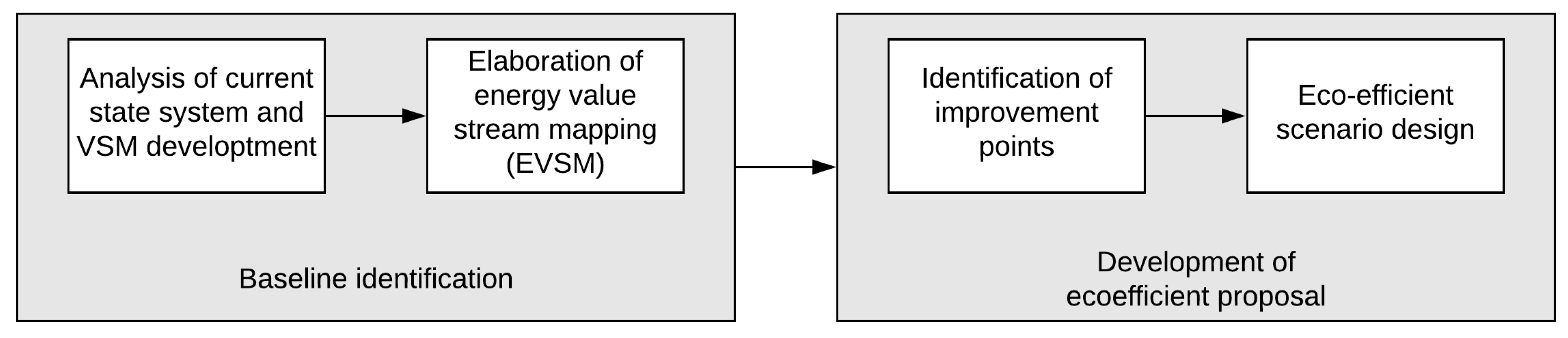

LCA and VSM methodologies were integrated into this work to design a tailor-made eco-efficient scheme for egg production. LCA was applied to determine the potential for environmental contribution through 18 impact categories for each production stage. The VSM, on the other hand, made it possible to identify opportunities in the system. The work plan for this research is shown in

Figure 1.

2.1. Life Cycle Assessment

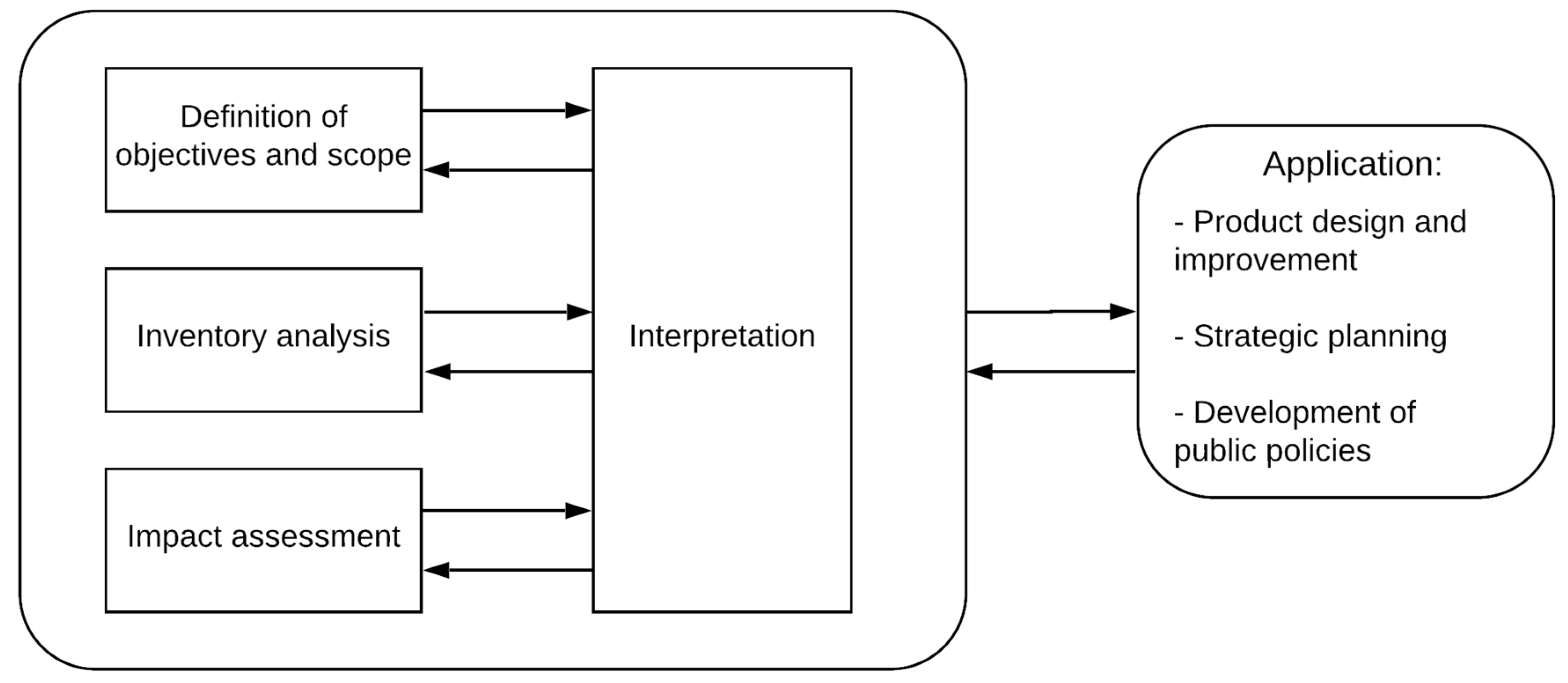

This methodology is oriented to the evaluation of the environmental impacts of products and services. It has four phases according to ISO 14040:2006 (

Figure 2), in which objectives and scopes that define inputs and outputs of a system product are limited.

2.1.1. Description of the System and Area of Study

The study of shelf egg production for the present work was conducted on a semi-technified farm, located in Tepatitlán de Morelos, Jalisco, Mexico, known as “

Laguna Colorada”; (20°45′48.811″ N; 102°49′47.504″ O). The location has an average elevation of 1880 m above sea level and an annual average temperature of 19.1 °C. In Mexico, there are three different production systems, characterized by their technological level: (i) technified, (ii) semi-technical, and (iii) backyard systems. The differences between these systems are due to the technology that is handled. A technified farm is firstly characterized by high technology and automated processes that allow handling of large numbers of animals and a reduction of costs, depending on the volume of production; and secondly by the forms of disposition of credit or risk capital and integration of social capital. The technified and semi-technical schemes make use of the maximum possible efficiency of the food conversion index, so that they produce more efficient food and conditions for production, with rigid sanitary controls [

23]. In the studied farm, only two parts of the process were automated (breeding and posture phases). The laying phase was handled manually by farmworkers. The chicken breed was Hy-Line W-36 and a battery cage system (450 cm

2, or three birds/cage) was used to house 96,000 1-day old chicks per poultry house. Adult laying hens were accommodated in three poultry houses.

The poultry houses at the studied farm have dimensions measuring 10 m × 3 m × 100 m and a controlled environment (31.46 °C for breeding, 20.81 °C for laying, and 21.92 °C for posture; humidity = 50% with forced ventilation). A total of 917 incandescent bulbs were used per poultry house to provide 15 lux (laying hens require illumination for 16–17 h/day). The eggs are manually collected and packed in cardboard boxes containing 360 eggs. Waste, such as manure and bird carcasses, were manually removed from the poultry houses and composted. The obtained data of the life cycle inventory correspond to the summer of 2016. The system at this farm is intensive for shelf egg production.

2.1.2. Functional Unit and Reference Flow

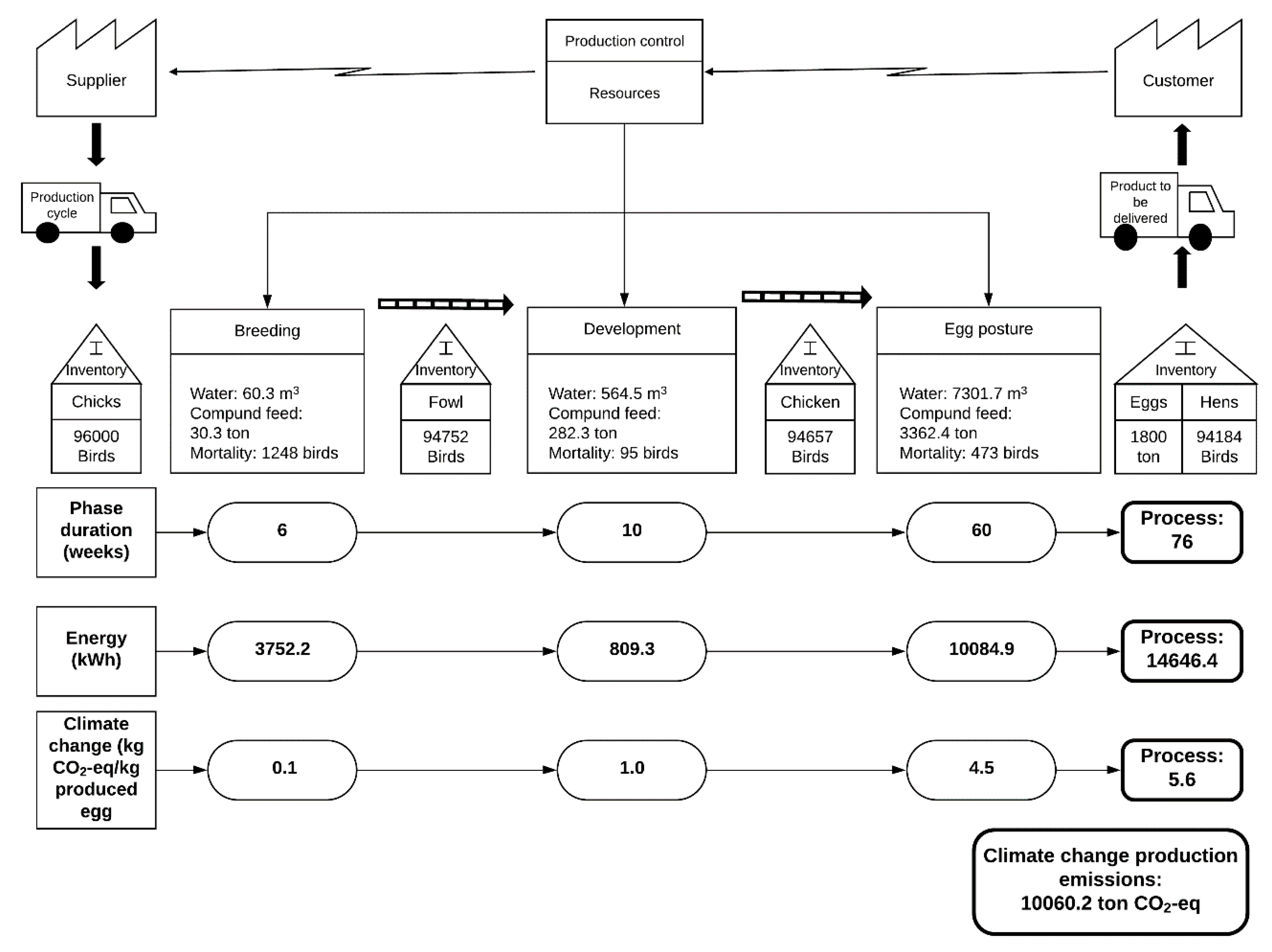

The functional unit was a kilogram of egg production on a semi-technified farm. A reference flow of 1,800,000 kg for egg production was presented for a total production period of 76 weeks (June 2016–February 2017).

2.1.3. System Limits

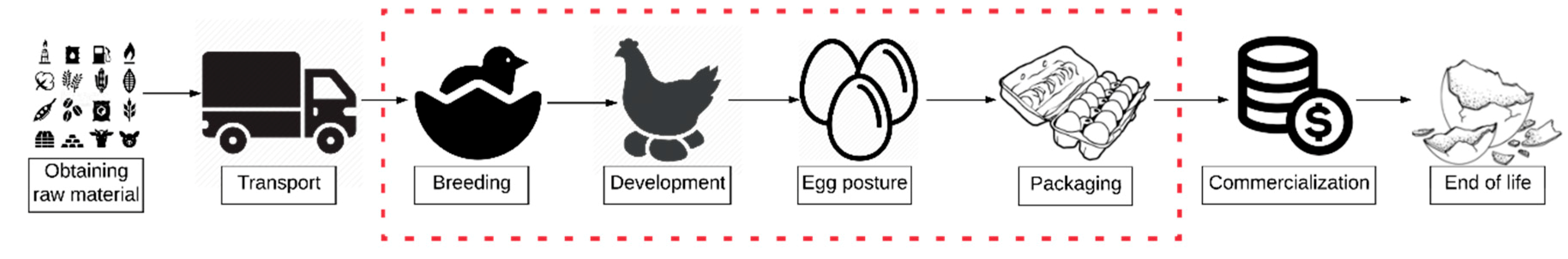

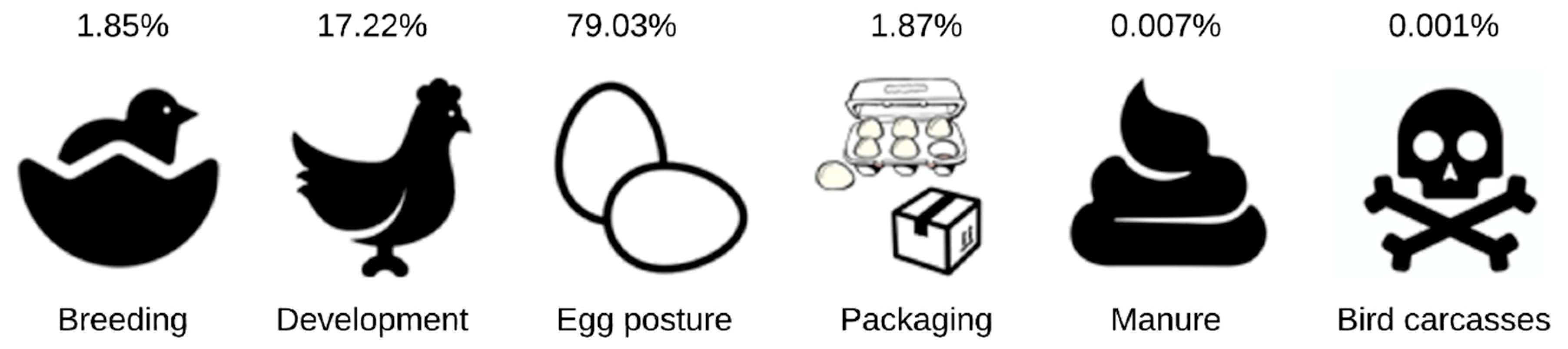

The system product was limited to the stages of chick breeding (6 weeks), bird development (10 weeks), egg laying (60 weeks), and egg product packaging.

Figure 3 represents the limits of the system.

2.1.4. Data Sources and Life Cycle Impact Assessment to Obtain Environmental Dimension Metrics

According to the limits of the system, both material and energy input data were obtained directly from the egg production poultry farm. For the environmental impact analysis, Ecoinvent 3.4 and Agri-footprint databases in SimaPro software, version 8.5, were used. The evaluation was carried out using the method “ReCiPe Midpoint V 1.13/World ReCiPe H”, which considers 18 midpoint impact categories (

Table 2). The most significant categories of impact on egg production were selected (

Section 3.1). Subsequently, a second impact assessment was carried out considering only the energy demand of the system (

Figure 1). The results obtained in both cases were the metrics for the environmental impact assessment.

2.1.5. Input Data of the LCA Limits

The data inventory was obtained directly from the poultry farm through surveys.

Table 3 contains the database of material inventory for egg production phases. Two products were obtained as residues, bird carcasses, and manure; both were composted.

Table 4 contains the fuel inventory database for the studied poultry farm.

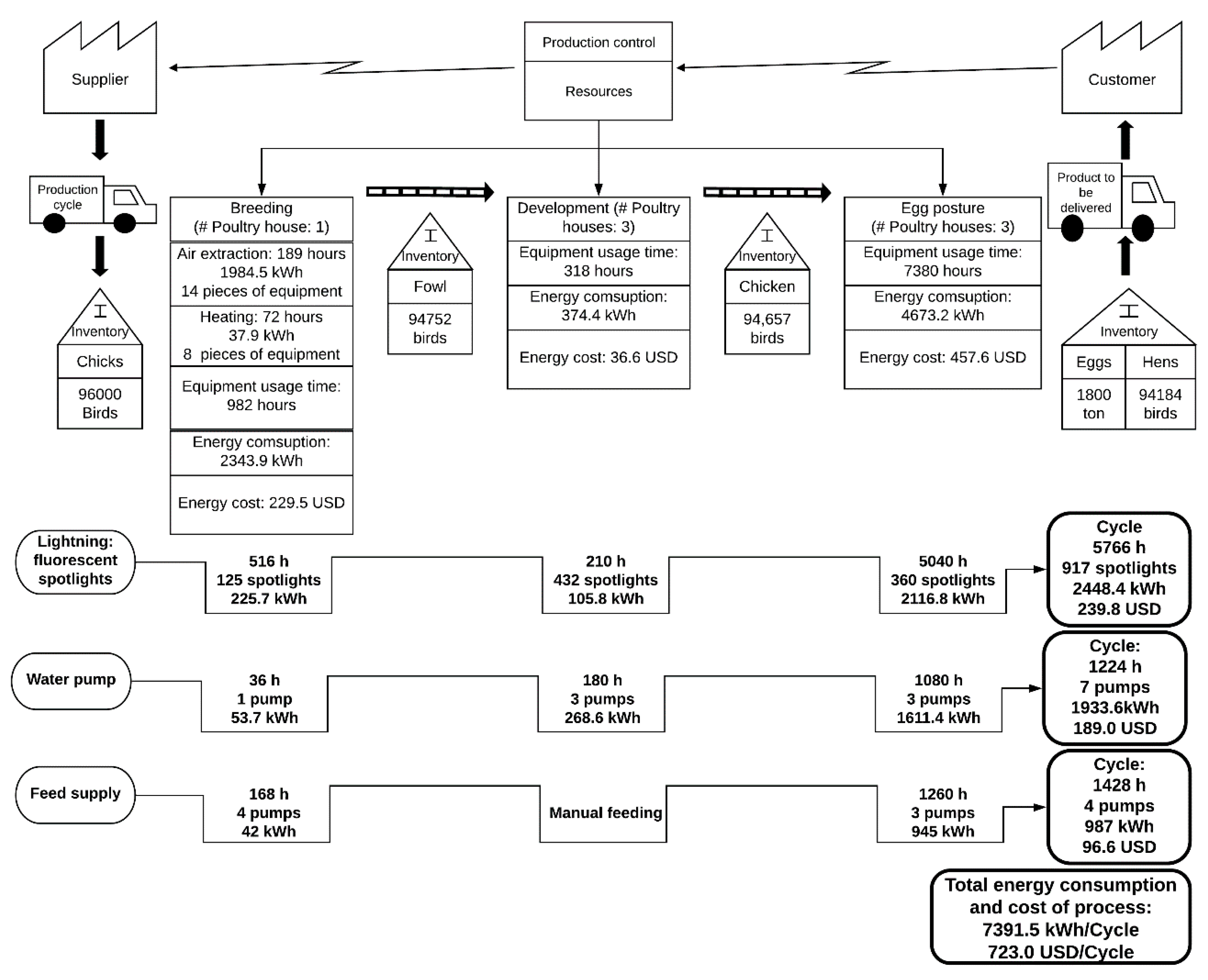

2.2. Value Stream Mapping

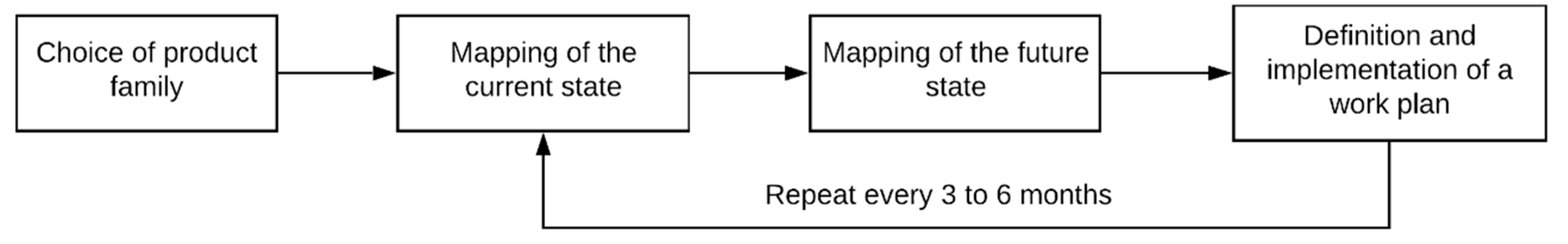

The primary function of this tool is to map activities with or without added value necessary to elaborate a family of products (or just one), following the process of a product from the raw material to its completion or delivery to the client [

19,

24] (

Figure 4).

The shelf egg is the product of interest and is obtained within 76 weeks of the system product process. At the end of the production cycle, a quantity of 1,800,000 kg of eggs were produced. The VSM was limited to the demand for inputs from the chick breeding stages (6 weeks), bird development (10 weeks), and egg posture of laying hens (60 weeks) within the study farm.

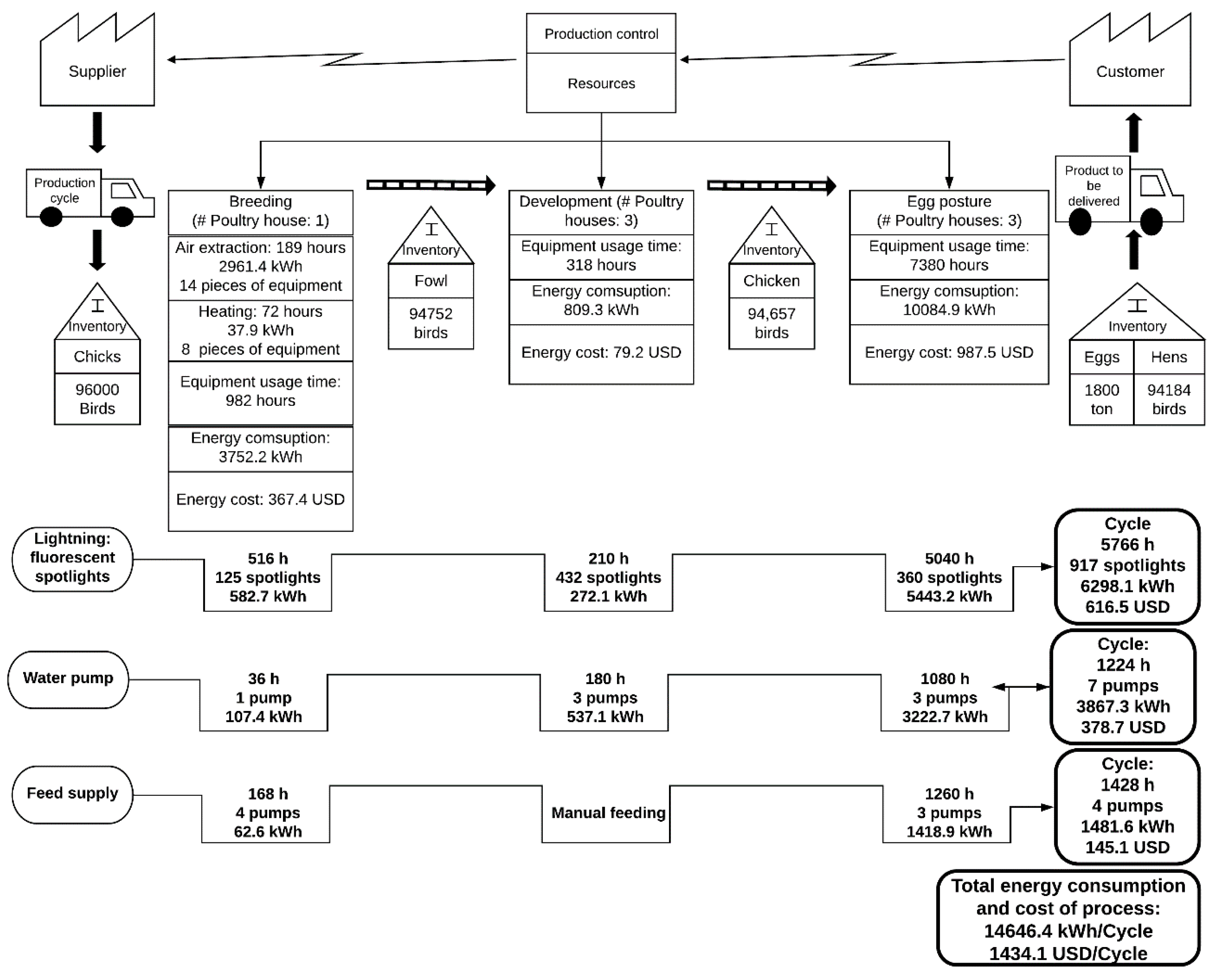

Data from the LCA inventory of energy inputs and materials were used. Data were classified according to the equipment used, and the inputs of LCA tools together with VSM were developed through a four part follow up (

Figure 5).

The equipment used in shelf egg production was classified according to the unit operation and corresponding stage. The standard energy consumption was calculated using shelf egg data. After, with the energy data, an energy flow map (EFM) was developed, presenting the total and partial energy expenditure of each stage of the process. Using Equations (1) and (2), the specific energy and energy productivity per kilogram of the produced egg was calculated.

An on-site analysis was carried out, where the equipment plate data were reviewed and the information from the equipment manufacturers was consulted. The pieces of equipment with the highest energy consumption at the farm were identified to propose more efficient alternatives. Energy billing concepts (energy consumption, power factor, demand factor) were also considered as relevant data in decision making for the eco-efficient scheme.

Once the improvement opportunities for the process had been identified, a flow map was drawn up to measure future value with an eco-efficient approach, using as a metric the substitution of a certain technology for one with greater energy efficiency. Finally, this was compared with the current scenario of the process only in the category of climate change.

4. Conclusions

The findings in this study contribute to improving the sustainable performance of the poultry industry and reducing its environmental impact. Lean manufacturing techniques, such as VSM, can improve the process by identifying opportunities for eliminating waste. The application of LCA to a study allows knowledge of the quality of the manufacturing process concerning the environment when identifying environmental impacts. However, when both technics are integrated, a visualization of the process with an eco-efficient approach is provided. This integral framework (LCA and VSM) helps to facilitate sustainable productivity and provides scientific value, intending to ensure best practices. Additionally, this framework offers leveraged benefits that meet lean and environmental needs.

4.1. Limitations Section

Comparisons of LCA are complicated, even when using the same methodology, as results can differ with particular assumptions in each study.

The results of an LCA study with national- or regional-level approaches may not be accurate for local applications, or vice versa. This study has an important geographical limitation to consider. The studied farm is located in the main egg-producing zone in Mexico (Jalisco State), which has favourable weather conditions for this activity. Other important egg-producing farms in Mexico are located in hot-dry or hot-humid climates. To provide thermal comfort to laying hens, technified farms are likely to use different technologies than those reported here. Different, additional, newer, or more modern equipment would imply variations of energy consumption as well. Therefore, the results from this semi-technified farm may not be suitable for small farms that employ manual handling.

The VSM results are also related to the limitations described for LCA.

4.2. Future Research Plan

The technification index for farms has not been reported in Mexico for the poultry sector. Therefore, the official reports of national greenhouse gases (GHG) for this sector do not consider differences among national shelf egg, hatching egg, or poultry production. For this reason, it is important to develop new research in this sector to recognize the real efficiency, impacts, and opportunities for energy management and limitation of environmental footprints.