A GHG Metric Methodology to Assess Onsite Buildings Non-Potable Water System for Outdoor Landscape Use

Abstract

1. Introduction

1.1. Research Background

1.2. Healthcare Context for Water Conservation

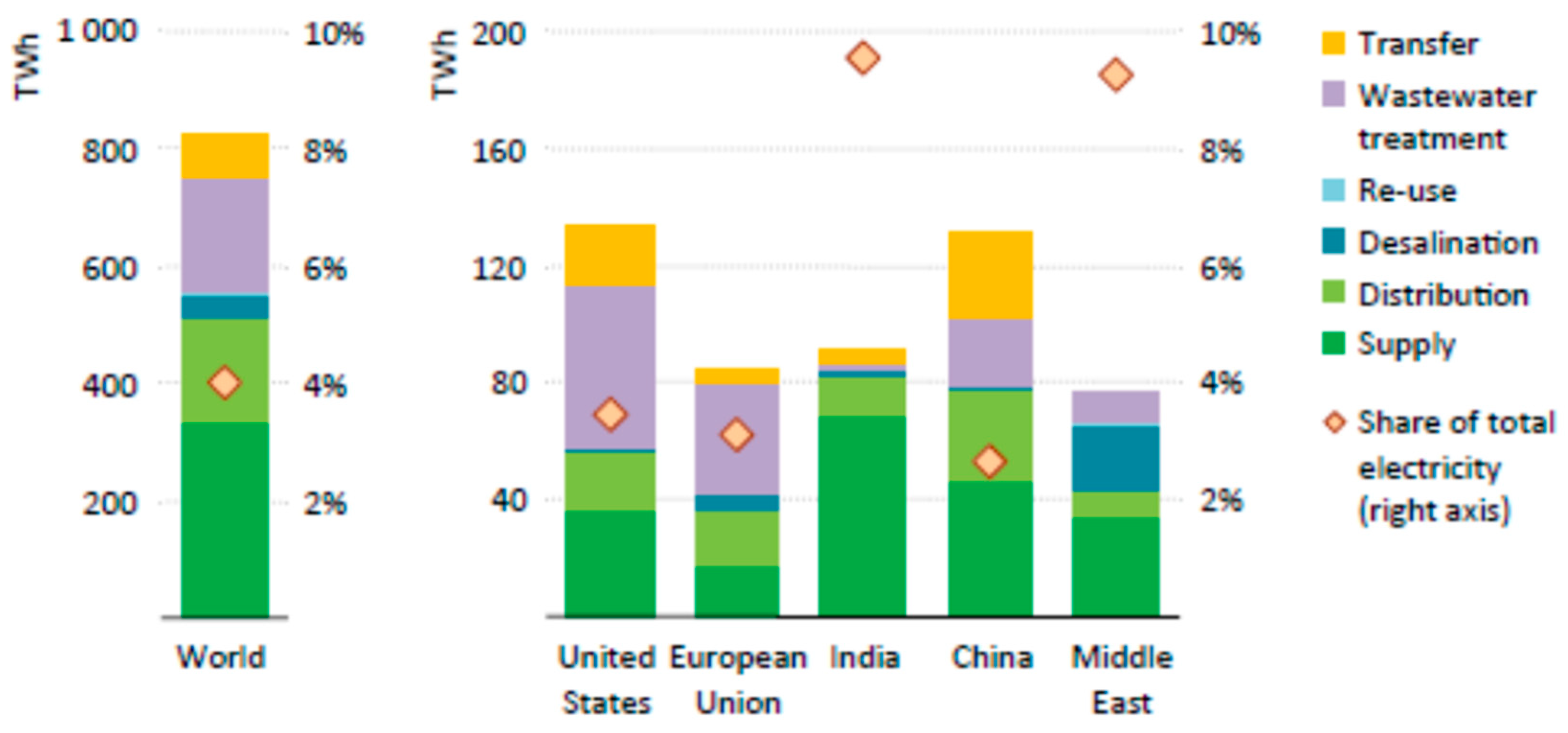

1.3. The Context of the Water Energy Nexus in Abu Dhabi

1.4. Greenhouse Gas (GHG) Emissions and Decarbonization

1.5. Gaps Analysis Leading to New Body of Knowledge

1.6. Original and Significant Contribution to New Body of Knowledge

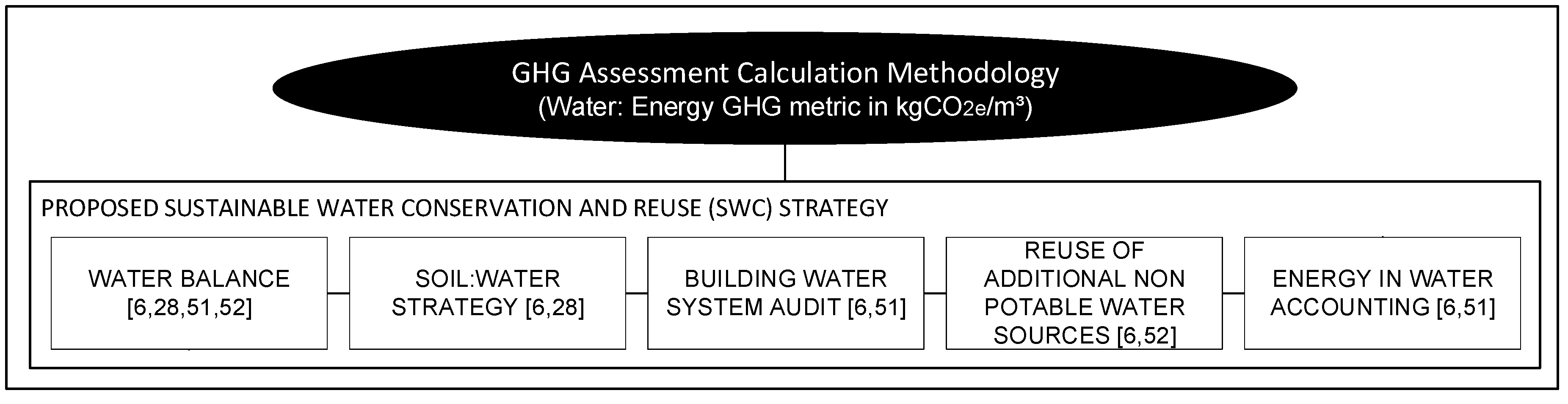

2. Materials and Methods

2.1. A Mixed Method Research

2.2. Medical facility case study (MFCS) Water System Description

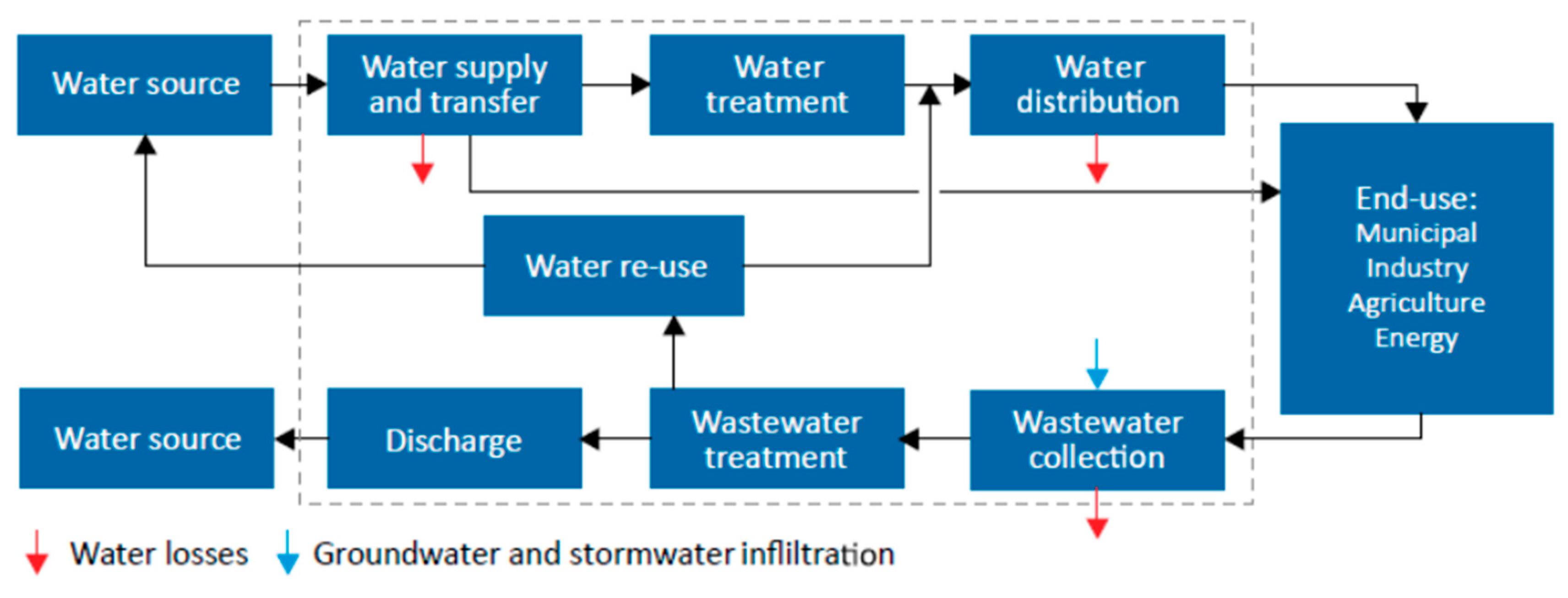

2.3. MFCS Energy and GHG Impact Boundaries

2.4. MFCS Energy Impact Calculation Method

2.4.1. Scope Two

2.4.2. Scope Three

2.4.3. Scope Two and Three Combined

2.5. MFCS GHG Impact Calculation Method

Calculation Process for Scope Two and Scope Three

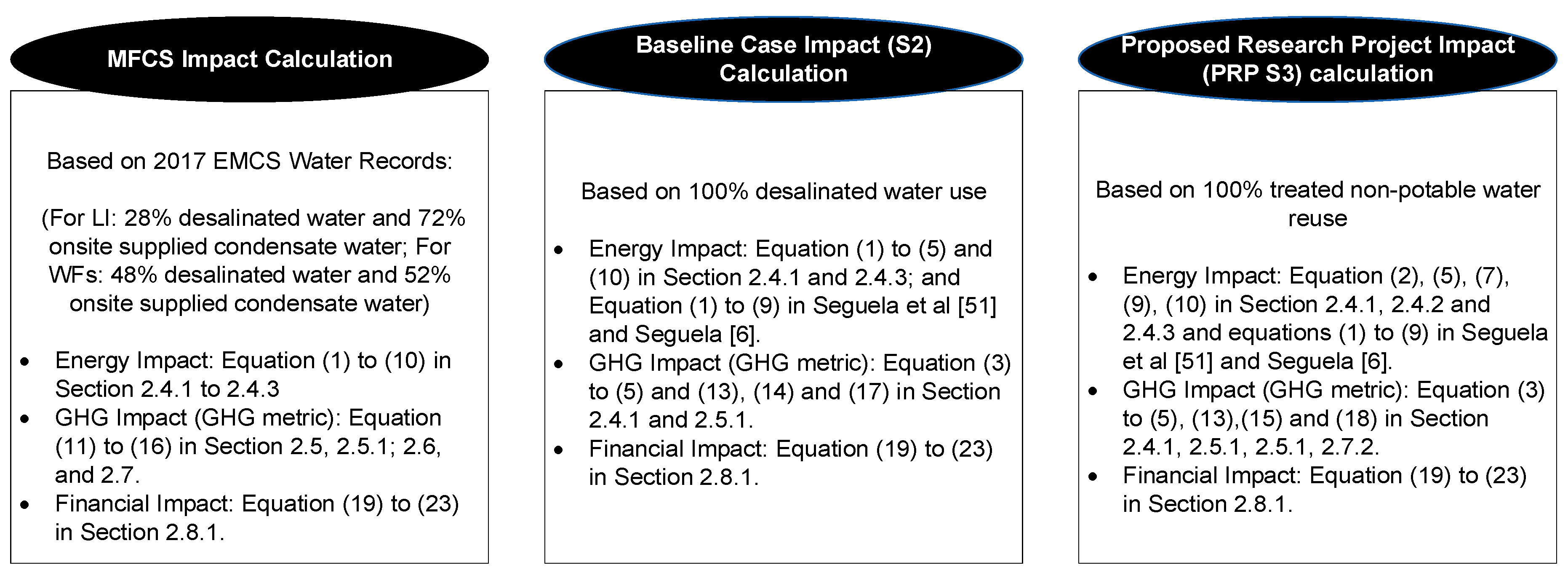

2.6. MFCS Calculation Evaluation against Alternative Scenarios (S2 and PRP S3)

2.7. MFCS 2017 EMCS Records

2.7.1. Baseline Case Scenario Two (S2)

2.7.2. Proposed Research Project Scenario Three (PRP S3)

2.8. MFCS Financial Impact Calculation Method

Discounted Cash Flow Method Analysis

3. Anticipated Results

3.1. MFCS Water System Energy Impact

3.2. MFCS Environmental Impact calculation

3.3. MFCS Financial Impact Calculation

4. Discussion

4.1. Contributions from the GHG Metric Methodology for Onsite Non-Potable Water Systems

- First, a mixture of condensate water and desalinated water (MFCS scenario);

- Second, desalinated water (Baseline Scenario 2, S2);

- Third, a case for additional non-potable water sources used as makeup water to the main water source (condensate water) such as fire sprinkler pump test water and RORW (Scenario 3, PRP S3).

4.2. Contributions and Target Audience

4.3. Research Limitations

4.3.1. Estimation of Cost and GHG Calculations

4.3.2. Energy Calculations

4.4. Recommendations

- A water balance to allow for the comparison of an onsite system as opposed to the use of municipal desalinated potable water. The water consumption records are to be collected and analyzed daily via sub flow meters connected to the EMCS. Additionally, these water data are to be compared with water bills to cross check the accuracy of the collected data and establish cost savings. This action research benefit is to help provide an account for the effect of non-potable water on landscape for water efficiency and water deficit offset feasibility analysis [6,28,51,52].

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AC CW | Air Conditioning condensate water |

| AD | Abu Dhabi |

| ADM | Abu Dhabi Municipality |

| AED | Emirati Dirham |

| D.Eng | Doctorate in Engineering |

| EAD | Abu Dhabi- Environment Agency |

| EMCS | Energy Monitoring and Control System |

| GHG | Greenhouse gas |

| IPCC | Intergovernmental Panel on Climate Change |

| LI | Landscape Irrigation |

| MED | Multi Effect Distillers |

| MFCS | Medical Facility Case Study |

| MSF | Multistage flash |

| RO | Reverse Osmosis |

| S2 | Baseline case scenario 2 |

| PRP S3 | Proposed research project Scenario 3 |

| TCR | The Climate Registry |

| TSE | Treated Sewage Effluent |

| UAE | United Arab Emirates |

| WF | Water feature |

| WFs | Water features |

Appendix A. Methodology

- 0.32 kWh/m3 accounts for ozone generation, drying of the feed gas cooling of the ozone generator, injection units and instrumentation control [55]

| Input Summary | Mean Average | ||||

|---|---|---|---|---|---|

| 1. Physical characteristics | |||||

| Outdoor elements | WFs | LI | |||

| Area (m2) | 3289 | 36,310 | |||

| 2. Operational parameters | |||||

| Pumps (h/day) | 11.7 | 13 | |||

| Backwash period (No per month)—assumption | 4 | n/a | |||

| Backwash duration (mins)—assumption | 15 | n/a | |||

| Refill period (years) | 0.5 | n/a | |||

| 3. Environmental Conditions | |||||

| Season (length) in days | 351 (14 days for maintenance) | 365 (2017); 366 (2016) | |||

| Rainfall (mm) average per month) | 3.80 mm (November to April); 0 mm (May to October); (SCAD, 2017) | ||||

| Evaporation (mm) average per month | 215 mm (November to April); 0 mm (December to March); (SCAD, 2017) | ||||

| 4. Existing Water System Components | |||||

| Pump Description | Pump Power (kW) | Pump Flow (m3/h) | Pump Usage per day (%) | WFs | LI |

| Number of pumps | |||||

| (P1) Pumps Set A | 4 | 17 | 30 | 1 | |

| (P1) Pumps Set B | 11 | 64 | 10 | 1 | |

| (P1) Pumps Set C | 4 | 17 | 30 | 1 | |

| (P1) Pumps Set D | 11 | 64 | 10 | 1 | |

| (P2) Pumps Set power | 18.5 | 64 | 100 | - | 1 |

| (P2) Pumps Set power | Not known | 10 | 100 | - | 1 |

| (P3) WE Pump Set | 7.5 | 45.5 | 100 | 1 | - |

| (P5) Pumps Set power | 11 | 63.3 | 100 | - | - |

| (P4) Ozone Filter Pump | 5.5 | Not known | 100 | 5 | - |

| (P4) Ozone Display Pump | 30 | Not known | 100 | 4 | - |

| (P4) Ozone Filter Pump | 2.2 | Not known | 100 | 2 | - |

| (P4) Ozone display Pump | 37.5 | Not known | 100 | 1 | - |

| (P4) Ozone display Pump | 3.7 | Not known | 100 | 1 | - |

| (P4) Ozone display Pump | 11.2 | Not known | 100 | 1 | - |

| Ozone Disinfection | 0.31 kWh/m3 [55] | 40.15 kWh/day | - | ||

| Water Product | Five Major Water Use Cycle Segments to Model GHG Emissions at Operations | GHG Protocol Scope [35,42,57,58] | Total GHG Emissions/Sinks in tCO2e | Energy Demand in kWh Per Year | Energy Intensity in kWh/m3 | Volume of Water Used in m3 | GHG Metric for Onsite Non Potable Water Use in (kgCO2e/m3) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Extract and Divert | 2. Place into Storage | 3. Conveyance | 4. Treatment | 5. Distribution | |||||||

| Medical Facility Case Study (MFCS) | |||||||||||

| Desalinated potable water use onsite as makeup water | These steps are included in the final emission factor generated by EAD [70] | 3 | Equation (14) | Equation (7) | 15.40 [20] | Make up water used onsite monitored by EMCS records | Equation (11) | ||||

| Air conditioning condensate water (A/C CW) | No emission other than scope 2 below | 3 | Equation (15) | Nil | Nil | Onsite generated and used and monitored by EMCS records | |||||

| 38% makeup desalinated water and 62% condensate water (AC CW) for both WFs and LI use | Nil because the condensate water is generated regardless of condensate water recycling or not | Gravity fed into raw water storage tank | AC CW conveyed to treatment plant by pump (P1)- see Figure A1 in Appendix A | AC CW treated to secondary and tertiary treatment for WFs and LI reuse | AC CW distributed to point of delivery onsite to WFs and LI | 2 | Equation (13) | Equation (5) | Equation (6) | Included in scope 3 above | |

| Baseline Scenario 2 (S2) | |||||||||||

| Desalinated potable water use onsite as makeup water | Included in scope 3 below | Pumped to storage. Refer to Figure A1 in Appendix A | Desalinated water conveyed to treatment plant by pump (P3) | Secondary and tertiary treatment for WFs only | Deasilated water distributed to point of delivery onsite to WFs and LI | 2 | Equation (13) | Equation (5) | Equation (6) | Make up water used onsite monitored by EMCS records | Equation (11) |

| Desalinated potable water use | These steps are included in the final emission factor generated by EAD [70] | 3 | Equation (14) | Equation (7) | 15.40 [20] | Included in scope 2 above | |||||

| Proposed Research Project Scenario 3 (PRP S3) | |||||||||||

| Reverse Osmosis Reject Water (RO RW) | Nil because the reject water is generated regardless of reject water recycling or not | Pumped to raw A/C CW storage tank. Assume a transfer pump consuming 0.11kWh/day (P8) Figure A1 and Table A1 in Appendix A. | Mixed with A/C CW in raw condensate water tanks (no extra power needed) | 3 | Equation (15) | Nil | Nil | Equation (4) in [6] | Equation (11) | ||

| 2 | Equation (13) | Part of Equation (5) below | Part of Equation (6) below | ||||||||

| Food waste Effluent wastewater (FEW) [6] | Dehydrator power (13 kWh per day) [6] | Pumped to storage. Assume a small transfer pump (power unknown) | Mixed with A/C CW in raw condensate water tanks (no extra power needed) [6] | 3 | Equation (15) | Nil | Nil | Estimate (85%-95%) of food weight [6] | |||

| 2 | Equation (13) | Part of Equation (5) below | Part of Equation (6) below | ||||||||

| Air conditioning condensate water (A/C CW) | Nil because the condensate water is generated regardless of condensate water recycling or not | Gravity fed into raw water storage tank | AC CW conveyed to treatment plant by pump (P1) Figure A1 and Table A1 in Appendix A | AC CW treated to secondary and tertiary treatment for WFs and LI | AC CW distributed to point of delivery onsite for WFs and LI use | 2 | Equation (13) | Equation (5) | Equation (6) | Onsite generated used and monitored by EMCS records | |

| No emission other than scope 2 above | 3 | Equation (15) | Nil | Nil | Onsite generated monitored by EMCS records | ||||||

| Fire Sprinkler Pump Test Water (FSPTW) | Nil because the water is used for testing the fire pumps regardless of fire sprinkler pump test water recycling or not. | Conveyed to storage through existing pump | Mixed with A/C CW in raw condensate water tanks (no extra power needed) | 3 | Equation (15) | Nil | Nil | Equation (1) in [6] Equation (2) in [6] Equation (3) in [6] | |||

References

- Köppen and Geiger. World Maps of Köppen-Geiger Climate Classification. Available online: http://koeppen-geiger.vu-wien.ac.at/present.htm (accessed on 6 February 2017).

- National Centre of Meteorology. Climate Yearly Report of AD 2003–2016. 2017. Available online: http://www.ncm.ae/en/climate-reports-yearly.html?id=26 (accessed on 6 February 2017).

- Pizzi, N.G. Water Treatment: Principles and Practices of Water Supply Operations, 4th ed.; American Water Works Association: Denver, CO, USA, 2010. [Google Scholar]

- Mitchell, K. From Increasing Supply to Managing Demand’, Al Manakh 2: Cont’d; Reisz, T., Ed.; Stichting Archis: Amsterdam, The Netherlands, 2009. [Google Scholar]

- World Bank. Adaptation to a Changing Climate in the Arab Countries: A Case for Adaptation Governance and Leadership in Building Climate Resilience; Verner, D., Ed.; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Seguela, G. Implementation and Evaluation of an Outdoor Water Conservation Strategy for Hospital Decarbonisation in an Arid Climate. Ph.D. Thesis, Cardiff Metropolitan University, Cardiff, UK, 2018. [Google Scholar]

- Cardno. Greywater/Condensate Water Risk Assessment Report; Medical Facility: Abu Dhabi, UAE, 2014. [Google Scholar]

- Creswell, J.W.; Creswell, J.D. Research and Design Qualitative, Quantitative and Mixed Methods Approaches; Sage Publication: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Healthcare Environmental Resource Center. Facilities Management-Water Conservation. Available online: http://www.hercenter.org/facilitiesandgrounds/waterconserve.cfm (accessed on 5 July 2015).

- Abu Dhabi Distribution Company. Water and Energy Tariffs 2017. Available online: https://www.addc.ae/en-US/residential/Documents/02-English.pdf (accessed on 1 January 2018).

- Ali, S.E.; Alsaman, A.S.; Harby, K.; Askalany, A.A.; Refaat Diab, M.; Ebrahim Yakoot, S.M. Recycling Brine Water of Reverse Osmosis Desalination Employing Adsorption Desalination: A Theoretical Simulation. Desalination. Available online: http://dx.doi.org/10.1016/j.desal.2016.12.0020011-9164 (accessed on 28 March 2017).

- Shahid, S.A.; Abdelfattah, M.A.; Othman, Y.; Kumar, A.; Taha, F.K.; Kelley, J.A.; Wilson, M.A. Innovative Thinking for Sustainable Use of Terrestrial Resources in AD Emirate Through Scientific Soil Inventory and Policy Development. In Developments in Soil Classification, Land Use Planning and Policy Implications; Shahid, S.A., Taha, F.K., Abdelfattah, M.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 3–49. [Google Scholar]

- Pacia, D.; Yeh, D. Adaptation to Climate for Water Utilities. In Water Reclamation and Sustainability; Ahuja, S., Ed.; Elsevier: San Diego, CA, USA, 2014; pp. 19–56. [Google Scholar]

- Balfaqih, H.; Al-Nory, M.T.; Nopiah, Z.M.; Saibani, N. Environmental and economic performance assessment of desalination supply chain. Desalination 2017, 406, 2–9. [Google Scholar] [CrossRef]

- Murad, A.; Nuaimiu, H.; Hammadi, M. Comprehensive Assessment of Water Resources in the United Arab Emirates (UAE). Water Resour. Manag. 2007, 21, 1449–1463. [Google Scholar] [CrossRef]

- Ministry of Energy UAE. 3rd National Communication under the United Nations Framework Convention on Climate Change. Available online: https://www.moenr.gov.ae/assets/b8502605/uae-3rd-national-communication-report.aspx (accessed on 2 October 2017).

- Almaeeni, W.; Dawood, M.; I-Tsung, T. Strategic Water Reserve’s Effect on the Water Supply System in AD: A System Dynamics Approach. International Council on Systems Engineering; Wiley online Library: Hoboken, NJ, USA, 2014; Volume 24, pp. 759–774. [Google Scholar]

- Regulation Supervision Bureau. Technical Report. AD: RSB. Available online: http://rsb.gov.ae/en/publications/detail/technical-report-2015 (accessed on 27 April 2017).

- Dawoud, M.A. Strategic Water Reserve: New Approach for Old Concept in GCC Countries; Environment Agency: Bristol, UK, 2008. [Google Scholar]

- Ministry of Environment and Water. United Arab Emirates Water Conservation Strategy. Available online: http://extwprlegs1.fao.org/docs/pdf/uae147095.pdf (accessed on 6 February 2017).

- Cisneros, B.J. Water Recycling and Reuse: An Overview. In Water Reclamation and Sustainability, 1st ed.; Ahuja, S., Ed.; Elsevier: San Diego, CA, USA, 2014; pp. 431–454. [Google Scholar]

- XE. Xenon Laboratories. Currency Converter Rate. Available online: https://www.xe.com/currencyconverter/convert/?Amount=1&From=AED&To=GBP (accessed on 10 September 2017).

- Heid, J. The Paradox of Sustainability and AD, Al Manakh 2: Cont’d; Reisz, T., Ed.; Stichting Archis: Amsterdam, The Netherlands, 2009; pp. 118–119. [Google Scholar]

- World Bank. Seawater and Brackish Water Desalination in the Middle East, North Africa and Central Asia. Available online: http://documents.worldbank.org/curated/en/813191468191928325/pdf/335150v70Seawater0annex060cyprus.pdf (accessed on 25 February 2016).

- Einav, R.; Harussi, K.; Perry, D. The footprint of the desalination processes on the environment. Desalination 2003, 152, 141–154. [Google Scholar] [CrossRef]

- Einav, R.; Lokiec, F. Environmental aspects of a desalination plant in Ashkelon. Desalination 2003, 156, 79–85. [Google Scholar] [CrossRef]

- Regulation Supervision Bureau. Supporting the AD Economic Vision 2030. AD: RSB. Available online: http://rsb.gov.ae/assets/documents/770/vision2030may2013.pdf (accessed on 24 January 2017).

- Seguela, G.; Littlewood, J.R.; Karani, G. Eco-engineering strategies for soil restoration and water conservation: Investigating the application of soil improvements in a semi-arid climate in a Medical Facility Case Study. J. Ecol. Eng. 2017, 121, 53–64. [Google Scholar] [CrossRef]

- Environment Agency-AD. The Water Resources Management Strategy for the Emirates of AD 2014–2018. AD: EAD. Available online: https://www.ead.ae/Documents/PDF-Files/Executive-Summary-of-The-Water-Resources-Management-Strategy-for-the-Emirate-of-Abu-Dhabi-2014-2018-Eng.pdf (accessed on 30 January 2014).

- Jarrar, A. Utilization of Treated Sewage Effluent for Landscape Irrigation in Abu Dhabi City. In Proceedings of the Future Landscape & Public Realm Conference, Abu Dhabi, UAE, 13 November 2017. [Google Scholar]

- International Energy Agency. Water Energy Nexus; OECD/IEA: Paris, France. Available online: https://www.iea.org/publications/freepublications/publication/WorldEnergyOutlook2016ExcerptWaterEnergyNexus.pdf (accessed on 28 March 2018).

- Ferrell, L.; Sarrouh, S.; Walski, T.; Elliott, T.; Deavenport, S. Technology measures for energy efficiency. In Energy Management for Water Utilities; Dufresne, L., Ferrell, L., Eds.; American Water Works Association: Denver, CO, USA, 2016; pp. 59–96. [Google Scholar]

- Shashua-Bar, L.; Pearlmutter, D.; Evyatar, E. The cooling efficiency of urban landscape strategies in a hot dry climate. J. Landsc. Urban Plan. 2009, 92, 179–186. [Google Scholar] [CrossRef]

- Ferguson, B.K. Water conservation methods in urban LI: An exploratory overview. J. Am. Water Resour. Assoc. 2007, 23, 147–152. Available online: https://www.researchgate.net/publication/229481559 (accessed on 20 January 2017). [CrossRef]

- The Climate Registry. GENERAL Reporting Protocol Version 2.1. Available online: https://www.theclimateregistry.org/wp-content/uploads/2014/11/General-Reporting-Protocol-Version-2.1.pdf (accessed on 13 April 2017).

- Nair, S.; George, B.; Malano, H.M.; Arora, M.; Nawarathna, B. Water-Energy Greenhouse Gas Nexus of Urban Water Systems: Review of Concepts, State of-Art and Methods. J. Resour. Conserv. Recycl. 2014, 89, 1–10. Available online: https://doi.org/10.1016/j.resconrec.2014.05.007 (accessed on 18 January 2018). [CrossRef]

- Griffiths-Sattenspiel, B.; Wilson, W. The Carbon Footprint of Water. Portland: A River Network Report. Available online: https://albertawater.com/docs/CarbonFootprintofWater.pdf (accessed on 6 February 2017).

- California Public Utilities Commission. Embedded Energy in Water Studies-Study 2: Water Agency and Function Component Study and Embedded Energy Water Load Profiles. Available online: Ftp://ftp.cpuc.ca.gov/gopher-data/energy%20efficiency/Water%20Studies%201/Study%201%20-%20FINAL.pdf (accessed on 23 January 2016).

- California Public Utilities Commission. Embedded Energy in Water Studies-Study 1: State-Wide and Regional Water-Energy Relationship. Available online: Ftp://ftp.cpuc.ca.gov/gopher-data/energy%20efficiency/Water%20Studies%202/Study%202%20-%20FINAL.pdf (accessed on 23 January 2016).

- United Nations. Status of Ratification of the UN Framework Convention on Climate Change. Available online: https://unfccc.int/sites/default/files/resource/docs/cop3/inf02.pdf (accessed on 3 February 2017).

- United Nations. UN Framework Convention on Climate Change. Climate Change: Impacts, Vulnerabilities, and Adaptation in Developing Countries. Available online: https://unfccc.int/resource/docs/publications/impacts.pdf (accessed on 3 February 2017).

- The Climate Registry. Water Energy GHG Guidance. Available online: https://www.theclimateregistry.org/wp-content/uploads/2015/12/Water-Energy-GHG-Guidance-December-2015.pdf (accessed on 13 April 2017).

- Fay, M.; Hallegatte, S.; Vogt-Schilb, A.; Rozenberg, R.; Narloch, U.; Kerr, T. Decarbonizing Development: Three Steps to a Zero-Carbon Future; World Bank: Washington, DC, USA, 2015. [Google Scholar]

- Intergovernmental Panel on Climate Change. Climate Change 2014: Synthesis Report; United Nations Environment Programme (UNEP) and the World Meteorological Organization (WMO): Geneva, The Netherlands, 2014. [Google Scholar]

- Environment Agency-AD. AD State of Environment Report 2017. AD: EAD. Available online: https://www.ead.ae/Publications/Abu%20Dhabi%20State%20of%20Environment%20Report%202017/EAD-full-report.pdf (accessed on 28 March 2018).

- Walsh, B.P.; Murray, N.S.; O’Sullivan, D.T.J. The Water Energy Nexus, an ISO50001 Water Case Study and The Need for a Water Value System. J. Water Resour. Ind. 2015, 10, 15–28. Available online: https://doi.org/10.1016/j.wri.2015.02.001 (accessed on 18 January 2018). [CrossRef]

- International Standard Organization. ISO 14046:2016. Environmental Management Water Footprint Principles, Requirements and Guidelines; ISO: Geneva, The Netherlands, 2016. [Google Scholar]

- International Standard Organization. ISO 50001:2017. Energy Management Systems. Requirements with Guidance for Use; ISO: Geneva, The Netherlands, 2017. [Google Scholar]

- Ruddell, B.L.; Richard, R.; Elizabeth, A. Adams Generalizing ecological, water and carbon footprint methods and their worldview assumptions using Embedded Resource Accounting. Water Resour. Ind. 2013, 1–2, 77–90. [Google Scholar] [CrossRef]

- World Resources Institute & World Business Council for Sustainable Development. The Greenhouse Gas Protocol: Technical Guidance for Calculating Scope Three Emissions, Version 01; WRI & WBCSD: Geneva, The Netherlands, 2013. [Google Scholar]

- Seguela, G.; Littlewood, J.R.; Karani, G. A study to Assess Non-Potable water Sources for Reducing energy Consumption in a Medical Facility Case Study. Energy Procedia 2017, 134, 797–806. Available online: https://doi.org/10.1016/j.egypro.2017.09.532 (accessed on 24 October 2017). [CrossRef]

- Seguela, G.; Littlewood, J.R.; Karani, G. Onsite food Waste Processing as an Opportunity to Conserve Water in a Medical Facility Case Study, AD. Energy Procedia 2017, 111, 548–557. Available online: http://dx.doi.org/10.1016/j.egypro.2017.03.217 (accessed on 27 March 2017). [CrossRef]

- Abu Dhabi Municipality. Irrigation Systems Operation and Maintenance, Parks and Recreation Facilities Division: AD, 2C Section 02800; ADM: Chicago, IN, USA, 2013; p. 5. [Google Scholar]

- Dufresne, L.; Ferrell, L. Energy Management for Water Utilities; American Water Works Association: Denver, CO, USA, 2016. [Google Scholar]

- Elliott, T.; Zeier, B.; Xagoraraki, I. Energy Use at Wisconsin’s Drinking Water Facilities; Energy Centre: Madison, WI, USA, 2003. Available online: https://www.seventhwave.org/sites/default/files/222-1.pdf (accessed on 3 February 2018).

- WRI & WBCSD. World Resources Institute & World Business Council for Sustainable Development. A Corporate Accounting and Reporting Standard; WRI & WBCSD: Geneva, The Netherlands, 2015. [Google Scholar]

- International Standard Organization. Greenhouse Gases- Part 1: Specification with Guidance at the Organization Level for Quantitation and Reporting of Greenhouse Gas Emissions and Removals; ISO: Geneva, The Netherlands, 2006. [Google Scholar]

- International Standard Organization. Greenhouse Gases- Part 2: Specification with Guidance at the Project Level for Quantitation, Monitoring and Reporting of Greenhouse Gas Emission Reductions or Removal Enhancements; ISO: Geneva, The Netherlands, 2006. [Google Scholar]

- Intergovernmental Panel on Climate Change. IPCC Guidelines for National Greenhouse Gas Inventories; United Nations Environment Programme (UNEP) and the World Meteorological Organization (WMO): Geneva, The Netherlands, 2006. [Google Scholar]

- Kay, M.; Hatcho, N. Small-Scale Pumped Irrigation: Energy and Cost; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 1992. [Google Scholar]

- Forrest, N.; Williams, E. Life Cycle Environmental Implications of Residential Swimming Pools, Environmental Science Technology; William, E., Ed.; ACS Publications: Washington, DC, USA, 2010; Volume 23, pp. 147–152. [Google Scholar]

- Gallion, T.; Harrison, T.; Hulverson, R.; Hristovski, K. Estimating Water, Energy and Carbon Footprints of Residential Swimming Pools. In Water Reclamation and Sustainability, 1st ed.; Ahuja, S., Ed.; Elsevier: San Diego, CA, USA, 2014; pp. 343–359. [Google Scholar]

- Conway, D.; Rothausen, S.G.S.A. Greenhouse-Gas Emissions from Energy Use in the Water Sector; Nature Ology Advance Online Publication: London, UK, 2011. [Google Scholar]

- Cheng, C.L. Study of the inter-relationship between water use and energy conservation for a building. Energy Build. 2002, 34, 261–266. [Google Scholar] [CrossRef]

- Chiu, Y.-R.; Liaw, C.-H.; Chen, L.-C. Optimizing rainwater harvesting systems as an innovative approach to saving energy in hilly communities. Renew. Energy 2009, 34, 492–498. [Google Scholar] [CrossRef]

- Retamal, M.; Glassmire, J.; Abeysuriya, K.; Turner, A.; White, S. The Water-Energy Nexus: Investigation into the Energy Implications of Household Rainwater Systems; University of Technology (UTS): Sydney, Australia. Available online: https://opus.lib.uts.edu.au/bitstream/10453/20456/4/retamaletal2009waterenergynexus.pdf (accessed on 16 January 2018).

- Vieira, A.S.; Beal, C.D.; Ghisi, E.; Steward, R.A. Energy Intensity of Rainwater Systems: A Review. J. Renew. Sustain. Energy Rev. 2014, 34, 225–242. [Google Scholar] [CrossRef]

- Ward, S.; Butler, D.; Menon, F.A. Benchmarking energy consumption and CO2 emissions from rainwater-harvesting systems: An improved method by proxy. Water Environ. 2012, 26, 184–190. [Google Scholar] [CrossRef]

- Reygadas, F. User Compliance, Field Efficacy, and Greenhouse Gas Emissions of an Ultraviolet Water Disinfection System and Other Drinking Water Treatment Alternatives for Rural Households in Mexico. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2014. [Google Scholar]

- Environment Agency-AD. Greenhouse Gas Inventory for AD Emirate. AD: EAD. Available online: https://www.ead.ae/Documents/PDF-Files/AD-Greenhouse-gas-inventory-Eng.pdf (accessed on 30 January 2014).

- International Standard Organization. ISO/TR 14069:2013 Greenhouse Gases—Quantification and Reporting of Greenhouse Gas Emissions for Organizations—Guidance for the Application of ISO 14064-1; ISO: Geneva, The Netherlands, 2013. [Google Scholar]

- Central Bank of the United Arab Emirates. United Arab Emirates Interest Rate. Available online: https://tradingeconomics.com/united-arab-emirates/interest-rate (accessed on 10 September 2017).

- Central Bank of the United Arab Emirates. United Arab Emirates Inflation Rate. Available online: https://tradingeconomics.com/united-arab-emirates/inflation-cpi (accessed on 6 February 2017).

- Letterman, R.D.; Driscoll, C.T.; Haddad, M.; Hau, H.A. Limestone Bed Contactors for Control of Corrosion at Small Water Utilities; National Service Center for Environmental Publications (NSCEP): Washington, DC, USA, 1986. [Google Scholar]

- Regulation Supervision Bureau. New Water and Electricity Tariffs Structure. AD: RSB. Available online: http://rsb.gov.ae/en/sector/new-water-and-electricity-tariffs-structure (accessed on 9 January 2016).

- Caperhart, B.; Turner, W.C.; Kennedy, W.J. Guide to Energy Management, 8th ed.; The Fairmont Press: Lilburn, GA, USA, 2008. [Google Scholar]

- Parker, S.A.; Walker, B.K. Boilers and Fired Systems. In Energy Management Handbook, 8th ed.; Doty, S., Turner, W.C., Eds.; The Fairmont Press: Lilburn, GA, USA, 2008; pp. 91–129. [Google Scholar]

- Deyong, C. Economic Analysis and Life Cycle Costing. In Guide to Energy Management, 5th ed.; Caperhart, B., Turner, W.C., Kennedy, W.J., Eds.; The Fairmont Press: Lilburn, GA, USA, 2008; pp. 133–174. [Google Scholar]

- Pratt, D. Economic Analysis. In Energy Management Handbook, 8th ed.; Doty, S., Turner, W.C., Eds.; The Fairmont Press: Lilburn, GA, USA, 2008; pp. 47–90. [Google Scholar]

- Doty, S.; Turner, W.C. Energy Management Handbook, 8th ed.; The Fairmont Press: Lilburn, GA, USA, 2013. [Google Scholar]

- Mackey, E.D.; Cushing, R.; Crozes, G.F. Practical Aspects of UV Disinfection; American Water Works Association (AWWA) Research Foundation: Denver, CO, USA, 2001. [Google Scholar]

| Description | MSF | MED | RO |

|---|---|---|---|

| Water cost production (USD/m3) | 1.10–1.25 | 0.75–0.85 | 0.68–0.82 |

| Energy use (kWh/m3) | 15.40 | 7.5 | 4–7 |

| Volume of saline feed water per m3 of fresh water | 4 | 3 | 2–2.5 |

| Abu Dhabi Water Supply | Desalination Technique Used | Water Production Share by Company |

|---|---|---|

| AMPC | MSF | 2% |

| TAPCO | MSF | 18% |

| GTTPC | MSF + MDF | 10% |

| ECPC | MSF | 6% |

| Existing Standards Related to Water and Energy Carbon Footprint Management | Scope | Address Both Energy Intensity and Water Reduction for Onsite Non-Potable Water Systems? (Yes or No) |

|---|---|---|

| International Standard Organization (ISO), 14046: 2016 Environmental management Water Footprint Principles, requirements and guidelines [47] | Applicable to products, processes and organizations and based on lifecycle assessments (LCA’s) to accurately quantify the water used, in a verifiable and consistent manner. | No. It addresses Water Consumption Reduction only. |

| ISO 50001:2017 Energy management systems. Requirements with guidance for use [48] | ISO 50001 requires the demonstration of continual improvement through the reduction in utilization of energy. | No. It does address all energy systems of an organization including heating boilers and sanitary facilities. |

| Water Usage Effectiveness (WUE) [46] | A metric to quantify water required for operating and cooling equipment for cloud computing industries and data centers. | No. It addresses Water Consumption Reduction only for specific industries. |

| Embedded Resource Accounting (ERA) [49] | It generalizes ecological, water, and carbon footprint methods by accounting for the net direct and indirect impacts of processes on arbitrarily defined resource stocks. | No. It is a generalized footprint methodology, which is used to derive footprints including water footprint [46]. |

| Water Energy Greenhouse Gas Metric (WEG) [35] | This establishes a series of WEG intensity metrics to enable water suppliers and consumers in Southern California to assess the GHG impact of their urban and agricultural water products. | No. The recycled water treatment and distribution and wastewater collection, treatment, and disposal are outside the scope of the WEG Guidance. The operational boundary ends at point-of delivery, or end-of-pipe. |

| GHG Protocol Corporate Value Chain (Scope three) Accounting & Reporting Standard [50] | The Scope Three Standard is the method to account for emissions from 15 categories of scope three activities (All other non-scope two indirect anthropogenic GHG emissions that occur in the value chain), both upstream and downstream of their operations. Unlike scope 1 and 2, scope three is not subject to verification by a third party. | No. Onsite non-potable water supply and water recycling GHG emissions are not defined. |

| Literature Review | Method for Calculating Pump Energy Intensity | Water End-Use |

|---|---|---|

| ▪ [67] ▪ [66] | ▪ Pump Input Power (kW) ▪ Pump Flow rate in cubic meter per hour (m3/h) ▪ Pump Start-up (kWh/start-up) ▪ Number of start-up operations (start-up/day) ▪ Power rate of standby mode (kW) ▪ Standby mode (hours/day) ▪ Rainwater consumption (m3) | Rainwater reuse for toilet flushing and laundry supply in single-story detached house |

| ▪ [68] | ▪ Volume pumped during constant flow operation (m3) ▪ Volume pumped during start-up (m3) ▪ Start-up energy factor (%) ▪ Motor pump power rating (kW) for efficiency calculation ▪ Motor input power (kW) for efficiency calculation ▪ Pump capacity (m3/h) | Rainwater reuse for toilet flushing in office building |

| ▪ [65] ▪ [64] | ▪ Liquid density in kilogram per cubic meter (kg/m3) ▪ Gravitation acceleration in meter per second squared (m/s2) ▪ Total head (m) ▪ Flow Rate in cubic meter per second (m3/s) ▪ Motor efficiency (%) ▪ Pump efficiency (%) | Rainwater reuse for single family one-story house |

| Calculation adapted from Forrest and Williams [61] and Gallion et al. [62] Equations (1)–(5) in Seguela et al. [51] | ▪ Electricity input (kWh) (Equation (5)): - Pump power (kW) - Use frequency (%) - Pumping shut down during maintenance in hours per day and days per year ▪ Total water consumption (m3) which considers: - WFs water precipitation, evaporation, backflush and refill (Equations (1)–(4)) | Water features (WFs) |

| Kay and Hatcho [60] for Equations (6)–(9) in Seguela et al. [51]; Conway and Rothausen [63] for Equation (7) (ibid.) | ▪ Peak power demand (kW) (Equation (6)) - Acceleration of gravity (9.81 m/s2) - Pump discharge (m3/s) - Pressure/head (m) - Pumping plant efficiency (%) ▪ Overall seasonal energy demand (kWh) (Equation (7)) - Volume of water (m3) - Pressure/head (m) - Water density (367 = 3600 (s/h) ÷ 9.81 (m/s2) - Pumping plant efficiency (%) ▪ Average daily hours (kWh): (Equation (8)) - Overall seasonal energy demand (kWh) - Crop duration (days) - Pump power (kW) ▪ Energy demand per day (kWh): (Equation (9)) - Peak power demand (kW) - Maximum daily pumping hours | Landscape irrigation (LI) |

| MFCS Scenario 1 | Baseline Case Scenario 2 (S2) | Proposed Research Project Scenario 3 (PRP S3) | |

|---|---|---|---|

| Initial investment (design and construction) | Water tanks, piping, flow meters, pumps, EMCS connection, UV disinfection and Ozone treatment systems. | Pumps, EMCS connection, and ozone disinfection treatment system. | Water tanks, piping, flow meters, pumps, EMCS connection, UV disinfection, and ozone treatment systems. |

| Annual landscape maintenance | ▪ Soil conditioner B. | ▪ Soil conditioner B. | |

| Annual water system maintenance | ▪ Chlorine; laboratory analysis; tank disinfection. | ▪ Chlorine; ▪ Laboratory analysis. | ▪ Chlorine; ▪ Laboratory analysis; ▪ Tank disinfection; ▪ Chemigation. |

| Annual water type consumption | ▪ Combined desalinated and non-potable water sources: WFs: 52% condensate water; 48% makeup water; LI: 72% condensate water; 28% makeup water. | 100% desalinated water consumption: ▪ WF water demand is based on the 2017 EMCS records. ▪ LI water demand is based on ADM [53] standard with no soil improvement. | 100% mixed non-potable water supply (condensate, fire sprinkler pump test water, RO reject water): ▪ WFs demand is based on Seguela et al.’s [28] water demand calculation. ▪ LI water demand is based on demand after soil improvement. |

| Additional parameters | ▪ Soil improvement partially implemented; 13 hours (h) run time irrigation controller per day, 10.67 h for the WF system. | ▪ 13 h run time irrigation controller per day; ▪ 10.67 h for the WF system. | ▪ Soil improvement 100% implemented; ▪ 8 h run time irrigation controller per day; ▪ 6 h for the WF system; ▪ Leaks detected and repaired; ▪ Hydraulic review recommendations 100% implemented; ▪ 365 days/year operations for the RORW pump and 1 day operation per year for the fire sprinkler pump test water. |

| For all three scenarios | |||

| Annual electrical consumption | Based on Seguela et al. [51] calculation method; except for scope three desalinated water use based on 15.40 kWh/m3 [20] | ||

| Annual energy tariff | AED 0.21/kWh, equivalent to USD 0.057/kWh [22] | ||

| Annual water tariff | The calculation will ignore the water and energy subsidies | AED 8.23/m3 equivalent to USD 2.24/m3 [22] | |

| Life span of the project (assumption) | 20 years | ||

| UAE interest rate in January 2018 (Central Bank of the United Arab Emirates [72]. | 4.8% | ||

| UAE inflation rate in January 2018 [73]. | 2.25% | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seguela, G.; Littlewood, J.R.; Karani, G. A GHG Metric Methodology to Assess Onsite Buildings Non-Potable Water System for Outdoor Landscape Use. Appl. Sci. 2020, 10, 1339. https://doi.org/10.3390/app10041339

Seguela G, Littlewood JR, Karani G. A GHG Metric Methodology to Assess Onsite Buildings Non-Potable Water System for Outdoor Landscape Use. Applied Sciences. 2020; 10(4):1339. https://doi.org/10.3390/app10041339

Chicago/Turabian StyleSeguela, Geraldine, John R. Littlewood, and George Karani. 2020. "A GHG Metric Methodology to Assess Onsite Buildings Non-Potable Water System for Outdoor Landscape Use" Applied Sciences 10, no. 4: 1339. https://doi.org/10.3390/app10041339

APA StyleSeguela, G., Littlewood, J. R., & Karani, G. (2020). A GHG Metric Methodology to Assess Onsite Buildings Non-Potable Water System for Outdoor Landscape Use. Applied Sciences, 10(4), 1339. https://doi.org/10.3390/app10041339