1. Introduction

In line with the quest to battle against the energy crisis and global climate change, wind energy is found to provide a technically and economically feasible solution, making it the most promising renewable energy technology in Europe and beyond (i.e., China, United States of America (USA), etc.) [

1]. Today, the vast majority of wind energy is generated from onshore wind farms. However, there is a limitation in the further growth of onshore wind farms as a result of visual impact and limited space available to deploy wind turbines. In comparison to land, there is more available space to deploy wind turbines at sea, and the wind shear is stronger at offshore locations, driving the wind industry to move offshore, currently aiming for offshore wind in Europe to reach 64.8 GW by 2030 [

1,

2,

3,

4].

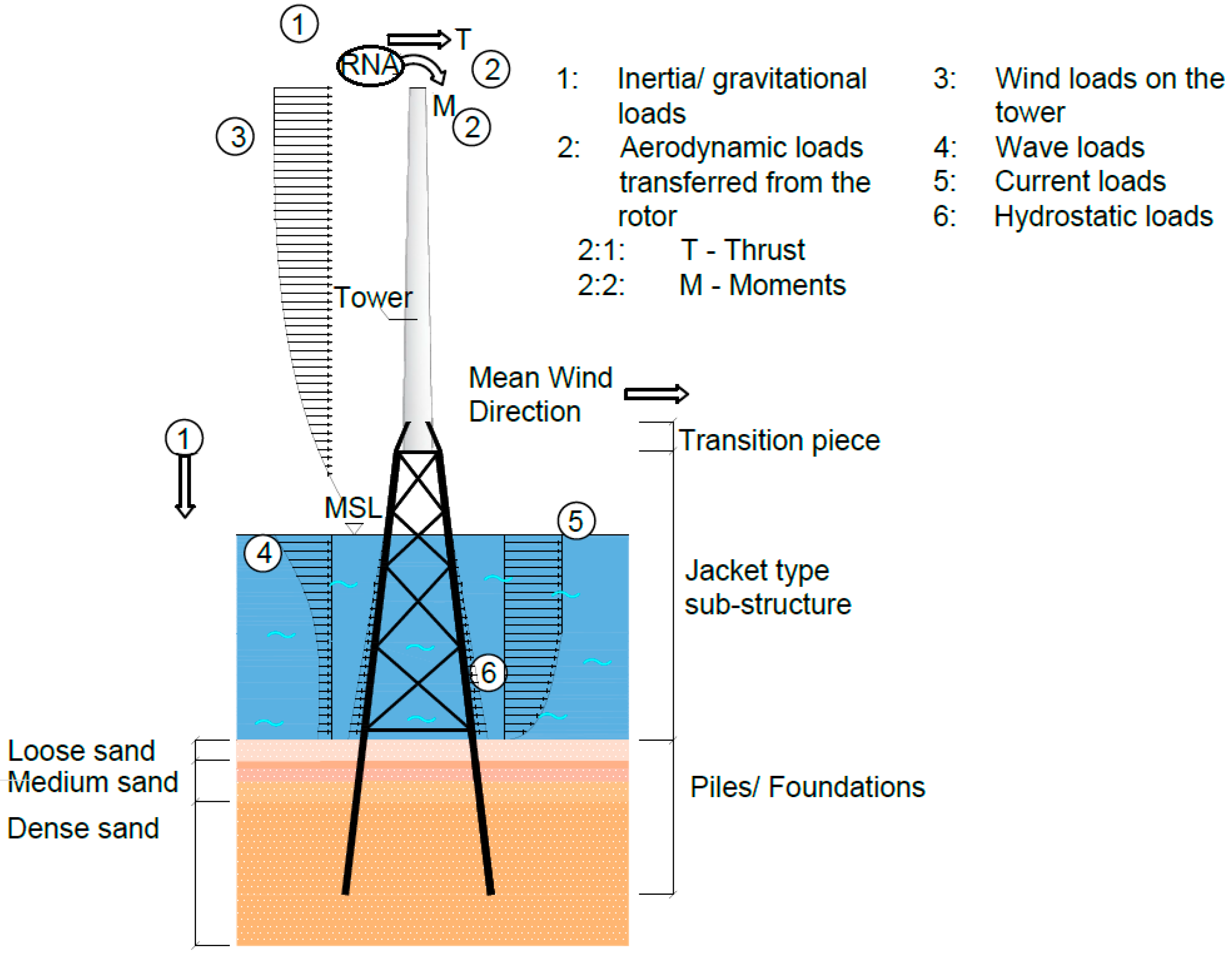

With few exceptions, most of the existing offshore wind turbines (OWTs) are installed on monopile foundations in shallow waters (depths < 50 m). However, as turbines become larger (>5 MW) and as water depth increases beyond 35–50 m, monopiles become progressively uneconomical, primarily because of modal requirements that force structural dimensions to grow even beyond fabrication and installation capabilities currently available [

5]. State-of-the-art research on monopile foundations can be found in References [

6,

7]. Space frame structures such as jackets, widely used in the petroleum industry, offer a lighter and yet stiff alternative to monopiles. Effective design of these structures from a turbine system dynamics perspective is a demanding task. Although jacket-type support structures could contribute to further developments in the offshore wind industry, research is still required to support their basic design and analysis [

5,

8], as well as to take into account the requirement for optimization due to both the serial production required and the nature of these unmanned structures. As a result of application-based research, several new methods and patents were developed aiming to resolve some of these issues [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18].

In a conventional structural analysis, the environmental loads, geometric dimensions, material properties, and parameters are treated as deterministic quantities, which are often expressed in the design through characteristic values incorporating partial safety factors for consideration of uncertainties. This type of analysis is adequate in cases where randomness is relatively small. However, structures used for offshore deployment are generally complex and subjected to high uncertainties introduced by the environment, manufacturing, and operational processes. Randomness in design parameters for such systems should be systematically accounted for via stochastic modeling, allowing for a better informed and potentially optimized design that would take into consideration the life cycle of the structure and associated time-variant mechanisms of damage. Reliability analysis enables an efficient approach to better understand the response of the system to variation of an input parameter, enabling the systematic modeling of uncertainties occurring from highly complex models, loading conditions, etc. [

19]. In particular, for offshore jacket foundations, soil-structure interactions and particularities of marine environments introduce considerable uncertainties (e.g., soil properties, wind, wave, and current loads, etc.), leading to the requirement of employing proper reliability analysis methods. A structural reliability model of OWT support structures requires two key components, i.e., (1) a structural model describing the structural behavior of OWT support structures, and (2) a suitable reliability assessment method which finds the reliability index

(or the probability of failure

) of critical members with respect to the constraints [

20].

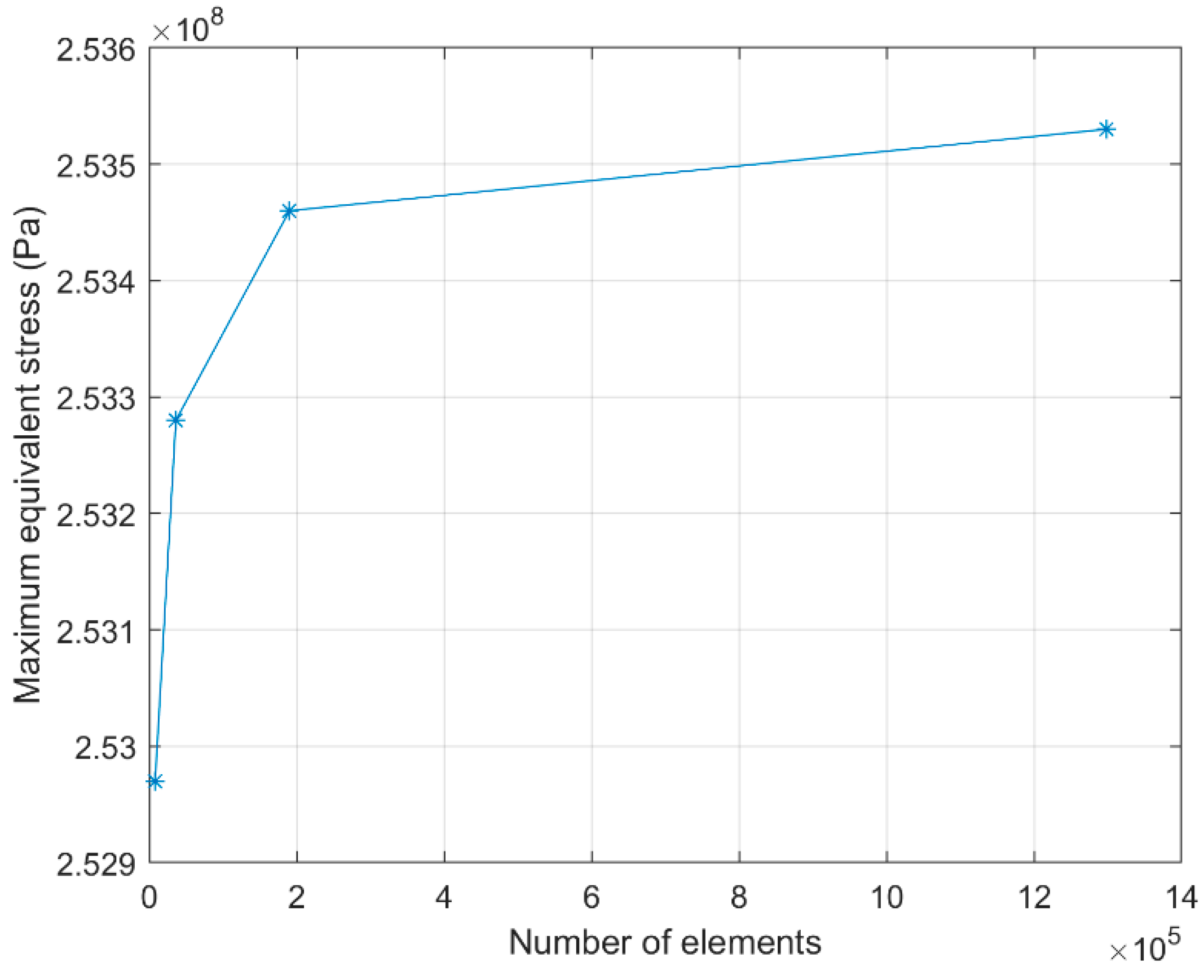

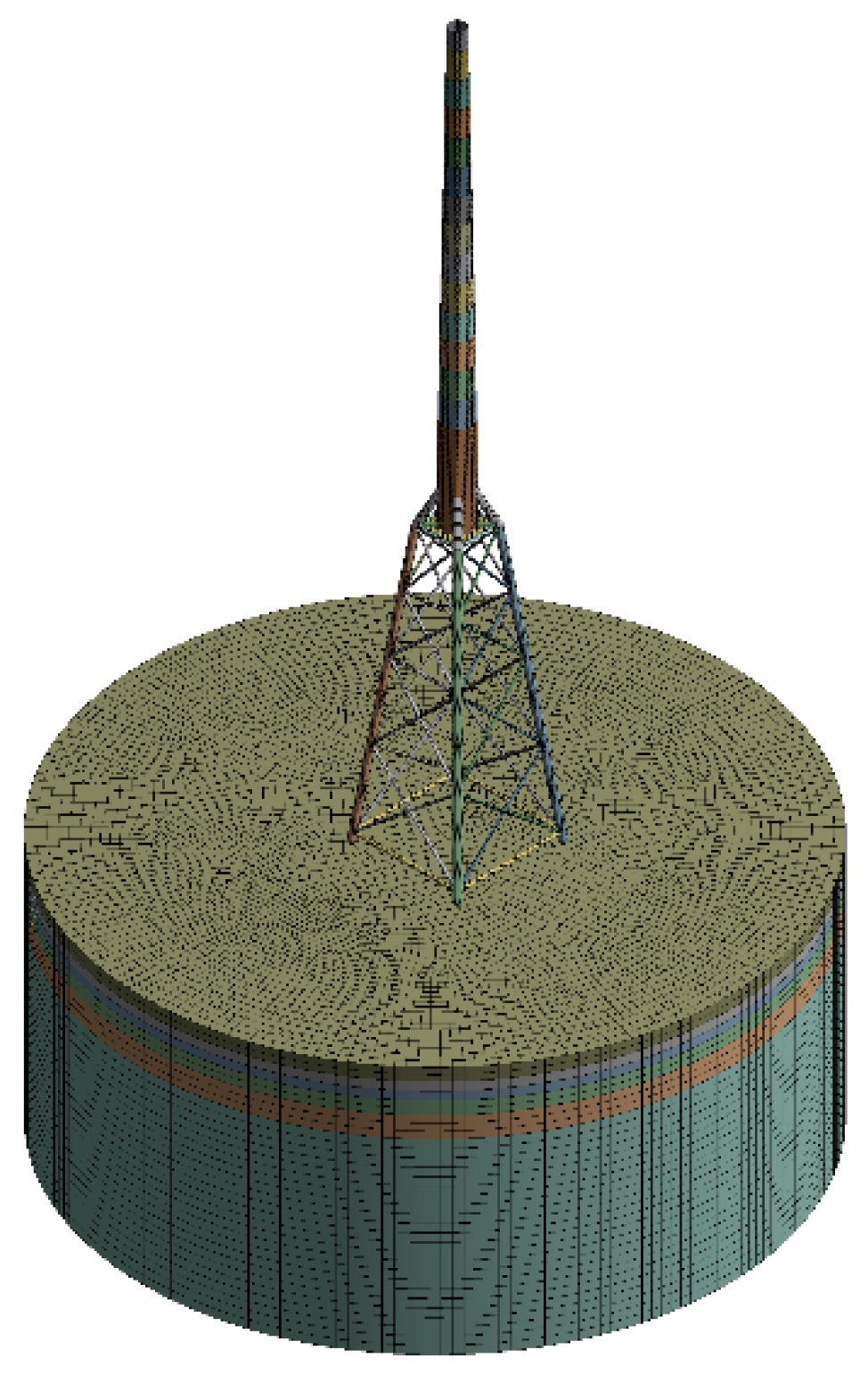

Structural models for OWT support structures can be roughly classified into two groups, i.e., one-dimensional (1D) beam models and three-dimensional (3D) finite element analysis (FEA) models. In the 1D beam model, the support structure is discretized into a sequence of elastic Euler or Timoshenko beam elements. It is computationally efficient and capable of accurately modeling global structural behavior, such as deflections and modal frequencies [

21]. However, it is incapable of accurately representing the structural responses at a local scale such as stress concentration effects [

22]. In the 3D FEA model, the jacket foundations are usually defined by applying brick or shell elements. In comparison to the one-dimensional beam model, the three-dimensional finite element model has the capability of examining detailed stress distributions and accurately capturing structural responses within the structure. The three-dimensional finite element analysis model was extensively applied to structural modeling of wind turbine structures due to its high fidelity [

1,

2,

23,

24,

25,

26,

27]. Thus, the 3D FEA model is adopted in this study to determine the structural responses of OWT jacket foundations.

Due to the fact that OWT jacket support structures are embedded via piles into the soil, it is important to consider soil-structure interaction in order to adequately capture their structural response. A simple method to model the soil is the p-y method, in which the soil is modeled using equivalent springs with stiffness based on soil properties. However, this method underestimates the deflection and the modal frequency. An alternative way of modeling the soil is 3D FEA with brick elements, which is capable of providing accurate and reliable results [

28,

29]. Considering the accuracy, 3D FEA with brick elements is adopted to model the soil later on in this study.

Several studies [

30,

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44] showed that structural reliability assessment is commonly applied to assess the safety level of OWT structures. Most reliability methods are established as time-invariant; however, in numerous instances, owing to the continuous degradation of the resistance of the structure through corrosion, fatigue, etc., or due to fluctuating loads in time, reliability models should be accounted for as time-variant [

45,

46]. At first, the structural reliability assessment focuses on the evaluation of the reliability of each component, assuming a series system formulation where a single point failure illustrates a global failure of the structure [

40,

47,

48]. In a second level, however, the embedded redundancy in the system is evaluated through methods such as push-over analysis, which is again based on the calculation of component reliability. Level I methods are deterministic reliability methods that only use one characteristic value to describe each uncertain variable. Common design standard formats, such as load resistance and allowable stress, belong to this category. These methods correspond to standard deterministic design methods. They can be combined with more advanced, higher-order methods in the case of partial safety factors calibration, which can optimize their application [

49]. The conventional structural reliability methods include level II (approximate) reliability methods or analytical techniques which consist of the first-order reliability method (FORM) [

50] and the second-order reliability method (SORM) [

51], as well as level III reliability methods which include Monte Carlo Simulations (MCS). In FORM, the limit state function is approached through Taylor’s expansion, and the problem of evaluating the reliability of a complex system is translated into a problem of mathematical optimization. SORM generally performs better in cases of highly nonlinear systems than FORM, while, in other cases, the two methods give similar results. MCS involves direct simulations and, hence, reduces the uncertainty in the results due to approximations in the solution algorithm. However, its application is constrained in the calculation of high probabilities for relatively non-complex engineering systems. MCS can be incorporated with variance reduction techniques, e.g., Latin hypercube sampling (LHS), weighted Latin hypercube sampling (WLHS), importance sampling, subset simulation, etc. [

19,

20,

45,

52].

The stochastic expansion consists of intrusive and non-intrusive formulations. An intrusive formulation is one whereby the representation of uncertainty is expressed explicitly within the analysis of the system. Practically, this refers to methods that use Karhunen-Leove expansion (K-L) and polynomial chaos expansion (PCE) to directly modify the stiffness matrix of a finite element analysis procedure, such as SSFEM (spectral stochastic FEM) and stochastic Galerkin FEM. On the other hand, non-intrusive formulations, such as stochastic response surface methods [

46,

49], represent uncertainties in a non-explicit way and treat the analysis code as a “black box” without requiring access to the source code. Both methods employed in this research constitute non-intrusive formulations.

The first method studied in this paper accounts for the use of a commercial tool (ANSYS DesignXplorer©), which considers randomness in input variables (such as material properties, boundary conditions, loads, and geometry) and characterizes them by the joint probability density function of the input variables. Mixed moments of order higher than two are assumed to be negligible, which means that the joint probability density function can be described by the marginal distribution functions and the correlation structure. Available tools offer several statistical distribution functions to specify the marginal distribution. The probabilistic methods implemented in the DesignXplorer© include Latin hypercube sampling, all versions of the central composite design of experiment (DOE) type, Box-Behnken design DOE type, variational technology, and Monte Carlo simulations on the response surface [

53,

54]. More information on these probabilistic methods can be found in References [

48,

54]. The benefit of the tool is in its user-friendly interface and direct link with FEM modeling. However, it relies on direct simulations, which is a limitation for the order of magnitude probabilities of interest for offshore and marine applications, and which cannot be generalized and integrated with more specialized tools for more advanced analysis.

The second approach, which was developed by the authors, proposes a non-intrusive stochastic formulation, which links the structural model to a reliability analysis algorithm through approximation modeling. In this case, quadratic response surface modeling is adopted in order to map the response of the structure in the domain of stochastic variables. The benefit of this approach is that it allows for high-fidelity computational tools to be employed for the analysis in a modular way, thereby extending its applicability to various engineering problems requiring advanced modeling techniques, and further permitting coupling with analytical reliability methods such as FORM and SORM, allowing for low values of probability of failure to be calculated.

This work aims to carry out a comparison of the two methods described above for a typical OWT jacket-type support structure considering various design constraints and stochastic variables. This paper is the first of its kind to study the structural reliability of an OWT jacket-type support structure using two methods and then comparing the results, as there is no work which reported the use of the post-processing tool inbuilt in ANSYS applied to an OWT jacket-type support structure to determine the probability of failure, nor any work comparing results from the probabilistic FEA in ANSYS to a non-intrusive stochastic formulation, which is also documented in this paper. Furthermore, the proposed non-intrusive method is verified against the commercial package, allowing for further complex engineering problems to be investigated without the need for a fully integrated application-specific tool, rather than through a modular approach which can allow the use of simpler and more computational efficient tools.

7. Results and Discussion

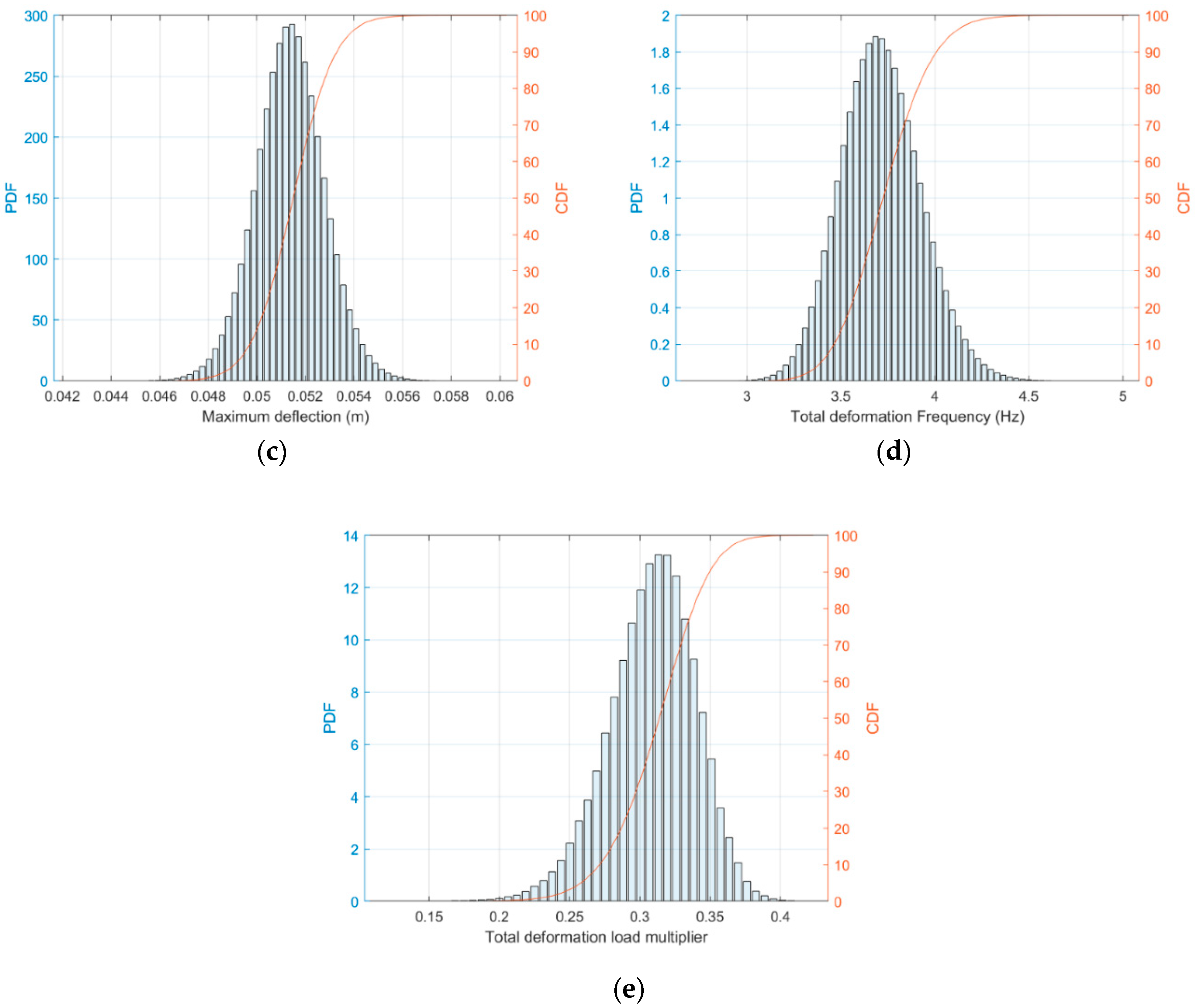

Figure 8a–e depict the probability density function (PDF) histogram and cumulative density function (CDF) of the output parameters for each design constraint from DesignXplorer©.

For the stress constraint case (ULS), the probability that maximum equivalent stress remains less than , , is about 0.99999867 which means that there is probability that the von Mises stress exceed the limit value of 323 MPa, i.e., . Therefore, the probability of failure of the critical component of the structure is considering the ULS (stress constraint) design criteria. The corresponding reliability index value is .

For the fatigue constraint case (FLS), the probability that the minimum safety factor is less than , , is about . Therefore, the probability of failure of the critical component of the structure is considering FLS design criteria (using time-invariant analysis). The corresponding reliability index value is .

For the deformation constraint (SLS), the DesignXplorer© simulation could not produce results within the region of , i.e., . The value , which is the value of the probability of failure, is expected to be very small, and this is identified as a limitation of the direct MCS requiring a prohibitively large number of simulations to estimate results of this magnitude. Similarly, for the buckling constraint case (ULS), the simulation could not produce the results within the region of , as this value is expected also to be very small.

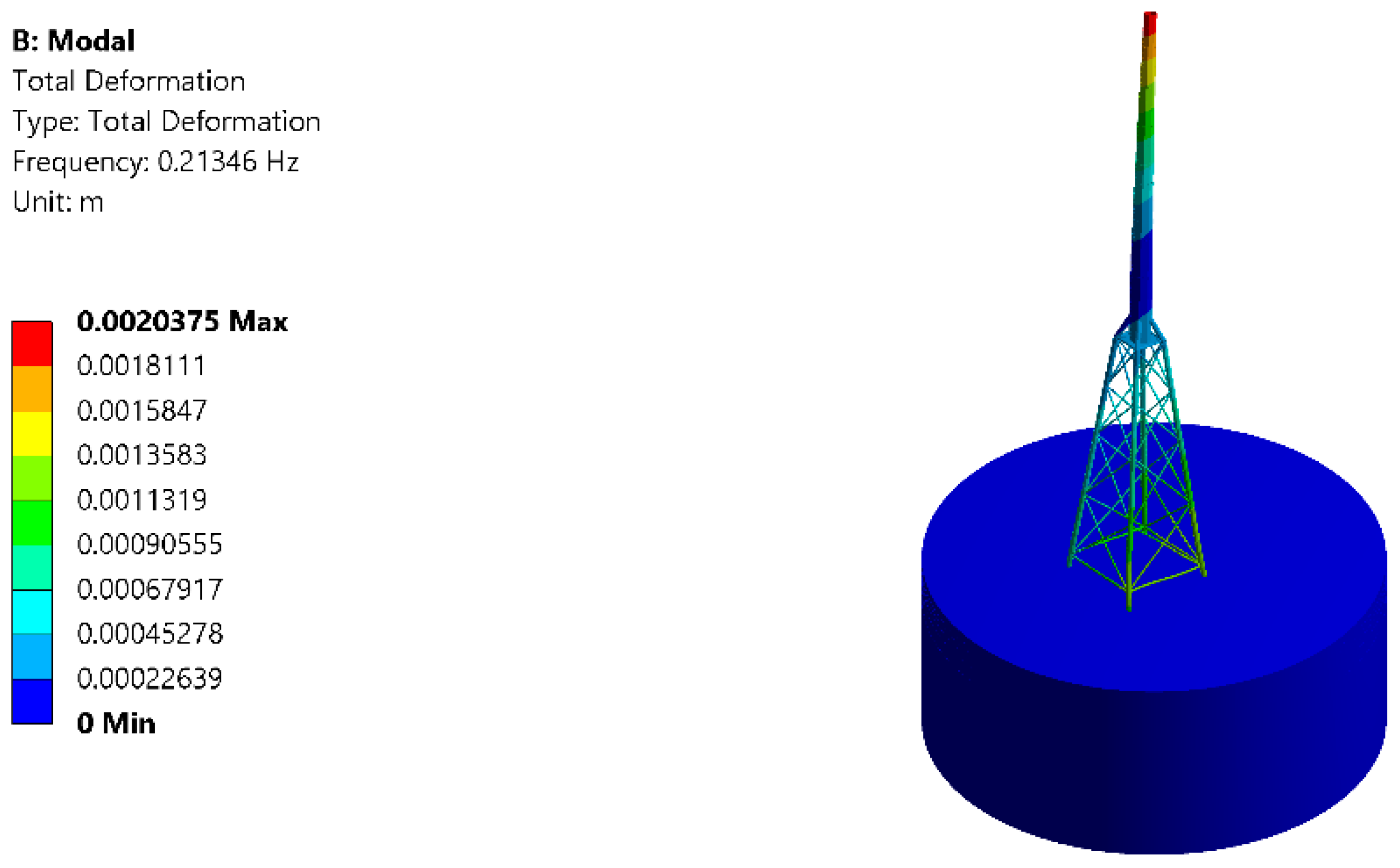

For the vibration constraint (SLS), the probability of failure of the critical component of the structure is about , and the corresponding .

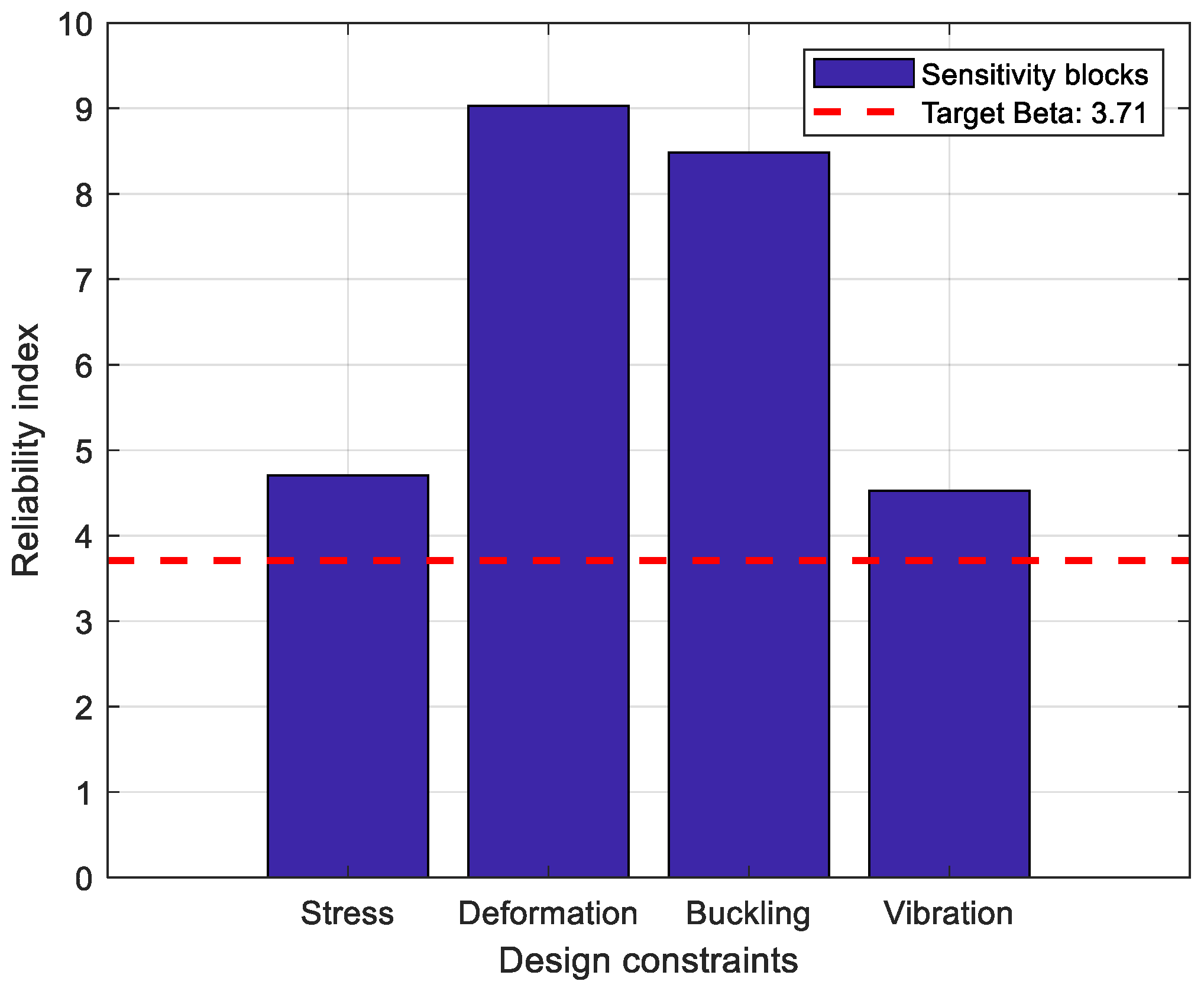

The results obtained from the non-intrusive formulation for each design constraint are depicted in

Figure 9 and

Table 10. The results obtained from a time-invariant fatigue reliability assessment employing the FORM are the reliability index,

, and probability of failure,

.

As evident from the results above, the reliability assessment performed on the structure shows that the present model, as designed and for the modeling of the stochastic variables considered, satisfies the recommended reliability assessment criteria, as the reliability indices for all the design constraints considered are within the design thresholds. The target reliability index for OWT support structures is typically 3.71, corresponding to a probability of failure of

according to the DNV [

91].

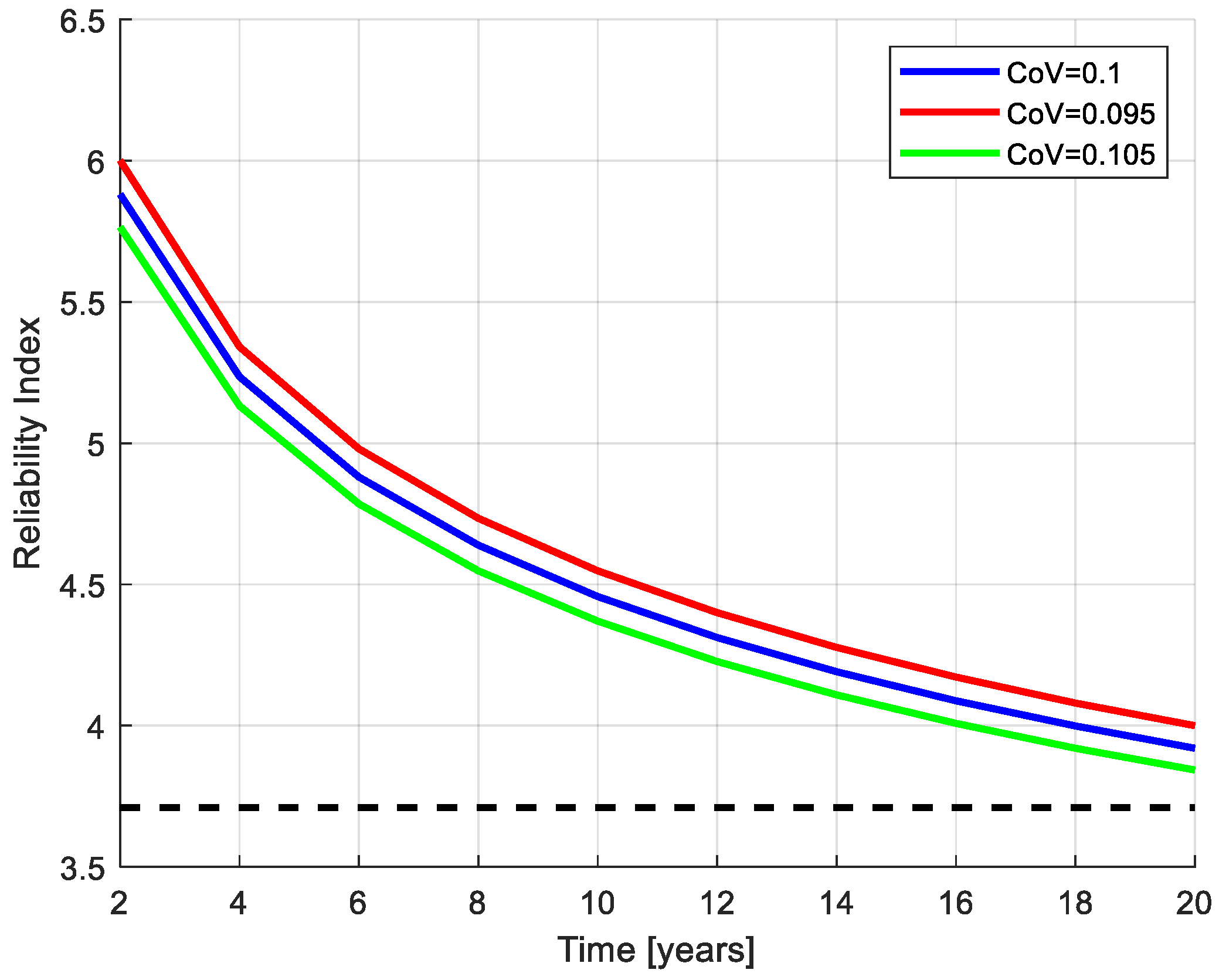

In this work, the time-variant fatigue reliability assessment was carried out using the fatigue analysis guidelines in the DNV standard [

71,

92], and this is presented in

Figure 10. In this study, the thickness-corrected cathodic-protected D curve given by DNV-OS-J101 [

71] is chosen for fatigue analysis. The intercept (A) and slope (m) of the S-N curve used for studying the fatigue life of steel structure in seawater for

are given as 15.606 and 5, respectively. From the time-variant fatigue reliability index curve, it can be observed that the structure maintains a reliability index of

, exceeding the defined threshold of target reliability as specified by DNV for the nominal 20 years of operation. It can be observed that the fatigue limit state dominates the design of OWT support structures, as the reliability index for the fatigue limit state is lower than other reliability index values (see the time-variant fatigue reliability assessment at time = 20 years).

As observed in

Table 11, the values of safety index,

, predicted by the non-intrusive reliability analysis formulation were marginally higher than those predicted by the ANSYS probabilistic analysis for the different design constraints. However, the difference in the predicted reliability index values from both methods remains consistently below 5%; hence, the agreement of the two methods can be considered sufficient. Furthermore, considering the observed time required, the FORM simulations run instantly compared to the LHS (as packaged in the ANSYS DesignXplorer©), which requires about 15 min to run on a high-performance computer (i.e., for the 1 × 10

7 samples).

Additionally, a case study is performed to investigate the effects of COV of the stochastic variables on the fatigue reliability index. In this case, two additional values of COV are considered, i.e., a 5% increase and 5% decrease. The calculated fatigue reliability index over 20-year service life with different values of COV is depicted in

Figure 11. As can be seen from

Figure 11, the reliability index is sensitive to the value of COV. The higher value of COV means higher uncertainties in stochastic variables, resulting in lower reliability.

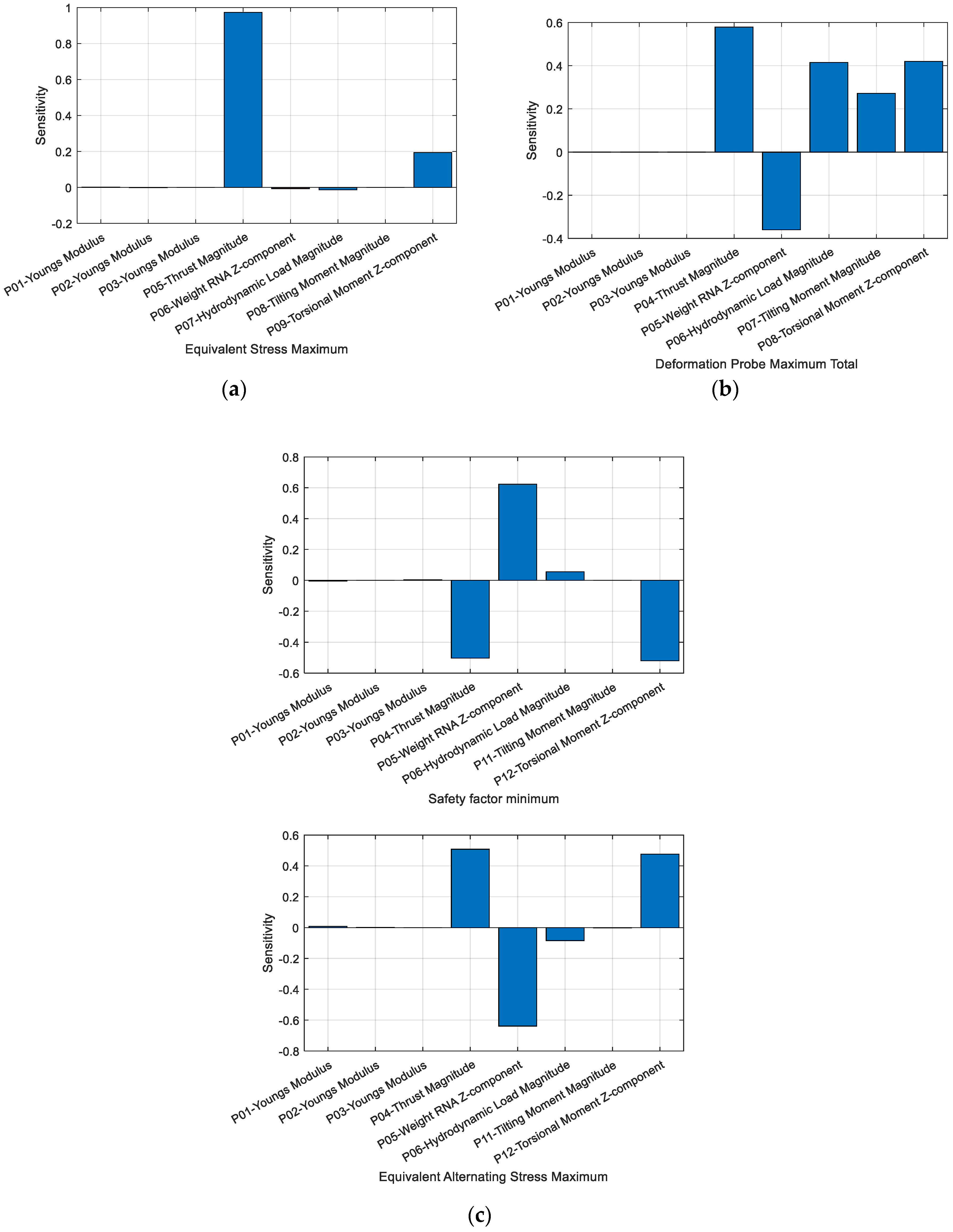

A global sensitivity analysis is also presented from the ANSYS probabilistic analysis for each of the design constraints through post-processing the results. These depict the most critical and important parameters that can radically change the response and reliability performance of the structure.

Figure 12a–e show how sensitive the input design variables are to the structure based on the different design criteria. The bar heights indicate sensitivity in these charts.

In

Figure 12a, for the probability distribution of the maximum equivalent von Mises stress, it can be observed that the thrust magnitude and the torsional moment are positively correlated with direct impact. The RNA weight and the hydrodynamic load are negatively correlated and have little influence but inversely. The Young’s modulus of the soil system and the tilting moment are neutral and have limited or no impact.

In

Figure 12b, for the probability distribution of the deformation at the jacket top, it can be observed that four variables are positively correlated with direct impact. These are the thrust load, hydrodynamic load, and tilting and torsional moments, which have significant influence. The Young’s modulus of the soil system has little or no impact. The RNA weight is negatively correlated and has a significant impact.

In

Figure 12c, for the probability distribution of the minimum output parameter safety factor, it can be observed that Young’s modulus of the soil system is neutral and has little or no impact. The RNA weight and hydrodynamic load are positively correlated with direct impact; the RNA weight has significant influence while the hydrodynamic load has quite some impact. The thrust and the torsional moments are negatively correlated and have significant influence but inversely. The tilting moment has very little or no impact.

As can be seen from

Figure 12d, the RNA weight and the thrust load have the highest impact and are positively and negatively correlated, respectively, with the other variables having little or no impact on the load multiplier probability distribution. It can also be observed that, in

Figure 12e, the structure self-weight has the highest direct impact, with the thrust load and the second soil strata having very little inverse impact on the distribution of the output parameter, the first eigen-frequency, and, hence, the reliability of the structure.