Rolling Bearing Fault Diagnosis Based on Wavelet Packet Transform and Convolutional Neural Network

Abstract

1. Introduction

2. Related Work

2.1. Convolutional Neural Networks

2.2. Wavelet Packet Transform

3. Proposed CNN-Based Fault Diagnosis Method

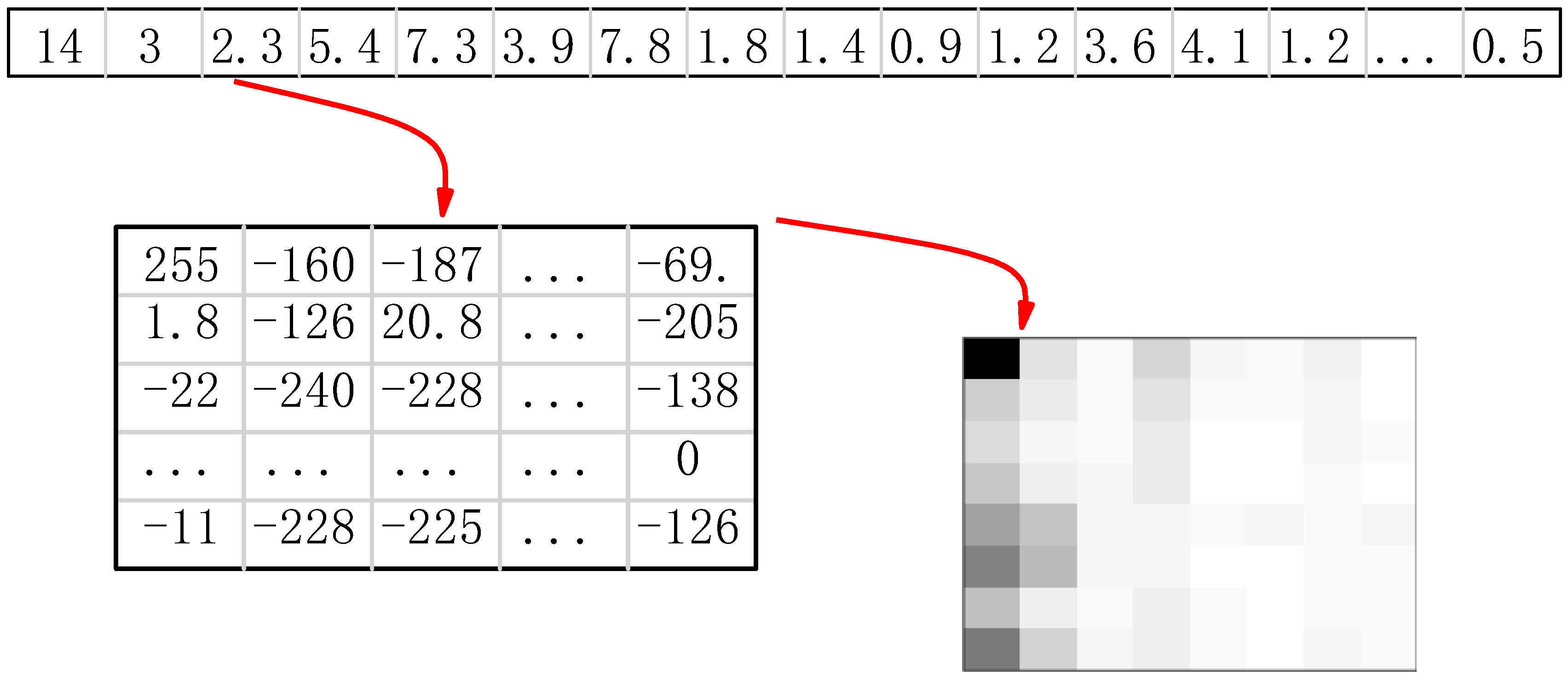

3.1. Data-to-Image Conversion Method

3.2. Fault Diagnosis Based on CNN

4. Experiment Studies

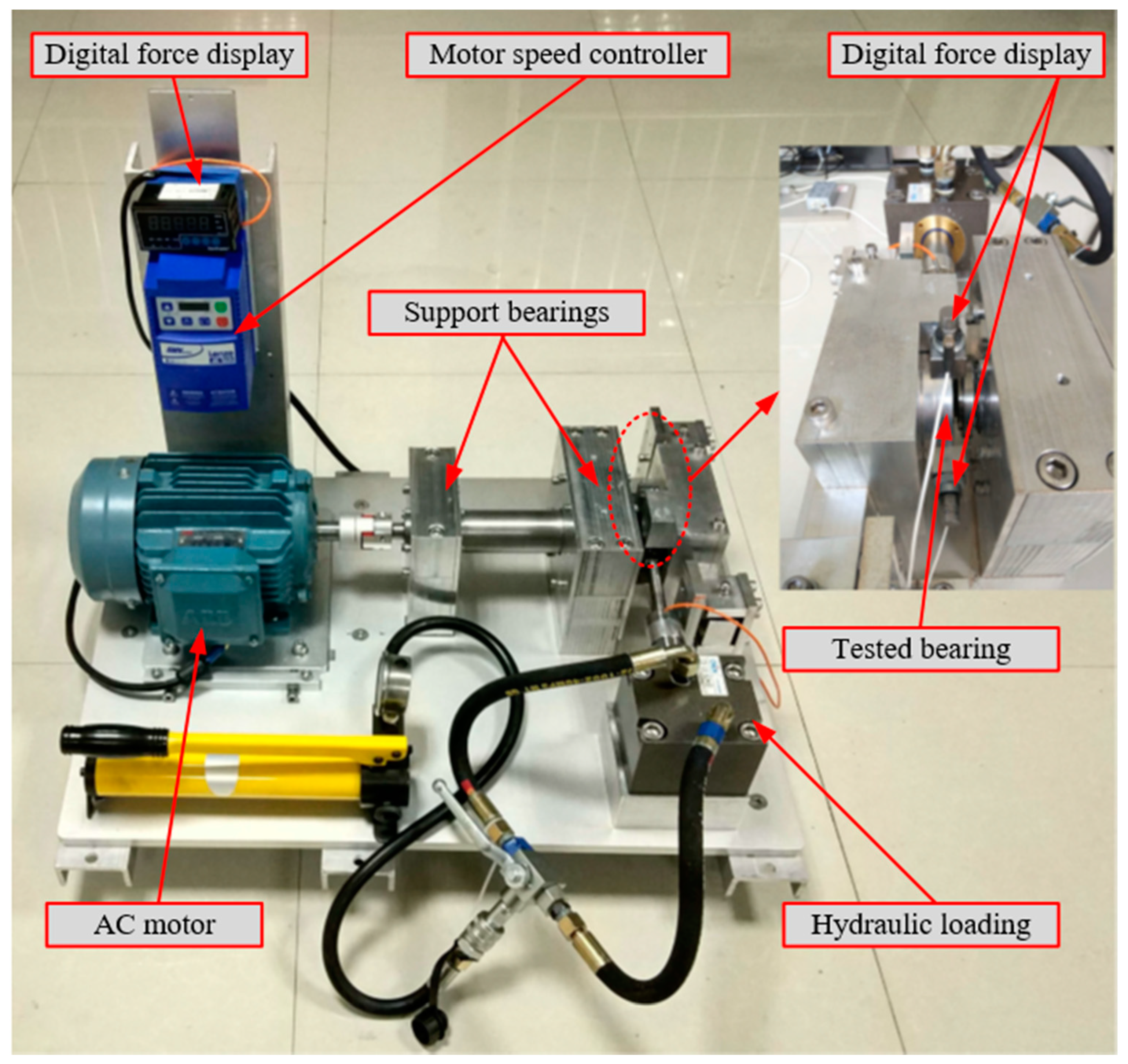

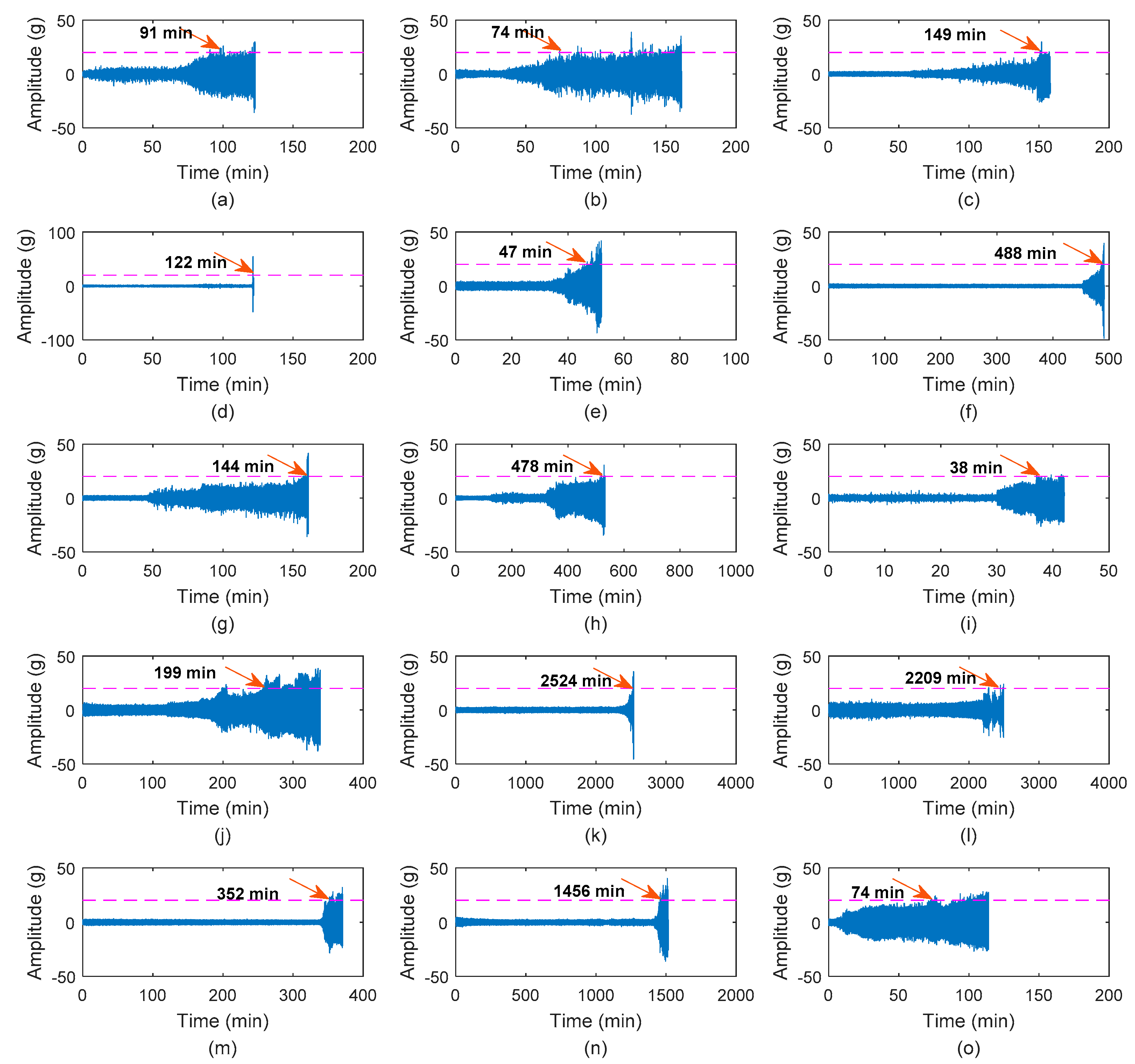

4.1. Experimental Setup and Data Description

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Esfahani, E.T.; Wang, S.; Sundararajan, V. Multisensor wireless system for eccentricity and bearing fault detection in induction motors. IEEE/ASME Trans. Mechatron. 2014, 19, 818–826. [Google Scholar] [CrossRef]

- Sun, Y.; Xiong, Z. An optimal weighted wavelet packet entropy method with application to real-time chatter detection. IEEE/ASME Trans. Mechatron. 2016, 21, 2004–2014. [Google Scholar] [CrossRef]

- Wu, J.; Wu, C.Y.; Cao, S.; Or, S.W.; Deng, C.; Shao, X.Y. Degradation data-driven time-to-failure prognostics approach for rolling element bearings in electrical machines. IEEE Trans. Ind. Electron. 2019, 66, 529–539. [Google Scholar] [CrossRef]

- Cheng, Y.W.; Zhu, H.P.; Wu, J.; Shao, X.Y. Machine health monitoring using adaptive kernel spectral clustering and deep long short-term memory recurrent neural networks. IEEE Trans. Ind. Inform. 2019, 15, 987–997. [Google Scholar] [CrossRef]

- Wu, J.; Hu, K.; Cheng, Y.; Zhu, H.; Shao, X.; Wang, Y. Data-driven remaining useful life prediction via multiple sensor signals and deep long short-term memory neural network. ISA Trans. 2019. [Google Scholar] [CrossRef]

- Li, G.Q.; Deng, C.; Wu, J.; Xu, X.B.; Shao, X.Y.; Wang, Y.H. Sensor data-driven bearing fault diagnosis based on deep convolutional neural networks and S-transform. Sensors 2019, 19, 2750. [Google Scholar] [CrossRef]

- He, Z.Y.; Shao, H.D.; Wang, P.; Janet, L.; Cheng, J.S.; Yang, Y. Deep transfer multi-wavelet auto-encoder for intelligent fault diagnosis of gearbox with few target training samples. Knowl.-Based Syst. 2019. [Google Scholar] [CrossRef]

- Wu, J.; Su, Y.H.; Cheng, Y.W.; Shao, X.Y.; Deng, C.; Liu, C. Multi-sensor information fusion for remaining useful life prediction of machining tools by adaptive network based fuzzy inference system. Appl. Soft Comput. 2018, 68, 12–23. [Google Scholar] [CrossRef]

- Wang, L.H.; Zhao, X.P.; Wu, J.X.; Xie, Y.Y.; Zhang, Y.H. Motor fault diagnosis based on short-time fourier transform and convolutional neural network. Chin. J. Mech. Eng. 2017, 30, 1–12. [Google Scholar] [CrossRef]

- Cheng, Y.W.; Zhu, H.P.; Hu, K.; Wu, J.; Shao, X.Y.; Wang, Y.H. Reliability prediction of machinery with multiple degradation characteristics using double-Wiener process and Monte Carlo algorithm. Mech. Syst. Signal Process. 2019, 134, 106333. [Google Scholar] [CrossRef]

- Zhao, M.H.; Tang, B.P.; Deng, L.; Pecht, M. Multiple wavelet regularized deep residual networks for fault diagnosis. Measurement 2020, 152, 107331. [Google Scholar] [CrossRef]

- Yang, Z.X.; Wang, X.B.; Wong, P.K. Single and Simultaneous Fault Diagnosis with Application to a Multistage Gearbox: A Versatile Dual-ELM Network Approach. IEEE Trans. Ind. Inform. 2018, 14, 5246–5255. [Google Scholar] [CrossRef]

- Tobon-Mejia, D.; Medjaher, K.; Zerhouni, N.; Tripot, G. A data-driven failure prognostics method based on mixture of Gaussians hidden Markov models. IEEE Trans. Rel. 2012, 61, 491–503. [Google Scholar] [CrossRef]

- Cai, B.; Huang, L.; Xie, M. Bayesian networks in fault diagnosis. IEEE Trans. Ind. Inform. 2017, 13, 2227–2240. [Google Scholar] [CrossRef]

- Soualhi, A.; Medjaher, K.; Zerhouni, N. Bearing health monitoring based on Hilbert–Huang transform support vector machine and regression. IEEE Trans. Instrum. Meas. 2015, 64, 52–62. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, X.; Niu, M. Rolling bearing fault diagnosis using an optimization deep belief network. Meas. Sci. Technol. 2015, 26, 115002. [Google Scholar] [CrossRef]

- Cao, P.; Zhang, S.L.; Tang, J. Pre-processing-free gear fault diagnosis using small datasets with deep convolutional neural network-based transfer learning. IEEE Access 2017, 6, 26241–26253. [Google Scholar] [CrossRef]

- Sun, W.; Shao, S.; Zhao, R.; Yan, R.; Zhang, X.; Chen, X. A Sparse Auto-encoder-Based Deep Neural Network Approach for Induction Motor Faults Classification. Measurement 2016, 89, 171–178. [Google Scholar] [CrossRef]

- Zhang, H.; Li, D. Applications of computer vision techniques to cotton foreign matter inspection: A review. Comput. Electron. Agric. 2014, 109, 59–70. [Google Scholar] [CrossRef]

- Phillips, J.P.; O’toole, J.A. Comparison of human and computer performance across face recognition experiments. Image Vis. Comput. 2014, 32, 74–85. [Google Scholar] [CrossRef]

- Ren, S.Q.; He, K.M.; Ross, G.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 39, 1137–1149. [Google Scholar] [CrossRef]

- Chen, Z.; Li, C.; Sanchez, R.-V. Gearbox Fault Identification and Classification with Convolutional Neural Networks. Shock Vib. 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, H.; Li, Y.; Xu, M.; Chen, Y. A fault diagnosis scheme for rotating machinery using hierarchical symbolic analysis and convolutional neural network. ISA Trans. 2019, 91, 235–252. [Google Scholar] [CrossRef]

- Hariharan, M.; Yaacob, S.; Awang, S.A. Pathological infant cry analysis using wavelet packet transform and probabilistic neural network. Expert Syst. Appl. 2011, 38, 15377–15382. [Google Scholar] [CrossRef]

- Vong, C.M.; Wong, P.K. Engine ignition signal diagnosis with Wavelet Packet Transform and Multi-class Least Squares Support Vector Machines. Expert Syst. Appl. 2011, 38, 8563–8570. [Google Scholar] [CrossRef]

- Chouakri, S.A.; Bereksi-Reguig, F.; Taleb-Ahmed, A. QRS complex detection based on multi wavelet packet decomposition. Appl. Math. Comput. 2011, 217, 9508–9525. [Google Scholar] [CrossRef]

- Wang, B.; Lei, Y.; Li, N.; Li, N. A Hybrid Prognostics Approach for Estimating Remaining Useful Life of Rolling Element Bearings. IEEE Trans. Rel. 2018, 1–12. [Google Scholar] [CrossRef]

| Condition Type | Class Label | Sample Number |

|---|---|---|

| Normal | 0 | 1200 |

| Inner race | 1 | 1200 |

| Outer race | 2 | 1200 |

| Cage | 3 | 1200 |

| Inner race and outer race | 4 | 1200 |

| Inner race, ball, cage and outer race | 5 | 1200 |

| Layer Name | Layer Parameters |

|---|---|

| Conv 1 | 3 × 3 × 64 |

| Max-pooling 1 | 2 × 2 |

| Conv 2 | 1 × 1 × 16 |

| Conv 3 | 1 × 1 × 16 |

| Max-pooling 2 | 2 × 2 |

| Class Label | 0 | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|

| Max | 100 | 96.11 | 100 | 99.44 | 99.72 | 99.72 |

| Min | 100 | 88.61 | 93.06 | 97.50 | 97.50 | 97.50 |

| Mean | 100 | 93.78 | 97.14 | 98.86 | 98.72 | 98.72 |

| Std | 0 | 2.41 | 2.28 | 0.639 | 0.683 | 0.683 |

| Method | Class Label | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | |

| Proposed method | 100 | 92.78 | 99.72 | 99.44 | 98.89 | 98.06 |

| Complex Tree | 100 | 90.0 | 94.72 | 97.22 | 93.33 | 95.83 |

| KNN | 100 | 91.39 | 98.06 | 95.00 | 99.44 | 94.44 |

| SVM | 100 | 98.33 | 92.11 | 97.78 | 91.67 | 95.98 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Deng, C.; Wu, J.; Chen, Z.; Xu, X. Rolling Bearing Fault Diagnosis Based on Wavelet Packet Transform and Convolutional Neural Network. Appl. Sci. 2020, 10, 770. https://doi.org/10.3390/app10030770

Li G, Deng C, Wu J, Chen Z, Xu X. Rolling Bearing Fault Diagnosis Based on Wavelet Packet Transform and Convolutional Neural Network. Applied Sciences. 2020; 10(3):770. https://doi.org/10.3390/app10030770

Chicago/Turabian StyleLi, Guoqiang, Chao Deng, Jun Wu, Zuoyi Chen, and Xuebing Xu. 2020. "Rolling Bearing Fault Diagnosis Based on Wavelet Packet Transform and Convolutional Neural Network" Applied Sciences 10, no. 3: 770. https://doi.org/10.3390/app10030770

APA StyleLi, G., Deng, C., Wu, J., Chen, Z., & Xu, X. (2020). Rolling Bearing Fault Diagnosis Based on Wavelet Packet Transform and Convolutional Neural Network. Applied Sciences, 10(3), 770. https://doi.org/10.3390/app10030770