Shear Band Characterization of Clayey Soils with Particle Image Velocimetry

Abstract

1. Introduction

2. Experimental Program

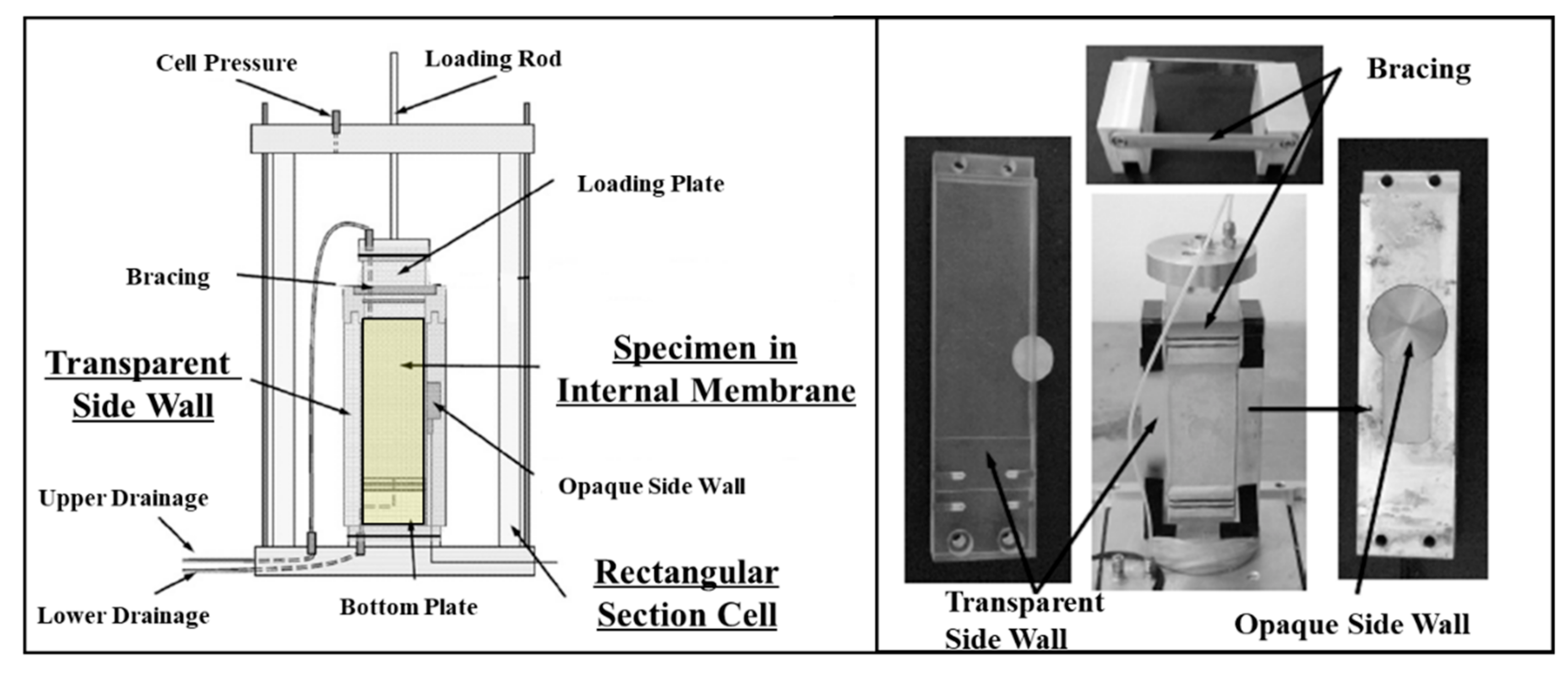

2.1. Test Apparatus

2.2. Preparation of Soil Specimens

2.3. Experimental Procedure and Conditions

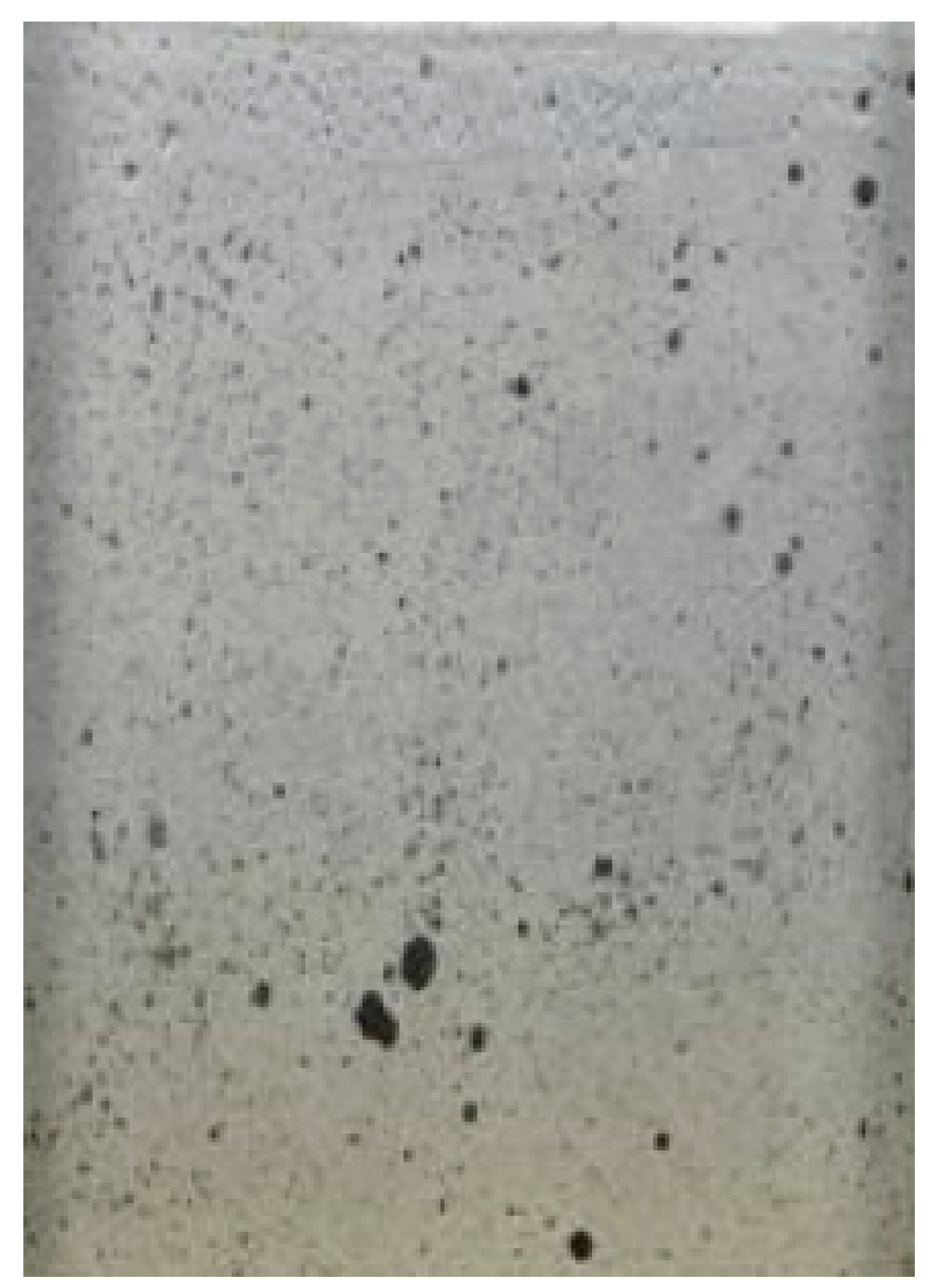

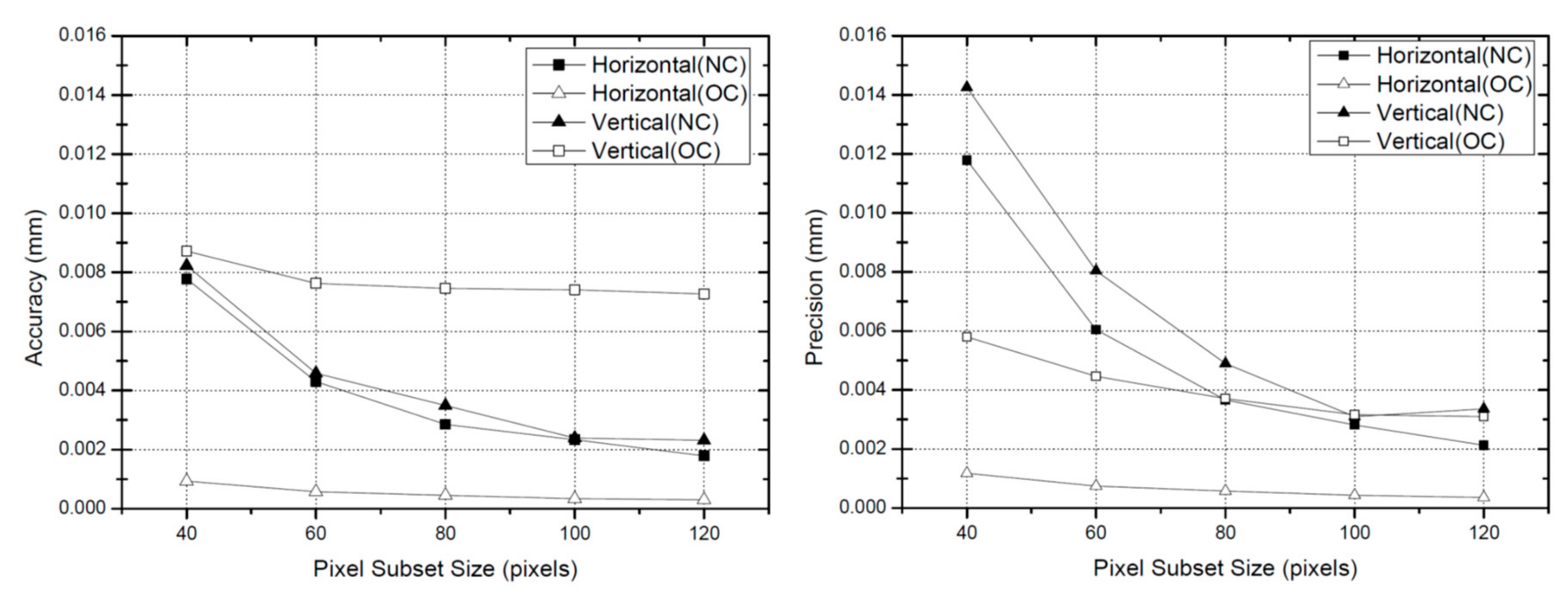

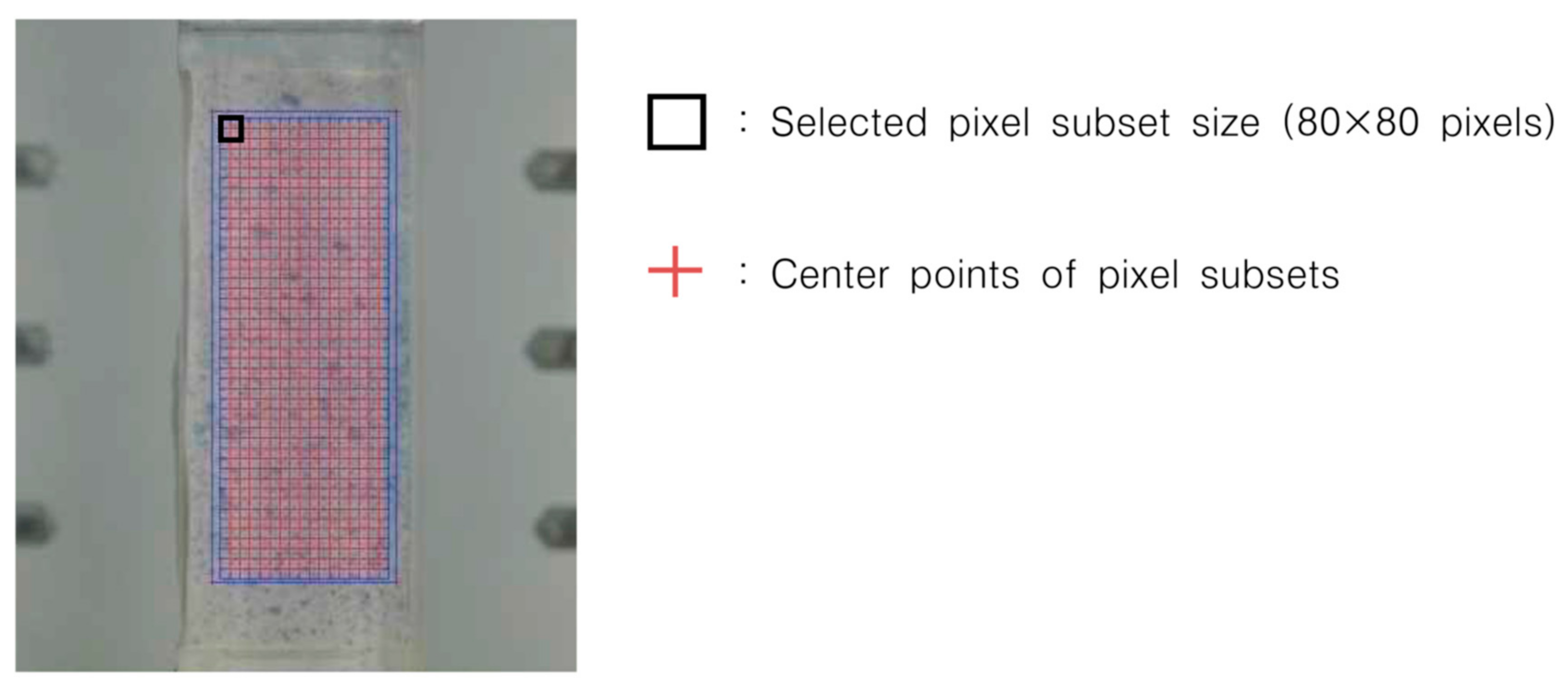

3. Digital Image Analysis

4. Experimental Results and Discussion

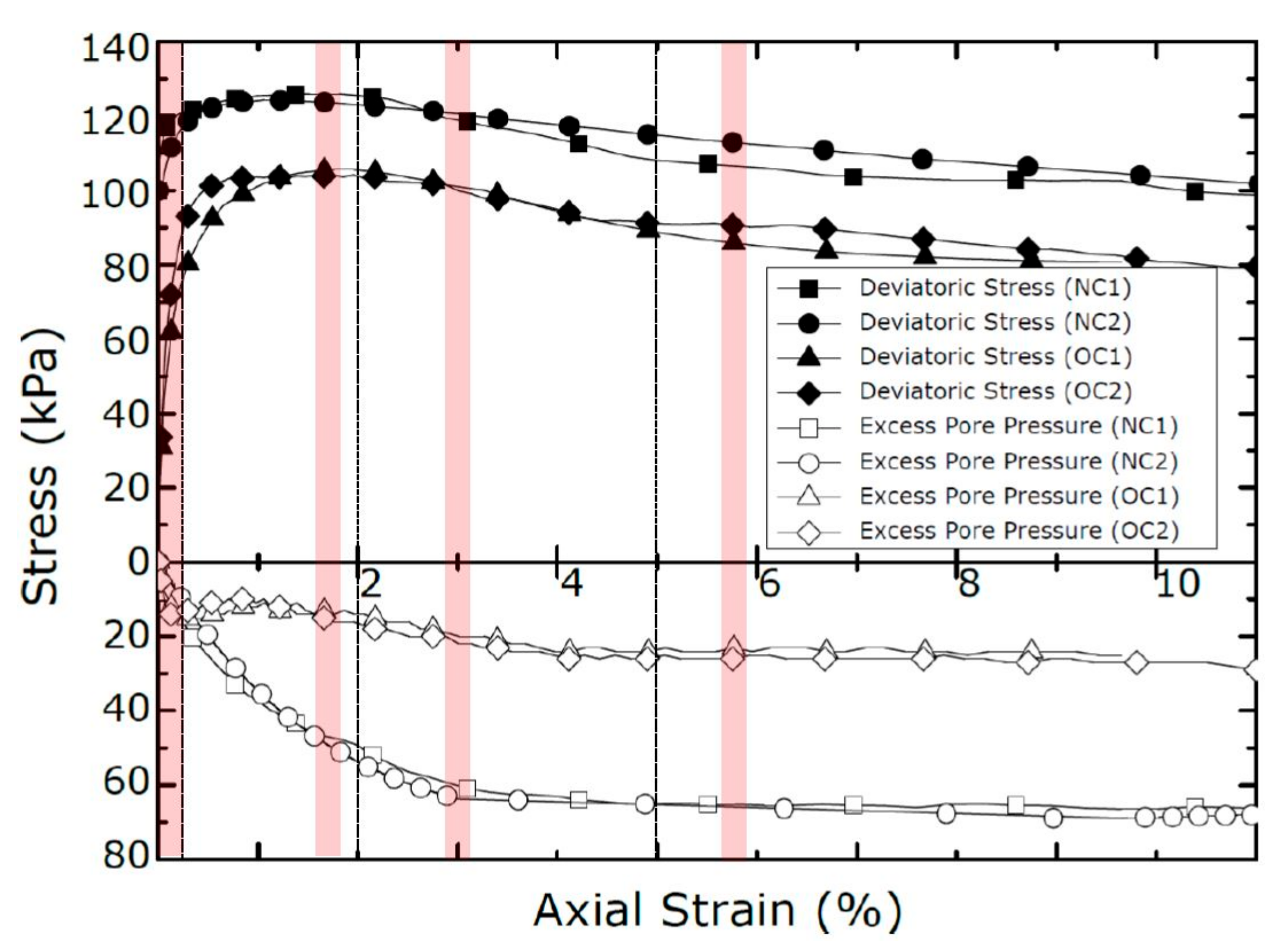

4.1. Global Stress–Strain Relationship during Shearing

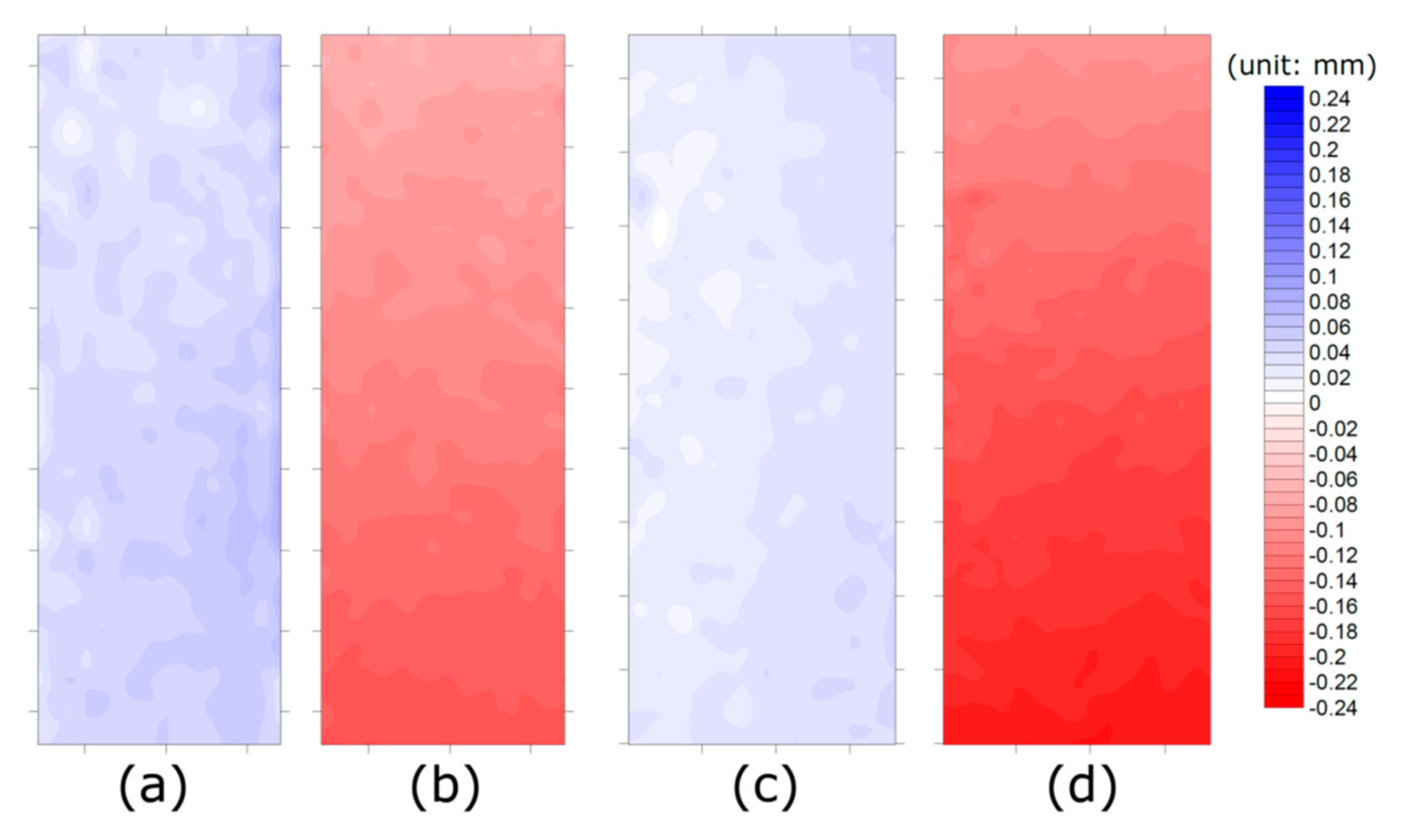

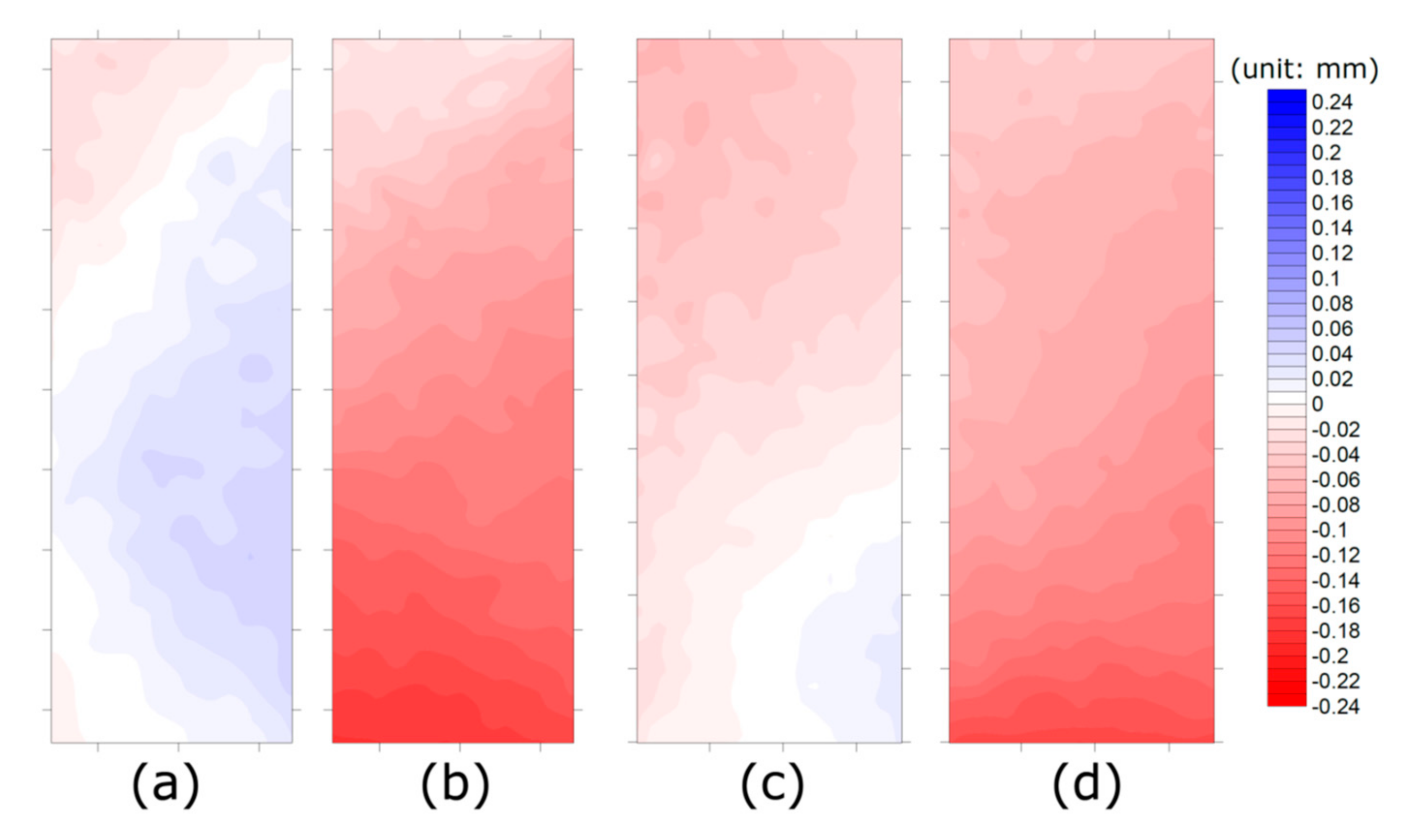

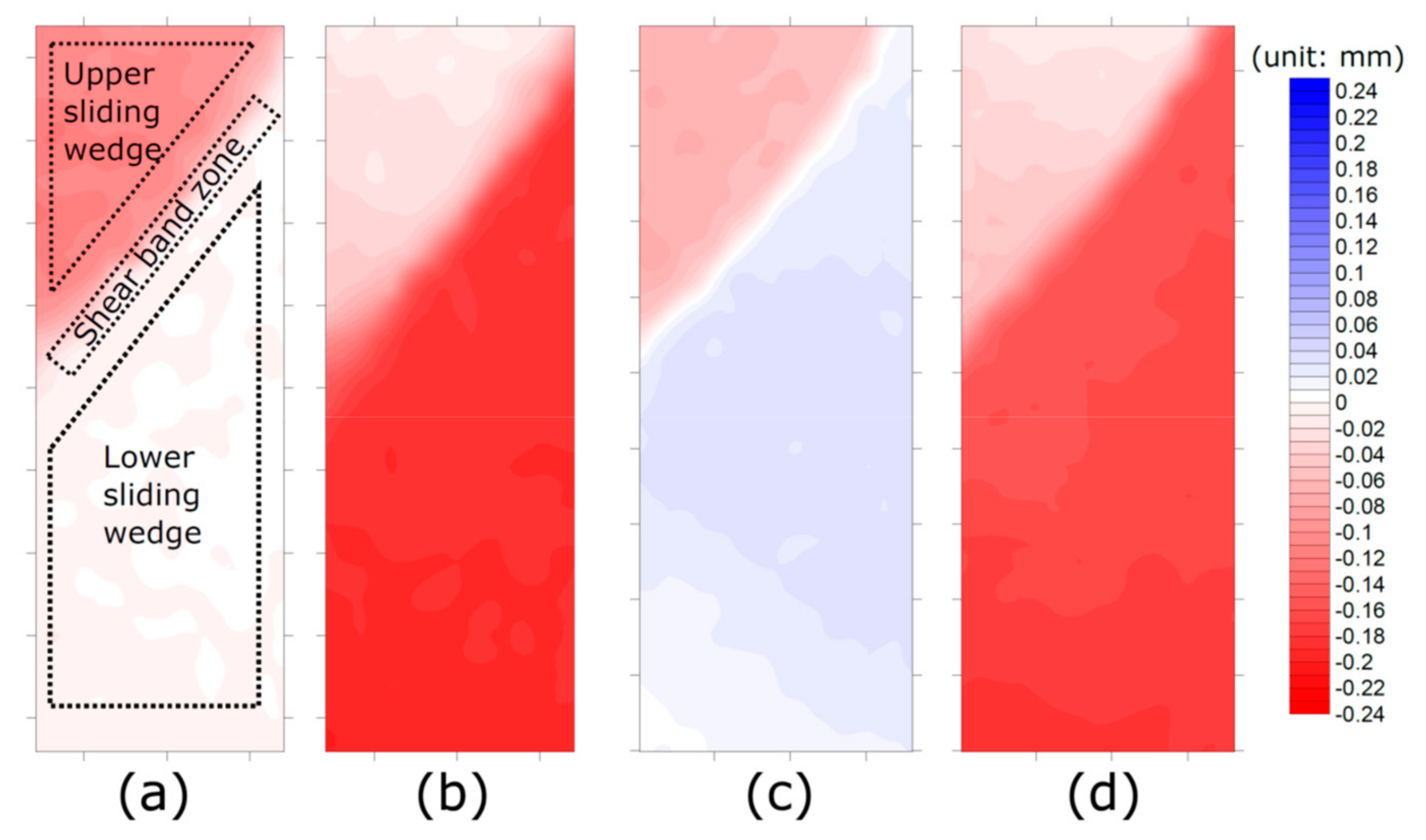

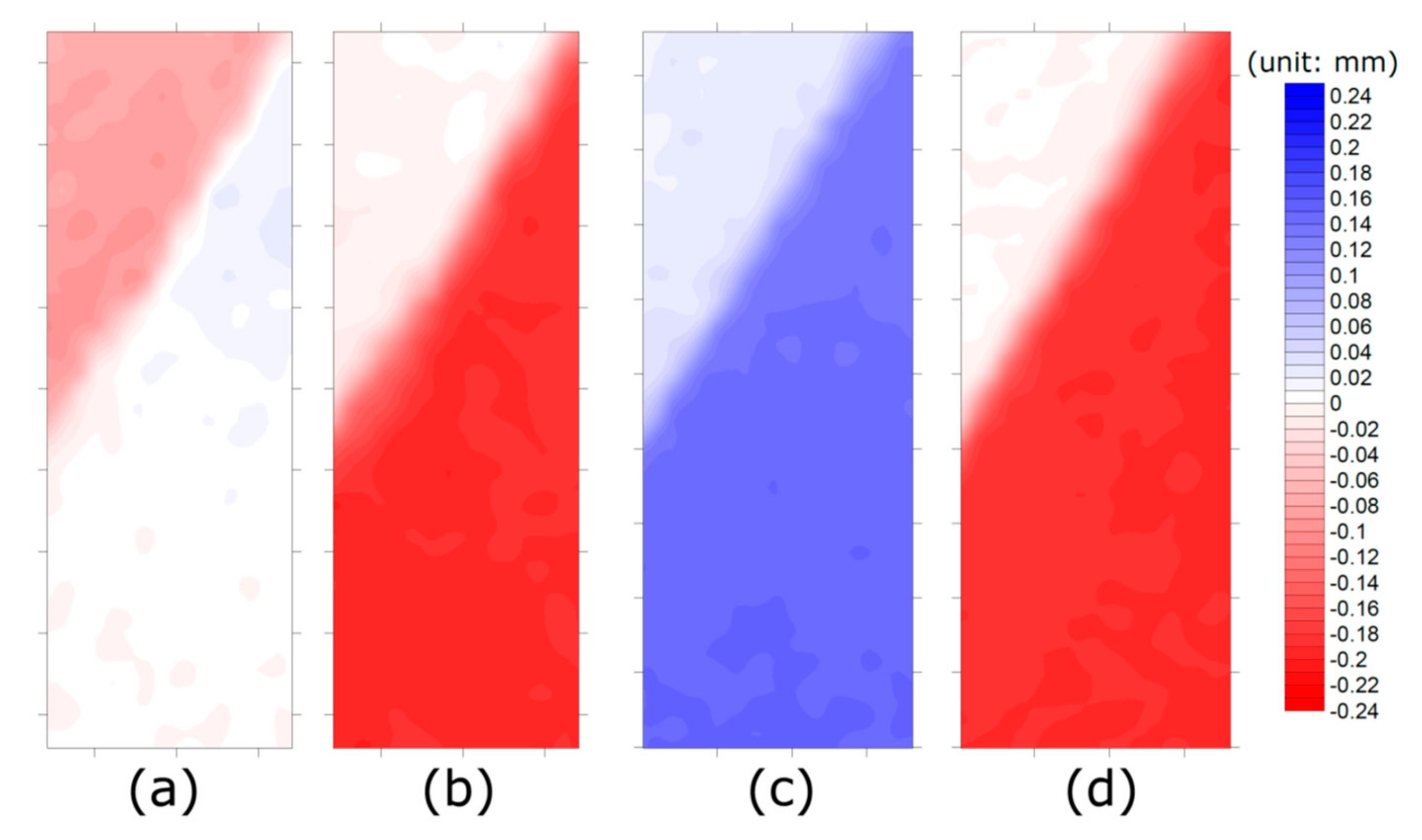

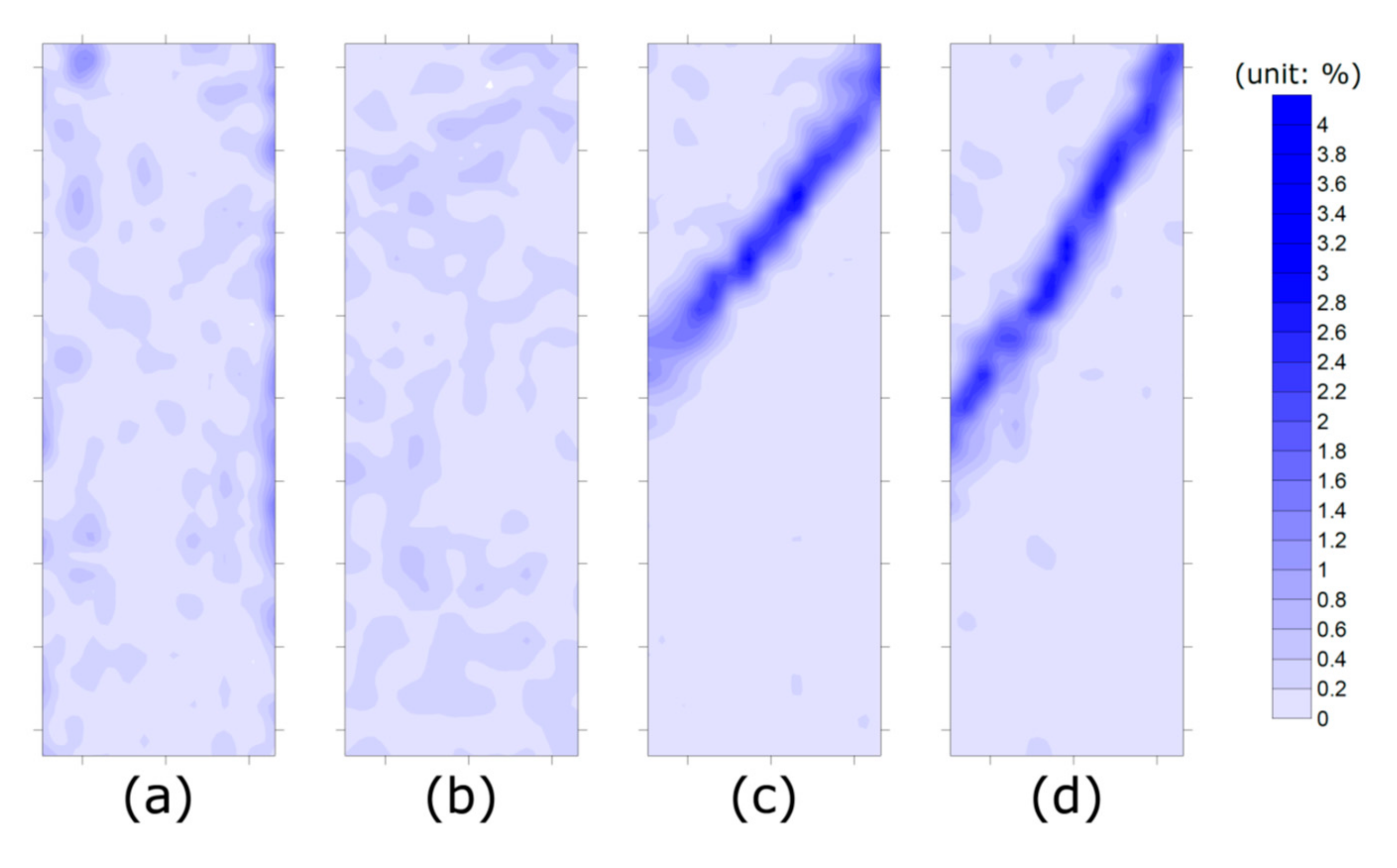

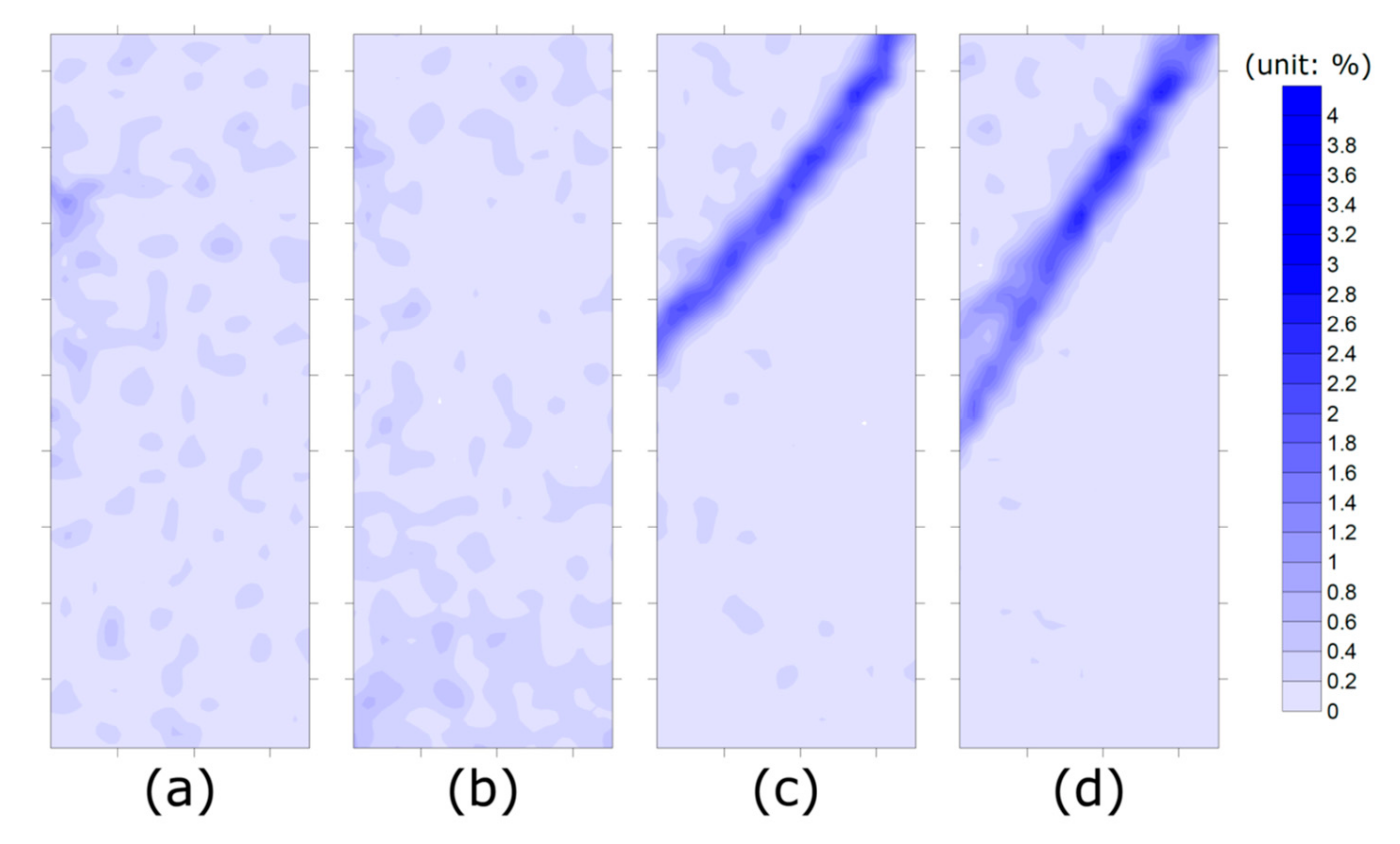

4.2. Localized Displacement Increment Field

4.3. Shear Band Characteristics: Angle and Thickness

5. Conclusions

- Both clays showed no clear shear deformation in the initial stage (εa = 0–0.25%). In the peak stage (εa = 0.25–2.00%), the shear deformation started to become concentrated, but a clear failure surface still had not appeared. The development of the failure surface tended to be more delayed in the OC clay.

- In the softening stage (εa = 2.00–5.00%), the specimens were divided into a shear band where the shear deformation was clearly concentrated as well as top and bottom parts where only rigid body movement occurred without shear deformation. In the steady-state stage (εa > 5.0%), the development of the shear band was completed, and the excess pore pressure remained at a fixed level.

- The slopes of the shear bands that formed in the NC and OC clays were compared to those calculated from existing equations. In the softening stage, the shear band slopes of both clays were similar to that of Roscoe [35]. In the steady-state stage, the slope of the final shear band was between those of Mohr–Coulomb and Arthur et al. [36] for the NC clay and similar to that of Arthur et al. [36] for the OC clay. This indicates that the dilatation angle mainly influences the softening stage when the shear band is continuously developing and that the internal friction angle influences the steady-state stage when the shear band slope is gradually increasing.

- For both clays, the shear band thickness tended to gradually increase as the shear band developed. In the softening stage, the thicknesses of the NC and OC clays were 4.42, 5.20, 3.84, and 4.66 mm, and they gradually increased up to 7.56, 6.34, 6.56, and 7.01 mm, respectively. The thickness of shear band of clayey soil did not show any particular tendency between NC and OC clays, but further research work with the experiments should be performed under the same effective confining stress of NC and OC clays.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lambe, T.W.; Whitman, R.V. Soil Mechanics; John Wiley & Sons: Hoboken, NJ, USA, 1969. [Google Scholar]

- Lin, H.; Penumadu, D. Strain Localization in Combined Axial-Torsional Testing on Kaolin Clay. J. Eng. Mech. 2006, 132, 555–564. [Google Scholar] [CrossRef]

- Mokni, M. Relations entre deformations en masse et deformations localisees dans les materiaux granulaires. Ph.D Thesis, Université Joseph Fourier UJF, Grenoble, France, 1992. [Google Scholar]

- Desrues, J.; Chambon, R.; Mokni, M.; Mazerolle, F. Void ratio evolution inside shear bands in triaxial sand specimens studied by computed tomography. Géotechnique 1996, 46, 529–546. [Google Scholar] [CrossRef]

- Chaney, R.; Demars, K.; Wong, R. Shear Deformation of Locked Sand in Triaxial Compression. Geotech. Test. J. 2000, 23, 158. [Google Scholar] [CrossRef]

- Alshibli, K.A.; Batiste, S.N.; Sture, S. Strain Localization in Sand: Plane Strain versus Triaxial Compression. J. Geotech. Geoenvironmental Eng. 2003, 129, 483–494. [Google Scholar] [CrossRef]

- Kuo, C.Y.; Frost, J.D. Uniformity Evaluation of Cohesionless Specimens using Digital Image Analysis. J. Geotech. Eng. 1996, 122, 390–396. [Google Scholar] [CrossRef]

- Alshibli, K.A.; Sture, S. Sand Shear Band Thickness Measurements by Digital Imaging Techniques. J. Comput. Civ. Eng. 1999, 13, 103–109. [Google Scholar] [CrossRef]

- Jang, D.J.; Frost, J.D. Use of Image Analysis to Study the Microstructure of a Failed Sand Specimen. Can. Geotech. J. 2000, 37, 1141–1149. [Google Scholar] [CrossRef]

- Haines, S.H.; Van Der Pluijm, B.A.; Ikari, M.J.; Saffer, D.M.; Marone, C. Clay fabric intensity in natural and artificial fault gouges: Implications for brittle fault zone processes and sedimentary basin clay fabric evolution. J. Geophys. Res. Space Phys. 2009, 114. [Google Scholar] [CrossRef]

- Haines, S.H.; Kaproth, B.; Marone, C.; Saffer, D.; Van Der Pluijm, B. Shear zones in clay-rich fault gouge: A laboratory study of fabric development and evolution. J. Struct. Geol. 2013, 51, 206–225. [Google Scholar] [CrossRef]

- Wojatschke, J.; Scuderi, M.M.; Warr, L.N.; Carpenter, B.M.; Saffer, D.; Marone, C. Geochemistry, Geophysics, Geosystems. Geochem. Geophys. Geosyst. 2016, 17, 3865–3881. [Google Scholar] [CrossRef]

- Orellana, L.F.; Scuderi, M.M.; Collettini, C.; Violay, M. Frictional Properties of Opalinus Clay: Implications for Nuclear Waste Storage. J. Geophys. Res. Solid Earth 2018, 123, 157–175. [Google Scholar] [CrossRef]

- Finno, R.J.; Harris, W.W.; Mooney, M.A.; Viggiani, G. Shear bands in plane strain compression of loose sand. Géotechnique 1997, 47, 149–165. [Google Scholar] [CrossRef]

- White, D.J.; Take, W.A.; Bolton, M.D. Soil Deformation Measurement using Particle Image Velocimetry (PIV) and Photogrammetry. Geothechnique 2003, 53, 619–631. [Google Scholar] [CrossRef]

- Rechenmacher, A.L.; Finno, R.J. Digital Image Correlation to Evaluate Shear Banding in Dilative Sands. Geotech. Test. J. 2004, 27, 13–22. [Google Scholar] [CrossRef]

- Jang, E.-R.; Jung, Y.-H.; Kim, J.-Y.; Chung, C.-K. Assessment of Shear Band Characteristics in Granular Soils Using Digital Image Analysis Technique for Plane Strain Tests. J. Korean Geotech. Soc. 2011, 27, 51–65. [Google Scholar] [CrossRef][Green Version]

- Saada, A.; Bianchini, G.; Liang, L. Cracks, bifurcation and shear bands propagation in saturated clays. Géotechnique 1994, 44, 35–64. [Google Scholar] [CrossRef]

- Callisto, L.; Calabresi, G. Mechanical behaviour of a natural soft clay. Géotechnique 1998, 48, 495–513. [Google Scholar] [CrossRef]

- Gylland, A.S.; Jostad, H.P.; Nordal, S. Experimental Study of Strain Localization in Sensitive Clays. Acta Geotech. 2014, 9, 227–240. [Google Scholar] [CrossRef]

- Sachan, A.; Penumadu, D. Strain Localization in Solid Cylindrical Clay Specimens Using Digital Image Analysis (Dia) Technique. Soils Found. 2007, 47, 67–78. [Google Scholar] [CrossRef]

- Rhee, Y. Experimental Evaluation of Strain-softening Behavior of Normally Consolidated Chicago Clays in Plane Strain Compression. Ph.D Thesis, Northwestern University, Evanston, IL, USA, 1991. [Google Scholar]

- Alshibli, K.A.; Akbas, I.S. Strain Localization in Clay: Plane Strain versus Triaxial Loading Conditions. Geotech. Geol. Eng. 2007, 25, 45–55. [Google Scholar] [CrossRef]

- Jang, E.-R.; Choo, Y.; Lee, W.-T.; Chung, C.-K. Restrained Effect of End Plate on Plane Strain Test Evaluated by Digital Image Correlation Method. J. Korean Geotech. Soc. 2008, 24, 25–36. [Google Scholar]

- Sheeran, D.E.; Krizek, R.J. Preparation of Homogenous Soil Samples by Slurry Consolidation. J. Mater. 1971, 6, 356–373. [Google Scholar]

- Zhang, Y.; Tan, T.; Leung, C. Application of particle imaging velocimetry (PIV) in centrifuge testing of uniform clay. Int. J. Phys. Model. Geotech. 2005, 5, 15–26. [Google Scholar] [CrossRef]

- Kim, J.; Woo, S.I.; Chung, C.-K. Assessment of non-uniform deformation during consolidation with lateral drainage using Particle Image Velocimetry (PIV). KSCE J. Civ. Eng. 2017, 22, 520–531. [Google Scholar] [CrossRef]

- Zhang, G.; Hu, Y.; Zhang, J.-M. New image analysis-based displacement-measurement system for geotechnical centrifuge modeling tests. Meas. J. Int. Meas. Confed. 2009, 42, 87–96. [Google Scholar] [CrossRef]

- Adrian, R.J. Particle-Imaging Techniques for Experimental Fluid Mechanics. Annu. Rev. Fluid Mech. 1991, 23, 261–304. [Google Scholar] [CrossRef]

- Kwak, T.Y.; Woo, S.I.; Kim, J.; Chung, C.-K. Model test assessment of the generation of underground cavities and ground cave-ins by damaged sewer pipes. Soils Found. 2019, 59, 586–600. [Google Scholar] [CrossRef]

- White, D.J.; Take, W.A. GeoPIV: Particle Image Velocimetry (PIV) Software for Use in Geotechnical Testing. Cambridge Univ. Eng. Dep. Tech. Rep. 2002, 322, 15. [Google Scholar]

- Kim, J.-Y.; Jang, E.-R.; Chung, C.-K. Evaluation of Accuracy and Optimization of Digital Image Analysis Technique for Measuring Deformation of Soils. J. Korean Geotech. Soc. 2011, 27, 5–16. [Google Scholar] [CrossRef][Green Version]

- Gu, C.; Wang, J.; Cai, Y.; Sun, L.; Wang, P.; Dong, Q. Deformation characteristics of overconsolidated clay sheared under constant and variable confining pressure. Soils Found. 2016, 56, 427–439. [Google Scholar] [CrossRef]

- Oda, M.; Kazama, H. Microstructure of shear bands and its relation to the mechanisms of dilatancy and failure of dense granular soils. Géotechnique 1998, 48, 465–481. [Google Scholar] [CrossRef]

- Roscoe, K.H. The Influence of Strains in Soil Mechanics. Géotechnique 1970, 20, 129–170. [Google Scholar] [CrossRef]

- Arthur, J.R.F.; Dunstan, T.; Al-Ani, Q.A.J.L.; Assadi, A. Discussion: Plastic deformation and failure in granular media. Géotechnique 1978, 28, 125–128. [Google Scholar] [CrossRef]

- Hicher, P.; Wahyudi, H.; Tessier, D. Microstructural analysis of strain localisation in clay. Comput. Geotech. 1994, 16, 205–222. [Google Scholar] [CrossRef]

| USCS Classification | MH |

|---|---|

| Liquid Limit, LL (%) | 65.3 |

| Plastic Index, PI (%) | 23.1 |

| Plastic Limit, PL (%) | 42.2 |

| Specific Gravity, Gs | 2.62 |

| Percent Finer than #200 Sieve (%) | 99.8 |

| Description | NC Clay | OC Clay | Back Pressure for Both Clays (u) | ||

|---|---|---|---|---|---|

| Effective Vertical Stress (σ1′) | Effective Horizontal Stress (σ3′) | Effective Vertical Stress (σ1′) | Effective Horizontal Stress (σ3′) | ||

| Loading | 200 kPa | 100 kPa | 200 kPa | 100 kPa | 100 kPa |

| Unloading | - | - | 50 kPa | 50 kPa | 100 kPa |

| Description | Stage | ψ | |||||

|---|---|---|---|---|---|---|---|

| NC1 | Softening | 37.1° | 13.2° | 52.1° | 63.6° | 51.6° | 57.6° |

| Steady state | 36.7° | 7.1° | 59.2° | 63.4° | 48.6° | 56.0° | |

| NC2 | Softening | 36.9° | 8.3° | 49.6° | 63.5° | 49.2° | 56.3° |

| Steady state | 36.1° | 1.5° | 56.1° | 63.1° | 45.8° | 54.4° | |

| OC1 | Softening | 39.0° | 12.8° | 51.7° | 64.5° | 51.4° | 58.0° |

| Steady state | 37.9° | 9.4° | 56.3° | 64.0° | 49.7° | 56.8° | |

| OC2 | Softening | 38.7° | 17.8° | 52.3° | 64.4° | 53.9° | 59.1° |

| Steady state | 38.1° | 9.3° | 55.2° | 64.1° | 49.7° | 56.9° |

| Description | NC1 | NC2 | OC1 | OC2 |

|---|---|---|---|---|

| Softening | 4.42 mm | 5.20 mm | 3.84 mm | 4.66 mm |

| Steady state | 7.56 mm | 6.34 mm | 6.56 mm | 7.01 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwak, T.-Y.; Park, K.-H.; Kim, J.; Chung, C.-K.; Baek, S.-H. Shear Band Characterization of Clayey Soils with Particle Image Velocimetry. Appl. Sci. 2020, 10, 1139. https://doi.org/10.3390/app10031139

Kwak T-Y, Park K-H, Kim J, Chung C-K, Baek S-H. Shear Band Characterization of Clayey Soils with Particle Image Velocimetry. Applied Sciences. 2020; 10(3):1139. https://doi.org/10.3390/app10031139

Chicago/Turabian StyleKwak, Tae-Young, Ka-Hyun Park, Joonyoung Kim, Choong-Ki Chung, and Sung-Ha Baek. 2020. "Shear Band Characterization of Clayey Soils with Particle Image Velocimetry" Applied Sciences 10, no. 3: 1139. https://doi.org/10.3390/app10031139

APA StyleKwak, T.-Y., Park, K.-H., Kim, J., Chung, C.-K., & Baek, S.-H. (2020). Shear Band Characterization of Clayey Soils with Particle Image Velocimetry. Applied Sciences, 10(3), 1139. https://doi.org/10.3390/app10031139