Effect of End-Effector Compliance on Collisions in Robotic Teleoperation

Abstract

Simple Summary

Abstract

1. Introduction

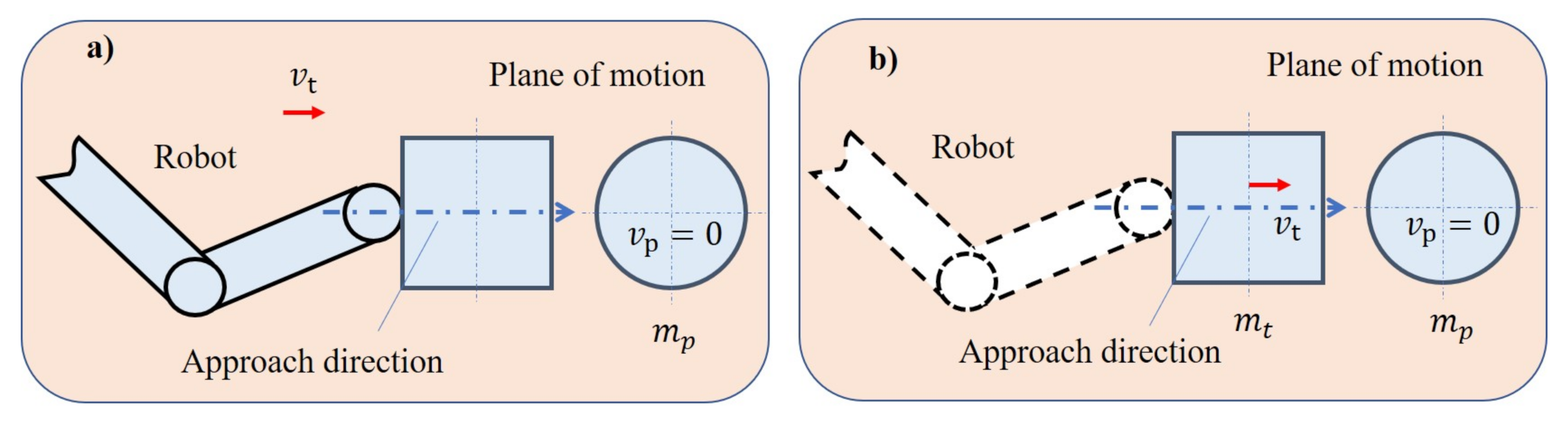

2. Impact between the Tool and the Object

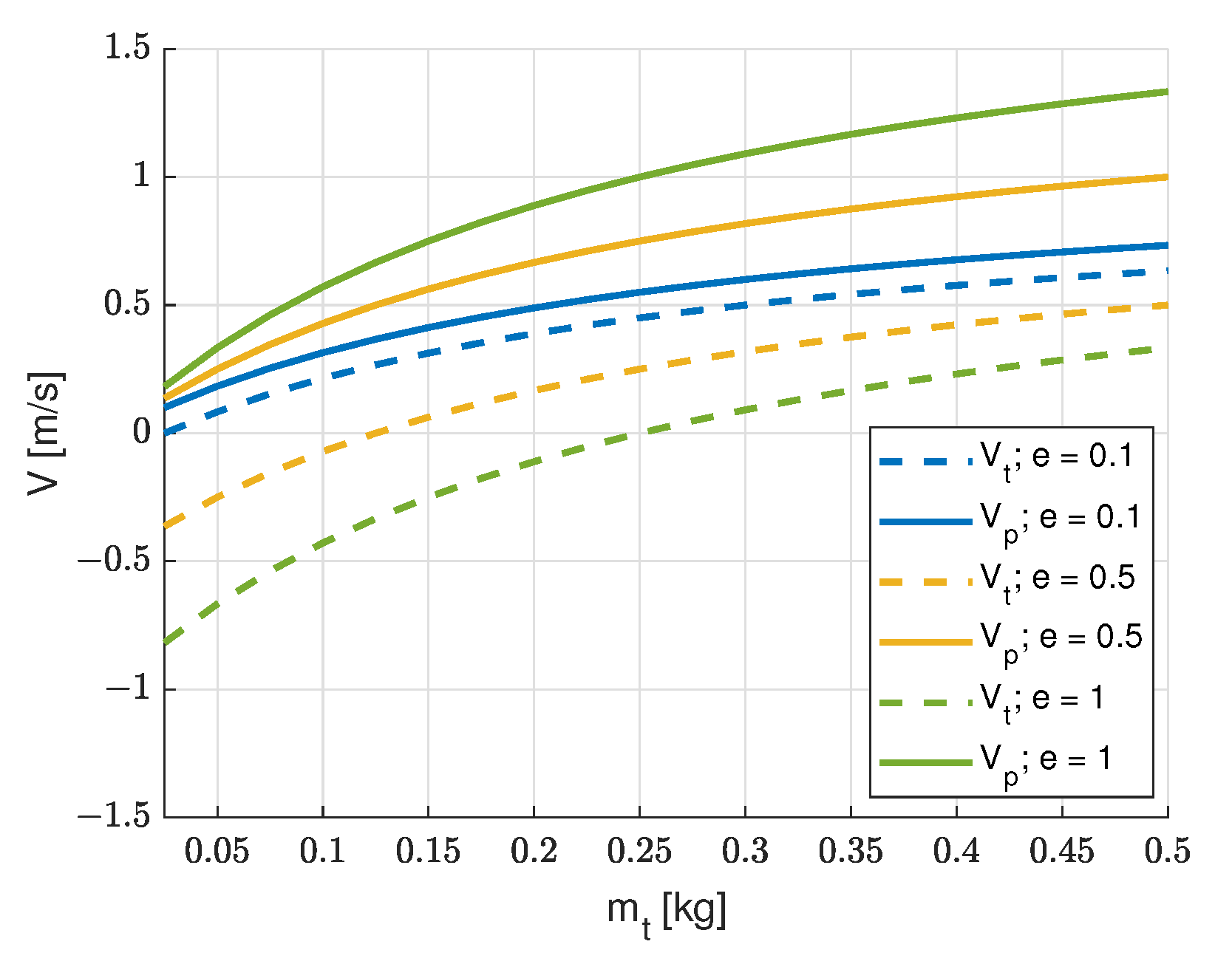

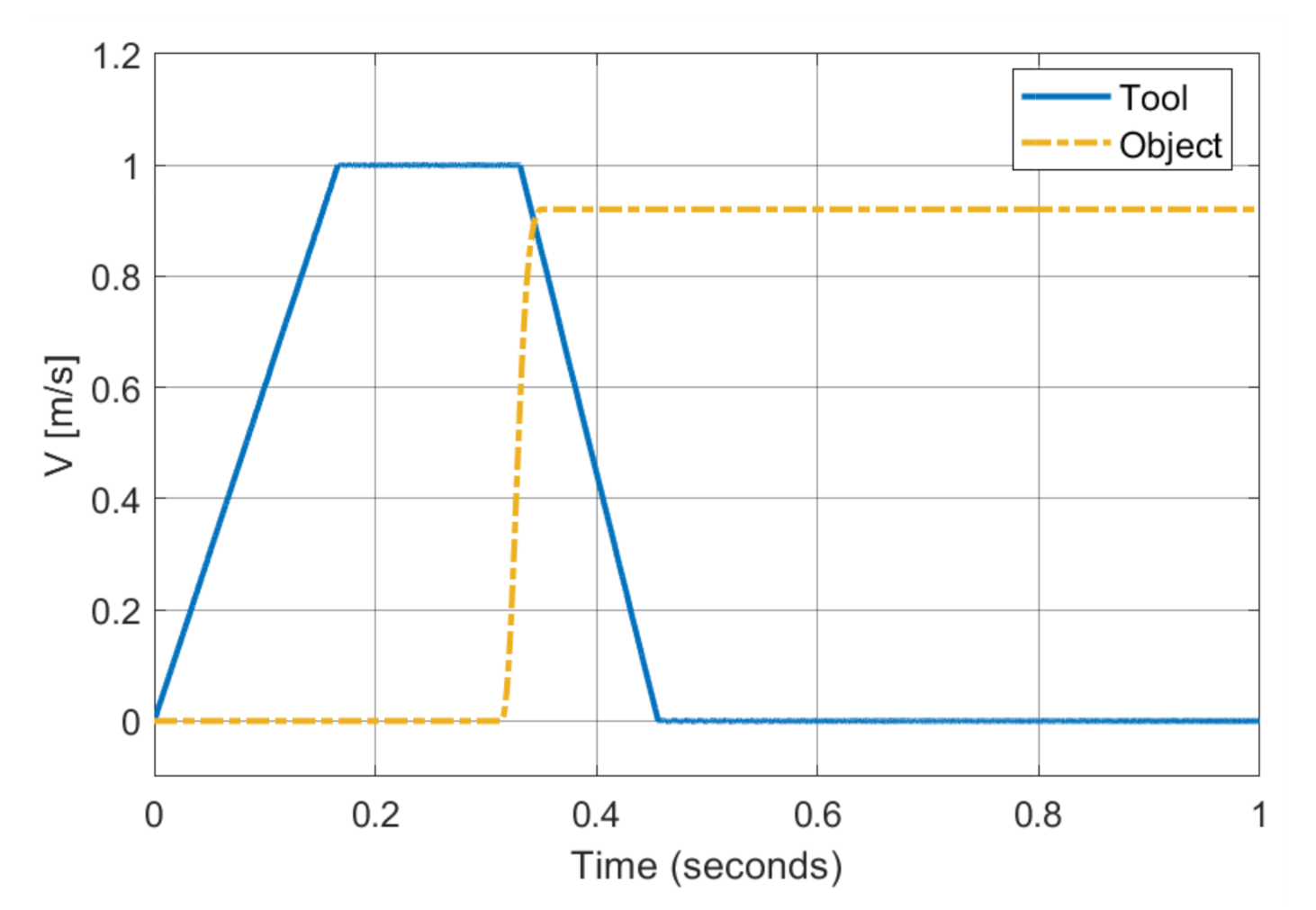

2.1. Instantaneous Impact

2.2. Non-Instantaneous Impact

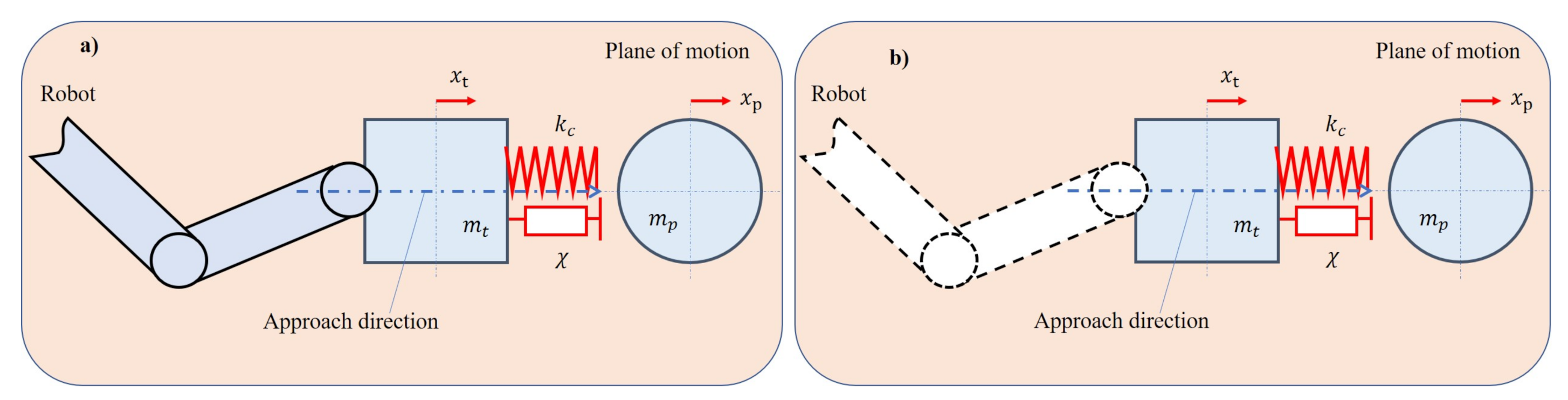

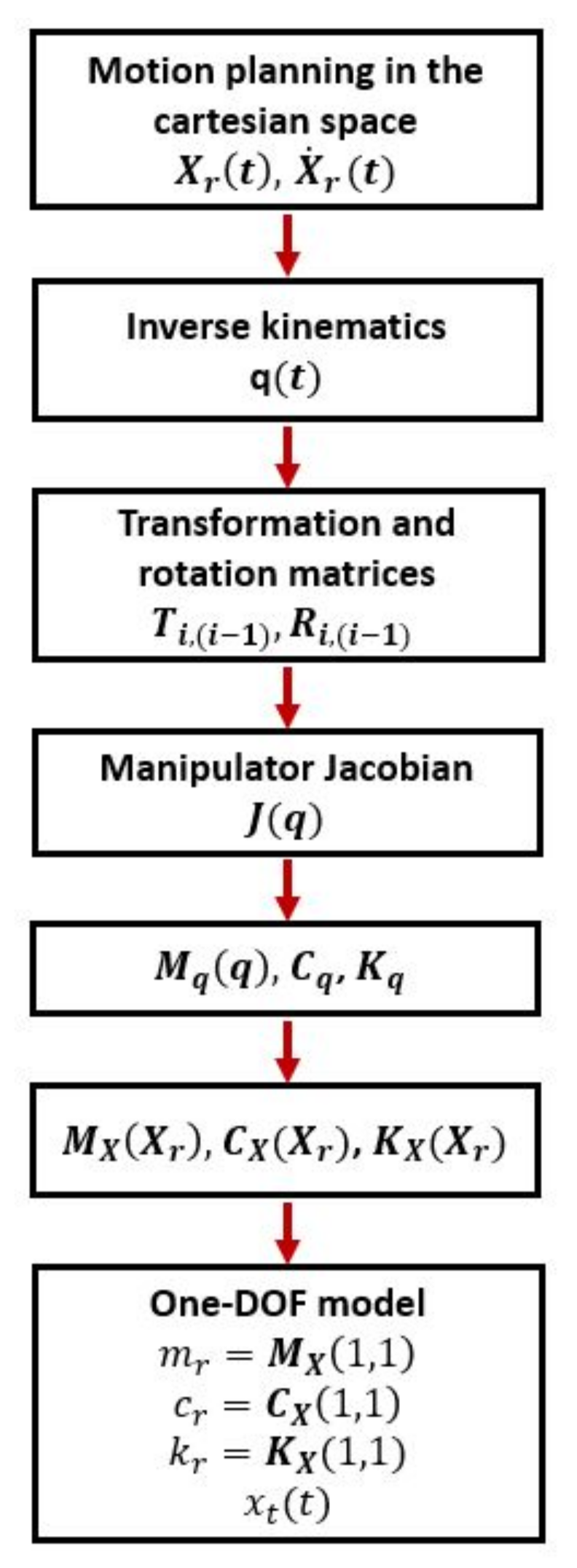

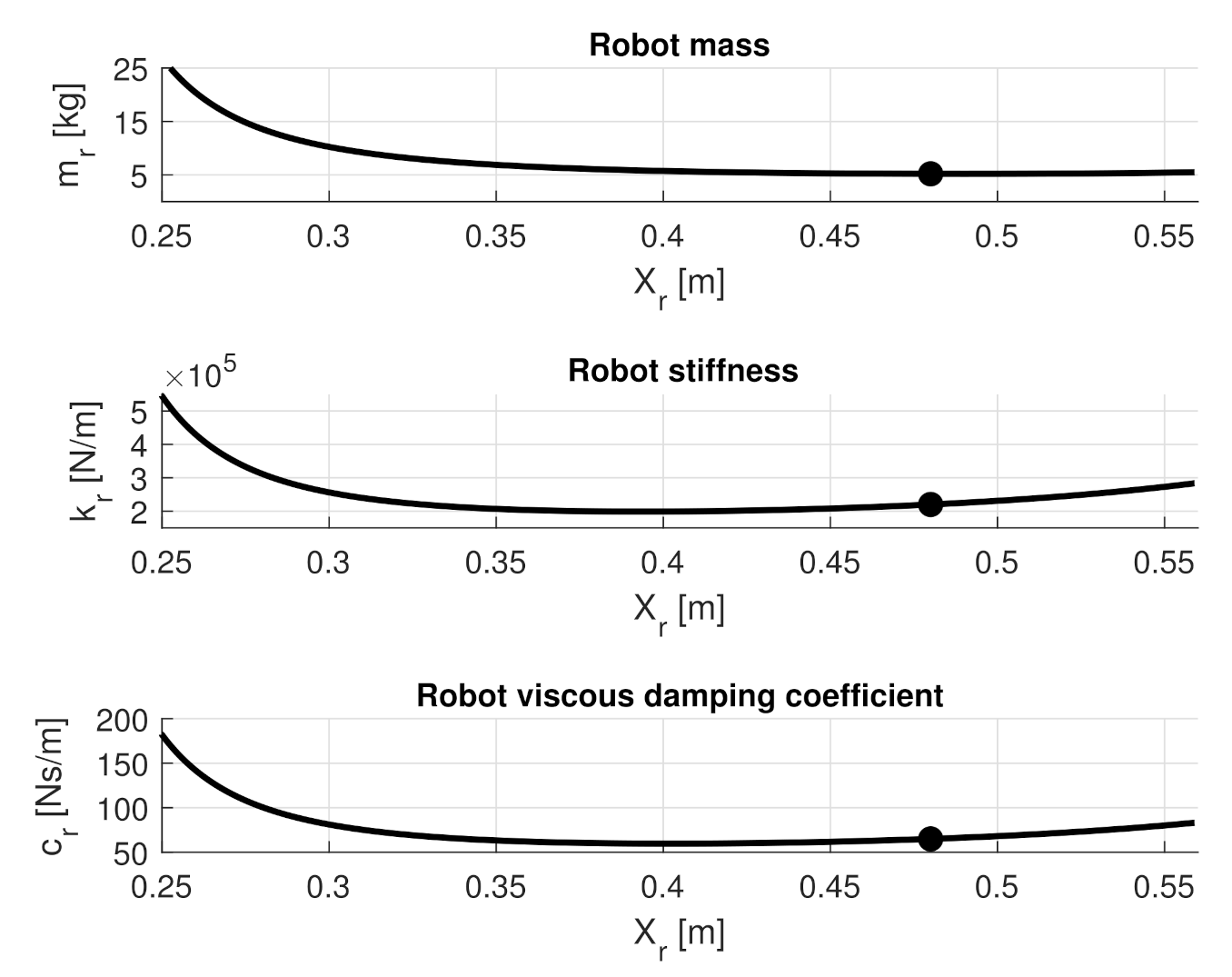

3. Effects of Robot Compliance

3.1. Model of Robot Compliance

- is the vector which contains the joint variables imposed by actuators;

- is the vector containing actual joint variables;

- is the robot mass matrix in the joint space;

- is the term related to centrifugal and Coriolis forces;

- is the robot viscous damping matrix in the joint space;

- is the robot stiffness matrix in the joint space; and

- is the term related to gravity forces.

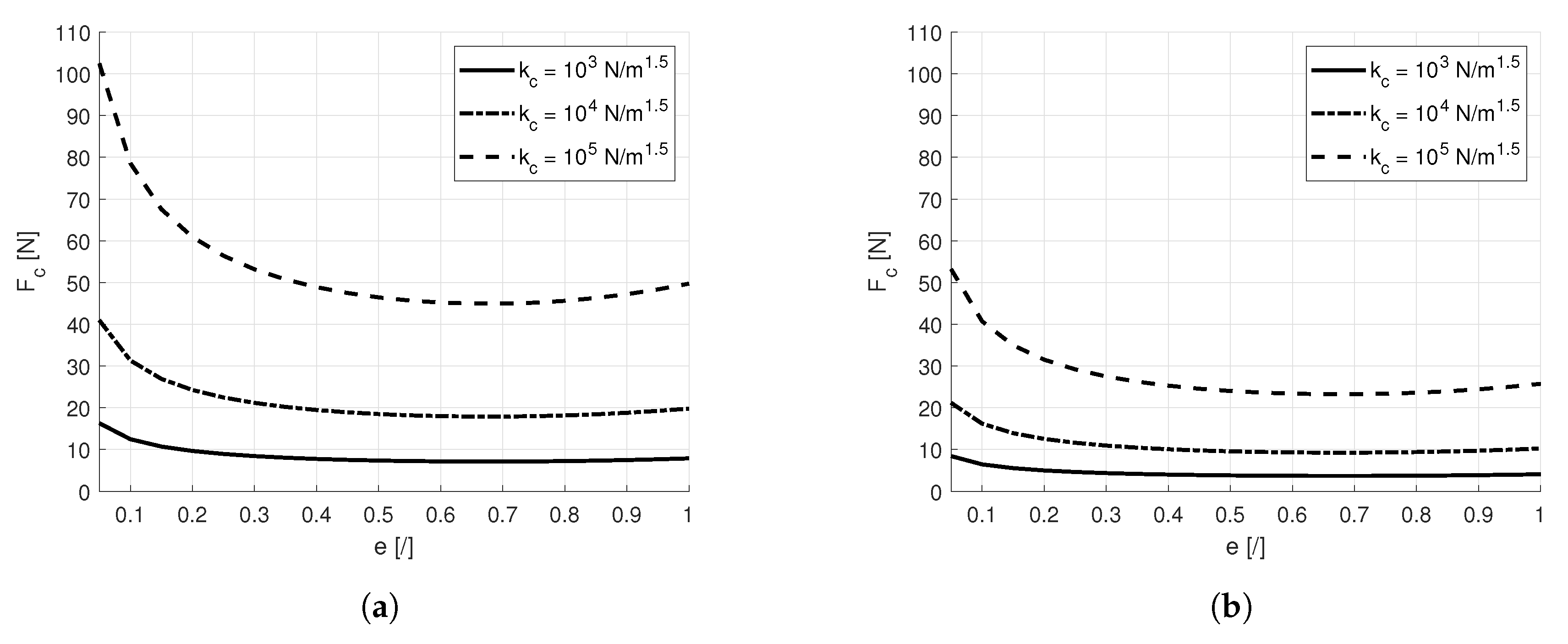

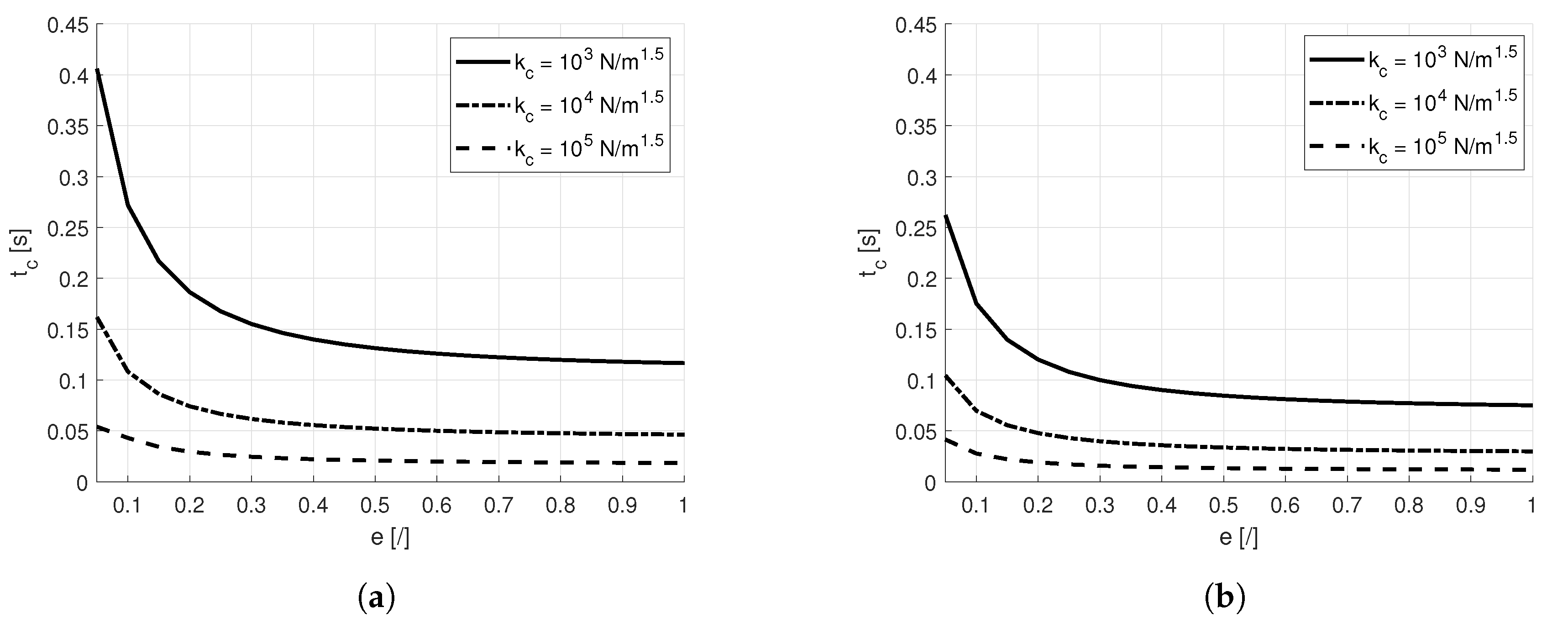

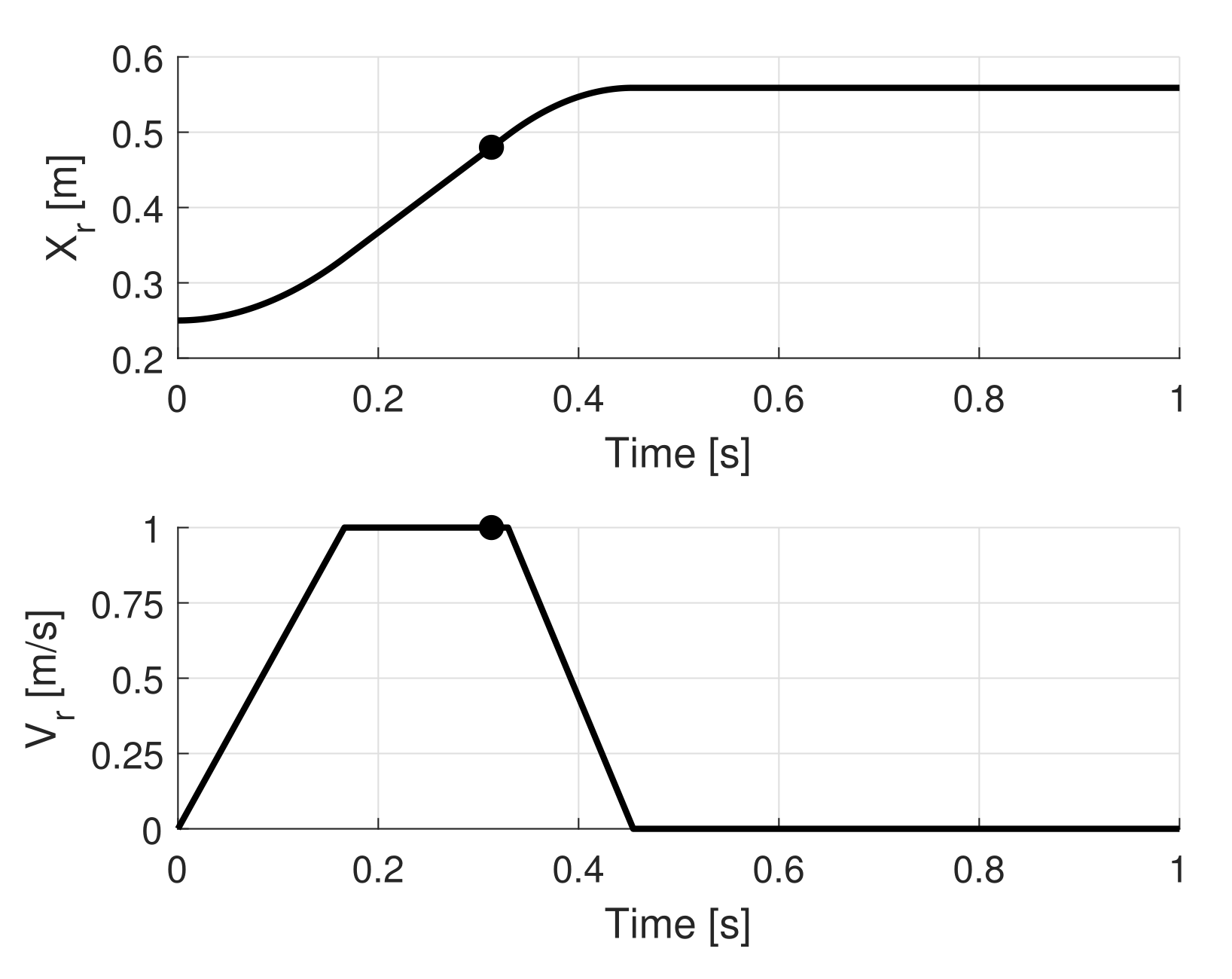

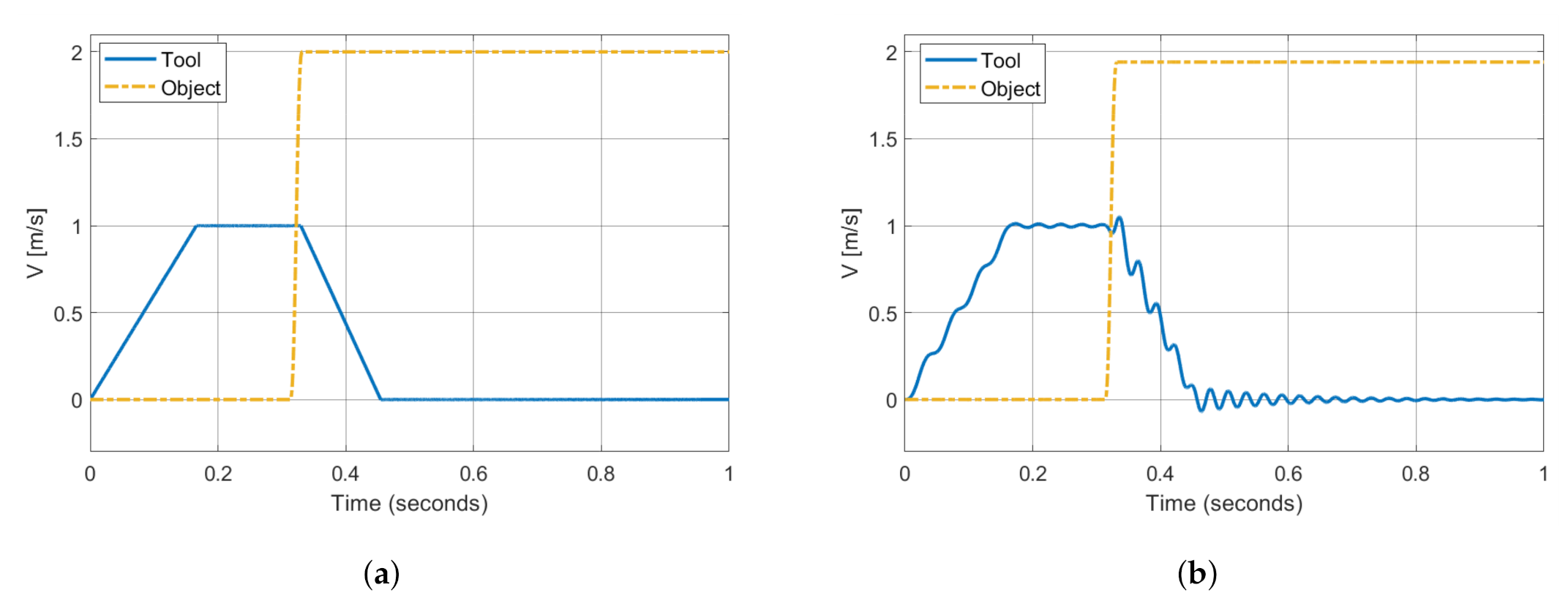

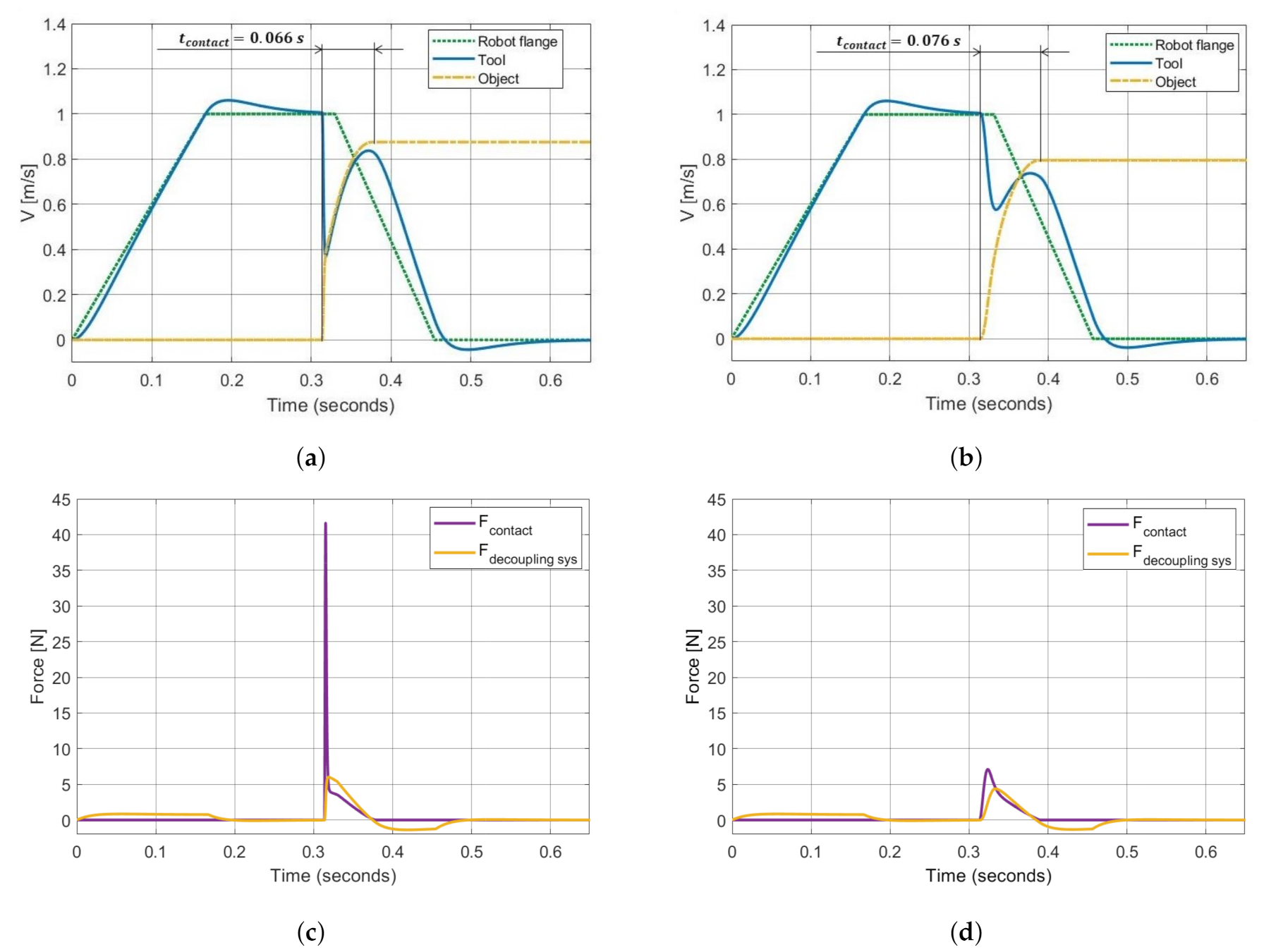

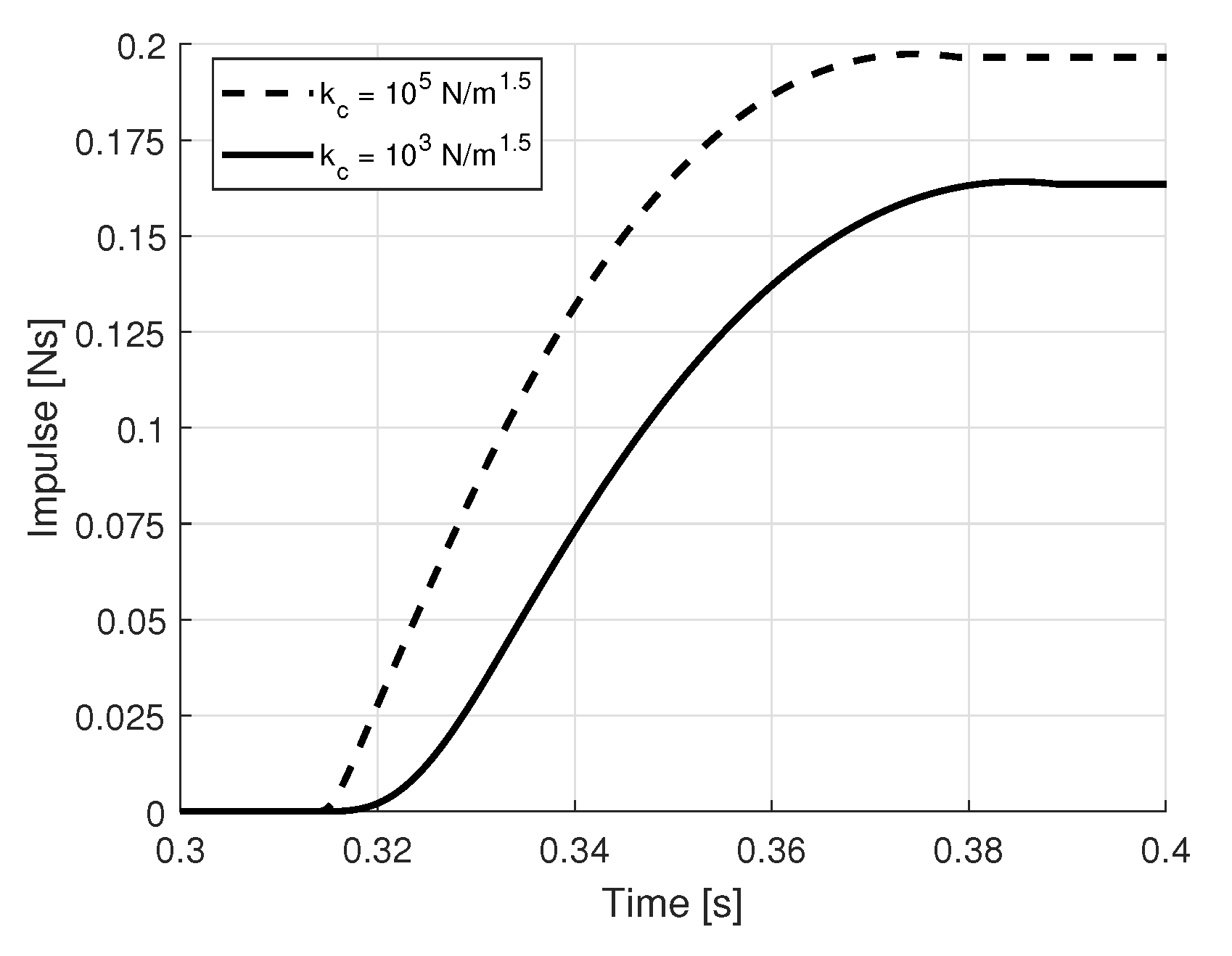

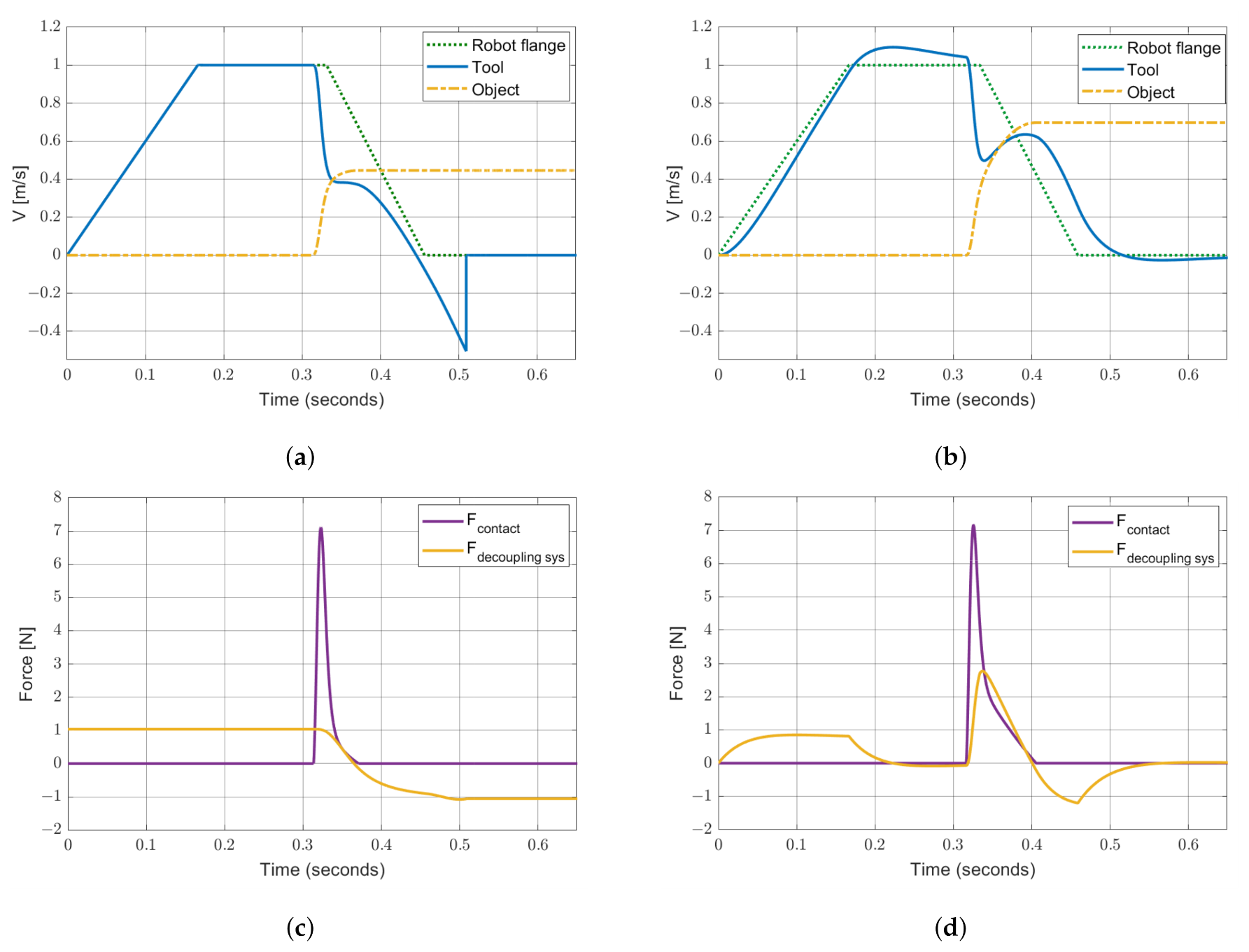

3.2. Numerical Results

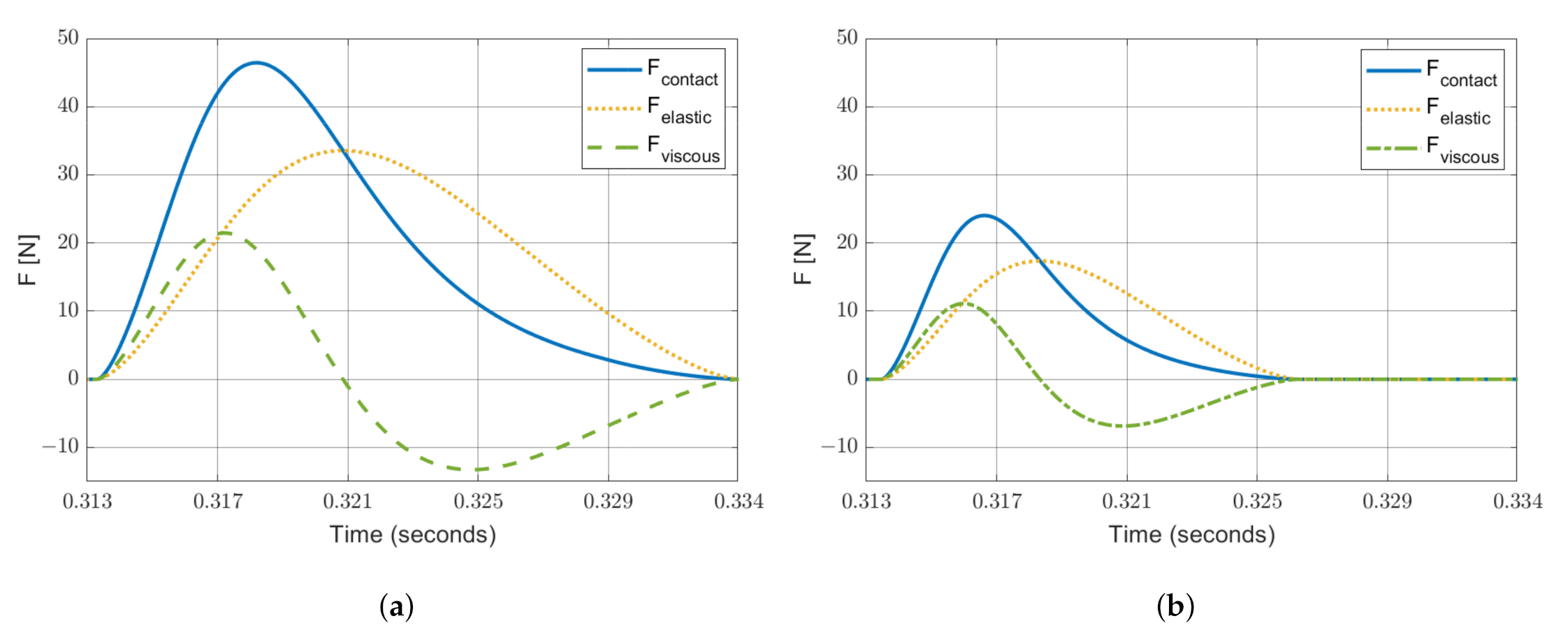

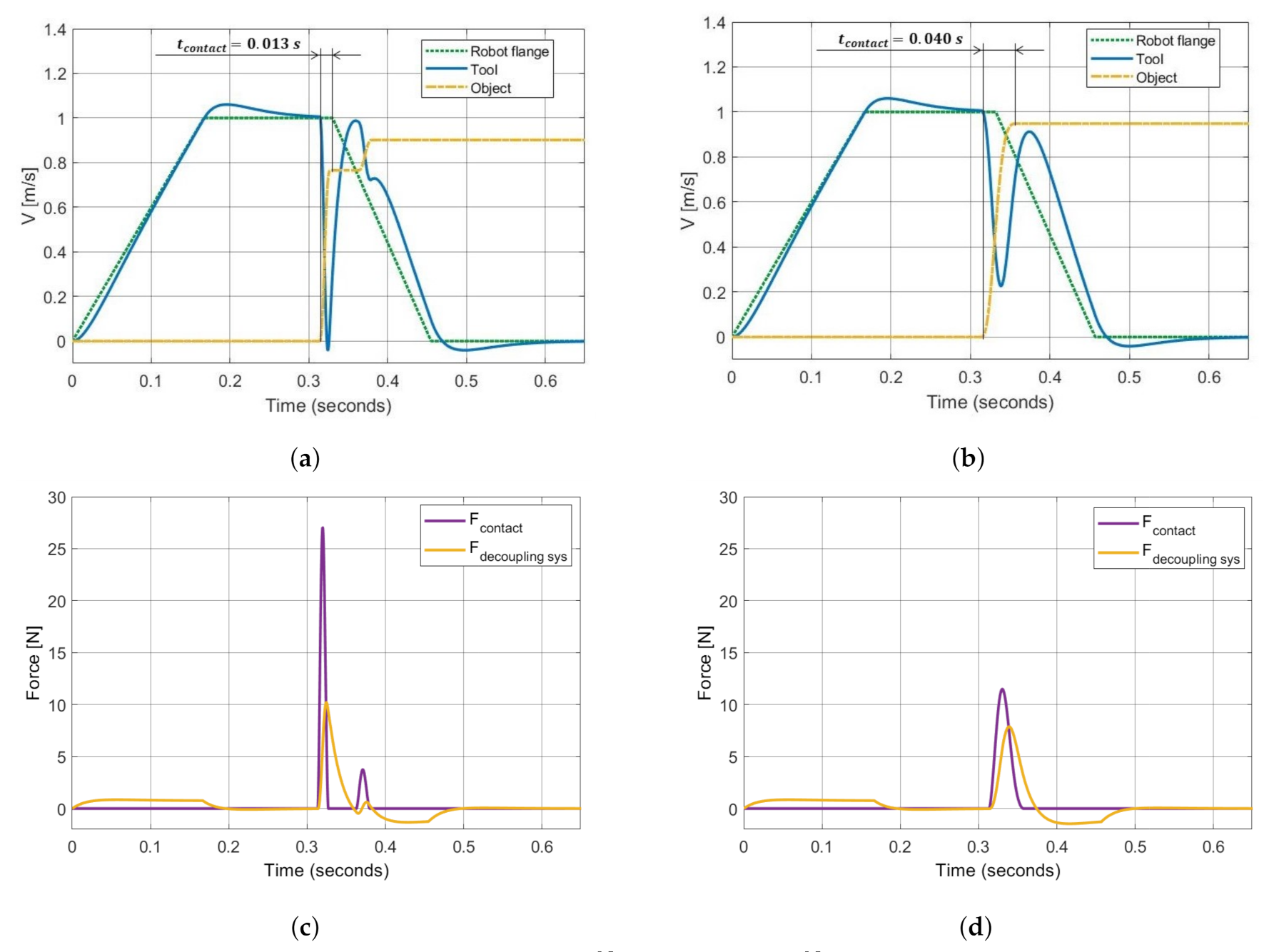

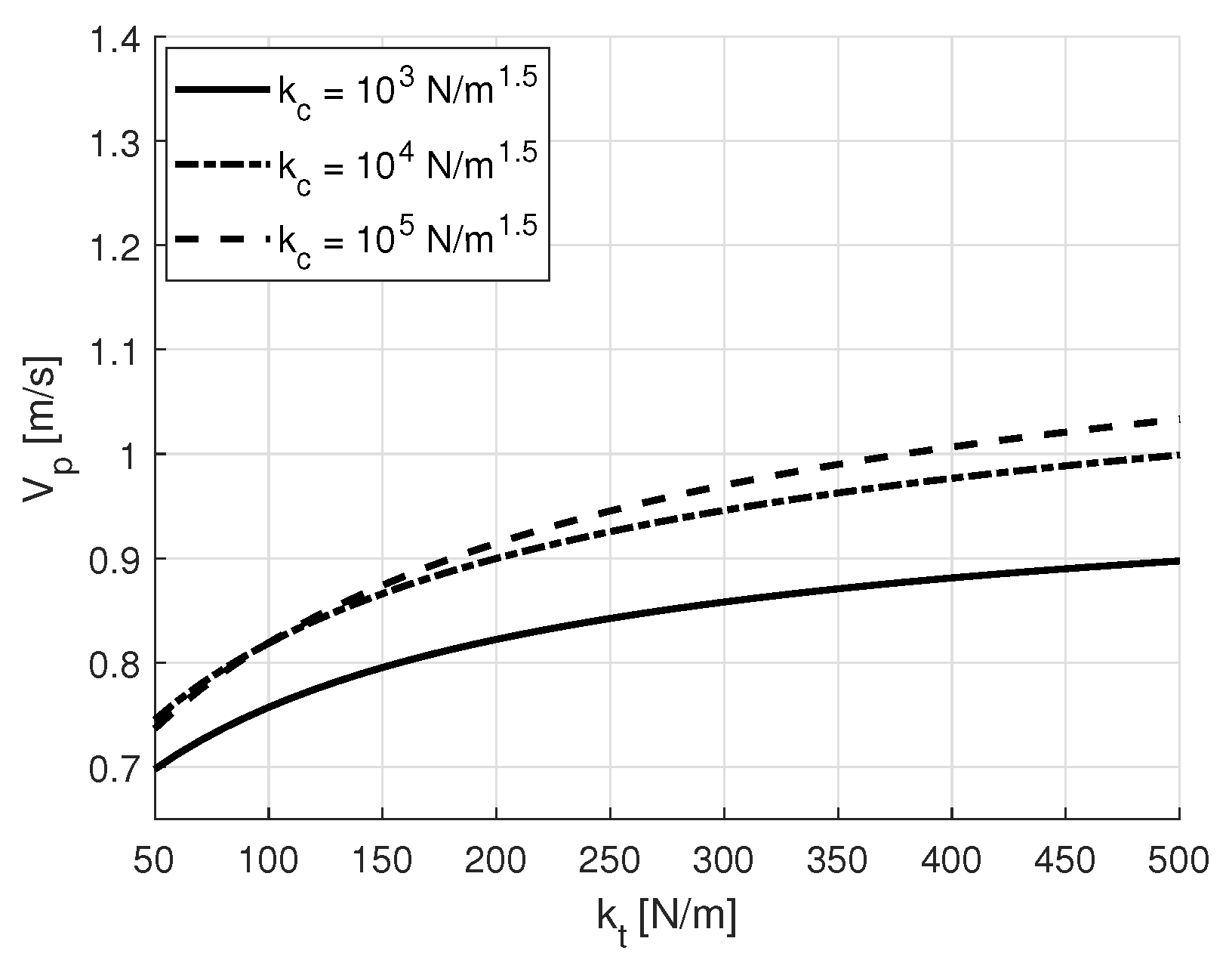

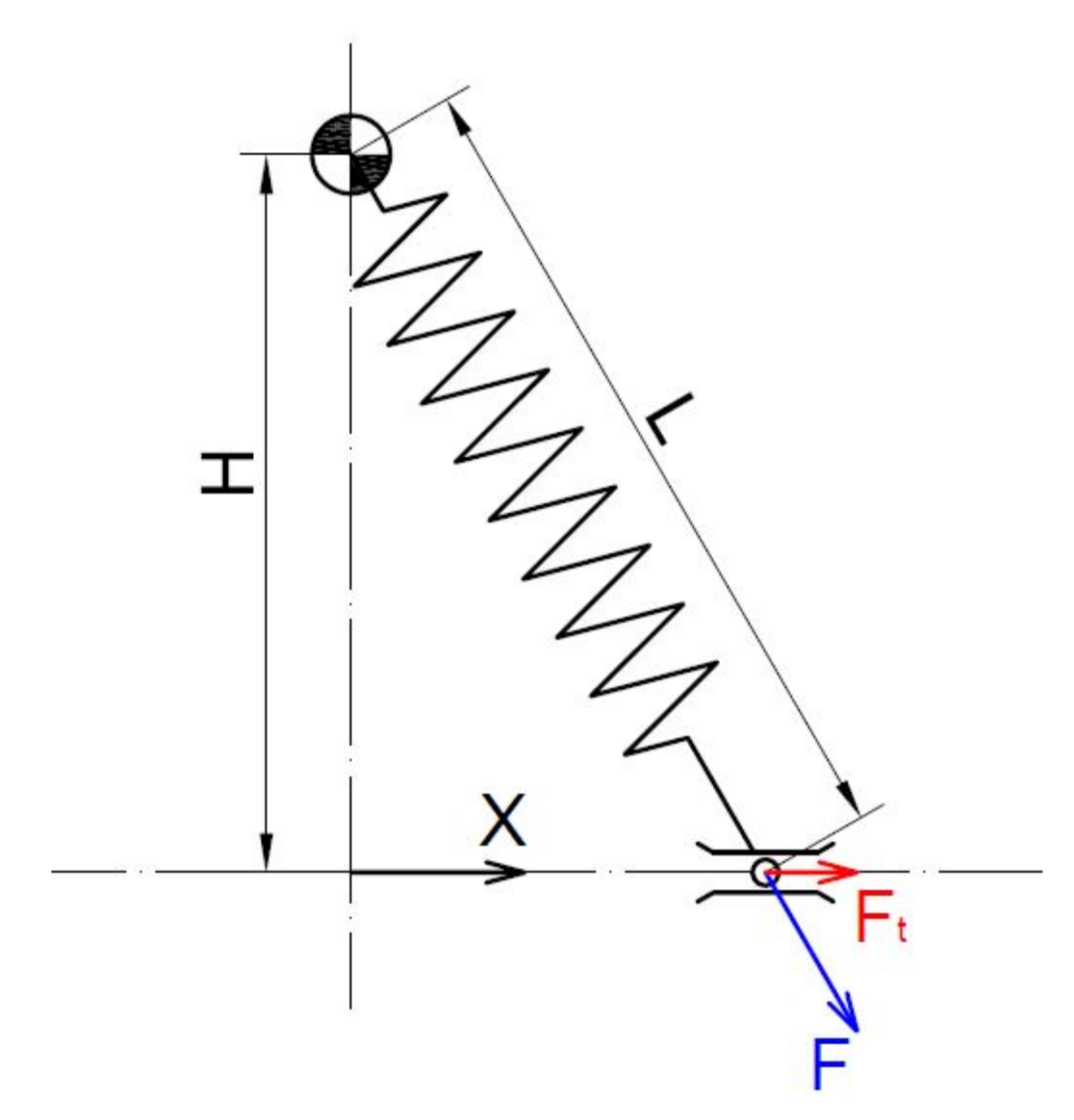

4. Effects of Tool Compliance

4.1. Model of Tool Compliance

4.2. Simulated Results

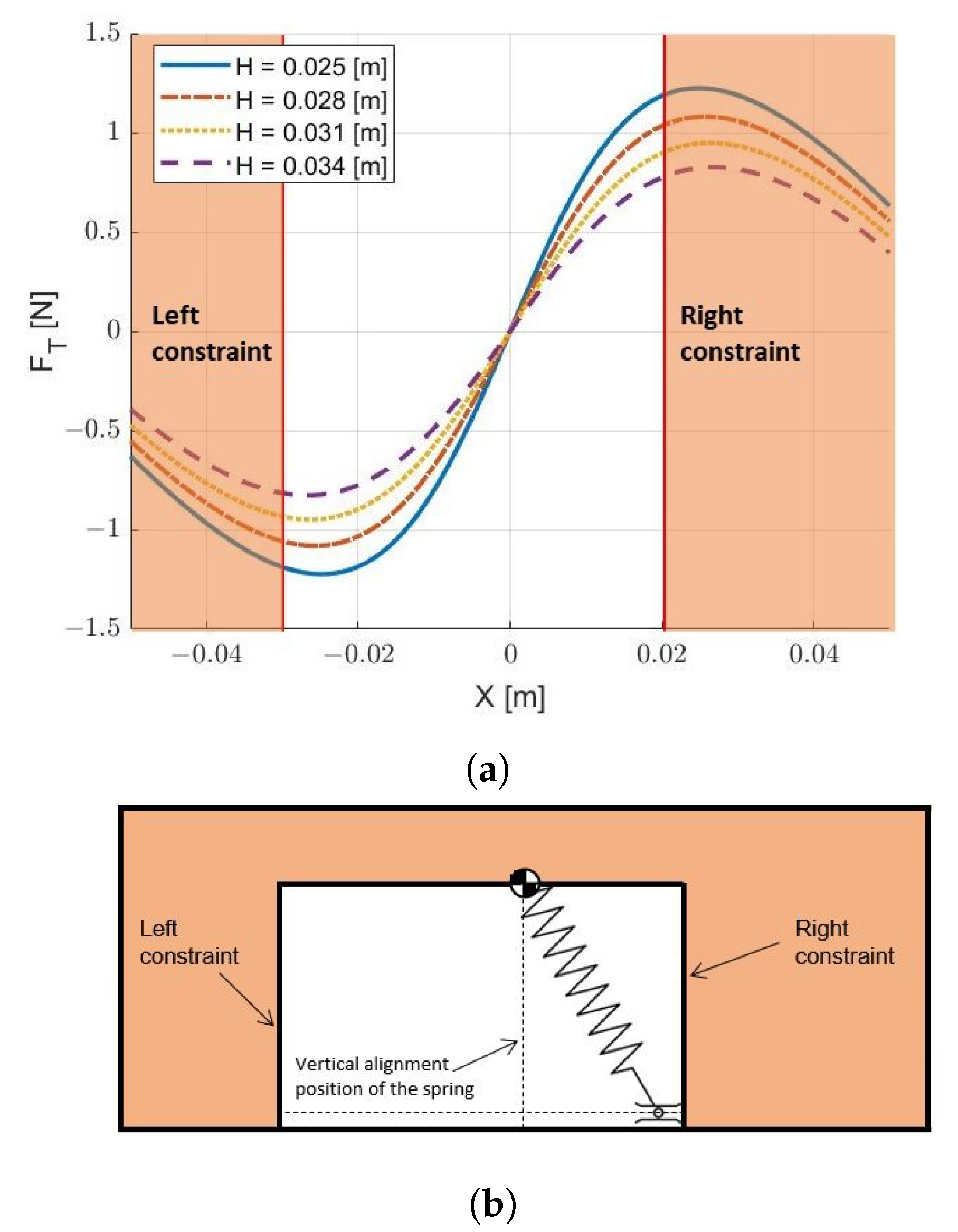

5. End-Effector Design

- The system has to be able to exert a minimum force on the tool to keep it in the desired position during the acceleration of the robot;

- The system has to prevent rebounds of the tool in order to avoid multiple collisions and the restitution of the energy absorbed in the impact;

- The impulse transmitted to the object should be as small as possible, according to Equation (22).

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hokayem, P.F.; Spong, M.W. Bilateral teleoperation: An historical survey. Automatica 2006, 42, 2035–2057. [Google Scholar] [CrossRef]

- Hashtrudi-Zaad, K.; Salcudean, S.E. Analysis of control architectures for teleoperation systems with impedance/admittance master and slave manipulators. Int. J. Robot. Res. 2001, 20, 419–445. [Google Scholar] [CrossRef]

- Sun, D.; Naghdy, F.; Du, H. Application of wave-variable control to bilateral teleoperation systems: A survey. Annu. Rev. Control 2014, 38, 12–31. [Google Scholar] [CrossRef]

- Chan, L.; Naghdy, F.; Stirling, D. Application of adaptive controllers in teleoperation systems: A survey. IEEE Trans. Hum. Mach. Syst. 2014, 44, 337–352. [Google Scholar]

- Uddin, R.; Ryu, J. Predictive control approaches for bilateral teleoperation. Annu. Rev. Control 2016, 42, 82–99. [Google Scholar] [CrossRef]

- Tai, K.; El-Sayed, A.R.; Shahriari, M.; Biglarbegian, M.; Mahmud, S. State of the art robotic grippers and applications. Robotics 2016, 5, 11. [Google Scholar] [CrossRef]

- Rosati, G.; Minto, S.; Oscari, F. Design and construction of a variable-aperture gripper for flexible automated assembly. Robot. Comput. Integr. Manuf. 2017, 48, 157–166. [Google Scholar] [CrossRef]

- Brown, M.K. A controlled impedance robot gripper. AT T Tech. J. 1985, 64, 937–969. [Google Scholar] [CrossRef]

- Sprovieri, J. Watch your fingers! Assembly 2004, 47, 1–10. [Google Scholar]

- Brach, R.M. Mechanical Impact Dynamics: Rigid Body Collisions; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Skrinjar, L.; Slavič, J.; Boltežar, M. A review of continuous contact-force models in multibody dynamics. Int. J. Mech. Sci. 2018, 145, 171–187. [Google Scholar] [CrossRef]

- Hunt, K.H.; Crossley, F.R.E. Coefficient of restitution interpreted as damping in vibroimpact. J. Appl. Mech. 1975, 42, 440–445. [Google Scholar] [CrossRef]

- Marhefka, D.W.; Orin, D.E. Simulation of contact using a nonlinear damping model. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; Volume 2, pp. 1662–1668. [Google Scholar]

- Schwab, A.; Meijaard, J.; Meijers, P. A comparison of revolute joint clearance models in the dynamic analysis of rigid and elastic mechanical systems. Mech. Mach. Theory 2002, 37, 895–913. [Google Scholar] [CrossRef]

- Hu, S.; Guo, X. A dissipative contact force model for impact analysis in multibody dynamics. Multibody Syst. Dyn. 2015, 35, 131–151. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Zhang, G.; Gan, Z.; Pan, Z.; Cui, H.; Zhu, Z. Machining with flexible manipulator: Toward improving robotic machining performance. In Proceedings of the 2005 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Monterey, CA, USA, 24–28 July 2005; IEEE: Piscataway, NJ, USA, 2005; pp. 1127–1132. [Google Scholar]

- Bottin, M.; Cocuzza, S.; Comand, N.; Doria, A. Modeling and Identification of an Industrial Robot with a Selective Modal Approach. Appl. Sci. 2020, 10, 4619. [Google Scholar] [CrossRef]

- Doria, A.; Cocuzza, S.; Comand, N.; Bottin, M.; Rossi, A. Analysis of the Compliance Properties of an Industrial Robot with the Mozzi Axis Approach. Robotics 2019, 8, 80. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics: Modelling, Planning and Control; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- OMRON. Omron Adept Viper s650/s850 Robot with MB-60R/eMB-60R User’s Guide; OMRON: Osaka City, Japan, 2016. [Google Scholar]

- Bottega, W.J. Engineering Vibrations; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Borboni, A.; Faglia, R. Parasitic Phenomena in the Dynamics Of Industrial Devices; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Borboni, A.; Lancini, M.; Faglia, R. Residual Vibration Reduction With Commanded Motion Optimization. Volume 2: Dynamics, Vibration and Control; Energy; Fluids Engineering; Micro and Nano Manufacturing. In Engineering Systems Design and Analysis; ASME: New York, NY, USA, 2014. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tommasino, D.; Cipriani, G.; Doria, A.; Rosati, G. Effect of End-Effector Compliance on Collisions in Robotic Teleoperation. Appl. Sci. 2020, 10, 9077. https://doi.org/10.3390/app10249077

Tommasino D, Cipriani G, Doria A, Rosati G. Effect of End-Effector Compliance on Collisions in Robotic Teleoperation. Applied Sciences. 2020; 10(24):9077. https://doi.org/10.3390/app10249077

Chicago/Turabian StyleTommasino, Domenico, Giulio Cipriani, Alberto Doria, and Giulio Rosati. 2020. "Effect of End-Effector Compliance on Collisions in Robotic Teleoperation" Applied Sciences 10, no. 24: 9077. https://doi.org/10.3390/app10249077

APA StyleTommasino, D., Cipriani, G., Doria, A., & Rosati, G. (2020). Effect of End-Effector Compliance on Collisions in Robotic Teleoperation. Applied Sciences, 10(24), 9077. https://doi.org/10.3390/app10249077