Sandwich Panels with Polymeric Foam Cores Exposed to Blast Loading: An Experimental and Numerical Investigation

Abstract

1. Introduction

2. Materials

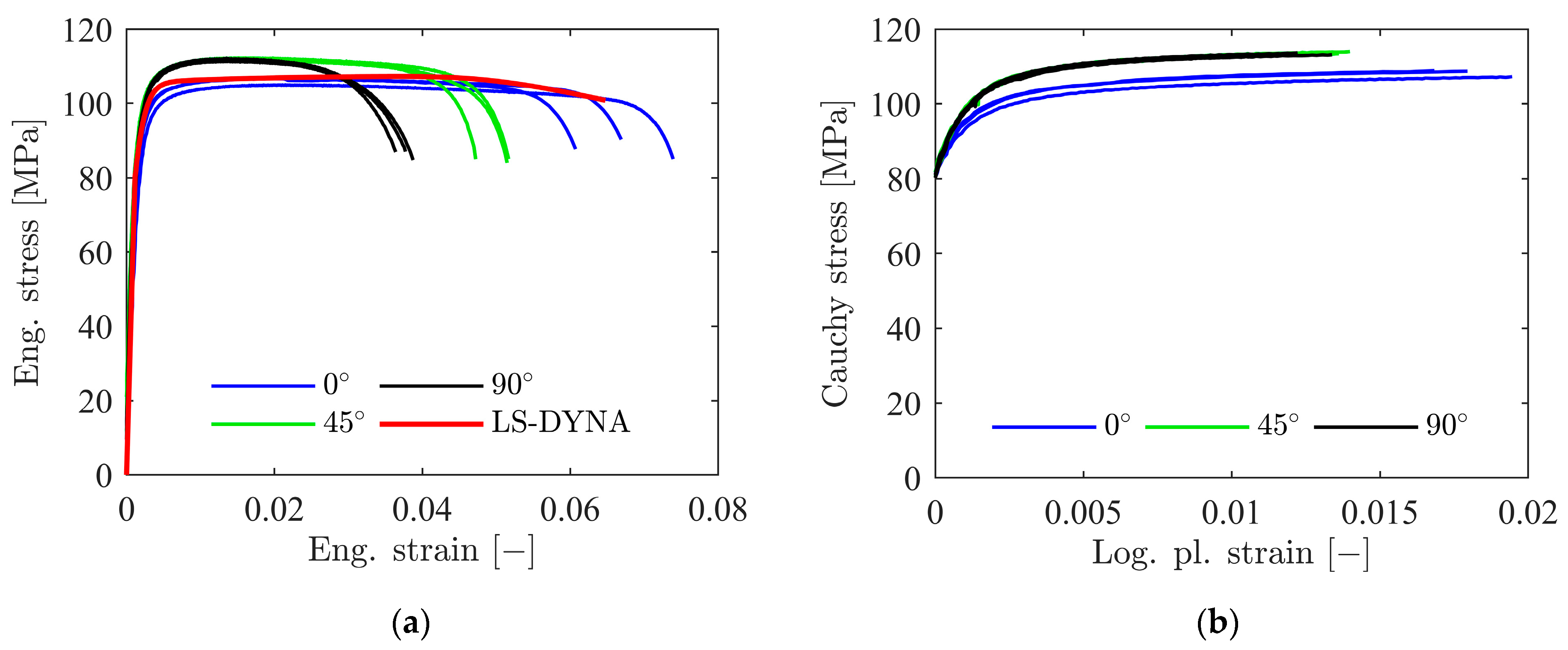

2.1. Aluminium Skins

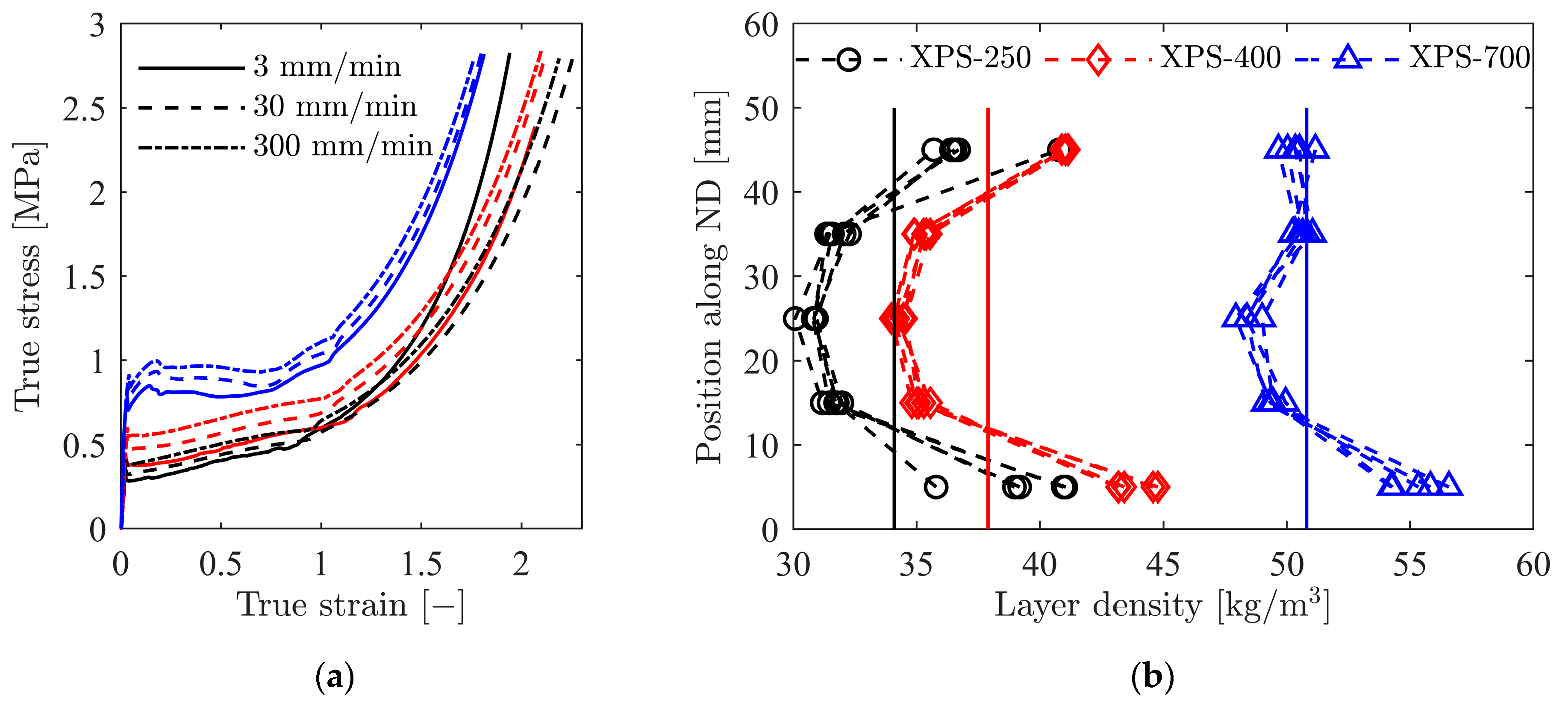

2.2. Foam Cores

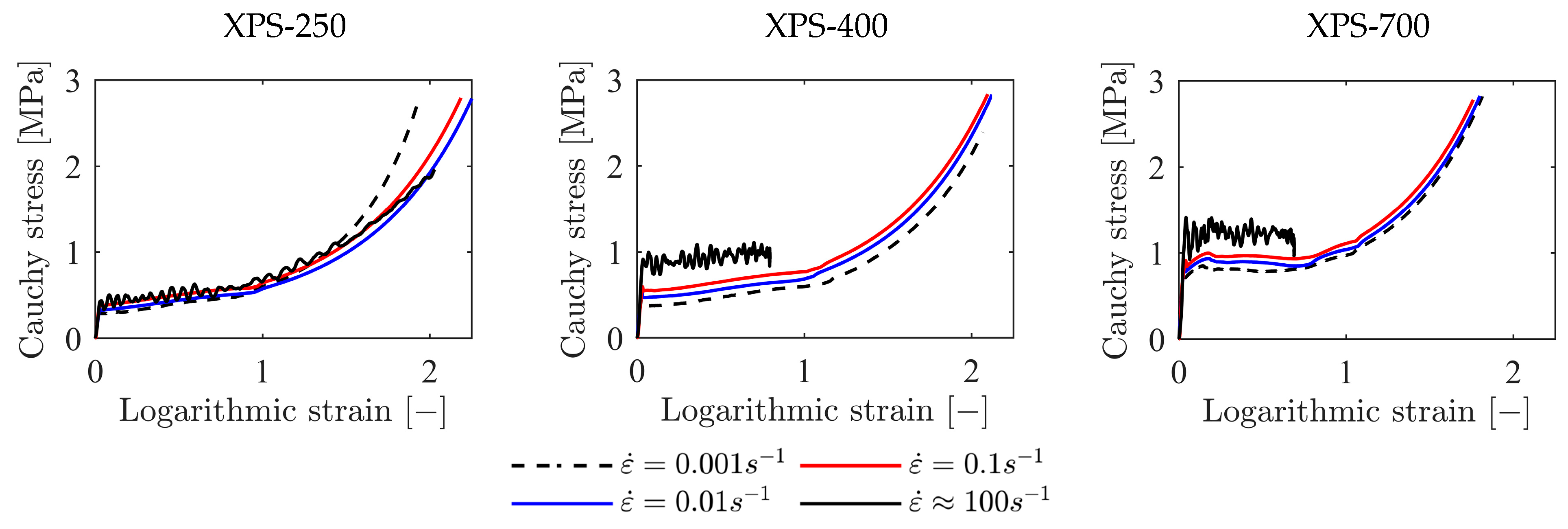

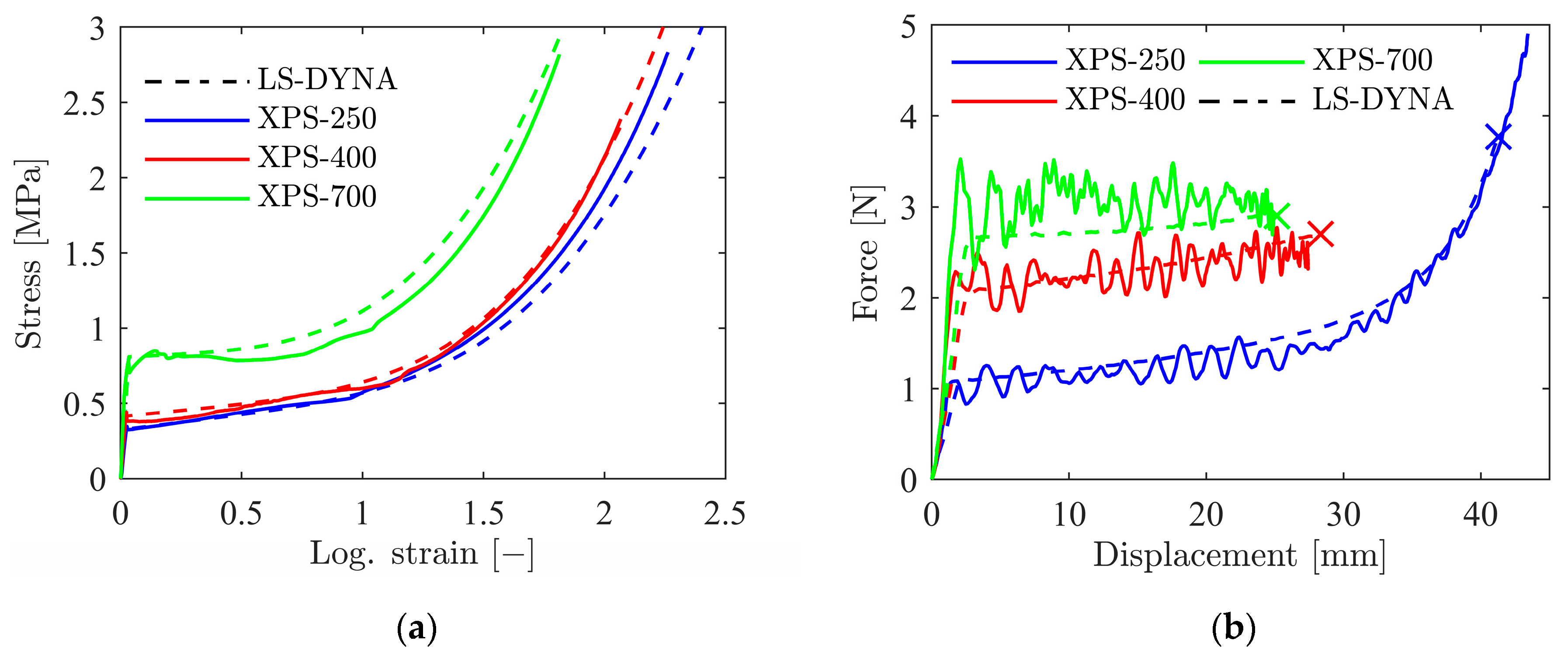

2.2.1. Uniaxial Compression Tests

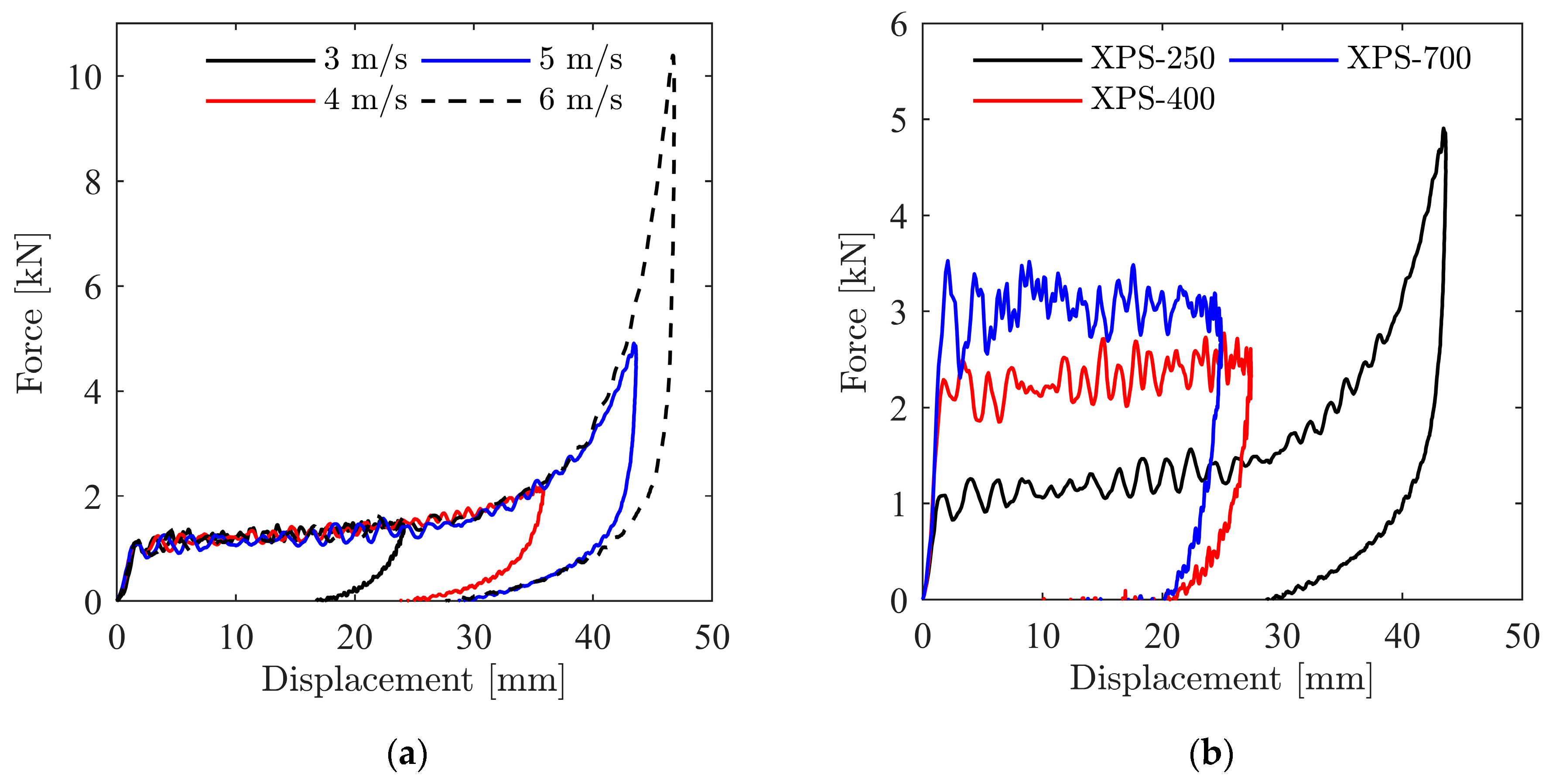

2.2.2. Low-Velocity Impact Tests

3. Component Tests

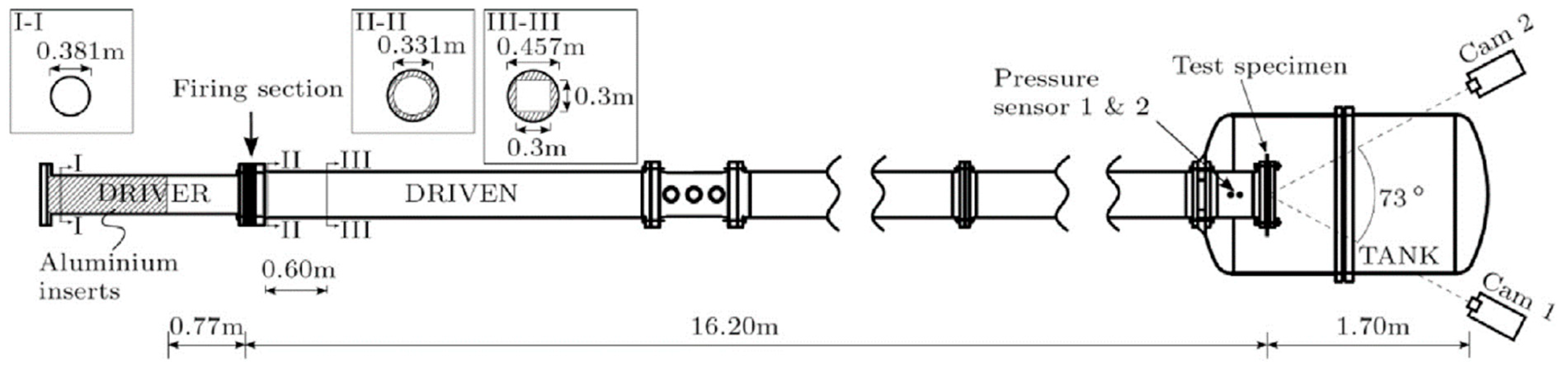

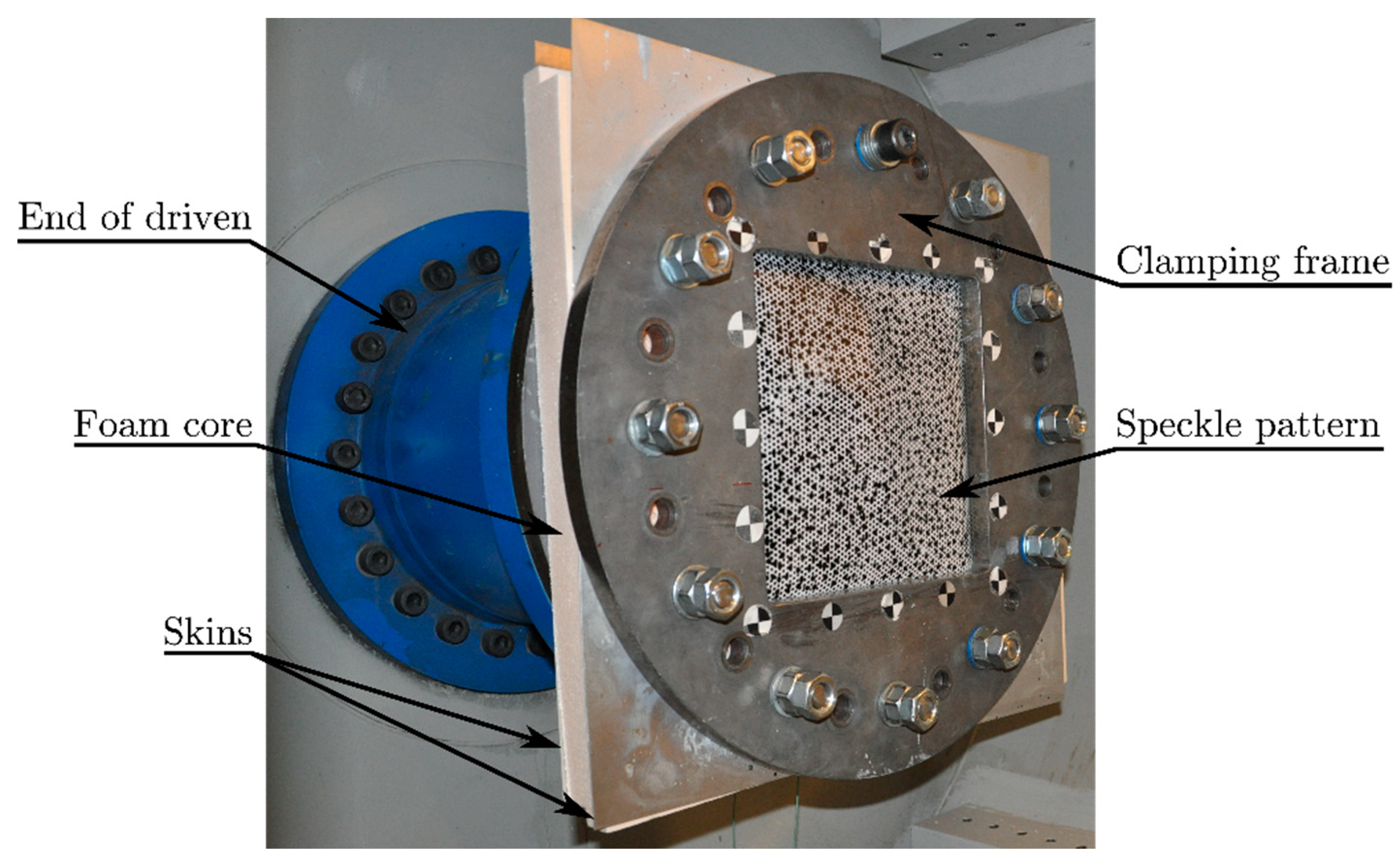

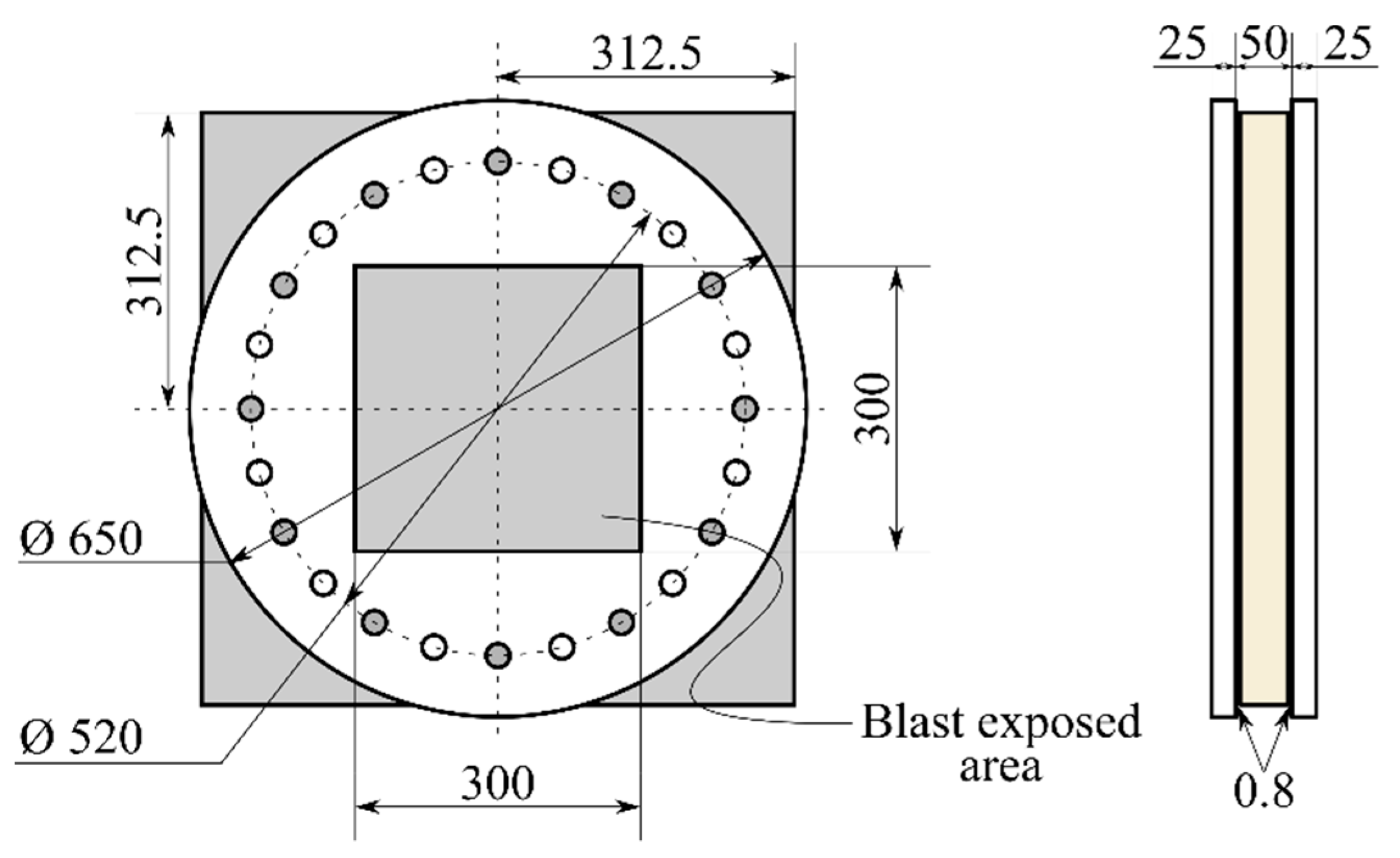

3.1. Experimental Setup

3.2. Blast Test Programme

3.3. Experimental Results

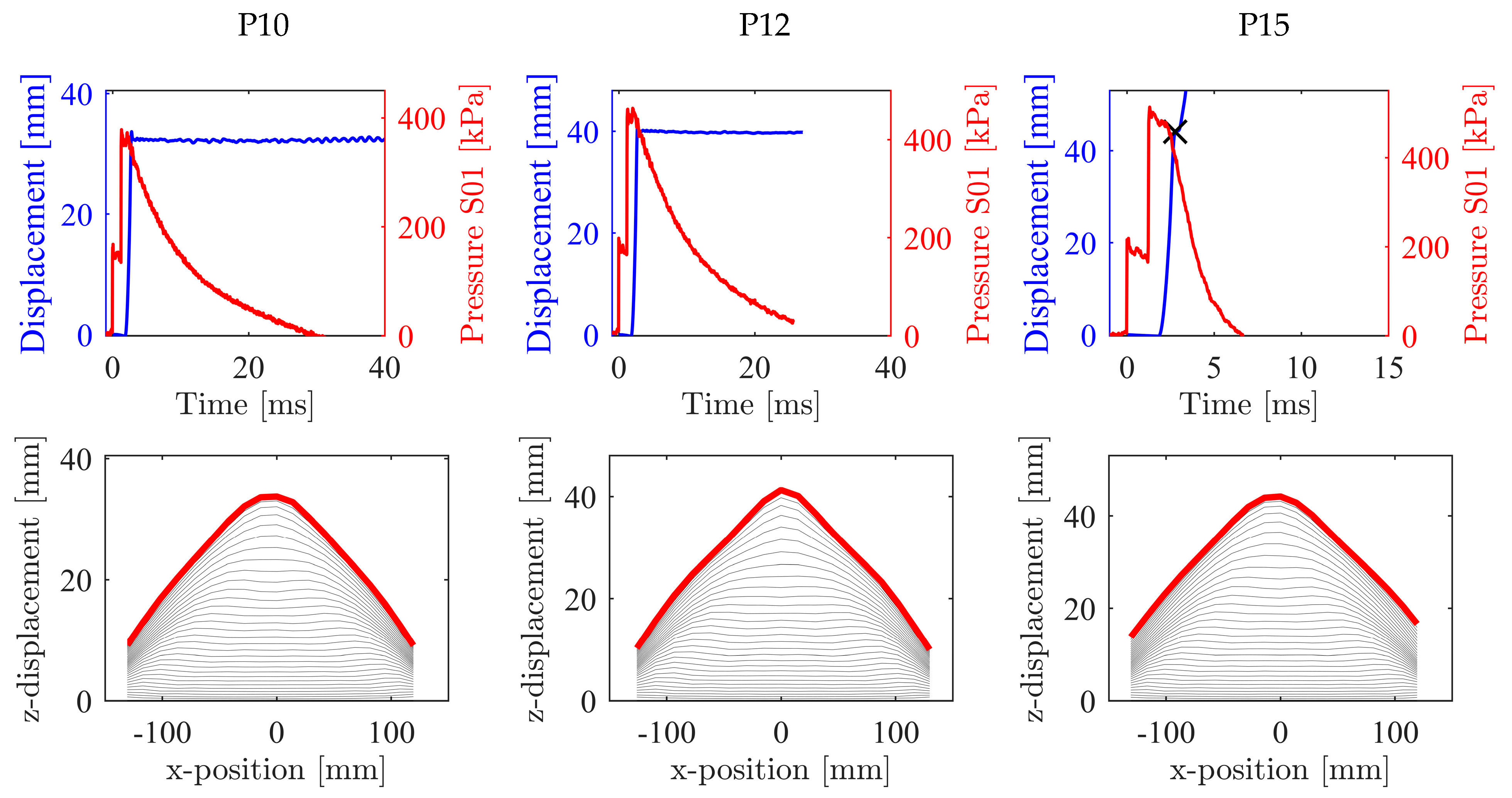

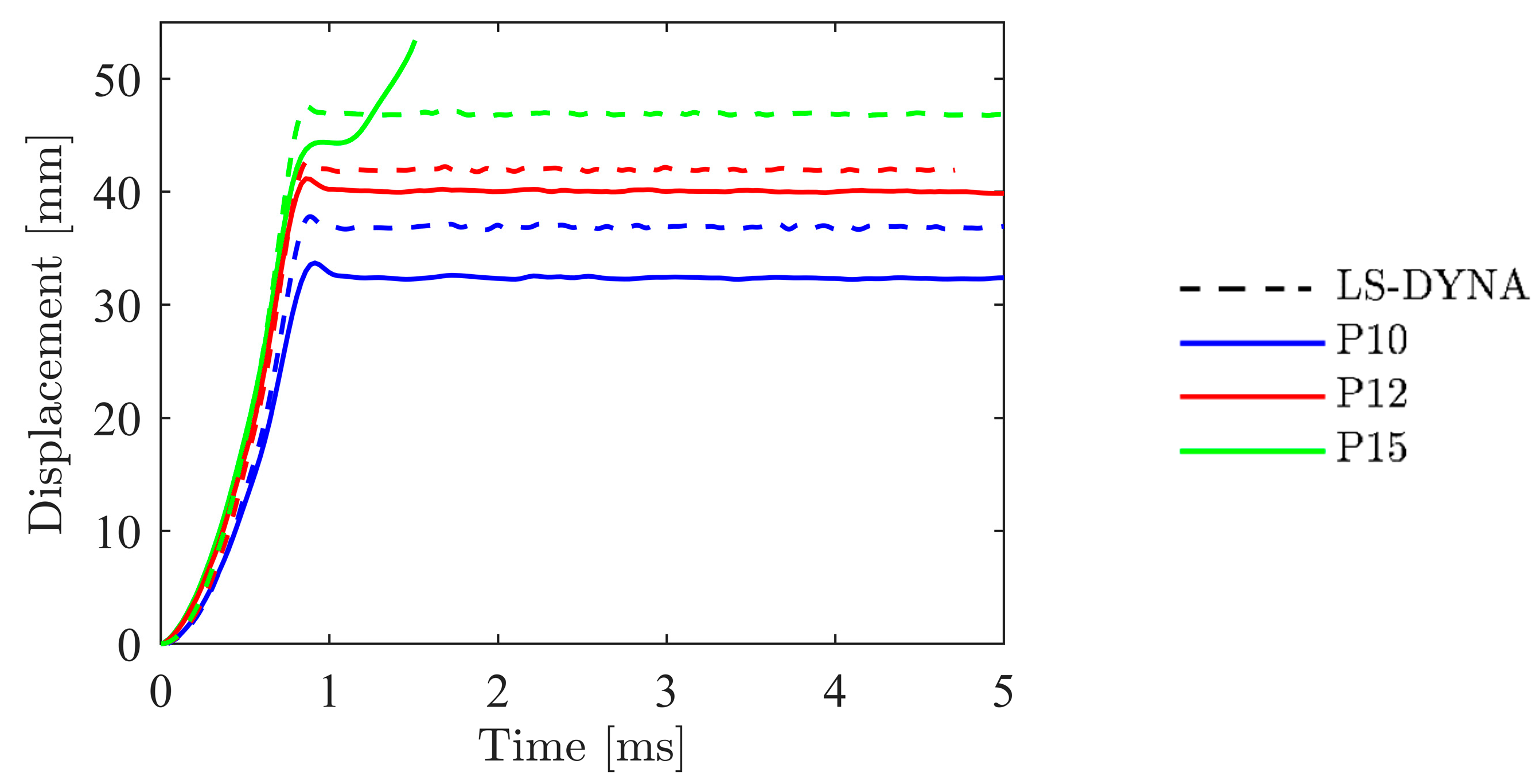

3.3.1. Aluminium Skins

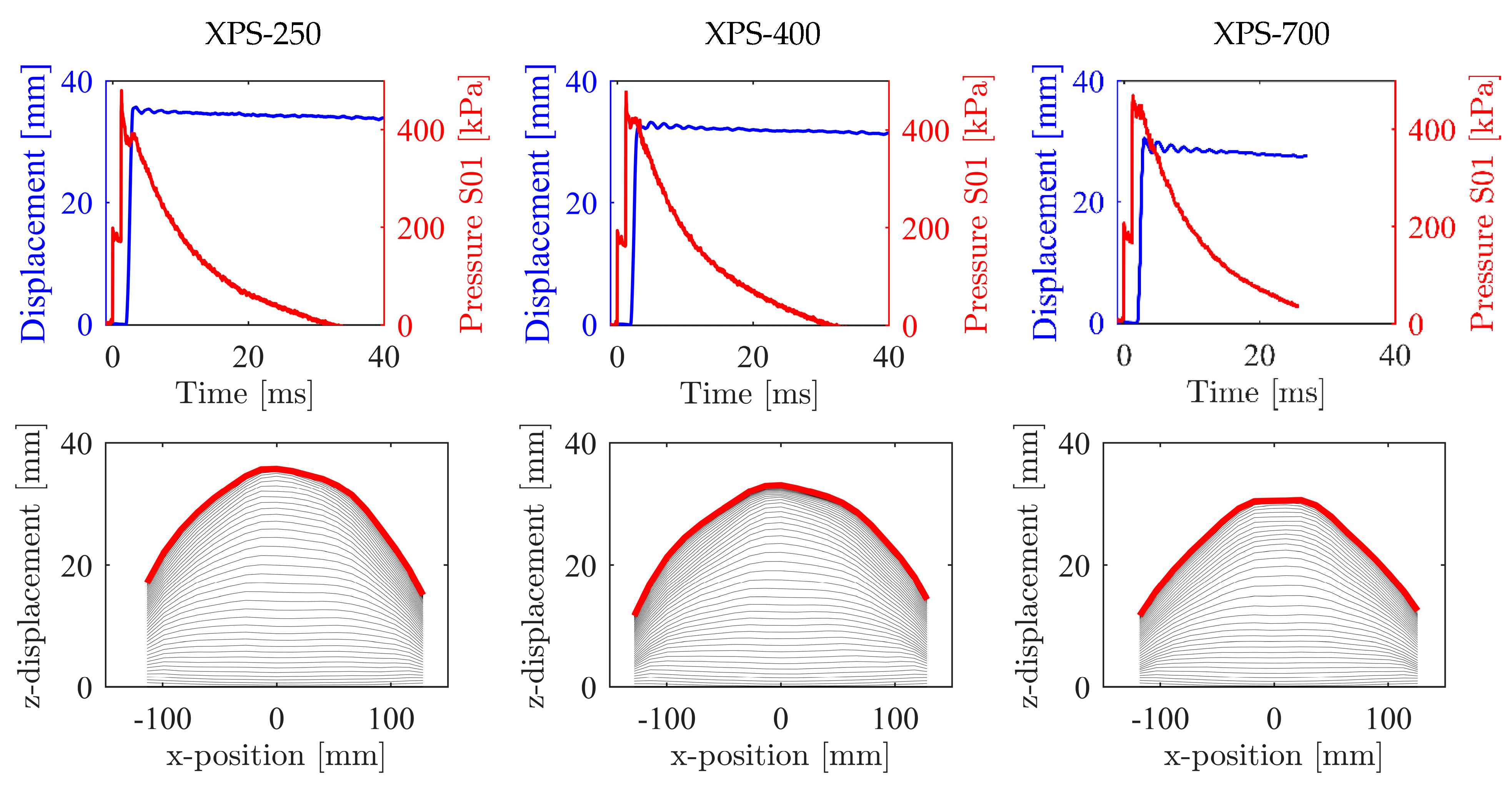

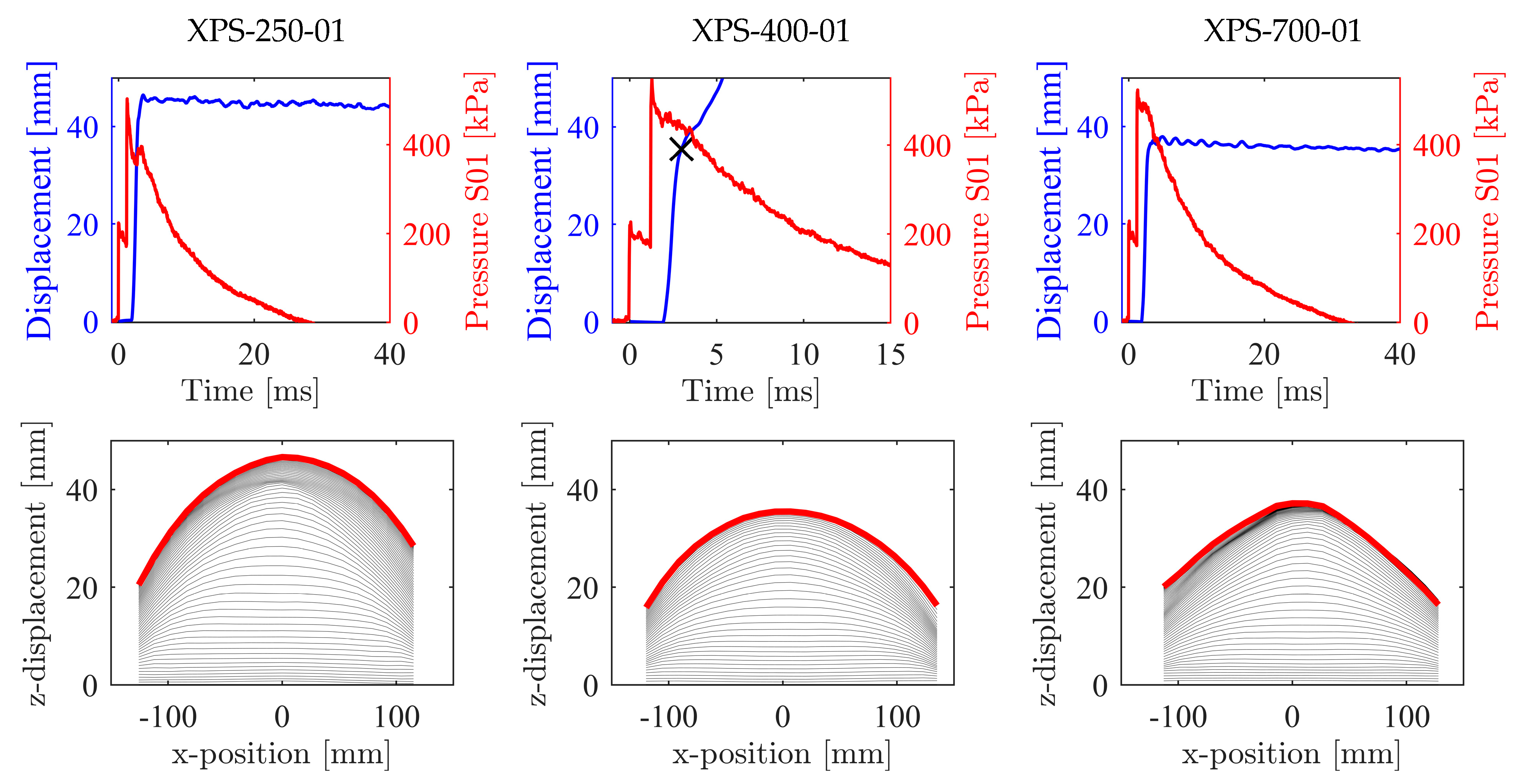

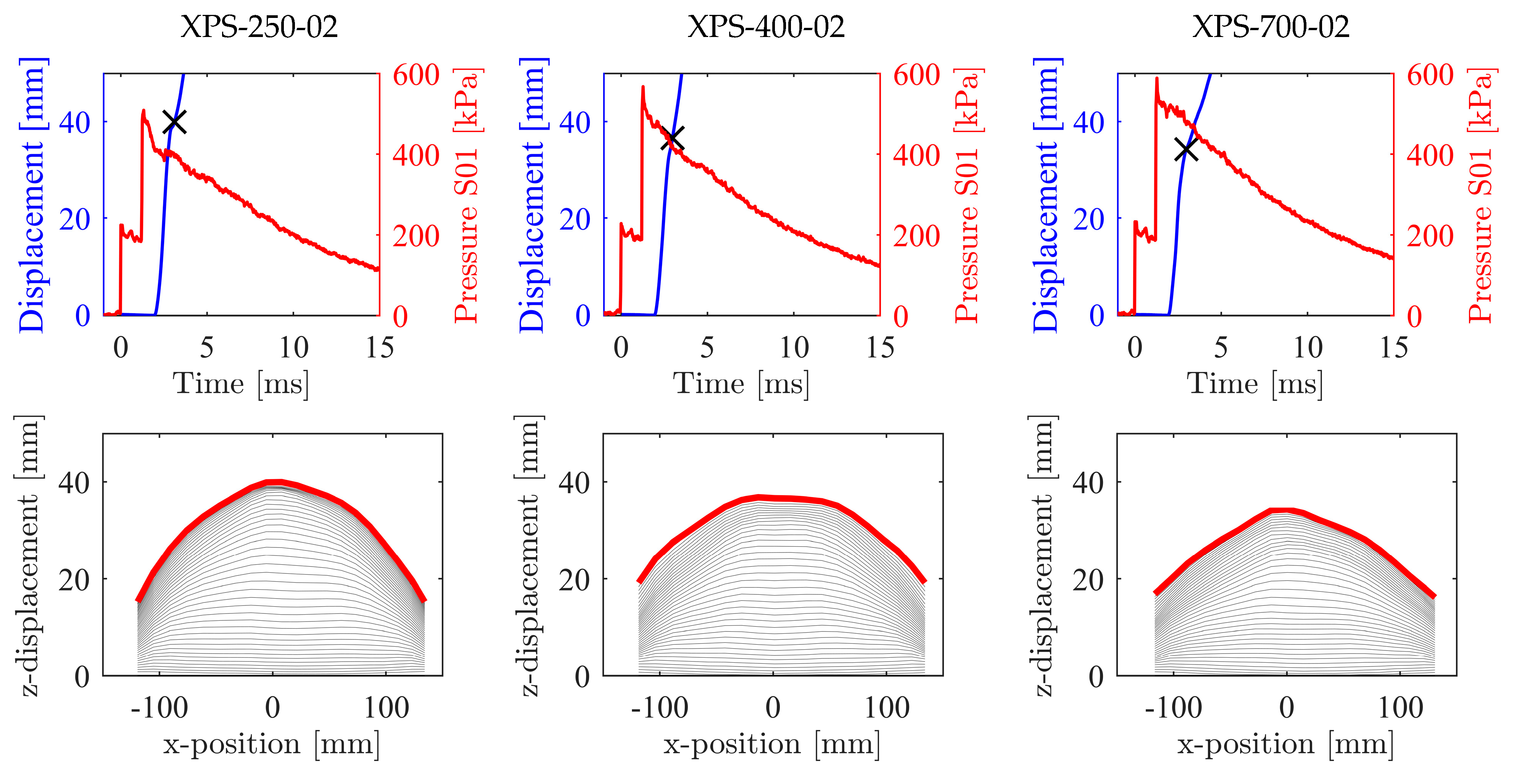

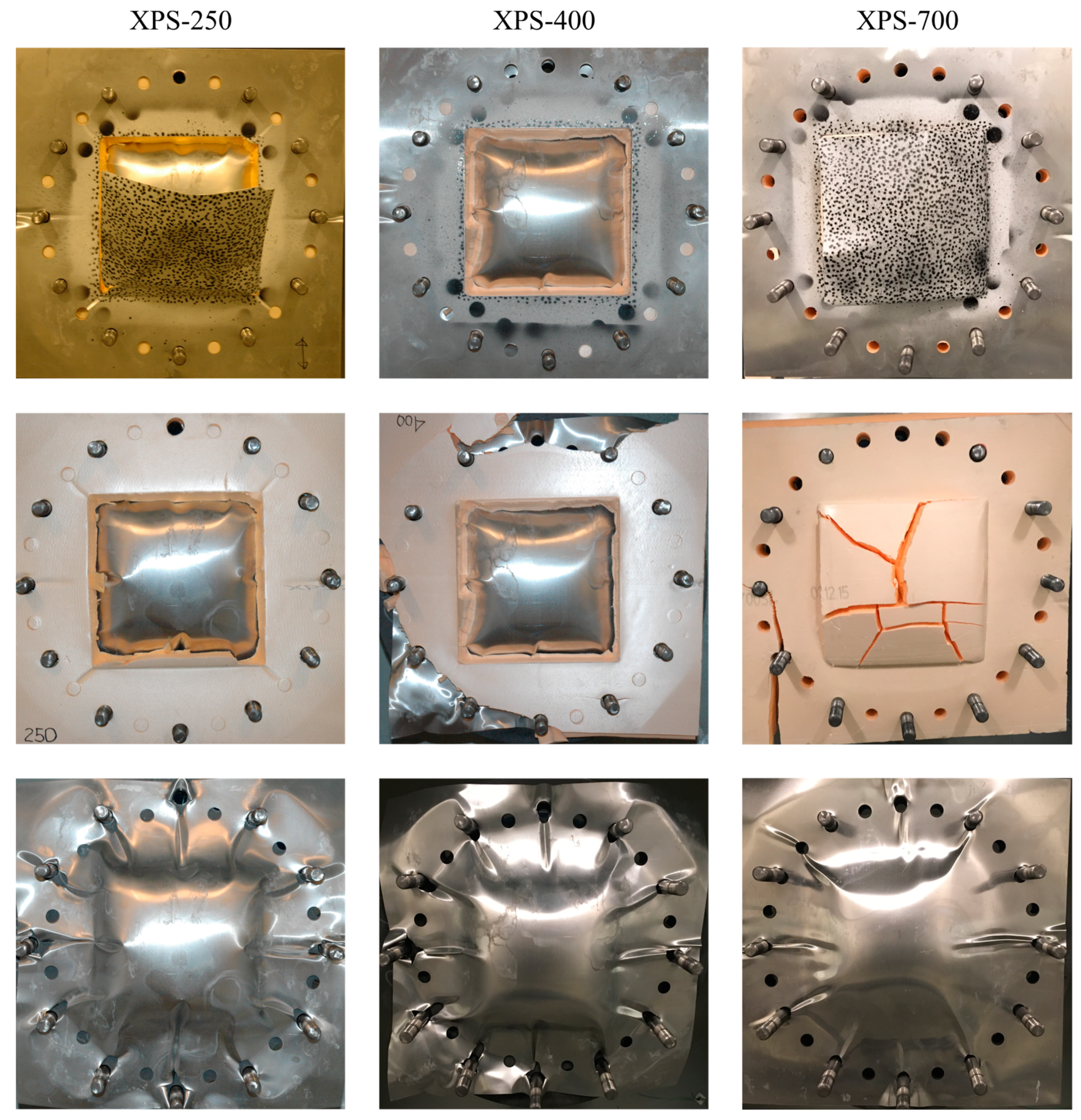

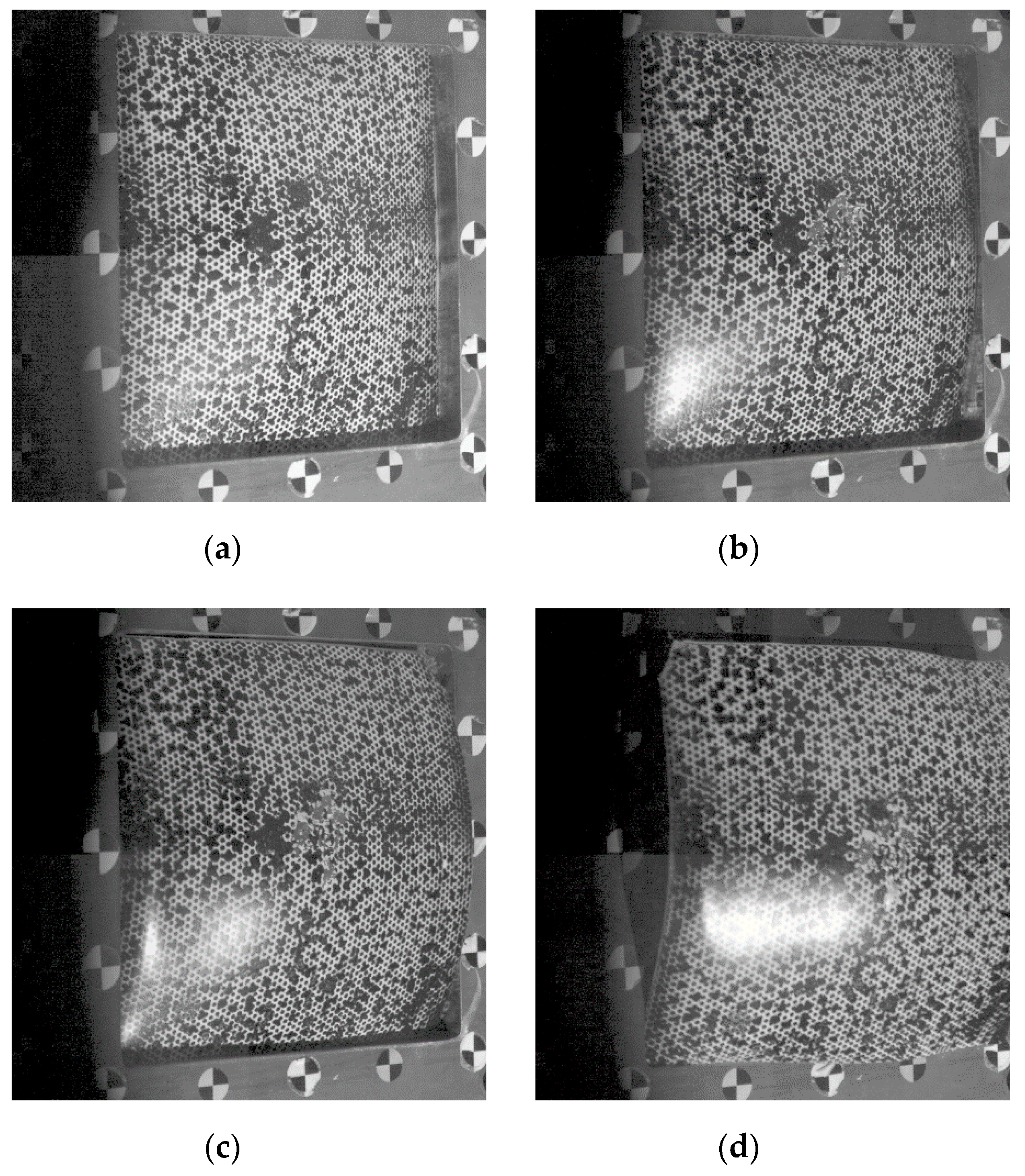

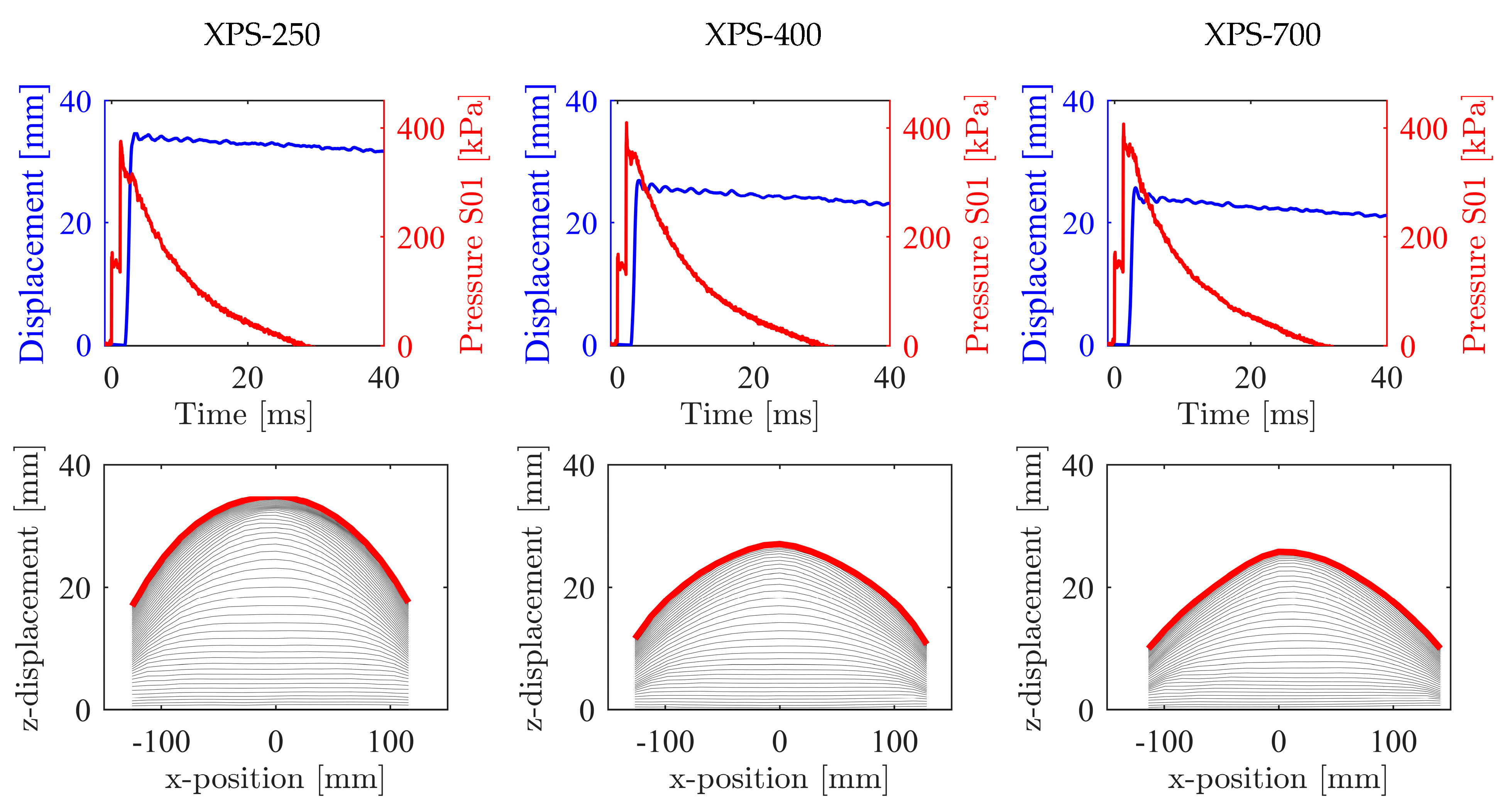

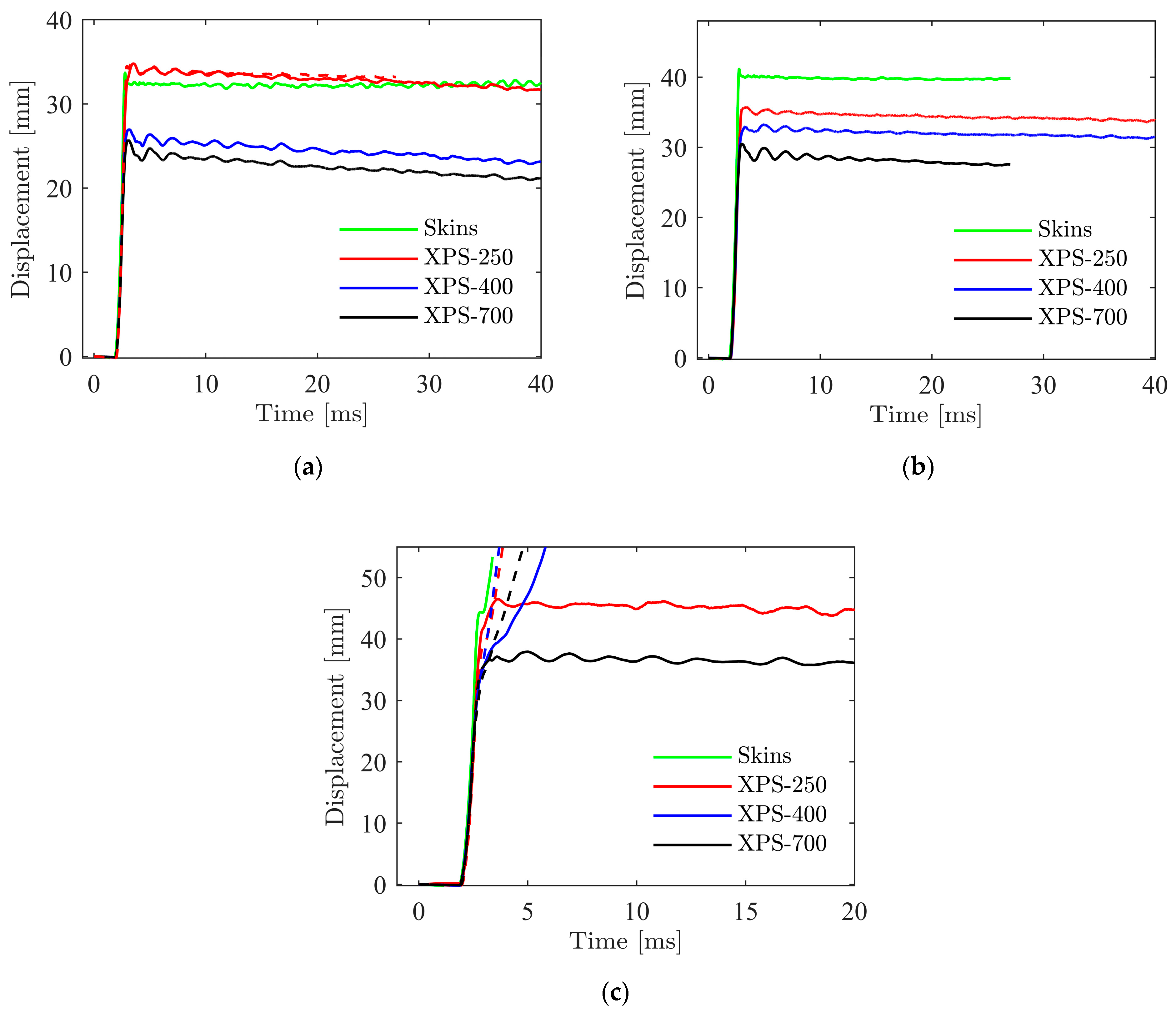

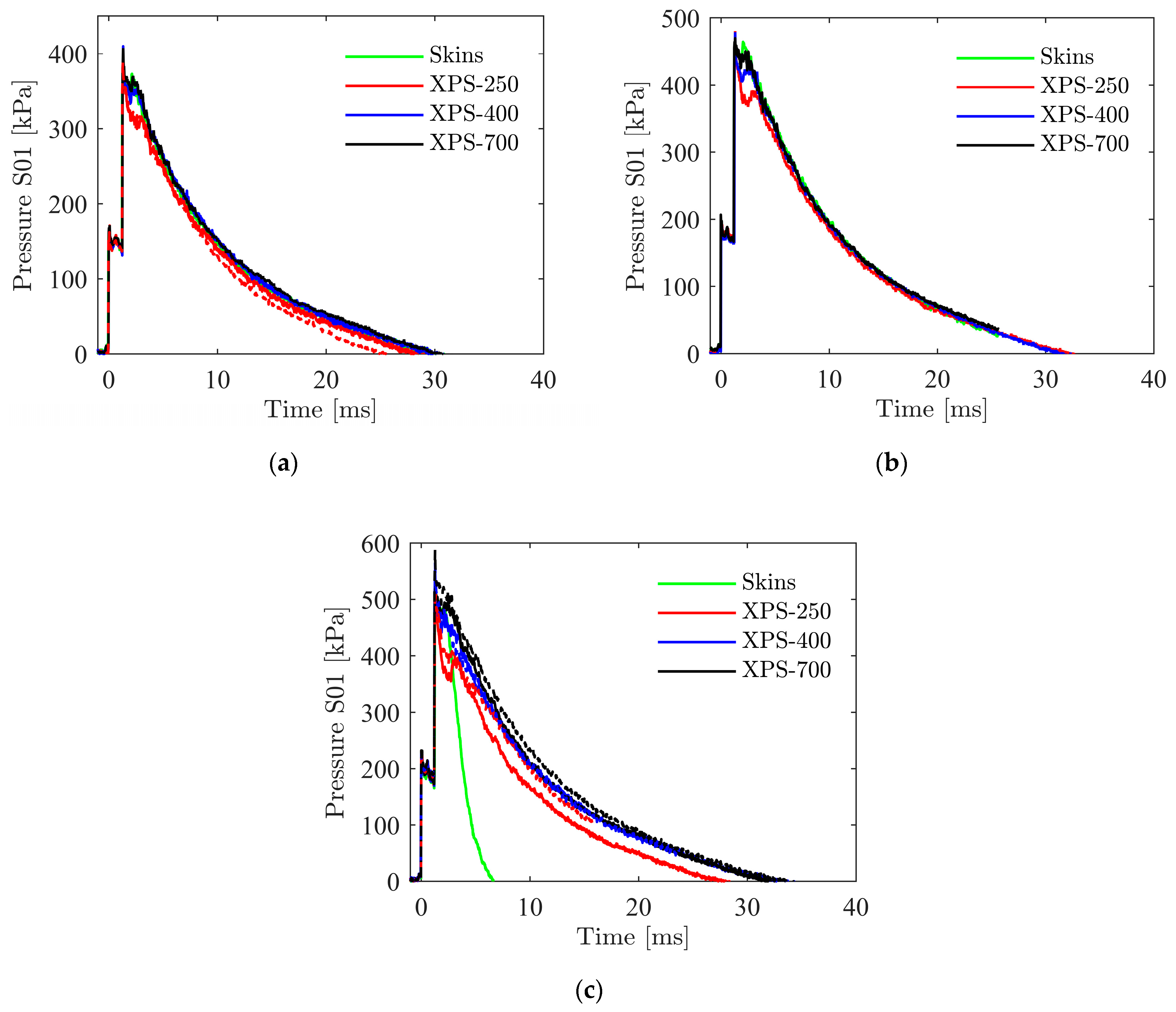

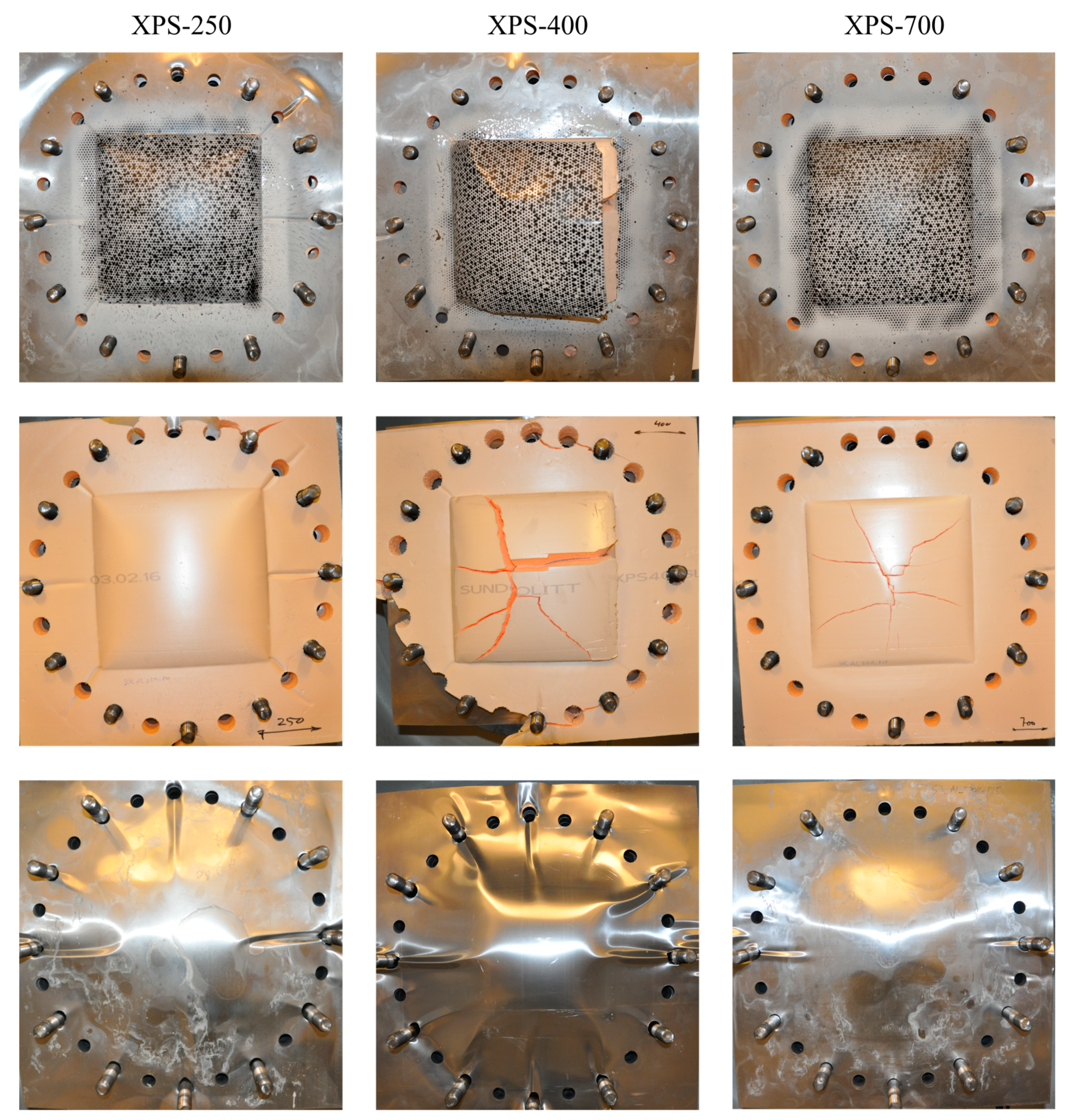

3.3.2. Sandwich Panels

4. Numerical Work

4.1. Constitutive Relations

4.2. Material Calibration

4.2.1. Aluminium Skins

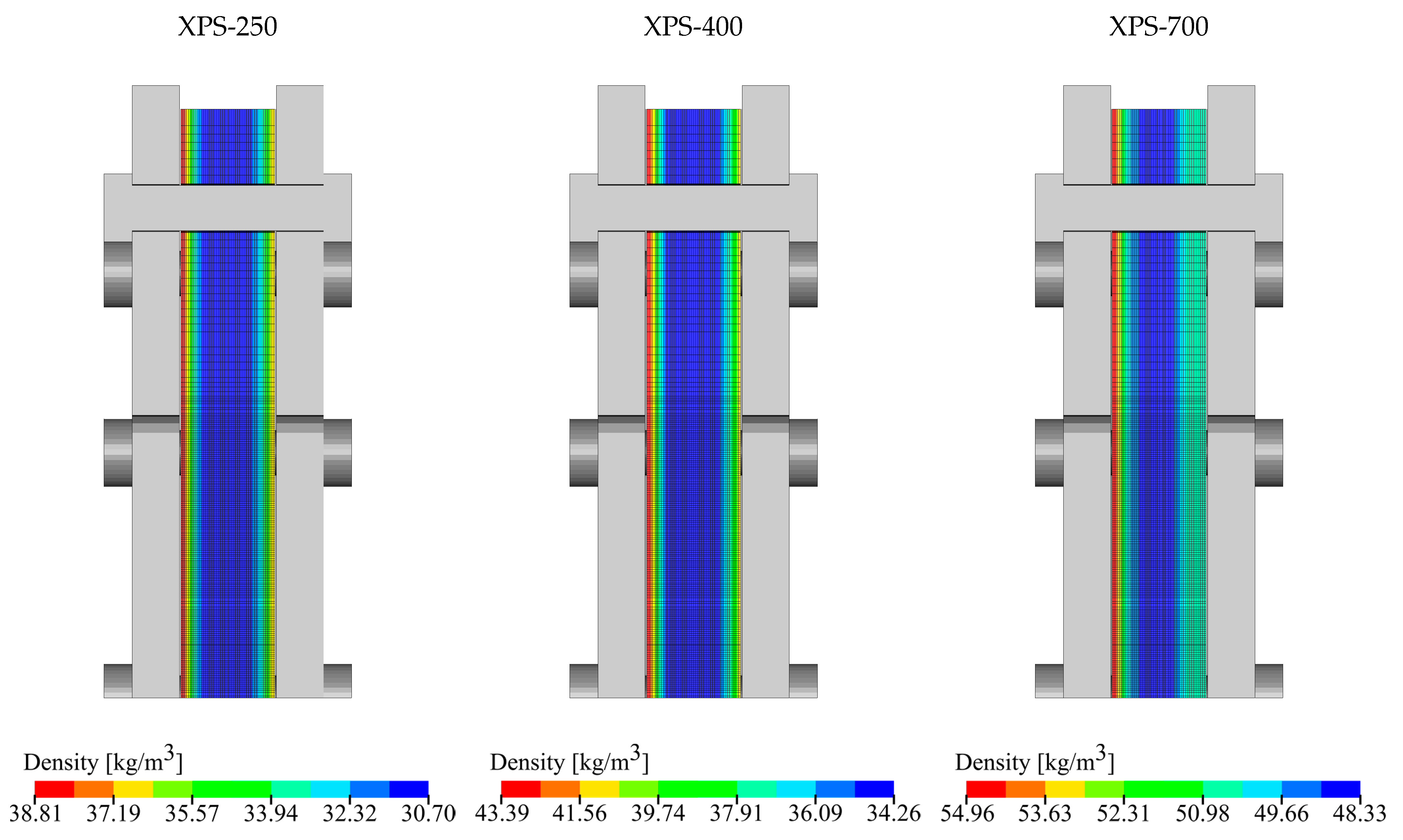

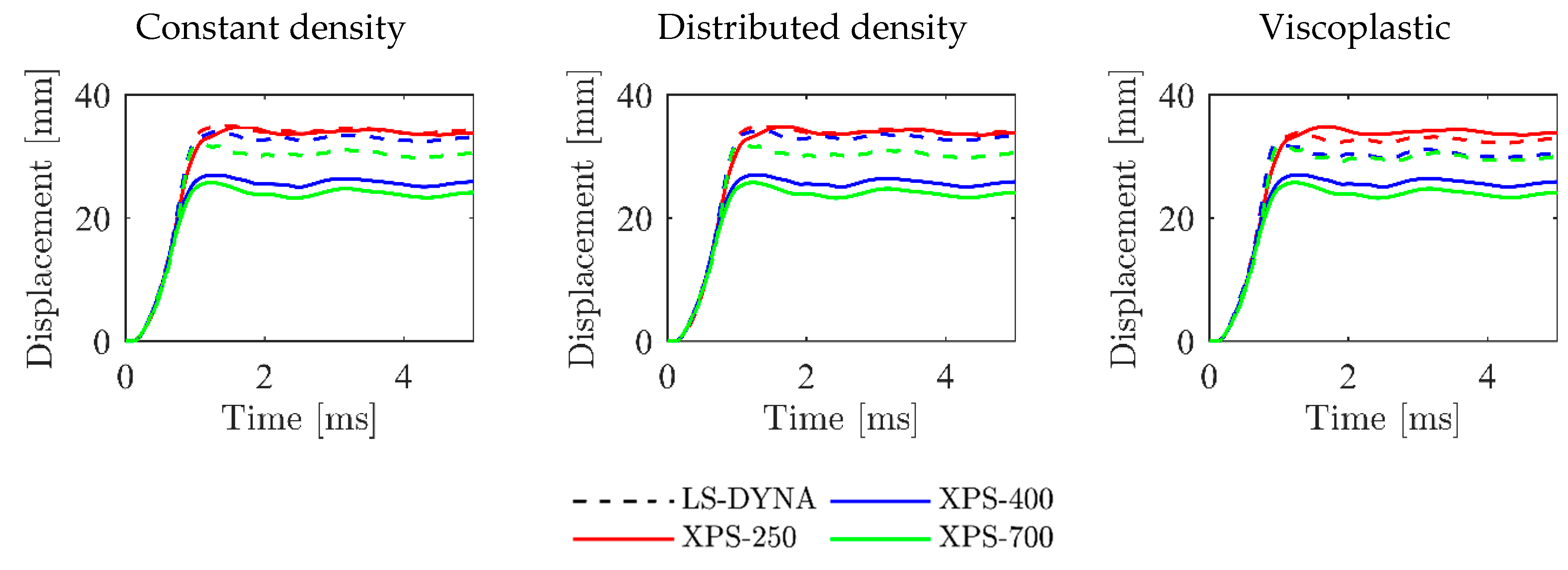

4.2.2. Foam Cores

4.3. Shock Tube Tests

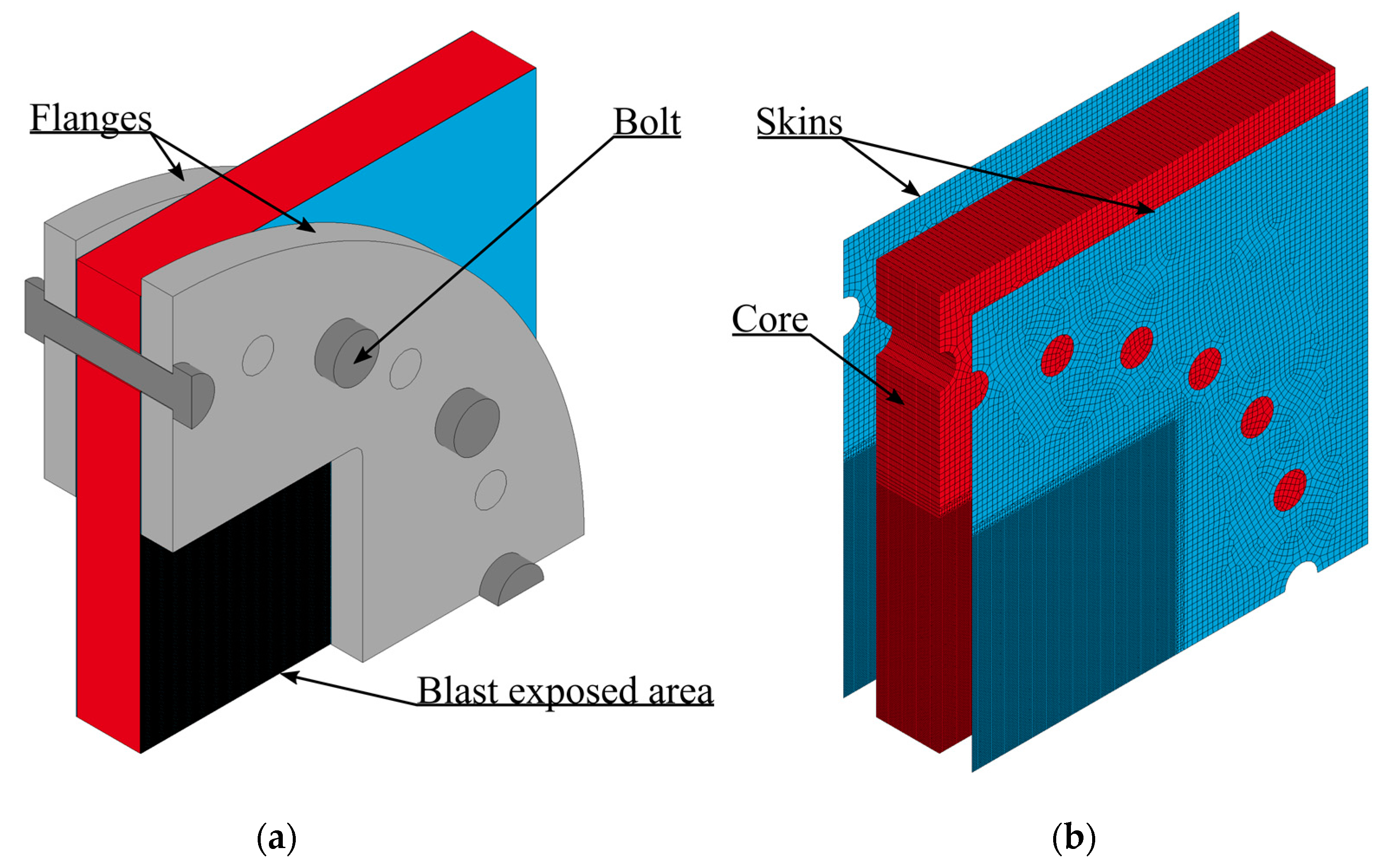

4.3.1. Numerical Model

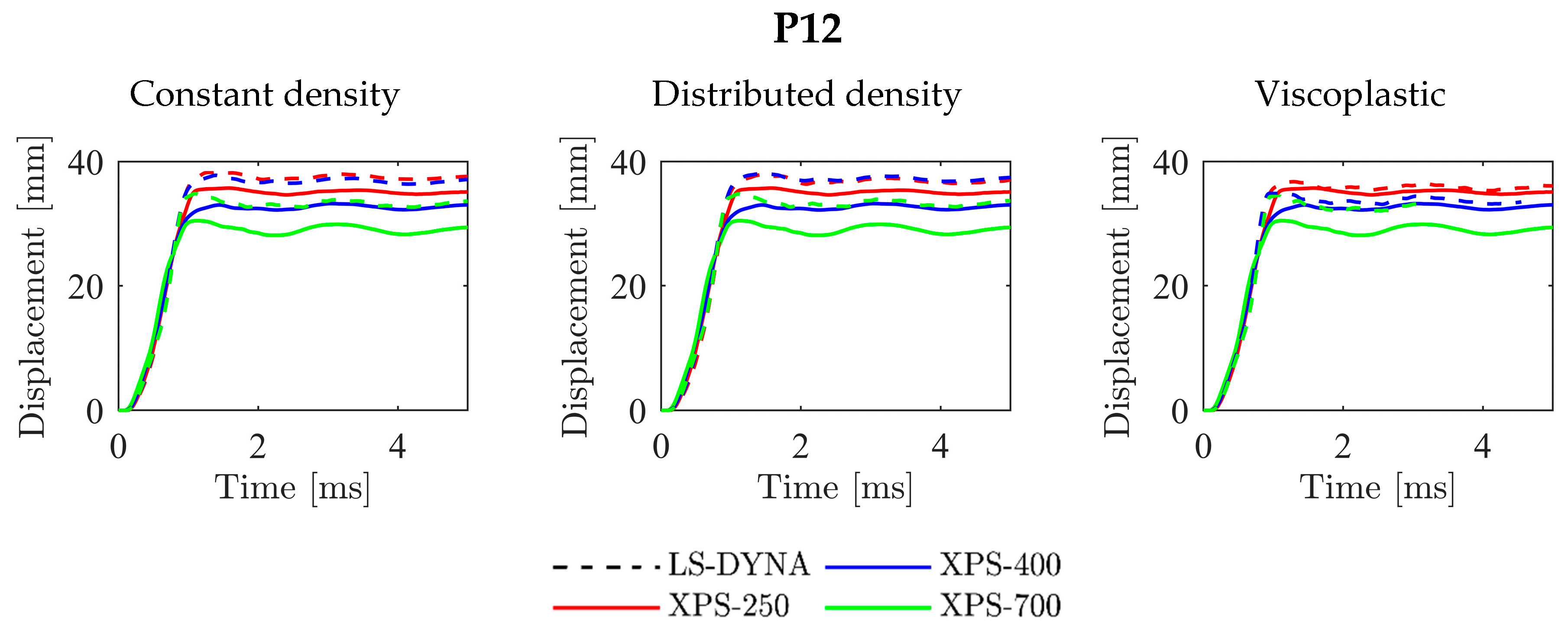

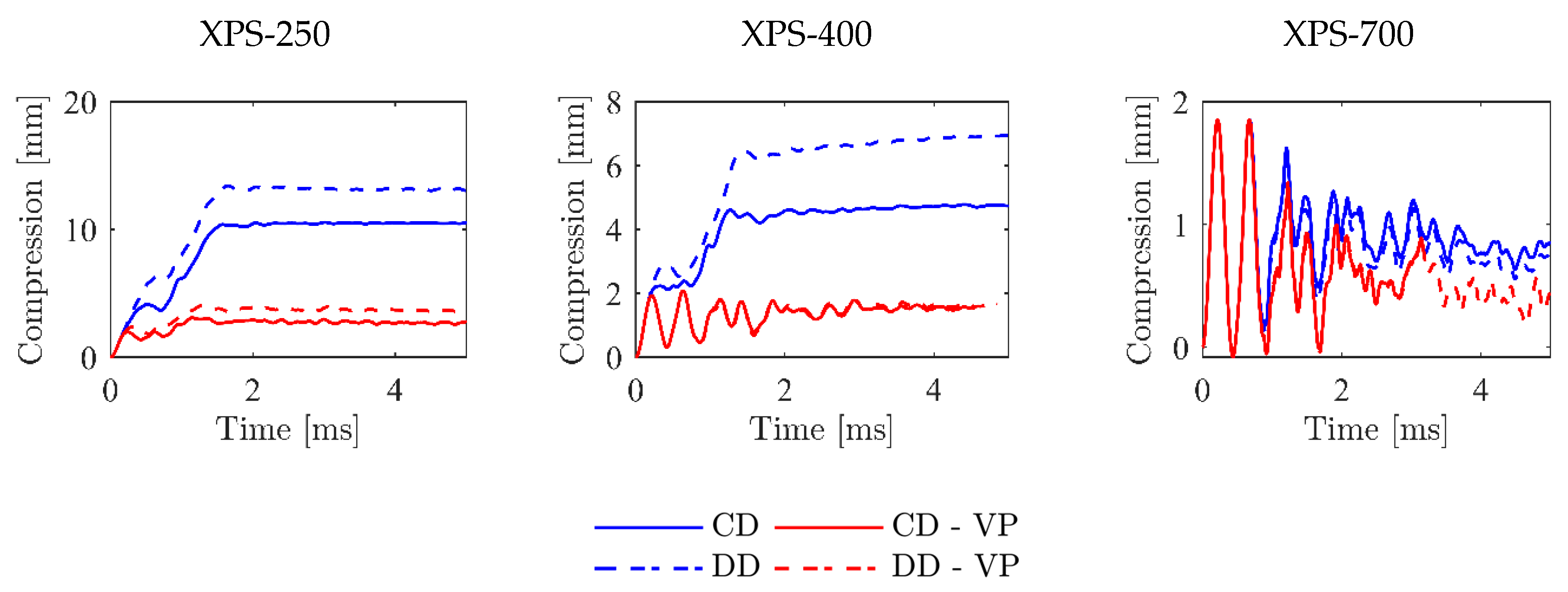

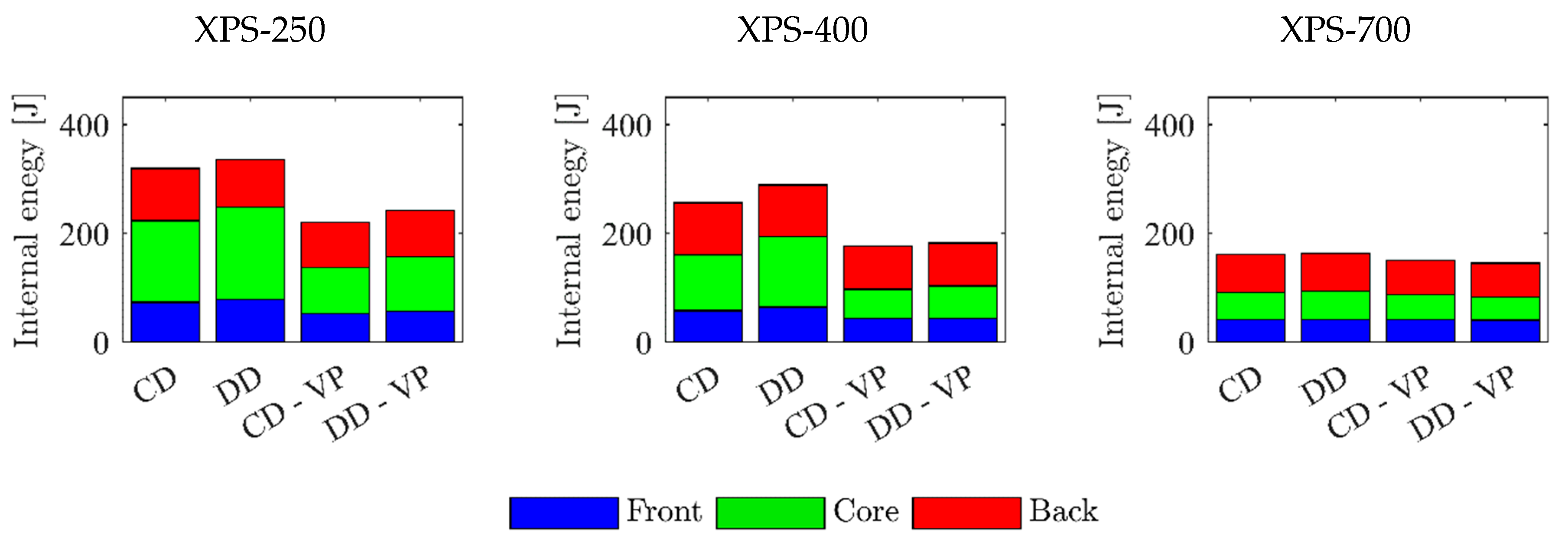

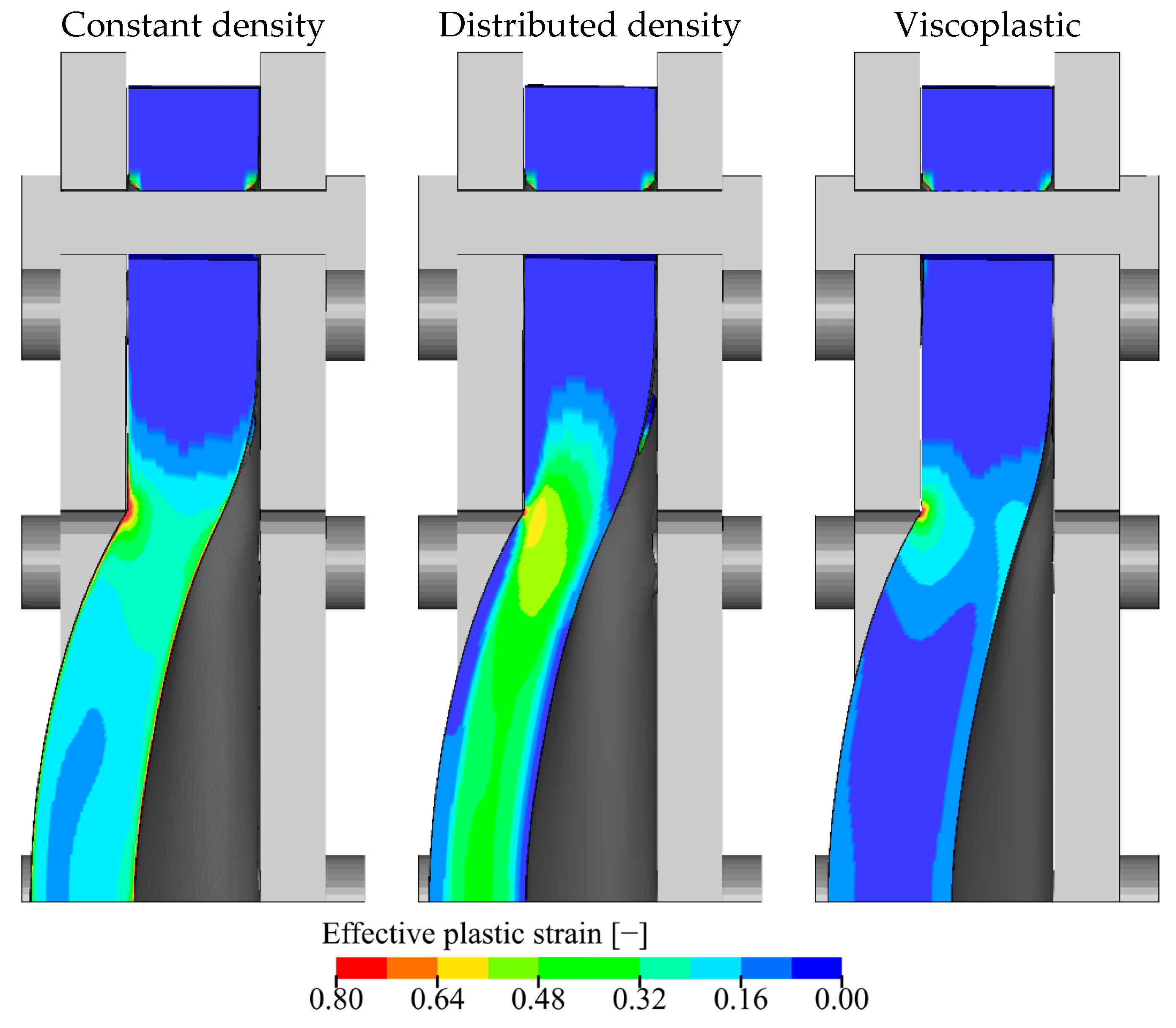

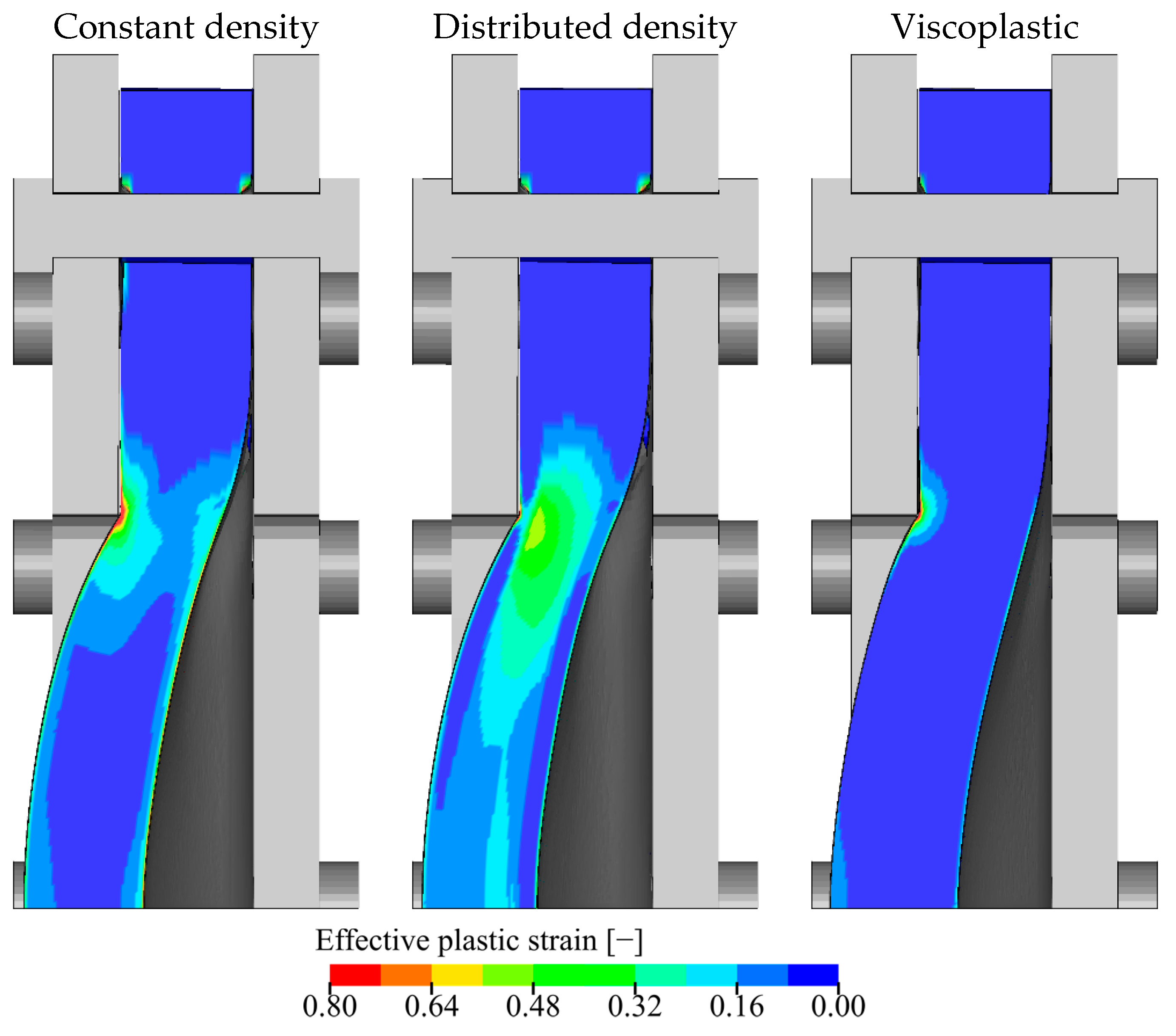

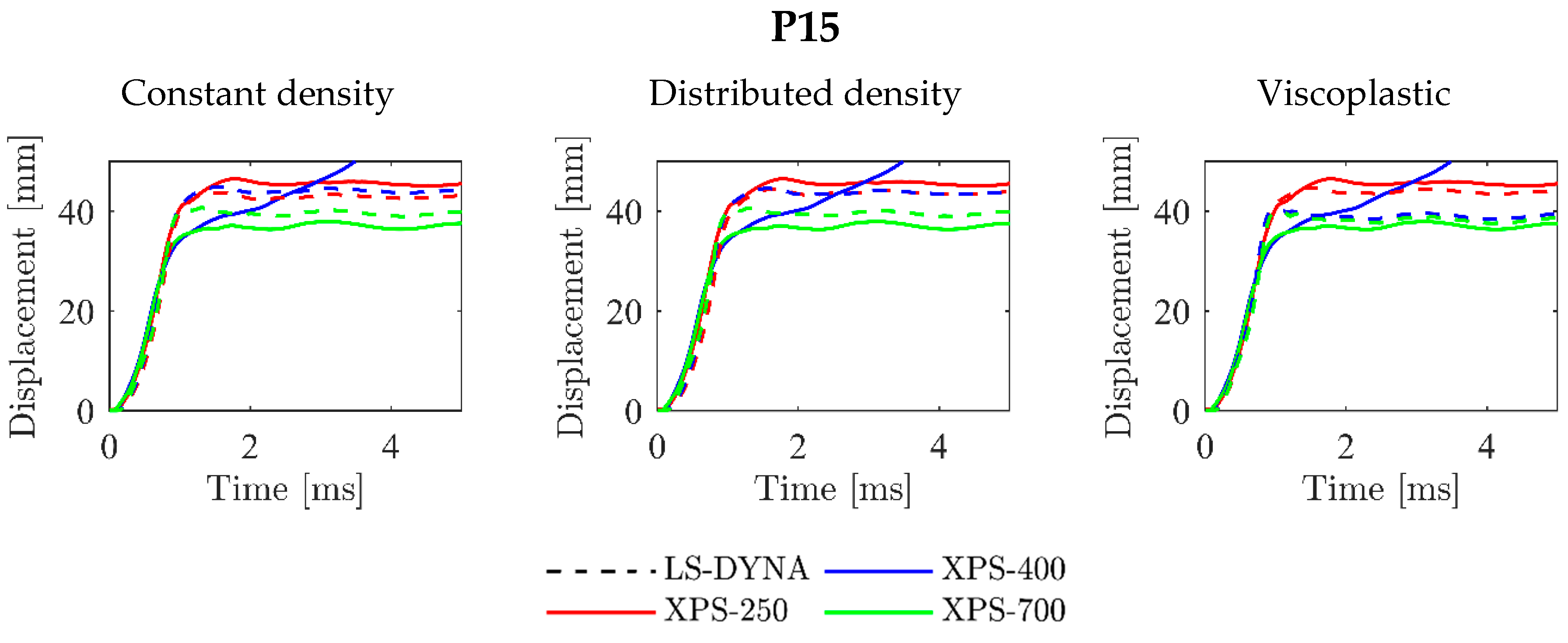

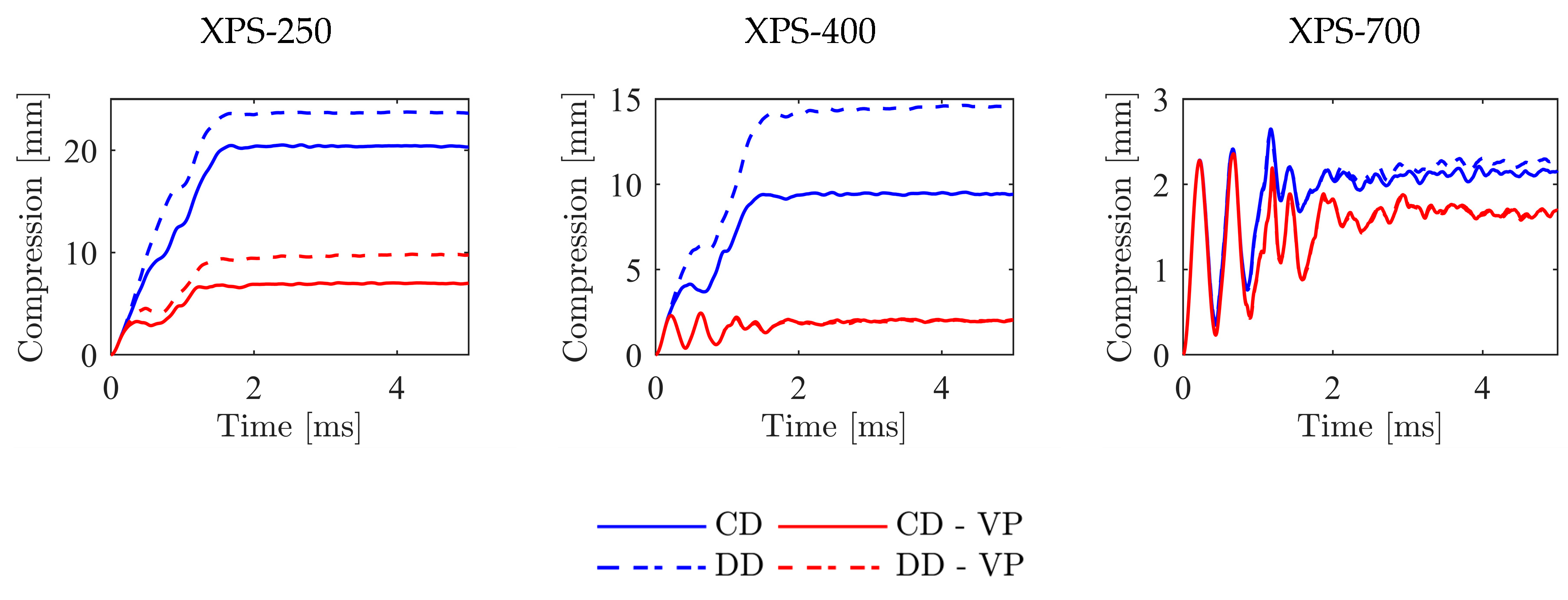

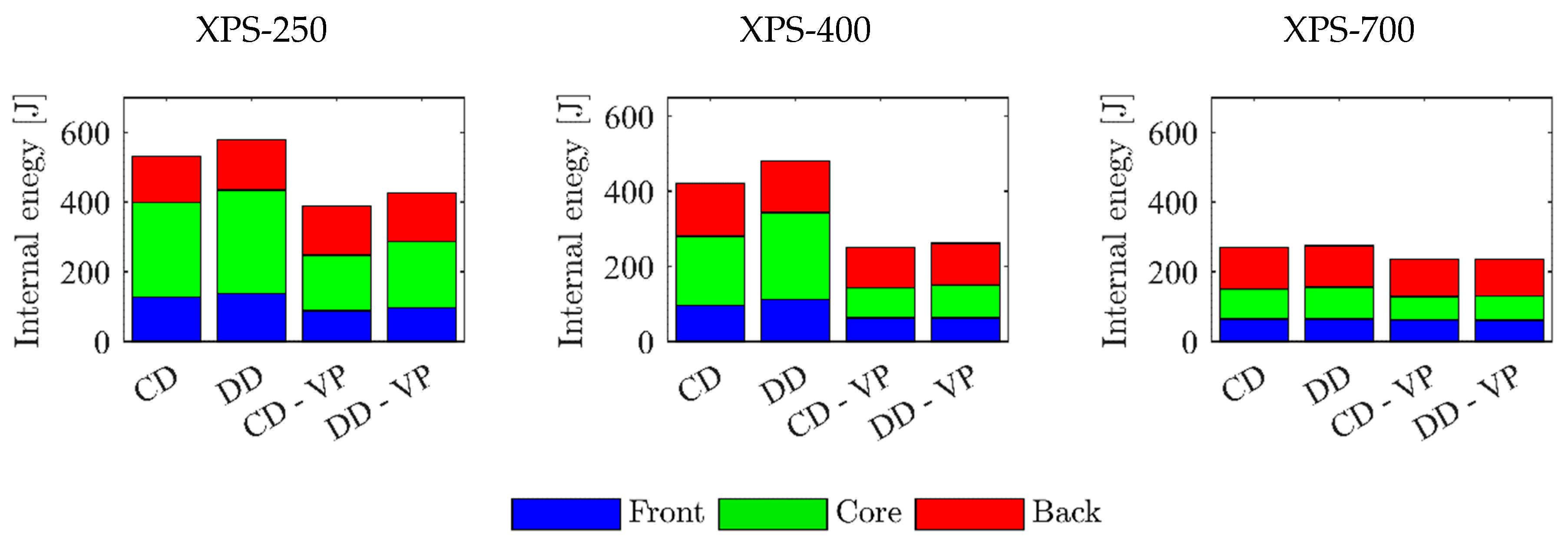

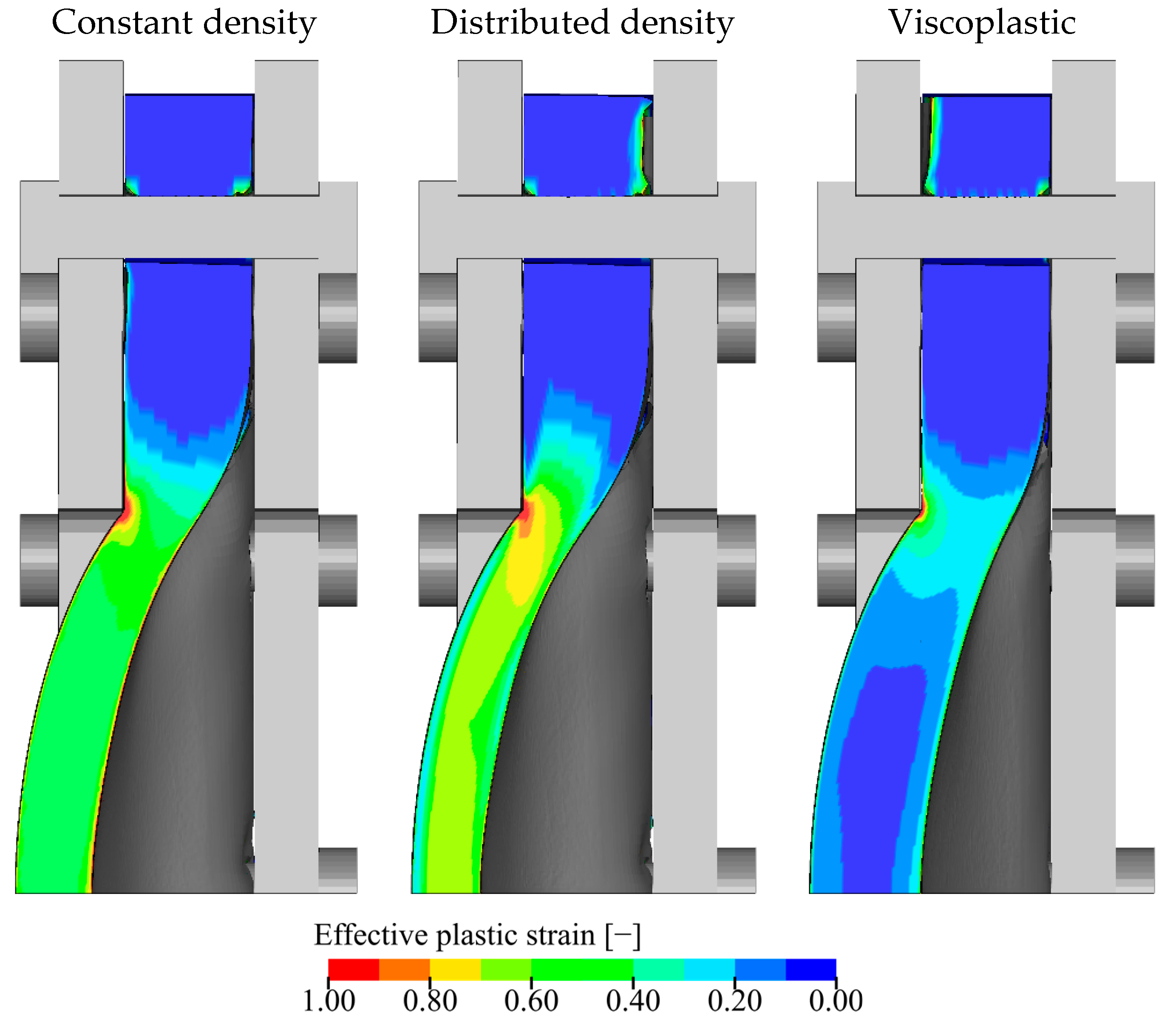

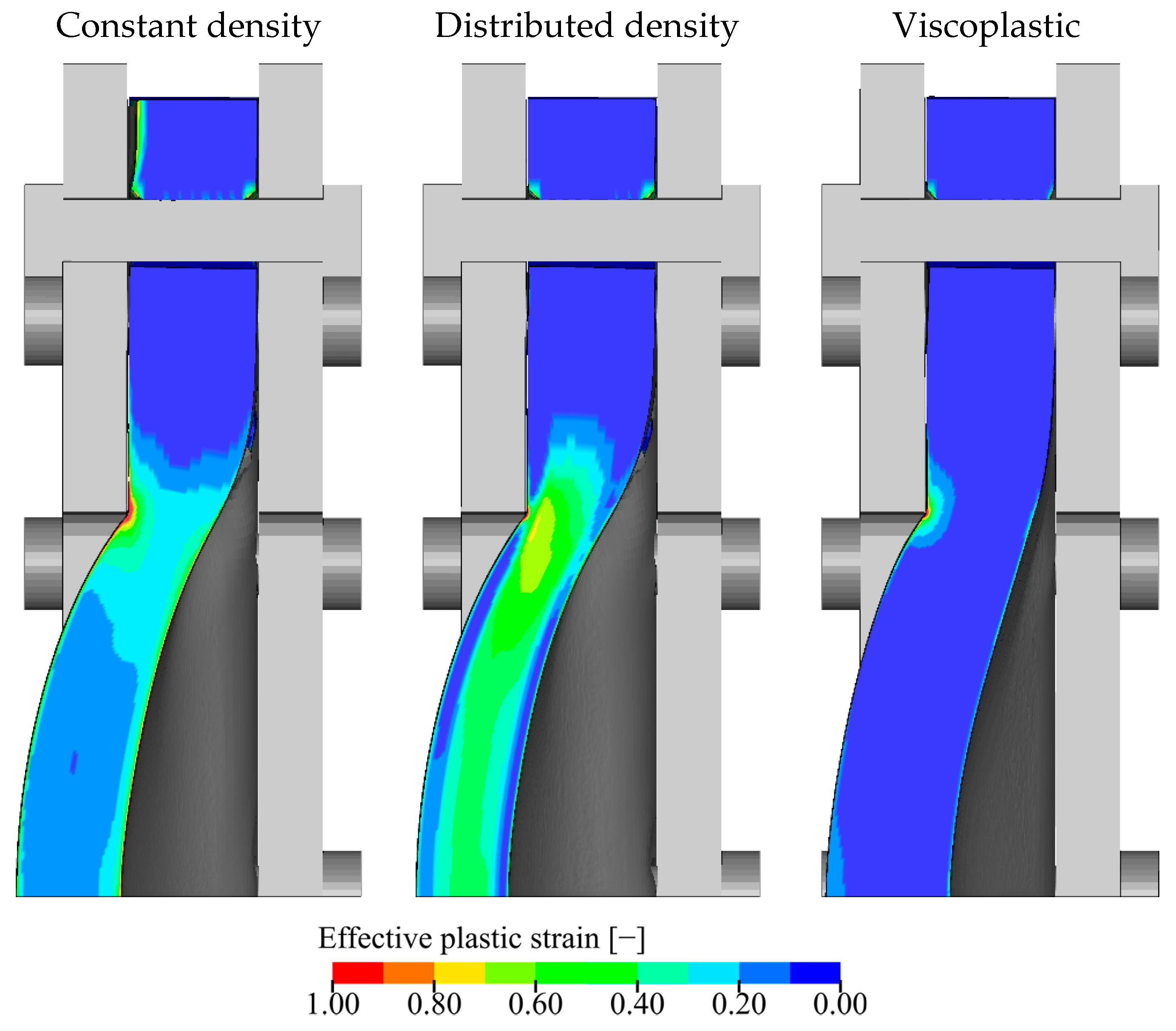

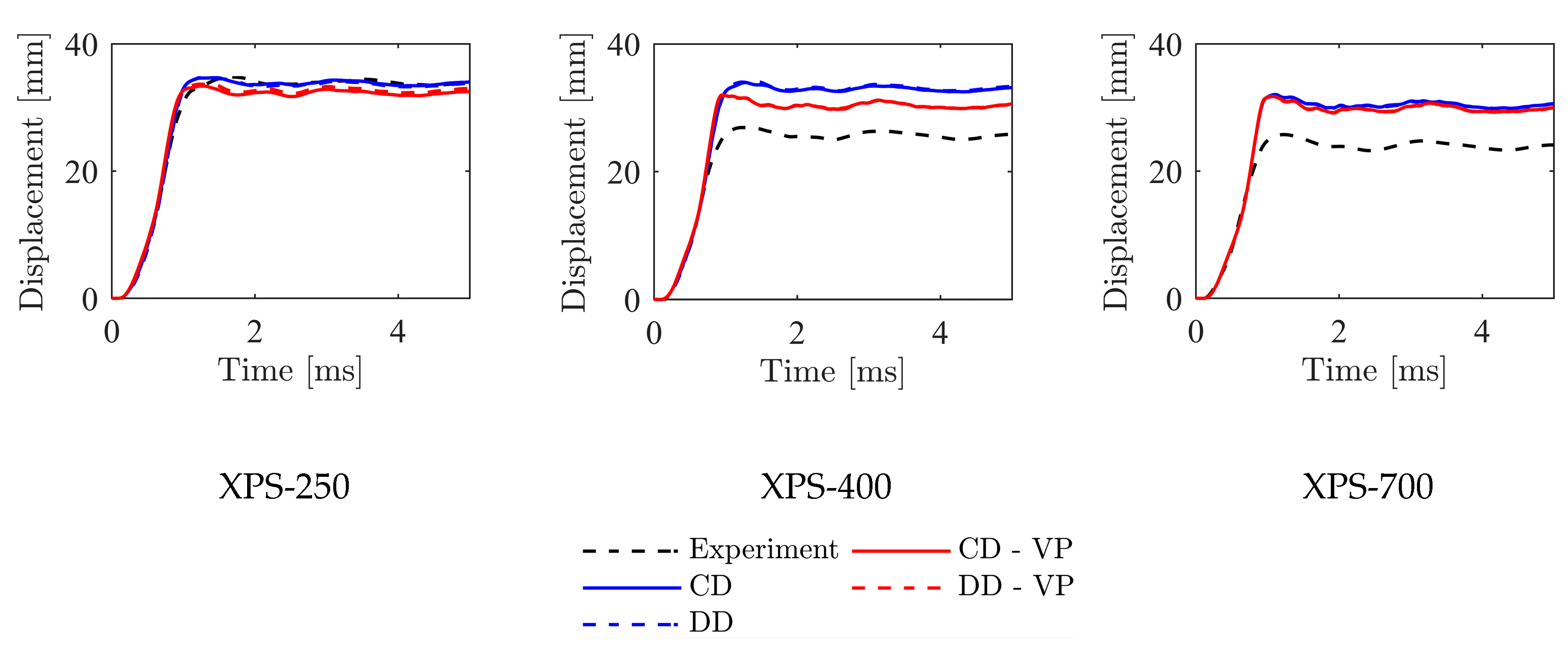

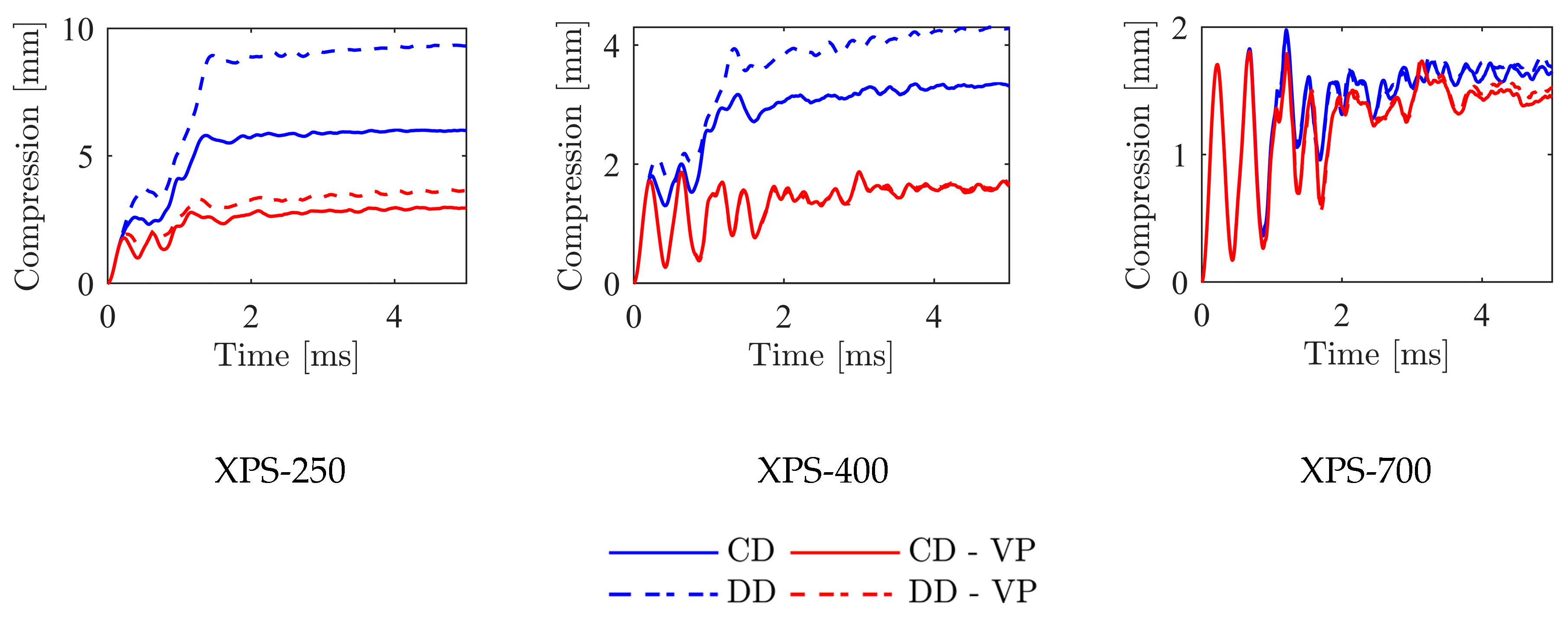

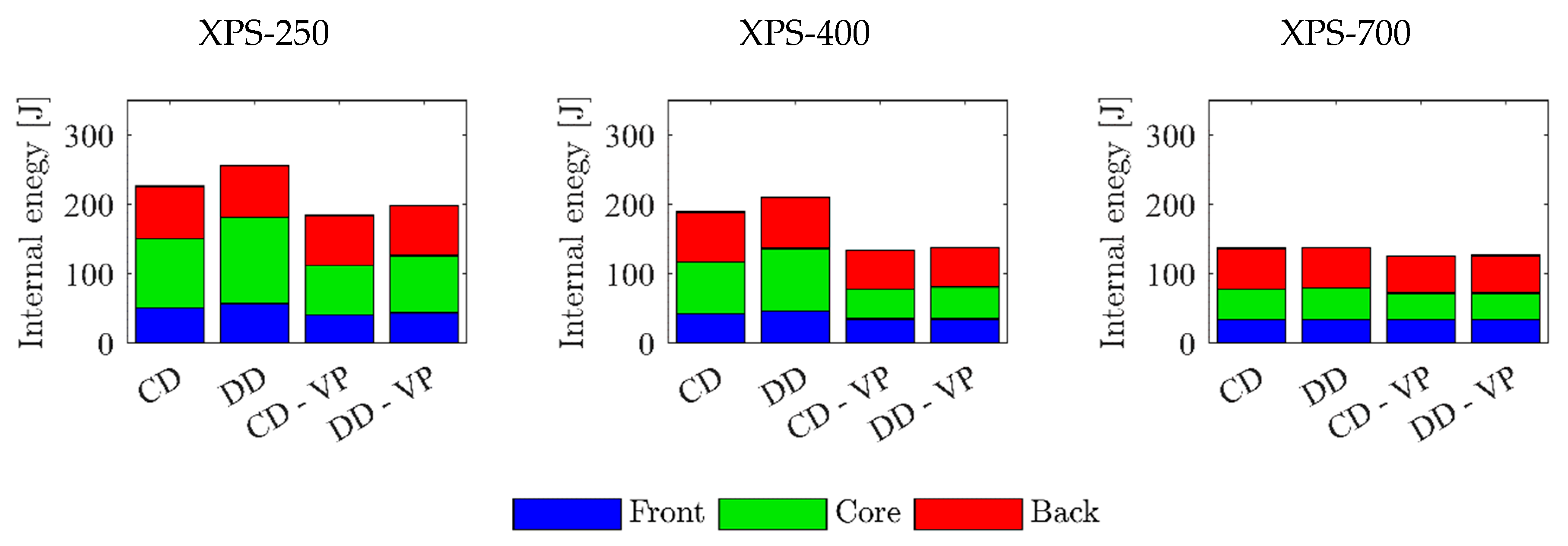

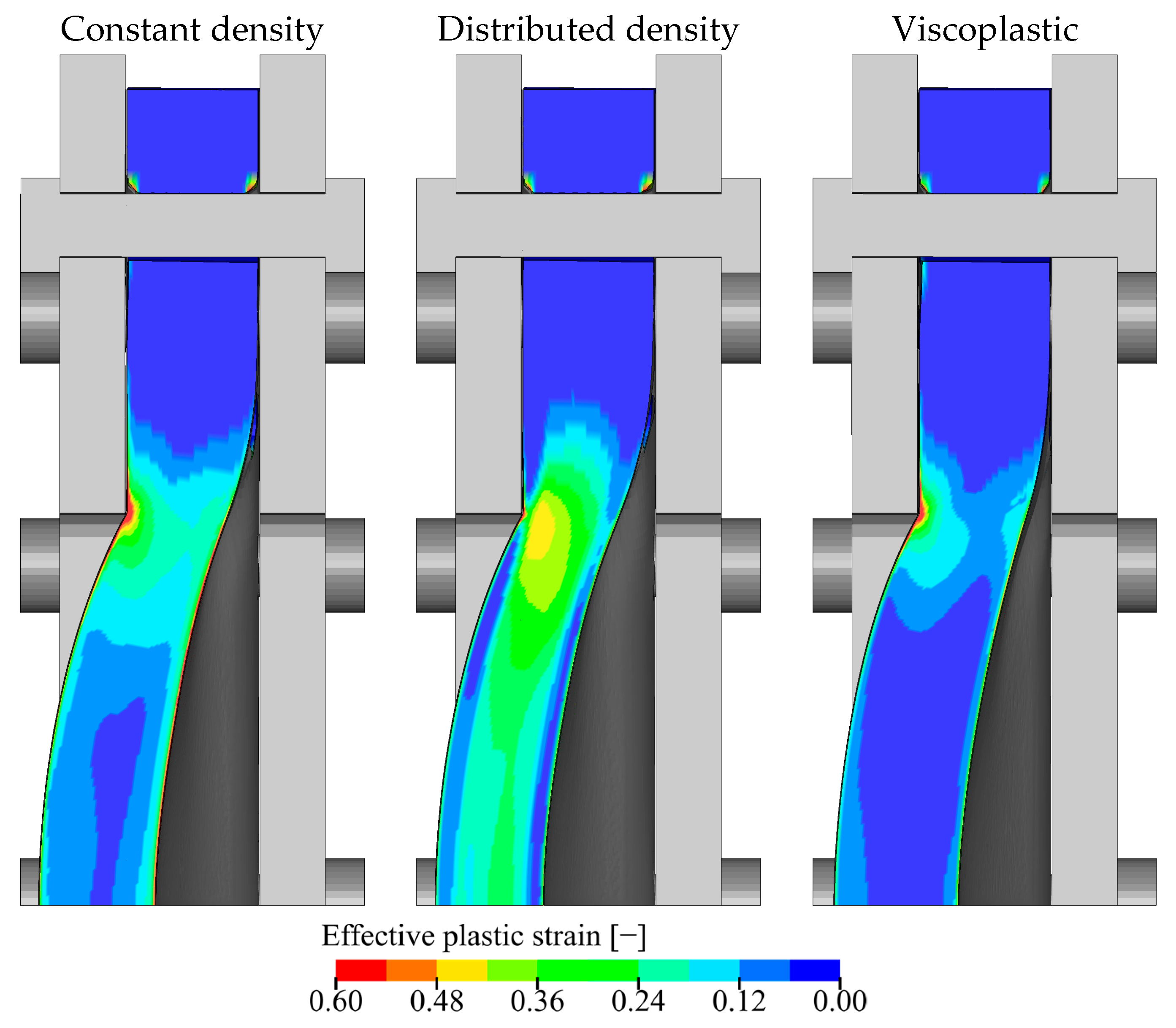

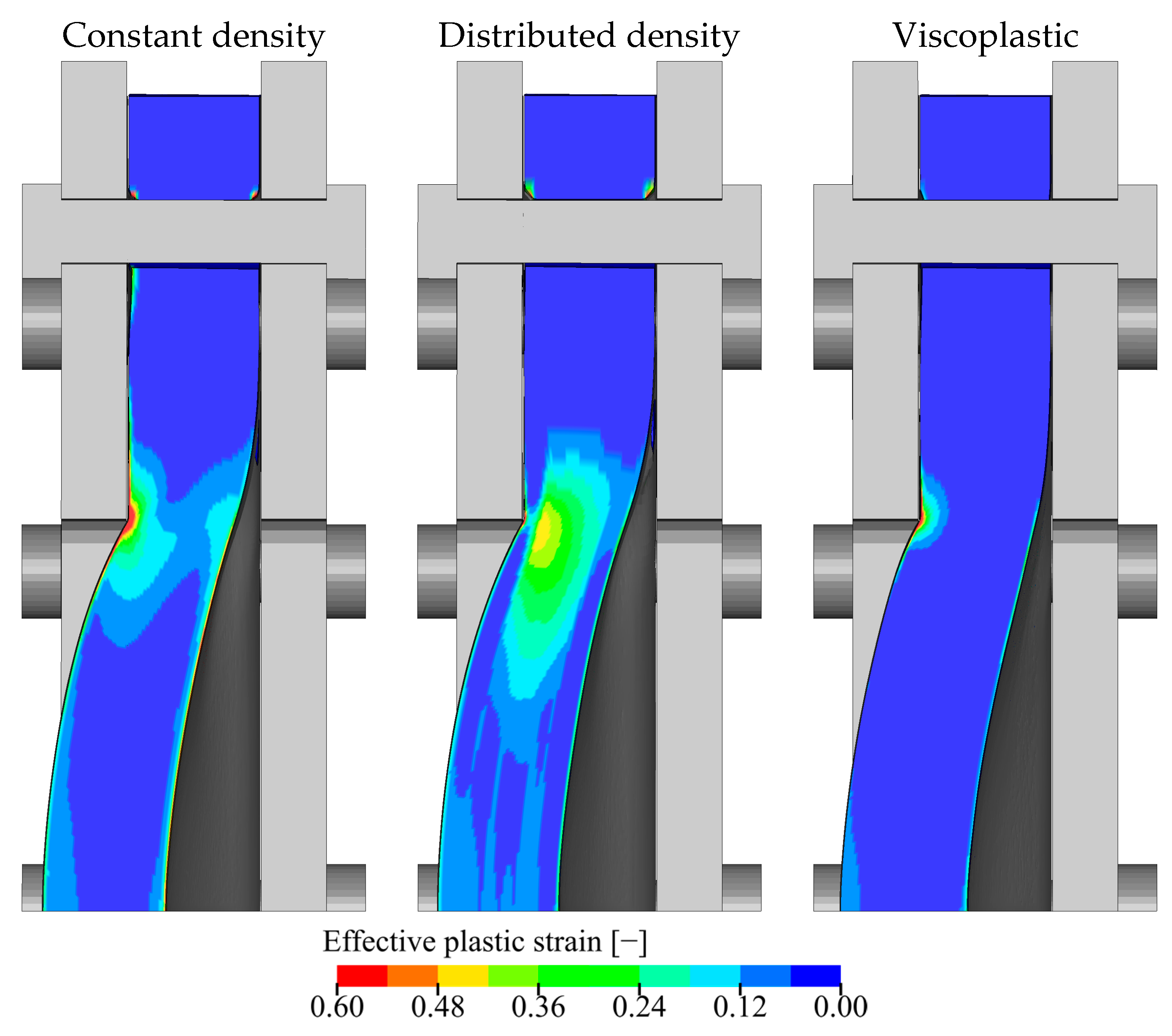

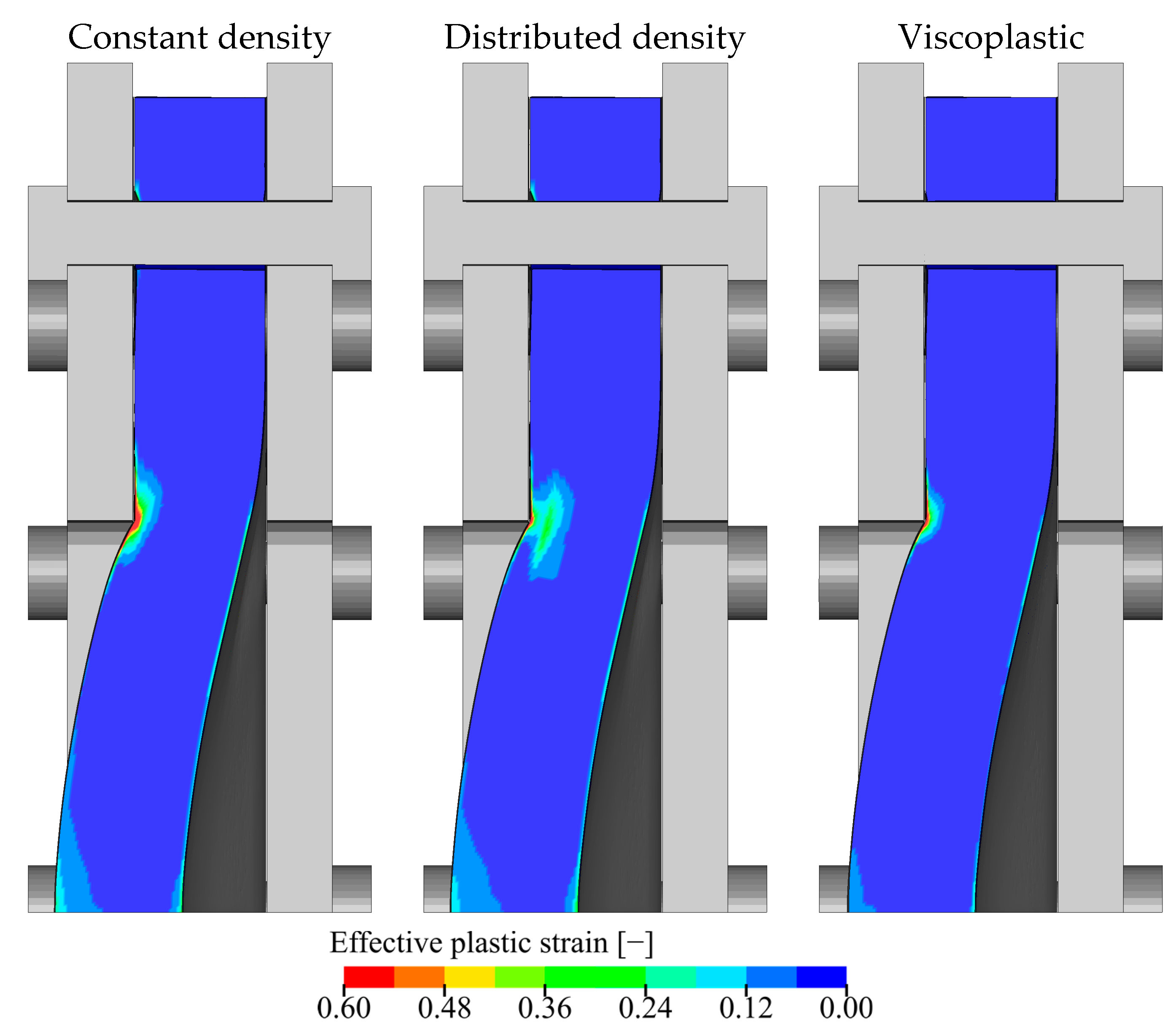

4.3.2. Blast Simulation Results

5. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Additional Figures

Appendix A.1. Experimental Data

Appendix A.2. Numerical Data

References

- Karagiozova, D.; Langdon, G.; Nurick, G. Blast attenuation in Cymat foam core sacrificial claddings. Int. J. Mech. Sci. 2010, 52, 758–776. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- Sun, Y.; Li, Q. Dynamic compressive behaviour of cellular materials: A review of phenomenon, mechanism and modelling. Int. J. Impact Eng. 2018, 112, 74–115. [Google Scholar] [CrossRef]

- Senol, K.; Shukla, A. Dynamic response of closed cell PVC foams subjected to underwater shock loading. Int. J. Impact Eng. 2019, 130, 214–225. [Google Scholar] [CrossRef]

- Reyes, A.; Børvik, T. Quasi-static behaviour of crash components with steel skins and polymer foam cores. Mater. Today Commun. 2018, 17, 541–553. [Google Scholar] [CrossRef]

- Reyes, A.; Børvik, T. Low velocity impact on crash components with steel skins and polymer foam cores. Int. J. Impact Eng. 2019, 132, 103297. [Google Scholar] [CrossRef]

- Fleck, N.A.; Deshpande, V.S. The Resistance of Clamped Sandwich Beams to Shock Loading. J. Appl. Mech. 2004, 71, 386–401. [Google Scholar] [CrossRef]

- Deshpande, V.; Fleck, N. One-dimensional response of sandwich plates to underwater shock loading. J. Mech. Phys. Solids 2005, 53, 2347–2383. [Google Scholar] [CrossRef]

- Tilbrook, M.; Deshpande, V.; Fleck, N.A. The impulsive response of sandwich beams: Analytical and numerical investigation of regimes of behaviour. J. Mech. Phys. Solids 2006, 54, 2242–2280. [Google Scholar] [CrossRef]

- Tilbrook, M.; Deshpande, V.S.; Fleck, N.A. Underwater blast loading of sandwich beams: Regimes of behaviour. Int. J. Solids Struct. 2009, 46, 3209–3221. [Google Scholar] [CrossRef]

- Shukla, A.; Salazar, C.; Kishore, S.; Matos, H. Dynamic Response of Composite Structures in Extreme Loading Environments. In Advances in Thick Section Composite and Sandwich Structures; Springer: Cham, Switzerland, 2020; pp. 1–42. [Google Scholar]

- Lee, S.W. Advances in Thick Section Composite and Sandwich Structures; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Gardner, N.; Wang, E.; Shukla, A. Performance of functionally graded sandwich composite beams under shock wave loading. Compos. Struct. 2012, 94, 1755–1770. [Google Scholar] [CrossRef]

- Jamil, A.; Guan, Z.; Cantwell, W.; Zhang, X.; Langdon, G.; Wang, Q. Blast response of aluminium/thermoplastic polyurethane sandwich panels—Experimental work and numerical analysis. Int. J. Impact Eng. 2019, 127, 31–40. [Google Scholar] [CrossRef]

- Chen, W.; Hao, H.; Hughes, D.; Shi, Y.; Cui, J.; Li, Z.-X. Static and dynamic mechanical properties of expanded polystyrene. Mater. Des. 2015, 69, 170–180. [Google Scholar] [CrossRef]

- Zhang, P.; Cheng, Y.S.; Liu, J.; Li, Y.; Zhang, C.; Hou, H.; Wang, C. Experimental study on the dynamic response of foam-filled corrugated core sandwich panels subjected to air blast loading. Compos. Part B Eng. 2016, 105, 67–81. [Google Scholar] [CrossRef]

- Li, Z.; Chen, W.; Hao, H. Numerical study of blast mitigation performance of folded structure with foam infill. Structures 2019, 20, 581–593. [Google Scholar] [CrossRef]

- Fahr, P.; Yazici, M.; Shukla, A. Shock response of filled corrugated sandwich structures under extreme temperatures. J. Sandw. Struct. Mater. 2018, 20, 130–149. [Google Scholar] [CrossRef]

- Kelly, M.; Arora, H.; Worley, A.; Kaye, M.; Del Linz, P.; Hooper, P.; Dear, J.P. Sandwich Panel Cores for Blast Applications: Materials and Graded Density. Exp. Mech. 2016, 56, 523–544. [Google Scholar] [CrossRef]

- Rolfe, E.; Kelly, M.; Arora, H.; Hooper, P.A.; Dear, J.P. Failure analysis using X-ray computed tomography of composite sandwich panels subjected to full-scale blast loading. Compos. Part B Eng. 2017, 129, 26–40. [Google Scholar] [CrossRef]

- Ye, N.; Zhang, W.; Li, D.; Huang, W.; Xie, W.; Huang, X.; Jiang, X. Dynamic response and failure of sandwich plates with PVC foam core subjected to impulsive loading. Int. J. Impact Eng. 2017, 109, 121–130. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, P.; Xiao, W.; Liu, J.; Cheng, Y. Experimental investigation on the performance of PVC foam core sandwich panels under air blast loading. Compos. Struct. 2019, 226, 111081. [Google Scholar] [CrossRef]

- Sun, G.; Wang, E.; Zhang, J.; Li, S.; Zhang, Y.; Li, Q. Experimental study on the dynamic responses of foam sandwich panels with different facesheets and core gradients subjected to blast impulse. Int. J. Impact Eng. 2020, 135, 103327. [Google Scholar] [CrossRef]

- Karen, I.; Yazici, M.; Shukla, A. Designing foam filled sandwich panels for blast mitigation using a hybrid evolutionary optimisation algorithm. Compos. Struct. 2016, 158, 72–82. [Google Scholar] [CrossRef]

- Aune, V.; Fagerholt, E.; Børvik, T.; Langseth, M. A shock tube facility to generate blast loading on structures. Int. J. Prot. Struct. 2016, 7, 340–366. [Google Scholar] [CrossRef]

- Available online: http://lstc.com/products/ls-dyna (accessed on 29 October 2020).

- Gruben, G.; Fagerholt, E.; Hopperstad, O.; Børvik, T. Fracture characteristics of a cold-rolled dual-phase steel. Eur. J. Mech. A Solids 2011, 30, 204–218. [Google Scholar] [CrossRef]

- Fagerholt, E. eCorr v4.0 Documentation. Available online: https://www.ntnu.edu/kt/ecorr (accessed on 29 October 2019).

- Grytten, F.; Børvik, T.; Hopperstad, O.; Langseth, M. Low velocity perforation of AA5083-H116 aluminium plates. Int. J. Impact Eng. 2009, 36, 597–610. [Google Scholar] [CrossRef]

- Available online: https://www.sundolitt.com/no/sundolitt/norway/standard-eps-og-xps/xps/ (accessed on 29 October 2020).

- Vestrum, O.; Langseth, M.; Børvik, T. Finite element modeling of porous polymer pipeline coating using X-ray micro computed tomography. Compos. Part B Eng. 2019, 172, 406–415. [Google Scholar] [CrossRef]

- Aune, V.; Valsamos, G.; Casadei, F.; Langseth, M.; Børvik, T. Fluid-structure interaction effects during the dynamic response of clamped thin steel plates exposed to blast loading. 2020. submitted. [Google Scholar]

- Aune, V.; Valsamos, G.; Casadei, F.; Larcher, M.; Langseth, M.; Børvik, T. Use of Damage-based Mesh Adaptivity to Predict Ductile Failure in Blast-loaded Aluminium Plates. Procedia Eng. 2017, 197, 3–12. [Google Scholar] [CrossRef]

- Børvik, T.; Hopperstad, O.; Berstad, T.; Langseth, M. A computational model of viscoplasticity and ductile damage for impact and penetration. Eur. J. Mech. Solids 2001, 20, 685–712. [Google Scholar] [CrossRef]

- Holmen, J.K.; Hopperstad, O.S.; Børvik, T. Low-velocity impact on multi-layered dual-phase steel plates. Int. J. Impact Eng. 2015, 78, 161–177. [Google Scholar] [CrossRef]

- Cronin, D.; Ouellet, S. Low density polyethylene, expanded polystyrene and expanded polypropylene: Strain rate and size effects on mechanical properties. Polym. Test. 2016, 53, 40–50. [Google Scholar] [CrossRef]

- Toksoy, A.K.; Güden, M. The strengthening effect of polystyrene foam filling in aluminium thin-walled cylindrical tubes. Thin-Walled Struct. 2005, 43, 333–350. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A. Isotropic models for metallic foams. J. Mech. Phys. Solids 2000, 48, 1253–1283. [Google Scholar] [CrossRef]

- Hanssen, A.; Hopperstad, O.; Langseth, M.; Ilstad, H. Validation of constitutive models applicable to aluminium foams. Int. J. Mech. Sci. 2002, 44, 359–406. [Google Scholar] [CrossRef]

- Reyes, A.; Hopperstad, O.S.; Berstad, T.; Hanssen, A.G.; Langseth, M. Constitutive modelling of aluminium foam including fracture and statistical variation of density. Eur. J. Mech. Solids 2003, 32, 815–835. [Google Scholar] [CrossRef]

- Available online: http://lstc.com/products/ls-opt (accessed on 29 October 2020).

- Mills, N.J. Polymer Foams Handbook: Engineering and Biomechanics Applications and Design Guide; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Cockcroft, M.G.; Latham, D.J. Ductility and workability of metals. J. Inst. Met. 1968, 96, 33–39. [Google Scholar]

- Deshpande, V.; Fleck, N.A. Multi-axial yield behaviour of polymer foams. Acta Mater. 2001, 49, 1859–1866. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|

| 0.04 | 0.32 | 0.001 | 0.002 | 0.000 | 0.000 | 0.02 | Balance |

| Material | Density, ρ [kg/m3] | Elastic Modulus, E [MPa] | Yield Stress, σy [MPa] | Plateau Stress, σp [MPa] | Densification Strain, εD [–] | |

|---|---|---|---|---|---|---|

| Mean | SD | |||||

| XPS-250 | 34.1 | 0.38 | 13.7 | 0.26 | 0.34 | 3.36 |

| XPS-400 | 37.9 | 0.65 | 18.5 | 0.41 | 0.49 | 3.68 |

| XPS-700 | 50.8 | 0.38 | 23.5 | 0.73 | 0.77 | 3.46 |

| Test | Nominal Firing Pressure [bar] | Core Material | [–] | PS01,in [kPa] | PS01,max [kPa] | umax [mm] |

|---|---|---|---|---|---|---|

| Sk_P10 | 10 | - | 1.46 | 167.9 | 378.4 | 33.3 |

| Sw_250_P10_1 | XPS-250 | 1.49 | 170.9 | 375.3 | 33.5 | |

| Sw_250_P10_2* | XPS-250 | 1.50 | 161.9 | 389.9 | 34.4 | |

| Sw_400_P10 | XPS-400 | 1.47 | 167.9 | 409.5 | 25.7 | |

| Sw_700_P10 | XPS-700 | 1.49 | 171.5 | 407.1 | 24.1 | |

| Sk_P12* | 12 | - | 1.57 | 198.9 | 461.8 | 41.2 |

| Sw_250_P12 | XPS-250 | 1.57 | 198.3 | 480.3 | 35.7 | |

| Sw_400_P12 | XPS-400 | 1.55 | 193.9 | 478.8 | 33.0 | |

| Sw_700_P12* | XPS-700 | 1.57 | 197.6 | 469.7 | 30.5 | |

| Sk_P15 | 15 | - | 1.59 | 218.5 | 512.7 | Failure |

| Sw_250_P15_1 | XPS-250 | 1.60 | 223.4 | 503.5 | 45.6 | |

| Sw_250_P15_2 | XPS-250 | 1.61 | 224.0 | 508.4 | Failure | |

| Sw_400_P15_1 | XPS-400 | 1.60 | 226.4 | 549.9 | Failure | |

| Sw_400_P15_2 | XPS-400 | 1.61 | 227.7 | 567.4 | Failure | |

| Sw_700_P15_1 | XPS-700 | 1.61 | 227.7 | 523.1 | 36.2 | |

| Sw_700_P15_2 | XPS-700 | 1.61 | 232.2 | 588.5 | Failure |

[MPa] | [MPa] | [MPa] | [MPa] | [MPa] |

|---|---|---|---|---|

| 80.0 | 25.7 | 1000.0 | 7.6 | 21.4 |

[GPa] | [–] | [kg/m3] | [–] | [s−1] |

|---|---|---|---|---|

| 70.0 | 0.30 | 2700 | 0.014 | 5 × 10−4 |

[MPa] | [–] | [–] | [–] | |

|---|---|---|---|---|

| [–] | ||||

| [–] | ||||

| [–] |

| Test | Nominal Firing Pressure [bar] | [kPa] | [ms] | [–] |

|---|---|---|---|---|

| P10 | 10 | 446.2 | 35.4 | 1.571 |

| P12 | 12 | 519.3 | 39.8 | 1.892 |

| P15 | 15 | 606.6 | 44.1 | 2.025 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brekken, K.A.; Reyes, A.; Berstad, T.; Langseth, M.; Børvik, T. Sandwich Panels with Polymeric Foam Cores Exposed to Blast Loading: An Experimental and Numerical Investigation. Appl. Sci. 2020, 10, 9061. https://doi.org/10.3390/app10249061

Brekken KA, Reyes A, Berstad T, Langseth M, Børvik T. Sandwich Panels with Polymeric Foam Cores Exposed to Blast Loading: An Experimental and Numerical Investigation. Applied Sciences. 2020; 10(24):9061. https://doi.org/10.3390/app10249061

Chicago/Turabian StyleBrekken, Kristoffer Aune, Aase Reyes, Torodd Berstad, Magnus Langseth, and Tore Børvik. 2020. "Sandwich Panels with Polymeric Foam Cores Exposed to Blast Loading: An Experimental and Numerical Investigation" Applied Sciences 10, no. 24: 9061. https://doi.org/10.3390/app10249061

APA StyleBrekken, K. A., Reyes, A., Berstad, T., Langseth, M., & Børvik, T. (2020). Sandwich Panels with Polymeric Foam Cores Exposed to Blast Loading: An Experimental and Numerical Investigation. Applied Sciences, 10(24), 9061. https://doi.org/10.3390/app10249061